Are you ready to stand out in your next interview? Understanding and preparing for Autoclave Curing interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Autoclave Curing Interview

Q 1. Explain the principles of autoclave curing.

Autoclave curing is a process used in composite manufacturing to consolidate and cure composite materials, primarily thermoset polymers, under controlled temperature and pressure within a sealed chamber. It involves applying heat and pressure to a part in a controlled environment to initiate a chemical reaction in the resin system, causing it to solidify and bond the reinforcement fibers. Think of it like baking a cake but on a much larger, more precise scale. The controlled environment ensures that the curing process happens evenly and produces a high-quality final product.

The process typically involves placing a prepreg (pre-impregnated fiber reinforcement) into the autoclave, evacuating the air to remove any trapped air pockets (voids), and then applying heat and pressure according to a carefully programmed cure cycle. This cycle dictates the temperature and pressure profile for optimal curing of the specific resin system used. The result is a high-performance composite part with improved mechanical properties such as strength, stiffness, and durability.

Q 2. What are the different types of autoclaves used in composite manufacturing?

Autoclaves used in composite manufacturing come in various sizes and configurations, catering to the dimensions and complexity of the parts being cured. Common types include:

- Horizontal Autoclaves: These are the most common type, where the part is loaded horizontally into a cylindrical chamber. They are versatile and can handle large parts.

- Vertical Autoclaves: In this design, the part is loaded vertically, offering advantages in certain applications, particularly with tall, slender parts.

- Out-of-Autoclave (OOA) Curing: While not strictly an autoclave, OOA curing systems use similar principles, employing flexible tooling and controlled heating and pressure, often with vacuum bags, to cure parts outside a pressurized chamber. This method is often chosen for larger parts or when autoclave access is limited.

- Specialized Autoclaves: Some autoclaves are designed for specific applications, such as those used in aerospace or medical device manufacturing, incorporating features like advanced monitoring and control systems.

The choice of autoclave depends on factors like part size, required precision, budget, and available space.

Q 3. Describe the role of pressure and temperature in autoclave curing.

Pressure and temperature are crucial parameters in autoclave curing, working synergistically to achieve optimal resin flow, void removal, and complete polymerization.

Temperature: Provides the energy required to activate the chemical reactions within the resin system, leading to polymerization (the process where the liquid resin transforms into a solid). Higher temperatures generally accelerate the curing process, but excessive temperatures can lead to degradation of the material or the creation of voids.

Pressure: Serves to consolidate the composite laminate, pushing out air and other volatiles, resulting in a denser, stronger part with fewer defects. Pressure also helps to maintain the desired shape and dimensions of the part during the curing process. For instance, in a high-performance aircraft part, precise control of pressure is critical for achieving dimensional accuracy.

The specific temperature and pressure profiles are determined by the resin system being used and the desired final properties of the composite part. These profiles are carefully programmed and monitored throughout the curing cycle.

Q 4. How do you ensure uniform curing within an autoclave?

Uniform curing is paramount for achieving consistent material properties throughout the composite part. Achieving this requires careful attention to several factors:

- Proper Part Placement: Ensuring the part is positioned correctly within the autoclave, avoiding areas of potential heat or pressure stagnation.

- Bleeder Systems and Vacuum Bags: Effective bleeders and vacuum bags are used to remove air and volatiles from the part, promoting even resin flow and minimizing void formation. A well-designed bleeder system ensures that air and resin can escape evenly from all areas of the part, thereby promoting uniform curing.

- Temperature and Pressure Sensors: Autoclaves are equipped with numerous sensors to monitor temperature and pressure at various locations within the chamber, providing real-time feedback and ensuring uniformity. Any deviation from the programmed cycle can indicate problems with uniformity.

- Autoclave Design: The autoclave’s design itself contributes significantly. Even heat distribution within the chamber is a key feature, often achieved using multiple heating elements and insulation.

- Cure Cycle Optimization: A well-defined cure cycle, developed through careful experimentation and analysis, is essential to ensure optimal temperature and pressure profiles for uniform curing. This often involves iterative testing and refinement.

Q 5. What are the common defects found in autoclave-cured parts, and how are they prevented?

Several defects can arise in autoclave-cured parts, impacting their quality and performance:

- Voids: Trapped air pockets weaken the structure and reduce mechanical properties. Preventing voids requires proper vacuum application and bleeders.

- Resin Rich Areas/Resin Starved Areas: Uneven resin distribution leads to localized variations in mechanical properties. This is often prevented via appropriate prepreg layup techniques and proper process control.

- Delamination: Separation of layers within the composite laminate, typically resulting from insufficient pressure or improper cure cycle. Preventing this involves careful layup, correct pressure application, and a suitably optimized cure cycle.

