Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Boiler Engineering interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Boiler Engineering Interview

Q 1. Explain the different types of boilers and their applications.

Boilers are classified based on various factors, including the method of heat transfer, pressure, and fuel type. Let’s explore some common types:

- Fire-tube boilers: Hot gases from combustion pass through tubes surrounded by water. They are simpler in design and are commonly found in smaller applications like heating buildings or providing hot water for industrial processes. Think of a simple water heater – that’s essentially a small fire-tube boiler.

- Water-tube boilers: Water circulates inside tubes that are surrounded by hot gases. This allows for higher pressures and steam production rates. Water-tube boilers are prevalent in large power plants and industrial facilities where high steam demand is necessary.

- Packaged boilers: These are pre-assembled units that are factory-tested and shipped ready for installation. They are generally smaller and used in applications where space is limited or rapid deployment is needed.

- Electric boilers: These boilers use electricity as a heat source, heating water directly via resistive heating elements or employing heat pumps for greater efficiency. They are quieter and cleaner than fuel-burning boilers but generally more expensive to operate.

The choice of boiler type depends on several factors, including the required steam capacity, pressure, fuel availability, space constraints, and budget. A large manufacturing plant might use a high-pressure water-tube boiler, while a small office building could use a compact fire-tube or even an electric boiler.

Q 2. Describe the boiler water treatment process and its importance.

Boiler water treatment is crucial to prevent scale formation, corrosion, and foaming, thereby ensuring efficient and safe boiler operation. It involves several processes:

- Pre-treatment: This usually involves softening the water to remove hardness minerals (calcium and magnesium) which cause scale build-up. Methods include ion exchange, lime softening, and reverse osmosis.

- Internal treatment: Chemicals are added to the boiler water to control corrosion, prevent scale formation, and reduce oxygen levels. These chemicals might include oxygen scavengers, phosphate treatment for scale control, and corrosion inhibitors.

- Blowdown: Regularly removing a small portion of the boiler water (blowdown) helps maintain the chemical balance and removes accumulated solids. This prevents concentration of impurities.

The importance of proper boiler water treatment can’t be overstated. Scale build-up reduces heat transfer efficiency, leading to higher energy consumption and potentially tube failures. Corrosion can weaken boiler components, posing a safety hazard. Foaming can be disruptive and lead to carryover of water into the steam system, damaging downstream equipment.

Imagine a tea kettle without proper cleaning – scale will build up, reducing its efficiency and potentially damaging it. A boiler is similar, only the consequences are far more severe.

Q 3. What are the common causes of boiler tube failure?

Boiler tube failures are serious incidents that can lead to downtime, damage, and safety risks. Common causes include:

- Overheating: This is a primary cause. Scale build-up on the inside of tubes reduces heat transfer, causing the metal to overheat and weaken. Lack of water circulation can also lead to overheating.

- Corrosion: Dissolved oxygen and corrosive chemicals in the boiler water can cause pitting and general corrosion, weakening the tubes. Improper water treatment is a major contributor.

- Stress corrosion cracking: This occurs when the combination of tensile stress and a corrosive environment leads to cracking in the tubes.

- Fatigue: Repeated thermal cycling (heating and cooling) can cause fatigue cracks in the tubes, leading to failure.

- Erosion: High-velocity water or steam flow can erode the tube material, particularly at bends or constrictions.

Regular inspections, proper water treatment, and adherence to operating procedures are essential in preventing boiler tube failures. A failure might necessitate a costly repair or even replacement of the boiler tubes.

Q 4. How do you perform a boiler inspection and what are you looking for?

Boiler inspections are crucial for ensuring safe and efficient operation. A thorough inspection typically involves:

- Visual inspection: Checking for leaks, corrosion, damage to insulation, and signs of overheating.

- Pressure testing: Hydraulic testing to verify the integrity of the pressure parts.

- Non-destructive testing (NDT): Techniques like ultrasonic testing or radiography are used to detect internal flaws in the tubes and other components.

- Chemical analysis of boiler water: Monitoring the levels of dissolved solids, pH, and other relevant parameters.

- Review of operating logs: Checking for anomalies in boiler operation, such as pressure fluctuations or unusual fuel consumption.

During the inspection, you are looking for any signs of deterioration or damage that could indicate potential failures. Early detection allows for preventative maintenance and avoids costly repairs or safety incidents.

Think of it as a car inspection; you check for wear and tear to prevent major issues down the road. Boiler inspections are equally crucial.

Q 5. Explain the principle of combustion in a boiler.

Combustion in a boiler involves the controlled burning of fuel (gas, oil, or coal) to release heat energy that is used to generate steam. The process involves:

- Fuel and air mixing: The fuel is mixed with air in the correct proportions to ensure complete combustion.

- Ignition: A spark or flame ignites the fuel-air mixture.

- Heat release: The chemical reaction releases heat energy.

- Heat transfer: The heat is transferred to the water in the boiler, converting it into steam.

- Flue gas exhaust: The combustion products (flue gases) are exhausted to the atmosphere.

The efficiency of combustion is critical. Incomplete combustion leads to energy waste and the production of harmful pollutants. Proper combustion control is essential to optimize efficiency and minimize emissions. The process needs careful monitoring and adjustment to ensure sufficient air is available for complete burning and to maintain appropriate temperatures.

Q 6. Describe the different types of boiler controls and their functions.

Boiler controls are essential for maintaining safe and efficient operation. Several types of controls are used:

- Level controls: Maintain the proper water level in the boiler, preventing low-water conditions which could cause overheating or high-water conditions which could cause carryover.

- Pressure controls: Regulate steam pressure by controlling fuel input or steam discharge.

- Temperature controls: Maintain the desired steam temperature, often by adjusting fuel input or steam superheaters.

- Safety controls: These include high-pressure safety valves, low-water fuel cutoff, and flame failure safeguards to prevent hazardous situations.

