Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Proper handling and storage of hazardous materials interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Proper handling and storage of hazardous materials Interview

Q 1. Describe the different classes of hazardous materials.

Hazardous materials are categorized into classes based on their inherent dangers. Think of it like sorting laundry – different fabrics require different washing cycles, just as different hazards need specific handling. The classification systems, such as those used by the UN and DOT, vary slightly but share the core principle of grouping similar hazards together for easier management and safety.

- Class 1: Explosives: Substances or articles that can produce an explosion.

- Class 2: Gases: Materials that are gaseous at normal temperatures and pressures, further subdivided by flammability, toxicity, and reactivity.

- Class 3: Flammable Liquids: Liquids that can easily ignite, like gasoline or ethanol.

- Class 4: Flammable Solids; Substances Liable to Spontaneous Combustion; Substances which, in contact with water, emit flammable gases: This class includes materials that can catch fire easily, spontaneously ignite, or react violently with water.

- Class 5: Oxidizing Substances and Organic Peroxides: Substances that can readily supply oxygen to fuel a fire (oxidizers) or that are inherently unstable and may explode.

- Class 6: Toxic and Infectious Substances: Materials that are poisonous or cause disease, subdivided into toxic and infectious substances.

- Class 7: Radioactive Materials: Materials emitting ionizing radiation that can damage living tissue.

- Class 8: Corrosive Substances: Materials that can chemically attack and damage materials, like strong acids or bases.

- Class 9: Miscellaneous Dangerous Goods: Substances or articles not included in other classes but that present a significant hazard during transport, such as lithium batteries.

Understanding these classes is crucial for safe handling, storage, and transportation.

Q 2. Explain the importance of Material Safety Data Sheets (MSDS).

Material Safety Data Sheets (MSDS), now often called Safety Data Sheets (SDS), are the ultimate guide for working with any chemical product. Imagine an instruction manual, but for chemicals. They are vital for understanding the hazards associated with a particular substance and taking the necessary precautions.

An SDS provides comprehensive information including:

- Chemical identification: Name, synonyms, CAS number (a unique identifier).

- Hazard identification: Health hazards, flammability, reactivity, environmental hazards.

- Composition/information on ingredients: The exact chemical makeup.

- First-aid measures: Steps to take in case of exposure.

- Fire-fighting measures: Appropriate extinguishing agents.

- Accidental release measures: Procedures for spills or leaks.

- Handling and storage: Safe practices to follow.

- Exposure controls/personal protection: Required PPE.

- Physical and chemical properties: Boiling point, melting point, etc.

- Stability and reactivity: Potential hazards associated with instability.

- Toxicological information: Health effects of exposure.

- Ecological information: Environmental impact.

- Disposal considerations: Proper waste disposal methods.

- Transport information: Regulations for shipping.

- Regulatory information: Compliance requirements.

Always consult the SDS before handling any hazardous material. It’s your primary source of information for ensuring safe practices.

Q 3. What are the key elements of a hazardous materials emergency response plan?

A robust hazardous materials emergency response plan is crucial. Think of it as a fire drill, but for chemical incidents. It’s a proactive approach designed to minimize damage and injury.

Key elements include:

- Pre-emergency planning: Identifying potential hazards, designating roles and responsibilities, establishing communication protocols.

- Emergency procedures: Detailed steps for handling spills, leaks, fires involving hazardous materials, including evacuation plans.

- Emergency response team: Trained personnel equipped to handle incidents.

- Personal protective equipment (PPE): Availability and proper use of appropriate PPE.

- Emergency equipment and supplies: Having appropriate containment materials, spill kits, decontamination supplies readily available.

- Training and drills: Regular training and practice exercises to ensure preparedness.

- Post-emergency procedures: Steps for cleanup, investigation, and preventing future incidents.

- Communication plan: A detailed method for notifying relevant authorities and personnel during an emergency.

- Documentation: Maintaining accurate records of training, drills, and incidents.

A well-defined plan significantly reduces risks and ensures a coordinated response during a hazardous materials incident.

Q 4. How do you ensure proper labeling and segregation of hazardous materials?

Proper labeling and segregation are fundamental to safe hazardous materials handling. Imagine organizing a toolbox – you wouldn’t put your hammer next to your delicate screwdriver. Similar logic applies here.

Labeling: Every container must have a clear and accurate label indicating the hazard class, chemical name, and any specific precautions. Labels must be durable and legible, adhering to regulations (e.g., Globally Harmonized System of Classification and Labelling of Chemicals or GHS).

Segregation: Incompatible materials must be stored separately to prevent reactions. For instance, strong acids should never be stored near strong bases, as their mixing can create dangerous heat or fumes. Common segregation rules are based on hazard classes, and specific guidelines exist for different storage environments.