- Wrinkling: Folding or creasing of the fabric layers during curing. This often stems from improper layup or insufficient pressure.

- Blistering: Formation of bubbles on the surface of the part. Often caused by trapped volatiles or uneven heating.

Prevention of these defects involves a combination of careful part preparation, appropriate prepreg selection, optimized cure cycles, meticulous autoclave operation, and robust quality control measures.

Q 6. Explain the importance of vacuum in autoclave curing.

Vacuum is an integral part of the autoclave curing process, primarily serving to remove trapped air and other volatiles (gases released during the curing process) from the composite laminate. This is essential for several reasons:

- Void Reduction: The removal of air significantly reduces the number of voids within the cured part, increasing strength and stiffness. Voids can act as stress concentrators, weakening the material and potentially leading to failure under load.

- Improved Resin Flow: Vacuum assists in the flow of resin throughout the laminate, ensuring proper wetting of the fibers and minimizing resin-rich or resin-starved areas. This contributes to uniform consolidation.

- Enhanced Consolidation: The vacuum helps to consolidate the laminate, leading to a denser and more compact structure, enhancing mechanical performance.

- Improved Surface Finish: By removing trapped gases, the vacuum contributes to a smoother surface finish of the cured part.

The vacuum is typically applied before the heat is introduced to the autoclave and is maintained throughout the initial stages of the curing cycle. The level of vacuum is carefully controlled to optimize the process and avoid damaging the composite material.

Q 7. What safety precautions are essential when operating an autoclave?

Safety is paramount when operating an autoclave. Essential precautions include:

- Proper Training: Operators must receive comprehensive training on autoclave operation, safety procedures, and emergency protocols.

- Personal Protective Equipment (PPE): Appropriate PPE, such as safety glasses, gloves, and hearing protection, must be worn at all times.

- Regular Inspection and Maintenance: The autoclave should undergo regular inspections and maintenance to ensure safe operation. This includes checks of pressure vessels, safety valves, and temperature sensors.

- Emergency Procedures: Operators must be familiar with emergency shutdown procedures and emergency contact information.

- Lockout/Tagout Procedures: Appropriate lockout/tagout procedures must be followed during maintenance or repairs to prevent accidental activation.

- Pressure Vessel Safety: Strict adherence to pressure limits and operating procedures is crucial to prevent explosions or other accidents. Regular pressure testing is essential.

- Material Compatibility: The materials used within the autoclave must be compatible with the operating temperature and pressure conditions to prevent accidents.

Failure to follow these safety precautions can lead to serious accidents, such as explosions or burns. Safety should always be the top priority when operating an autoclave.

Q 8. How do you monitor and control the curing cycle in an autoclave?

Monitoring and controlling the curing cycle in an autoclave is crucial for achieving optimal part quality. It involves precise regulation of temperature, pressure, and vacuum throughout the process. This is typically done using a sophisticated control system that monitors numerous sensors within the autoclave chamber.

Temperature Control: High-precision thermocouples strategically placed within the autoclave monitor the temperature profile. The system ensures the temperature follows a pre-programmed ramp-up, hold, and cool-down schedule, crucial for proper resin polymerization. Deviations from the setpoint are automatically corrected through adjustments to heating elements.

Pressure Control: Pressure is meticulously controlled to compress the prepreg material, eliminating voids and ensuring proper consolidation. Pressure is monitored via pressure transducers and adjusted via automated valves. The pressure profile is typically designed in conjunction with the temperature profile to achieve optimal resin flow and curing.

Vacuum Control: Vacuum is applied before and sometimes during the cure to remove trapped air and volatile organic compounds (VOCs) from the composite material. Vacuum levels are monitored and controlled via vacuum pumps and sensors. Improper vacuum control can lead to porosity in the final part.

Data Logging: All parameters (temperature, pressure, vacuum, time) are continuously logged and stored by the autoclave’s control system. This data is crucial for quality control, process optimization, and troubleshooting.

Example: Imagine curing a carbon fiber reinforced polymer (CFRP) part. The control system might follow a profile with an initial vacuum phase to remove air, followed by a gradual temperature increase under pressure to cure the resin, finally cooling down slowly under pressure to reduce residual stresses.

Q 9. Describe the process of autoclave qualification and validation.

Autoclave qualification and validation are critical steps to ensure the autoclave consistently produces high-quality cured parts. Qualification verifies the autoclave’s design and performance meets specifications, while validation demonstrates that the autoclave consistently produces parts that meet predefined quality criteria.

Qualification: This involves a series of tests to verify that the autoclave’s individual components (heating elements, pressure systems, sensors, control system) are functioning correctly. This may include tests to verify temperature uniformity, pressure accuracy, vacuum levels, and data logging accuracy. Documentation meticulously records all test results and configurations.

