Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Boiler Safety Techniques interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Boiler Safety Techniques Interview

Q 1. Explain the importance of regular boiler inspections and maintenance.

Regular boiler inspections and maintenance are paramount for ensuring safe and efficient operation. Think of it like a car – regular servicing prevents major breakdowns and extends its lifespan. Similarly, neglecting boiler maintenance can lead to costly repairs, production downtime, and even dangerous situations.

- Safety: Inspections identify potential hazards like leaks, corrosion, and faulty safety devices before they escalate into accidents.

- Efficiency: Regular cleaning and tuning optimize combustion, reducing fuel consumption and minimizing emissions. A poorly maintained boiler wastes energy and money.

- Longevity: Preventative maintenance extends the boiler’s operational life, saving you from the significant expense of premature replacement. Early detection of wear and tear allows for timely repairs.

- Compliance: Regular inspections demonstrate compliance with safety regulations and insurance requirements, avoiding potential fines or legal issues.

For example, a routine inspection might reveal a small crack in a pressure vessel, allowing for a simple and inexpensive repair before it becomes a major catastrophic failure.

Q 2. Describe the different types of boiler failures and their causes.

Boiler failures can be broadly categorized into several types, each with its own root causes:

- Pressure Vessel Failures: These are often caused by corrosion, overheating, or exceeding the design pressure. Imagine a balloon inflated beyond its limit – it will burst. Similarly, excessive pressure can cause a boiler to rupture.

- Tube Leaks: These can result from corrosion (especially in water-tube boilers), erosion, or overheating. Small leaks can lead to significant water loss and reduced efficiency, while larger leaks can cause a complete shutdown.

- Safety System Failures: Malfunctioning pressure relief valves, low water level cut-offs, or flame failure detectors can lead to dangerous overpressure or overheating conditions.

- Control System Failures: Problems with the boiler’s control system, including sensors, actuators, and programmable logic controllers (PLCs), can cause erratic operation or complete shutdown.

Causes often involve a combination of factors, such as poor maintenance, operator error, and design flaws. A thorough investigation is crucial to determine the root cause and prevent future failures.

Q 3. What are the key safety regulations and codes related to boiler operation?

Boiler safety regulations and codes vary by location, but common elements include:

- Regular Inspections: Frequency varies depending on boiler type, pressure, and age, but typically involves annual or bi-annual inspections by a qualified inspector.

- Pressure Vessel Certification: Boilers must be designed, manufactured, and installed to meet specific codes and standards (e.g., ASME Section I in the US).

- Safety Devices: Boilers must be equipped with pressure relief valves, low water level cut-offs, and other safety devices to prevent dangerous conditions.

- Operating Procedures: Detailed operating procedures must be established and followed by trained personnel. These procedures cover startup, shutdown, and emergency procedures.

- Water Treatment: Proper water treatment is crucial to prevent corrosion and scaling, ensuring boiler longevity and safety.

- Record Keeping: Meticulous record keeping of inspections, maintenance, and repairs is mandatory. This documentation is essential for demonstrating compliance.

Examples of relevant codes include ASME Boiler and Pressure Vessel Code (BPVC) in the US, and similar standards in other countries. Non-compliance can lead to significant penalties.

Q 4. How do you identify and mitigate risks associated with boiler operation?

Risk mitigation in boiler operation starts with a thorough hazard analysis, identifying potential risks and their likelihood and consequences. This involves:

- Regular Inspections and Maintenance: As previously discussed, proactive maintenance significantly reduces the risk of failures.

- Operator Training: Well-trained operators are critical for safe and efficient operation. Training should cover all aspects of operation, maintenance, and emergency procedures.

- Emergency Response Plan: A comprehensive emergency response plan should be in place, detailing procedures for handling various emergencies (e.g., leaks, fires, explosions).

- Regular Audits: Internal audits ensure adherence to safety procedures and identify areas for improvement. Regular review of the hazard analysis is also essential.

