Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Bioburden Control and Management interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Bioburden Control and Management Interview

Q 1. Define bioburden and explain its significance in pharmaceutical manufacturing.

Bioburden refers to the total number of viable microorganisms (bacteria, fungi, viruses, etc.) present on or in a material or product. In pharmaceutical manufacturing, controlling bioburden is paramount because these microorganisms can contaminate products, leading to spoilage, reduced efficacy, and, most critically, potential harm to patients. Imagine a sterile injectable drug contaminated with bacteria – the consequences could be life-threatening. Therefore, rigorous bioburden control is a cornerstone of Good Manufacturing Practices (GMP) to ensure product safety and quality.

Q 2. Describe the methods used to monitor bioburden in a cleanroom environment.

Monitoring bioburden in a cleanroom involves several methods, primarily focusing on environmental and product sampling. Environmental monitoring uses techniques like active air sampling (using air samplers that draw a defined volume of air onto a growth medium) and passive air sampling (using settling plates or contact plates left exposed to collect airborne microorganisms). Surface monitoring involves taking swabs or contact plates from surfaces within the cleanroom to assess microbial contamination levels. Product sampling directly assesses the bioburden on the final product before sterilization. All samples are then incubated under specific conditions, and the resulting colony-forming units (CFUs) are counted to quantify the bioburden. Regular monitoring helps identify contamination sources and ensure effective cleaning and disinfection protocols are in place. For example, a sudden spike in CFUs might indicate a breach in cleanroom integrity, requiring immediate investigation.

Q 3. Explain the difference between sterilization and disinfection.

Sterilization and disinfection are both methods of reducing microbial load, but they differ significantly in their outcomes. Sterilization is a process that eliminates all forms of microbial life, including bacterial spores, fungi, and viruses. It renders a product sterile, meaning it is free from living microorganisms. Think of surgical instruments – they must be completely sterile. Disinfection, on the other hand, reduces the number of microorganisms to a safe level, but it doesn’t necessarily eliminate all of them, especially highly resistant spores. Disinfection is sufficient for many non-sterile products or surfaces, like cleaning a laboratory bench. The difference is crucial: sterility guarantees absence of viable organisms, while disinfection only lowers the microbial population to an acceptable level.

Q 4. What are the key parameters to consider when validating a sterilization process?

Validating a sterilization process is critical to ensure its effectiveness. Key parameters include:

- Biological Indicators (BIs): These are preparations of resistant microorganisms (usually Geobacillus stearothermophilus for moist heat sterilization) used to monitor the lethality of the sterilization process. Their survival or death indicates the efficacy of the sterilization cycle.

- Physical Parameters: These include temperature, pressure (for steam sterilization), and exposure time. Accurate monitoring and recording of these parameters are essential to ensure the process meets pre-defined specifications.

- Sterility Assurance Level (SAL): This is the probability of a single surviving microorganism after sterilization. Pharmaceutical products often require a SAL of 10-6, meaning a one in a million chance of a single surviving microorganism.

- Process Mapping and Documentation: Comprehensive records of the entire sterilization process, including parameters, equipment calibration, and BI results, are needed to demonstrate process validity and compliance.

Validation typically involves multiple runs under varying conditions to demonstrate robustness and consistency.

Q 5. How do you interpret bioburden test results and determine appropriate actions?

Interpreting bioburden test results requires careful consideration. The number of CFUs obtained is compared to pre-defined acceptance criteria, which depend on the product, its intended use, and the manufacturing environment. Results exceeding the acceptable limits indicate a potential contamination issue. Investigating the source is crucial using a root cause analysis (RCA), which involves identifying potential factors contributing to the high bioburden. This might involve reviewing environmental monitoring data, cleaning and disinfection procedures, personnel practices, and equipment functionality. Appropriate corrective and preventive actions (CAPA) are then implemented, such as enhanced cleaning, improved personnel training, or equipment repair or replacement. Retesting is performed to confirm the effectiveness of the CAPA.

Q 6. Describe the different types of sterilization methods and their applications.

Various sterilization methods exist, each with specific applications:

- Steam Sterilization (Autoclaving): Uses moist heat under pressure to kill microorganisms. Widely used for heat-stable materials and equipment.

- Dry Heat Sterilization: Employs high temperatures without pressure, suitable for materials that cannot withstand moist heat.

- Ethylene Oxide (EtO) Sterilization: A gaseous sterilant effective against a broad range of microorganisms, including spores; used for heat-sensitive medical devices.

- Gamma Irradiation: Uses high-energy gamma rays to kill microorganisms; effective for a wide range of products, but may alter some materials.

