Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Applying Finishes interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Applying Finishes Interview

Q 1. What types of surface preparation are crucial before applying finishes?

Proper surface preparation is paramount to achieving a durable and aesthetically pleasing finish. Think of it like preparing a canvas for a masterpiece – a flawed base will ruin the final product, no matter how skilled the artist. This involves several crucial steps, depending on the substrate (the material being finished):

- Cleaning: Removing dirt, grease, dust, and any previous coatings is vital. Methods include solvent cleaning, pressure washing, abrasive blasting (for tougher jobs), or even simple wiping with a clean cloth.

- Repairing: Filling holes, cracks, or imperfections with appropriate fillers or putties. This ensures a smooth, even surface for the finish to adhere to.

- Sanding: Smoothing out any irregularities after filling or to create the desired surface texture. This typically involves using progressively finer grit sandpaper, from coarser grits for initial leveling to finer grits for a final smooth surface. The choice of grit depends on the material and the desired finish.

- Priming (often necessary): Applying a primer creates a uniform surface, improves adhesion, and often seals the substrate, preventing the finish coat from being absorbed unevenly. Different primers are available for different materials and finishes.

For example, before painting a wooden door, I’d clean it thoroughly, fill any dents or scratches with wood filler, sand it smooth, and then apply a primer specifically designed for wood before applying the final paint coat. Failing to do so could lead to poor adhesion, uneven color, and a shorter lifespan for the finish.

Q 2. Describe your experience with different types of paint spray equipment.

My experience with paint spray equipment spans various types, each suited for different applications and scales of projects. I’m proficient with:

- Airless sprayers: These are powerful and efficient for large-scale projects, like painting houses or industrial structures. They atomize paint under high pressure, delivering a consistent coating quickly. However, they require careful handling to prevent overspray and require regular cleaning to prevent clogging.

- HVLP (High-Volume, Low-Pressure) sprayers: These provide a finer finish with less overspray than airless sprayers. They are ideal for detailed work or when working with delicate surfaces, but they can be slower than airless systems.

- Conventional (pressure-fed) sprayers: These use compressed air to atomize the paint, offering good control and a decent finish. They are more suitable for smaller projects and are easier to clean than airless systems, but they tend to require more skill to master.

- Electrostatic sprayers: These apply an electrostatic charge to the paint particles, improving transfer efficiency and minimizing overspray. They are particularly useful when painting metal objects where even coating is critical.

In my previous role, I used an airless sprayer to paint the exterior of a large office building, while an HVLP sprayer was ideal for finishing delicate trim work in a high-end residential project. Selecting the right equipment is crucial for achieving optimal results and efficiency.

Q 3. How do you ensure uniform coating thickness and avoid runs or sags?

Achieving a uniform coating thickness and preventing runs or sags requires a combination of technique, equipment selection, and material properties. It’s all about controlled application.

- Proper Spray Technique: Maintaining a consistent distance from the surface, using smooth, even strokes, and avoiding overlapping too much are essential. Imagine painting with a gentle, even mist rather than a heavy stream.

- Appropriate Viscosity: The paint’s consistency is critical. Too thick, and it’ll run; too thin, and it might be uneven. Adjusting the viscosity by adding thinner (following manufacturer instructions) is often necessary.

- Multiple Thin Coats: Applying several thin coats is always preferable to one thick coat. This allows for proper drying time between coats, preventing runs and ensuring even coverage. Think of layering – each thin layer contributes to the overall build.

- Environmental Conditions: Temperature and humidity play a significant role. High temperatures can cause faster drying and potential runs, while high humidity can slow down drying and cause issues with adhesion.

- Surface Preparation: A properly prepared surface is less likely to cause issues with runs and sagging.

If runs or sags occur, I’d often lightly sand the affected area once completely dry before applying a subsequent coat to level out the imperfections.

Q 4. Explain the importance of proper ventilation and safety precautions when applying finishes.

Ventilation and safety are paramount when applying finishes. Many paints and coatings contain volatile organic compounds (VOCs) which are harmful if inhaled. This necessitates strict adherence to safety protocols.

- Ventilation: Working in a well-ventilated area, ideally outdoors or with exhaust fans, is crucial to dissipate VOCs. This minimizes the risk of inhaling fumes.

- Personal Protective Equipment (PPE): Always wear appropriate PPE, including respirators (rated for the specific VOCs), safety glasses, gloves, and protective clothing to prevent skin and eye irritation and inhalation hazards. The specific type of PPE depends on the materials being used.

- Fire Safety: Many finishes are flammable, so ensuring no open flames are present and having a fire extinguisher nearby are essential precautions.

- Proper Disposal: Used materials and containers should be disposed of according to local regulations to prevent environmental harm.

For example, when spraying a large area indoors, I always ensure adequate ventilation by utilizing several industrial-grade exhaust fans, and never work without a properly fitted respirator. I’d also provide clear instructions to other workers regarding safety procedures.

Q 5. What are the common causes of finish defects like orange peel, pinholes, or fisheyes?

Several factors can contribute to common finish defects:

- Orange Peel: This textured appearance is often due to excessive spraying distance, improper spray gun settings, too low air pressure (with conventional sprayers), or too high viscosity (thickness) of the paint.

- Pinholes: These tiny holes can be caused by trapped air bubbles in the paint, contamination of the surface, insufficient curing time for the previous layer, or inadequate surface preparation.