Validation: This phase focuses on demonstrating that the autoclave consistently produces parts conforming to predetermined specifications. This often involves curing qualification parts – test specimens made from the intended materials and designed to assess various aspects of the cured composite such as mechanical properties (tensile strength, flexural strength) and void content. These parts are extensively tested, and the results are compared against acceptance criteria. A validation report documents the process, results, and conclusions. A successful validation demonstrates that the autoclave is capable of producing consistently high-quality parts under specified conditions.

Example: For a specific CFRP laminate, the validation might involve curing several test panels and then testing them for tensile strength and interlaminar shear strength. If the results are within the acceptable range defined in the material specifications, the validation is considered successful.

Q 10. What are the different types of resins used in autoclave curing?

A wide variety of resin systems are used in autoclave curing, each with its own properties and curing characteristics.

- Epoxy Resins: These are among the most common resins used, offering a good balance of mechanical properties, chemical resistance, and ease of processing. They come in various formulations, allowing for adjustments to viscosity, curing temperature, and other properties.

- Polyimide Resins: These high-performance resins offer exceptional thermal stability and chemical resistance, making them ideal for applications requiring high-temperature performance. However, they typically have higher curing temperatures and longer cure cycles compared to epoxies.

- Bismaleimides (BMIs): BMIs provide high-temperature capability and good mechanical strength, often used in aerospace and high-performance applications. They typically require higher curing temperatures and pressures than epoxies.

- Cyanate Ester Resins: These offer excellent electrical properties, low dielectric constant, and good thermal stability. They find applications in printed circuit board fabrication and other electronic components.

The selection of resin depends on factors such as the desired mechanical properties, service temperature, chemical resistance, and processing requirements of the final part.

Q 11. How do you select the appropriate curing cycle for a specific resin system?

Selecting the appropriate curing cycle for a specific resin system is crucial for achieving the desired properties of the cured composite part. The choice of cycle parameters is guided by the resin manufacturer’s recommendations, material properties, and part geometry.

The resin manufacturer’s data sheet provides crucial information on the recommended cure cycle, including temperature, pressure, and time parameters. These recommendations are based on extensive testing and ensure optimal curing of the resin system. Deviations from the recommended cycle should be carefully considered and justified.

Factors influencing cycle selection:

- Resin Type: Different resins have vastly different curing behaviors and require specific temperature and pressure profiles.

- Part Geometry: Thick parts require slower heating and cooling rates to prevent internal stresses and temperature gradients.

- Prepreg Material: The type of prepreg (fabric, unidirectional tape) influences the cure cycle due to differences in resin content and fiber architecture.

- Desired Properties: The specific mechanical properties and performance requirements of the final part will guide the optimization of the cure cycle.

Example: A thicker part made from a high-temperature polyimide prepreg would require a longer cure cycle with slower heating and cooling rates compared to a thinner part made from an epoxy prepreg.

Q 12. Explain the concept of cure monitoring in autoclave curing.

Cure monitoring is the process of observing and measuring the curing process in real-time to ensure the resin reaches the desired degree of cure and to detect potential problems early. This is done using various methods.

Methods of Cure Monitoring:

- Differential Scanning Calorimetry (DSC): This technique measures the heat flow associated with the curing reaction, providing insights into the degree of cure and reaction kinetics.

- Dielectric Analysis: This method monitors changes in the dielectric properties of the resin during curing, which are related to the degree of cure and viscosity changes.

- Fiber Optic Sensors: These sensors can be embedded within the composite laminate and measure temperature and strain during the cure, providing localized information on the curing process.

- Acoustic Emission Monitoring: This technique monitors acoustic signals generated during curing, which can be used to detect defects such as delaminations or voids.

Importance: Real-time cure monitoring allows for immediate intervention if problems are detected, preventing the production of defective parts and optimizing the curing process. It enhances quality control, reduces waste, and ensures consistent part quality.

Q 13. What are the limitations of autoclave curing?

While autoclave curing offers excellent control and repeatability, it has certain limitations:

- High Capital Cost: Autoclaves are expensive to purchase and maintain, requiring significant investment.

- Large Footprint: Autoclaves occupy considerable space, limiting their suitability for smaller production facilities.

- Long Cycle Times: Autoclave curing processes typically involve longer cycle times compared to other curing methods.

- Limited Part Size: The size of parts that can be cured is limited by the dimensions of the autoclave chamber.

- Energy Consumption: Autoclaves consume significant energy, particularly for high-temperature applications.

These limitations should be considered when deciding whether autoclave curing is the appropriate technique for a particular application. Alternative curing methods, such as oven curing or out-of-autoclave (OOA) curing, might be more suitable depending on the specific circumstances.

