Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Ability to handle and dispose of contaminated waste safely interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Ability to handle and dispose of contaminated waste safely Interview

Q 1. Describe the different classes of hazardous waste.

Hazardous waste is classified into different categories based on its characteristics and potential hazards. These classifications help determine appropriate handling, storage, and disposal methods. Key classes include:

- Ignitable wastes: Substances that can easily catch fire (e.g., solvents, paints).

- Corrosive wastes: Substances that can corrode metals (e.g., strong acids, strong bases).

- Reactive wastes: Substances that are unstable and readily react violently with other materials (e.g., explosives, certain chemicals).

- Toxic wastes: Substances that are poisonous or cause health problems (e.g., pesticides, heavy metals like lead and mercury).

- Infectious wastes: Substances containing pathogenic microorganisms that can cause disease (e.g., contaminated medical equipment, cultures).

The specific classification is crucial as it dictates the required safety protocols and disposal pathways. For example, ignitable wastes require specific storage in fire-resistant containers, while toxic wastes need specialized treatment before disposal to prevent environmental contamination.

Q 2. Explain the proper procedures for handling infectious medical waste.

Handling infectious medical waste demands stringent protocols to prevent the spread of disease. The process generally involves these steps:

- Segregation at the source: Separating infectious waste (sharps, bandages, etc.) from regular trash using clearly labeled, puncture-resistant containers. This prevents accidental exposure.

- Packaging: Securing the waste in leak-proof containers and bags, often color-coded for easy identification. Sharps must be placed in rigid, puncture-resistant containers.

- Storage: Storing the waste temporarily in designated areas, usually refrigerated or at room temperature, depending on the waste type, to prevent further contamination and degradation. Storage duration is usually limited.

- Transportation: Transferring the waste to an authorized treatment facility using designated vehicles, often requiring specific documentation and permits. This process must comply with all local, state and federal regulations.

- Treatment and disposal: The waste is then treated, often through incineration, autoclaving (sterilization using high pressure steam), or other approved methods to render it non-infectious and safe for final disposal.

Imagine a hospital dealing with a contaminated needle; proper handling ensures both staff and community safety.

Q 3. What are the regulations governing the transportation of hazardous waste?

Transportation of hazardous waste is heavily regulated to ensure public and environmental safety. Regulations, often managed at the federal and state levels (such as the US Department of Transportation (DOT) and EPA), dictate:

- Manifest System: A detailed tracking system that documents the generation, transportation, and disposal of hazardous waste. This ensures accountability throughout the process.

- Packaging Requirements: Specific packaging and labeling standards to prevent leaks and ensure clear identification of the hazardous materials, indicating the nature of the hazard (e.g., corrosive, flammable).

- Vehicle Specifications: Requirements for trucks and other vehicles used to transport hazardous waste, often including specific safety features and proper placarding to warn others of the hazardous contents.

- Driver Training: Drivers must receive specialized training to handle hazardous materials safely and comply with regulations.

- Emergency Response Plans: Procedures must be in place to address any accidents or spills during transportation.

Failure to comply can lead to significant fines and legal consequences, stressing the importance of careful planning and adherence to regulations.

Q 4. How do you ensure compliance with OSHA and EPA regulations for waste disposal?

Ensuring compliance with OSHA (Occupational Safety and Health Administration) and EPA (Environmental Protection Agency) regulations requires a multi-faceted approach:

- Employee Training: Providing comprehensive training to all personnel involved in handling, storing, and disposing of hazardous waste, covering safety procedures and regulatory requirements.

- Proper Equipment and PPE: Using appropriate equipment (containers, handling tools) and personal protective equipment (PPE) such as gloves, respirators, and safety glasses to protect workers from exposure to hazards.

- Regular Inspections: Conducting routine inspections to ensure compliance with all regulations, identifying potential hazards, and taking corrective actions if necessary.

- Record Keeping: Maintaining meticulous records of waste generation, handling, storage, transportation, and disposal, including manifests and training certifications. This is essential for audits and demonstrating compliance.

