Preparation is the key to success in any interview. In this post, we’ll explore crucial Aerial Fiber Optic Installation interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Aerial Fiber Optic Installation Interview

Q 1. Describe the different types of aerial fiber optic cable.

Aerial fiber optic cables come in various types, primarily differentiated by their construction, fiber count, and protective outer sheath. Think of it like choosing the right rope for a specific job – some are strong enough for heavy lifting, others are more flexible for tighter spaces.

- Single-Mode Fiber (SMF): Uses a tiny core, transmitting a single light beam over long distances with minimal signal loss. This is the workhorse for long-haul telecommunications, like connecting cities.

- Multi-Mode Fiber (MMF): Has a larger core, allowing multiple light beams to travel simultaneously. Suitable for shorter distances, like within a building or campus network. It’s like having multiple lanes on a highway, each carrying data.

- Loose Tube Cable: Fibers are housed within loose tubes, filled with a water-resistant gel, providing excellent protection against moisture. It’s a popular choice for aerial installations.

- Ribbon Cable: Fibers are arranged in ribbons, simplifying handling and splicing. This is efficient for high-fiber-count applications, reducing the number of individual tubes.

- Armored Cable: Offers added protection against rodents, abrasion, and physical damage. Essential in environments with potential hazards like construction zones or areas with wildlife.

The choice of cable type depends on factors like distance, bandwidth requirements, environmental conditions, and budget. For example, a long-haul backbone network will utilize SMF loose tube cable for its superior long-distance capabilities and environmental protection, whereas a short building connection might use MMF ribbon cable for cost-effectiveness and easier termination.

Q 2. Explain the process of installing aerial fiber optic cable.

Installing aerial fiber optic cable is a complex process requiring careful planning and execution. It involves several key stages, much like building a bridge – you need a solid foundation and a precise plan before starting.

- Route Planning and Survey: Determining the optimal cable route, considering factors like terrain, accessibility, and potential obstacles.

- Pole and Hardware Installation: Establishing sturdy mounting points on existing poles or installing new ones, as well as mounting hardware like clamps, rings, and strain relief devices.

- Cable Pulling: Carefully pulling the cable through the route, using winches or other specialized equipment to ensure minimal stress on the fibers. This requires experience and precision to avoid damage.

- Cable Suspension: Securely attaching the cable to the poles and hardware, ensuring proper tension and preventing sagging. This often involves specialized techniques and tools to distribute the weight evenly.

- Splicing and Termination: Connecting the cable to network equipment, involving precise splicing of the fibers and attaching appropriate connectors. This is a critical step requiring specialized training and equipment.

- Testing and Documentation: Thoroughly testing the cable for signal quality and attenuation, followed by creating detailed documentation of the installation for future reference and maintenance.

Throughout the process, stringent adherence to safety procedures is crucial to prevent accidents and protect the integrity of the fiber optic cable.

Q 3. What safety precautions are essential when working with aerial fiber optic cable?

Safety is paramount when working with aerial fiber optic cable. Think of it like working at heights – proper safety measures are not optional. Here are some essential precautions:

- Fall Protection: Harness systems and appropriate safety lines are mandatory when working at heights. Always use appropriate fall protection equipment.

- Electrical Safety: Being aware of and avoiding contact with overhead power lines is vital, as even a near miss can be fatal. Always maintain a safe distance from power lines and never attempt work near them without proper training and clearance.

- Protective Gear: Wearing safety glasses, gloves, and hard hats is essential to protect against cuts, abrasions, and falls.

- Proper Training: All personnel involved in the installation must have the necessary training and certifications. It is not a DIY project.

- Weather Conditions: Avoid working during storms, high winds, or other adverse weather conditions. Safety protocols often specify acceptable weather limits.

- Traffic Control: If the installation is near roadways, establishing appropriate traffic control measures is crucial to prevent accidents.

Regular safety meetings and risk assessments are crucial to ensure adherence to safety protocols and to identify and mitigate potential hazards.

Q 4. How do you identify and troubleshoot common aerial fiber optic cable faults?

Identifying and troubleshooting faults in aerial fiber optic cables requires systematic approaches and specialized testing equipment. It’s like diagnosing a car problem – you need the right tools and knowledge.

- Visual Inspection: Check for physical damage, such as cuts, bends, or kinks in the cable.

- Optical Time-Domain Reflectometer (OTDR): This instrument measures signal attenuation and identifies breaks, splices, or connector problems along the cable’s length. It’s a key tool for pinpointing the location of a fault.

- Optical Power Meter (OPM): Measures the optical power at various points in the system to identify signal loss. This helps to narrow down the section with an issue.

- Fiber Inspection Scope: Allows visual examination of the fiber end faces for cleanliness and damage. Dirt or scratches can severely impact signal quality.

- Continuity Tester: Checks the continuity of the cable’s metallic components, such as the armor or grounding wires.

By systematically applying these tests, you can often quickly identify and pinpoint the fault. Once located, repair or replacement can be performed accordingly.

Q 5. What are the different types of fiber optic connectors and their applications?

Various fiber optic connectors are available, each designed for specific applications and cable types. Selecting the right connector is crucial for reliable signal transmission.