Q 14. Describe different types of autoclave layup techniques.

Autoclave layup techniques describe the methods used to prepare the composite materials within the autoclave prior to curing. The goal is to create a void-free, well-consolidated laminate with the desired fiber orientation and resin content.

Common Layup Techniques:

- Hand Layup: This is a relatively simple technique where prepreg plies are manually placed onto a mold. It is suitable for smaller parts or prototypes but can be less efficient and consistent for larger-scale production.

- Tape Layup: Automated tape laying machines precisely position and consolidate prepreg tapes onto a mold, providing high precision and repeatability, ideal for complex part geometries.

- Automated Fiber Placement (AFP): AFP systems use robotic arms to place continuous fibers onto a mold, resulting in high-quality and consistent laminates. This technique is particularly suitable for large aerospace components.

- Prepreg Drape: Prepreg fabrics are draped onto a mold and often further consolidated using vacuum bagging or other techniques before going into the autoclave. The drape itself is important for minimizing wrinkles or uneven fiber distribution.

The choice of layup technique depends on factors such as part complexity, production volume, desired quality, and cost considerations. For instance, hand layup is often suitable for low-volume prototypes, while AFP is preferred for high-quality, large-scale production of complex parts.

Q 15. How do you troubleshoot common autoclave problems, such as pressure leaks or temperature inconsistencies?

Troubleshooting autoclave issues requires a systematic approach. Pressure leaks, for instance, can stem from faulty seals, damaged gaskets, or even improperly tightened bolts. I’d start by visually inspecting all seals and connections, looking for any visible damage or signs of wear. A leak test using compressed air or a specialized leak detection solution can pinpoint the precise location of the leak. Temperature inconsistencies could be due to faulty thermocouples, an issue with the heating system, or an uneven distribution of heat within the autoclave chamber. I’d first verify the accuracy of the thermocouples using a calibrated thermometer. If the thermocouples are fine, I’d move on to checking the heating elements and ensuring proper airflow within the chamber. Regular preventative maintenance, like cleaning and lubricating moving parts, is crucial in preventing many of these problems.

For example, in one project, we discovered a small crack in a gasket causing a pressure leak. Replacing the gasket completely resolved the issue. Another time, inconsistent temperatures were traced to a malfunctioning control valve, requiring its replacement. Documentation and a detailed logbook are essential to tracking these problems and preventing recurrence.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is the role of bleeder systems in autoclave curing?

Bleeder systems in autoclave curing are vital for controlling pressure and removing trapped air or volatile compounds from the curing part and the autoclave chamber. Think of it like slowly letting air out of a balloon. If air isn’t allowed to escape gradually, pressure can build up unevenly, leading to inconsistencies in the cured material. A bleeder system, typically a valve or series of valves, allows for the controlled venting of air or gases throughout the curing cycle. This prevents the formation of voids or bubbles in the composite part, ensures uniform pressure distribution, and reduces the risk of delamination or other defects. A properly functioning bleeder system is critical for obtaining high-quality, consistent results.

For example, in carbon fiber layups, the presence of trapped air can significantly weaken the final part. The bleeder system helps to remove this air, resulting in a stronger and more reliable part. The type and size of the bleeder system will depend on the size of the part being cured and the type of material.

Q 17. Explain the importance of proper tooling and fixturing in autoclave curing.

Proper tooling and fixturing are absolutely essential for successful autoclave curing. They ensure that the composite part cures under uniform pressure and temperature, resulting in consistent quality. Poor tooling can lead to warping, distortion, or incomplete curing of the part. The tooling needs to be strong enough to withstand the high pressures and temperatures of the autoclave and provide adequate support to the part during the curing cycle. Fixturing, on the other hand, ensures that the part is held securely and accurately within the tooling. This prevents shifting or movement that could lead to defects. The materials used for both tooling and fixturing should be selected carefully to withstand the autoclave environment and not react with the composite materials. Think of it like baking a cake: you need the right pan and supports to get a perfectly shaped and evenly cooked cake. The same logic applies to autoclave curing.

In a recent project, we utilized custom-designed aluminum tooling with precisely engineered fixturing to cure large, complex aerospace components. The tooling’s design included features to ensure even pressure distribution across the part’s surface, and the fixturing provided crucial support to prevent warping during the high-pressure phase. The result was a part with excellent dimensional stability and superior mechanical properties.

Q 18. How do you perform a visual inspection of an autoclave-cured part?

A visual inspection of an autoclave-cured part is a critical step in quality control. The inspection should be performed under controlled lighting conditions, typically with magnification aids like a loupe or microscope. I look for any visible defects such as voids, delaminations, wrinkles, resin-rich areas or dry spots, surface imperfections (e.g., scratches or blemishes), and any inconsistencies in the cure or finish. Documentation of the findings through photographs or detailed written reports is crucial. The level of detail in the visual inspection will depend on the application and the criticality of the part. For instance, aerospace applications often require a far more rigorous visual inspection than less critical applications.

