Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Boiler Erecting interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Boiler Erecting Interview

Q 1. Explain the process of boiler erection from initial site preparation to final commissioning.

Boiler erection is a complex process requiring meticulous planning and execution. It begins with site preparation, ensuring a level foundation capable of supporting the boiler’s weight and associated equipment. This includes ground surveys, foundation construction according to the boiler manufacturer’s specifications, and access road construction for heavy equipment. Next comes the unpacking and inspection of all boiler components. Each part is meticulously checked against the manufacturer’s documentation to ensure completeness and absence of damage. The assembly phase follows, starting with the base structure and proceeding upwards, carefully aligning and fitting each component according to the manufacturer’s drawings and specifications. Precise measurements and alignment tools are essential at this stage. Piping and instrumentation are installed concurrently, ensuring proper connections and leak-free systems. This often involves specialized welding and fitting techniques. Once the physical structure is complete, hydrostatic testing is conducted to verify structural integrity and identify any leaks. After successful testing, the boiler undergoes insulation and cladding for efficient heat retention and safety. Finally, the boiler is commissioned, a process involving initial start-up, performance testing, and fine-tuning to optimize efficiency and ensure compliance with safety regulations.

Think of it like building a very complex Lego castle: each brick (component) must fit perfectly and securely, and the entire structure needs to withstand stress (pressure). Every step requires precision and adherence to plans.

Q 2. Describe your experience with different types of boilers (e.g., water tube, fire tube).

My experience encompasses both water tube and fire tube boilers. Water tube boilers, which circulate water through tubes surrounded by hot gases, are commonly found in large-scale power generation and industrial applications. I’ve worked extensively on Babcock & Wilcox units, known for their reliability and efficiency. These projects demanded precise alignment of hundreds of tubes and meticulous welding. Fire tube boilers, with hot gases passing through tubes surrounded by water, are typically smaller and found in heating applications. I’ve overseen installations of various fire tube boilers, including those used for district heating, highlighting my proficiency in working across different scales and designs. Each type necessitates a different approach to erection, understanding the unique characteristics of heat transfer and pressure dynamics is crucial. For instance, the tube expansion in water tube boilers requires precise pre-bending techniques to avoid leaks during operation. This experience allows me to adapt effectively to the demands of diverse boiler systems.

Q 3. What safety procedures are essential during boiler erection?

Safety is paramount during boiler erection. We follow a stringent safety protocol, which includes: pre-job safety briefings emphasizing site-specific hazards and risk mitigation strategies, lockout/tagout procedures to prevent accidental energy release, mandatory use of personal protective equipment (PPE), such as hard hats, safety glasses, and steel-toe boots, implementation of fall protection systems, especially for working at heights, proper lifting and rigging techniques to prevent equipment damage and injuries, confined space entry procedures for safe access to internal boiler components, and adherence to all relevant OSHA and industry safety standards. A dedicated safety officer is present throughout the project to monitor compliance and address any potential safety issues immediately.

Imagine a highly coordinated orchestra: every musician (worker) plays their part flawlessly and in harmony (safe manner) to avoid any dissonance (accident).

Q 4. How do you ensure the alignment and proper fitting of boiler components?

Accurate alignment and fitting are crucial for optimal boiler performance and safety. We use a combination of methods, including laser alignment systems for precise positioning of large components, optical plummets and levels for verifying vertical and horizontal alignment, and shims and precision-machined parts to correct any minor misalignments. The use of alignment charts provided by the manufacturer guide the process. Regular dimensional checks are performed throughout the erection process to ensure components fit within tolerances. Components are often temporarily secured using jigs and fixtures to maintain alignment during the welding process. Experience and understanding of thermal expansion properties of different materials are essential for ensuring the assembly remains aligned under varying operating conditions.

Think of it like assembling a fine clock: every gear must mesh perfectly for the mechanism to function correctly. Precise measurements and careful adjustments are essential for a perfectly working system.

Q 5. What are the common challenges encountered during boiler erection, and how do you overcome them?

Challenges vary; however, some common issues include: site constraints like limited space or challenging terrain, material handling difficulties involving oversized or heavy components, delays in material delivery, discrepancies in drawings or specifications, and unexpected site conditions like soil instability. To overcome these, we employ proactive measures, such as thorough site surveys and risk assessments beforehand. Detailed planning of material handling procedures, including crane usage and access routes, helps reduce logistical problems. Open communication with suppliers and clients is crucial to manage delays and resolve discrepancies. Adaptability and problem-solving skills are key to navigating unexpected challenges on-site, often involving creative solutions using available resources and expertise.

Encountering unforeseen challenges is a reality in construction. Our approach is to anticipate potential problems, prepare contingency plans, and maintain a flexible attitude to overcome any obstacles effectively.

Q 6. Describe your experience with boiler pressure testing and inspection.