Examples of segregation include:

- Separating flammable materials from oxidizers.

- Storing corrosive materials in compatible containers.

- Keeping incompatible chemicals away from each other.

Correct labeling and segregation prevent accidents by ensuring clear identification and preventing hazardous reactions.

Q 5. What are the regulations governing the transportation of hazardous materials?

Transportation of hazardous materials is strictly regulated to protect public safety and the environment. Regulations vary by country and region, but common threads exist.

Key regulatory bodies include:

- Department of Transportation (DOT) in the United States: Establishes stringent requirements for packaging, labeling, shipping papers, and driver training.

- International Maritime Organization (IMO): Sets regulations for the transportation of hazardous materials by sea.

- International Air Transport Association (IATA): Establishes regulations for air transport.

Regulations cover aspects like:

- Packaging and labeling: Specific requirements for packaging materials and labels indicating hazard class.

- Shipping papers: Detailed documentation accompanying the shipment detailing the materials, quantities, and hazards.

- Emergency response information: Providing emergency contact information for response teams.

- Driver training: Specific training for drivers handling hazardous materials.

- Route planning: Avoiding sensitive areas or choosing appropriate transportation modes.

Non-compliance can result in significant fines and legal penalties.

Q 6. Describe the proper procedures for handling a chemical spill.

Handling a chemical spill requires a calm, controlled response. Think of it as a medical emergency – you need to assess, contain, and then treat.

Procedures typically involve:

- Assessment: Identify the spilled substance, the area affected, and potential risks.

- Evacuation: Clear the area, ensuring personnel are at a safe distance.

- Containment: Use appropriate materials (spill kits) to contain the spill, preventing it from spreading. This may involve using absorbents, dams, or other barriers.

- Notification: Alert emergency services and relevant authorities, providing details of the spill.

- Cleanup: Employ appropriate cleanup techniques based on the substance and using designated personal protective equipment (PPE).

- Disposal: Properly dispose of contaminated materials following regulations.

- Documentation: Record the incident, including cleanup procedures, and any injuries or damage.

The specific steps will depend on the type and quantity of the spilled material. Always refer to the SDS for guidance.

Q 7. Explain the different types of personal protective equipment (PPE) used when handling hazardous materials.

Personal Protective Equipment (PPE) is essential when working with hazardous materials. It’s your first line of defense.

Types of PPE include:

- Respiratory protection: Respirators, masks, and self-contained breathing apparatus (SCBA) to prevent inhalation of hazardous fumes or dust.

- Eye protection: Safety glasses, goggles, and face shields to protect eyes from splashes or impacts.

- Skin protection: Gloves, aprons, suits (e.g., Tyvek suits), and boots to prevent skin contact with chemicals.

- Hearing protection: Earplugs or muffs to protect against loud noises from machinery or processes.

- Body protection: Full-body suits to provide complete protection from hazardous materials.

The choice of PPE depends entirely on the specific hazards. Always select the appropriate level of protection based on the risk assessment and the SDS information. Using the wrong PPE can be more dangerous than using no PPE at all.

Q 8. How do you inspect and maintain storage facilities for hazardous materials?

Inspecting and maintaining hazardous materials storage facilities is crucial for preventing accidents and ensuring compliance. It’s not a one-time event but a continuous process involving regular checks and proactive maintenance.

- Regular Inspections: These should be conducted at least monthly, more frequently for highly reactive materials. We look for things like structural integrity (cracks in walls, damaged roofs), proper ventilation, adequate spill containment, functioning fire suppression systems, and the correct labeling and segregation of materials. We also check for signs of leakage, corrosion, or deterioration of containers.

- Maintenance: This involves addressing any issues found during inspections. This could range from simple repairs like patching cracks to more extensive work like replacing corroded pipes or upgrading ventilation systems. Preventative maintenance, such as regular cleaning and inspections of fire suppression systems, is key to extending the lifespan of the facility and minimizing risk.

- Documentation: Meticulous record-keeping is vital. All inspections and maintenance activities must be documented, including the date, time, issues found, actions taken, and the individuals responsible. This documentation is critical for demonstrating compliance during audits.

- Emergency Preparedness: The facility should have a comprehensive emergency plan, including procedures for dealing with spills, fires, and other emergencies. This plan should be regularly reviewed and practiced through drills.

For example, in one facility, a routine inspection revealed a small crack in a containment wall. Addressing this early prevented a much larger and more costly repair later, and importantly, prevented potential environmental contamination.

Q 9. What are the common hazards associated with the storage of flammable materials?

Flammable materials pose several significant hazards during storage. The primary concern is fire, which can be devastating in terms of property damage, injury, and environmental impact.

- Ignition Sources: Flammable materials can easily ignite from various sources such as sparks, static electricity, open flames, or even hot surfaces. Improper handling or storage can create conditions conducive to ignition.