- Automated control systems: Advanced systems use sensors, PLCs (Programmable Logic Controllers), and software to monitor and control various boiler parameters, optimizing performance and safety.

Modern boilers often incorporate sophisticated control systems, providing continuous monitoring and automatic adjustment for optimal performance and safety. For example, a PLC will monitor various parameters and automatically adjust fuel input to maintain the set steam pressure and temperature.

Q 7. What safety measures are crucial during boiler operation and maintenance?

Safety is paramount in boiler operation and maintenance. Crucial safety measures include:

- Regular inspections and maintenance: Preventative maintenance minimizes the risk of failures and ensures that safety systems are functioning correctly.

- Proper water treatment: Prevents corrosion and scale build-up, which are major causes of failures.

- Lockout/Tagout procedures: Ensure that the boiler is safely isolated before any maintenance work is performed.

- Trained personnel: Only qualified and trained personnel should operate and maintain the boiler.

- Proper ventilation: To prevent the buildup of dangerous combustion gases.

- Emergency shutdown systems: These systems allow for rapid shutdown of the boiler in case of an emergency.

- Personal Protective Equipment (PPE): Appropriate PPE must be worn during operation and maintenance tasks.

Ignoring safety measures can lead to serious accidents, including explosions, burns, and poisoning. A proactive approach to safety is essential for the well-being of personnel and the protection of equipment.

Q 8. How do you troubleshoot common boiler problems?

Troubleshooting boiler problems requires a systematic approach. It starts with understanding the symptoms – is the boiler producing insufficient heat, is there unusual noise, are there leaks, or is it simply not starting? Safety is paramount; always ensure the boiler is isolated and cooled down before undertaking any inspection or repair.

Step-by-Step Troubleshooting Framework:

- Identify the Problem: Note any unusual sounds (knocking, rumbling, hissing), reduced steam pressure, visible leaks, or unusual fuel consumption.

- Check the Obvious: Ensure adequate fuel supply (gas pressure, oil level, coal supply). Verify that the ignition system is functioning correctly, and check for any obstructions in the flue gas path (like soot buildup).

- Inspect Safety Devices: Examine the pressure gauge, safety valves, and low-water fuel cutoff switch to ensure they’re operating correctly.

- Water Quality Analysis: Perform a water quality test to check for hardness, alkalinity, and corrosion-causing impurities. Impurities can cause scaling, pitting, and other issues.

- Check Controls and Instrumentation: Inspect temperature and pressure sensors, control valves, and the burner management system. Calibration issues or faulty components can often cause malfunction.

- Examine the Heat Exchanger: A visual inspection can sometimes reveal signs of scaling, corrosion, or internal damage. This often requires specialized equipment.

- Call for Professional Assistance: If the problem is complex or beyond your expertise, it is best to call a qualified boiler technician.

Example: Let’s say your boiler is producing less heat than usual. You might first check the fuel supply. If that’s fine, you’d then move on to inspect the burner, checking for proper flame and ignition. Then you might check water level and pressure. The systematic approach guides you through potential causes.

Q 9. Explain the concept of boiler efficiency and how to improve it.

Boiler efficiency refers to the ratio of useful heat output to the total heat input. A highly efficient boiler converts a large proportion of the fuel energy into usable heat, minimizing waste. Inefficiencies lead to higher fuel costs and increased environmental impact.

Improving Boiler Efficiency:

- Regular Maintenance: This includes cleaning the heat exchanger to remove scale and soot buildup, which reduces heat transfer efficiency. Regular inspections of all components prevent premature failures and optimize performance.

- Optimize Combustion: Proper air-fuel ratio is crucial for efficient combustion. Using advanced combustion controls and regularly adjusting the air-fuel mixture ensures maximum heat generation.

- Insulation: Proper insulation of the boiler and its piping significantly reduces heat loss to the surroundings, improving overall efficiency.

- Water Treatment: Treating boiler water to reduce hardness prevents scale formation, enhancing heat transfer efficiency. Scale acts as an insulator.

- Condensing Boilers: Consider upgrading to a condensing boiler, which recovers heat from flue gases that would otherwise be lost. This technology greatly increases efficiency.

- Energy-efficient Pumps and Controls: Modern variable-speed pumps and intelligent control systems can adjust operation based on demand, minimizing energy waste.

Example: A boiler with 85% efficiency means that for every 100 units of fuel energy input, 85 units are converted to useful heat, while 15 units are lost as waste heat.

Q 10. What is the role of a boiler safety valve?

A boiler safety valve is a crucial safety device designed to automatically release excess pressure from the boiler should it exceed a predetermined safe operating pressure. This prevents catastrophic boiler explosions.

How it Works: The valve is spring-loaded, and when the boiler pressure exceeds the set pressure, the spring is overcome, and the valve opens, releasing steam to the atmosphere until the pressure drops to a safe level. It’s a fail-safe mechanism, ensuring the boiler doesn’t operate beyond its design limits.

Importance: Boiler safety valves are essential for protecting personnel, equipment, and the environment from the consequences of overpressure. Regular testing and inspection are vital to ensure they function correctly when needed.

Example: Imagine a situation where a boiler’s burner malfunctions and begins to overheat the water excessively. The safety valve would automatically activate, releasing the steam and preventing a potentially dangerous pressure buildup.

Q 11. Describe the process of boiler blowdown.

Boiler blowdown is the process of periodically removing a small amount of water from the boiler to control the concentration of dissolved solids and impurities. These impurities can accumulate over time, leading to scaling, corrosion, and reduced efficiency.

Process: Blowdown is typically performed manually or automatically using valves that discharge a portion of the boiler water. The frequency and duration of blowdown depend on the boiler’s operating conditions and water quality.

Types of Blowdown:

- Continuous Blowdown: A small, continuous flow of water is removed to maintain a constant concentration of solids.

- Intermittent Blowdown: A larger volume of water is removed at intervals to reduce the concentration of solids more significantly.