- Beta Irradiation: Similar to gamma irradiation, but uses lower energy beta particles.

- Electron Beam Sterilization: Uses accelerated electrons to achieve sterilization.

- Filtration Sterilization: Removes microorganisms from liquids or gases by passing them through a filter with a pore size small enough to retain bacteria and other microorganisms. Commonly used for heat-sensitive solutions.

The choice of method depends on the nature of the product, its sensitivity to heat and radiation, and regulatory requirements.

Q 7. What are the critical control points in aseptic processing to minimize bioburden?

Aseptic processing aims to maintain sterility throughout the manufacturing process. Critical control points include:

- Environmental Control: Maintaining a cleanroom environment with controlled air quality, temperature, and humidity to minimize microbial contamination.

- Personnel Practices: Employing aseptic techniques by personnel, including proper gowning, hand hygiene, and movement within the cleanroom.

- Equipment Design and Maintenance: Using equipment designed to prevent contamination and maintaining it in a sterile condition.

- Material Selection: Using sterile materials and components, and handling them carefully to prevent contamination.

- Process Validation: Regularly validating aseptic processing steps to ensure their effectiveness in maintaining sterility.

- Cleaning and Disinfection: Employing robust and validated cleaning and disinfection protocols to remove microbial contamination from surfaces and equipment.

Failure at any of these points can compromise sterility, leading to product contamination.

Q 8. Explain the importance of environmental monitoring in bioburden control.

Environmental monitoring is the cornerstone of bioburden control in pharmaceutical manufacturing. It’s like a health check for your facility, continuously assessing the microbial load in the air, on surfaces, and in the water used in the manufacturing process. By regularly monitoring these areas, we identify potential contamination sources *before* they impact product quality and patient safety.

Think of it as a proactive strategy. Instead of waiting for a product recall, we use monitoring to detect and mitigate risks early. This includes identifying trends, evaluating the effectiveness of cleaning and disinfection procedures, and ensuring compliance with regulatory standards. For example, high levels of airborne bacteria near a filling line might indicate a problem with the HEPA filters, allowing us to address it immediately and prevent contaminated product from being released.

Q 9. How do you investigate and resolve a bioburden excursion?

A bioburden excursion, meaning an unexpectedly high level of microbial contamination, requires a thorough investigation. It’s akin to a medical detective case. We begin by clearly defining the scope of the excursion: what product, what location, what microbial species? We then proceed systematically.

- Isolate the Source: Review environmental monitoring data, production records, and personnel activities around the time of the excursion. Did a cleaning procedure fail? Was there a maintenance issue? Was there a change in raw materials?

- Root Cause Analysis: Employ tools like the 5 Whys or a Fishbone diagram to thoroughly examine potential causes and identify the root cause. Let’s say our investigation finds that an HVAC system malfunction increased airborne particulates, leading to the excursion. We need to understand why the malfunction occurred, was it due to lack of maintenance, aging equipment, etc.

- Corrective Actions: Implement corrective actions to address the root cause. This could include equipment repair or replacement, revised cleaning protocols, staff retraining, or improved supply chain management.

- Preventive Actions: Develop and implement preventative actions to prevent future excursions. These could involve enhancing preventive maintenance schedules, introducing improved monitoring techniques, or revising standard operating procedures.

- Verification: Finally, we verify the effectiveness of corrective and preventive actions through monitoring and trending of the data.

Q 10. Describe the regulatory requirements for bioburden control in pharmaceutical manufacturing.

Regulatory requirements for bioburden control in pharmaceutical manufacturing are stringent and vary depending on the product type (e.g., sterile injectables vs. non-sterile products) and the regulatory authority (e.g., FDA, EMA). However, common themes include:

- Good Manufacturing Practices (GMP): GMP guidelines establish the framework for controlling bioburden throughout the manufacturing process. They demand comprehensive environmental monitoring programs, detailed cleaning and disinfection procedures, and robust quality control checks.

- Specific Limits: Regulatory bodies often set limits on acceptable bioburden levels in raw materials, intermediate products, and finished goods. Exceeding these limits can lead to product rejection and regulatory action.

- Documentation: Meticulous documentation is crucial. All environmental monitoring data, cleaning validation results, and investigations into excursions must be thoroughly documented and readily available for audit purposes.

- Aseptic Processing: For sterile products, regulations strictly define aseptic processing techniques and require extensive validation to demonstrate their effectiveness in preventing microbial contamination.

Non-compliance can result in warning letters, import alerts, product recalls, and even facility closure. This underscores the importance of adhering strictly to regulatory requirements and proactively maintaining bioburden control.

