Cracking a skill-specific interview, like one for Boiler Repair and Troubleshooting, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Boiler Repair and Troubleshooting Interview

Q 1. Describe your experience with different types of boilers (e.g., steam, hot water, firetube, watertube).

My experience encompasses a wide range of boiler types, from simple firetube boilers often found in smaller commercial settings to complex watertube boilers used in large industrial facilities and power plants. I’ve worked extensively with both steam and hot water boilers, understanding their unique operational characteristics and maintenance requirements. Firetube boilers, where hot gases pass through tubes surrounded by water, are typically more straightforward in design, while watertube boilers, with water circulating through tubes surrounded by hot gases, demand a higher level of expertise due to their intricate design and higher pressures.

- Firetube Boilers: I’ve diagnosed and repaired numerous issues in these units, including issues with burner controls, leaky tubes, and low water levels, often in smaller facilities such as restaurants or laundromats.

- Watertube Boilers: My experience with watertube boilers includes working on high-pressure systems, performing preventative maintenance, and troubleshooting complex problems involving superheaters, economizers, and feedwater systems in large industrial complexes. For example, I once resolved a major issue with a watertube boiler’s superheater by identifying a damaged tube through a thorough inspection and careful pressure testing.

- Steam Boilers: I’m adept at understanding and maintaining the intricacies of steam generation, pressure regulation, and the associated safety systems, such as pressure relief valves.

- Hot Water Boilers: I’m familiar with the nuances of hot water circulation systems and the challenges of maintaining consistent water temperature and pressure, particularly in larger building heating systems.

Q 2. Explain the process of boiler water treatment and its importance.

Boiler water treatment is crucial for preventing scaling, corrosion, and other issues that can significantly reduce boiler efficiency and lifespan. It involves a multi-faceted approach aimed at controlling water chemistry. Think of it like this: your boiler is a high-pressure system – treating the water is like treating a precious engine with specialized oil. Without proper treatment, you’re setting yourself up for costly repairs and early failure.

The process typically includes:

- Chemical Treatment: Adding chemicals like oxygen scavengers (to prevent corrosion), scale inhibitors (to prevent mineral buildup), and dispersants (to keep solids suspended) to the boiler feedwater. The precise chemical treatment depends on the water’s initial quality and the boiler’s operating conditions.

- Water Softening: Removing hardness minerals (calcium and magnesium) to prevent scale formation. This might involve ion exchange or other water softening techniques.

- Blowdown: Regularly purging a small amount of boiler water to remove accumulated solids and maintain the desired concentration of chemicals.

- Regular Testing: Frequent testing of water samples to monitor the levels of various parameters (pH, conductivity, alkalinity, etc.) and adjust chemical treatments as needed.

Neglecting boiler water treatment leads to reduced heat transfer efficiency, increased fuel consumption, tube failures, and ultimately, costly repairs and downtime.

Q 3. How do you troubleshoot a boiler low water level alarm?

A low water level alarm is a serious safety issue that requires immediate attention. It indicates a critical shortage of water in the boiler, which could lead to overheating and catastrophic failure. The troubleshooting process is systematic:

- Safety First: Turn off the burner immediately to prevent further damage.

- Visual Inspection: Carefully inspect the water gauge glass and check the water level indicators. Is the reading accurate? Are there any visible leaks? Look for steam leaks around valves and fittings.

- Check Water Feed System: Verify that the feedwater pump is functioning correctly and supplying water to the boiler. Is the feedwater tank full? Are there any blockages in the feedwater lines?

- Inspect Float Switch and Low-Water Cutoff: Ensure that these safety devices are functioning correctly. A malfunctioning float switch might not trigger the alarm, even with low water levels.

- Check for Leaks: Look for leaks in the boiler shell, tubes, or fittings. Small leaks can lead to a gradual loss of water and trigger the low-water level alarm. A pressure test might be necessary.

- Examine Pressure Relief Valve: Ensure the pressure relief valve is not leaking. Excessive pressure relief could lead to water loss.

- Consider External Factors: Check if there is excessive steam demand or if the boiler is working under heavier-than-normal loads. Overloading can lead to a low water level more quickly.

Once the cause is identified, take appropriate corrective actions, such as repairing leaks, replenishing water, and addressing any malfunctions in the water feed system. Always follow safety procedures and consult relevant manuals when working with boilers.

Q 4. What are the common causes of boiler burner malfunctions?

Boiler burner malfunctions are a frequent source of problems. They can stem from various issues, impacting efficient and safe operation. Here are some common culprits:

- Fuel Supply Issues: Problems with the fuel supply line, like clogs, leaks, or low fuel pressure, can prevent sufficient fuel from reaching the burner.

- Ignition Problems: A faulty igniter, electrodes, or gas valve can prevent the burner from lighting. This could involve a simple component replacement like a spark plug, or it could indicate more systemic issues with the system’s electrics.

