The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Boiler Operation Techniques interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Boiler Operation Techniques Interview

Q 1. Explain the principle of water circulation in a boiler system.

Water circulation in a boiler is crucial for efficient heat transfer and preventing overheating. The principle relies on the density difference between hot and cold water. Hot water, being less dense, rises, while cooler, denser water descends. This creates a natural convection current. In larger boilers, or those operating at higher pressures, this natural circulation might be insufficient, necessitating forced circulation using pumps. Think of it like a giant thermos – the hot water at the top wants to rise, and the cooler water at the bottom wants to sink, constantly cycling the water around the heat source (the furnace) to absorb the heat evenly and then release that heat to the steam generation process.

In a typical natural circulation system, water enters the boiler drum at the bottom. It then flows down through the downcomer pipes to the bottom headers near the furnace tubes. As the water passes through the heated tubes, it absorbs heat and becomes steam. This hot water-steam mixture rises due to its lower density through the riser pipes back to the drum, completing the loop. Forced circulation systems use pumps to accelerate this process, ensuring more rapid and efficient heat transfer, particularly beneficial in large industrial boilers or those operating under high pressure.

Q 2. Describe the different types of boiler feedwater treatments.

Boiler feedwater treatment is essential to prevent scaling, corrosion, and fouling within the boiler system. It involves several processes aimed at removing impurities from the raw water that would otherwise damage boiler components and reduce efficiency. The key treatments include:

- Chemical Treatment: This is the most common method and involves adding chemicals to treat water before it enters the boiler. Examples include:

- Oxygen Scavengers: (e.g., hydrazine, sodium sulfite) Remove dissolved oxygen, which is a major cause of corrosion.

- pH Control Agents: (e.g., caustic soda, ammonia) Adjust the water’s pH to a slightly alkaline level (around 9-10) to minimize corrosion.

- Scale Inhibitors: (e.g., phosphates, polyphosphates) Prevent the formation of scale by interfering with the crystallization of minerals.

- Physical Treatment: These methods physically remove impurities. Examples include:

- Filtration: Removes suspended solids.

- Softening: Removes hardness-causing minerals like calcium and magnesium using ion exchange or lime softening.

- Deionization: Removes dissolved ions and impurities using ion-exchange resins. This is typically used for high-pressure boilers.

The specific treatment depends on the boiler’s size, pressure, and the quality of the raw water source. A poorly treated boiler will experience significant issues with scaling, corrosion, and reduced efficiency – leading to expensive repairs and potentially unsafe operations.

Q 3. What are the safety precautions for operating a high-pressure boiler?

Operating high-pressure boilers requires strict adherence to safety procedures. Negligence can lead to serious accidents. Key precautions include:

- Regular Inspections: Thorough inspections of all boiler components, including pressure vessels, piping, valves, and safety devices, are crucial and must be conducted according to a strict schedule and documented.

- Pressure Gauges & Safety Valves: Regularly check pressure gauges for accuracy and ensure safety valves are functioning correctly and set to the appropriate pressure limits. Testing and calibration are essential.

- Water Level Monitoring: Continuous monitoring of water levels is critical. Low water levels can lead to overheating and damage. High water levels can cause water carryover into the steam lines. Appropriate alarm systems should be implemented.

- Lockout/Tagout Procedures: Strict lockout/tagout (LOTO) procedures must be followed for any maintenance or repair activities. This is crucial to prevent accidental startups that could lead to serious injury or damage.

- Proper Training: Boiler operators require thorough training on boiler operation, safety procedures, and emergency response protocols. Competent and certified operators are paramount.

- Emergency Shutdown Procedures: All operators should be familiar with the emergency shutdown procedures in case of any unexpected event. Regular drills can ensure readiness for unexpected situations.

- Personal Protective Equipment (PPE): Always use appropriate PPE, including safety glasses, gloves, and heat-resistant clothing.

A high-pressure boiler failure can have catastrophic consequences. Adherence to these safety protocols is not optional; it is a legal and ethical necessity.

Q 4. How do you identify and address boiler water level issues?

Maintaining the correct water level in a boiler is critical for safety and efficiency. Water level issues, whether too high or too low, can cause significant problems. Here’s how to identify and address them:

Identification: Water levels are monitored using water gauges (glass or electronic).

- Low Water Level: Indicates potential overheating and damage to the boiler tubes. This can lead to a dangerous boiler explosion. Alarms should sound if the water level falls below a safe minimum.

- High Water Level: Can cause water carryover into the steam lines, leading to water hammer (a violent shock wave) which could damage the piping or prime the steam turbine. Water in the steam can also damage the equipment using the steam. Again, alarms should sound if the water level rises beyond a predetermined maximum.

Addressing the Issues:

- Low Water Level: Carefully and gradually add feedwater to bring the level back to the normal operating range. Investigate the cause of the low water level (feedwater pump failure, leak, etc.).

- High Water Level: Carefully reduce the feedwater supply. Check for any blockages or malfunctions in the water level control system. Investigate for steam leaks that could lead to a false high level reading.

Always follow the manufacturer’s instructions for operating and troubleshooting the boiler system. If the problem persists or you are unsure of the cause, consult a qualified boiler technician.

Q 5. What are the common causes of boiler scaling and how to prevent them?