Q 11. What are the common microorganisms found in pharmaceutical manufacturing environments?

The types of microorganisms encountered in pharmaceutical manufacturing environments vary widely, depending on factors such as the facility’s location, environmental controls, and product type. However, some common culprits include:

- Bacteria: Gram-positive bacteria like Bacillus and Staphylococcus, and Gram-negative bacteria such as Pseudomonas and Enterobacteriaceae, are frequently isolated.

- Fungi: Molds, such as Aspergillus and Penicillium, and yeasts, such as Candida, are also commonly found, often thriving in humid environments.

- Spore-forming bacteria: Bacillus and Clostridium species are particularly challenging because their spores are highly resistant to many sterilization methods.

Understanding the prevalent microorganisms in a specific facility is crucial to tailor cleaning and disinfection strategies and to develop effective environmental monitoring programs. This involves regular identification and characterization of isolates from environmental samples. For instance, a facility repeatedly isolating Pseudomonas from its water system might need to implement more robust water treatment and sanitation practices.

Q 12. Explain the principles of aseptic technique and its role in bioburden control.

Aseptic technique is a set of practices designed to prevent the introduction of microorganisms into sterile environments. It’s fundamental for maintaining bioburden control, particularly in the manufacturing of sterile pharmaceuticals. Imagine a surgeon operating—meticulous care is taken to prevent infection. The same principle applies here.

Key principles include:

- Environmental Control: Maintaining cleanroom environments with controlled air pressure, temperature, and humidity to minimize microbial growth and contamination.

- Personal Protective Equipment (PPE): Using appropriate gowns, gloves, masks, and shoe covers to limit the introduction of microorganisms from personnel.

- Sterile Equipment and Materials: Utilizing only sterile equipment, materials, and media, and employing proper sterilization techniques.

- Workflow: Designing workflows to minimize the risk of contamination. This includes unidirectional airflow, specific movement patterns, and effective cleaning and disinfection practices.

- Validation: Regularly validating aseptic processes to ensure their effectiveness in preventing microbial contamination.

Aseptic technique is critical for the production of sterile products. Failure to follow these techniques can have dire consequences, ranging from product spoilage to life-threatening infections.

Q 13. What are the limitations of bioburden testing?

Bioburden testing, while essential, has its limitations. It’s not a perfect predictor of sterility. Here’s why:

- Detection Limits: Tests have sensitivity limits. Low levels of microorganisms might go undetected.

- Viable vs. Non-viable: Only viable (living) microorganisms are detected. Dead microorganisms won’t show up, even if their presence indicates past contamination or incomplete sterilization.

- Sampling Bias: Samples may not be representative of the entire population. A negative result doesn’t guarantee the absence of contamination elsewhere.

- Recovery Efficiency: The effectiveness of the test method in recovering microorganisms from the sample can vary.

- Time-consuming and Resource-intensive: Testing requires time, specialized equipment, and skilled personnel.

Despite these limitations, bioburden testing is a valuable tool. It provides crucial information for risk assessment and process control, and when coupled with other quality control measures, contributes significantly to assuring product quality and safety.

Q 14. How do you determine the appropriate sampling plan for bioburden monitoring?

Determining the appropriate sampling plan for bioburden monitoring involves a risk-based approach. It’s not a one-size-fits-all situation. The plan should be tailored to the specific manufacturing process, product type, and facility risk profile.

Factors to consider include:

- Critical Control Points (CCPs): Identify areas where microbial contamination would pose the highest risk to product quality, for instance, near filling lines or open manufacturing steps.

- Environmental Factors: Consider factors like air quality, humidity, temperature, and the presence of water systems, which can influence microbial growth.

- Product Type: Sampling frequency will be more frequent for sterile products compared to non-sterile products.

- Historical Data: Analyze past monitoring data to identify trends and areas requiring increased attention.

- Regulatory Requirements: Adhere to regulatory guidance on environmental monitoring frequency and methodologies.

Using a risk assessment tool, you can establish a sampling plan that focuses on the highest-risk areas and ensures effective monitoring. This can involve the systematic collection and analysis of samples of air, surfaces, and water to monitor microbial presence and trends over time. Regular review and adjustments of the sampling plan are essential to maintain its effectiveness.

Q 15. What are the key performance indicators (KPIs) for bioburden control?

Key Performance Indicators (KPIs) for bioburden control are crucial for monitoring the effectiveness of contamination prevention strategies. They provide a quantitative measure of the success of these efforts. Think of them as the vital signs of your bioburden management system. Effective KPIs are specific, measurable, achievable, relevant, and time-bound (SMART).