- Rapid Fire Spread: Many flammable materials are volatile and burn rapidly, making fire suppression challenging. The rapid spread of flames can quickly overwhelm a facility, especially if proper fire prevention measures are not in place.

- Toxic Fumes: Burning flammable materials often produce toxic and hazardous fumes, which can cause respiratory problems, or even death if inhaled. These fumes can also spread quickly.

- Explosions: Some flammable materials can explode under certain conditions, such as when they are confined and heated. This explosion could be devastating to the facility and the surrounding environment.

Imagine a warehouse storing solvents without proper ventilation – a single spark could ignite the materials, leading to a rapid fire spread, toxic fume release and a potential explosion.

Q 10. How do you identify and mitigate risks associated with hazardous materials handling?

Identifying and mitigating risks associated with hazardous materials handling involves a systematic approach that prioritizes safety.

- Hazard Identification: The first step is a thorough identification of all potential hazards. This involves reviewing Safety Data Sheets (SDS) for each material, considering the properties of the materials (flammability, toxicity, reactivity, etc.), and assessing the potential for exposure to workers and the environment.

- Risk Assessment: Once hazards are identified, we assess the likelihood of an incident occurring and its potential consequences. This helps prioritize which risks need to be addressed first.

- Mitigation Strategies: Based on the risk assessment, we develop and implement control measures to reduce or eliminate the risks. These measures can include engineering controls (e.g., ventilation systems, spill containment), administrative controls (e.g., safety training, procedures), and personal protective equipment (PPE) such as respirators, gloves, and eye protection.

- Emergency Response: We develop and practice emergency response plans to handle spills, leaks, fires, and other incidents. This includes having the necessary equipment and trained personnel.

- Training: All personnel handling hazardous materials must receive comprehensive training on safe handling, storage, and emergency procedures.

For example, if we identify a high risk of chemical exposure during a particular process, we might install a local exhaust ventilation system and require workers to wear respirators.

Q 11. What are the legal requirements for the disposal of hazardous waste?

Legal requirements for hazardous waste disposal are complex and vary by jurisdiction, but generally involve several key aspects:

- Waste Characterization: First, the waste must be accurately characterized to determine its hazardous properties. This typically involves laboratory testing to identify the components and their concentrations.

- Manifest System: Most jurisdictions utilize a manifest system to track hazardous waste from its generation to its final disposal. This ensures accountability and prevents illegal dumping.

- Permitted Disposal Facilities: Hazardous waste must be disposed of at permitted facilities that have the appropriate technology and permits to handle the specific types of waste.

- Compliance Reporting: Regular reporting is required to regulatory agencies to demonstrate compliance with all applicable rules and regulations.

- Treatment and Disposal Methods: The chosen treatment and disposal method must be appropriate for the waste’s characteristics, considering factors such as toxicity, reactivity, and volume.

Failure to comply with these regulations can result in significant fines and penalties.

Q 12. Explain the process of conducting a risk assessment for hazardous materials.

A risk assessment for hazardous materials is a systematic process designed to identify and evaluate the risks associated with handling, storing, using, and disposing of these materials. It’s a crucial step in developing a comprehensive safety program.

- Identify Hazards: Start by listing all potential hazards associated with the material, including its physical, chemical, and biological properties (flammability, toxicity, reactivity, etc.). Consult the SDS for detailed information.

- Identify Exposure Pathways: Determine how workers or the environment could be exposed to the hazardous material. This includes considering scenarios such as spills, leaks, fires, and routine handling.

- Assess the Likelihood and Severity: For each identified hazard and exposure pathway, assess the likelihood of an incident occurring (e.g., low, medium, high) and the severity of the consequences (e.g., minor injury, major injury, fatality, environmental damage).

- Evaluate the Risk: Combine the likelihood and severity to determine the overall risk level. A simple matrix can be used to categorize risks (low, medium, high).

- Develop Control Measures: Based on the risk assessment, develop and implement control measures to reduce or eliminate the risks. These could include engineering controls, administrative controls, and PPE.

- Monitor and Review: Regularly monitor the effectiveness of the control measures and review the risk assessment periodically to account for changes in operations or new information.

For example, a risk assessment might reveal a high risk of skin burns from handling a corrosive chemical. The control measures could include providing appropriate gloves and safety training.

Q 13. Describe your experience with inventory management of hazardous materials.

Effective inventory management of hazardous materials is crucial for safety, compliance, and cost control. It requires a robust system that tracks the location, quantity, and condition of all materials. I have extensive experience implementing and maintaining such systems.

- Database System: Utilizing a computerized database system allows for real-time tracking of inventory levels, expiry dates, and location of materials. This helps prevent stockouts and ensures that materials are used before they expire.