- SC (Subscriber Connector): A common connector known for its reliability and ease of use. It’s a good all-around choice.

- FC (Ferrule Connector): A robust connector with a threaded coupling, ensuring a secure connection, often preferred in environments with vibrations.

- LC (Lucent Connector): A smaller, high-density connector, ideal for high-fiber-count applications, particularly in data centers.

- ST (Straight Tip Connector): A push-pull connector, but less commonly used now due to its susceptibility to misalignment.

- MT-RJ (Mechanical Transfer Registered Jack): A connector designed to terminate two fibers simultaneously, allowing for dual-fiber connections.

The choice of connector is usually determined by the application and the density requirements of the system. For example, high-density data center deployments favor LC connectors due to their small size and ability to pack more fibers into a small space, whereas SC connectors are frequently found in field deployments due to their reliability and ease of termination.

Q 6. Explain the process of splicing fiber optic cables.

Splicing fiber optic cables involves precisely joining two fiber ends to restore signal continuity. It’s a delicate process requiring precision and specialized equipment – imagine perfectly aligning two incredibly fine threads.

- Fiber Preparation: The fiber ends are carefully cleaved to ensure a perfectly flat and perpendicular surface. This requires a precise cleaver to avoid imperfections.

- Fusion Splicing: The most common method involves using a fusion splicer to melt the fiber ends together, creating a strong and transparent fusion. The splicer uses an electric arc to carefully melt the ends together.

- Mechanical Splicing: Uses a sleeve and precision alignment tools to mechanically join the fibers, relying on physical clamping mechanisms. This method may be slightly less precise than fusion splicing.

- Inspection: After splicing, the joint is inspected with a microscope to ensure proper alignment and minimal loss. This is a critical step for ensuring signal quality.

- Testing: The splice is then tested using an OTDR to verify low insertion loss and high return loss. This ensures the splice is performing properly and does not introduce signal impairments.

Proper splicing is vital for maintaining the integrity of the optical signal, ensuring minimal signal loss and avoiding interruptions. Improper splicing can lead to signal attenuation, power loss, and ultimately, connection failures.

Q 7. What are the different types of fiber optic splices?

Different types of fiber optic splices exist, each with its advantages and disadvantages. The choice depends on factors such as the environment, the type of fiber, and budget considerations.

- Fusion Splices: Creates a permanent bond by melting the fiber ends together using an electric arc. It’s preferred for its low loss and high reliability. It’s considered the most durable option, and best for long-term connections.

- Mechanical Splices: Join the fibers using a precision alignment sleeve and clamping mechanism. These are quicker to implement, but may offer slightly higher loss and slightly lower reliability than fusion splicing. They are suitable for environments with temperature fluctuations or harsh conditions where fusion splices could weaken over time.

- Pre-connectorized Splices: Factory-terminated connectors that simply plug together. This provides a quick and easy solution but may have higher insertion loss than fusion or mechanical splicing. It’s useful for rapid deployments where minimizing installation time is a priority.

The choice of splice type will depend on the specific needs of the project and environmental considerations. For example, fusion splicing is generally preferred for permanent, high-reliability applications, while mechanical splicing may be more suitable for temporary installations or environments subject to significant temperature changes.

Q 8. How do you test fiber optic cables for continuity and loss?

Testing fiber optic cables for continuity and loss is crucial to ensure a reliable network. Continuity testing verifies a complete, unbroken path for the signal, while loss testing measures signal degradation during transmission. We use specialized equipment for this.

Continuity Testing: This is often done with a simple fiber optic light source and a power meter. The light source injects light into one end of the fiber, and the power meter measures the light at the other end. A reading indicates continuity; no reading suggests a break.

Loss Testing: This is more complex and requires an Optical Time-Domain Reflectometer (OTDR). The OTDR sends pulses of light down the fiber and analyzes the reflected light to identify losses caused by bends, connectors, or other imperfections. The results are displayed graphically, showing the location and magnitude of any loss.

For example, during a recent installation, we used an OTDR to pinpoint a microbend in a cable causing significant signal attenuation. The OTDR helped us isolate the problem quickly, saving time and resources.

Q 9. What is OTDR and how is it used in aerial fiber optic installation?

An Optical Time-Domain Reflectometer (OTDR) is a sophisticated device that measures light loss and reflections within a fiber optic cable. Think of it like an ultrasound for fiber optics. It sends light pulses down the fiber and measures how much light is reflected back at different points.

In aerial fiber optic installation, the OTDR is indispensable. It helps identify:

- Cable breaks or cuts: A significant reflection indicates a break.

- Splices and connectors: These appear as smaller reflections, indicating the connection points.

- Bends and microbends: These cause light loss and are visible as attenuation on the OTDR trace.

- Fiber quality: The OTDR can reveal variations in the fiber’s manufacturing quality.

Before burying or suspending the cable, we use the OTDR to verify the quality of the entire fiber run, ensuring minimal signal loss and proper installation. We document the OTDR results, making troubleshooting much easier later.

Q 10. Describe the different types of aerial cable hardware (e.g., clamps, grips, etc.)