- Bioburden Levels: This is the most fundamental KPI, representing the number of microorganisms (bacteria, fungi, etc.) present on a surface or in a product before sterilization. Regular monitoring of bioburden levels at different stages of production helps identify contamination hotspots. For example, consistently high bioburden levels on a particular piece of equipment might indicate a need for improved cleaning protocols.

- Environmental Monitoring Results: This tracks microbial counts in the manufacturing environment (air, surfaces, personnel). A significant increase in environmental bioburden can signal potential contamination risks.

- Sterility Assurance Level (SAL): This KPI ensures the efficacy of sterilization processes. It defines the probability of a single unit being non-sterile after sterilization (e.g., a SAL of 10-6 means a probability of 1 in 1 million of a non-sterile unit).

- Alert/Action Levels: Pre-defined thresholds for bioburden or environmental monitoring results. Exceeding these levels triggers an investigation and corrective actions.

- Rate of Non-Conforming Units: This KPI tracks the percentage of products failing bioburden testing or sterility testing. A high rate points towards a systemic issue needing immediate attention.

- Training Compliance: Ensuring personnel are properly trained in aseptic techniques and bioburden control is a critical indirect KPI. Proper training directly impacts the effectiveness of all other KPIs.

By tracking these KPIs, we can proactively identify and address potential contamination risks, ensuring consistent product quality and patient safety.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with different types of microbial identification methods.

Microbial identification is a cornerstone of bioburden control. My experience encompasses a range of methods, each with its strengths and limitations. The choice of method depends on factors such as the type of microorganism suspected, the available resources, and the required speed of identification.

- Traditional Culture-Based Methods: These involve isolating microorganisms on various growth media, followed by morphological characterization and biochemical testing. This approach is reliable but time-consuming, often taking several days to obtain results. For example, Gram staining allows for initial classification of bacteria based on cell wall properties.

- Automated Microbial Identification Systems: These systems use sophisticated software to analyze microbial growth patterns and biochemical reactions, providing faster identification than traditional methods. Examples include Vitek and Biolog systems, which can significantly shorten turnaround times.

- Molecular Methods: These methods are increasingly used for rapid and accurate microbial identification. Polymerase Chain Reaction (PCR) and other nucleic acid-based techniques target specific microbial DNA or RNA sequences. PCR is particularly valuable for detecting fastidious microorganisms (those difficult to culture) and for identifying microorganisms rapidly during outbreaks.

- MALDI-TOF Mass Spectrometry: This cutting-edge technology measures the unique protein profiles of microorganisms, providing rapid and highly accurate identification. It’s becoming increasingly popular due to its speed and ease of use.

In my previous roles, I’ve successfully employed a combination of these methods, often using rapid methods for initial screening and confirmation, then applying more detailed analyses as necessary.

Q 17. How do you ensure data integrity in bioburden testing and reporting?

Data integrity in bioburden testing and reporting is paramount for maintaining confidence in the results and ensuring regulatory compliance. It requires meticulous attention to detail at every stage of the process. Think of it like building a sturdy house: if the foundation is weak, the whole structure is compromised.

- Standard Operating Procedures (SOPs): Detailed SOPs dictate every aspect of testing, from sample collection and handling to data recording and analysis. Strict adherence to SOPs ensures consistency and reduces errors.

- Calibration and Validation: Regular calibration and validation of all equipment used in bioburden testing are essential to ensure accurate results. Think of it as regular checkups for your laboratory instruments to make sure they’re producing reliable data.

- Chain of Custody: Maintaining a detailed chain of custody for all samples ensures traceability and prevents sample mix-ups or tampering.

- Electronic Data Management Systems (EDMS): EDMS offer enhanced data security and facilitate audits. They provide a secure, auditable trail of all data generated throughout the testing process.

- Audits and Reviews: Regular internal audits and external reviews scrutinize all aspects of the data generation and reporting process to identify potential weaknesses or deviations from established procedures.

- Trained Personnel: Personnel involved in bioburden testing should be properly trained and qualified to ensure accurate and reliable data collection and analysis.

By implementing these measures, we create a robust system that ensures the accuracy, reliability, and integrity of our bioburden data, minimizing the risks associated with flawed or compromised information.

Q 18. Explain the concept of sterility assurance levels (SAL).

Sterility Assurance Level (SAL) is a probabilistic statement about the sterility of a product after a sterilization process. It’s not a guarantee of absolute sterility, but a measure of the probability that a given unit remains non-sterile after treatment. Think of it like buying a lottery ticket – you can’t be 100% certain of winning, but the odds are clearly stated.