For example, a risk assessment might identify the risk of a pressure relief valve failure. Mitigation strategies would include regular inspection and testing of the valve, along with a backup safety system.

Q 5. Explain the process of boiler water treatment and its importance.

Boiler water treatment is essential to prevent scaling, corrosion, and other problems that can damage the boiler and reduce efficiency. It involves:

- Chemical Treatment: Adding chemicals to the boiler water to control pH, alkalinity, and other parameters. This prevents corrosion and scaling.

- Water Softening: Removing hardness minerals (calcium and magnesium) that cause scale formation. This can involve ion exchange or other methods.

- Oxygen Scavenging: Removing dissolved oxygen from the boiler water to prevent corrosion. Oxygen is a major contributor to corrosion.

- Blowdown: Periodically removing a small amount of boiler water to control solids concentration. This prevents the buildup of impurities.

The importance lies in maintaining the boiler’s integrity and preventing costly repairs or failures. Scaling can reduce heat transfer efficiency, leading to increased fuel consumption and potential overheating. Corrosion weakens the boiler components, increasing the risk of leaks or ruptures. Proper water treatment safeguards against these problems.

Q 6. Describe your experience with boiler combustion efficiency optimization.

My experience with boiler combustion efficiency optimization involves a multifaceted approach. I’ve worked on several projects that used techniques such as:

- Combustion Air Analysis: Precisely measuring and adjusting the air-fuel ratio to optimize combustion. This typically involves using specialized instruments to measure oxygen levels in the flue gas.

- Burner Tuning: Adjusting burner settings to achieve the best flame pattern and complete combustion. This minimizes fuel consumption and emissions.

- Flue Gas Analysis: Analyzing the composition of the flue gas to identify inefficiencies and potential problems. High levels of carbon monoxide indicate incomplete combustion.

- Insulation Inspection: Checking the boiler’s insulation to ensure minimal heat loss. Poor insulation significantly reduces efficiency.

- Data Logging and Analysis: Using data loggers to monitor boiler performance over time, identifying trends and areas for improvement. This allows for data-driven optimization.

In one particular project, we achieved a 15% improvement in combustion efficiency by optimizing the air-fuel ratio and burner settings, resulting in significant cost savings for the client.

Q 7. How do you handle boiler emergencies and safety incidents?

Handling boiler emergencies requires a calm, methodical approach. My response involves:

- Immediate Shutdown: If a safety concern arises (e.g., high pressure, low water level), the boiler must be immediately shut down according to established procedures.

- Emergency Response Plan Activation: Following the established emergency response plan, which includes isolating the boiler, notifying relevant personnel, and initiating safety protocols.

- Isolation and Containment: Containing the hazard to prevent further escalation. This may involve shutting off fuel supplies, venting pressure, or evacuating the area.

- Emergency Services Notification: Contacting appropriate emergency services (fire department, paramedics) if needed.

- Damage Assessment and Investigation: Once the emergency is under control, a thorough assessment of the damage is conducted, followed by a root cause investigation to prevent future incidents.

- Documentation: Maintaining detailed records of the emergency, response actions, and investigation findings. This information is critical for learning from the incident and preventing similar occurrences.

Safety is paramount. Every action is guided by a commitment to protecting personnel and preventing further damage.

Q 8. What are the different types of boiler safety valves and their functions?

Boiler safety valves are crucial for preventing overpressure, a major safety hazard. Several types exist, each designed for specific applications and pressure ranges.

- Safety Relief Valves (SRVs): These are spring-loaded valves that automatically open when the boiler pressure exceeds a predetermined setpoint. They’re designed for rapid pressure release and are commonly found in most boiler systems. Think of them as a pressure relief mechanism similar to a car’s pressure relief valve for the radiator.