Aerial fiber optic cable installation relies on a variety of specialized hardware to secure and protect the cable. These include:

- Clamps: These are used to attach the cable to supporting structures like poles and messenger wires. Different clamp types exist, including those designed for different cable sizes and materials. Some are designed for quick release and others for a permanent connection.

- Grips: These provide additional support, usually used in conjunction with clamps, particularly in areas with high wind loads or vibration. They prevent excessive stress on the cable.

- Suspension hardware: This includes messenger wire, support structures (e.g., strand, aerial cable), and various mounting brackets to support the messenger wire itself.

- Splice closures: These protect the splices in the cable, keeping out moisture and other contaminants. They’re crucial for maintaining signal quality.

- Strain relief hardware: This reduces tension on the cable at points of attachment, preventing damage and extending cable life.

Choosing the right hardware is vital. For example, using the wrong clamp can damage the cable, leading to signal loss or failure. We always select hardware appropriate for the cable type, environmental conditions, and the overall cable route.

Q 11. How do you ensure proper grounding and bonding during aerial fiber optic installation?

Proper grounding and bonding are crucial for safety and to protect the fiber optic cable from lightning strikes and voltage surges. It involves connecting the cable’s metallic components (such as the armoring or metallic strands within the cable) to earth ground.

Grounding: This involves creating a path for electrical current to flow safely into the earth in the event of a surge. We typically use ground rods driven deep into the earth and connected to the metallic components of the cabling system.

Bonding: This interconnects all metallic parts of the system, including the grounding rod, the cable sheath (if metallic), and any supporting hardware, ensuring that they are all at the same electrical potential. This prevents voltage differences that could damage equipment or create a shock hazard.

We meticulously document all grounding and bonding connections. This documentation is essential for safety inspections and troubleshooting in the event of a problem. Neglecting grounding and bonding can lead to serious safety risks and equipment damage.

Q 12. What are the regulations and standards governing aerial fiber optic cable installation?

Aerial fiber optic cable installation is governed by a range of regulations and standards that vary by location. These standards prioritize safety, network performance, and long-term reliability. In general, we adhere to industry best practices and local and national codes.

Examples of relevant standards include:

- TIA/EIA standards: These provide guidelines for cable installation, testing, and documentation.

- IEC standards: These are international standards that often influence national regulations.

- National electrical codes (NEC): These codes dictate safety requirements and standards for electrical installations, many of which are applicable to fiber optic cabling.

- Local ordinances and permits: Always check for local regulations pertaining to aerial cable installations, rights-of-way, and other specific requirements.

It’s critical to understand and comply with these standards to avoid costly mistakes, potential liabilities, and ensure the network’s longevity.

Q 13. Explain the concept of fiber optic attenuation and its significance.

Fiber optic attenuation refers to the gradual loss of optical power as light travels through the fiber cable. Imagine it as a whisper getting fainter the further it travels. This loss is measured in decibels per kilometer (dB/km).

Attenuation is significant because it limits the distance over which a signal can be transmitted without amplification. High attenuation necessitates the use of repeaters or amplifiers along the cable route to boost the signal strength and maintain network performance. Several factors contribute to attenuation, including:

- Bending of the fiber: Sharp bends increase attenuation.

- Material absorption: The fiber itself absorbs some light.

- Scattering of light: Imperfections in the fiber cause light scattering.

- Connector losses: Connectors and splices introduce additional losses.

Managing attenuation is vital for designing efficient and reliable fiber optic networks. We use OTDRs to measure attenuation and plan accordingly.

Q 14. How do you manage slack in aerial fiber optic cable?

Managing slack in aerial fiber optic cable is essential to prevent damage caused by wind, temperature changes, or other environmental factors. Excessive tension can cause microbends, impacting signal quality, while insufficient slack can lead to cable breakage.

We use several techniques to manage slack:

- Slack loops: Strategic loops of cable are created at various points along the route, absorbing excess movement.

- Slack storage areas: Designated areas are established to store extra cable, often near support structures.

- Careful cable routing: Planning the route carefully minimizes the need for excessive slack.

- Appropriate hardware: Using hardware designed for slack management, such as strain relief devices, is crucial.

The amount of slack required depends on factors such as cable length, environmental conditions, and the type of support structure. Underestimating or overestimating slack can both lead to problems. Careful planning and attention to detail are critical to successful slack management.

Q 15. How do you handle difficult terrain or environmental conditions during installation?

Handling challenging terrain and environmental conditions during aerial fiber optic installation requires meticulous planning and the use of specialized equipment. Think of it like navigating a complex puzzle – each piece (terrain feature) needs careful consideration.

Steep inclines and rough terrain: We utilize specialized climbing gear, including harnesses, ropes, and ascenders, ensuring safety while navigating difficult slopes. In some cases, we may need to employ helicopters or drones for cable deployment in extremely inaccessible areas.

Adverse weather: Safety is paramount. High winds, heavy rain, or snow can halt operations completely. We monitor weather forecasts closely and suspend work when conditions are unsafe. We also use appropriate protective gear and equipment to withstand the elements.