The SAL is typically expressed as a probability, such as 10-3 (one in a thousand) or 10-6 (one in a million). A lower SAL indicates a higher level of sterility assurance. For instance, a SAL of 10-6 is typically required for medical devices that directly interact with the bloodstream. The SAL is determined by considering the initial bioburden levels, the sterilization method’s effectiveness, and the product’s characteristics.

The SAL is a critical parameter in the validation of sterilization processes. Validation studies are conducted to demonstrate that a sterilization process consistently achieves the required SAL. These studies involve determining the bioburden, subjecting the product to sterilization, and then conducting sterility tests on the samples. The results are used to estimate the SAL of the sterilization process.

Q 19. How do you manage and investigate microbial contamination incidents?

Microbial contamination incidents require a prompt, thorough, and systematic investigation. The goal is to identify the root cause, implement corrective actions, and prevent recurrence. Imagine it as solving a detective mystery – we need to gather evidence, analyze clues, and find the culprit.

My approach involves a structured investigation, including:

- Immediate Containment: Isolate the contaminated product and prevent further contamination.

- Root Cause Analysis: A systematic investigation to identify the source of the contamination, using tools like 5 Whys and Fishbone diagrams. Potential causes could include inadequate cleaning, faulty equipment, compromised personnel practices, or environmental factors.

- Corrective and Preventive Actions (CAPA): Implement effective corrective actions to address the immediate issue and preventive actions to stop recurrence. This might involve revising cleaning procedures, replacing equipment, retraining staff, or modifying environmental controls.

- Documentation: Meticulous documentation of the entire investigation process, including findings, corrective actions, and preventive actions. This documentation is crucial for tracking progress and demonstrating regulatory compliance.

- Follow-up: Ongoing monitoring to ensure the effectiveness of corrective and preventive actions and to prevent future incidents.

Through this systematic approach, we can effectively manage and prevent future contamination incidents, minimizing the risk to product quality and patient safety.

Q 20. What are the best practices for cleaning and sanitizing equipment to reduce bioburden?

Effective cleaning and sanitization are fundamental to bioburden control. It’s like washing your hands before preparing food – a critical step to prevent contamination. The process involves a combination of physical and chemical methods.

- Cleaning: This is the physical removal of visible soil and debris from equipment surfaces. Methods include manual cleaning with detergents and brushes, automated cleaning systems (CIP/SIP), and ultrasonic cleaning. The choice of method depends on the type of equipment and the level of soiling. For example, a high-pressure washer might be used for removing debris from large manufacturing equipment.

- Sanitization: This reduces the microbial load on cleaned surfaces to an acceptable level. Sanitizers can be chemical agents (e.g., quaternary ammonium compounds, chlorine-based compounds, peracetic acid) or physical agents (e.g., heat). The selection of sanitizers requires careful consideration of their efficacy against different microorganisms, material compatibility, and potential toxicity.

- Validation: Cleaning and sanitization processes must be validated to demonstrate their effectiveness. This involves establishing standardized procedures, monitoring their effectiveness, and regularly reviewing and updating the procedures to maintain their effectiveness.

- Personnel Training: Proper training of personnel in cleaning and sanitization techniques is essential to ensure consistent and effective procedures.

By implementing robust cleaning and sanitization practices, we can significantly reduce bioburden levels and minimize the risk of microbial contamination in the manufacturing environment.

Q 21. Describe your experience with different types of microbial growth media.

Various microbial growth media are used in bioburden testing, each designed to support the growth of specific types of microorganisms. Think of them as specialized diets for different types of microbes.

- Tryptic Soy Agar (TSA): A general-purpose medium supporting the growth of a wide range of bacteria and fungi. It’s often used for initial screening.

- Sabouraud Dextrose Agar (SDA): A selective medium favoring the growth of fungi over bacteria. It’s commonly used to isolate and quantify fungi.

- Nutrient Agar (NA): Another general-purpose medium used for the cultivation of various microorganisms.

- Blood Agar: An enriched medium containing blood, which supports the growth of fastidious microorganisms (those with complex nutritional requirements). It is often used in the identification of streptococci.

- Selective and Differential Media: These media are designed to inhibit the growth of certain microorganisms while promoting the growth of others, or to differentiate between different types of microorganisms based on their metabolic characteristics.

- Fluid Thioglycollate Medium (FTM): A broth medium used to test the sterility of products or to detect the presence of anaerobes (microorganisms that thrive in oxygen-free environments).