- Regular Stock Checks: Regular physical inventory checks are essential to verify the accuracy of the database and identify any discrepancies. This also allows for timely identification of damaged containers or materials that need to be disposed of.

- Proper Labeling and Segregation: Maintaining accurate labeling and proper segregation of incompatible materials is vital for preventing dangerous reactions and accidents.

- Security Measures: Restricting access to hazardous materials storage areas and implementing security measures like locks and surveillance systems are critical to preventing theft or unauthorized access.

- Disposal Tracking: Keeping records of hazardous waste disposal, including the quantities disposed of, disposal method, and disposal facility, is crucial for compliance purposes.

In a previous role, I implemented a barcode system for tracking hazardous materials, improving inventory accuracy and reducing the time needed for stocktaking significantly. This also allowed for better control over the materials and improved the efficiency of our warehouse operations.

Q 14. How do you ensure compliance with OSHA regulations related to hazardous materials?

Ensuring compliance with OSHA regulations related to hazardous materials requires a multifaceted approach. It’s not just about following the rules, but understanding their implications and integrating them into daily operations.

- Training: All employees who handle hazardous materials must receive comprehensive training on OSHA regulations, hazard communication, safe handling procedures, and emergency response. Records of this training must be maintained.

- Hazard Communication: OSHA’s Hazard Communication Standard requires employers to provide employees with information about hazardous chemicals through Safety Data Sheets (SDS) and labels.

- Personal Protective Equipment (PPE): Appropriate PPE must be provided and used according to OSHA guidelines. This includes things like respirators, gloves, eye protection, and protective clothing. Employees must be properly trained in the selection and use of appropriate PPE.

- Emergency Planning: A comprehensive emergency plan must be in place, including procedures for handling spills, leaks, fires, and other emergencies. This plan must be regularly reviewed and practiced through drills.

- Record Keeping: Detailed records must be maintained on all aspects of hazardous materials handling, including training, inspections, maintenance, and incident reports. These records are essential for demonstrating compliance during audits.

- Regular Audits: Conducting regular internal audits helps to identify any compliance gaps and take corrective actions. This proactive approach helps prevent violations and ensures ongoing compliance.

By consistently implementing these measures, we can ensure a safe work environment and avoid potential penalties for non-compliance.

Q 15. What is your experience with hazardous waste tracking and reporting?

Hazardous waste tracking and reporting is crucial for environmental compliance and safety. My experience encompasses the entire lifecycle, from initial waste generation through proper disposal. This includes using specialized software to meticulously document the type, quantity, and location of hazardous waste. I’m proficient in generating manifests, completing regulatory reports (like those required by the EPA), and maintaining detailed records for audits. For example, in my previous role, we utilized a software system that integrated with our inventory management to automatically generate waste manifests, minimizing errors and ensuring compliance with all applicable regulations. We also conducted regular internal audits to ensure data accuracy and process adherence. This proactive approach prevented potential penalties and maintained a strong safety record.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your understanding of Globally Harmonized System of Classification and Labelling of Chemicals (GHS).

The Globally Harmonized System of Classification and Labelling of Chemicals (GHS) is an internationally recognized standard for classifying and communicating the hazards of chemicals. It provides a consistent approach to hazard communication across countries, reducing confusion and improving safety. My understanding of GHS includes the classification of chemicals based on their physical, health, and environmental hazards; the use of standardized pictograms, signal words (such as ‘Danger’ or ‘Warning’), and hazard statements to clearly communicate risks; and the inclusion of precautionary statements to advise on safe handling and storage. For instance, understanding GHS allows me to quickly identify the hazards of a chemical by examining its label, enabling me to select appropriate PPE and handling procedures. This ensures that everyone handling the chemical is fully aware of its potential dangers and how to mitigate them.

Q 17. How do you manage incompatible materials during storage?

Managing incompatible materials is paramount to prevent dangerous chemical reactions. Incompatible materials, when stored together, can react violently, creating fires, explosions, or releasing toxic fumes. My approach involves segregating materials according to their chemical properties using a detailed compatibility chart. This chart acts as a reference for identifying potential hazards and assigning them to separate storage areas, often with dedicated storage cabinets or designated zones within a warehouse. For example, strong oxidizers are always kept far away from flammable materials. Similarly, acids and bases are stored in separate areas to prevent neutralization reactions that can generate heat and potentially cause damage. We also utilize secondary containment measures, like spill pallets, to capture any potential leaks.

Q 18. What are the signs and symptoms of exposure to common hazardous materials?

The signs and symptoms of exposure to hazardous materials vary greatly depending on the specific substance and the route of exposure (inhalation, skin contact, ingestion). However, some common signs include:

- Respiratory irritation: Coughing, shortness of breath, wheezing

- Skin irritation: Redness, itching, burning, blistering

- Eye irritation: Burning, redness, tearing

- Neurological effects: Headache, dizziness, nausea, confusion

- Gastrointestinal effects: Nausea, vomiting, diarrhea

Q 19. Explain the procedures for emergency evacuation in case of a hazardous materials incident.