- Emergency Preparedness: Developing and regularly testing emergency response plans to handle spills, accidents, and other unforeseen events.

Imagine a scenario where a company fails to properly train employees. This could result in accidents, environmental damage, and serious legal repercussions. A proactive approach, on the other hand, ensures worker safety and environmental protection.

Q 5. Describe your experience with waste segregation and sorting.

My experience with waste segregation and sorting spans various settings, including industrial plants and healthcare facilities. Effective segregation is the cornerstone of safe and efficient waste management. It typically involves:

- Establishing clear waste streams: Defining different categories of waste (hazardous, non-hazardous, recyclable, etc.) and providing clearly labeled containers for each.

- Training personnel: Educating employees on proper waste segregation techniques, including the identification of different waste types and their appropriate containers.

- Implementing visual aids: Using color-coded bins, labels, and signage to improve clarity and reduce errors.

- Regular monitoring and audits: Periodically checking the accuracy of waste segregation to identify and correct any issues.

- Utilizing specialized equipment: In some cases, incorporating machinery to assist in the sorting and processing of waste, especially large-scale operations.

For example, in a manufacturing facility, I implemented a color-coded system with detailed instructions for various types of industrial waste, significantly reducing cross-contamination and improving recycling rates.

Q 6. What are the different methods of waste disposal (e.g., incineration, landfill, recycling)?

Several methods exist for disposing of waste, each with advantages and disadvantages. The choice depends on the waste type and local regulations:

- Incineration: Burning waste at high temperatures to reduce its volume and destroy hazardous components. This is effective for certain types of waste but produces air emissions that need to be carefully controlled.

- Landfilling: Burying waste in designated landfills. This method is cost-effective but can lead to groundwater contamination if not properly managed. Modern landfills utilize liners and leachate collection systems to mitigate this risk.

- Recycling: Processing waste materials to recover valuable resources and create new products. This is environmentally friendly but requires effective collection and sorting systems.

- Composting: Breaking down organic waste (food scraps, yard waste) using natural processes. This creates nutrient-rich soil amendment.

- Treatment and neutralization: Chemical or biological processes to render hazardous waste less harmful before disposal or reuse.

The best method often involves a combination of approaches, creating an integrated waste management strategy.

Q 7. Explain the process of selecting an appropriate waste disposal method.

Selecting the appropriate waste disposal method is a critical decision that needs to consider several factors:

- Waste characterization: Identifying the type and properties of the waste (hazardous or non-hazardous, ignitable, corrosive, etc.).

- Regulatory compliance: Understanding and adhering to all applicable local, state, and federal regulations regarding waste disposal.

- Cost-effectiveness: Evaluating the financial implications of different disposal methods, considering transportation, treatment, and disposal fees.

- Environmental impact: Assessing the potential environmental consequences of each method, such as air and water pollution, greenhouse gas emissions, and potential soil contamination.

- Technological feasibility: Determining whether the necessary technologies and infrastructure are available for a particular disposal method.

- Public health and safety: Prioritizing the protection of public health and safety throughout the process.

For instance, a facility generating large quantities of medical waste would likely prioritize incineration or autoclaving to eliminate pathogens and reduce volume, while a company generating large volumes of recyclable materials would focus on recycling programs. A thorough risk assessment and cost-benefit analysis are usually involved in the selection process.

Q 8. How do you identify and assess risks associated with hazardous waste handling?

Identifying and assessing risks associated with hazardous waste handling is paramount for safety and environmental protection. It involves a systematic process, often following a risk assessment matrix. First, we identify the hazardous waste – its chemical composition, physical properties (like flammability or reactivity), and quantity. We then consider the potential exposure pathways – how could people or the environment come into contact with it? This could be through inhalation, skin contact, ingestion, or environmental leaching. Next, we evaluate the potential consequences of exposure, ranging from minor irritation to severe health effects or environmental damage. Finally, we establish control measures, prioritizing those that eliminate the hazard entirely (e.g., substituting a less hazardous material), then engineering controls (e.g., enclosed systems), administrative controls (e.g., strict work practices), and lastly, personal protective equipment (PPE).