Boiler scaling is a common problem caused by the deposition of mineral salts on the boiler’s internal surfaces. These deposits reduce heat transfer efficiency, leading to increased fuel consumption, overheating, and potential tube failures. Common causes include:

- Hard Water: Water containing high levels of dissolved minerals like calcium and magnesium is the primary culprit. These minerals precipitate out of solution as the water heats up and forms scale.

- Poor Water Treatment: Inadequate water treatment is a leading cause. If the scale inhibitors aren’t properly applied, or if the water’s pH isn’t appropriately controlled, scaling is more likely.

- Leaks: Leaks in the boiler system can introduce additional minerals from external sources.

Prevention:

- Proper Water Treatment: Employing appropriate chemical treatments, as discussed previously, is the most effective preventive measure. This includes using scale inhibitors and controlling the water’s pH.

- Water Softening: Pre-treating the feedwater to remove hardness-causing minerals before it enters the boiler.

- Regular Blowdown: Regularly removing concentrated minerals through the blowdown process, as discussed in the next answer.

- Regular Inspections: Periodic inspections of the boiler’s internal surfaces can help detect and address scaling issues early on.

Ignoring boiler scaling can lead to serious damage and costly repairs. Preventive measures are essential for ensuring safe and efficient boiler operation.

Q 6. Explain the role of a boiler blowdown process.

The boiler blowdown process is a crucial aspect of boiler maintenance designed to remove impurities and prevent scaling. It involves periodically discharging a portion of the boiler water, thereby reducing the concentration of dissolved solids and suspended matter. Think of it like draining a small amount of water from a bathtub to keep the overall concentration of soap and dirt low. This process is essential for maintaining boiler efficiency and extending its lifespan.

There are two main types of blowdown:

- Surface Blowdown: This removes sludge and other solids from the surface of the boiler water. It is performed regularly and removes accumulated solids which are less likely to be transported by the water circulation.

- Bottom Blowdown: This removes more concentrated dissolved solids from the bottom of the boiler. It is performed less frequently and helps control the overall concentration of dissolved salts in the boiler water. Because the solids are likely to have precipitated into a concentrated form, this is used more aggressively to control the overall amount of dissolved solids.

The frequency of blowdown depends on factors such as boiler operating pressure, water quality, and the type of boiler. Regular blowdown helps prevent the formation of scale, reduces the risk of corrosion, and extends the boiler’s operational life. Improper blowdown can lead to mineral build-up and damage to the equipment. A proper blowdown schedule must be followed for safe operation.

Q 7. Describe the different types of boiler safety valves and their functions.

Boiler safety valves are critical for preventing overpressure and ensuring safe boiler operation. They automatically open to release steam when the boiler pressure exceeds a predetermined limit. Several types exist:

- Spring-Loaded Safety Valves: These are the most common type. A spring resists the pressure of the steam, and when the pressure exceeds the spring’s force, the valve opens, releasing the excess steam.

- Weighted Safety Valves: These valves utilize a weight to counteract the steam pressure. When the steam pressure overcomes the weight, the valve lifts and releases steam.

- Pilot-Operated Safety Valves: These valves use a smaller pilot valve to control the opening of the main safety valve. This is more sensitive to pressure changes and can provide quicker responses in emergency situations.

- Dual-Purpose Safety Valves: These valves combine both a safety function and a pressure-reducing function. They reduce the pressure before it builds to the emergency level.

The function of all safety valves is to prevent dangerous overpressurization. Regular testing and maintenance are critical to ensure these valves function correctly and reliably in case of emergencies. Failure to maintain these valves could result in a catastrophic failure.

Q 8. How do you interpret boiler pressure gauges and other instrumentation?

Interpreting boiler pressure gauges and other instrumentation is crucial for safe and efficient boiler operation. It’s like monitoring a patient’s vital signs – you need to understand what’s normal and what indicates a problem. Pressure gauges show the steam pressure within the boiler, usually in pounds per square inch (psi) or bars. A steady reading within the operating range is ideal. Fluctuations outside this range may signal issues requiring immediate attention. Other instrumentation includes:

Water level gauges: These indicate the water level in the boiler drum. Maintaining the correct water level is critical to prevent overheating or water hammer. Low water levels are extremely dangerous and can lead to boiler tube failure.

Temperature gauges: These monitor the temperature of the water and steam. Excessive temperatures can lead to overheating and damage.

Flow meters: These measure the flow rate of fuel and water. Anomalies might suggest fuel inefficiency or water circulation problems.

Safety valves: These are crucial safety devices that automatically release excess pressure to prevent explosions. Regular testing is vital to ensure they function correctly.

For example, a sudden drop in pressure might indicate a leak, while a consistently high water level might suggest a problem with the feedwater system. Regularly checking and recording these readings helps identify trends and potential problems before they escalate into major incidents.

Q 9. What are the common causes of boiler tube leaks?

Boiler tube leaks are a serious concern, potentially leading to significant downtime and costly repairs. Several factors contribute to these leaks:

Corrosion: This is a major culprit, especially in areas exposed to high temperatures and corrosive chemicals in the water. Improper water treatment is often the root cause. Think of it like rust eating away at a metal pipe – eventually, it’ll fail.

Overheating: Insufficient water level in the boiler can cause sections of the tubes to overheat, leading to weakening and eventual failure. This is often due to operational errors or faulty instrumentation.