- Air-Fuel Ratio Issues: An incorrect air-fuel mixture leads to incomplete combustion and burner instability. This could be caused by issues with the blower motor, damper malfunction or other airflow issues. Think of it like trying to start a bonfire with too little oxygen.

- Flame Sensor Problems: A malfunctioning flame sensor fails to detect the flame, causing the burner to shut down prematurely or fail to start altogether. This requires careful diagnostic testing of the sensor and its circuitry.

- Control System Malfunctions: Issues with the boiler’s control system, including the burner control unit, could lead to inappropriate burner operation or shutdowns.

- Dirty Burner or Nozzles: Accumulated soot or debris on the burner nozzles can impede fuel flow and combustion efficiency. Regular cleaning is essential.

Troubleshooting burner malfunctions usually involves systematic checks, starting with the simplest potential problems. Always follow safety procedures, and consult schematics and manuals when necessary.

Q 5. Describe your experience with boiler safety controls and interlocks.

Boiler safety controls and interlocks are critical for preventing accidents and ensuring safe operation. These safeguards are layered, providing multiple lines of defense against potential hazards. I’m highly experienced in understanding and maintaining these systems, including their regular testing and calibration.

My experience includes working with:

- High and Low-Water Cutoffs: Prevent operation when water levels are too high or low, avoiding overheating or water hammer.

- Pressure Relief Valves: Release excess pressure to prevent boiler explosions. Regular testing is crucial to ensure proper functioning.

- Flame Failure Safeguards: Automatically shut down the burner if the flame is extinguished.

- Overtemperature Limit Switches: Shut down the boiler if the temperature exceeds safe limits.

- Interlocks: Prevent simultaneous operation of conflicting functions, such as starting the burner before the feedwater pump is on. These work like a series of checks, preventing the system from starting or continuing if parameters are unsafe.

Regular inspection and testing of safety controls and interlocks are critical. A preventative maintenance plan, including scheduled checks and calibration, ensures continued safe operation and minimizes the risk of accidents.

Q 6. How do you identify and repair boiler leaks?

Identifying and repairing boiler leaks requires a methodical approach, combining visual inspection with diagnostic tools. The location and severity of the leak determine the repair method. Small leaks might be manageable through patching, but larger leaks may require more extensive repairs, potentially involving welding or replacing components.

- Locate the Leak: Carefully inspect the boiler for visible signs of leaks, such as steam or water escaping. Pay attention to seams, joints, and fittings. Sometimes, moisture stains or discoloration can indicate a leak.

- Determine Severity: Assess the extent of the leak. Small leaks might be manageable with a patch or sealant, while larger leaks may necessitate more involved repairs.

- Isolate the Section: If possible, isolate the affected section of the boiler to minimize downtime and further damage. This may involve shutting off valves or isolating specific components.

- Repair Methods: The repair method depends on the location and nature of the leak. Small leaks in fittings might require tightening or replacing gaskets. Leaks in the boiler shell or tubes might require welding or replacing sections.

- Pressure Testing: After repairs, pressure testing is crucial to ensure that the leak has been successfully addressed. This involves pressurizing the boiler to verify there are no further leaks.

Remember, always prioritize safety when repairing boiler leaks. Consult relevant safety procedures and manuals before undertaking any repairs.

Q 7. Explain your understanding of boiler efficiency and how to improve it.

Boiler efficiency refers to how effectively the boiler converts fuel energy into usable heat. Improving boiler efficiency means getting more heat output for the same amount of fuel, reducing operating costs and environmental impact. It’s like squeezing more juice from the same orange.

Improving boiler efficiency can involve several strategies:

- Regular Maintenance: Preventative maintenance is key. Cleaning the boiler tubes and burner nozzles, inspecting safety controls, and ensuring proper water treatment significantly improve efficiency.

- Proper Combustion Control: Optimizing the air-fuel ratio is crucial. This involves adjusting the burner to ensure complete combustion and minimize fuel wastage. Monitoring flue gas analysis helps ensure optimum combustion.

- Insulation: Proper insulation minimizes heat loss, reducing the amount of fuel needed to maintain the desired temperature. Think of it as keeping the heat where it belongs.

- Water Treatment: Scaling reduces heat transfer, so proper water treatment is essential for maintaining optimal efficiency.

- Modernization: Upgrading to more efficient burners or controls can significantly improve overall efficiency. Consider energy-saving technologies such as variable-speed drives for pumps.

Regular monitoring of key parameters like fuel consumption, flue gas temperature, and boiler efficiency provides valuable insights into the boiler’s performance and helps identify areas for improvement.

Q 8. What are the common causes of boiler scale and how to prevent it?

Boiler scale, that hard crusty mineral deposit inside your boiler, is primarily caused by dissolved minerals in the water, like calcium and magnesium. Think of it like a kettle left with hard water – eventually, that residue builds up. These minerals precipitate out of solution as the water heats and evaporates, sticking to the boiler’s internal surfaces.