- Fisheyes: These crater-like defects are usually caused by contamination from silicones, oils, or other contaminants on the surface. Thorough cleaning is crucial to prevent this.

For instance, if I notice orange peel, I’d adjust the spray gun settings and potentially thin the paint to ensure a smoother finish in subsequent coats. Fisheyes necessitate a thorough cleaning of the surface before reapplication.

Q 6. How do you troubleshoot issues with adhesion or curing of finishes?

Troubleshooting adhesion and curing issues requires systematic investigation. Here’s a step-by-step approach:

- Identify the Problem: Is the finish peeling, cracking, or simply not adhering properly? Is it curing too slowly or too quickly?

- Review Surface Preparation: Was the surface cleaned, repaired, and primed correctly? Insufficient preparation is often the root cause of poor adhesion.

- Check Environmental Conditions: Were the temperature, humidity, and ventilation suitable for the specific finish being applied? Extremes can hinder curing and adhesion.

- Examine Paint/Coating Properties: Was the correct product used for the substrate? Was the paint mixed and thinned according to the manufacturer’s instructions? Incompatible materials can cause adhesion failures.

- Inspect Application Technique: Was the finish applied correctly? Was the correct spray pressure or brush technique used? Improper application can lead to uneven coverage and poor adhesion.

For instance, if the finish is peeling, I would first investigate the surface preparation; perhaps insufficient cleaning or improper priming was the issue. If it’s curing too slowly, I might need to check the temperature and humidity levels and ensure proper ventilation.

Q 7. Describe your experience with different types of paint and coatings (e.g., water-based, solvent-based, powder coatings).

My experience includes working with a wide range of paints and coatings:

- Water-Based Paints: These are environmentally friendly, low-odor options suitable for many interior applications. They are typically easier to clean up than solvent-based paints but may require more coats for full coverage.

- Solvent-Based Paints: These offer excellent durability and coverage but have strong odors and require specialized cleaning solvents. They are often chosen for exterior applications or when high durability is essential.

- Powder Coatings: These are applied electrostatically as a dry powder and then cured in an oven. They offer superior durability, scratch resistance, and a wide range of colors and finishes. They are particularly common in industrial applications.

- Specialty Coatings: This category includes epoxy coatings for corrosion resistance, polyurethane for high gloss and durability, and various other specialized formulations designed for specific purposes (e.g., marine environments, high-temperature applications).

Choosing the right type of paint or coating is dictated by the application, environmental conditions, and required properties of the final finish. For example, I’d use a powder coating for a metal fence that requires high durability and weather resistance, while I would opt for a water-based paint for interior walls where low odor and VOCs are crucial.

Q 8. What are your preferred methods for cleaning and maintaining spray equipment?

Maintaining spray equipment is crucial for consistent finish quality and longevity. My preferred method involves a multi-step process. Immediately after use, I flush the system thoroughly with the appropriate thinner, as recommended by the manufacturer, to remove any remaining finish. This prevents clogging and ensures the equipment is ready for the next job. For example, with a water-based finish, I’d use clean water, while a solvent-based finish requires its specific thinner. Then, I disassemble any removable parts, such as air caps and fluid tips, and clean them meticulously using a brush and thinner, paying close attention to any orifices. After thorough cleaning, I reassemble the equipment, ensuring all parts are correctly aligned. Finally, I store the equipment in a clean, dry place to prevent corrosion and damage.

Regular maintenance, beyond immediate cleaning, includes periodically checking for wear and tear on parts like the needle and nozzle. Replacing worn parts prevents uneven spray patterns and ensures consistent performance. Think of it like regularly changing the oil in a car – it extends the life and improves the function of the equipment.

Q 9. How do you determine the appropriate drying time for different finishes?

Determining the appropriate drying time for different finishes depends on several factors: the type of finish (e.g., lacquer, enamel, polyurethane), the thickness of the applied coat, the ambient temperature and humidity, and the level of cure required. Manufacturers usually provide guidelines on the data sheet, specifying drying times for handling, recoating, and full cure. However, these are just guidelines. I always conduct practical tests to determine the actual drying time in my specific environment. This involves applying a test coat to a sample and then checking the dry time through touch tests at regular intervals. For example, a thick coat of oil-based paint might require 24 hours to dry completely, while a thin coat of water-based varnish might only need a few hours.

In humid conditions, drying times increase significantly, as the moisture in the air slows the evaporation process. Conversely, warmer temperatures accelerate drying. I always take environmental factors into account when determining drying times and might even use fans or dehumidifiers in some situations to control the drying environment and ensure a quality finish.

Q 10. What safety data sheets (SDS) are relevant to your work and how do you use them?

Safety Data Sheets (SDS) are essential for safe handling of all materials used in finishing. They provide critical information on hazards, safe handling procedures, emergency response measures, and disposal methods. Relevant SDS would include those for all paints, stains, thinners, sealers, and any other chemicals I use. Before starting any project, I carefully review the SDS for each product, noting any precautions regarding personal protective equipment (PPE) such as respirators, gloves, and eye protection. For example, an SDS for a solvent-based polyurethane might warn of flammability and respiratory irritation, specifying the need for proper ventilation and a respirator.

I also maintain a centralized system for storing and accessing SDS, ensuring they are readily available to anyone working with the materials. Following the SDS guidelines is not just best practice; it’s crucial for my health and safety, and that of my colleagues.

Q 11. Explain your experience with different finishing techniques (e.g., brushing, rolling, spraying).