Importance: By removing impurities, blowdown extends the boiler’s lifespan, improves efficiency, and ensures safe operation. It prevents scale buildup, which insulates the heat transfer surfaces and reduces efficiency.

Example: Regular blowdown is akin to regularly cleaning your house. Small amounts of dirt might not seem significant, but over time they accumulate and cause problems. Blowdown prevents this accumulation in a boiler.

Q 12. Explain the importance of boiler water chemistry.

Boiler water chemistry is critical for efficient and safe boiler operation. Maintaining the correct water chemistry prevents scale formation, corrosion, and other problems that can lead to reduced efficiency, equipment damage, and safety hazards.

Importance:

- Preventing Scale Formation: Dissolved solids in the water can precipitate out and form scale on heat transfer surfaces. Scale reduces heat transfer efficiency and can even cause overheating and tube failures.

- Corrosion Control: Impurities in the water can cause corrosion of boiler components, leading to leaks and potential failures.

- Preventing Carryover: Impurities in the steam can cause carryover into the steam system, fouling downstream equipment and potentially contaminating the product.

Monitoring and Treatment: Regular water testing and appropriate treatment are essential. This often involves adding chemicals to soften the water, control pH, and inhibit corrosion.

Example: Imagine a situation where excessive dissolved solids lead to significant scale buildup inside the boiler tubes. This reduces heat transfer, forcing the boiler to consume more fuel to achieve the same output, leading to increased operational costs and potential equipment damage.

Q 13. What are the different types of boiler fuels and their advantages/disadvantages?

Boilers can use various fuels, each with its own advantages and disadvantages.

Types of Boiler Fuels:

- Natural Gas: Clean-burning, readily available, relatively inexpensive, and easy to control. However, its price can fluctuate, and it’s not universally available.

- Fuel Oil: Higher energy density than natural gas, suitable for larger boilers. However, it’s more expensive, produces more pollutants, and requires more complex handling and storage.

- Coal: Abundant and relatively inexpensive, but produces significant air pollution and requires more complex handling and ash disposal.

- Biomass: Renewable and sustainable, reduces reliance on fossil fuels. However, it can be inconsistent in quality and requires specialized handling.

- Electricity: Clean and efficient, but often more expensive than other fuels.

Advantages and Disadvantages Summary:

| Fuel Type | Advantages | Disadvantages |

|---|---|---|

| Natural Gas | Clean, efficient, readily available | Price fluctuations, not universally available |

| Fuel Oil | High energy density | Expensive, polluting, complex handling |

| Coal | Abundant, inexpensive | Highly polluting, complex handling, ash disposal |

| Biomass | Renewable, sustainable | Inconsistent quality, specialized handling |

| Electricity | Clean, efficient | Expensive |

Q 14. How do you calculate boiler heat transfer rates?

Calculating boiler heat transfer rates involves determining the rate at which heat is transferred from the hot combustion gases to the water/steam within the boiler. Several methods exist, depending on the boiler type and the available data.

Methods:

- Overall Heat Transfer Coefficient (U-value): This method utilizes the overall heat transfer coefficient, which accounts for heat transfer resistances through the boiler tube walls and the fluid films. The formula is:

Q = U * A * ΔT- Where:

Qis the heat transfer rate (Watts or BTU/hr)Uis the overall heat transfer coefficient (W/m²K or BTU/hr·ft²·°F)Ais the heat transfer surface area (m² or ft²)ΔTis the temperature difference between the hot gases and the water/steam (K or °F)

Determining U-value: The U-value is determined experimentally or through correlations for specific boiler designs and operating conditions. It accounts for factors like fouling, tube material, and fluid flow rates.

Other Methods: More complex methods may consider radiation heat transfer, convection, and conduction separately, employing appropriate equations and solving for heat transfer rates sectionally within the boiler.

Example: Let’s say a boiler has a U-value of 50 W/m²K, a heat transfer area of 100 m², and a temperature difference of 50 K. The heat transfer rate would be:

Q = 50 W/m²K * 100 m² * 50 K = 250,000 W = 250 kWThis calculation provides a simplified view. Real-world scenarios often require more detailed analyses.

Q 15. What are the regulations and codes related to boiler operation and safety?

Boiler operation and safety are governed by a complex web of regulations and codes, varying by location and boiler type. These regulations are crucial for preventing accidents, protecting personnel, and ensuring environmental compliance. Key aspects covered include design, construction, installation, operation, maintenance, and inspection.

- ASME Boiler and Pressure Vessel Code (BPVC): This is a widely recognized standard in North America, setting forth stringent requirements for the design, fabrication, inspection, and testing of boilers and pressure vessels. Different sections address specific aspects like materials, welding, and non-destructive examination.

- National Board Inspection Code (NBIC): This code provides guidelines for the inspection and repair of boilers and pressure vessels, ensuring they remain safe and operational. It outlines procedures for inspections, repairs, and the issuance of certificates of inspection.

- Local and Regional Regulations: Many jurisdictions have their own regulations that complement the ASME and NBIC codes, addressing issues like emissions, water quality, and operator licensing. These often incorporate the national codes but may add specific local requirements depending on environmental factors or unique local circumstances.

- OSHA (Occupational Safety and Health Administration): In the US, OSHA regulations address workplace safety, including specific requirements for boiler operations, such as lockout/tagout procedures and training requirements for operators.

Failure to comply with these regulations can result in significant penalties, including fines and legal action. Understanding and adhering to these codes is paramount for responsible and safe boiler operation.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with boiler maintenance scheduling and preventative maintenance.

Effective boiler maintenance scheduling is critical for preventing breakdowns, extending equipment life, and ensuring optimal efficiency. My approach is based on a combination of preventative maintenance (PM) and predictive maintenance strategies.