- Fusible Plugs: These are relatively simple safety devices containing a metal alloy that melts at a specific temperature. If the boiler water level drops critically and the boiler overheats, the plug melts, releasing steam and alerting operators to the problem. While effective, they are considered a secondary safety mechanism compared to SRVs.

- Rupture Discs: These are disposable pressure relief devices consisting of a thin metal disc that bursts at a specific pressure. They provide a one-time pressure release and are often used in conjunction with SRVs. Once ruptured, they must be replaced.

The choice of valve depends on the boiler’s size, pressure rating, and application. For instance, high-pressure boilers will typically use SRVs with robust construction and higher capacity.

Q 9. Explain the principles of boiler pressure control and regulation.

Boiler pressure control and regulation maintain safe and efficient operation by keeping the pressure within acceptable limits. This is achieved through a combination of components and strategies.

- Feedwater Control: Precisely regulating the rate of feedwater entering the boiler directly influences steam generation and pressure. Too much feedwater can lead to overpressure; too little can cause low water levels. Modern systems often utilize sophisticated control loops to maintain a constant water level.

- Safety Valves: As previously discussed, safety valves are the primary pressure relief mechanism, preventing catastrophic overpressure scenarios. Their proper functioning and regular testing are paramount.

- Pressure Reducing Valves (PRVs): In applications requiring a lower downstream pressure, PRVs reduce the pressure of the steam or hot water leaving the boiler, protecting downstream equipment.

- Blowdown Valves: Used to periodically remove accumulated solids and impurities from the boiler, they indirectly influence pressure by reducing the water volume.

Effective pressure control relies on a combination of automatic control systems (like PLC-based systems) and careful operator monitoring. Regular inspections, calibration, and maintenance of all pressure control components are vital for safety and reliability.

Q 10. Describe your experience with boiler instrumentation and control systems.

My experience encompasses a wide range of boiler instrumentation and control systems. I’ve worked with everything from basic analog gauges to advanced digital control systems featuring SCADA (Supervisory Control and Data Acquisition) integration.

This includes proficiency in using instruments such as pressure gauges, temperature sensors (thermocouples, RTDs), level indicators (float switches, ultrasonic sensors), and flow meters. I have hands-on experience with PLC programming (specifically Allen-Bradley and Siemens platforms) for controlling feedwater pumps, fuel systems, and safety interlocks. I am also familiar with different communication protocols like Modbus and Profibus.

In a recent project involving a large industrial boiler, I implemented a new control system that integrated predictive maintenance algorithms, significantly improving efficiency and reducing downtime. This involved analyzing sensor data to identify potential issues before they escalated into major problems.

Q 11. How do you ensure compliance with environmental regulations regarding boiler emissions?

Compliance with environmental regulations is a critical aspect of boiler operation. This primarily focuses on minimizing harmful emissions like NOx (nitrogen oxides), SOx (sulfur oxides), and particulate matter.

- Low NOx Burners: Utilizing burners designed to minimize NOx formation is a key strategy. These can include staged combustion techniques or low-NOx burners.

- Selective Catalytic Reduction (SCR): This is a post-combustion technique that uses a catalyst to reduce NOx emissions. Ammonia is often injected into the flue gas to react with NOx, converting it to harmless nitrogen and water.

- Flue Gas Desulfurization (FGD): This process reduces SOx emissions, particularly relevant for boilers burning sulfur-containing fuels. FGD systems typically use lime or limestone to absorb SOx from the flue gas.

- Particulate Matter Control: Electrostatic precipitators or fabric filters can effectively remove particulate matter from the flue gas, ensuring compliance with emission limits.

Regular monitoring and testing of emissions using certified equipment is crucial to maintain compliance. Documentation of all emission measurements and any corrective actions taken is essential for regulatory audits.

Q 12. What is your experience with different types of boilers (e.g., water-tube, fire-tube)?

I possess extensive experience with various boiler types, including water-tube and fire-tube boilers. My experience spans both small-scale and large industrial applications.