My experience encompasses a range of finishing techniques, each with its strengths and weaknesses. Brushing is ideal for detailed work and achieving a textured effect, but it can be labor-intensive and susceptible to brush marks if not applied correctly. I’ve successfully used brushing techniques on intricate moldings, achieving a very fine and controlled finish. Rolling is faster and more efficient for larger surfaces but doesn’t provide the same level of control as brushing. I often use rolling for painting large walls or flat panels, relying on a quality roller to minimize visible streaks.

Spraying offers the smoothest finish, particularly with high-quality equipment, and is ideal for consistent coverage over large areas. However, proper training and experience are crucial to avoid runs and drips. I’m proficient in various spraying techniques, from airless spraying for larger projects to HVLP (High Volume Low Pressure) for finer work where precise control is essential. The choice of technique is always driven by the project’s requirements and the desired outcome.

Q 12. How do you ensure color consistency and matching across multiple parts or surfaces?

Ensuring color consistency is paramount. My approach involves meticulous color matching and preparation. Before starting a project involving multiple parts or surfaces, I always mix enough paint or coating to complete the entire job. This prevents variations in color caused by mixing different batches of paint. If I’m using a pre-mixed color, I always use the same batch number for all surfaces. For custom color matching, I rely on tools like colorimeters, ensuring accurate measurements and consistent results. I also use paint charts and mixing guides for reference. If inconsistencies arise, I utilize small test panels to fine-tune the color before applying it to the final piece.

Maintaining consistent environmental conditions during application also helps to achieve uniformity. Factors like temperature and humidity can influence the final appearance of the finish. This includes ensuring good ventilation and controlled lighting.

Q 13. What is your experience with mixing and tinting paints or coatings?

I’m experienced in mixing and tinting paints and coatings, accurately following manufacturer instructions and using calibrated equipment. This involves precisely measuring pigments and basecoats to achieve the desired color. I’m familiar with both manual and automated tinting systems, understanding how to input color formulas and adjust for variations in base materials. For example, when tinting a basecoat, I’ll use a calibrated scale to measure the precise amount of pigment to be added to achieve the correct shade.

Accuracy is essential; even a small discrepancy can lead to noticeable color differences. I always perform thorough mixing to ensure a uniform color throughout the batch, avoiding color gradients or streaks. I also document my mixing ratios and procedures to maintain consistency.

Q 14. Describe your experience with different types of sanding and surface preparation techniques.

Surface preparation is crucial for a high-quality finish. My experience spans a range of sanding and surface preparation techniques, tailored to the material and the desired outcome. I use various grits of sandpaper, starting with coarser grits to remove imperfections and gradually moving to finer grits to achieve a smooth, even surface. I’m proficient in hand sanding for detailed work and using power sanders for larger areas. Power sanders offer efficiency, but control is key to avoid damage. For example, I’ll utilize orbital sanders for flat surfaces and detail sanders for intricate areas.

Beyond sanding, I use various other surface preparation methods, including cleaning with appropriate solvents to remove dust and grease, filling imperfections with wood filler or spackle, and applying primers to enhance adhesion and improve the final finish. The choice of technique depends on the surface material (wood, metal, plastic, etc.) and the type of finish being applied. A poorly prepared surface will always result in a poor-quality finish.

Q 15. How do you identify and address incompatibility issues between different coatings?

Identifying and addressing incompatibility issues between coatings is crucial for a durable and aesthetically pleasing finish. Incompatibility arises when the chemical properties of one coating negatively interact with the layer beneath it, leading to issues like peeling, blistering, discoloration, or poor adhesion. The key is to understand the chemical composition and properties of each coating.

- Thorough Material Review: Before applying any coating, I always carefully review the manufacturer’s data sheets for compatibility information. This includes checking for specific recommendations regarding substrate types, prior coatings, and curing conditions.

- Testing (when possible): Whenever feasible, I conduct small-scale tests on sample pieces to assess compatibility. This involves applying the coatings in the planned sequence and observing the reaction over time. This proactive approach is far less costly than dealing with a large-scale failure.

- Addressing Issues: If incompatibility is identified, solutions may include: selecting compatible coatings, applying a suitable primer or intercoat, altering application methods (such as using thinner coats), or addressing issues with the underlying substrate (e.g., improper cleaning or preparation).

For example, applying an oil-based paint over a water-based primer can result in the oil paint not adhering properly and peeling off. Careful attention to the manufacturer’s specifications and possibly a compatibility test would prevent this.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is your experience with quality control procedures for applied finishes?

Quality control in applied finishes is paramount to ensuring project success and client satisfaction. My approach employs a multi-stage process throughout the finishing operations.

- Substrate Preparation Inspection: Before even considering applying a finish, I meticulously inspect the substrate for imperfections such as cracks, damage, or inadequate cleaning. This initial check prevents issues down the line.

- Coating Application Monitoring: During the application process, I monitor the consistency, thickness, and evenness of the coating, ensuring adherence to the manufacturer’s recommendations. Any deviations are immediately addressed.

- Visual Inspection and Testing: After each coating layer is applied and cured, a thorough visual inspection is performed for defects like runs, sags, orange peel, or pinholes. Depending on the project and coating type, I may also conduct adhesion tests.

- Documentation: Maintaining detailed records of the materials used, application methods, curing times, and any quality control tests are indispensable. This information is vital for troubleshooting and ensuring consistency across projects.