Obstacles: Trees, power lines, and buildings present obstacles. We use sophisticated surveying techniques and employ trained spotters to ensure safe clearance and avoid damage. For example, specialized tools and techniques are used to carefully navigate around existing utilities.

Water bodies: We might need to use specialized boats or barges for cable crossings or utilize underground conduits where feasible.

In essence, a successful installation in challenging environments depends on a robust safety plan, experienced personnel, and adaptable equipment.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the common causes of fiber optic cable damage?

Fiber optic cable damage, unfortunately, is a common occurrence. It’s akin to handling a delicate strand of glass – care is essential. The most frequent causes include:

Rodent damage: Rodents, especially squirrels and rats, are attracted to the protective jackets of some cables, leading to significant damage.

Construction activities: Excavation and heavy equipment operation near buried or aerial cables often result in accidental cuts or crushing.

Harsh weather: Extreme temperature fluctuations, ice buildup, or strong winds can put stress on the cables, leading to breakage or fiber degradation. For example, prolonged exposure to UV radiation can weaken the outer jacket.

Accidental damage: Tree limbs falling on cables, or vehicles striking poles supporting the cables, are common causes of damage.

Improper installation: Incorrect tensioning, inadequate support structures, or insufficient protection against environmental factors during the initial installation can lead to premature damage.

Preventing damage requires careful planning, regular inspections, and robust cable protection measures.

Q 17. Describe your experience with different types of aerial cable placement techniques.

My experience encompasses several aerial cable placement techniques. Each approach is chosen based on the specific project requirements, terrain, and budget.

Hand-pulling: This method is suitable for shorter spans and less challenging terrain. It’s a slower but more controlled process. We carefully guide the cable through the route, ensuring no excessive stress or kinks.

Reel deployment: This involves using a specialized reel to smoothly deploy the cable over longer distances. Precise control of the cable payout is crucial to prevent tangling or damage.

Helicopter deployment: For extremely long spans or difficult-to-reach areas, helicopters offer a highly efficient solution. This requires precise coordination and specialized rigging to ensure the cable is safely deployed.

Aerial platforms/bucket trucks: These are commonly used for access to poles or overhead structures to facilitate attachment and tensioning of the cable.

I’m proficient in all these techniques and can adapt my approach to any situation.

Q 18. How do you ensure the proper tension of aerial fiber optic cable?

Ensuring proper tension in aerial fiber optic cable is critical for its longevity and performance. Too much tension can lead to breakage, while too little tension can result in sagging and potential damage. We use a combination of techniques:

Tension meters: These instruments precisely measure the tension in the cable, allowing us to maintain the optimal level specified by the manufacturer.

Sag calculations: Before installation, we calculate the expected sag based on the cable’s properties, span length, and anticipated environmental conditions. This helps determine the appropriate tension.

Tensioning equipment: We employ specialized tensioning equipment, such as winches and tensioning clamps, to precisely control the cable’s tension during installation.

Post-installation checks: After installation, we perform thorough checks to ensure the cable’s tension remains within the acceptable range.

The goal is to strike a balance, ensuring the cable hangs securely without excessive stress.

Q 19. What is your experience with aerial fiber optic cable maintenance and repair?

Aerial fiber optic cable maintenance and repair is a crucial aspect of ensuring network uptime and data integrity. Think of it as regular check-ups for a vital artery of communication. My experience covers:

Regular inspections: We conduct visual inspections of the cables and support structures, looking for signs of damage, such as cuts, abrasions, or sagging.

Fault location: Using specialized OTDR (Optical Time-Domain Reflectometer) equipment, we pinpoint the exact location of faults or breaks in the fiber optic cable.

Splicing and repair: We are skilled in splicing damaged fiber optic cables using fusion splicing techniques to restore connectivity. This involves precise alignment and fusion of the broken fibers.

Cable replacement: In cases of significant damage or deterioration, we may need to replace sections or entire lengths of the cable.

Proactive maintenance is key to preventing costly repairs and service interruptions.

Q 20. Describe your experience using various fiber optic test equipment.

Proficiency with fiber optic test equipment is essential for ensuring the quality and integrity of the installed network. It’s like having a comprehensive medical toolkit for diagnosing and treating any network ailment.

OTDR (Optical Time-Domain Reflectometer): This instrument is indispensable for locating faults, measuring fiber loss, and assessing the overall health of the fiber optic cable. I can interpret OTDR traces to diagnose and pinpoint problems with precision.

Optical Power Meter (OPM): Used to measure the optical power levels at various points in the network, ensuring sufficient signal strength and identifying attenuation issues. This helps to ensure the network is operating at optimal performance.

Light Source: Generates a stable light signal for testing purposes, working in tandem with the OPM to assess signal transmission.

Visual Fault Locator (VFL): Helps to quickly locate physical breaks or bends in the fiber optic cable. It’s often the first tool used when tracing the source of a fault.

My expertise extends to interpreting the data from these instruments and using the information to troubleshoot and resolve network issues.

Q 21. How familiar are you with different types of aerial cable support structures?