Emergency evacuation procedures for hazardous materials incidents are critical for minimizing harm to personnel. Our protocols begin with activating the emergency response system – this could involve pulling a fire alarm or calling emergency services. Next, immediate evacuation is ordered following pre-determined escape routes, avoiding the affected area. Employees are trained to assemble at a designated assembly point, where attendance is confirmed. Emergency responders, both internal and external, then assess the situation and begin remediation efforts. Regular drills ensure everyone understands their roles and escape routes, minimizing confusion in a crisis. For example, we regularly conduct mock evacuations, simulating different scenarios to improve response time and team coordination. Post-incident debriefings provide opportunities for improvement and adjustment to our plans.

Q 20. How do you train employees on safe handling and storage practices?

Employee training is a cornerstone of safe handling and storage practices. Our training program incorporates a multi-faceted approach, including initial classroom training, hands-on practical demonstrations, and regular refresher courses. The curriculum covers hazard identification, proper handling procedures, emergency response protocols, and the use of personal protective equipment (PPE). We utilize interactive training methods, including videos and case studies, to engage employees and promote knowledge retention. For example, we use real-life incident reports to highlight the consequences of unsafe practices. Furthermore, we emphasize ongoing training and encourage employees to ask questions and report any safety concerns. Regular quizzes and assessments monitor employee comprehension and ensure compliance.

Q 21. Describe your experience with incident reporting and investigation related to hazardous materials.

My experience with incident reporting and investigation related to hazardous materials includes thorough documentation, root cause analysis, and corrective action planning. Following any incident, a detailed report is compiled, outlining the circumstances, affected individuals, and environmental impact. A root cause analysis is performed to identify the underlying factors contributing to the incident, which often involves interviewing witnesses and reviewing safety procedures. This information is crucial for developing corrective actions to prevent recurrence. For example, if a spill occurred due to inadequate labeling, we’d implement a new labeling system and enhance employee training on proper chemical identification. The focus is on preventing future incidents, learning from past mistakes, and continually improving safety protocols.

Q 22. How do you ensure the proper ventilation of areas where hazardous materials are stored?

Proper ventilation in hazardous materials storage areas is crucial to prevent the buildup of harmful vapors, gases, or dust that can pose serious health risks. The approach depends heavily on the specific hazards involved. For instance, storing volatile organic compounds (VOCs) requires a significantly different ventilation strategy than handling asbestos.

Methods for ensuring adequate ventilation include:

- Local Exhaust Ventilation (LEV): This involves using hoods, vents, or other devices to capture contaminants at their source, preventing them from dispersing into the wider atmosphere. Imagine a fume hood in a chemistry lab – it’s a prime example of LEV. The effectiveness depends on proper hood design and airflow rates, regularly checked and maintained.

- General Dilution Ventilation: This method relies on introducing fresh air to dilute the concentration of airborne contaminants. Think of this as simply increasing the overall air exchange rate within the storage area. While simpler to implement than LEV, it requires a much higher airflow rate to be effective for highly hazardous materials. The calculation of the necessary airflow is crucial, frequently guided by industry regulations and safety data sheets (SDS).

- Mechanical Ventilation Systems: These systems use fans and ducts to create controlled airflow, pushing contaminated air out and bringing in fresh air. Regular inspection and maintenance, including filter changes, are essential for consistent effectiveness. Consider scenarios where this is critical, such as storing materials that generate significant heat or have a high potential for creating explosive mixtures.

In practice, a combination of these methods is often employed to ensure optimal safety. Regular monitoring of air quality, as discussed later, is essential to validate the effectiveness of the ventilation system.

Q 23. What are the different methods for neutralizing hazardous materials?

Neutralizing hazardous materials is a complex process that requires specialized knowledge and equipment. The method chosen depends entirely on the specific material’s properties and the risks involved. There’s no one-size-fits-all solution; a wrong approach could even worsen the situation.

Methods of Neutralization include:

- Chemical Neutralization: This involves using a chemical substance to react with the hazardous material, rendering it less harmful. For instance, neutralizing an acid spill might involve using a base like sodium bicarbonate. However, this process can create new byproducts, so careful consideration is essential and requires a deep understanding of chemical reactions and potential new hazards generated.

- Physical Neutralization: This may involve methods like containment, dilution with large quantities of water (if appropriate for the material), or absorption using absorbent materials like spill pads. This approach often relies on isolating and preventing further dispersion of the hazardous substance.

- Biological Neutralization: In some cases, microorganisms can be used to break down hazardous materials. This is a slower process, often used for organic pollutants in soil or water remediation. Bioremediation requires highly controlled conditions and monitoring to be effective.