For example, consider handling mercury-contaminated soil. We’d identify mercury as the hazard, its toxicity as the consequence, and exposure pathways like skin contact or inhalation of mercury vapor. Control measures would include using respirators and protective gloves (PPE), containing the soil in sealed containers (engineering control), and establishing strict protocols for handling and transportation (administrative control).

Q 9. What are the personal protective equipment (PPE) requirements for handling contaminated waste?

Personal Protective Equipment (PPE) for handling contaminated waste varies drastically depending on the specific hazard. There’s no one-size-fits-all solution. A thorough risk assessment dictates the appropriate PPE. Generally, this could include:

- Respiratory Protection: Respirators, ranging from dust masks to self-contained breathing apparatus (SCBA), depending on the airborne hazards.

- Skin and Eye Protection: Gloves (nitrile, neoprene, or specialized materials depending on chemical compatibility), eye protection (goggles or face shields), and protective clothing (e.g., coveralls, aprons).

- Foot Protection: Safety boots to protect against punctures and chemical spills.

- Other Protective Gear: Depending on the waste, this could include hearing protection, hard hats, or even specialized suits.

For instance, handling asbestos requires a specialized respirator and a full-body suit. Working with corrosive chemicals necessitates chemical-resistant gloves and eye protection. Proper training on PPE selection, use, and maintenance is essential.

Q 10. Describe your experience with emergency response procedures related to waste spills or accidents.

Emergency response training is a cornerstone of safe waste handling. I’ve participated in numerous emergency response drills and actual incidents involving waste spills and accidents. My training covers containment, evacuation, and notification procedures. In the event of a spill, the immediate priority is to secure the area, preventing further contamination and protecting personnel. This involves using absorbent materials, diking agents, and other containment tools to prevent the spread. Then, proper cleanup procedures are followed, adhering strictly to safety protocols and relevant regulations. We always ensure the appropriate emergency services are notified, providing detailed information about the nature and quantity of the spilled material.

I remember one instance where a drum of solvent unexpectedly ruptured. My immediate actions involved evacuating the area, contacting emergency responders, and deploying spill containment booms to limit the spread of the solvent. Post-incident, we conducted a thorough investigation, identifying the cause and implementing preventive measures to avoid future occurrences.

Q 11. How do you maintain accurate records and documentation for waste disposal activities?

Maintaining accurate records and documentation is not just good practice; it’s a legal requirement in most jurisdictions. These records act as a crucial audit trail and demonstrate compliance. We meticulously document every stage of waste handling, from generation to final disposal. This includes:

- Waste Characterization: Detailed descriptions of the waste, including its chemical composition, physical properties, and estimated quantity.

- Waste Handling Procedures: Documentation of all procedures followed, including safety measures, PPE used, and any unusual occurrences.

- Transportation Records: Detailed information on the transportation of the waste, including the transporter’s details and the route taken.

- Disposal Records: Records of the waste disposal facility used and the method of disposal employed.

We typically use a combination of paper-based and electronic systems to maintain these records, ensuring data integrity and accessibility. This information is vital for tracking waste streams, assessing environmental impact, and ensuring regulatory compliance. We often utilize specialized waste management software to streamline this process and enhance data accuracy.

Q 12. Explain the importance of waste minimization and recycling strategies.

Waste minimization and recycling are critical components of a sustainable waste management strategy. Minimizing waste at the source reduces the amount of hazardous material requiring disposal, lessening the environmental burden and the associated costs. This can be achieved through process optimization, material substitution, and improved operational efficiency. Recycling diverts waste from landfills and recovers valuable materials, reducing the demand for virgin resources and minimizing environmental impact.

For example, implementing a closed-loop system for solvents in a manufacturing process minimizes waste generation, reducing both disposal costs and environmental pollution. Recycling programs for plastics, metals, and other recyclable materials reduce landfill space and conserve natural resources. Implementing a robust waste audit can reveal opportunities for significant waste reduction and improved recycling practices.

Q 13. What are the environmental impacts of improper waste disposal?