- Water-Tube Boilers: These are characterized by water circulating inside tubes surrounded by hot gases. They are suitable for high-pressure, high-capacity applications, offering advantages in terms of efficiency and safety due to the larger water volume. I have worked extensively on Babcock & Wilcox and Riley Power designs.

- Fire-Tube Boilers: These boilers have hot gases passing through tubes surrounded by water. They are typically used for lower pressure applications and are simpler in design compared to water-tube boilers. I have worked with both horizontal return tubular and vertical fire-tube designs, common in smaller heating applications.

My experience extends to understanding the specific operational characteristics, maintenance requirements, and safety considerations for each boiler type. For example, water-tube boilers require careful monitoring of water chemistry to prevent corrosion and scaling. Fire-tube boilers, due to their construction, have a higher risk of overheating if the water level drops.

Q 13. Explain the process of boiler start-up and shutdown procedures.

Boiler start-up and shutdown procedures are critical for safety and equipment longevity. They must be followed meticulously to prevent accidents and damage.

Start-up: Typically involves a systematic approach: 1) Pre-operational checks (inspections, level checks); 2) Filling the boiler with water (and purging air); 3) Ignition and gradual flame establishment; 4) Slow pressure increase (monitoring water level, pressure, and temperature); and 5) reaching operational pressure and load. Each step involves specific checks and safety protocols.

Shutdown: This involves a controlled reduction in load and pressure. 1) Reducing fuel supply and flame; 2) Controlled venting of steam to reduce pressure; 3) Monitoring water level to prevent overheating; 4) Complete pressure drop to atmospheric pressure; and 5) Securing the boiler system. The specific steps depend on the boiler type and size.

Detailed written procedures are essential and operator training is crucial. Failure to adhere to proper start-up or shutdown procedures can lead to serious safety issues such as boiler explosions or equipment damage.

Q 14. Describe your experience with boiler troubleshooting and repair.

My experience in boiler troubleshooting and repair is extensive, covering a wide range of issues. I employ a systematic approach that combines theoretical knowledge with practical experience.

Troubleshooting Process: 1) Gather information (symptoms, operating history); 2) Identify potential causes (using diagnostic tools and analyzing data); 3) Test hypotheses (carefully and safely); 4) Implement corrective actions (repair or replacement); and 5) Verification (to ensure the issue is resolved).

Examples of common issues I’ve addressed include low boiler efficiency (often linked to burner adjustments or fouling), water leaks (requiring pressure testing and component replacement), and control system malfunctions (resolved through PLC diagnostics and programming). For instance, I recently solved a boiler efficiency issue by identifying and replacing a faulty fuel injector that was resulting in incomplete combustion. It involved systematic fault isolation through analysis of O2 and CO levels in the exhaust gases.

Q 15. What are the common causes of boiler corrosion and how can they be prevented?

Boiler corrosion is a significant concern, leading to reduced efficiency, potential failure, and safety hazards. It’s primarily caused by chemical reactions between the boiler’s metal components and the water or steam inside. Common causes include:

- Oxygen corrosion: Dissolved oxygen in the boiler water reacts with iron, forming rust (iron oxide). This is a very aggressive form of corrosion.

- Carbon dioxide corrosion: Carbon dioxide dissolved in water forms carbonic acid, which attacks the boiler metal, particularly at lower pH levels.

- Caustic corrosion: High concentrations of caustic chemicals (like sodium hydroxide) can cause localized corrosion, especially in areas with high heat transfer.

- Chloride corrosion: Chloride ions are extremely corrosive and can initiate pitting corrosion, leading to localized thinning of the boiler metal. Even small amounts can be detrimental.

Prevention strategies involve carefully controlling water chemistry:

- Oxygen scavenging: Using chemical oxygen scavengers (e.g., hydrazine, catalyzed sodium sulfite) to remove dissolved oxygen from the feedwater.