Water hammer: This occurs when rapidly changing water flow causes shock waves that damage the tubes. It’s like repeatedly slamming a pipe with a hammer. Proper water treatment and flow control help prevent it.

Fouling and scaling: Buildup of deposits on the inside of the tubes reduces heat transfer efficiency and can lead to localized overheating and failure. Regular cleaning is crucial. This is like the buildup of plaque in arteries, restricting flow and creating pressure points.

Erosion: High-velocity water or steam can erode the tubes over time, especially at bends or constrictions. This is similar to the wearing down of a riverbank by flowing water.

Fatigue: Repeated cycles of heating and cooling can cause metal fatigue, leading to cracks and leaks. This is comparable to bending a paperclip back and forth until it breaks.

Identifying the root cause is critical for effective remediation. This often involves thorough inspection, water analysis, and operational review.

Q 10. Explain the process of boiler start-up and shutdown procedures.

Safe and efficient boiler start-up and shutdown procedures are non-negotiable for operational safety and equipment longevity. They’re like carefully warming up and cooling down your car engine to prevent damage.

Start-up:

Pre-operational checks: Inspect all gauges, valves, safety devices, and water levels before starting.

Water level check and filling: Ensure the boiler is filled with the correct level of treated water.

Air purging: Carefully purge the air from the system to prevent damage.

Ignition and burner adjustment: Ignite the burners and carefully adjust the fuel and air supply to achieve optimal combustion.

Pressure build-up: Gradually raise the boiler pressure to the operating range, closely monitoring all parameters.

Load increase: Gradually increase the load on the boiler as pressure stabilizes.

Shutdown:

Load reduction: Gradually reduce the load on the boiler to minimize thermal stress.

Burner shutdown: Safely shut down the burners, following the manufacturer’s instructions.

Pressure reduction: Allow the pressure to decrease gradually to avoid thermal shock.

Draining and cleaning: Once the pressure is low enough, drain the boiler and clean it if necessary.

Inspection: Conduct a post-shutdown inspection to check for any issues.

Detailed written procedures, specific to the boiler type, should be followed rigorously. Deviation from these procedures can lead to serious safety hazards.

Q 11. How do you maintain optimal boiler efficiency?

Maintaining optimal boiler efficiency is paramount for reducing operational costs and environmental impact. It’s a continuous process involving several key strategies:

Regular cleaning: Remove soot and scale buildup from heat transfer surfaces. Think of it as unclogging arteries to improve blood flow; clean surfaces allow for efficient heat transfer.

Proper combustion control: Optimize the fuel-air mixture for complete combustion, minimizing unburned fuel and pollutants. Think of it like a perfectly tuned engine – efficient and clean.

Water treatment: Use proper water treatment chemicals to prevent scale and corrosion. This is like keeping your car’s cooling system clean and topped off.

Insulation maintenance: Ensure proper insulation to minimize heat loss. This is like keeping your house well-insulated in winter – retaining heat improves efficiency.

Regular inspections: Monitor boiler performance and identify areas for improvement through data analysis. Regular check-ups identify potential problems before they become major ones.

Air/Fuel Ratio Control: Precisely regulating the mix for optimum burning and minimizing waste. A simple analogy is baking a cake – the right ingredients in the right proportion result in a better outcome.

Regular monitoring of key parameters, such as fuel consumption, steam production, and stack gas emissions, helps identify deviations from optimal performance. Tools like energy audits can pinpoint areas for improvement. This systematic approach significantly reduces energy consumption and operating costs.

Q 12. Describe the importance of regular boiler inspections and maintenance.

Regular boiler inspections and maintenance are critical for ensuring safety, reliability, and efficiency. It’s akin to regular health checkups for humans; preventative maintenance is always cheaper than reactive repairs.

Importance:

Safety: Regular inspections identify potential hazards before they lead to accidents or explosions.

Reliability: Preventative maintenance minimizes unexpected downtime and maximizes boiler uptime.

Efficiency: Keeping the boiler clean and well-maintained ensures optimal performance and reduces energy consumption.

Longevity: Proper maintenance extends the lifespan of the boiler, saving on replacement costs.

Compliance: Regular inspections help ensure compliance with safety regulations and environmental standards.

A typical maintenance schedule includes visual inspections, pressure testing, cleaning, and component replacement as needed. Regular inspections allow for early detection of issues like corrosion, leaks, or scaling, leading to timely and cost-effective repairs. Ignoring this can lead to catastrophic failure, significant downtime, and potentially even safety hazards.

Q 13. What are the different types of boiler fuels and their characteristics?

Boilers utilize various fuels, each with distinct characteristics influencing operational efficiency, cost, and environmental impact. Choosing the right fuel is critical. It’s like choosing the right tool for a job.

Natural Gas: Clean-burning, readily available, and relatively inexpensive. However, its price can fluctuate.

Fuel Oil: A liquid fuel offering higher energy density compared to natural gas, but it is more polluting and requires more complex handling and storage.

Coal: High energy density and abundant, but it’s associated with high pollution and ash handling challenges.

Biomass: Renewable fuel from organic matter, offering carbon neutrality in theory, but with efficiency and logistics issues.

Electricity: Electric boilers are efficient and clean, but electricity costs vary, and the electricity’s source (renewable vs. fossil fuel) influences its overall environmental impact.