Boiler pressure testing and inspection are critical for ensuring operational safety. Pressure testing involves filling the boiler with water and pressurizing it to a specified level, exceeding the maximum operating pressure to test its structural integrity. This requires specialized equipment and expertise. We follow strict procedures, including leak detection using various methods like dye penetrant testing. Visual inspection is conducted at all stages, examining welds, pipe connections, and other critical components for defects. We also carry out non-destructive testing (NDT), such as radiographic testing or ultrasonic testing, to identify internal flaws. All results are meticulously documented and compared to acceptance criteria defined by the ASME code and project specifications. Post-testing, a thorough inspection is performed, and a detailed report is prepared, including any identified deficiencies and recommended corrective actions.

It’s akin to giving a thorough medical checkup to the boiler before allowing it to operate; this ensures safety and efficiency.

Q 7. Explain your understanding of ASME Boiler and Pressure Vessel Code.

The ASME Boiler and Pressure Vessel Code (BPVC) is a comprehensive standard covering design, fabrication, inspection, and testing of boilers and pressure vessels. It’s crucial for ensuring public safety. My understanding encompasses various sections of the code relevant to boiler erection, including Section VIII (Rules for Construction of Pressure Vessels), which details construction standards for various types of pressure vessels. Section I (Power Boilers) covers the design and construction requirements for power boilers. I’m proficient in interpreting the code’s requirements for materials, welding procedures, non-destructive testing, and hydro testing. Adherence to the ASME code is not just a regulatory requirement; it’s a cornerstone of safe and reliable boiler operation. Throughout my career, I have consistently ensured that every stage of boiler erection—from design review to final commissioning—complies with all relevant ASME code requirements. It’s a critical component of ensuring safety and reliability.

Q 8. How do you interpret and follow boiler erection drawings and specifications?

Interpreting boiler erection drawings and specifications is the cornerstone of successful boiler installation. It’s like reading a complex recipe for a giant machine. I begin by thoroughly reviewing the general arrangement drawings to understand the overall layout and the relationship between different components. This includes the location of all major parts, like the drum, headers, tubes, and supports. Then, I meticulously examine the detail drawings, which provide precise dimensions, tolerances, and material specifications for each individual part. These drawings often include welding symbols, which I interpret to understand the type of weld required, its size, and the specific welding procedure to be followed. Finally, I cross-reference the drawings with the specifications, which detail the materials, quality standards, and testing requirements. For example, a specification might dictate that a specific grade of steel must be used for the pressure parts, and I must ensure that the material certifications match these specifications. I always look for potential clashes or discrepancies between drawings and specifications, highlighting them for discussion and resolution within the team.

Think of it as building with LEGOs – the general arrangement drawing is like the overall picture on the box, while the detail drawings show you how to put each individual piece together. Missing instructions or unclear diagrams can lead to problems. My experience allows me to anticipate potential issues and proactively address them before they impact the project timeline or safety.

Q 9. What are your experiences with different welding techniques used in boiler erection?

My experience encompasses a wide range of welding techniques commonly used in boiler erection, including Shielded Metal Arc Welding (SMAW), Gas Metal Arc Welding (GMAW), and Gas Tungsten Arc Welding (GTAW). SMAW, or stick welding, is robust and versatile, ideal for field welding in various positions, especially when dealing with thicker sections or less accessible joints. I’ve used it extensively for joining pressure parts and support structures. GMAW, or MIG welding, offers higher deposition rates and cleaner welds, suitable for thinner materials and automated processes. I’ve utilized GMAW for joining smaller piping and components. GTAW, or TIG welding, provides exceptional precision and control, crucial for welding high-quality components requiring a refined finish. This technique is particularly important in areas requiring leak-proof joints in thinner sections. Beyond the basic techniques, I’m also proficient in specialized welding methods such as submerged arc welding (SAW), used for large-scale, high-production welding in controlled environments.

The choice of welding technique depends greatly on the specific application, material thickness, accessibility, and required weld quality. Each technique requires a thorough understanding of parameters like amperage, voltage, wire feed speed, and shielding gas composition to achieve optimal results, ensure quality, and prevent defects like porosity or incomplete penetration. Safety procedures, such as personal protective equipment (PPE) and proper ventilation, are paramount in each scenario.

Q 10. How do you ensure quality control throughout the boiler erection process?

Quality control in boiler erection is paramount – a flaw can have catastrophic consequences. My approach is multifaceted, starting with incoming material inspection. We verify material certifications and conduct dimensional checks to ensure conformance to specifications. During the welding process, we implement rigorous procedures including visual inspection, non-destructive testing (NDT), and documented welder qualifications. NDT techniques like radiographic testing (RT) and ultrasonic testing (UT) are employed to detect internal flaws. We meticulously document every step of the process, maintaining detailed records of welds, inspections, and any corrective actions. Regular dimensional checks are performed throughout the erection process to ensure alignment and proper fit-up. We work closely with third-party inspectors for independent verification of quality and compliance with codes and standards.