Improper waste disposal has severe environmental consequences. It can contaminate soil and water resources, impacting human health and ecosystems. Landfills can leach hazardous substances into groundwater, contaminating drinking water sources. Airborne emissions from improperly managed waste can contribute to air pollution, impacting respiratory health and exacerbating climate change. Improper disposal of hazardous materials can lead to soil contamination, harming plant life and potentially entering the food chain.

For example, the improper disposal of heavy metals can lead to bioaccumulation in the food chain, posing risks to human health. Uncontrolled burning of waste releases harmful pollutants into the atmosphere, contributing to respiratory problems and acid rain. The environmental and economic costs associated with remediating sites contaminated by improper waste disposal are often substantial.

Q 14. Describe your experience with using specialized equipment for waste handling (e.g., forklifts, containers).

I have extensive experience operating and maintaining specialized waste handling equipment, including forklifts, various types of containers (drums, IBC totes, roll-off containers), and specialized transfer pumps for liquids. Forklifts are crucial for moving large containers of waste safely and efficiently. Proper training and certification are necessary to operate these vehicles safely, ensuring compliance with workplace safety regulations. The type of container used depends on the waste’s physical and chemical properties. For example, corrosive chemicals might require special lined containers. Transfer pumps are necessary for safely moving liquids, avoiding spills and potential exposures. Regular maintenance and inspection of all equipment are essential to ensure safe and reliable operation.

I’ve been involved in projects involving the use of specialized containers for radioactive waste, requiring strict adherence to radiation safety protocols and specialized handling procedures. My expertise extends to maintaining detailed operational logs and performing routine inspections to ensure the equipment remains in safe working condition.

Q 15. How do you ensure the safe disposal of radioactive waste?

Safe radioactive waste disposal is a multi-step process prioritizing containment and minimizing environmental impact. It begins with meticulous segregation of waste based on its radioactivity level – high-level, intermediate-level, and low-level. High-level waste, typically spent nuclear fuel, requires specialized long-term storage solutions, often in deep geological repositories designed to isolate the waste for millennia. This involves extensive geological surveys, rigorous engineering, and ongoing monitoring. Intermediate-level waste, such as contaminated equipment, might undergo processes like compaction or cementation to reduce volume and immobilize radionuclides before disposal in dedicated facilities. Low-level waste, such as slightly contaminated clothing or tools, might be disposed of in near-surface repositories after appropriate treatment or simply stored until the radioactivity decays to safe levels.

For example, in managing spent nuclear fuel, the process includes removing the fuel assemblies from the reactor, transporting them in heavily shielded casks, and placing them in temporary storage pools before eventual transfer to a geological repository. Every step involves stringent safety protocols and regulatory oversight.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is your understanding of the Resource Conservation and Recovery Act (RCRA)?

The Resource Conservation and Recovery Act (RCRA) is the cornerstone of US hazardous waste management. It establishes a cradle-to-grave system for hazardous and some non-hazardous waste, covering everything from its generation and transportation to treatment, storage, and disposal. Key aspects include defining hazardous waste characteristics, establishing permitting requirements for facilities handling such waste, and enforcing stringent regulations to prevent environmental contamination and protect human health. RCRA also mandates a comprehensive waste management plan for generators, focusing on minimizing waste generation, proper segregation, labeling, and tracking throughout its lifecycle. Failure to comply with RCRA can result in substantial penalties.

Imagine RCRA as a comprehensive instruction manual for handling dangerous waste materials. It guides companies from how to correctly label a waste container to ensuring a suitable facility handles final disposal, with regular audits to ensure compliance.

Q 17. Describe your experience with environmental audits and inspections.

I have extensive experience with environmental audits and inspections, both conducting them and undergoing them. My experience encompasses various industrial sectors, including nuclear, chemical, and manufacturing. During audits, I meticulously review waste management documentation, such as manifests, treatment records, and disposal permits. I also conduct on-site inspections of waste storage areas, treatment facilities, and disposal sites, evaluating compliance with regulatory standards and best practices. I have been involved in identifying and documenting non-compliances, recommending corrective actions, and verifying their implementation. This process includes sampling and analysis of environmental matrices (soil, water, air) to assess potential contamination.