Imagine a situation where a batch of paint has been improperly mixed. A rigorous quality control process would catch this discrepancy before it leads to a costly rework.

Q 17. How do you handle unexpected issues or problems during the finishing process?

Unexpected issues during finishing are inevitable, but a structured approach helps mitigate their impact. My response begins with a thorough assessment of the problem.

- Problem Identification: The first step is accurately identifying the nature of the issue. Is it a coating defect, a substrate problem, or a procedural error?

- Root Cause Analysis: I investigate the root cause to understand why the problem occurred. This may involve reviewing the application process, checking material compatibility, or assessing environmental factors.

- Solution Implementation: Once the root cause is identified, I develop and implement a solution. This may involve corrective actions such as removing the defective coating, re-preparing the substrate, or adjusting the application techniques.

- Preventive Measures: After resolving the immediate issue, I implement preventive measures to avoid similar problems in the future. This could involve training, improved procedures, or stricter quality control measures.

For example, if blistering occurs during the curing process, I would investigate whether it’s due to poor substrate preparation, trapped moisture, or an incompatibility between coatings. The solution could be a more thorough cleaning and priming of the surface, or perhaps switching to a different coating entirely.

Q 18. How do you manage and dispose of hazardous waste materials generated during finishing?

Managing and disposing of hazardous waste generated during finishing operations is crucial for environmental protection and worker safety. My approach adheres strictly to all relevant regulations and best practices.

- Waste Segregation: I meticulously segregate different types of hazardous waste – solvents, paints, thinners, etc. – into clearly labeled containers.

- Proper Storage: Hazardous waste is stored in a secure location, compliant with safety regulations, to prevent spills or unauthorized access.

- Licensed Disposal: I contract with licensed hazardous waste disposal companies to ensure environmentally sound disposal methods are used. All disposal is documented thoroughly.

- Waste Minimization: I actively employ waste reduction strategies, such as using smaller quantities of materials, recycling where possible, and adopting application techniques that minimize waste generation.

Ignoring proper hazardous waste disposal can have serious environmental and legal consequences. Responsible handling protects our environment and avoids potential penalties.

Q 19. Describe your experience with using specialized finishing tools and equipment.

My experience encompasses a wide range of specialized finishing tools and equipment, including spray guns (HVLP, airless), rollers, brushes, sanders (orbital, belt), and various surface preparation tools.

- Spray Equipment: I’m proficient in using different types of spray guns, adjusting air pressure and fluid viscosity to achieve optimal finishes. Understanding the nuances of different spray techniques (e.g., fan pattern control) is essential for a high-quality finish.

- Surface Preparation Tools: I’m adept at using various sanding tools to prepare surfaces for optimal adhesion. Choosing the right grit for the task is critical.

- Maintenance and Calibration: I’m knowledgeable about the proper maintenance and calibration of these tools to ensure optimal performance and prolong their lifespan. Regular cleaning and maintenance prevent clogging and ensure consistency.

For instance, using an HVLP (High Volume Low Pressure) spray gun minimizes overspray and reduces the amount of hazardous waste generated, showcasing my commitment to efficiency and environmental responsibility.

Q 20. Explain your understanding of different surface preparation methods (e.g., sanding, priming).

Surface preparation is arguably the most important step in the finishing process. It determines the adhesion, durability, and overall appearance of the final finish. My understanding of these methods is extensive.

- Sanding: Sanding is used to smooth the surface, remove imperfections, and create a profile that promotes adhesion. The choice of grit depends on the substrate and desired finish (e.g., finer grits for smoother surfaces).

- Priming: Primers serve several crucial roles: improving adhesion, sealing porous surfaces, blocking stains, and providing a uniform base for the topcoat. Choosing the right primer is key. For example, an oil-based primer might be used on bare wood, while a specialized primer might be needed for metal.

- Cleaning: Thorough cleaning removes dust, grease, and other contaminants that can interfere with adhesion. Appropriate cleaning solvents must be selected to avoid damage to the substrate.

Imagine trying to paint a rusty metal surface without proper surface preparation. The paint would likely peel off quickly due to poor adhesion. Preparation is foundational to a long-lasting, professional finish.

Q 21. How do you ensure compliance with environmental regulations related to finishing operations?

Compliance with environmental regulations related to finishing operations is not just a legal requirement, but an ethical responsibility. My approach involves a multi-faceted strategy.

- Material Selection: I choose materials with low volatile organic compound (VOC) content, adhering to local and national air quality regulations.

- Proper Ventilation: I ensure adequate ventilation during the application process to prevent the buildup of hazardous fumes.

- Waste Management: As discussed earlier, I strictly adhere to all hazardous waste management regulations, using licensed disposal companies and maintaining meticulous records.

- Staying Updated: I stay abreast of changes in environmental regulations through professional development and industry publications. This proactive approach ensures ongoing compliance.

Ignoring environmental regulations can lead to significant fines and reputational damage. Responsible practices are integral to my professional standards.

Q 22. What are your experience with different types of wood finishes?

My experience with wood finishes spans a wide range, encompassing both traditional and modern methods. I’m proficient in applying various types, including:

- Oil-based finishes: These offer excellent depth and richness, particularly linseed oil, tung oil, and Danish oil. I’ve used these extensively on furniture projects, appreciating their ability to penetrate deeply and enhance the wood’s natural beauty. For example, I recently used a tung oil finish on a cherry wood dining table, resulting in a warm, lustrous finish that highlighted the wood’s grain beautifully.