Familiarity with various aerial cable support structures is paramount for ensuring the long-term stability and protection of the fiber optic network. The choice of structure is based on factors such as cable type, span length, terrain, and environmental conditions. Some common structures include:

Utility poles: Wooden, concrete, or steel poles are widely used for supporting aerial cables. Proper anchoring and grounding are critical.

Self-supporting aerial cables: These cables have a robust design that enables them to support themselves without relying on external structures over shorter spans.

Aerial cable trays/racks: These provide support and protection for the cables, often attached to existing structures or poles.

Suspension bridges and specialized structures: For long spans or challenging terrain, specialized suspension systems and structures may be required.

Understanding the strengths and limitations of each structure is vital for ensuring a safe and reliable installation.

Q 22. How do you handle situations where there’s limited access or visibility during installation?

Limited access during aerial fiber optic installation is a common challenge. We overcome this using a multi-pronged approach. First, thorough pre-installation planning is crucial. This includes detailed route surveys using advanced mapping tools and potentially drone inspections to assess the terrain and identify obstacles beforehand. Second, we utilize specialized equipment such as mini-excavation tools for navigating tight spaces or deploying small, maneuverable drones equipped with cameras to inspect hard-to-reach areas. Finally, innovative techniques like directional drilling or utilizing existing utility pathways are employed to minimize the need for extensive access points. For example, on a recent project in a densely populated urban area, we successfully used a combination of drone inspection and micro-trenching to minimize disruption and install fiber optic cable without impacting pedestrian traffic.

Essentially, it’s about thinking creatively and leveraging technology to overcome physical limitations while maintaining safety and efficiency.

Q 23. Describe your experience with working at heights and adhering to safety protocols.

Safety is paramount in our operations. My experience working at heights involves extensive training in fall protection, including proper use of harnesses, lanyards, and safety lines. I’m certified in both confined space entry and working at heights. Every project begins with a detailed risk assessment, specifically targeting potential fall hazards. We always utilize appropriate safety equipment and strictly adhere to all OSHA regulations and company safety protocols. For instance, we employ spotters during lifts and regularly inspect all equipment before each day’s work. Regular safety meetings emphasize risk mitigation and best practices, creating a strong safety culture within the team.

Q 24. What are your preferred methods for documenting aerial fiber optic cable installations?

Comprehensive documentation is key to ensuring project traceability, maintainability, and accountability. Our preferred methods include a combination of approaches. First, we use Geographic Information Systems (GIS) mapping software to record the precise location of the fiber optic cables, splicing points, and any other relevant infrastructure. This creates a digital ‘as-built’ record easily accessible by all stakeholders. Second, we maintain detailed written records, including daily reports detailing progress, material usage, and any encountered challenges. Finally, we often capture visual records – including photographs and videos – of the entire installation process. This visual documentation provides a powerful record for later reference, helping identify potential issues or discrepancies.

Q 25. How do you coordinate with other crews or utility companies during installation?

Coordination with other crews and utility companies is essential for a successful and safe installation. We actively engage in open communication through daily briefings, scheduled meetings, and consistent collaboration with representatives from other utility companies. This involves sharing detailed route plans, notifying them of our planned work, and obtaining any necessary permits or permissions. We always adhere to established One-Call procedures, ensuring that all underground utilities are properly marked and avoided. In projects with multiple crews, we use radio communication and digital tracking systems to coordinate movements and avoid conflicts. For example, during a recent highway project, clear communication with the traffic management team was essential to minimize disruption to traffic flow.

Q 26. How do you identify and resolve conflicts with existing infrastructure?

Conflicts with existing infrastructure are addressed proactively through rigorous pre-planning and on-site assessment. We use advanced detection tools, such as ground penetrating radar (GPR), to identify underground utilities and potential conflicts before beginning excavation. When conflicts are unavoidable, we employ various techniques, including directional drilling, micro-trenching, or adjusting the cable route to minimize impact. If necessary, we consult with engineers and utility company representatives to find the optimal solution. Detailed documentation of these conflicts and resolutions is included in our final project reports, ensuring that any future work can account for these situations.

Q 27. Describe a challenging aerial fiber optic installation project and how you overcame it.

One particularly challenging project involved installing fiber optic cable across a heavily wooded and mountainous terrain with unpredictable weather. The difficult access and the risk of damage to the environment presented significant hurdles. We overcame these challenges through careful planning, utilizing specialized equipment such as helicopters for cable deployment and employing skilled climbers for difficult sections of the route. We also implemented stringent environmental protection measures to minimize our footprint. Continuous communication and flexible adaptation to unexpected weather delays were crucial to the project’s success. The project ultimately highlighted the importance of preparedness, adaptability, and effective teamwork in complex situations.

Q 28. What are your career goals in the field of aerial fiber optic installation?

My career goals center around continued professional development in aerial fiber optic installation, focusing on improving efficiency, safety, and sustainability. I aim to become a lead installer, mentoring and training newer technicians, and contributing to the development of innovative installation techniques. I’m also interested in exploring opportunities within project management, overseeing complex aerial fiber optic installation projects and ensuring their successful completion while maintaining the highest standards of quality and safety. Ultimately, I want to play a role in expanding the reach of high-speed internet access through reliable and efficient aerial fiber optic infrastructure.