- pH control: Maintaining the boiler water pH within the recommended range (typically slightly alkaline) to minimize acid corrosion. This often involves using chemicals like amines or phosphates.

- Water treatment: Employing a comprehensive water treatment program that includes pre-treatment of feedwater to remove impurities, regular blowdown, and monitoring of key parameters.

- Corrosion inhibitors: Adding corrosion inhibitors to the boiler water to create a protective film on the metal surfaces.

- Regular inspection: Conducting regular internal inspections of the boiler to identify and address any signs of corrosion early.

For example, in a power plant setting, a failure to effectively scavenge oxygen could lead to significant corrosion within a few months, requiring expensive repairs or even boiler replacement. A proactive water treatment plan is crucial.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you monitor and control boiler water chemistry parameters?

Monitoring and controlling boiler water chemistry is critical for safe and efficient operation. Key parameters include:

- pH: Indicates acidity or alkalinity. Optimal pH helps prevent corrosion and scaling.

- Dissolved oxygen: Must be minimized to prevent oxygen corrosion.

- Conductivity: Measures the total dissolved solids, indicating water purity.

- Silica: High silica levels can lead to scaling and boiler tube failures.

- Phosphate: Used for scale control and corrosion inhibition.

- Hydrazine (or other oxygen scavengers): Levels are monitored to ensure effective oxygen removal.

Monitoring involves regular testing of boiler water samples using specialized equipment, including portable meters and laboratory analysis. Control involves adjusting chemical feed rates based on test results to maintain parameters within specified limits. For instance, if the pH starts to fall below the acceptable range, we’d increase the feed rate of a neutralizing chemical. Automated control systems are increasingly used to precisely maintain these parameters. Failure to monitor and control chemistry can result in costly damage or safety issues.

Q 17. What is your experience with Non-Destructive Testing (NDT) methods for boiler inspection?

My experience with Non-Destructive Testing (NDT) methods for boiler inspection is extensive. I’ve utilized several techniques, including:

- Ultrasonic Testing (UT): Used to detect flaws like cracks, pitting, or thinning in boiler tubes and pressure vessels. UT uses high-frequency sound waves to create an image of the internal structure.

- Radiographic Testing (RT): Employs X-rays or gamma rays to reveal internal defects. This is particularly useful for detecting weld imperfections or corrosion under insulation.

- Magnetic Particle Testing (MT): Detects surface and near-surface cracks in ferromagnetic materials (like steel). A magnetic field is applied, and magnetic particles are used to visualize the cracks.

- Dye Penetrant Testing (PT): Identifies surface-breaking flaws. A dye is applied to the surface, and excess dye is removed. A developer reveals any cracks by drawing the dye to the surface.

I’ve been involved in several inspections where NDT has played a crucial role in identifying potential problems before they escalated into major failures. For example, during an inspection of an aged boiler, UT revealed significant thinning in a section of tubing, leading to the planned replacement of that section, thereby preventing a potential catastrophic failure.

Q 18. Explain your understanding of boiler safety relief valve testing and maintenance.

Boiler safety relief valves (SRV) are crucial safety devices designed to prevent overpressure. Testing and maintenance are vital for ensuring their proper operation. Testing typically involves:

- Periodic testing: SRVs are tested at regular intervals (frequency determined by regulations and boiler type) to verify they open and close at their set pressure.

- Hydrostatic testing: The valve is subjected to a specified pressure to check for leaks and proper seating.

- Full-lift testing: The valve is fully opened to check for full lift and free movement. Usually performed by a certified technician.

Maintenance includes:

- Regular inspection: Visual inspection to check for corrosion, damage, or obstructions.

- Cleaning: Cleaning the valve to remove any accumulated debris.

- Calibration: Ensuring the valve opens and closes at the correct pressure.

- Component replacement: Replacing worn or damaged components as needed.