The choice of growth medium is determined by the expected types of microorganisms, the test objectives, and regulatory requirements. In my experience, I’ve worked extensively with various media, selecting the appropriate ones based on the specific needs of each bioburden testing scenario.

Q 22. How do you maintain and calibrate bioburden testing equipment?

Maintaining and calibrating bioburden testing equipment is crucial for accurate and reliable results. This involves a multi-faceted approach encompassing preventative maintenance, regular calibration, and meticulous record-keeping.

- Preventative Maintenance: This includes regular cleaning and sanitization of equipment to prevent cross-contamination and ensure optimal functionality. For example, incubators require periodic cleaning with appropriate disinfectants, while autoclaves need regular checks of seals and pressure gauges.

- Calibration: Calibration ensures the equipment is performing within its specified tolerances. This often involves using certified standards, such as calibrated thermometers for incubators or certified reference strains for microbial counts. Calibration frequency varies depending on the equipment and regulatory requirements, often documented in Standard Operating Procedures (SOPs).

- Record-Keeping: Detailed and accurate records are essential. These records should include the date of calibration, the results, the equipment’s identification number, and the technician’s signature. This documentation is crucial for demonstrating compliance during audits.

Think of it like a car: regular maintenance (oil changes, tire rotations) and timely repairs keep it running smoothly and accurately. Similarly, regular maintenance and calibration of bioburden testing equipment are essential for accurate results and regulatory compliance.

Q 23. What are your experiences with different types of bioburden testing methods (e.g., membrane filtration, pour plate)?

My experience encompasses various bioburden testing methods, each with its strengths and limitations.

- Membrane Filtration: This is a highly sensitive method, particularly useful for low bioburden samples. It involves filtering a sample through a membrane filter, then placing the filter on a growth medium to cultivate any microorganisms. I’ve used this method extensively for testing water and other low-bioburden fluids. The precision of this method is crucial when dealing with sensitive products.

- Pour Plate Method: This is a simpler method suitable for a wider range of samples but less sensitive than membrane filtration. It involves mixing the sample with molten agar and pouring it into a petri dish. The colonies that grow are then counted to determine the bioburden. I’ve used this for testing samples with a higher expected bioburden, such as raw materials.

- Spread Plate Method: Similar to the pour plate method but involves spreading a sample onto the surface of a solidified agar plate. This method is useful for assessing the viability of microorganisms and observing colony morphology.

The choice of method depends on factors such as the expected bioburden level, the nature of the sample, and regulatory requirements. Each method requires meticulous attention to detail to avoid errors that can lead to inaccurate results.

Q 24. Describe your understanding of GMP, and its influence on Bioburden Control.

Good Manufacturing Practices (GMP) are a set of guidelines designed to ensure the quality and safety of manufactured products, including pharmaceuticals and medical devices. GMP heavily influences bioburden control by providing a framework for minimizing microbial contamination throughout the manufacturing process.

- Environmental Monitoring: GMP emphasizes regular monitoring of the manufacturing environment to identify and address potential sources of contamination. This includes air sampling, surface sampling, and personnel monitoring.

- Cleanroom Control: Maintaining controlled environments (cleanrooms) with appropriate air filtration and cleanliness levels is a cornerstone of GMP. These environments drastically reduce the bioburden in the production area.

- Personnel Training: GMP requires comprehensive training for personnel involved in manufacturing to ensure they understand and adhere to proper aseptic techniques and contamination control procedures.

- Documentation and Record-Keeping: GMP mandates detailed and accurate documentation of all bioburden testing results, deviations, and corrective actions. This traceability is essential for demonstrating compliance.

In essence, GMP provides the regulatory framework, and bioburden control provides the practical implementation to ensure product safety and quality. Failure to adhere to GMP principles can result in product recalls, regulatory sanctions, and even harm to patients.

Q 25. Explain the difference between endotoxin testing and bioburden testing.

While both endotoxin testing and bioburden testing assess the microbial content of a product or environment, they target different aspects of microbial contamination.

- Bioburden Testing: This measures the total number of viable microorganisms (bacteria, fungi, yeasts) present in a sample. It gives an overall picture of the microbial load.

- Endotoxin Testing: This specifically detects endotoxins, which are lipopolysaccharides (LPS) found in the outer membrane of Gram-negative bacteria. Endotoxins are potent pyrogens, meaning they can induce fever and other adverse reactions in humans, even if the bacteria themselves are no longer viable. Endotoxin testing is critical for products that come into direct contact with the bloodstream.

Think of it this way: bioburden testing is like counting all the people in a room, while endotoxin testing is like specifically identifying the people carrying a highly contagious virus. Both are important for safety, but they provide different types of information.