Key Topics to Learn for Aerial Fiber Optic Installation Interview

- Fiber Optic Cable Types and Properties: Understanding different fiber types (single-mode, multi-mode), their characteristics, and applications in aerial installations.

- Aerial Cable Installation Techniques: Mastering techniques like pulling, splicing, terminating, and securing fiber optic cables in aerial environments, including considerations for various terrains and weather conditions.

- Safety Regulations and Procedures: Familiarity with OSHA and industry-specific safety standards for working at heights, handling specialized equipment, and mitigating risks associated with aerial installations.

- Splicing and Termination Techniques: In-depth knowledge of fusion splicing, mechanical splicing, and termination methods, including troubleshooting common issues and ensuring optimal signal transmission.

- Testing and Troubleshooting: Understanding the use of OTDRs, power meters, and other testing equipment to identify and resolve faults in aerial fiber optic networks.

- Aerial Infrastructure Components: Knowledge of various components like poles, anchors, hardware, and strain relief systems used in aerial fiber optic deployments.

- Network Design and Planning: Basic understanding of network design principles and how they relate to aerial fiber optic deployments, including considerations for cable routing and future scalability.

- Problem-Solving and Decision-Making: Ability to analyze and troubleshoot complex problems encountered during installation, repair, or maintenance of aerial fiber optic networks.