Failure to properly test and maintain SRVs can lead to boiler overpressure, potentially causing explosions or catastrophic failures. A detailed log of all tests and maintenance activities should be kept for regulatory compliance and equipment history.

Q 19. Describe your experience with boiler blowdown procedures and their importance.

Boiler blowdown is the process of removing a portion of boiler water to control the concentration of dissolved solids and impurities. It’s crucial for preventing scaling, corrosion, and carryover (impurities being carried with the steam). The procedure typically involves:

- Continuous blowdown: A small, continuous stream of water is discharged to maintain a constant level of dissolved solids.

- Intermittent blowdown: Larger volumes of water are discharged at intervals, often manually or automatically controlled.

The importance of blowdown stems from its ability to control water chemistry and prevent potential problems. Without regular blowdown, the concentration of dissolved solids increases, leading to scaling on heat transfer surfaces, which reduces efficiency and can even cause tube failures. Scaling is especially problematic in high-pressure boilers. Carryover contaminates the steam used in power generation and industrial processes.

For example, in a high-pressure boiler, improper blowdown management can significantly reduce boiler efficiency and increase maintenance costs.

Q 20. How do you interpret boiler operating data and identify potential problems?

Interpreting boiler operating data is critical for efficient operation and identifying potential problems. Key data points include:

- Pressure: Monitors the boiler’s operating pressure and helps identify leaks or other pressure-related issues.

- Temperature: Tracks water and steam temperatures, indicating efficiency and potential overheating.

- Water level: Crucial for preventing low water conditions, which can damage the boiler.

- Fuel consumption: Helps assess boiler efficiency and identify potential fuel waste.

- Steam flow rate: Indicates the amount of steam being generated, providing insights into demand and efficiency.

- Chemical treatment data: Provides information about water chemistry and its impact on boiler operation.

Identifying potential problems involves analyzing trends and deviations from normal operating parameters. For example, a sudden increase in fuel consumption with a consistent steam output suggests a decrease in boiler efficiency, potentially due to scaling or other issues. Similarly, consistently high conductivity indicates a need for more frequent blowdown. Modern boiler control systems use data analytics and sophisticated algorithms to detect anomalies and alert operators to potential problems.

Q 21. Explain the role of safety interlocks and other safety devices in boiler systems.

Safety interlocks and other safety devices are crucial for preventing accidents and ensuring safe operation. These devices work together to automatically shut down the boiler or prevent hazardous conditions from occurring. Examples include:

- Low water level cutoff: Automatically shuts down the boiler if the water level falls below a safe limit, preventing overheating and damage.

- High-pressure safety valve: Relieves excess pressure to prevent boiler explosions. (Already discussed in detail in a previous answer).

- Flame failure safeguard: Shuts off the fuel supply if the flame fails, preventing dangerous gas accumulation.

- Interlocks preventing access to dangerous areas: Prevent access to hazardous areas during operation.

- Pressure switches and sensors: Monitor pressure and initiate shutdown in case of dangerous pressure excursions.

- Temperature switches and sensors: Monitor temperature and trigger alarms or shutdowns to prevent overheating.

These devices work in concert to create multiple layers of protection. The failure of one safety device often does not result in a hazard because other safety devices are also in place. Regular testing and maintenance of these systems are essential to ensure they function correctly. A comprehensive safety management system incorporates these devices and strict operating procedures to minimize risk.

Q 22. Describe your experience with different types of boiler fuels and their associated safety concerns.

My experience encompasses a wide range of boiler fuels, including natural gas, fuel oil (both light and heavy), propane, and biomass. Each fuel presents unique safety concerns. Natural gas, while relatively clean-burning, requires careful attention to leak detection and prevention, employing technologies like gas detectors and regular inspections of piping and connections. Fuel oil necessitates robust storage solutions to prevent spills and leaks, minimizing fire risks through proper tank maintenance and grounding. Heavy fuel oils, in particular, present higher viscosity challenges, demanding appropriate pumping systems and pre-heating strategies to avoid operational issues and potential blockages. Propane, a highly flammable fuel, needs secure storage in approved tanks, coupled with careful handling procedures to avoid accidental release. Finally, biomass fuels, such as wood chips or pellets, introduce additional considerations regarding dust control, efficient combustion to minimize emissions (and subsequent air quality issues), and handling to avoid dust explosions.