The choice of fuel depends on several factors, including cost, availability, environmental regulations, and the specific requirements of the application. For example, a large industrial plant might favor coal due to its energy density, while a smaller facility might prefer natural gas for its ease of use and cleaner emissions.

Q 14. Explain the concept of boiler combustion efficiency.

Boiler combustion efficiency refers to the percentage of the fuel’s energy content that is effectively converted into usable heat for steam generation. It’s a measure of how well the boiler uses the fuel, minimizing waste. Think of it as the fuel economy of your car – higher efficiency means less fuel consumed for the same amount of work.

Factors influencing combustion efficiency:

Air-fuel ratio: Precise control is critical for complete combustion. Too much air wastes energy heating excess air, while too little results in incomplete combustion, producing pollutants and wasting fuel.

Burner design: Well-designed burners ensure effective mixing of fuel and air for optimal combustion.

Excess oxygen: Measuring oxygen in the flue gas helps determine the completeness of combustion. Lower excess oxygen indicates higher efficiency, but needs careful monitoring to avoid incomplete combustion.

Flue gas temperature: High flue gas temperatures indicate energy loss; heat that should be transferred to the water is exiting as waste heat.

Improving combustion efficiency involves optimizing these factors through regular maintenance, tuning, and data analysis. This helps reduce fuel consumption, operating costs, and environmental impact.

Q 15. How do you troubleshoot a boiler malfunction?

Troubleshooting a boiler malfunction requires a systematic approach. Think of it like diagnosing a car problem – you wouldn’t just start replacing parts randomly! You need to gather information, analyze the situation, and then take targeted action.

- Identify the Problem: Begin by noting any unusual sounds (knocking, banging, hissing), smells (burning fuel, sulfur), or visual cues (leaks, smoke). Check gauges for pressure, temperature, and water level deviations from normal operating parameters. Has there been a recent change in fuel type, load demand, or maintenance activity?

- Consult Monitoring Systems: Modern boilers often have sophisticated monitoring systems that provide real-time data and historical trends. Analyzing this data can pinpoint the source of the malfunction. For example, a sudden drop in steam pressure might indicate a leak, while a high water level could suggest a faulty feedwater control valve.

- Check Safety Devices: Verify the operation of safety devices such as pressure relief valves, low-water fuel cutoff switches, and flame safeguard systems. These devices are crucial for preventing accidents and should be checked regularly.

- Inspect the Burner System: Problems with the burner – including faulty ignition, poor combustion, or clogged nozzles – are common causes of boiler malfunctions. Proper inspection involves checking for flame stability, fuel supply pressure, and air-fuel mixture.

- Examine the Heat Transfer Surfaces: Scale buildup, fouling, or corrosion on heat transfer surfaces can significantly reduce efficiency and lead to overheating. Regular cleaning and inspection are essential to prevent these issues.

- Investigate Water Chemistry: Poor water chemistry can cause severe damage to the boiler. Regular testing and treatment are crucial to maintain the correct pH, alkalinity, and dissolved solids levels.

- Consult Maintenance Logs and Manuals: Keep detailed maintenance logs to track repairs and identify recurring issues. Refer to the boiler’s operation and maintenance manual for troubleshooting guidance specific to your boiler model.

Example: Imagine a boiler suddenly shuts down. Checking the gauges reveals low water level. The low-water fuel cutoff has likely activated, indicating a potential leak or feedwater problem. Further investigation might uncover a cracked pipe or a malfunctioning feedwater pump.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the environmental regulations related to boiler operation?

Environmental regulations related to boiler operation are stringent and vary by location, but generally aim to minimize air and water pollution. These regulations focus on limiting emissions of pollutants like nitrogen oxides (NOx), sulfur dioxide (SO2), particulate matter (PM), and carbon monoxide (CO).

- Air Emission Standards: Regulations often specify limits on the concentration of pollutants in the boiler’s exhaust gases. Compliance often requires the use of pollution control devices such as selective catalytic reduction (SCR) systems for NOx reduction and low-NOx burners.

- Water Discharge Regulations: Regulations govern the discharge of wastewater from boiler blowdown and cleaning operations. This typically involves limits on the concentration of dissolved solids, suspended solids, and other pollutants. Proper water treatment and blowdown management are essential for compliance.

- Fuel Requirements: Regulations may specify the allowable types and qualities of fuel used in boilers, potentially limiting sulfur content in fuel oil to reduce SO2 emissions.

- Permitting and Reporting: Operating a boiler often requires permits and regular reporting of emissions data to the relevant environmental authorities. Failure to comply can result in hefty fines and legal action.

Example: In many regions, boilers exceeding a certain thermal input capacity must be equipped with continuous emissions monitoring systems (CEMS) to track pollutant levels in real-time and ensure compliance with environmental regulations.

Q 17. Describe the different types of boiler controls and their functions.

Boiler controls are the brain of the operation, ensuring safe and efficient performance. They range from simple on/off switches to sophisticated computer-based systems.

- On/Off Controls: These are the simplest form, typically used in smaller boilers. They simply start and stop the boiler based on a set temperature or pressure threshold.

- Proportional Controls: These controls adjust the fuel input proportionally to the boiler’s demand, preventing large fluctuations in steam pressure or temperature. They offer improved efficiency and stability compared to on/off controls.