- Hard Water: The most significant culprit. The higher the mineral content in your water supply, the faster scale forms.

- Water Temperature: Higher temperatures accelerate mineral deposition.

- Water Chemistry: The pH level and alkalinity of the water influence scale formation. Certain chemicals can either promote or inhibit scale buildup.

- Insufficient Water Treatment: Failure to use water softeners, filters, or chemical treatments specifically designed to prevent scaling.

Preventing scale involves a multi-pronged approach:

- Water Softening: Install a water softener to remove calcium and magnesium ions before they enter the boiler. This is often the most effective solution.

- Chemical Treatment: Using appropriate water treatment chemicals can help to control scale formation. These chemicals often act to inhibit crystal growth or even dissolve existing scale. Always consult a water treatment specialist to determine the right chemical treatment for your specific boiler and water conditions.

- Regular Blowdowns: Periodically purging a small amount of water from the boiler removes accumulated solids, including scale precursors. This helps maintain water quality and prevents excessive build-up.

- Proper Boiler Operation: Following the manufacturer’s recommendations for operation and maintenance helps to minimize scale formation. This includes maintaining proper water levels and operating temperatures.

For instance, I once worked on a commercial boiler where neglected water treatment led to a significant scale buildup that drastically reduced efficiency and nearly caused a catastrophic failure. Implementing a regular water softening and blowdown program completely solved the problem.

Q 9. Describe your experience with boiler combustion analysis.

Boiler combustion analysis is crucial for optimizing efficiency and minimizing emissions. My experience involves using specialized instruments to measure the key parameters of the combustion process, such as oxygen levels in the flue gas (O2), carbon monoxide (CO), carbon dioxide (CO2), and temperature. This data is then analyzed to determine the efficiency of fuel combustion and identify any potential issues.

I’m proficient in interpreting the results to identify problems like incomplete combustion (high CO levels indicating insufficient air), excess air (low CO2 and high O2, suggesting wasted fuel), and improper fuel-to-air ratios. I use this data to adjust burner settings, ensure proper air-fuel mixing, and optimize the overall combustion process. This often involves using data loggers to monitor combustion parameters over time and identify trends.

For example, I recently conducted a combustion analysis on a large industrial boiler that was experiencing lower than expected efficiency. By analyzing the flue gas composition, I identified an imbalance in the air-fuel mixture caused by a partially clogged air intake. Cleaning the intake and adjusting the burner settings resulted in a 15% increase in efficiency and a significant reduction in fuel costs.

Q 10. How do you perform a boiler inspection?

A thorough boiler inspection is a systematic process involving a visual examination, pressure testing (where applicable), and a review of operational logs. Safety is paramount throughout this process.

- External Inspection: This involves visually inspecting the boiler’s exterior for any signs of damage, leaks, corrosion, or wear. I pay close attention to insulation, piping, valves, and safety devices.

- Internal Inspection (where safe and possible): If the boiler allows access, I inspect the interior for scale buildup, corrosion, and any signs of internal damage. This might involve using a borescope for inaccessible areas.

- Pressure Testing: Depending on the boiler type and its operating pressure, a pressure test might be conducted to check for leaks. This ensures the integrity of the pressure vessels and associated piping.

- Controls and Safety Devices Inspection: A critical step involves checking the functionality of all safety devices like pressure relief valves, high-temperature cutoffs, and low-water fuel cutoffs. This includes verifying their proper calibration and operational readiness.

- Operational Log Review: Reviewing operational logs, including temperature, pressure, and fuel consumption data, can help identify trends and potential problems.

- Documentation: All findings are meticulously documented with photographs and detailed reports, including recommendations for repairs or maintenance.

Imagine it like a thorough medical checkup for your boiler. A comprehensive inspection prevents costly breakdowns and ensures safe and efficient operation.

Q 11. What are the safety precautions you take when working on a boiler?

Safety is my top priority when working on boilers. I strictly adhere to all relevant safety regulations and always follow a lock-out/tag-out procedure to prevent accidental energization during maintenance or repairs. Specific precautions include:

- Lockout/Tagout (LOTO): This crucial procedure ensures that power to the boiler is completely isolated and locked out before any work begins. Each worker involved will add their own lock and tag.

- Personal Protective Equipment (PPE): Using appropriate PPE, including safety glasses, gloves, hearing protection, and flame-resistant clothing, is mandatory. The type of PPE will depend on the specific task.

- Confined Space Entry Procedures (if applicable): If entering a confined space, such as a boiler drum, I adhere to stringent confined space entry procedures, including atmospheric testing and having a standby person.

- Hot Work Permits (if applicable): For any work involving open flames or sparks, a hot work permit must be obtained, and appropriate fire prevention measures must be in place.

- Awareness of High Temperatures and Pressures: Boilers operate under high temperatures and pressures; constant awareness and caution are paramount. I never rush and thoroughly inspect all equipment before touching it.