- Incineration: For certain materials, controlled burning at high temperatures can effectively destroy the hazardous components. However, this method generates air emissions that need careful management and compliance with environmental regulations. This approach carries significant environmental responsibility and is not always appropriate or environmentally sound.

Each neutralization method demands rigorous safety precautions and adherence to strict protocols, including proper personal protective equipment (PPE), emergency response planning, and waste disposal procedures. It’s crucial to always consult SDS and follow established best practices.

Q 24. How do you conduct a workplace inspection to identify potential hazardous materials hazards?

A thorough workplace inspection for hazardous materials hazards is a systematic process requiring a detailed understanding of potential risks. It’s not just a visual sweep; it involves careful observation and documentation.

Steps in conducting a workplace inspection:

- Preparation: Review existing safety data sheets (SDS), permits, and previous inspection reports. Understand the types of hazardous materials present and their associated risks.

- Visual Inspection: Observe storage areas for signs of leaks, spills, damaged containers, improper labeling, inadequate ventilation, or accumulation of waste. Pay close attention to details, including container integrity, emergency response equipment availability, and the physical layout.

- Documentation: Thoroughly document all findings, including photos and notes. This documentation serves as a record for corrective actions and future inspections. Be precise in your observations; a poorly documented issue is impossible to track.

- Testing and Sampling: Depending on the materials and suspected hazards, air quality testing or material sampling might be necessary to confirm the presence or concentration of hazardous substances. Proper sample collection and lab analysis methods are critical here.

- Review and Corrective Action: After the inspection, review all findings and create a plan for correcting identified hazards. This might include improvements to storage practices, employee training, new safety equipment, or repairs.

A practical example would be inspecting a laboratory where chemicals are used. This would involve checking for proper ventilation in fume hoods, assessing the integrity of chemical storage cabinets, verifying appropriate labeling on containers, and ensuring the availability of appropriate spill response kits. Regular inspections are critical; hazards can emerge unexpectedly.

Q 25. What is your experience with using specialized equipment for handling hazardous materials?

My experience with specialized equipment for handling hazardous materials is extensive. This includes both the practical use of this equipment and the critical understanding of its limitations and proper maintenance.

Examples of equipment I’ve used include:

- Spill response equipment: This includes absorbents, containment booms, and pumps for liquids, and specialized vacuum systems for powders and solids. The proper selection of absorbent depends on the specific hazardous material involved; using the wrong one can worsen the problem.

- Personal Protective Equipment (PPE): I’m proficient in using respirators, protective suits, gloves, and eye protection specific to different hazards. Training and proper fit testing are absolutely paramount for this equipment to be effective.

- Respiratory protection: I’m experienced in selecting and using various respirator types, from air-purifying respirators to supplied-air respirators, based on the specific hazards present. The appropriate respirator is paramount for preventing inhalation exposure.

- Decontamination equipment: This includes showers, equipment wash stations, and specialized cleaning agents for removing hazardous materials from personnel and equipment. Understanding the specific cleaning processes for different materials is critical.

Beyond operational experience, I understand the importance of regular maintenance and inspection of all equipment. Malfunctioning equipment can create more serious hazards than the substance itself.

Q 26. Explain the importance of regular monitoring of air quality in hazardous materials storage areas.

Regular monitoring of air quality in hazardous materials storage areas is essential to ensure employee safety and environmental compliance. It’s a proactive measure to prevent exposure to harmful substances.

Importance of air quality monitoring:

- Early Detection of Leaks: Monitoring can detect even small leaks or spills before they become significant health or environmental hazards. This allows for quick remediation, minimizing exposure and potential damage.

- Compliance with Regulations: Many jurisdictions have strict regulations regarding permissible exposure limits (PELs) for various hazardous substances. Regular monitoring ensures compliance and prevents potential penalties.

- Protection of Employees: By providing real-time data on air quality, monitoring enables the prompt identification and response to any hazardous situations, protecting workers from potential health problems.

- Evaluation of Ventilation Effectiveness: Air quality monitoring provides data that helps assess the efficacy of the existing ventilation system. If concentrations are consistently high, it may indicate that adjustments or upgrades are needed.

Methods include using fixed or portable monitoring equipment to measure the concentration of specific hazardous substances in the air. This data is then compared to established permissible exposure limits (PELs) to determine whether corrective actions are needed.

Q 27. Describe your experience with developing and implementing safety programs for hazardous materials handling.

I have extensive experience in developing and implementing safety programs for hazardous materials handling. This involves more than simply writing a policy; it necessitates a deep understanding of relevant regulations, risk assessment techniques, and effective communication strategies.