Imagine a watchmaker assembling a complex timepiece. Each component must meet stringent tolerances, and each connection must be flawless. We treat boiler erection with the same level of precision and care, ensuring that every weld, every fitting, and every component meets the highest quality standards, to provide a safe, efficient, and long-lasting unit.

Q 11. Describe your experience with troubleshooting boiler system issues.

Troubleshooting boiler system issues requires a systematic approach that combines practical experience and analytical skills. I start by thoroughly reviewing the system’s operating parameters, looking for deviations from normal operating conditions. This may involve analyzing pressure gauges, temperature readings, water level indicators, and fuel flow rates. I then assess visual indicators, checking for signs of leaks, corrosion, or damage. If a problem is identified in a specific component, I may use tools like a thermal imager to isolate the location of the fault. For electrical issues, I employ multimeters and other electrical testing equipment.

I recall an incident where a boiler exhibited unexpectedly low steam production. Through careful analysis, we discovered a buildup of scale within the boiler tubes, hindering heat transfer. This was addressed through a chemical cleaning process, restoring the boiler’s efficiency. Troubleshooting, for me, is less about guessing and more about systematically eliminating possibilities until the root cause is identified. Every experience provides invaluable insight that further sharpens my problem-solving abilities.

Q 12. What are the common causes of boiler leaks, and how do you repair them?

Boiler leaks can stem from several sources, including faulty welds, corrosion, erosion, or damage to tubes or other components. Faulty welds, often caused by improper welding techniques or insufficient weld penetration, are a common culprit. Corrosion, often accelerated by acidic water conditions, can weaken metal and lead to leaks. Erosion can occur due to high-velocity water flow, particularly in areas with sharp bends or restrictions in piping. Physical damage from external factors, like impacts or vibrations, can also cause leaks. Repair techniques vary depending on the cause and location of the leak. Small leaks in tubes might be patched with specialized repair compounds or plugs. More significant leaks may require cutting out and replacing the damaged section. For faulty welds, re-welding is usually necessary, following stringent quality control procedures.

It’s critical to identify the underlying cause of the leak to prevent recurrence. A seemingly minor leak today can become a major problem later. Repairing a leak is not simply patching a hole; it’s about understanding the root cause to ensure the long-term integrity and safety of the system. For example, if corrosion is the root cause, addressing the water chemistry issues is just as important as repairing the leak itself.

Q 13. How do you handle unexpected delays or problems during a project?

Unexpected delays and problems are inevitable in large-scale projects like boiler erection. My approach focuses on proactive risk management and efficient problem-solving. First, I carefully evaluate the nature and impact of the delay or problem. Then, I work with the project team to identify potential solutions, considering various factors including cost, schedule, and safety. This may involve adjusting the work schedule, procuring replacement parts, or consulting with specialists to resolve technical issues. Open communication is vital. I keep all stakeholders informed of the situation and progress, ensuring transparency and collaboration. I have extensive experience using project management software to track progress and identify potential bottlenecks.

In one instance, a critical component arrived late due to unforeseen circumstances with the supplier. I immediately engaged with the supplier and implemented an alternative solution by using a readily available substitute while expediting delivery of the original component. This minimized the project delay and kept everything on track. Effective communication and resourcefulness are crucial to overcome such challenges.

Q 14. Describe your experience with working at heights and using fall protection equipment.

Working at heights is an inherent part of boiler erection, and safety is my utmost priority. I’m thoroughly trained in fall protection techniques and the use of appropriate safety equipment, including harnesses, lanyards, and safety nets. I always ensure that all safety equipment is inspected and certified before each use. I adhere strictly to all safety protocols and regulations. Before commencing any work at heights, I carefully assess the working environment, identifying any potential hazards and implementing necessary precautions. This includes using scaffolding, securing access points, and establishing clear communication procedures to ensure the safety of everyone involved. I lead by example, consistently demonstrating and enforcing safe work practices for my team.

Think of it like mountaineering; each step must be planned carefully to avoid any mistakes. My experience ensures I can tackle work at height safely and effectively, knowing that protecting the team and me is non-negotiable. The best project is a completed project, and that only happens when safety comes first.

Q 15. What is your experience with different types of rigging equipment and techniques?

My experience with rigging equipment spans a wide range, encompassing everything from basic chain hoists and wire rope slings to more complex systems like crane lifts and specialized lifting beams. I’m proficient in selecting the appropriate rigging based on load capacity, center of gravity, and environmental factors. For instance, working with a large pressure vessel, we’d use multiple wire rope slings configured in a bridle system for even load distribution to prevent stress concentration. For smaller components, chain hoists might suffice. I’m also well-versed in various rigging techniques, including proper hitching, knot tying (e.g., bowline, clove hitch), and the importance of taglines for controlled movement and safety. My practical experience includes working with both static and dynamic rigging, understanding their distinct properties and limitations.

- Chain Hoists: Used frequently for lifting moderate weights and offer excellent control.