I always remember a colleague who suffered a minor burn due to a failure to properly isolate a section of piping before beginning repairs. This incident reinforced the importance of stringent safety protocols.

Q 12. Explain the process of boiler start-up and shutdown.

Boiler start-up and shutdown procedures are critical for safe and efficient operation. The exact procedures vary depending on the boiler type, but some common steps include:

Start-up:

- Pre-Start Checks: Ensure all safety devices are functional, water levels are correct, and there are no leaks.

- Fuel Supply Check: Verify the fuel supply (gas, oil, or other) is available and at the correct pressure.

- Ignition and Burner Start: Follow the manufacturer’s instructions for igniting the burners and bringing the boiler up to its operating temperature gradually.

- Monitoring: Closely monitor the boiler’s performance, including water level, pressure, and temperature.

Shutdown:

- Reduce Load: Gradually reduce the boiler’s load by decreasing the burner’s firing rate.

- Turn Off Burners: Once the load is reduced, safely turn off the burners.

- Cool Down: Allow the boiler to cool down gradually to prevent thermal shock. This process can take several hours, depending on the boiler size and design.

- Drain and Purge: Depending on the boiler type and design, the boiler may need to be drained and purged to prevent corrosion.

Ignoring proper start-up and shutdown procedures can lead to equipment damage, reduced efficiency, and, importantly, safety hazards.

Q 13. How do you diagnose and repair boiler pressure problems?

Boiler pressure problems can stem from various sources. Diagnosing and repairing them requires a systematic approach.

Diagnosing Pressure Problems:

- Low Pressure: This could indicate leaks in the system, insufficient water feed, or a faulty pressure relief valve.

- High Pressure: This could result from an overheated boiler, a malfunctioning pressure relief valve, or a problem with the feedwater system.

- Pressure Fluctuations: Unstable pressure might point to issues with the feedwater pump, control valves, or a leak that varies with boiler operation.

Repairing Pressure Problems:

The repair strategy depends on the diagnosed cause. It could involve:

- Leak Repair: Identifying and repairing leaks using appropriate welding or patching techniques. This sometimes necessitates hydrostatic testing to verify the repair’s success.

- Feedwater System Adjustments: Adjusting the feedwater pump or valve settings to ensure proper water supply to maintain pressure within the acceptable range.

- Pressure Relief Valve Inspection/Replacement: Inspecting and repairing or replacing a faulty pressure relief valve. This often necessitates pressure testing the valve to confirm its functionality.

- Control System Calibration: Recalibrating the boiler’s control system to maintain optimal pressure levels.

For example, I once dealt with a boiler experiencing fluctuating pressure. After thorough inspection, I discovered a failing control valve that needed replacement. Replacing the valve immediately resolved the issue.

Q 14. Describe your experience with boiler control systems (e.g., PLC, DCS).

My experience encompasses various boiler control systems, including Programmable Logic Controllers (PLCs) and Distributed Control Systems (DCSs). PLCs are commonly used in smaller boilers, offering programmable logic to automate and control various boiler functions such as burner control, feedwater regulation, and safety interlocks.

DCSs are prevalent in larger, more complex boiler systems. They offer distributed control capabilities, allowing for greater redundancy, scalability, and advanced monitoring features. I’m proficient in troubleshooting and programming both types of systems. I’m familiar with various communication protocols, including Modbus, Profibus, and Ethernet/IP, used in these control systems.

My work has involved troubleshooting PLC code to identify and rectify issues such as incorrect logic leading to unsafe shutdowns or inefficient operation. With DCS systems, I’ve had experience configuring and optimizing control loops to maintain stable operating parameters and improve overall system efficiency. The use of historical data and trend analysis within these systems helps identify and prevent future problems.

For instance, I once resolved a recurring issue with a boiler’s automatic shutdown sequence by identifying a bug in the PLC code responsible for monitoring water level. Modifying the code and testing it resolved the problem, avoiding costly downtime.

Q 15. How do you troubleshoot a boiler that is overheating?

A boiler overheating is a serious issue that can lead to damage or even explosion. Troubleshooting begins with safety: turn off the boiler immediately and allow it to cool down before proceeding. Never attempt repairs on a hot boiler.

The most common causes of overheating are:

- Low water levels: This is the most frequent culprit. A lack of water reduces the heat transfer capacity, leading to overheating. Check the water level gauge and refill if necessary, following manufacturer instructions. If the level keeps dropping despite refilling, investigate for leaks.

- Scale buildup: Mineral deposits reduce heat transfer efficiency and can cause localized overheating. Regular chemical cleaning or descaling is essential preventative maintenance.

- Malfunctioning pump: A faulty circulation pump prevents proper water flow, leading to uneven heating and overheating in certain sections of the boiler.

- Faulty thermostat: A malfunctioning thermostat can fail to shut off the burner, resulting in continuous heating and overheating. This needs professional replacement.