- Example: During a project involving a biomass boiler, we implemented a sophisticated dust collection system along with regular cleaning and maintenance schedules to mitigate the risk of explosions. This involved thorough risk assessment and a detailed safety plan.

- Example: In another project, we discovered a significant leak in a natural gas line feeding a boiler through a regular maintenance inspection, averting a potentially disastrous situation.

Q 23. What is your experience with boiler energy management and efficiency improvements?

Boiler energy management and efficiency improvements are crucial for both economic and environmental reasons. My experience includes implementing various strategies, including optimizing boiler operation through advanced control systems, implementing efficient combustion techniques, and leveraging waste heat recovery systems. For instance, we’ve seen significant energy savings by using a sophisticated control system that monitors and adjusts fuel input based on real-time demand, avoiding over-firing and unnecessary energy waste. Retrofitting boilers with air-fuel ratio controllers significantly enhanced combustion efficiency in several projects, reducing fuel consumption and minimizing emissions. Moreover, integrating waste heat recovery systems into the plant’s processes allowed us to reuse heat that would otherwise be lost, further reducing overall energy costs.

Example: In one project, we were able to reduce fuel consumption by 15% by implementing a combination of these strategies. This not only resulted in substantial cost savings but also lessened the environmental impact of the facility’s operations.

Q 24. How do you document boiler maintenance and inspection activities?

Boiler maintenance and inspection activities are meticulously documented using a combination of digital and physical records. We utilize a computerized maintenance management system (CMMS) to schedule and track all activities. This system allows for the creation of comprehensive work orders, which include detailed descriptions of the work performed, parts used, and associated costs. All inspections, including pressure tests, visual inspections, and non-destructive testing, are documented with detailed reports, including photographs and any identified deficiencies. These reports are then filed within the CMMS and retained according to regulatory requirements. We also maintain a physical logbook for immediate recording of crucial information, such as boiler operating parameters and any unusual occurrences, which is then later transcribed into the CMMS. This dual system ensures data redundancy and quick access to essential information in case of emergencies.

Example: Our CMMS allows us to generate customized reports on maintenance history, assisting with predictive maintenance and identifying potential equipment failures before they occur. It ensures compliance and simplifies audits.

Q 25. Describe your familiarity with relevant safety standards (e.g., ASME, API).

I am deeply familiar with relevant boiler safety standards, including ASME (American Society of Mechanical Engineers) Section I (Power Boilers) and Section IV (Heating Boilers), and API (American Petroleum Institute) standards relevant to boilers used in oil and gas applications. My understanding extends beyond mere familiarity with the standards; I actively apply them throughout the entire lifecycle of boiler projects, from design and construction to operation and maintenance. ASME codes dictate the design, fabrication, inspection, and testing of boilers, ensuring they operate safely and reliably. API standards provide guidance on specific aspects, particularly in the context of oil and gas refineries and petrochemical plants. I ensure all our operations, designs, and maintenance procedures rigorously adhere to these codes and standards, utilizing them to inform risk assessments and safety protocols.

Example: For instance, we use ASME Section I as the guiding principle for the design and construction of high-pressure power boilers, ensuring that all welds and components are thoroughly inspected and certified to meet the required standards.

Q 26. Explain your understanding of boiler insurance and risk management.