Key elements of a comprehensive hazardous materials safety program:

- Risk Assessment: This identifies potential hazards and evaluates their likelihood and severity. It forms the basis for determining appropriate control measures and safety protocols. A thorough risk assessment considers various scenarios, including normal operations, accidents, and emergencies.

- Standard Operating Procedures (SOPs): Detailed procedures should be developed for every task involving hazardous materials, covering safe handling, storage, transportation, and emergency response. SOPs must be easily accessible and regularly reviewed.

- Employee Training: Thorough training programs should be implemented, covering hazard identification, safe work practices, emergency procedures, and the proper use of PPE. Training should be tailored to the specific materials being handled and should include practical demonstrations.

- Emergency Response Planning: A robust emergency response plan is crucial, including procedures for spills, leaks, fires, and other incidents. This includes clearly defining roles and responsibilities, establishing communication channels, and practicing emergency response drills. This isn’t a document that sits on a shelf; it should be tested and updated regularly.

- Record Keeping: Maintaining accurate records of inspections, training, incidents, and corrective actions is crucial for demonstrating compliance and identifying areas for improvement. It’s essential to keep detailed documentation.

In a recent project, I successfully developed and implemented a safety program for a chemical manufacturing plant, resulting in a significant reduction in incidents and improved employee safety and environmental compliance.

Key Topics to Learn for Proper Handling and Storage of Hazardous Materials Interview

- Hazard Identification and Classification: Understanding Globally Harmonized System of Classification and Labelling of Chemicals (GHS) and different hazard classes (e.g., flammable, corrosive, toxic).

- Personal Protective Equipment (PPE): Selecting and properly using appropriate PPE based on identified hazards (e.g., respirators, gloves, eye protection, protective clothing).

- Safe Handling Procedures: Practical application of safe handling techniques for different hazardous materials, including transfer methods, spill response, and emergency procedures.

- Storage Requirements: Understanding and applying appropriate storage conditions based on material properties (e.g., temperature control, segregation, compatibility, ventilation).

- Regulatory Compliance: Familiarity with relevant legislation, regulations, and standards related to hazardous materials handling and storage (e.g., OSHA, EPA).

- Spill Response and Emergency Procedures: Developing a practical understanding of spill response protocols, including containment, cleanup, and reporting procedures. This includes knowing what to do in case of an emergency.

- Waste Management: Understanding proper disposal procedures for hazardous waste, including segregation, labeling, and transportation requirements.

- Documentation and Record Keeping: Maintaining accurate and thorough records related to hazardous materials handling and storage, including inventory, training, and incident reports.

- Risk Assessment and Mitigation: Conducting risk assessments to identify potential hazards and implementing effective control measures to mitigate risks.

- Communication and Training: Effectively communicating hazard information to colleagues and ensuring proper training on safe handling and storage procedures.