For example, a small void in a critical structural component might be a cause for rejection, while a minor surface blemish on a less critical part might be acceptable. In some cases, we might use non-destructive testing techniques like ultrasonic inspection to further investigate any potential concerns revealed during the visual inspection.

Q 19. What are the advantages and disadvantages of using an autoclave versus other curing methods?

Autoclave curing offers several advantages over other methods such as oven curing or press molding. The most significant is its ability to cure large, complex parts under uniform pressure and temperature, resulting in superior mechanical properties and dimensional stability. It minimizes void formation and provides excellent control over the curing process. However, autoclaves are expensive to purchase and operate, requiring specialized facilities and trained personnel. The curing cycle times can also be longer compared to other methods.

- Advantages: Uniform pressure and temperature distribution, high-quality parts with excellent mechanical properties, minimal void formation, suitable for large and complex parts.

- Disadvantages: High initial investment cost, high operating costs, longer curing cycle times, requires specialized facilities and trained personnel.

Oven curing, for example, is simpler and cheaper but may result in uneven curing and reduced part quality, especially for thick or complex geometries. Press molding provides good dimensional control, but it’s less versatile and may be unsuitable for parts with intricate shapes. The choice of curing method is ultimately determined by factors such as part complexity, production volume, and budget constraints.

Q 20. Describe your experience with different autoclave control systems.

I have extensive experience with various autoclave control systems, ranging from older, analog systems to modern, computer-controlled systems. Older analog systems rely on mechanical components and gauges, requiring meticulous manual adjustments and monitoring. They can be less precise and more prone to human error. Modern computer-controlled systems, on the other hand, offer superior precision and repeatability, allowing for automated control of temperature, pressure, and vacuum. They typically include data logging capabilities for monitoring and analysis of the curing cycle. I’m proficient in using programmable logic controllers (PLCs) to manage and optimize autoclave processes, and I’m familiar with various software packages for cycle programming and data analysis. Experience includes working with systems from leading manufacturers like [mention specific manufacturers if comfortable]. The critical aspect is understanding the underlying principles of control and ensuring the system is properly calibrated and maintained to achieve accurate and repeatable results.

Q 21. How do you ensure the quality and consistency of autoclave-cured parts?

Ensuring quality and consistency in autoclave-cured parts requires a multi-faceted approach. It begins with rigorous process control, including careful monitoring of the curing cycle parameters, such as temperature, pressure, and vacuum levels. Maintaining accurate calibration of all instruments, like thermocouples and pressure gauges, is essential. Regular preventative maintenance of the autoclave itself, including cleaning and lubrication of moving parts, is also crucial. The use of standardized procedures and detailed work instructions helps to minimize variability in the process. A comprehensive quality control program, incorporating visual inspections, non-destructive testing (NDT) techniques, and destructive testing, ensures that the cured parts meet the required specifications. Statistical process control (SPC) can be employed to monitor process performance and identify potential problems before they lead to defects. Proper documentation and record-keeping allow for tracing the production history of each part and facilitate any necessary corrective actions.

In my experience, a strong emphasis on employee training, proper material handling, and a commitment to continuous improvement are equally important for consistently achieving high quality in autoclave curing. This includes regular audits and reviews of the processes to identify any areas for optimization and improvement.

Q 22. Explain the importance of documentation in autoclave curing processes.

Documentation in autoclave curing is paramount for quality control, traceability, and regulatory compliance. It’s the backbone of ensuring consistent, high-quality parts and proving adherence to specifications. Think of it as a detailed recipe and a meticulous log of every step in baking a complex cake – if something goes wrong, you need to know exactly what happened and when.

- Batch Records: These meticulously track the materials used (resin type, fiber type, quantities), curing cycle parameters (temperature, pressure, time), and any deviations from the standard procedure. They include operator signatures and quality control check-off points.

- Calibration Logs: Autoclave sensors, pressure gauges, and temperature controllers must be regularly calibrated. Records of these calibrations are critical for validating the accuracy of the curing process. Imagine baking with a faulty oven thermometer – your results would be inconsistent and potentially disastrous.

- Maintenance Logs: Preventative maintenance is crucial to the longevity and reliability of the autoclave. Detailed logs track all scheduled and unscheduled maintenance activities, including repairs, replacements, and service records.

- Non-Conformance Reports: Any deviation from the expected outcome, be it a defect in a cured part or a process malfunction, must be documented in detail. This allows for root-cause analysis and implementation of corrective actions, preventing future recurrences.