- Proportional-Integral-Derivative (PID) Controls: These advanced controllers provide even more precise control by considering the rate of change of the controlled variable (e.g., temperature). This leads to faster response times and reduced overshoot.

- Programmable Logic Controllers (PLCs): PLCs are computer-based systems that manage complex boiler operations, including sequencing multiple control functions, monitoring multiple parameters, and providing alarm and safety interlocks.

- Distributed Control Systems (DCS): DCS systems are used in large industrial boiler installations to control and monitor multiple boilers and related equipment. They offer a centralized control interface and enhanced data analysis capabilities.

Functions of Boiler Controls: Typical functions include maintaining desired steam pressure or temperature, managing fuel and air flow, controlling water level, monitoring safety interlocks, and providing data logging and alarming.

Q 18. How do you manage boiler water chemistry?

Managing boiler water chemistry is crucial for preventing corrosion, scale formation, and other problems that can reduce efficiency and damage the boiler. It’s like keeping your car’s engine clean and properly lubricated to ensure it runs smoothly.

- Regular Water Testing: Regular testing of boiler water is necessary to monitor key parameters such as pH, alkalinity, conductivity, and dissolved oxygen. Testing frequency depends on boiler size, operating pressure, and water quality.

- Water Treatment: Based on testing results, appropriate chemical treatments are added to control pH, prevent corrosion, and inhibit scale formation. Common treatments include adding chemicals to adjust pH, remove dissolved oxygen, and control silica levels.

- Blowdown: Regular blowdown removes dissolved solids and other impurities from the boiler water, preventing concentration buildup that can lead to scaling and corrosion. The frequency of blowdown is determined based on water quality and boiler operating conditions.

- External Treatment: Pre-treatment of feedwater before entering the boiler can reduce the workload on internal water treatment processes. This may involve filtration, ion exchange, or reverse osmosis to remove impurities.

Example: If a boiler exhibits increased corrosion, water testing might reveal low pH. Adding a neutralizing chemical, such as caustic soda, can adjust the pH to the optimal range, reducing corrosion.

Q 19. What are the signs of boiler overheating and how to prevent them?

Boiler overheating is a serious issue that can lead to significant damage and even explosions. Think of it like overheating a car engine – it can cause irreparable harm.

- Signs of Overheating: High steam pressure, low water level, excessive steam temperature, bulging or leaking pressure vessels, unusual noises (e.g., rumbling or screaming), and tripped safety devices are all potential indicators of overheating.

- Prevention Strategies:

- Maintain Proper Water Level: Ensure adequate water level at all times by properly adjusting feedwater control valves and regularly monitoring gauges.

- Monitor Steam Pressure and Temperature: Keep a close eye on steam pressure and temperature, and respond promptly to any unusual readings.

- Clean Heat Transfer Surfaces: Regular cleaning removes scale and deposits, improving heat transfer and preventing overheating.

- Regular Inspection and Maintenance: Regular inspections and preventative maintenance identify and address potential problems before they escalate.

- Proper Combustion Control: Maintaining proper air-fuel ratios is essential for preventing excessive temperatures.

- Functional Safety Systems: Ensure safety devices such as pressure relief valves, low-water fuel cutoff, and high-temperature alarms are functional.

Example: If the steam pressure gauge shows a rapid increase and the low-water alarm triggers, immediately reduce the fuel supply and carefully investigate the cause of the low water level to prevent further overheating.

Q 20. Explain the importance of boiler safety interlocks.

Boiler safety interlocks are crucial for preventing accidents and ensuring safe operation. They act as safeguards, preventing the boiler from operating under unsafe conditions. Consider them as a multi-layered security system for your boiler.

- Low-Water Fuel Cutoff: This interlock automatically shuts off the fuel supply if the water level drops below a safe minimum, preventing overheating and potential damage.

- High-Pressure Safety Valve: This valve automatically vents excess steam if the pressure exceeds a preset limit, preventing pressure vessel rupture.

- Flame Safeguard System: This system ensures that fuel is only supplied when a stable flame is present, preventing fuel buildup and potential explosions.

- High-Temperature Alarms: Alarms alert operators to dangerously high temperatures, allowing for timely intervention.

- Interlocks for Access to Hazardous Areas: These prevent access to dangerous parts of the boiler while it is operating.

Importance: Safety interlocks are crucial for preventing catastrophic failures, minimizing the risk of injuries, and ensuring the continued safe operation of the boiler. Regular testing and maintenance of these systems are essential.

Q 21. How do you handle emergency situations in a boiler room?

Handling emergency situations in a boiler room requires a calm, methodical approach. Prior planning and training are essential. Think of it like a fire drill – knowing what to do before an emergency arises significantly improves your response.

- Activate Emergency Procedures: Immediately activate the plant’s emergency procedures, including notifying emergency services and plant personnel.

- Assess the Situation: Quickly and safely assess the nature and extent of the emergency. Determine the source of the problem and the potential hazards involved.

- Take Immediate Corrective Actions: Take immediate action to mitigate the situation, following established emergency procedures. This may involve shutting down the boiler, isolating fuel supplies, or evacuating the area.

- Control the Emergency: Use available resources and equipment to control the emergency, following safety procedures and using appropriate personal protective equipment (PPE).

- Prevent Further Incidents: Once the immediate danger has been mitigated, work to prevent further incidents by addressing the root cause of the problem.