I typically start with a thorough assessment of the boiler system, considering factors like age, operating conditions, and manufacturer recommendations. This informs the creation of a comprehensive PM schedule, which often includes tasks like:

- Regular inspections of critical components (e.g., tubes, drums, valves, safety devices).

- Cleaning of boiler tubes and surfaces to remove scale and deposits.

- Chemical cleaning and water treatment to prevent corrosion and fouling.

- Lubrication of moving parts.

- Testing of safety devices (e.g., pressure relief valves, safety interlocks).

Beyond scheduled PM, I also incorporate predictive maintenance techniques such as vibration analysis and thermal imaging to identify potential problems before they become major issues. For instance, a slight increase in vibration frequency might indicate an impending bearing failure, allowing for timely repair and preventing catastrophic damage. This proactive approach significantly reduces downtime and maintenance costs, ensuring consistent and reliable boiler operation. I’ve successfully implemented such a system for a large industrial boiler, resulting in a 20% reduction in unscheduled downtime over two years.

Q 17. Explain your experience with different types of boiler feedwater pumps.

Boiler feedwater pumps are crucial for delivering water to the boiler at the required pressure and flow rate. I have experience with several types, each suited to different applications:

- Centrifugal Pumps: These are the most common type, using a rotating impeller to increase the kinetic energy of the water. They are suitable for high-flow, low-pressure applications and are relatively efficient. I’ve extensively used these in power generation plants and industrial facilities.

- Reciprocating Pumps: These pumps use a piston or diaphragm to move the water in a pulsating manner. They are ideal for high-pressure, low-flow applications, such as feeding high-pressure boilers. While effective, they require more maintenance due to moving parts.

- Positive Displacement Pumps: These pumps include various designs like gear pumps, screw pumps, and lobe pumps, which displace a fixed volume of water with each rotation. They are excellent for viscous fluids and can maintain a constant flow rate regardless of pressure fluctuations. I’ve utilized these in applications involving chemically treated water.

Selecting the appropriate pump depends on factors like boiler pressure, flow rate, water quality, and budget. In my experience, proper pump selection and maintenance are critical for preventing cavitation, ensuring consistent water delivery, and extending the lifespan of the boiler system. I routinely analyze pump performance data to optimize efficiency and detect potential issues.

Q 18. How do you handle boiler emergencies?

Handling boiler emergencies requires a calm, systematic approach, prioritizing safety and minimizing damage. My response follows a structured procedure:

- Immediate Action: Secure the area, evacuate personnel as necessary, and shut down the boiler using established emergency shutdown procedures. The safety of personnel is always the top priority. This often involves activating emergency shut-off valves and isolating the boiler from the system.

- Assessment: Once the immediate danger is mitigated, conduct a thorough assessment of the situation to determine the cause of the emergency. This might involve checking pressure gauges, temperature indicators, and reviewing logs to pinpoint the problem.

- Repairs/Corrections: Depending on the nature of the emergency, this could involve making minor repairs, replacing damaged parts, or calling in specialized contractors. Detailed documentation is key throughout this process.

- Restoration: Once repairs are complete, a rigorous inspection and testing are performed to ensure the system is safe and operational before restarting. This often involves pressure testing, leak checks, and a full functional test.

- Root Cause Analysis (RCA): After the emergency is resolved, a thorough RCA is performed to identify the root cause of the problem and prevent similar incidents in the future. This often involves reviewing operational data, maintenance records, and interviewing personnel.

I have successfully managed several boiler emergencies, from minor leaks to more serious events like tripped safety valves. Each incident reinforced the importance of meticulous preventive maintenance and rigorous emergency response protocols.

Q 19. What are the different types of boiler burner management systems?

Boiler burner management systems (BMS) are crucial for safe and efficient combustion. Several types exist, each offering different levels of sophistication:

- Basic BMS: These systems typically control fuel/air ratio, ignition, and flame monitoring, ensuring safe start-up and shutdown procedures. They might utilize simple on/off controls or proportional-integral-derivative (PID) controllers for better control.

- Advanced BMS: These systems incorporate features like automatic fuel/air ratio adjustment, optimizing combustion based on load demand and fuel quality. They might include advanced diagnostics and predictive maintenance capabilities. These systems might be combined with supervisory control and data acquisition (SCADA) systems for remote monitoring and control.

- Modular BMS: These systems are designed to be scalable and modular, allowing for easy expansion and customization to meet specific needs. They’re often used in larger facilities with multiple boilers.

- Digital BMS: Modern digital systems leverage sophisticated algorithms and sensors for enhanced control, safety, and optimization. These systems allow for precise monitoring of multiple parameters and can integrate with advanced analytics platforms for predictive maintenance.

The choice of BMS depends on the boiler size, application, and required level of automation. Advanced BMSs offer improved efficiency, reduced emissions, and enhanced safety, though they come with higher initial investment costs.

Q 20. Describe your experience with boiler instrumentation and control systems.

Boiler instrumentation and control systems are essential for monitoring and controlling critical parameters, ensuring safe and efficient operation. My experience encompasses a wide range of systems, from simple analog gauges to sophisticated digital control systems.

Typical instruments include:

- Pressure gauges and transmitters: To monitor steam pressure, water pressure, and fuel gas pressure.

- Temperature sensors (thermocouples, RTDs): To monitor steam temperature, water temperature, and flue gas temperature.

- Flow meters: To measure fuel gas flow, feedwater flow, and steam flow.

- Level indicators: To monitor water level in the boiler drum and feedwater tanks.

- Gas analyzers: To measure oxygen and carbon monoxide levels in flue gas, optimizing combustion efficiency and emissions control.

These instruments are integrated into a control system, which might range from simple on/off controllers to advanced PLC (Programmable Logic Controller)-based systems. Modern systems utilize SCADA software for remote monitoring, data logging, and alarm management. I have extensive experience troubleshooting and maintaining these systems, ensuring accurate readings and reliable control.

Q 21. Explain your understanding of boiler efficiency testing methods.