Without thorough documentation, troubleshooting becomes a nightmare, and regulatory audits can become significant challenges. It’s a crucial aspect of running a successful and compliant autoclave curing operation.

Q 23. How do you handle non-conforming parts in autoclave curing?

Handling non-conforming parts involves a systematic process designed to identify the root cause of the failure, contain the problem, and prevent future occurrences. This is where thorough documentation from the autoclave process plays a vital role.

- Isolation and Identification: Immediately isolate the non-conforming parts to prevent further use or mixing with conforming parts. Carefully document the part’s identification number and the specific non-conformances observed (e.g., voids, delamination, insufficient cure).

- Root Cause Analysis: A thorough investigation is undertaken to determine the underlying cause of the non-conformity. This may involve reviewing the batch records, examining the part itself (possibly with destructive testing), and inspecting the autoclave’s operational logs. For instance, insufficient vacuum pressure might lead to voids, while improper resin mixing could result in delamination.

- Corrective and Preventative Actions: Based on the root cause analysis, corrective actions are implemented to address the immediate problem (e.g., adjusting the curing cycle parameters, replacing faulty equipment). Preventative actions are implemented to prevent future recurrences (e.g., improved operator training, enhanced quality control checks).

- Disposition: A decision is made on the disposition of the non-conforming parts. Options may include repair, rework, scrap, or concessionary use (with appropriate approvals). This disposition must be documented.

- Documentation: All actions taken, from initial identification to final disposition, must be meticulously documented in a non-conformance report (NCR). This report serves as a record of the event, the corrective actions taken, and the preventative measures implemented.

This structured approach ensures that non-conforming parts are handled efficiently, preventing defects from reaching the customer and continually improving the autoclave curing process.

Q 24. What are the environmental considerations associated with autoclave curing?

Environmental considerations in autoclave curing are primarily focused on minimizing emissions and waste. Autoclaves consume significant energy and can generate emissions during the curing process. This requires mindful attention to sustainability and regulatory compliance.

- Volatile Organic Compound (VOC) Emissions: Many resins used in autoclave curing release VOCs during the curing process. These emissions can contribute to air pollution and have health implications. Proper ventilation and potentially VOC abatement systems are critical for minimizing environmental impact. We often employ closed-loop systems or activated carbon filters to mitigate these emissions.

- Energy Consumption: Autoclaves are energy-intensive equipment. Implementing energy-efficient practices, such as optimizing curing cycles and using insulation to minimize heat loss, is essential for reducing energy consumption and operational costs.

- Waste Management: The process generates waste, including resin remnants, used consumables, and potentially defective parts. Proper waste handling and disposal practices, compliant with local and national regulations, are vital. This typically involves segregation of waste streams for proper recycling or disposal.

- Water Consumption: While less significant than energy and VOCs, some autoclave operations might require water for cooling or cleaning. Minimizing water usage through efficient cooling systems is a good environmental practice.

Implementing sustainable practices not only benefits the environment but also contributes to cost savings and a positive corporate image. Environmental compliance is often mandated, requiring strict adherence to emission standards and waste management regulations.

Q 25. Describe your experience with preventative maintenance on autoclaves.

Preventative maintenance is crucial for ensuring the safe and efficient operation of an autoclave, preventing costly downtime and extending its lifespan. My experience emphasizes a proactive approach, rather than reactive repairs.

- Scheduled Maintenance: I’ve always adhered to a rigorous schedule of preventative maintenance, including regular inspections of seals, safety interlocks, heating elements, and pressure sensors. This often follows a manufacturer’s recommended schedule, adjusted based on usage frequency and observed wear and tear.

- Calibration and Verification: Precise temperature and pressure control are paramount. I’ve managed the calibration and verification of all sensing and control equipment using traceable standards and documented procedures. Any deviations are investigated and addressed promptly.

- Cleaning and Sanitization: Maintaining a clean autoclave is crucial for preventing contamination and ensuring consistent curing results. Regular cleaning and sanitization procedures, including proper removal of resin residues and thorough drying, are an essential part of the maintenance plan.

- Component Replacement: Certain components have a finite lifespan. Predictive maintenance techniques, like monitoring vibration levels or thermal cycles, help anticipate failures and schedule replacements proactively. This avoids unexpected downtime and associated production losses.

- Documentation: All maintenance activities are meticulously documented, including dates, performed actions, and responsible personnel. This documentation is essential for tracking maintenance history, identifying trends, and facilitating regulatory compliance.

A well-planned preventative maintenance program not only extends the life of the autoclave but also ensures the consistency and quality of the cured parts, contributing to overall operational efficiency and profitability.

Q 26. Explain your understanding of different resin transfer molding techniques related to autoclave curing.