- Lacquer finishes: Known for their fast drying times and durable, hard surface, lacquers are ideal for projects requiring a high-gloss finish and resistance to scratches. I’ve successfully applied nitrocellulose lacquers and catalyzed lacquers on various projects, carefully controlling the application process to avoid runs and imperfections.

- Varnish finishes: Varnishes provide a protective layer with varying degrees of gloss, offering good durability and UV protection. I’ve worked with both oil-based and polyurethane varnishes, understanding the nuances of their application and drying characteristics.

- Shellac finishes: A traditional finish offering a warm, amber tone, shellac is a natural resin that provides a durable yet elegant finish. I have experience using shellac on antique restoration projects, requiring careful attention to detail and multiple thin coats.

- Water-based finishes: These environmentally friendly options are becoming increasingly popular. I’m experienced in applying water-based polyurethane and acrylic finishes, appreciating their low odor and easy cleanup.

This diverse experience allows me to select the optimal finish for any project, considering factors like the wood type, desired aesthetic, and intended use.

Q 23. What are the key differences between solvent-based and water-based finishes?

Solvent-based and water-based finishes differ significantly in their composition, application, and environmental impact. Solvent-based finishes, such as traditional lacquers and varnishes, use volatile organic compounds (VOCs) as solvents. This gives them a strong odor, requires more careful ventilation during application, and can be harmful to the environment. On the other hand, water-based finishes use water as the solvent, making them significantly lower in VOCs, safer to use and better for the environment. The drying process also differs; solvent-based finishes typically dry through solvent evaporation, while water-based finishes dry through water evaporation and polymerization.

Here’s a table summarizing the key differences:

| Feature | Solvent-Based | Water-Based |

|---|---|---|

| VOCs | High | Low |

| Odor | Strong | Low |

| Drying Time | Generally faster | Generally slower |

| Cleanup | Requires solvents | Easy cleanup with water |

| Durability | Generally more durable | Increasingly durable with advancements |

| Cost | Often more expensive | Often less expensive |

The choice between the two depends on the project requirements, environmental concerns, and personal preference. For example, a fast-drying lacquer might be preferred for a high-volume production line, while a water-based polyurethane might be better suited for a home project where low odor is a priority.

Q 24. How do you choose the appropriate finish for a specific substrate or application?

Choosing the right finish involves careful consideration of several factors. The substrate (wood type, its porosity, existing finish), the desired aesthetic (gloss level, color, grain enhancement), and the intended use (indoor/outdoor, high-traffic area, food contact) are all critical. For example:

- Hardwoods like oak and maple: These dense woods can handle a variety of finishes, from oil-based to water-based polyurethanes. The choice depends primarily on the desired aesthetic.

- Softwoods like pine: These are more porous and might require a wood conditioner or multiple coats to achieve a smooth finish. A durable water-based finish is often a good option.

- High-traffic areas: These require a very durable finish such as a catalyzed lacquer or a high-quality polyurethane.

- Food contact surfaces: Only FDA-approved finishes should be used to ensure safety.

I approach the selection process methodically, discussing the project’s specifics with the client, conducting tests if needed, and selecting the finish that optimally meets both aesthetic and functional requirements. This ensures a high-quality and long-lasting result.

Q 25. What is your experience with UV-cured finishes?

My experience with UV-cured finishes is substantial. These finishes are applied in a liquid state and then cured using ultraviolet (UV) light. This rapid curing process is advantageous in high-volume production, offering faster turnaround times than traditional methods. UV-cured finishes are also known for their exceptional durability and resistance to chemicals and scratches. I’ve worked with UV-cured polyurethane and acrylic finishes, employing precise application techniques to ensure consistent coverage and a flawless finish.

I understand the specialized equipment required for UV curing, including UV lamps and conveyor systems. It also requires understanding the specific chemical properties of UV-curable resins to achieve optimal curing and avoid issues like incomplete curing or yellowing over time.

For example, I was involved in a project where we switched from a traditional lacquer finish to a UV-cured system for a high-volume furniture manufacturer. This resulted in a significant increase in production speed and a higher quality, more durable finish.

Q 26. How do you ensure the longevity and durability of applied finishes?

Ensuring longevity and durability requires a multi-faceted approach, starting with proper surface preparation. This includes sanding to the correct grit, cleaning the surface thoroughly, and filling any imperfections. The chosen finish plays a crucial role. High-quality finishes, properly applied, offer superior protection. Application techniques are also key; thin, even coats are crucial to prevent runs and drips, ensuring a uniform finish. Finally, proper curing and post-application care can also significantly enhance the finish’s lifespan. This might involve avoiding exposure to harsh chemicals or excessive moisture depending on the type of finish applied.

For example, I’ve witnessed the detrimental effects of improper surface preparation on a project where insufficient sanding led to a patchy finish. On the other hand, meticulously prepared surfaces with multiple thin coats of a high-quality polyurethane have resulted in remarkably durable finishes lasting for many years.

Q 27. Describe a time you had to troubleshoot a complex finishing problem.

One challenging project involved a custom-made mahogany desk that developed a significant blotchiness after applying a high-end oil-based finish. The blotchiness wasn’t visible initially and only appeared after the finish had dried. This was a complex problem because the blotchiness was significantly altering the visual appeal. I systematically investigated several potential causes, such as inconsistencies in the wood’s moisture content and potential reactions between the finish and the wood itself. I first ruled out issues with the application process and the finish itself. This led to testing the wood’s moisture content and pinpointing areas of inconsistent moisture.