- Air in the system: Air trapped in the system impedes water circulation, causing overheating and inefficient operation. Bleeding the system (releasing trapped air) can resolve this.

- Blocked flues: Restricted airflow from blocked or dirty flues can cause overheating as the combustion gases can’t escape properly.

Troubleshooting involves systematically checking each of these areas. Start with the simplest, like water levels and air in the system, before moving on to more complex issues that require specialized tools or expertise. If you’re unsure about any step, call a qualified boiler technician.

Example: I once encountered a boiler overheating due to a clogged condensate drain line. The buildup of condensate restricted the water flow, causing the boiler to overheat. Clearing the drain line immediately resolved the problem.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain your understanding of boiler codes and regulations.

Boiler codes and regulations vary by location but are crucial for ensuring safe and efficient operation. They cover aspects such as installation, operation, maintenance, and emission standards. Familiarization with local and national codes, such as the ASME Boiler and Pressure Vessel Code (in the US), is essential for safe practice. These codes specify design requirements, safety devices (pressure relief valves, temperature limits), and inspection procedures. Failure to adhere to these regulations can lead to fines, legal action, and, most importantly, safety hazards.

Regulations often mandate regular inspections and maintenance by certified technicians, ensuring boilers are operating within safe parameters and meeting emission standards. These inspections verify the proper functioning of safety devices and identify potential problems before they escalate.

Example: The local authority may require annual inspections for boilers above a certain capacity, including testing of safety valves and combustion efficiency analysis. These inspections help prevent accidents and ensure compliance.

Q 17. How do you handle emergency situations during boiler operation?

Emergency situations with boilers require immediate and decisive action, prioritizing safety above all else. My approach follows a structured protocol:

- Secure the area: Evacuate the immediate vicinity and restrict access to prevent injury.

- Shut down the boiler: Turn off the fuel supply and any electrical power immediately. This is the first and most crucial step.

- Assess the situation: Identify the nature of the emergency – is there a fire, a leak, or an unusual noise?

- Call emergency services: If necessary, immediately contact the fire department, emergency medical services, or a qualified boiler technician. Provide them with details of the situation and the boiler’s location.

- Prevent further damage: If safe to do so, take steps to mitigate further damage – for example, turning off ancillary equipment or isolating the affected area.

- Document the incident: Record details of the emergency, including the time, cause (if known), and actions taken. This documentation is critical for insurance claims and investigation.

Example: I once responded to a boiler fire caused by a fuel leak. My immediate action was to shut off the fuel supply and call the fire department, then work with them to extinguish the flames while ensuring everyone’s safety.

Q 18. Describe your experience with boiler maintenance schedules and preventative maintenance.

Preventative maintenance is crucial for extending the lifespan of a boiler, optimizing efficiency, and preventing breakdowns. A well-defined maintenance schedule is essential. This typically involves:

- Regular inspections: Visual inspections for leaks, corrosion, or damage.

- Cleaning: Removing scale buildup and soot from heat exchangers and burners.

- Testing safety devices: Regularly testing pressure relief valves, high-temperature cut-offs, and other safety components.

- Combustion analysis: Analyzing the efficiency of the combustion process to optimize fuel consumption and minimize emissions.

- Component replacement: Replacing worn-out parts before they fail, such as seals, gaskets, and pumps.

The frequency of these tasks depends on the boiler type, fuel used, and operating conditions. Some boilers require daily checks, while others might only need annual inspections. A comprehensive maintenance log should be kept to track all activities.

Example: For a gas-fired boiler in a commercial setting, we typically recommend a quarterly inspection, including combustion analysis, and an annual comprehensive service including cleaning and component checks.

Q 19. What are the common causes of boiler stack emissions problems?

Problems with boiler stack emissions often indicate inefficient combustion or malfunctioning components. Common causes include:

- Insufficient air supply: Insufficient oxygen for complete combustion leads to the production of carbon monoxide (CO) and other pollutants.

- Excess air: While not as harmful as insufficient air, it leads to wasted fuel and reduced efficiency.

- Fuel quality issues: Low-quality fuel, containing impurities, can produce excessive emissions.

- Malfunctioning burner: A faulty burner can cause incomplete combustion, leading to increased emissions.

- Dirty or clogged heat exchanger: Reduced heat transfer efficiency can result in incomplete combustion and increased emissions.

- Faulty draft inducer: This component helps to remove combustion gases; malfunctioning it results in incomplete combustion and emissions problems.

Analyzing the stack emissions (using a flue gas analyzer) is crucial for diagnosing the problem. The readings will help pinpoint issues such as CO levels, oxygen levels, and combustion efficiency.

Example: High levels of CO in stack emissions suggest incomplete combustion, potentially due to a malfunctioning burner or insufficient air supply.

Q 20. How do you interpret boiler performance data?