Q 26. How do you handle deviations or OOS results during bioburden testing?

Handling deviations or Out-of-Specification (OOS) results in bioburden testing requires a systematic and thorough investigation. The goal is to identify the root cause of the deviation and implement corrective and preventive actions (CAPA) to prevent recurrence.

- Immediate Action: Isolate the affected batch and prevent its release. Review the testing procedures and equipment to rule out any procedural or equipment-related errors.

- Investigation: Conduct a thorough investigation to identify the root cause of the OOS result. This may involve reviewing environmental monitoring data, production records, and personnel training records. It might include re-testing the original sample and investigating potential sources of contamination in the environment, processes, or raw materials.

- Corrective Actions: Implement corrective actions to address the identified root cause. This could range from retraining personnel to improving cleaning procedures or replacing contaminated equipment.

- Preventive Actions: Develop and implement preventive actions to prevent similar deviations from occurring in the future. This might include changes to SOPs, improved quality control measures, or updated equipment maintenance schedules.

- Documentation: Document the entire investigation, corrective actions, and preventive actions in a detailed report. This report should be reviewed and approved by appropriate personnel.

The key to effectively handling OOS results is a proactive approach involving a thorough investigation, the implementation of CAPA, and rigorous documentation.

Q 27. How do you ensure compliance with relevant regulatory guidelines (e.g., USP, EP)?

Ensuring compliance with relevant regulatory guidelines, such as those published by the United States Pharmacopeia (USP) and the European Pharmacopoeia (EP), is paramount. This is achieved through a comprehensive quality management system (QMS).

- Standard Operating Procedures (SOPs): Detailed, well-defined SOPs for all aspects of bioburden testing are essential, ensuring consistency and adherence to regulatory requirements. These procedures should align with the USP and EP guidelines.

- Method Validation: Bioburden testing methods need validation to demonstrate their accuracy, precision, and reliability. Validation protocols should be meticulously documented and comply with regulatory standards.

- Audits: Regular internal and external audits are crucial to ensure adherence to GMP principles and regulatory requirements. Audits assess all aspects of the bioburden control program, including documentation, equipment calibration, and personnel training.

- Training: Adequate training of personnel involved in bioburden testing is vital to ensure the quality and reliability of the data generated.

- Deviations and CAPA: A robust system for handling deviations and implementing corrective and preventive actions (CAPA) is vital for maintaining compliance. Each deviation should be investigated and documented.

Compliance isn’t a one-time event; it’s an ongoing process that requires continuous monitoring, improvement, and adaptation to evolving regulatory guidance.

Q 28. Describe a situation where you had to troubleshoot a bioburden-related problem. What was your approach to resolving the issue?

In a previous role, we experienced unexpectedly high bioburden levels in a batch of sterile syringes. The initial investigation revealed no obvious deviations from our standard operating procedures. This situation immediately prompted a systematic troubleshooting approach.

- Review of Production Records: We started by meticulously reviewing production records for that batch, looking for any anomalies in environmental monitoring data, personnel changes, or deviations in the sterilization cycle. We found a slight temperature fluctuation during the sterilization process that was initially dismissed as minor.

- Environmental Monitoring Enhancement: We increased the frequency of environmental monitoring around the production area and found a higher-than-normal concentration of airborne microorganisms. The source was traced to a recently installed HVAC system filter requiring replacement.

- Re-evaluation of Sterilization Parameters: Based on the findings, we re-evaluated the sterilization cycle parameters, including temperature and duration, using a more robust validation process.

- HVAC System Upgrade: The faulty HVAC filter was replaced, and a regular maintenance schedule for all HVAC systems was established.

- Personnel Retraining: Finally, personnel involved in sterilization were retrained on the importance of consistently adhering to SOPs and reporting any deviations promptly.

The systematic approach ensured we identified the root causes, implemented effective corrective actions, and improved our overall bioburden control process. It also reinforced the importance of a well-defined process for investigating and rectifying deviations from expected results.

Key Topics to Learn for Bioburden Control and Management Interview

- Microbiological Monitoring Strategies: Understanding and applying various methods for environmental monitoring, including air sampling, surface sampling, and water testing. Consider the advantages and limitations of each technique.

- Sterilization and Disinfection Techniques: Deep dive into the principles and applications of sterilization methods (e.g., autoclaving, gamma irradiation, ethylene oxide) and disinfection methods (e.g., chemical disinfectants, UV sterilization). Be prepared to discuss validation and efficacy testing.

- Aseptic Techniques and Cleanroom Environments: Mastering the principles of aseptic processing and the design and operation of cleanrooms, including ISO classifications and environmental control strategies.