My solution involved a multi-step process: First, I carefully sanded the affected areas to remove the uneven finish. Next, I applied a wood conditioner to equalize the wood’s moisture absorption. Finally, I reapplied the oil-based finish, applying very thin, even coats and monitoring the drying carefully. This time, I ensured that the wood’s surface was fully conditioned before the finish application. This resolved the issue, resulting in a beautifully finished desk that met the client’s expectations.

Q 28. What are your skills in using computer-aided design (CAD) or similar software relevant to the job?

While my primary expertise lies in the practical application of finishes, I have experience with CAD software, primarily for visualizing projects and creating detailed finish specifications. I’m proficient in using software like AutoCAD and SketchUp to create 2D and 3D models that aid in visualizing the final product and in precise detailing of finishing processes. This allows me to effectively communicate design intent to clients and colleagues and prepare detailed plans for efficient and accurate finish application. This also helps in accurately estimating materials needed for a project.

For instance, I recently used SketchUp to create a 3D model of a custom cabinet to accurately plan the finishing process, including the number of coats required and the best strategy to apply them to achieve a seamless transition between surfaces.

Key Topics to Learn for Applying Finishes Interview

- Surface Preparation: Understanding various surface preparation techniques (cleaning, sanding, priming) and their impact on finish adhesion and longevity. Consider the different materials and their unique preparation needs.

- Finish Selection: Knowing the properties of different finishes (e.g., paints, stains, varnishes, lacquers) and choosing the appropriate finish for various substrates and applications. Discuss factors like durability, aesthetics, and environmental impact.

- Application Techniques: Mastering different application methods (brushing, rolling, spraying) and understanding the impact of technique on the final finish. Explore the nuances of each method and their suitability for different projects.

- Troubleshooting Common Issues: Identifying and resolving common problems like brush strokes, uneven coverage, bubbling, and sagging. This demonstrates practical problem-solving skills crucial in the field.

- Health and Safety: Understanding and adhering to relevant health and safety regulations concerning the handling and application of finishes, including proper ventilation and personal protective equipment (PPE).

- Finishing Processes & Techniques: Explore specialized techniques like French polishing, antiquing, distressing, and other advanced methods depending on the specific job requirements.

- Material Knowledge: Deep understanding of different paint types (oil-based, water-based, etc.), their properties, drying times, and compatibility.