- Wire Rope Slings: Essential for heavier loads, requiring careful inspection for wear and tear.

- Bridle Systems: Distribute the load evenly across multiple slings, crucial for oversized and oddly shaped components.

- Crane Lifts: Essential for the largest components, requiring a thorough understanding of load charts and crane capabilities.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure the proper insulation and lagging of boiler components?

Proper insulation and lagging of boiler components is critical for maintaining efficiency, preventing heat loss, and ensuring worker safety. We adhere to stringent standards, selecting insulation materials appropriate for the operating temperature and environment. For high-temperature areas, materials like calcium silicate or ceramic fiber are used. In lower-temperature zones, fiberglass or mineral wool might be suitable. The installation process involves carefully fitting the insulation to minimize gaps and air pockets, ensuring a tight seal. We use specialized tools and techniques to achieve proper thickness and coverage. For example, we meticulously wrap pipes and vessels, ensuring complete coverage without compromising structural integrity. Regular inspections are vital to detect any signs of damage, wear, or degradation and allow for timely repairs or replacements. This prevents energy waste and maintains the longevity of the boiler system. Failure to properly insulate can lead to significant energy losses, increased operational costs, and potential safety hazards from contact with hot surfaces.

Q 17. Describe your experience with boiler maintenance and repair procedures.

My boiler maintenance and repair experience involves a wide range of tasks, from routine inspections and cleaning to complex repairs and troubleshooting. I’m proficient in identifying and addressing issues such as leaks, corrosion, scaling, and burner malfunctions. I am familiar with various diagnostic tools, including pressure gauges, thermocouples, and combustion analyzers. For example, diagnosing a burner issue might involve checking fuel supply, ignition system components, and flame sensing devices. A leak detection process may include pressure testing and visual inspections. My repair procedures always emphasize safety, including lockout/tagout procedures for safe access to components. A typical process involves meticulous documentation, including before-and-after pictures. Furthermore, I ensure that all repairs adhere to relevant codes and standards. I believe in proactive maintenance to prevent costly breakdowns, extending the life of boiler systems significantly.

Q 18. What are the different types of boiler fuels and their associated safety considerations?

Boilers can utilize various fuels, each with unique safety considerations. Common fuels include natural gas, fuel oil, and coal. Natural gas poses risks associated with leaks and explosions, necessitating regular leak detection and robust ventilation systems. Fuel oil presents fire hazards and requires proper storage and handling procedures. Coal handling involves dust control measures to avoid respiratory problems and potential fire risks. Safety protocols always include proper personal protective equipment (PPE), regular inspections of fuel storage and delivery systems, and comprehensive emergency response plans. For each fuel type, we implement specific safety measures based on the fuel’s properties and handling requirements. Each fuel storage area is designed to be fire resistant. Regular training on safe handling and emergency procedures is crucial for all personnel.

Q 19. How familiar are you with the different types of boiler controls and instrumentation?

I’m very familiar with various boiler controls and instrumentation, ranging from basic pressure and temperature gauges to sophisticated PLC-based control systems. My expertise encompasses the understanding of safety interlocks, automated control sequences, and data acquisition systems. I have experience working with pressure switches, level sensors, temperature transmitters, and flow meters. The understanding of these systems allows for efficient operation and precise control of the boiler, optimizing performance and ensuring safety. I’m also proficient in using diagnostic software to monitor system parameters, identify potential problems, and optimize control strategies for enhanced efficiency. Working with PLC systems allows for customization and remote monitoring of boiler operations.

Q 20. Explain your experience with boiler efficiency optimization techniques.

Boiler efficiency optimization is a key focus in my work. Techniques include regular cleaning of heat exchangers to remove scale and deposits which impede heat transfer. Optimizing combustion air-fuel ratios using combustion analyzers to ensure complete combustion and minimize emissions. Implementing proper insulation and lagging to reduce heat loss. Regular maintenance of pumps, valves, and other components to reduce pressure drops and improve overall efficiency. Modernizing control systems can lead to more precise regulation and monitoring, resulting in optimized operation. For example, identifying and rectifying air leaks in the boiler system can drastically improve its efficiency. By implementing these techniques, we can reduce energy consumption and lower operational costs while minimizing environmental impact.

Q 21. How do you manage a team of boiler erectors and ensure efficient work flow?

Managing a team of boiler erectors requires strong leadership, effective communication, and a commitment to safety. I employ clear communication strategies to ensure everyone understands their roles and responsibilities. I utilize a collaborative approach to problem-solving, encouraging team members to contribute their expertise. Safety is paramount; I enforce strict safety protocols and conduct regular safety briefings. To ensure efficient workflow, I implement a structured approach to project execution, with clear timelines and milestones. This involves delegating tasks based on individual expertise, coordinating resources effectively, and monitoring progress regularly. Addressing any issues or conflicts promptly and fairly is vital in maintaining a productive team environment. Team-building activities foster positive morale and effective collaboration. I believe in providing constructive feedback and supporting individual growth within the team.