- Post-Incident Analysis: Following the emergency, conduct a thorough post-incident analysis to identify weaknesses in procedures or equipment, and implement improvements to prevent similar events in the future.

Example: If a boiler explosion occurs, immediate actions would include shutting off all fuel supplies, evacuating the area, and contacting emergency responders. A post-incident analysis would then investigate the cause of the explosion to prevent future occurrences.

Q 22. What is the role of a boiler economizer?

A boiler economizer is a heat recovery device installed in the exhaust gas pathway of a boiler. Its primary role is to preheat the boiler feedwater using the waste heat from the flue gases before they are released to the atmosphere. This significantly improves the boiler’s overall efficiency by reducing the amount of fuel needed to generate steam.

Think of it like this: imagine you’re heating water on a stove. Instead of letting the heat from the pan escape into the air, the economizer captures that heat and uses it to pre-heat the *next* batch of water. This reduces the energy you need to spend on heating the fresh water.

Economizers are typically used in larger boiler systems where the heat recovery potential justifies the investment. They are particularly effective in situations with high-temperature flue gases, which offer more heat for recovery.

Q 23. Describe the process of boiler water testing and analysis.

Boiler water testing and analysis is crucial for maintaining boiler efficiency, preventing corrosion, and ensuring safe operation. The process involves regularly sampling the boiler water and analyzing its chemical properties. Key parameters include:

- pH: Measures the acidity or alkalinity of the water. Maintaining the correct pH range is essential to prevent corrosion. Too acidic (low pH) can lead to metal attack, while too alkaline (high pH) can cause scale formation.

- Dissolved Oxygen (DO): Oxygen dissolved in the water can cause pitting and other forms of corrosion. The goal is to minimize DO levels.

- Alkalinity (Total, Carbonate, Caustic): These parameters indicate the buffering capacity of the water, which helps maintain a stable pH. Imbalances can lead to corrosion or scaling.

- Silica (SiO2): Excessive silica can form deposits on boiler tubes, reducing heat transfer efficiency.

- Hardness (Calcium and Magnesium): These minerals contribute to scale formation, which is a major concern for boiler efficiency and safety.

- Chloride (Cl-): High chloride concentrations indicate potential for corrosion.

- Sulfate (SO4-): Excessive sulfate can contribute to scaling and corrosion.

Testing methods include titrations, spectrophotometry, and conductivity measurements. The results are compared against industry standards and manufacturer’s recommendations to identify any issues and adjust water treatment accordingly. Regular testing allows for proactive measures to prevent boiler problems.

Q 24. What are the different types of boiler burners and their applications?

Boiler burners are crucial for efficient and safe combustion. Different types cater to various fuel sources and boiler designs:

- On-Off Burners: Simple and cost-effective, they cycle between fully on and fully off. Suitable for smaller boilers with less stringent control requirements.

- Modulating Burners: These offer precise fuel control, adjusting the flame size to match the boiler’s steam demand. They are more efficient and better for maintaining stable steam pressure.

- Pulverized Coal Burners: Used in large power plants, these burners finely grind coal into powder for more efficient combustion. They require complex systems for coal handling and ash removal.

- Oil Burners: Used with various types of fuel oil, their design varies depending on the oil viscosity and pressure.

- Gas Burners: Burn natural gas or propane, offering clean combustion and relatively easy control. These are very common in industrial and commercial settings.

The choice of burner depends on factors like fuel type, boiler capacity, efficiency requirements, and emission regulations. Each type comes with its own safety features and maintenance requirements.

Q 25. Explain the difference between natural circulation and forced circulation boilers.

The key difference between natural circulation and forced circulation boilers lies in how the water circulates through the boiler system:

- Natural Circulation Boilers: Rely on density differences between hot and cold water to drive circulation. Hot water, being less dense, rises upwards within the boiler tubes, while cooler water sinks down. This natural convection is driven by gravity and temperature differentials.

- Forced Circulation Boilers: Use pumps to actively circulate the water, regardless of temperature differences. This allows for higher heat transfer rates and the use of smaller, more compact boiler designs. They can operate at higher pressures and offer better control of water temperature.

Natural circulation boilers are simpler and require less maintenance but have lower efficiency compared to forced circulation. Forced circulation boilers require more initial investment in pumps but offer greater efficiency and flexibility.

An analogy would be a coffee maker; a natural circulation system would be like simply heating the water, relying on the hot water rising to the top; a forced circulation system uses a pump actively pushing the water through the system for faster heating.

Q 26. Describe the importance of proper boiler insulation.

Proper boiler insulation is vital for safety, efficiency, and cost savings. Insulation reduces heat loss from the boiler shell and pipes, leading to several benefits:

- Improved Efficiency: Less heat is lost to the surroundings, meaning less fuel is needed to generate the same amount of steam, saving energy and operational costs.

- Reduced Risk of Burns: Insulation protects personnel from accidental burns caused by hot surfaces.

- Extended Boiler Life: Reducing temperature fluctuations caused by heat loss helps prevent thermal stress on boiler components, extending their lifespan.

- Better Working Environment: Reduced heat loss creates a safer and more comfortable working environment.

The type and thickness of insulation are selected based on the operating temperature and environmental conditions. Regular inspections are essential to ensure the insulation is intact and performing optimally. Damaged insulation should be promptly repaired to prevent heat loss and potential safety hazards.