For example, in one audit, we discovered a chemical manufacturing facility was incorrectly classifying some waste streams, leading to potential environmental risks. We worked with the facility to reclassify the waste, implement improved handling protocols, and ultimately prevent potential contamination.

Q 18. How do you manage waste generated from laboratory settings?

Managing laboratory waste is critical due to the diverse range of hazardous materials involved. My approach emphasizes segregation at the source – each waste stream (e.g., sharps, chemicals, biologicals, radioactive materials) is collected separately in appropriate containers with proper labeling. Detailed records, including waste generation dates and quantities, are meticulously maintained. Waste is then processed according to established protocols, often involving neutralization of chemicals, autoclaving of biological materials, and proper packaging of radioactive materials. Finally, waste is entrusted to licensed disposal companies specializing in handling laboratory waste, ensuring compliance with relevant regulations.

Think of it like organizing a highly complex puzzle – each piece (waste type) needs a specific place and process to ensure it’s handled safely and without risks of cross-contamination.

Q 19. How do you handle situations involving contaminated soil or groundwater?

Handling contaminated soil or groundwater requires a comprehensive approach involving site characterization, remediation strategy development, and execution. Site characterization involves detailed sampling and analysis to define the extent and nature of the contamination. This allows us to determine the appropriate remediation technologies. Remediation strategies can range from in-situ techniques like bioremediation (using microorganisms to break down contaminants) or pump-and-treat (extracting and treating groundwater) to ex-situ methods, involving excavation and off-site treatment of contaminated soil. The choice depends on factors like the type and concentration of contaminants, site geology, and regulatory requirements. Ongoing monitoring is crucial to ensure remediation effectiveness and protect human health and the environment.

For example, I was involved in a project where contaminated soil was treated using bioremediation, significantly reducing costs and minimizing the environmental impact compared to excavation and landfilling.

Q 20. What is your experience with waste treatment technologies (e.g., biological treatment, chemical treatment)?

I have extensive experience with various waste treatment technologies. Biological treatment involves using microorganisms to break down organic contaminants, suitable for biodegradable wastes. Chemical treatment encompasses a wider range of techniques, including neutralization, oxidation, reduction, precipitation, and adsorption, used to treat various inorganic and organic contaminants. For example, neutralization is used to adjust the pH of acidic or alkaline wastes, rendering them less hazardous. Incineration is another significant treatment method, reducing waste volume significantly and destroying many hazardous substances, although it requires strict air pollution control measures. The selection of the most appropriate technology hinges on the specific characteristics of the waste and regulatory requirements.

Choosing the right technology is like selecting the right tool for a job; you wouldn’t use a hammer to screw in a screw – similarly, you must choose the right treatment based on the waste’s composition.

Q 21. How do you communicate effectively with regulatory agencies concerning waste disposal?

Effective communication with regulatory agencies is paramount. It requires proactive engagement, transparency, and accurate reporting. I maintain open channels of communication, providing regular updates on waste management activities, including any deviations from plans and their corrective actions. I ensure all documentation, such as permits, manifests, and monitoring reports, is complete, accurate, and submitted on time. This includes clear and concise reporting on incidents or unexpected events, and actively seeking clarification or guidance when needed. A collaborative approach fosters trust and mutual understanding, helping navigate potential challenges proactively.

Building a strong relationship with regulatory agencies is like building a strong bridge – consistent communication and transparency are fundamental for maintaining a successful working relationship.

Q 22. Describe your experience in developing and implementing waste management plans.

Developing and implementing waste management plans requires a systematic approach, encompassing everything from initial assessment to ongoing monitoring. It begins with a thorough characterization of the waste stream – identifying the types, quantities, and hazards present. For example, in a hospital setting, this would include differentiating between infectious waste, pharmaceutical waste, and general waste. This characterization dictates the appropriate handling, storage, and disposal methods.