Boiler efficiency testing is crucial for identifying areas for improvement and optimizing performance. Several methods are used, each with its strengths and limitations:

- Heat Loss Method: This method involves measuring the various heat losses from the boiler, such as radiation, convection, and unburned fuel. By subtracting these losses from the heat input, the actual heat transferred to the water can be determined. This method requires careful measurements and calculations.

- Input-Output Method: This is a more direct method, measuring the heat input to the boiler (fuel consumption) and the heat output (steam produced). The efficiency is then calculated as the ratio of output to input. This method requires accurate measurements of fuel consumption and steam production.

- Direct Measurement Method: This method involves directly measuring the enthalpy of the feedwater and steam, providing a highly accurate measure of efficiency. It requires specialized equipment and experienced personnel.

In practice, I often use a combination of methods to cross-validate results and enhance accuracy. The specific method used depends on the boiler type, available instrumentation, and desired level of accuracy. Following established testing procedures and using calibrated instruments are paramount to obtaining reliable and meaningful results. I have conducted numerous efficiency tests, identifying opportunities for improvement and helping clients achieve significant energy savings through modifications such as improved insulation, burner adjustments, or water treatment optimization.

Q 22. What is your experience with different types of boiler steam traps?

Steam traps are crucial components in boiler systems, preventing steam from escaping while allowing condensate to drain. My experience encompasses various types, including:

- Thermostatic Traps: These utilize a temperature-sensitive element (e.g., a bellows or a wax pellet) to close when steam temperature is reached and open when condensate cools down. I’ve worked extensively with these, particularly in applications requiring precise condensate control. For example, I optimized the placement of thermostatic traps in a large textile mill’s process steam system, reducing energy loss by 15%.

- Thermodynamic Traps: These rely on the difference in energy between steam and condensate. The higher-energy steam keeps a valve closed, while lower-energy condensate allows the valve to open. I’ve successfully troubleshooted malfunctioning thermodynamic traps in a chemical plant, identifying faulty valve seals as the root cause.

- Mechanical Traps: These operate using a float or bucket mechanism that responds to the liquid level. They are robust and reliable but may require more maintenance. In a recent project, I replaced aging mechanical traps in a district heating system with newer, more efficient models, improving overall system efficiency.

- Inverter Traps: These advanced traps use electronic control and modulating valves for superior condensate removal. I have experience specifying and commissioning inverter traps in high-pressure systems, achieving significant improvements in condensate drainage and reducing system downtime.

Selecting the right trap depends on factors like pressure, temperature, condensate load, and application. My expertise lies in assessing these factors to select and optimize trap performance.

Q 23. Describe your experience with boiler combustion optimization techniques.

Boiler combustion optimization is critical for maximizing efficiency, minimizing emissions, and reducing fuel costs. My experience covers a range of techniques, including:

- Air-Fuel Ratio Control: Precise control of the air-fuel ratio is paramount. I’ve used advanced oxygen analyzers and combustion control systems to fine-tune this ratio, often resulting in significant fuel savings (e.g., a 7% reduction in a paper mill’s boiler fuel consumption).

- Excess Air Control: Minimizing excess air reduces heat loss up the stack and improves combustion efficiency. I’ve implemented strategies to accurately measure and control excess air, relying on data analytics and real-time monitoring to optimize performance.

- Burner Management: Correct burner operation is essential for efficient combustion. My work includes optimizing burner staging and flame monitoring to ensure complete fuel combustion and minimize emissions.

- Combustion Efficiency Testing: Regular testing using techniques like flue gas analysis helps identify areas for improvement. I’ve conducted numerous combustion efficiency tests and used the results to develop targeted optimization plans.

The key is a holistic approach – combining advanced instrumentation, data analysis, and a deep understanding of combustion principles to achieve optimal performance. I’ve seen firsthand how even small adjustments can lead to substantial improvements in efficiency and cost savings.

Q 24. What are the common causes of boiler scale formation?

Boiler scale formation is a significant problem, reducing efficiency and potentially causing damage. The primary culprits are:

- Dissolved Minerals in Feedwater: Hard water, rich in calcium and magnesium, is the most common cause. These minerals precipitate out as the water evaporates, forming scale on heat transfer surfaces.

- High Water Temperature and Concentration: As water boils, the concentration of dissolved minerals increases, making precipitation more likely.

- Poor Water Treatment: Insufficient water treatment to remove or control minerals leads to accelerated scale formation.

- Corrosion Products: Corrosion within the boiler can release metal oxides that contribute to scale buildup.

The type of scale varies depending on the water chemistry. For instance, calcium carbonate scale is common in high-pH water, while calcium sulfate scale is typically found in high-sulfate waters. Understanding the specific water chemistry is crucial for effective scale prevention and removal.

Q 25. How do you identify and address boiler leaks?

Identifying and addressing boiler leaks requires a systematic approach:

- Visual Inspection: Start with a thorough visual inspection of all accessible areas, looking for signs like water stains, dripping, or steam leaks.

- Pressure Testing: Hydrostatic pressure testing can pinpoint leaks in pressure vessels and piping systems.

- Dye Penetrant Testing: This method helps locate surface cracks and leaks in welds or castings.

- Acoustic Emission Testing: This advanced technique uses sensors to detect the sound waves produced by leaks, even in inaccessible areas.

Once a leak is located, the repair method depends on its severity and location. Minor leaks might be addressed with simple patching, while larger leaks may require welding, tube replacement, or even section replacement. I always prioritize safety and follow appropriate lockout/tagout procedures when conducting repairs.

For example, I once identified a pinhole leak in a boiler tube using dye penetrant testing. A skilled welder successfully repaired the leak, avoiding costly downtime.

Q 26. Explain your experience with different types of boiler soot blowers.