Interpreting boiler performance data is essential for optimizing efficiency and identifying potential problems. This data often includes:

- Fuel consumption: Monitoring fuel consumption helps to identify trends and detect inefficiencies.

- Water temperature: Tracking water temperature helps to assess the boiler’s ability to meet heating demands.

- Pressure: Monitoring pressure helps to identify leaks or other problems.

- Stack temperature: Analyzing stack temperature helps to evaluate combustion efficiency.

- Combustion efficiency: Indicates how effectively the boiler is converting fuel into heat.

- O2 and CO levels: Show the completeness of combustion and the level of pollutants.

Analyzing this data, often using software or data loggers, allows for the identification of trends and deviations from optimal performance. Consistent monitoring enables early detection of potential problems, allowing for proactive maintenance and preventing costly repairs.

Example: A gradual increase in fuel consumption over time, without a corresponding increase in heat output, could indicate scale buildup in the heat exchanger, reducing its efficiency.

Q 21. Explain your experience with different types of boiler fuel (e.g., natural gas, oil, biomass).

My experience encompasses various boiler fuel types, each with unique characteristics and challenges:

- Natural Gas: A common and relatively clean fuel. Maintenance focuses on burner adjustments, combustion efficiency, and gas line safety.

- Oil: Requires careful handling due to potential spills and storage requirements. Maintenance involves cleaning fuel lines, burner nozzles, and addressing potential issues with oil viscosity.

- Biomass: This includes wood pellets, chips, or other organic materials. Maintenance includes handling ash buildup, ensuring proper fuel feeding, and addressing potential issues with moisture content in the fuel.

Each fuel type requires specific safety procedures and maintenance techniques. For example, oil boilers require careful attention to fuel storage and handling to prevent leaks and fires, while biomass boilers require regular ash removal to maintain efficiency and prevent damage.

Example: When working with biomass boilers, I focus on ensuring the correct moisture content of the fuel is maintained to prevent inefficient combustion and excessive emissions. Incorrect moisture levels can negatively impact the boiler’s efficiency and lifespan.

Q 22. How do you troubleshoot a boiler that is not producing enough steam or hot water?

Insufficient steam or hot water from a boiler points to a problem in its heat generation or distribution. Troubleshooting involves a systematic approach. First, check the fuel supply – is there enough gas, oil, or electricity? Inspect the burner for proper ignition and flame; a weak or irregular flame indicates combustion issues needing attention. Next, examine the water level; a low water level dramatically reduces heating capacity. Low water can be caused by leaks, a faulty feedwater pump, or a problem with the level control.

Then, assess the boiler’s pressure. Low pressure signifies a leak somewhere in the system. A pressure gauge will quickly indicate this. Finally, check the boiler’s heat exchanger. Scale buildup on the heat exchanger reduces its efficiency and limits heat transfer. This often requires chemical cleaning or descaling. Consider the circulating pump; a malfunctioning pump hinders proper water circulation, leading to inadequate heating. Listen for unusual noises; humming or grinding sounds suggest pump problems.

Example: I once dealt with a boiler producing lukewarm water. After verifying fuel supply and water level, I discovered a significant amount of scale buildup in the heat exchanger, dramatically reducing its effectiveness. A thorough chemical cleaning restored the boiler’s performance.

Q 23. Describe your experience with boiler pump maintenance and repair.

Boiler pump maintenance is crucial for efficient and safe operation. I have extensive experience maintaining and repairing various types of boiler pumps, including centrifugal and positive displacement pumps. Routine maintenance involves checking for leaks, inspecting the pump’s bearings and seals for wear, and lubricating moving parts as per the manufacturer’s specifications. I also regularly check the pump’s impeller for damage or wear. If the pump is not priming correctly, I troubleshoot the system to find the cause, which could involve air locks in the piping or a faulty check valve.

Repair work ranges from replacing worn seals and bearings to handling more complex issues like impeller replacement or motor repair. I’ve worked with different pump types, diagnosing issues like cavitation (formation of vapor bubbles within the pump) and ensuring proper pump alignment. My experience includes troubleshooting pump failures and performing preventative maintenance to avoid costly downtime.

Example: I recently repaired a boiler pump experiencing severe cavitation. By carefully inspecting the pump’s suction line, I found a blockage causing a significant pressure drop, leading to the cavitation. After clearing the blockage and balancing the pump system, the cavitation problem was solved, and the pump operated efficiently.

Q 24. What are the common causes of boiler noise problems?

Boiler noise problems are usually indicators of underlying issues. Common causes include:

- Water hammer: This is a sharp banging sound caused by sudden changes in water flow, often due to trapped air or rapid valve closure. Air vents need to be checked and air bled from the system.

- Loose or worn components: These can include loose pipes, fittings, or pump components creating rattling or vibrating noises. Tightening loose connections or replacing worn parts usually solves the problem.

- Scale buildup: Mineral deposits can create a rattling or knocking sound as they loosen and impact the boiler’s internal components. Chemical cleaning is often the solution.