Q 22. Describe your experience with working on large-scale boiler projects.

My experience encompasses a wide range of large-scale boiler projects, from initial design review and fabrication oversight to on-site erection, testing, and commissioning. I’ve worked on projects involving both utility boilers in power plants, exceeding 1000 MW capacity, and industrial boilers for refineries and chemical plants. One notable project involved the erection of a 500 MW supercritical boiler for a power generation facility. This required precise coordination of a large team, meticulous adherence to safety protocols and a deep understanding of complex piping systems and pressure vessels.

In another project, I was responsible for the erection of a waste heat recovery boiler in a refinery setting. This involved integrating the boiler into an existing process unit, necessitating careful planning and execution to minimize downtime. These experiences have given me a comprehensive understanding of the challenges involved in large-scale boiler projects, from logistical planning and resource management to the intricacies of aligning and welding heavy components.

Q 23. What are your skills in using various hand and power tools used in boiler erection?

My proficiency extends to a wide array of hand and power tools common in boiler erection. This includes, but isn’t limited to: hydraulic wrenches for tightening large bolts, various sizes of welders (MIG, TIG, stick) for different metals and applications, cutting and grinding tools for precise material shaping, lifting equipment like chain hoists and cranes and measurement tools like levels and plumb bobs. Safety is paramount, and I am skilled in the safe and efficient operation of all equipment, adhering strictly to all relevant safety regulations. For instance, I’m proficient in using laser alignment tools to ensure precise positioning of boiler components, minimizing the risk of misalignment and structural damage.

I’m also adept at utilizing specialized tools like expansion joint alignment tools and tube rolling tools for accurate and efficient installation. I understand that proper tool selection is crucial for both safety and efficiency, and I always prioritize the best tool for the job.

Q 24. Describe your experience with working with different types of boiler materials (steel, alloys).

My experience encompasses a variety of boiler materials, including carbon steel, various low-alloy steels, stainless steels, and specialized alloys. Each material requires a unique approach to handling, fabrication, and welding. Carbon steel, for instance, is common in boiler construction due to its strength and weldability. However, it is susceptible to corrosion and requires appropriate protective coatings. Low-alloy steels often offer improved strength and creep resistance at high temperatures. Understanding these properties allows for correct material selection, minimizing risks and ensuring longevity of the installed boiler.

I’ve worked extensively with stainless steels for applications requiring corrosion resistance, especially in the handling of flue gases. The use of specialized alloys, like those with high chromium content for high-temperature applications, also falls within my expertise. I always carefully review material specifications to ensure that correct materials and welding procedures are used, and I am adept at identifying different materials through visual inspection and material testing techniques.

Q 25. How do you ensure compliance with all relevant safety regulations and codes?

Compliance with safety regulations is a core tenet of my work ethic. I meticulously follow OSHA (Occupational Safety and Health Administration) guidelines, ASME (American Society of Mechanical Engineers) codes, and any other relevant local or national standards. This includes mandatory safety training, use of Personal Protective Equipment (PPE) such as hard hats, safety glasses, and appropriate clothing, and regular safety inspections of equipment and the work area. I’m also familiar with lockout/tagout procedures and confined space entry protocols.

Before starting any work, I thoroughly review the project’s safety plan and conduct job hazard analyses. I am also actively involved in reporting any near misses or unsafe conditions to the site supervisor and working collaboratively to mitigate any potential risks. My proactive approach ensures that not only are all regulations adhered to, but that safety is prioritized above all else, creating a safe and productive work environment.

Q 26. What are your strengths and weaknesses regarding boiler erection work?

One of my greatest strengths is my meticulous attention to detail. Boiler erection demands precision, and I take pride in my ability to perform tasks accurately and efficiently. My experience with complex projects has honed my problem-solving skills, allowing me to effectively address challenges that inevitably arise during a large-scale project. I also work collaboratively well with others, fostering a positive and productive team environment. My ability to read and interpret complex engineering drawings is another significant asset.

A potential area for improvement is delegation. While I possess a strong work ethic and a desire to ensure everything is done correctly, I’m learning to delegate tasks more effectively to team members, trusting their expertise and allowing for more efficient workflow. I’m actively working on improving this aspect of my work style through targeted training and active participation in team discussions.

Q 27. What are your salary expectations?

My salary expectations are commensurate with my experience and skills within the industry standards for a Boiler Erector with my level of expertise. I am open to discussing this further based on the specifics of the role and the compensation package offered.

Q 28. Why are you interested in this Boiler Erector position?

I’m highly interested in this Boiler Erector position because I’m seeking a challenging and rewarding role within a reputable organization. Your company’s reputation for quality workmanship and commitment to safety aligns perfectly with my professional values. I am particularly drawn to the opportunity to contribute my skills and experience to significant projects, particularly those that incorporate the latest technologies and industry best practices.