- Bioburden Reduction Strategies: Explore different approaches to minimize microbial contamination throughout the manufacturing process, including cleaning and sanitization procedures, and personnel practices.

- Regulatory Compliance and Documentation: Understanding relevant regulations (e.g., GMP, FDA guidelines) and the importance of accurate and complete documentation of bioburden control activities. Prepare to discuss record-keeping best practices.

- Risk Assessment and Mitigation: Develop skills in identifying and assessing potential sources of microbial contamination and implementing effective mitigation strategies. This includes understanding different risk assessment methodologies.

- Data Analysis and Interpretation: Be comfortable interpreting microbiological data, identifying trends, and taking appropriate corrective actions based on the results. This includes understanding statistical methods relevant to microbiological data.

- Investigation of Microbial Contamination Events: Develop your skills in effectively investigating and resolving occurrences of microbial contamination, including root cause analysis and corrective and preventative actions (CAPA).

Next Steps

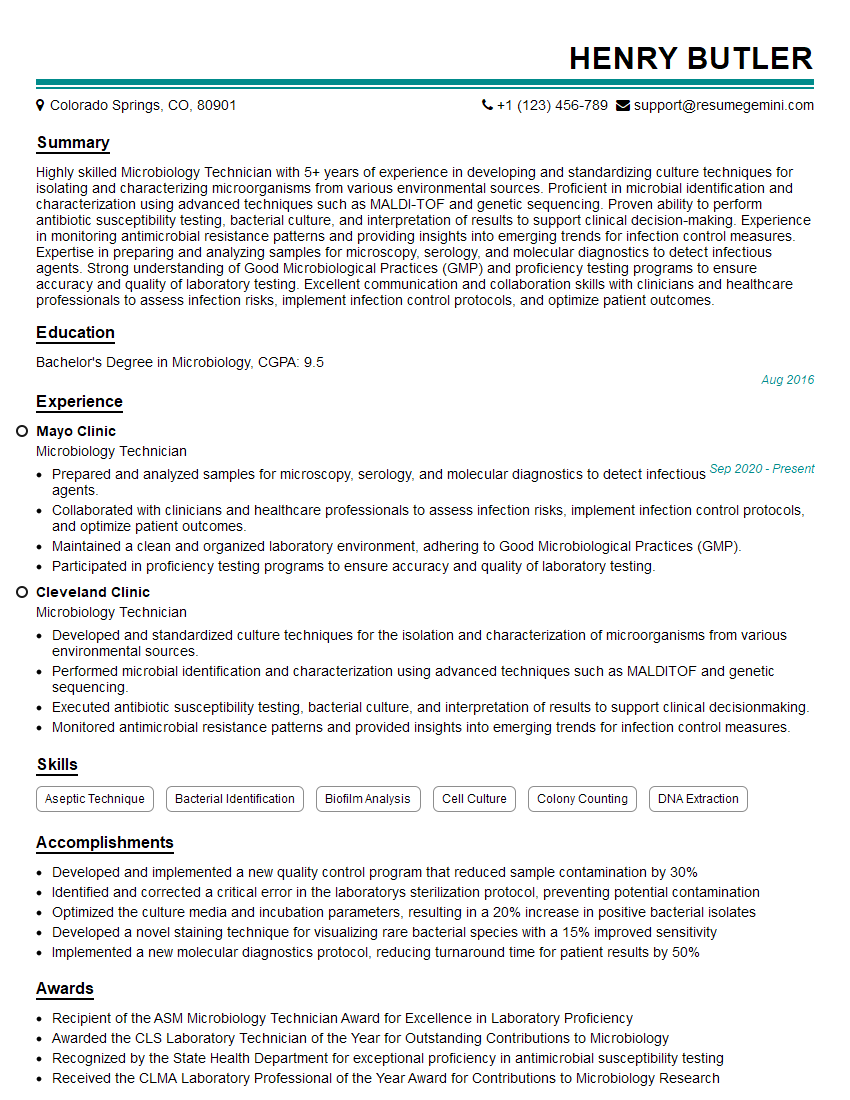

Mastering Bioburden Control and Management is crucial for career advancement in the pharmaceutical, biotech, and medical device industries. These skills are highly sought after, opening doors to leadership roles and increased earning potential. To maximize your job prospects, creating a strong, ATS-friendly resume is essential. ResumeGemini is a trusted resource to help you build a professional and impactful resume. We provide examples of resumes tailored to Bioburden Control and Management to guide you. Invest the time to craft a resume that showcases your skills and experience effectively – it’s your first impression with potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?