Next, we develop a plan that outlines procedures for segregation, packaging, labeling, storage, transportation, and final disposal. This plan includes emergency procedures and staff training protocols. In a manufacturing facility, we might incorporate detailed procedures for the safe handling of chemical waste, including specific PPE requirements and spill response protocols. The plan is then implemented, with regular audits and adjustments made based on performance monitoring. This feedback loop ensures the plan remains effective and compliant with evolving regulations.

Crucially, a robust plan addresses waste minimization strategies – aiming to reduce the volume and hazard level of waste generated in the first place. For example, a shift to reusable containers instead of single-use plastics significantly reduces waste volume and environmental impact. Successful implementation isn’t just about ticking boxes; it requires a strong commitment to safety and environmental responsibility throughout the organization.

Q 23. Explain the process of obtaining permits for waste disposal activities.

Obtaining permits for waste disposal activities varies depending on location and the type of waste, but generally involves a multi-step process. It begins with a detailed application to the relevant environmental agency, typically including a comprehensive waste management plan. This plan needs to detail the volume and type of waste generated, the proposed handling and disposal methods, and the location of storage and disposal sites. The application often requires technical data such as chemical composition analysis for hazardous waste.

The agency will review the application, potentially conducting site inspections to ensure compliance with regulations. This might involve checking for proper storage facilities, safety measures, and adherence to environmental standards. Once the application is approved, a permit is issued, typically with specific conditions and limitations. These might include restrictions on the types and quantities of waste that can be handled, and regular reporting requirements to demonstrate ongoing compliance. Failure to comply with permit conditions can lead to penalties, including fines and permit revocation.

It’s important to remember that permit requirements are dynamic. Regulations change, so maintaining ongoing compliance requires regular review and updating of the waste management plan and ongoing communication with the permitting agency. I’ve personally navigated this process numerous times, and I’m well-versed in the nuances of different jurisdictions.

Q 24. How do you ensure the security and integrity of waste storage areas?

Securing waste storage areas is paramount to preventing unauthorized access, environmental contamination, and potential health hazards. This involves both physical security measures and procedural controls. Physical security could include things like locked containers, fences, security cameras, and alarm systems. The type of security required depends on the hazard level of the waste. For example, highly toxic or radioactive waste requires far more stringent security measures than general municipal waste. However, even for less hazardous materials, access control is critical.

Procedural controls are just as important. Access to storage areas should be restricted to authorized personnel only, with clear protocols for entry and exit. Detailed records should be kept of all waste movements, with specific tracking of who handled the waste and when. Regular inspections are essential to identify and address any security breaches or vulnerabilities promptly. Proper signage is vital to ensure that everyone understands the hazards and precautions required. Finally, having a well-defined emergency response plan in place, including procedures for dealing with unauthorized entry or accidental releases, is crucial.

For example, during my work at a pharmaceutical company, we utilized a combination of physical security measures (locked storage rooms, security cameras) and procedural controls (access badges, meticulously documented waste transfer logs) to maintain the security and integrity of our waste storage areas. This approach ensured strict adherence to safety and environmental regulations.

Q 25. What are your strategies for preventing cross-contamination during waste handling?

Preventing cross-contamination is fundamental in safe waste handling. This involves a multi-layered approach starting with proper waste segregation at the source. Different waste streams must be kept entirely separate to prevent mixing. Clear labeling systems are key, using standardized color-coded containers or labels that easily identify the contents. For example, ‘Infectious Waste’ containers would be distinctly marked and handled separately from ‘Recyclable Materials.’

Next, appropriate personal protective equipment (PPE) is vital. This might include gloves, aprons, respirators, and eye protection, selected based on the specific hazards of the waste being handled. Regular cleaning and disinfection of handling equipment and storage areas are also crucial. Procedures for cleaning spills should be clearly defined and readily available. We must carefully manage the tools used. For example, dedicated tools and equipment should be used for specific waste types, to avoid accidental cross-contamination.