- Pump problems: A faulty pump can produce humming, whining, or grinding noises. The pump may need repair or replacement.

- Burner issues: An improperly operating burner may generate unusual noises, including roaring or popping sounds.

Troubleshooting involves careful listening to locate the source of the noise and then systematically inspecting the suspected components.

Q 25. How do you identify and repair boiler refractory damage?

Refractory damage in a boiler is a serious issue that can compromise its efficiency and safety. Refractory materials line the furnace, protecting the boiler shell from extreme heat. Identifying damage involves visual inspection, looking for cracks, spalling (chipping or flaking), erosion, or bulging. I use a combination of visual checks and sometimes infrared thermography to detect heat leaks indicative of refractory damage. Small cracks might be repaired with refractory cement, but extensive damage requires more involved repair or replacement.

Repair typically involves removing the damaged refractory, cleaning the area, and applying new refractory material in layers. The new material needs to be properly cured before the boiler is restarted. The process is crucial as it ensures the safety and longevity of the boiler. Ignoring refractory damage can lead to heat loss, boiler shell overheating, and potential structural failure.

Example: I once encountered significant spalling in a boiler’s refractory lining. After careful inspection and removal of the damaged sections, I applied a high-temperature refractory mortar in multiple layers, ensuring proper curing time. Post-repair inspection confirmed the restoration of the boiler’s thermal integrity.

Q 26. Explain your experience with boiler blowdown procedures.

Boiler blowdown is a crucial process to remove impurities, such as dissolved solids and suspended matter, from the boiler water. Regular blowdown prevents scale formation and corrosion, ensuring boiler efficiency and longevity. I have extensive experience performing both continuous and intermittent blowdown procedures, following strict safety protocols. The frequency of blowdown depends on factors like boiler water quality, operating pressure, and type of boiler.

Continuous blowdown is a slow, continuous process that maintains a steady removal of impurities, while intermittent blowdown involves a periodic discharge of a larger volume of water. Both methods help maintain the boiler’s water quality within acceptable limits. I carefully monitor the blowdown process, ensuring the boiler water level and pressure remain within safe operating ranges. Improper blowdown can lead to water hammer and other operational problems. Proper training and adherence to safety guidelines are essential.

Example: I regularly perform blowdown procedures on a large industrial boiler. Following the manufacturer’s recommendations and using calibrated equipment, I meticulously control the blowdown rate to maintain water quality and prevent excessive water loss, minimizing operational disruptions.

Q 27. Describe your experience with boiler modernization and upgrades.

Boiler modernization and upgrades enhance efficiency, reduce emissions, and improve safety. I have been involved in several projects, encompassing various aspects, from assessing the existing boiler system and identifying areas for improvement to overseeing the installation of new components. Upgrades can range from replacing old burner systems with more efficient, low-NOx burners, to installing modern control systems for optimized operation. Other upgrades might include implementing economizers to recover waste heat or upgrading the feedwater system for improved efficiency.

I work closely with clients to understand their specific needs and budget constraints, designing solutions tailored to their operational requirements. The process involves careful planning, sourcing suitable equipment, and managing the installation and commissioning phases. Post-upgrade, I provide thorough training to ensure the client’s personnel can effectively operate and maintain the upgraded system.

Example: I recently oversaw the modernization of an aging boiler system by replacing its inefficient burner with a high-efficiency condensing burner. This upgrade significantly reduced fuel consumption and emissions while enhancing the boiler’s overall performance.

Q 28. What are your strategies for continuous improvement in boiler maintenance and repair?

Continuous improvement in boiler maintenance and repair involves a multi-faceted approach. This starts with regular preventative maintenance schedules based on the boiler’s operational data and manufacturer’s recommendations. I use data-driven techniques to track key performance indicators such as fuel consumption, water quality parameters, and maintenance frequency. This allows me to identify trends and proactively address potential issues before they become major problems.

Furthermore, I stay up-to-date with the latest technologies and best practices in boiler maintenance and repair through professional development courses, industry publications, and networking with other experts. I also implement robust record-keeping to document maintenance activities and repairs, facilitating future troubleshooting and allowing the identification of recurrent issues. By regularly reviewing maintenance data and seeking ways to improve our processes, we can continue to optimize our maintenance programs, ensuring efficient and reliable boiler operation.

Example: By analyzing historical maintenance data, I identified a pattern of recurring issues related to a specific pump component. Proactive replacement of this component based on predictive modeling significantly reduced downtime and maintenance costs.

Key Topics to Learn for Boiler Repair and Troubleshooting Interview

- Boiler System Fundamentals: Understanding boiler types (gas, oil, electric), components (burner, heat exchanger, pump, controls), and operating principles. Practical application: Diagnosing common malfunctions based on system knowledge.

- Troubleshooting Techniques: Systematic approaches to fault finding, including visual inspection, pressure testing, combustion analysis, and the use of diagnostic tools. Practical application: Explaining your step-by-step process for identifying and resolving a boiler malfunction.