Furthermore, I’m eager to learn and develop my skills further within your team. The opportunity to work on complex projects, with the chance to work closely with experienced professionals, is a significant motivator for me. I believe my dedication, work ethic, and extensive experience make me a strong candidate for this position.

Key Topics to Learn for Boiler Erecting Interview

- Blueprint Reading and Interpretation: Understanding and interpreting complex engineering drawings, specifications, and schematics for boiler assembly.

- Safe Lifting and Rigging Techniques: Practical application of safe lifting procedures, including proper rigging techniques, load calculations, and crane operation safety protocols.

- Boiler Components and Assembly Procedures: Detailed knowledge of boiler components (drums, tubes, headers, etc.) and the step-by-step procedures for their assembly, ensuring precise alignment and secure connections.

- Welding and Fabrication Techniques: Understanding various welding methods used in boiler construction and fabrication, including quality control and inspection procedures.

- Quality Control and Inspection: Applying quality control measures throughout the erection process, identifying and resolving discrepancies, ensuring adherence to safety standards and engineering specifications.

- Troubleshooting and Problem Solving: Identifying and addressing potential problems during the erection process, proposing solutions, and applying problem-solving skills in challenging situations.

- Safety Regulations and Compliance: Thorough understanding of relevant safety regulations, OSHA standards, and compliance procedures related to boiler erection.

- Material Handling and Storage: Safe and efficient handling and storage of boiler components and materials, minimizing risk of damage or injury.

- Teamwork and Communication: Effectively communicating with team members, supervisors, and engineers to ensure smooth and efficient project execution.

- Project Management Principles: Basic understanding of project scheduling, resource allocation, and progress monitoring within a boiler erection project.