The transportation of waste also requires careful consideration. Waste should be transported in clearly marked, sealed containers to prevent leakage or spillage. Vehicles used for transport should be appropriately cleaned and disinfected between uses. Regular training for staff on safe waste handling practices is vital to ensure everyone understands and adheres to these procedures, minimizing the risk of cross-contamination.

Q 26. Describe your experience with using waste tracking software or databases.

My experience with waste tracking software and databases has been extensive. These systems are essential for managing large volumes of waste effectively and maintaining compliance. Such software typically allows for detailed tracking of waste from generation to final disposal. This includes information on the type and quantity of waste, its location, handling procedures, and final destination. Some systems even include features for generating reports to satisfy regulatory requirements.

For example, in a previous role, we used a system that integrated with our laboratory information management system (LIMS). This enabled automatic generation of waste manifests based on lab experiments, minimizing manual data entry and reducing errors. The software also generated real-time reports on waste volumes, identifying areas for improvement in waste minimization. The database function allowed us to readily retrieve information for audits or investigations, quickly proving compliance with regulations.

These systems enhance traceability, allowing us to quickly identify the source of any contamination or handling issue. This capability is invaluable for problem-solving and minimizing environmental risks. Effective waste tracking software significantly streamlines the entire process, improving efficiency, and ensuring transparency and accountability.

Q 27. How do you stay updated on the latest regulations and best practices in waste management?

Staying current with waste management regulations and best practices is an ongoing process. This requires a multi-pronged approach. I actively subscribe to relevant professional journals and newsletters such as those published by environmental agencies and industry associations. This provides me with timely updates on regulatory changes and emerging best practices. I also participate in industry conferences and workshops to network with other professionals and learn about new technologies and approaches.

Online resources are invaluable. I regularly check the websites of environmental protection agencies for updates to regulations and guidance documents. Many professional organizations offer online training courses and webinars on waste management topics. Furthermore, maintaining relationships with regulatory bodies is crucial. This ensures I am aware of any changes or upcoming inspections. For example, if a new hazardous waste regulation is being proposed, I make sure to understand its implications and adapt our waste management procedures accordingly. This proactive approach ensures I maintain a high level of expertise and compliance.

Key Topics to Learn for Ability to Handle and Dispose of Contaminated Waste Safely Interview

- Waste Classification and Characterization: Understanding different types of contaminated waste (biological, chemical, radioactive) and their associated hazards. Learn about proper identification and segregation techniques.

- Personal Protective Equipment (PPE): Selecting and using appropriate PPE (gloves, respirators, protective clothing) based on the type of waste and potential hazards. Practice explaining the rationale behind PPE choices in different scenarios.

- Safe Handling Procedures: Mastering techniques for the safe handling, transportation, and storage of contaminated waste, including minimizing spills and cross-contamination. Consider specific procedures for different waste types.

- Regulations and Compliance: Familiarity with relevant local, national, and international regulations regarding waste disposal and environmental protection. Be prepared to discuss adherence to safety protocols and reporting procedures.

- Waste Treatment and Disposal Methods: Understanding various waste treatment and disposal methods (incineration, landfilling, biological treatment) and their appropriateness for different waste types. Be able to discuss the pros and cons of each method.

- Emergency Response Procedures: Knowing how to respond to spills, accidents, or other emergencies involving contaminated waste. Practice explaining your approach to emergency situations and containment strategies.

- Documentation and Record Keeping: Understanding the importance of accurate and complete documentation of all waste handling and disposal activities. Be prepared to discuss record-keeping best practices and compliance with regulatory requirements.

- Risk Assessment and Mitigation: Ability to conduct risk assessments to identify potential hazards and implement appropriate control measures to minimize risks to human health and the environment.