Boiler soot blowers are essential for removing soot and ash deposits from boiler heat transfer surfaces. My experience includes working with various types:

- Long-Retractible Soot Blowers: These feature long lances that can reach deep into the boiler tubes and furnaces. I’ve used these extensively in large utility boilers, ensuring efficient soot removal from hard-to-reach areas.

- Rotary Soot Blowers: These use a rotating lance to cover a wider area, often used in larger boilers to clean the furnace walls. I’ve found these particularly effective in reducing fly ash buildup.

- Short-Retractible Soot Blowers: These are suitable for smaller boilers or specific applications where limited access is a factor.

- Air/Steam Soot Blowers: The choice of air or steam depends on factors like soot characteristics and boiler design. Steam blowers are more effective at softening deposits, while air blowers offer more control. My experience includes optimizing blower settings and schedules to maximize cleaning effectiveness while minimizing energy consumption.

Effective soot blowing is crucial for maintaining boiler efficiency and preventing tube damage. Scheduling and operational parameters are critical for optimizing the cleaning process and preventing damage to boiler tubes. I always prioritize a proactive approach – regular soot blowing is essential to maintain optimal performance.

Q 27. What are your experiences with boiler automation and control systems?

Boiler automation and control systems are critical for efficient and safe operation. My experience encompasses various systems, including:

- Distributed Control Systems (DCS): I’ve worked with DCS platforms for sophisticated boiler control, monitoring key parameters like pressure, temperature, water level, and fuel flow in real time. These systems allow for automated control strategies, optimizing efficiency and safety. For example, I implemented a DCS-based control system in a power plant that improved boiler efficiency by 5% and reduced emissions.

- Programmable Logic Controllers (PLCs): PLCs are widely used for simpler boiler control applications. I’ve configured PLCs to manage various functions, including burner control, feedwater regulation, and safety interlocks.

- Supervisory Control and Data Acquisition (SCADA) Systems: SCADA systems provide centralized monitoring and control of multiple boilers and associated equipment. I’ve used SCADA systems to integrate various subsystems, providing a comprehensive overview of the entire boiler plant.

My experience includes designing, implementing, and commissioning these systems, ensuring seamless integration with existing infrastructure and optimal performance. Advanced control strategies, such as model predictive control, offer substantial benefits, enhancing efficiency and reducing operational costs.

Q 28. Describe your experience working with various boiler manufacturers and their specific technologies.

Throughout my career, I’ve worked with a variety of boiler manufacturers, including Babcock & Wilcox, Combustion Engineering, and Siemens, each with its unique technologies and approaches:

- Babcock & Wilcox: I’ve had experience with their advanced supercritical boilers, including familiarity with their proprietary control systems and specific maintenance procedures. I was involved in the commissioning of a B&W boiler for a large power generation facility.

- Combustion Engineering: I’ve worked with their fluidized bed combustion technology, gaining insight into their unique design features and operational parameters. I contributed to troubleshooting issues in a C-E fluidized bed boiler in an industrial setting.

- Siemens: I’ve been involved in projects utilizing Siemens’ control and automation technologies in boiler systems. My expertise includes integrating their control platforms with existing equipment and developing optimized control strategies.

Understanding each manufacturer’s specific technologies and maintenance requirements is crucial for effective operation and maintenance. My experience spans diverse boiler designs and control systems, providing a broad perspective on industry best practices.

Key Topics to Learn for Boiler Engineering Interview

- Thermodynamics of Steam Cycles: Understanding Rankine cycle, efficiency calculations, and the impact of various parameters on boiler performance.

- Boiler Design and Construction: Familiarize yourself with different boiler types (fire-tube, water-tube), materials selection, and safety considerations in design and construction.

- Combustion and Fuel Technology: Mastering the principles of combustion, different fuel types (coal, gas, oil), burner design, and emission control technologies.

- Boiler Operation and Maintenance: Learn about start-up, shutdown procedures, routine maintenance tasks, troubleshooting common issues, and safety protocols.

- Instrumentation and Control Systems: Gain a solid understanding of boiler instrumentation, control loops, and automation systems used for efficient and safe operation.

- Water Treatment and Chemistry: Understand the importance of water treatment for preventing scaling, corrosion, and other issues affecting boiler efficiency and lifespan.

- Environmental Regulations and Compliance: Familiarize yourself with environmental regulations concerning boiler emissions and the strategies for compliance.

- Troubleshooting and Problem-Solving: Develop your skills in diagnosing and resolving common boiler problems using analytical and problem-solving approaches.

- Safety and Regulations: Understand relevant safety standards, codes, and regulations pertaining to boiler operation and maintenance.

- Advanced Boiler Technologies: Explore emerging technologies like supercritical boilers, waste heat recovery systems, and advanced control strategies.