Next Steps

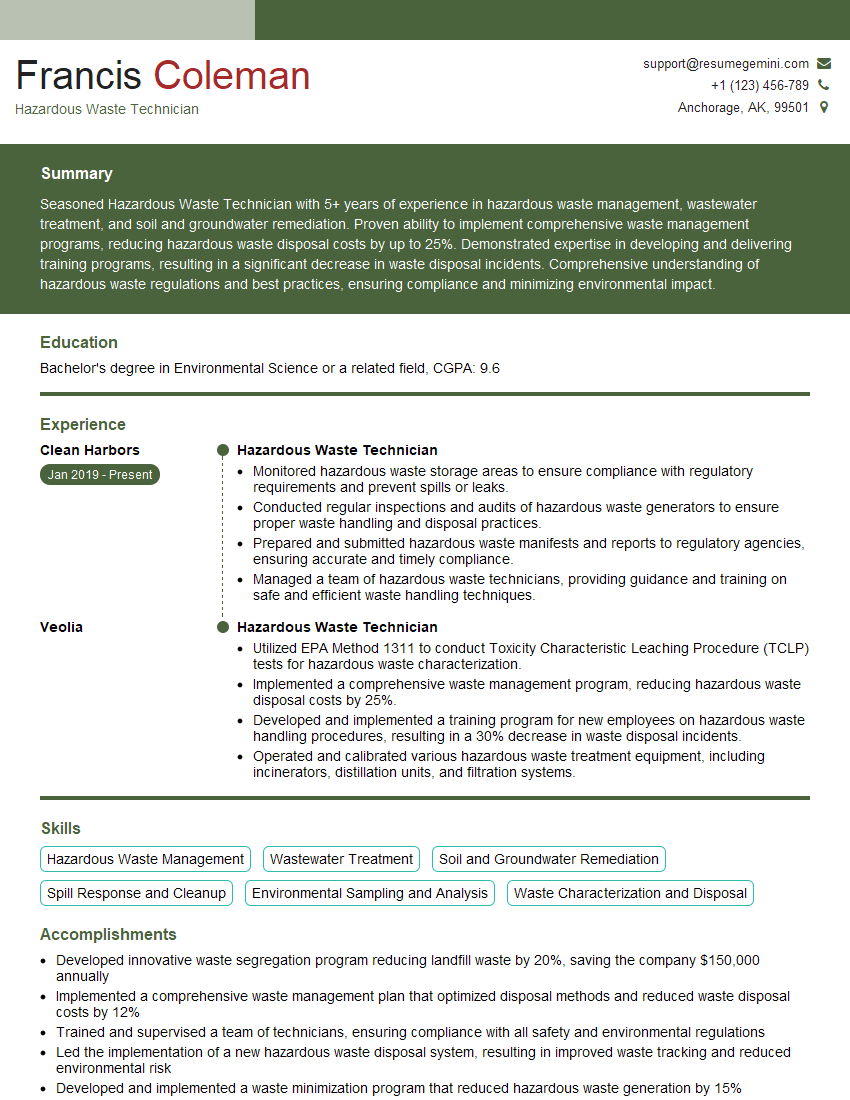

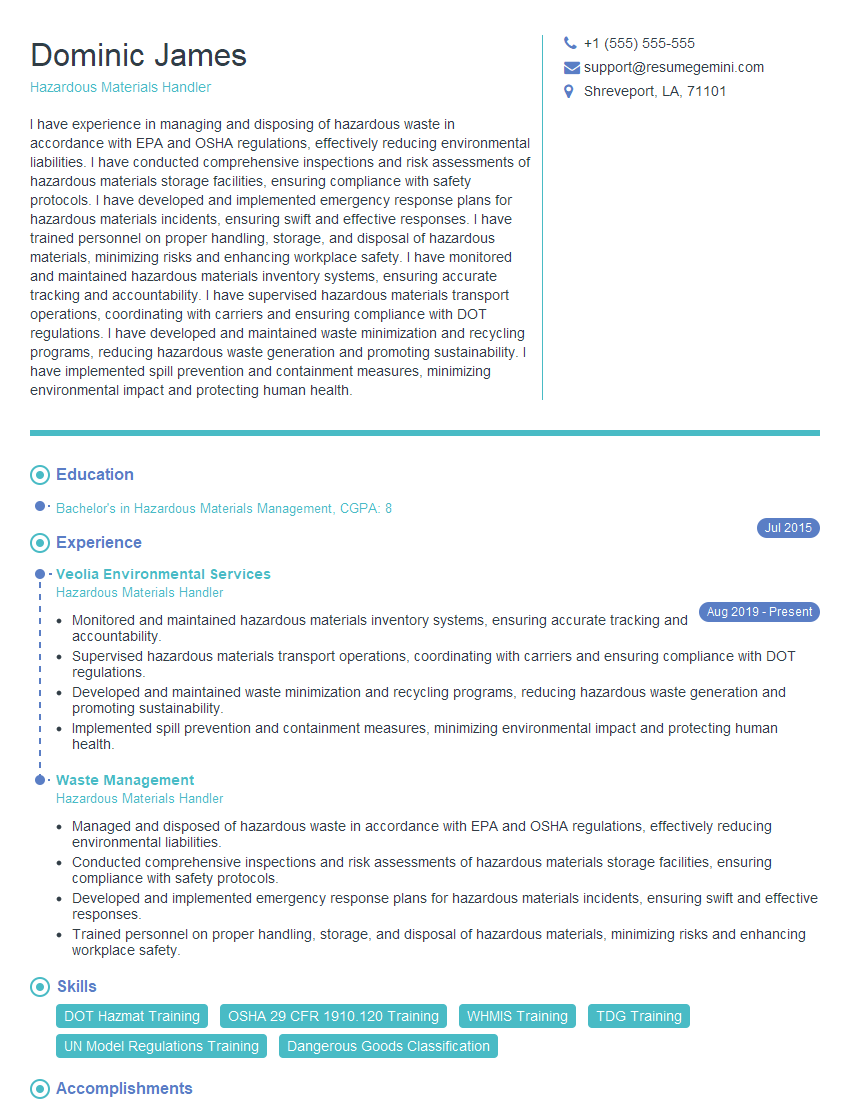

Mastering proper handling and storage of hazardous materials significantly enhances your career prospects in various industries, demonstrating your commitment to safety and compliance. A well-crafted resume is crucial for showcasing these skills effectively to potential employers. Creating an ATS-friendly resume is key to getting your application noticed. To help you build a professional and impactful resume, we recommend using ResumeGemini. ResumeGemini provides tools and resources to create a compelling document that highlights your expertise. Examples of resumes tailored to the Proper handling and storage of hazardous materials field are available to guide your resume creation process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Live Rent Free!

https://bit.ly/LiveRentFREE

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?