- Safety Procedures: Understanding and adhering to safety regulations, lockout/tagout procedures, and handling hazardous materials. Practical application: Describing your experience prioritizing safety in a high-pressure situation.

- Combustion Efficiency and Optimization: Analyzing fuel consumption, adjusting burner settings, and identifying inefficiencies. Practical application: Explaining how you would improve the efficiency of a poorly performing boiler.

- Maintenance and Preventative Measures: Performing routine maintenance tasks, identifying potential problems before they occur, and extending boiler lifespan. Practical application: Describing a preventative maintenance schedule you’d implement.

- Hydraulic Systems: Understanding water pressure, flow rates, and pump operation within the boiler system. Practical application: Troubleshooting issues related to water circulation and pressure.

- Electrical Controls and Wiring Diagrams: Interpreting wiring schematics, troubleshooting electrical faults, and ensuring safe electrical operation. Practical application: Explaining how you would troubleshoot a faulty electrical component.

- Regulatory Compliance: Familiarity with relevant codes and regulations related to boiler operation and safety. Practical application: Explaining how you ensure compliance with all applicable regulations.

Next Steps

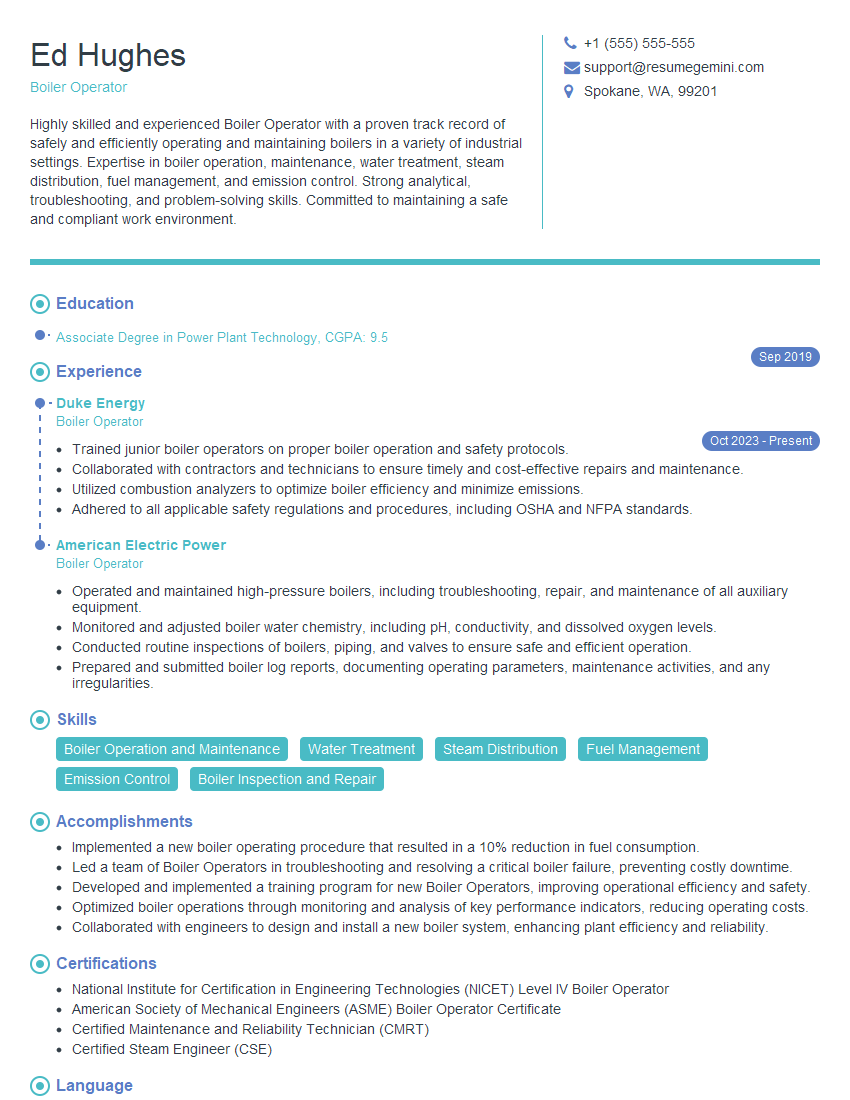

Mastering Boiler Repair and Troubleshooting opens doors to rewarding careers with excellent growth potential. Advancement opportunities are abundant for skilled technicians who consistently demonstrate proficiency and a commitment to safety. To maximize your job prospects, create a compelling and ATS-friendly resume that showcases your skills and experience effectively. ResumeGemini is a trusted resource to help you build a professional resume that stands out. We provide examples of resumes tailored to Boiler Repair and Troubleshooting to guide you. Let ResumeGemini help you present your qualifications in the best possible light and land your dream job.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?