Resin Transfer Molding (RTM) is a composite manufacturing process where resin is injected into a closed mold containing reinforcement fibers. Autoclave curing is often used to consolidate the RTM parts, leading to improved mechanical properties. Several techniques exist:

- Liquid Resin Transfer Molding (LRTM): The most common RTM process where liquid resin is injected under low pressure. The autoclave provides the necessary pressure and temperature for cure.

- High-Pressure Resin Transfer Molding (H-RTM): Uses higher injection pressures, resulting in faster cycle times and potentially improved fiber compaction. Autoclave curing is still crucial for final consolidation and resin flow.

- Structural Reaction Injection Molding (SRIM): Combines RTM with reaction injection molding (RIM) principles. Reactive resins are mixed just prior to injection, leading to faster curing times, often still requiring autoclave post-cure.

- Vacuum Assisted Resin Transfer Molding (VARTM): Uses vacuum to assist in resin flow, reducing the need for very high injection pressures. The autoclave aids in consolidating the part and removing residual air.

My experience involves working with various RTM techniques and optimizing autoclave curing parameters to achieve the desired mechanical properties, while ensuring consistency and reproducibility. For example, adjusting the pressure profile in the autoclave can significantly impact the final fiber volume fraction and void content in the cured part. Understanding the interplay between the RTM injection and autoclave curing phases is key to success.

Q 27. How do you interpret autoclave cure data and identify potential issues?

Interpreting autoclave cure data involves analyzing the temperature, pressure, and vacuum profiles recorded during the curing process. This helps to evaluate the cure quality and identify potential issues.

- Temperature Profiles: A slow and controlled temperature ramp is usually desired to avoid thermal stresses and ensure a homogeneous cure. Deviations from the setpoint indicate possible issues with heating elements, insulation, or sensor malfunction.

- Pressure Profiles: The pressure profile monitors the resin flow and consolidation. A steady pressure increase indicates proper compaction, while fluctuations might indicate leaks or incomplete resin flow.

- Vacuum Profiles: Vacuum is essential to remove air from the mold, reducing void formation. If the vacuum doesn’t reach the desired level, it may lead to defects in the cured part. Sudden drops might indicate a leak in the mold or vacuum system.

- Data Analysis Software: Specialized software packages are used to plot and analyze the data, allowing for easy visualization of any deviations from the expected profiles. Outlier detection algorithms can be used to pinpoint potential issues.

For example, a sudden drop in pressure during the curing cycle might indicate a leak in the mold or a problem with the pressure regulator. Similarly, a non-uniform temperature profile might suggest an issue with the autoclave’s heating system or uneven heat distribution within the chamber. By carefully analyzing the data, potential issues can be identified and corrected, preventing the production of defective parts.

Q 28. What are your experiences with various materials used in autoclave curing (e.g., carbon fiber, Kevlar, etc.)?

My experience encompasses various materials used in autoclave curing, each with unique characteristics requiring careful consideration of curing parameters.

- Carbon Fiber: A high-strength, high-stiffness material commonly used in aerospace and high-performance applications. It requires careful control of temperature and pressure to avoid fiber damage during curing.

- Kevlar: Known for its high strength-to-weight ratio and excellent ballistic properties. It typically requires lower curing temperatures compared to carbon fiber.

- Glass Fiber: A cost-effective reinforcement material with good mechanical properties. It’s more tolerant of variations in curing parameters compared to carbon or Kevlar.

- Aramid Fibers (e.g., Nomex): Used where high-temperature resistance is critical. They have specific curing requirements that need to be precisely followed.

- Epoxy Resins: Common matrix materials that offer good adhesion, strength, and chemical resistance. Their curing behavior is heavily influenced by temperature and pressure, making accurate control crucial.

- Polyimide Resins: Used in high-temperature applications, requiring precise control over curing cycles to avoid degradation.

Selecting appropriate materials and optimizing the autoclave curing parameters for each specific material combination is essential for producing high-quality, defect-free composite parts. My expertise includes understanding the material properties and their impact on the overall curing process. For instance, the resin viscosity and flow characteristics will significantly affect the required curing pressure and time. Similarly, the coefficient of thermal expansion of the fibers must be considered to avoid thermal stresses during the cure cycle.

Key Topics to Learn for Autoclave Curing Interview

- Understanding Autoclave Principles: Grasp the fundamental physics and chemistry behind autoclave curing, including pressure, temperature, and their effects on material properties.

- Material Science in Autoclave Curing: Explore the different materials commonly cured in autoclaves (composites, polymers, etc.) and their specific curing requirements.

- Process Optimization and Control: Learn about the parameters affecting the curing process (cycle time, pressure profiles, temperature ramps) and how to optimize them for consistent results and material quality.