Q 27. How do you ensure compliance with boiler safety regulations?

Ensuring compliance with boiler safety regulations involves a multifaceted approach:

- Regular Inspections and Maintenance: Following a strict schedule for inspections, both internal and external, to detect any anomalies or potential issues early. This includes checking safety valves, pressure gauges, water levels, and all components relevant to safe operation.

- Documentation and Record Keeping: Maintaining detailed records of inspections, maintenance activities, repairs, and water testing results is critical. This provides a clear history of the boiler’s operation and compliance status.

- Operator Training and Certification: Ensuring boiler operators are adequately trained and certified to operate the system safely and efficiently. Regular refresher training is important to maintain proficiency.

- Compliance with Local and National Codes: Staying abreast of all applicable local, regional and national codes and regulations regarding boiler operation and safety. This may include specific requirements for pressure testing, safety devices, and emission controls.

- Emergency Procedures and Response Plans: Having well-defined procedures to handle any emergencies such as leaks, pressure surges, or equipment failures. Regular drills are crucial to familiarize personnel with these procedures.

Compliance is not merely about avoiding penalties but about ensuring the safe and efficient operation of a potentially hazardous piece of equipment. A proactive approach is always best.

Q 28. What are your strengths and weaknesses related to boiler operation?

My strengths lie in my extensive experience troubleshooting and resolving complex boiler issues, coupled with my strong understanding of boiler chemistry and water treatment. I possess a keen eye for detail, meticulously inspecting equipment and maintaining accurate records. My experience spans various boiler types and sizes, giving me a broad practical understanding. For example, I successfully resolved a critical boiler tube leak at a major manufacturing facility through swift diagnosis and coordinated repairs, preventing significant downtime and potential safety hazards.

My primary weakness is occasionally being overly meticulous in my work, sometimes leading to taking a longer time to complete tasks than initially expected. However, I am actively working on improving time management skills while maintaining my high standards of quality and thoroughness. This involves prioritizing tasks and optimizing my workflow processes. I am confident in my ability to balance thoroughness with time efficiency.

Key Topics to Learn for Boiler Operation Techniques Interview

- Boiler Water Chemistry: Understanding water treatment processes, chemical analysis, and their impact on boiler efficiency and longevity. Practical application includes troubleshooting water quality issues and preventing scale formation.

- Combustion and Fuel Efficiency: Mastering the principles of combustion, including stoichiometry and flame control. Practical application involves optimizing burner adjustments for maximum efficiency and minimizing emissions.

- Boiler Controls and Instrumentation: Understanding the function and operation of various boiler control systems, including pressure, temperature, and level controllers. Practical application includes diagnosing and troubleshooting malfunctions in these systems.

- Safety Procedures and Regulations: Thorough knowledge of safety protocols, lockout/tagout procedures, and relevant industry regulations (e.g., OSHA). Practical application includes demonstrating a commitment to safe operating practices.

- Troubleshooting and Maintenance: Developing systematic approaches to diagnosing boiler malfunctions and performing preventative maintenance tasks. Practical application includes identifying common boiler problems and applying effective solutions.

- Steam Generation and Distribution: Understanding the principles of steam generation, including the thermodynamic processes involved. Practical application includes managing steam pressure and flow to meet plant demands.

- Energy Conservation and Optimization: Applying strategies to improve boiler efficiency and reduce energy consumption. Practical application includes implementing measures to minimize heat loss and optimize fuel usage.