Next Steps

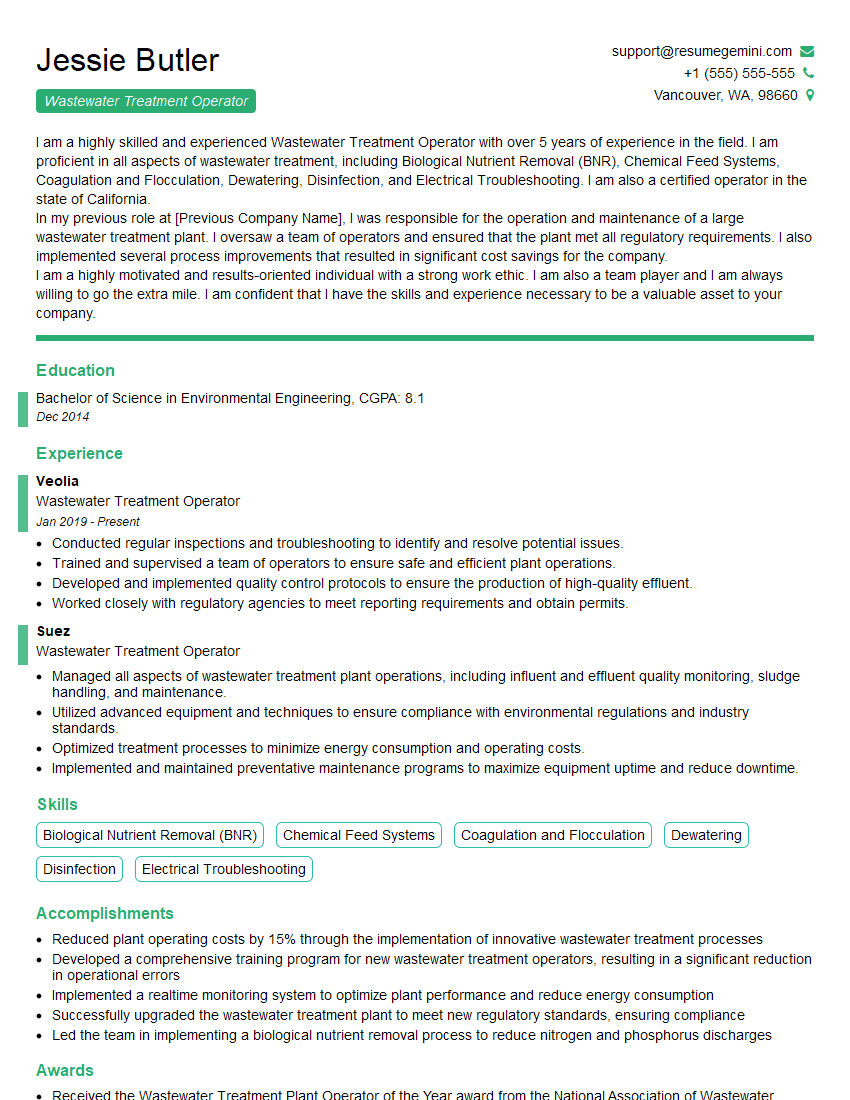

Mastering the safe handling and disposal of contaminated waste is crucial for career advancement in many industries, demonstrating your commitment to safety and environmental responsibility. A strong resume showcasing this expertise is essential. Create an ATS-friendly resume that highlights your skills and experience effectively. Use ResumeGemini to build a professional and impactful resume tailored to your specific experience in handling contaminated waste. Examples of resumes tailored to this field are available to help guide your process. Invest time in crafting a compelling document to increase your chances of landing your dream job.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

hello,

Our consultant firm based in the USA and our client are interested in your products.

Could you provide your company brochure and respond from your official email id (if different from the current in use), so i can send you the client’s requirement.

Payment before production.

I await your answer.

Regards,

MrSmith

hello,

Our consultant firm based in the USA and our client are interested in your products.

Could you provide your company brochure and respond from your official email id (if different from the current in use), so i can send you the client’s requirement.

Payment before production.

I await your answer.

Regards,

MrSmith

These apartments are so amazing, posting them online would break the algorithm.

https://bit.ly/Lovely2BedsApartmentHudsonYards

Reach out at [email protected] and let’s get started!

Take a look at this stunning 2-bedroom apartment perfectly situated NYC’s coveted Hudson Yards!

https://bit.ly/Lovely2BedsApartmentHudsonYards

Live Rent Free!

https://bit.ly/LiveRentFREE

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?