- Autoclave Equipment and Operation: Familiarize yourself with the different types of autoclaves, their components (e.g., heating systems, pressure vessels, safety mechanisms), and safe operating procedures.

- Quality Control and Testing: Understand the various methods for testing cured materials (e.g., mechanical testing, non-destructive testing) to ensure they meet specifications.

- Troubleshooting and Problem Solving: Develop your ability to identify and resolve common issues encountered during the autoclave curing process, such as void formation, delamination, or incomplete curing.

- Safety Regulations and Procedures: Become familiar with relevant safety regulations and best practices for operating autoclaves and handling hazardous materials.

- Process Monitoring and Data Analysis: Understand how to interpret data from autoclave sensors and use this information for process optimization and quality control.

- Advanced Curing Techniques: Explore more advanced techniques such as resin transfer molding (RTM) or out-of-autoclave curing methods.

Next Steps

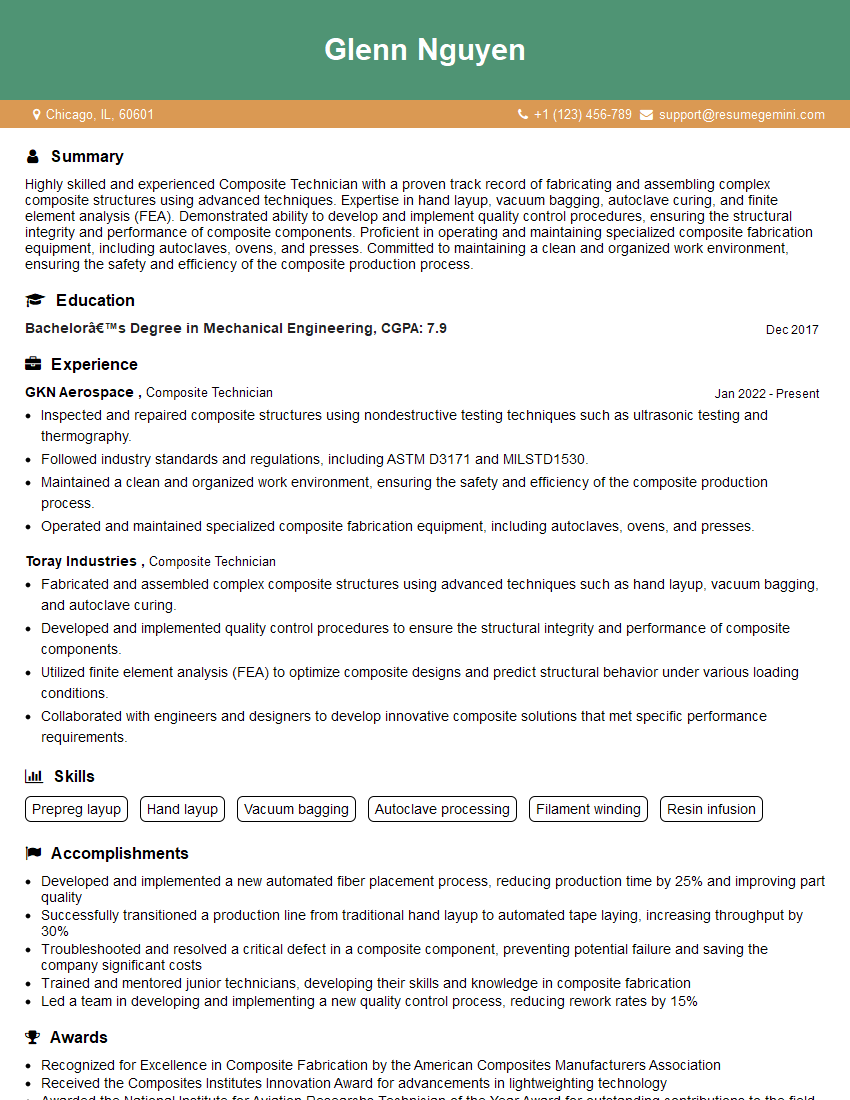

Mastering autoclave curing opens doors to exciting career opportunities in advanced manufacturing, aerospace, and other high-tech industries. To stand out from the competition, a well-crafted resume is essential. Building an ATS-friendly resume significantly increases your chances of getting your application noticed. ResumeGemini is a trusted resource that can help you create a professional and impactful resume, tailored to highlight your skills and experience in autoclave curing. Examples of resumes specifically designed for autoclave curing professionals are available to guide you. Take the next step toward your dream career today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Take a look at this stunning 2-bedroom apartment perfectly situated NYC’s coveted Hudson Yards!

https://bit.ly/Lovely2BedsApartmentHudsonYards

Live Rent Free!

https://bit.ly/LiveRentFREE

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?