Next Steps

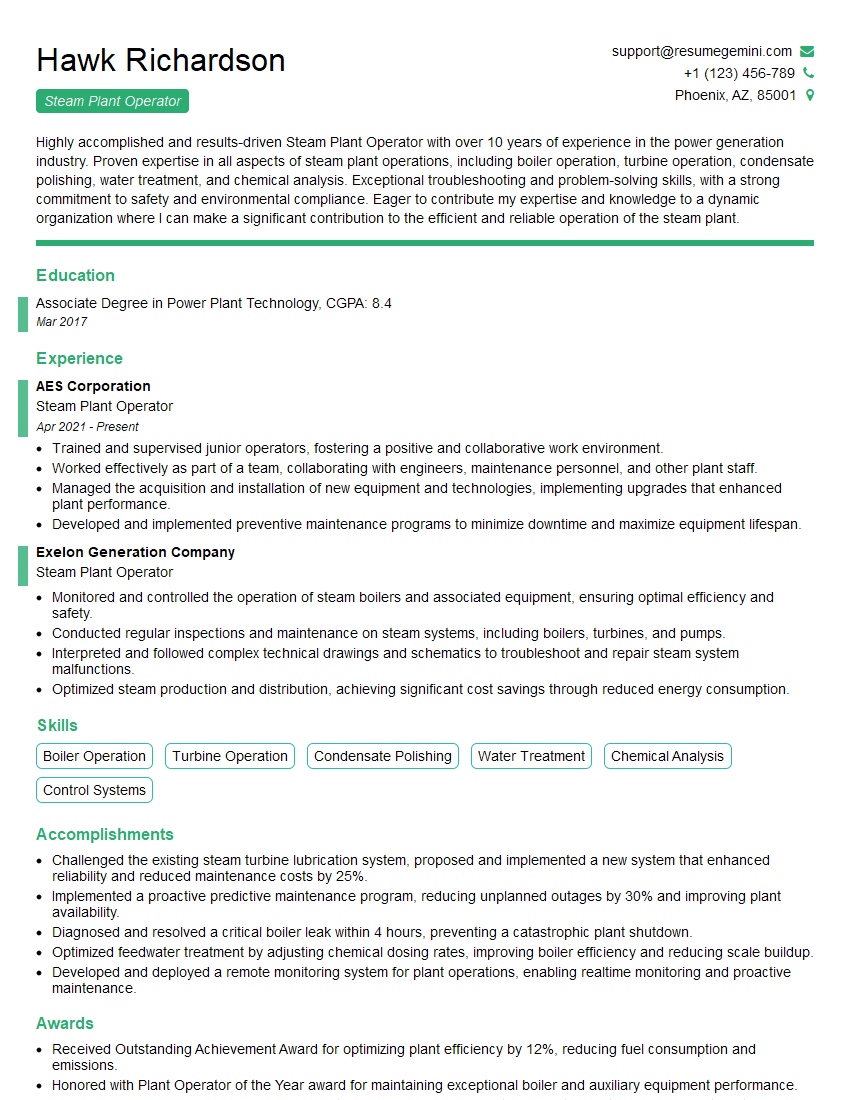

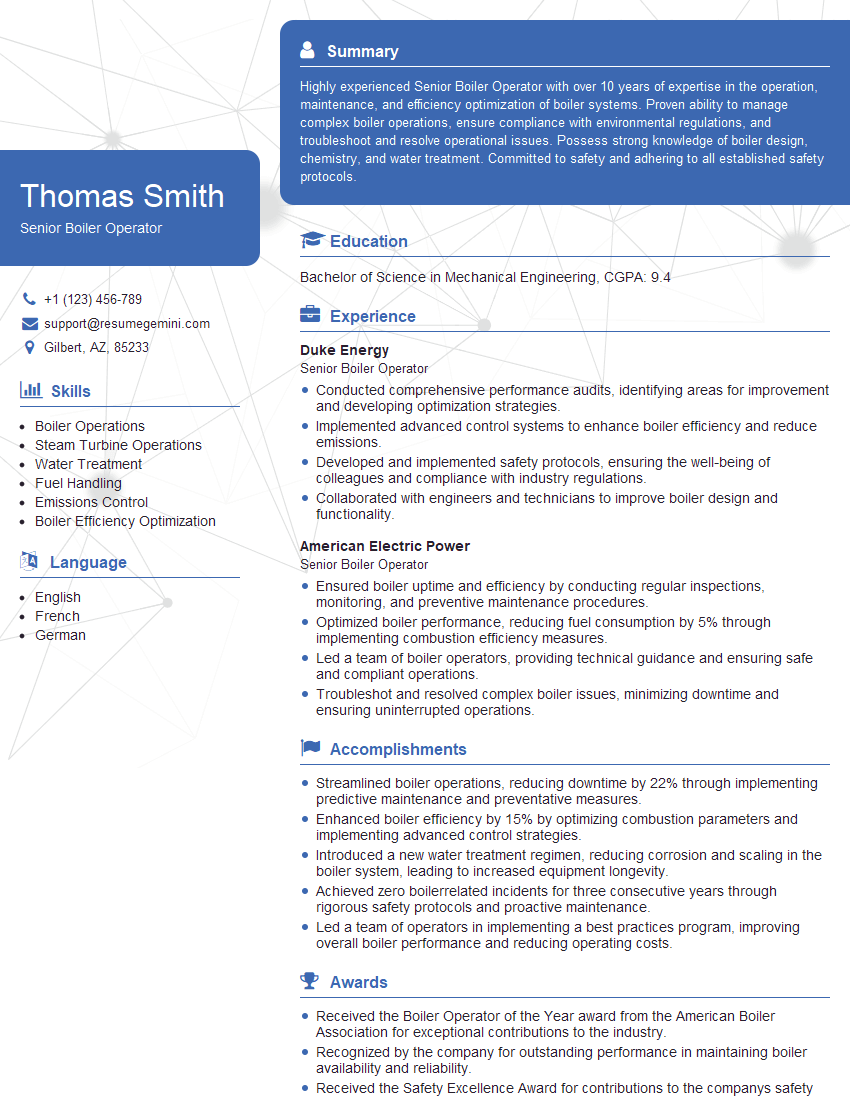

Mastering Boiler Operation Techniques is crucial for career advancement in the power generation and industrial sectors, opening doors to higher-paying roles and greater responsibility. A strong resume is essential to showcase your skills and experience to potential employers. Creating an ATS-friendly resume maximizes your chances of getting your application noticed. We recommend using ResumeGemini, a trusted resource, to build a professional and effective resume. ResumeGemini provides examples of resumes tailored to Boiler Operation Techniques, ensuring your application stands out from the competition.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

These apartments are so amazing, posting them online would break the algorithm.

https://bit.ly/Lovely2BedsApartmentHudsonYards

Reach out at [email protected] and let’s get started!

Take a look at this stunning 2-bedroom apartment perfectly situated NYC’s coveted Hudson Yards!

https://bit.ly/Lovely2BedsApartmentHudsonYards

Live Rent Free!

https://bit.ly/LiveRentFREE

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?