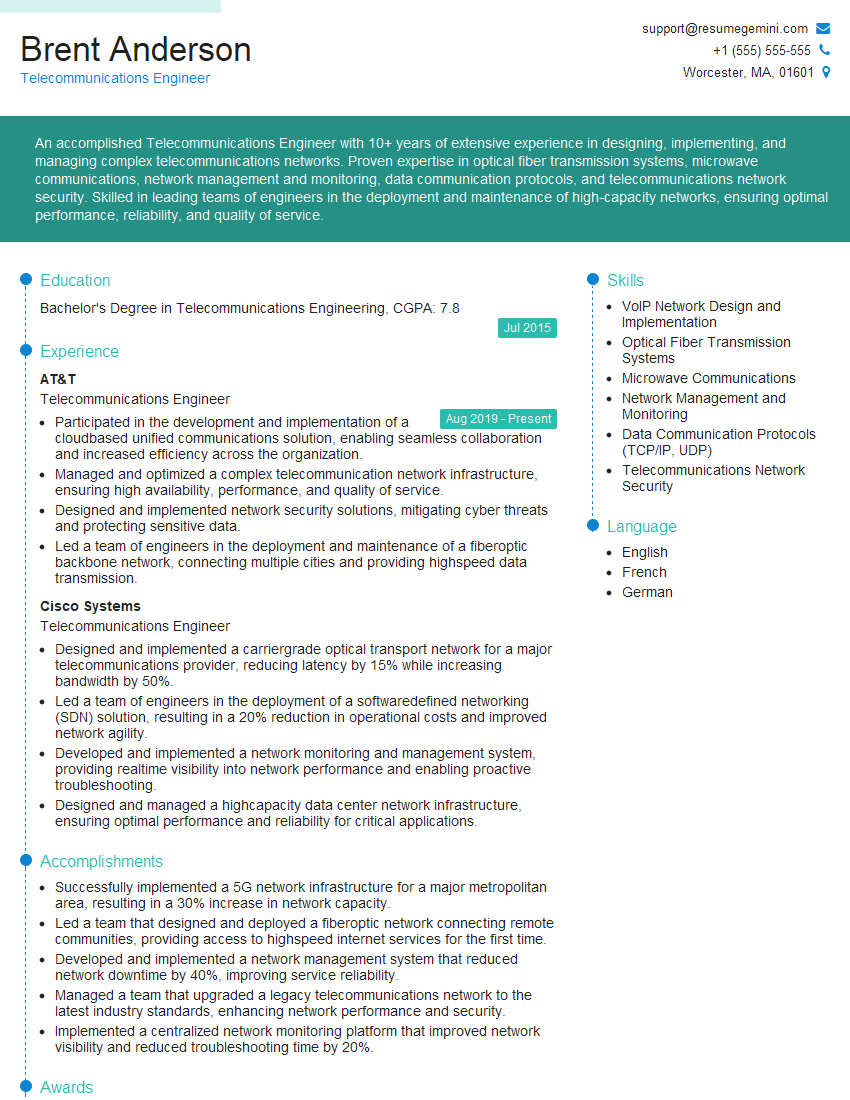

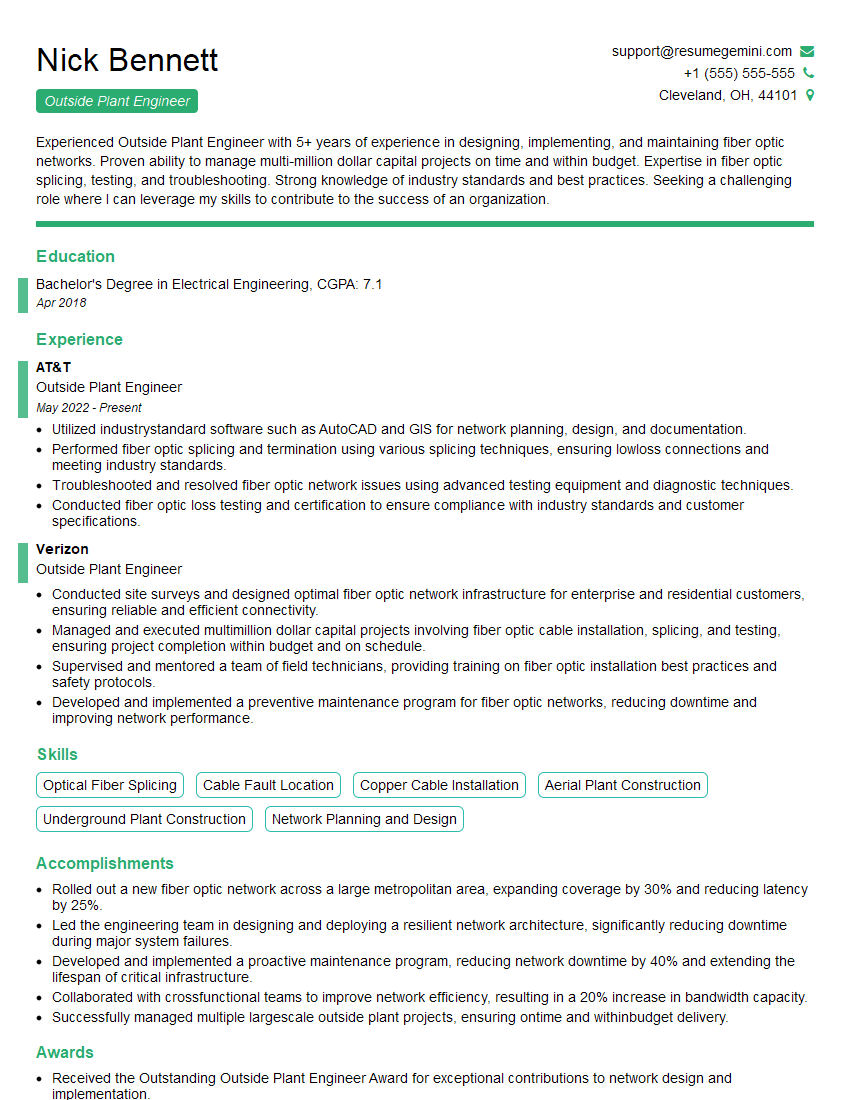

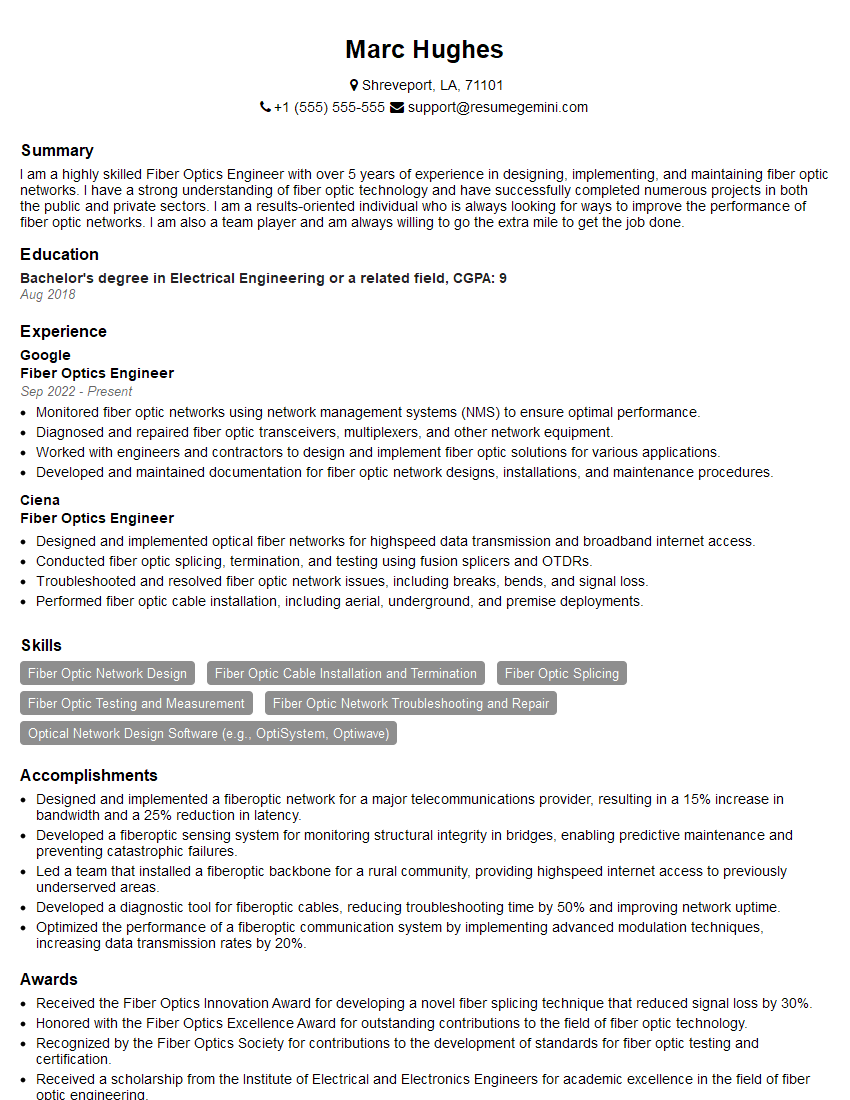

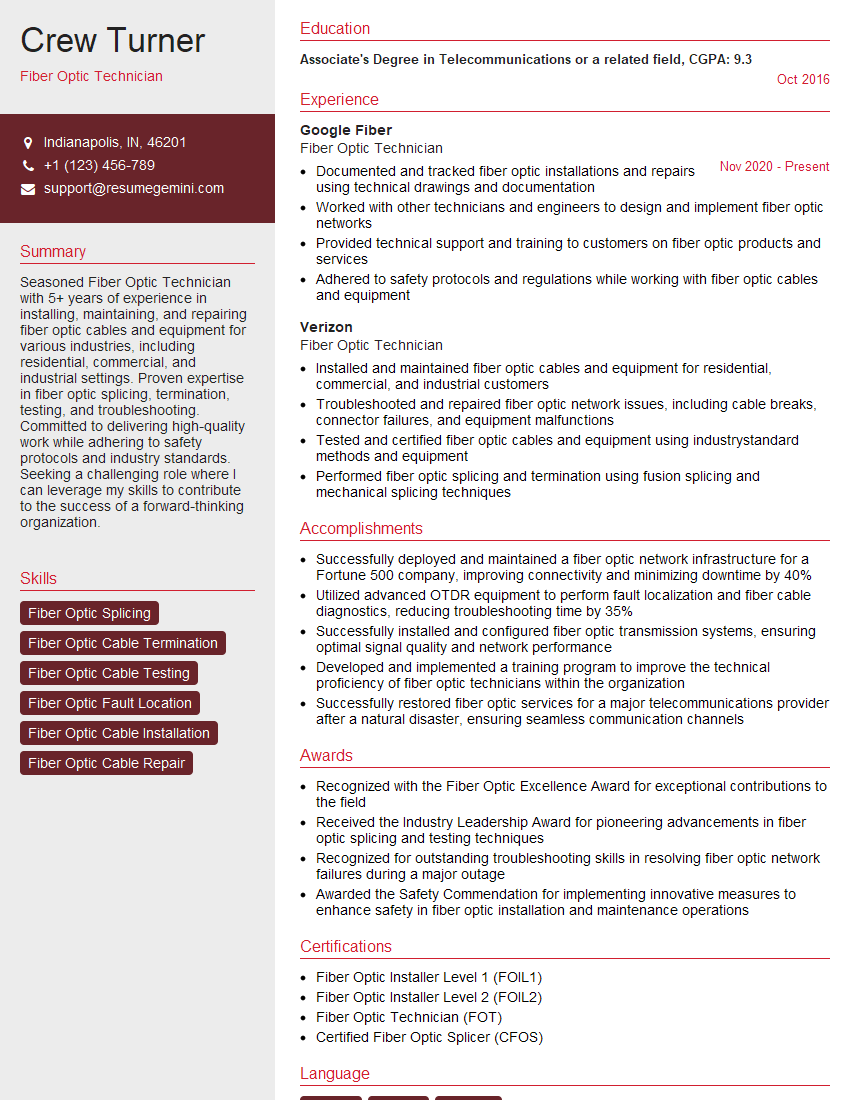

Next Steps

Mastering aerial fiber optic installation opens doors to exciting and rewarding career opportunities in a rapidly growing industry. This specialized skillset is highly sought after, offering excellent prospects for advancement and competitive salaries. To significantly improve your chances of landing your dream job, it’s crucial to present your qualifications effectively. Creating an ATS-friendly resume is essential for getting past applicant tracking systems and into the hands of hiring managers. ResumeGemini is a trusted resource that can help you build a professional and impactful resume, maximizing your chances of interview success. We offer examples of resumes tailored specifically to Aerial Fiber Optic Installation to guide you through the process. Invest the time to craft a compelling resume – it’s your first impression and a critical step toward your career goals.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

hello,

Our consultant firm based in the USA and our client are interested in your products.

Could you provide your company brochure and respond from your official email id (if different from the current in use), so i can send you the client’s requirement.

Payment before production.

I await your answer.

Regards,

MrSmith

hello,

Our consultant firm based in the USA and our client are interested in your products.

Could you provide your company brochure and respond from your official email id (if different from the current in use), so i can send you the client’s requirement.

Payment before production.

I await your answer.

Regards,

MrSmith

These apartments are so amazing, posting them online would break the algorithm.

https://bit.ly/Lovely2BedsApartmentHudsonYards

Reach out at [email protected] and let’s get started!

Take a look at this stunning 2-bedroom apartment perfectly situated NYC’s coveted Hudson Yards!

https://bit.ly/Lovely2BedsApartmentHudsonYards

Live Rent Free!

https://bit.ly/LiveRentFREE

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?