Next Steps

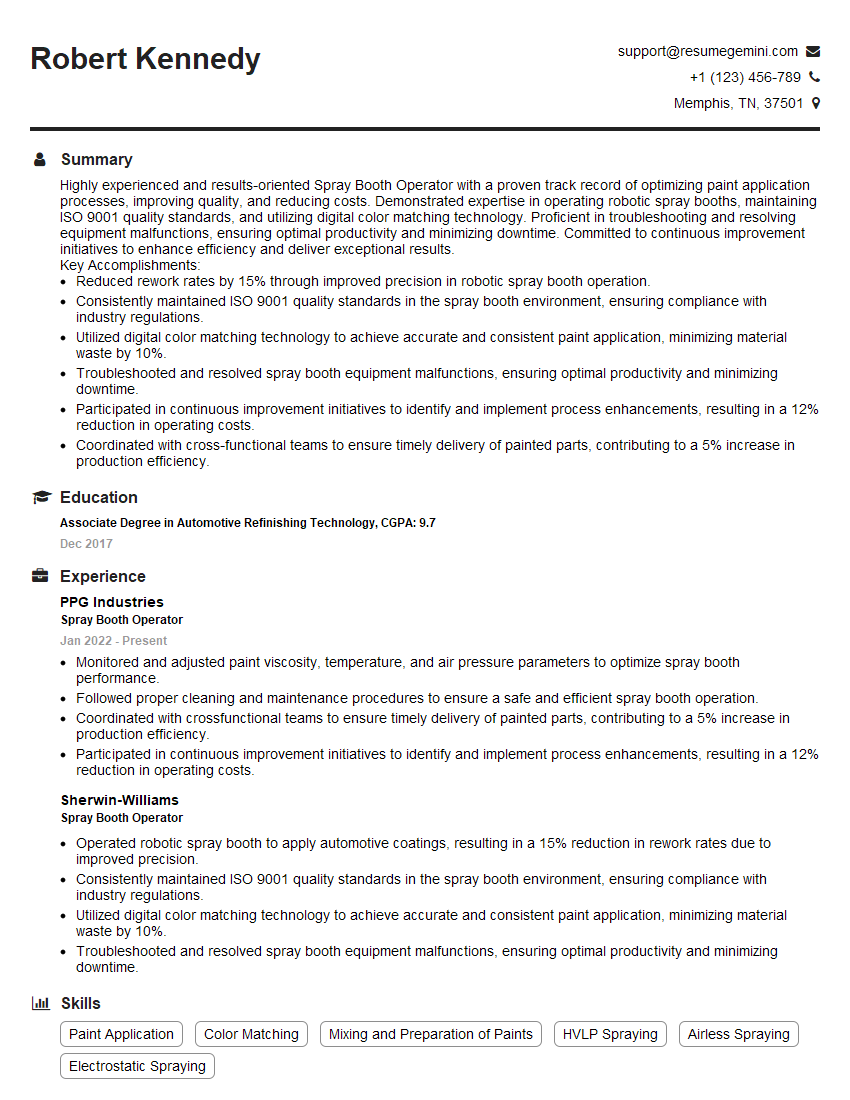

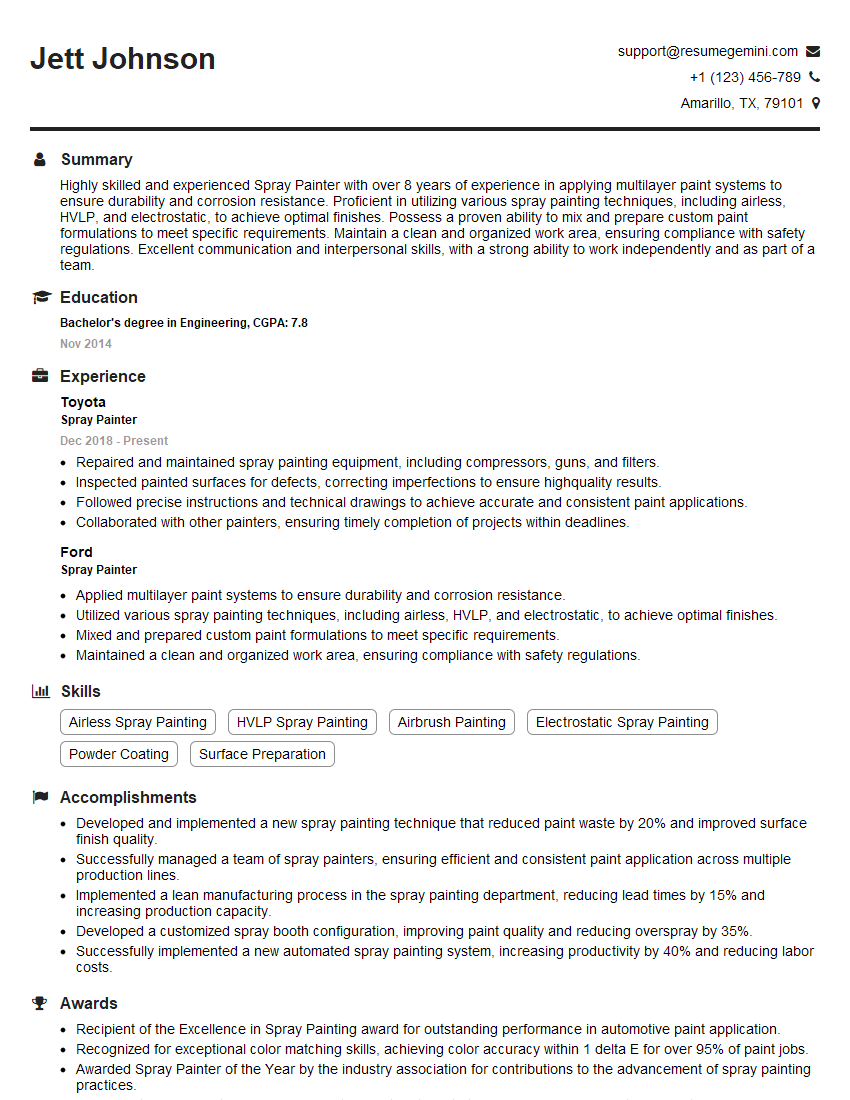

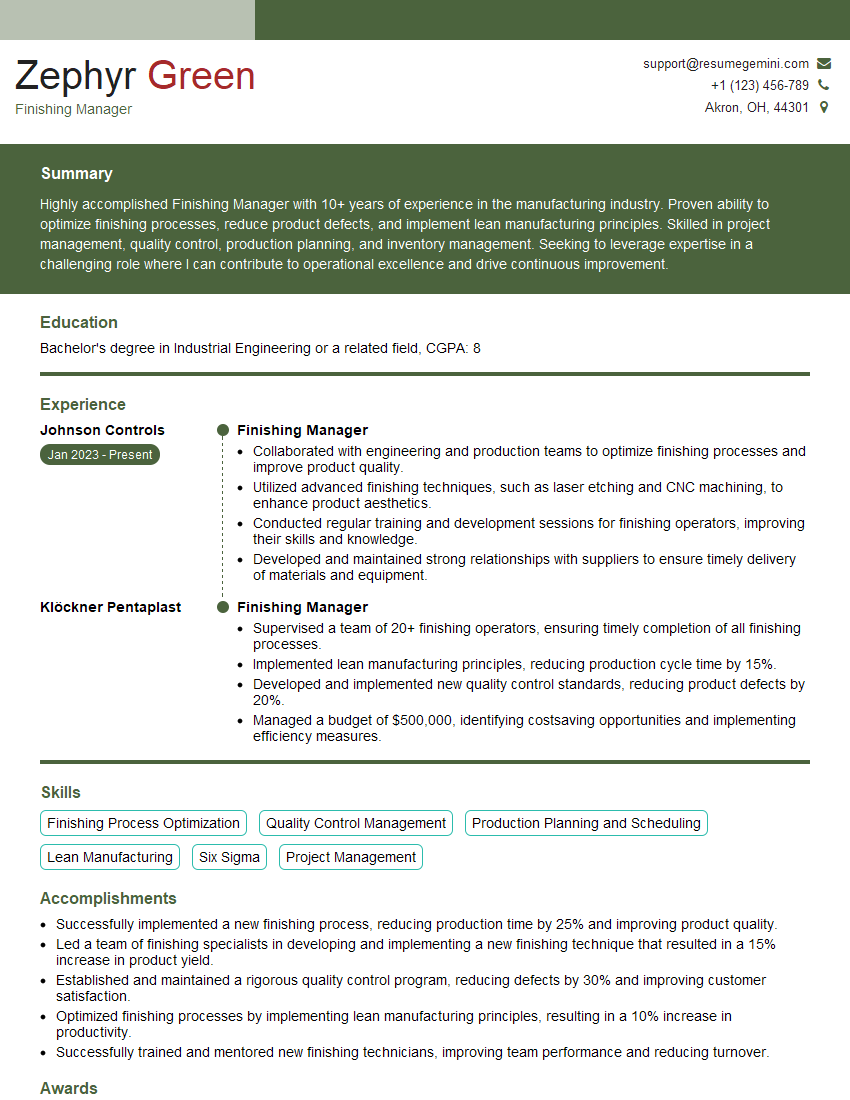

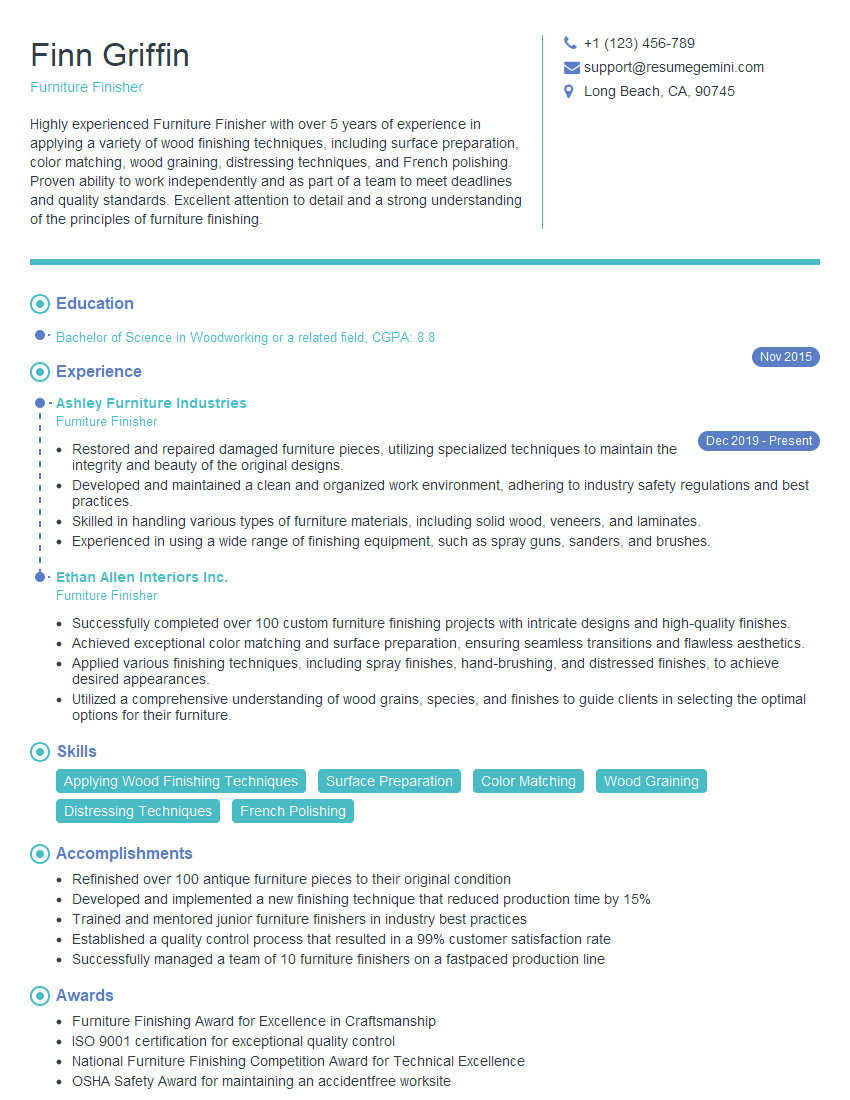

Mastering the art of applying finishes opens doors to exciting career opportunities in various industries, from construction and manufacturing to furniture restoration and custom fabrication. A strong understanding of these techniques showcases your practical skills and attention to detail, making you a highly valuable asset. To maximize your job prospects, create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional and impactful resume. Examples of resumes tailored to Applying Finishes are available to guide you through the process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

hello,

Our consultant firm based in the USA and our client are interested in your products.

Could you provide your company brochure and respond from your official email id (if different from the current in use), so i can send you the client’s requirement.

Payment before production.

I await your answer.

Regards,

MrSmith

hello,

Our consultant firm based in the USA and our client are interested in your products.

Could you provide your company brochure and respond from your official email id (if different from the current in use), so i can send you the client’s requirement.

Payment before production.

I await your answer.

Regards,

MrSmith

These apartments are so amazing, posting them online would break the algorithm.

https://bit.ly/Lovely2BedsApartmentHudsonYards

Reach out at [email protected] and let’s get started!

Take a look at this stunning 2-bedroom apartment perfectly situated NYC’s coveted Hudson Yards!

https://bit.ly/Lovely2BedsApartmentHudsonYards

Live Rent Free!

https://bit.ly/LiveRentFREE

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?