Next Steps

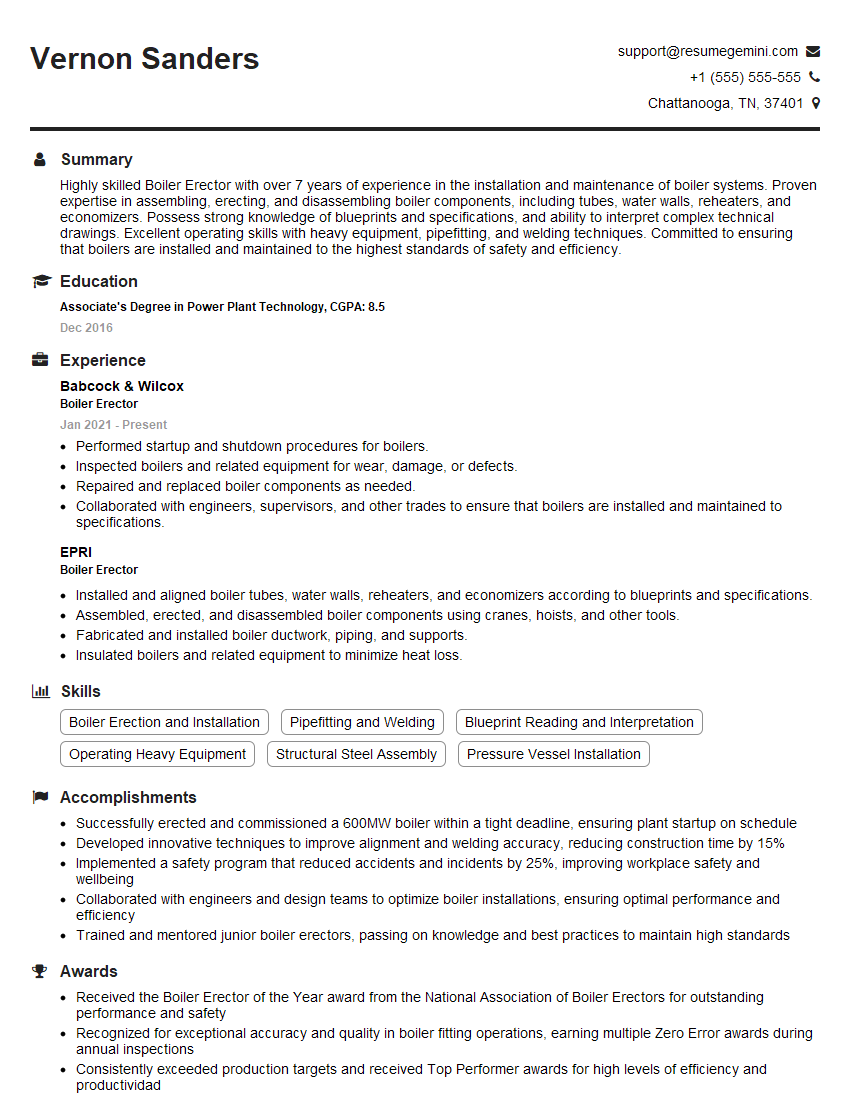

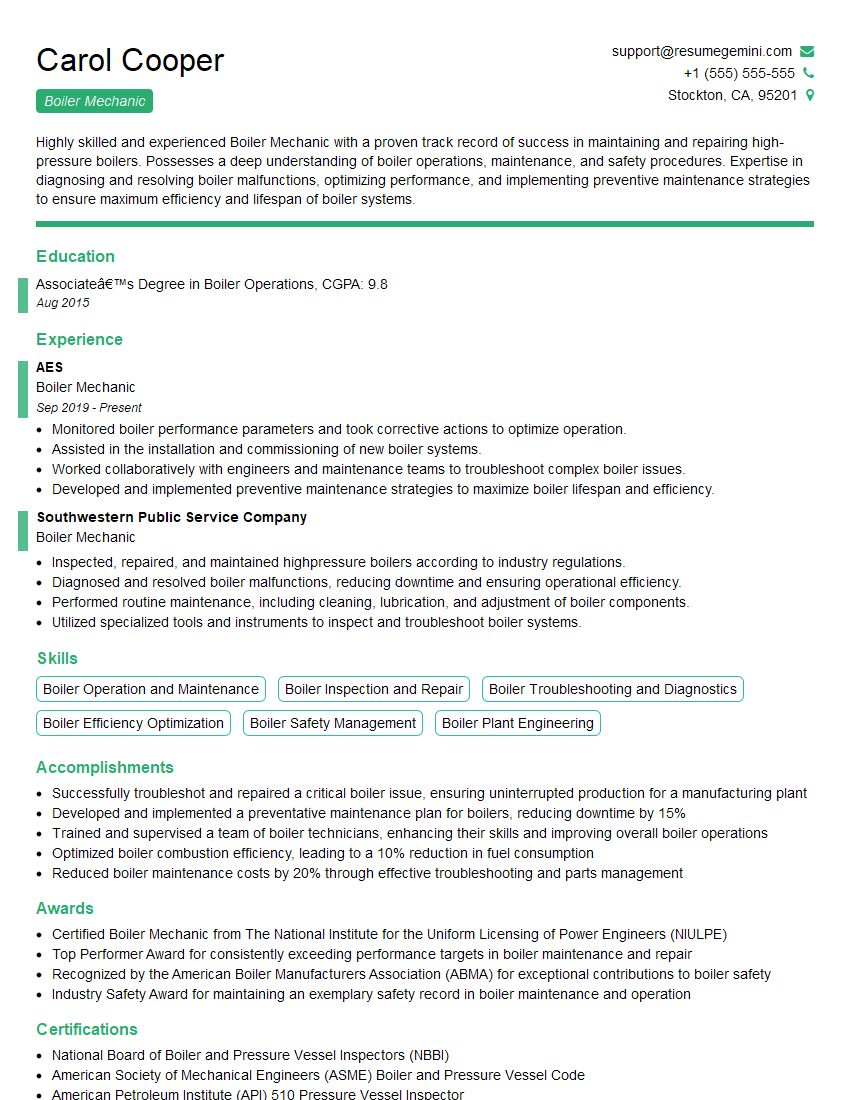

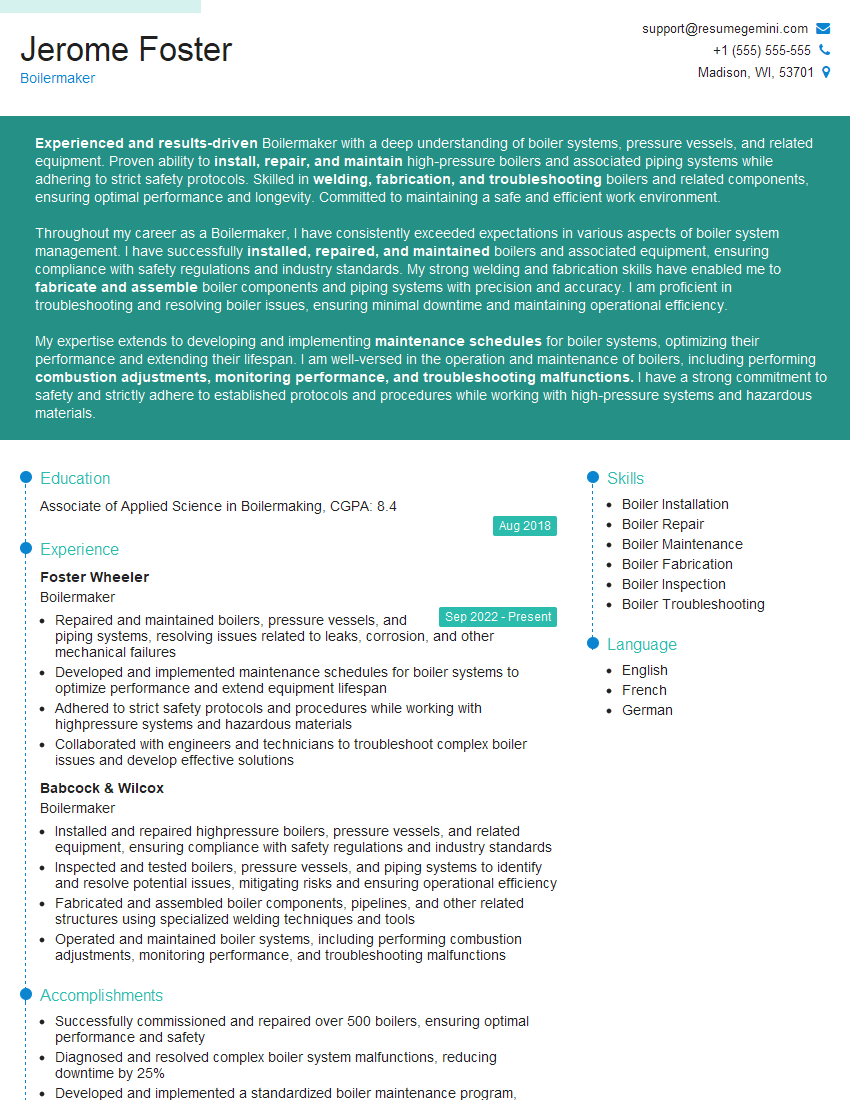

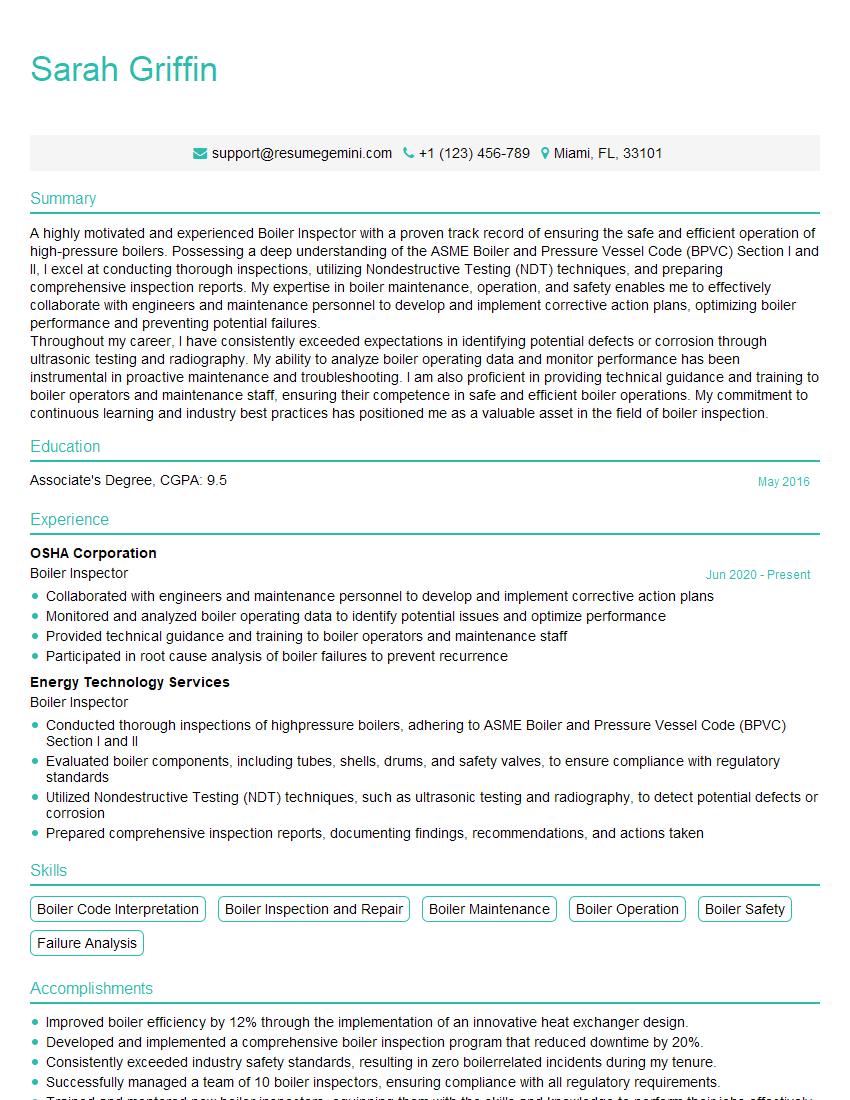

Mastering Boiler Erecting opens doors to a rewarding career with excellent growth potential, offering opportunities for advancement and specialization within the energy sector. To maximize your job prospects, it’s crucial to present your skills and experience effectively. Creating an ATS-friendly resume is essential for getting your application noticed by recruiters. ResumeGemini can significantly help you build a professional and impactful resume that highlights your qualifications and experience. They provide examples of resumes tailored to the Boiler Erecting field, helping you showcase your expertise to potential employers. Take the next step towards your dream career today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?