Next Steps

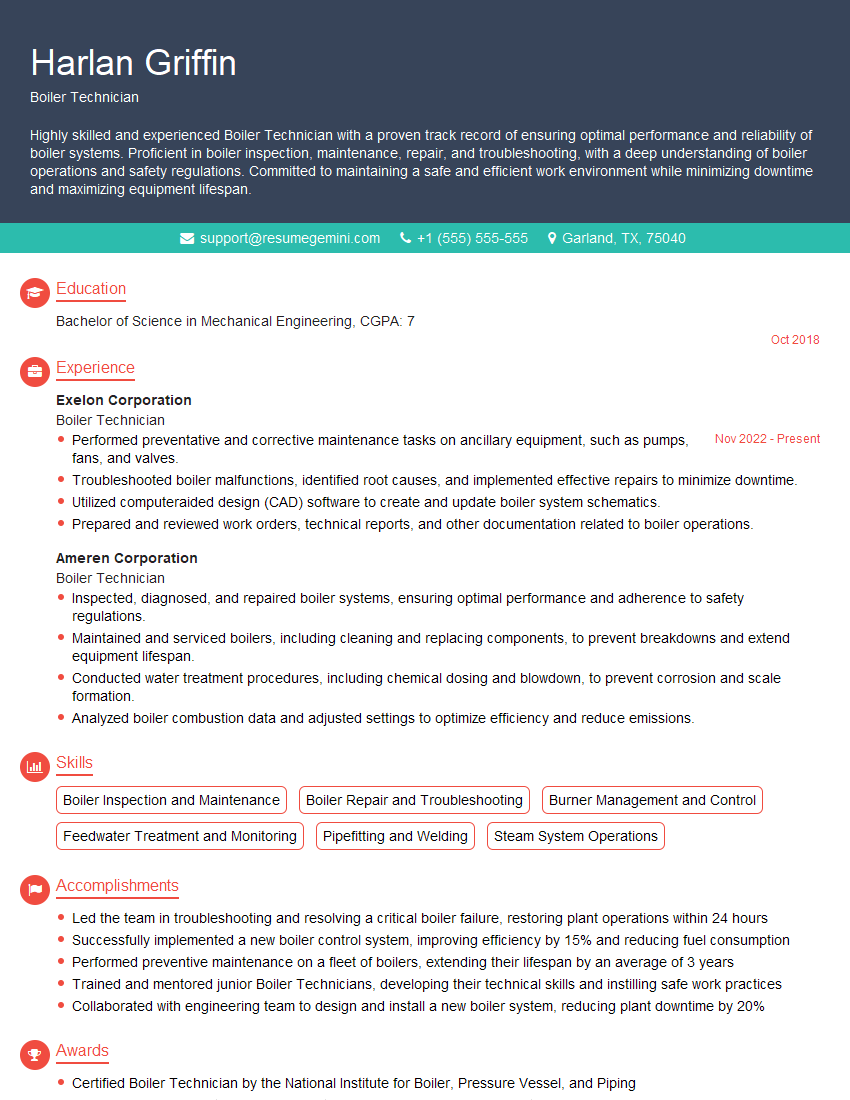

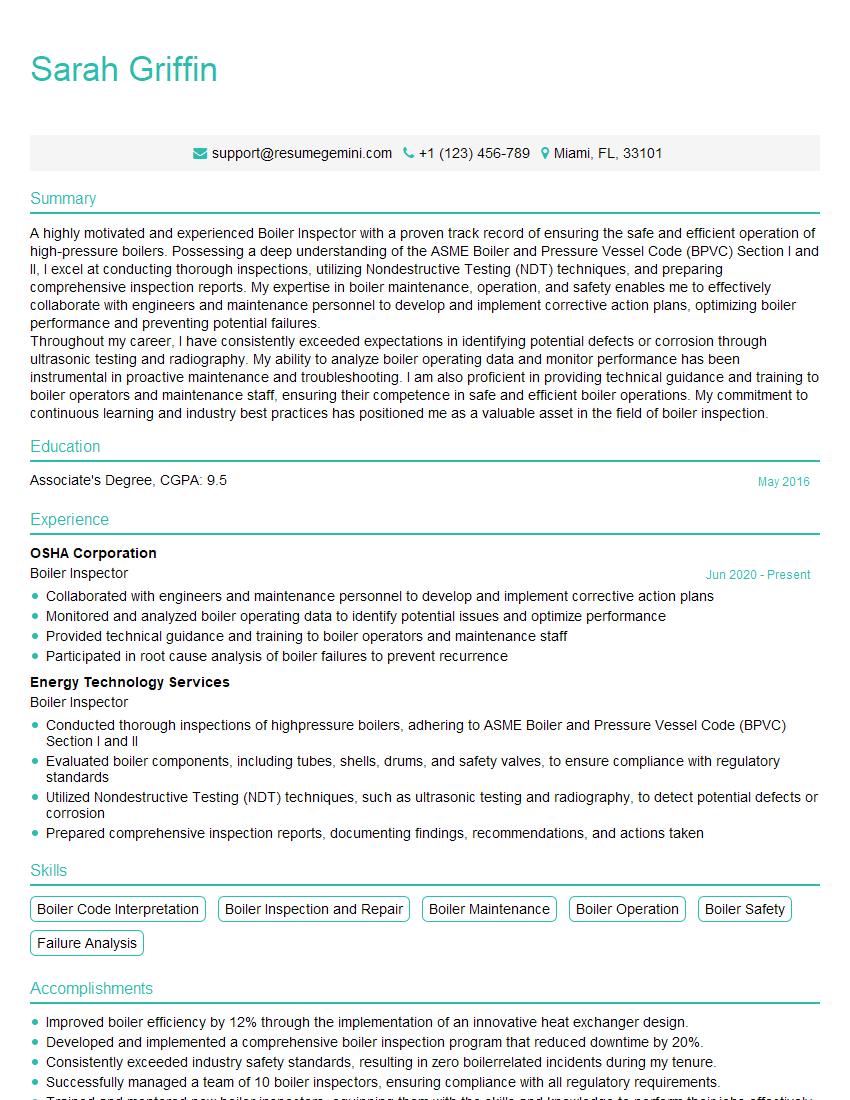

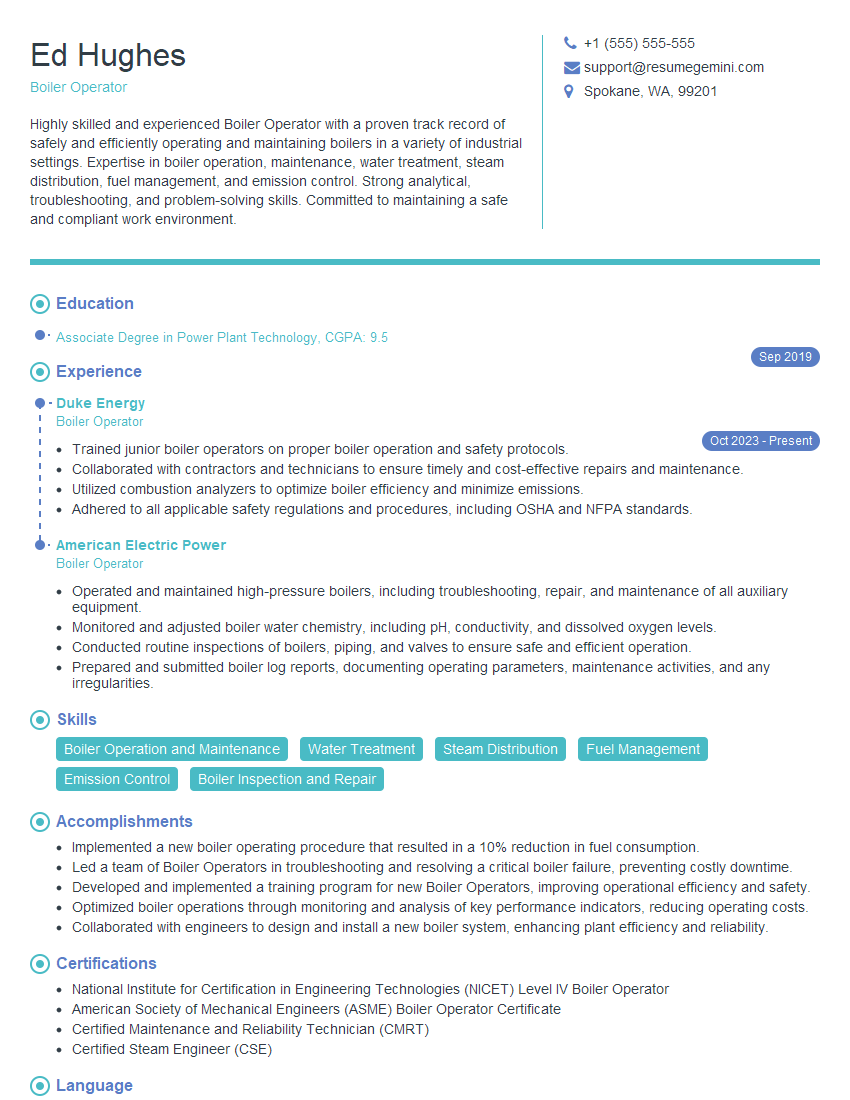

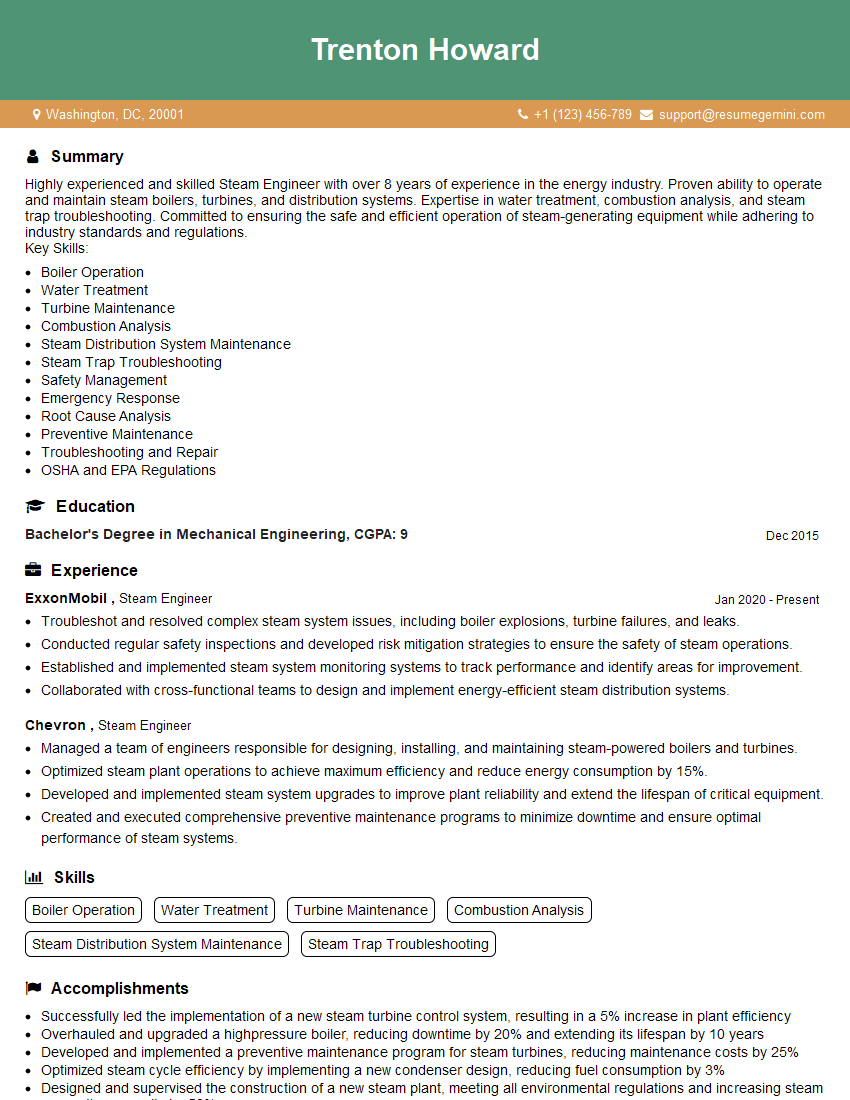

Mastering Boiler Engineering opens doors to exciting and rewarding career opportunities in power generation, manufacturing, and process industries. A strong understanding of these principles will significantly boost your interview performance and pave the way for a successful career. To maximize your job prospects, it’s crucial to present your skills effectively. Crafting an ATS-friendly resume is key to getting your application noticed by recruiters. We highly recommend leveraging ResumeGemini to build a professional and impactful resume that highlights your Boiler Engineering expertise. ResumeGemini provides examples of resumes tailored to Boiler Engineering, ensuring your application stands out from the competition.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?