Boiler insurance and risk management go hand-in-hand. Understanding boiler insurance is crucial for mitigating financial losses resulting from boiler failures or accidents. Comprehensive insurance policies cover various scenarios, including property damage, liability claims, business interruption, and equipment repair or replacement. The selection of the appropriate insurance coverage hinges on a detailed risk assessment that factors in boiler type, age, operating conditions, and potential hazards. My role includes conducting these assessments, identifying potential risks, and recommending appropriate mitigation strategies, which are then translated into insurance policy specifications. Effective risk management involves proactive measures, such as regular maintenance, operator training, and adherence to safety standards, all of which reduce the likelihood of incidents and thereby lower insurance premiums.

Example: A thorough risk assessment might identify the possibility of water hammer in a specific boiler system, leading to the implementation of water hammer arrestors and modification of operational procedures to reduce the risk. This proactive measure not only protects the boiler but also impacts the insurance premiums by demonstrating a commitment to safety.

Q 27. How do you ensure the safe handling and storage of boiler chemicals?

Safe handling and storage of boiler chemicals, such as water treatment chemicals, are paramount for operator safety and environmental protection. We adhere to strict protocols, including the use of proper personal protective equipment (PPE), such as gloves, goggles, and respirators, when handling these chemicals. Storage areas are designated for specific chemicals, clearly labeled with hazard warnings, and kept away from incompatible substances. The storage facilities are designed to prevent spills and leaks and include appropriate containment systems to address any incidents. Proper disposal procedures are also essential, with adherence to local and national environmental regulations. Regular inspections of storage areas ensure that chemical containers are properly labeled and in good condition and that there are no leaks or spills.

Example: We use secondary containment systems for chemical storage, ensuring that any spills are contained within designated areas, preventing contamination of the surrounding environment.

Q 28. Describe your experience with the training and supervision of boiler operators.

Training and supervision of boiler operators are critical for safe and efficient boiler operation. Our training programs encompass both theoretical and practical aspects of boiler operation and maintenance, adhering to all relevant safety standards and regulations. The training involves classroom sessions covering boiler theory, safety procedures, emergency response protocols, and routine maintenance tasks. Practical training takes place on-site, under the supervision of experienced professionals, where operators gain hands-on experience with the specific boiler systems they will operate. Ongoing supervision involves regular check-ins, performance evaluations, and adherence to safety protocols. We use competency-based assessments to ensure operators understand and can demonstrate safe operational practices.

Example: We use a comprehensive checklist system to ensure that operators follow proper start-up and shutdown procedures, mitigating the risk of accidents and maximizing the operational lifespan of the boiler.

Key Topics to Learn for Your Boiler Safety Techniques Interview

Ace your upcoming interview by mastering these essential areas of boiler safety. Remember, a strong understanding of both theory and practical application is key.

- Boiler Operation and Control Systems: Understand the principles behind boiler operation, including fuel delivery, combustion, steam generation, and pressure regulation. Explore different types of control systems and their functionalities.

- Safety Valves and Pressure Relief Devices: Learn the design, operation, and maintenance of various safety valves and pressure relief devices. Be prepared to discuss their importance in preventing catastrophic failures.

- Water Treatment and Chemistry: Master the principles of water treatment to prevent scaling, corrosion, and other issues that compromise boiler efficiency and safety. Understand water quality parameters and their impact.

- Inspection and Maintenance Procedures: Familiarize yourself with regular inspection and maintenance procedures, including visual inspections, non-destructive testing methods, and preventative maintenance schedules. Understand relevant codes and regulations.

- Emergency Procedures and Response: Know the proper procedures for handling emergencies, such as boiler leaks, fires, and pressure surges. Understand the role of safety protocols and emergency shutdown systems.

- Boiler Codes and Regulations: Demonstrate familiarity with relevant boiler codes and regulations (e.g., ASME, local regulations). Be prepared to discuss their implications for safe operation and maintenance.

- Troubleshooting and Problem-Solving: Practice diagnosing common boiler problems and developing effective solutions. This includes understanding the root cause analysis and implementing corrective actions.

Next Steps: Boost Your Career with a Powerful Resume

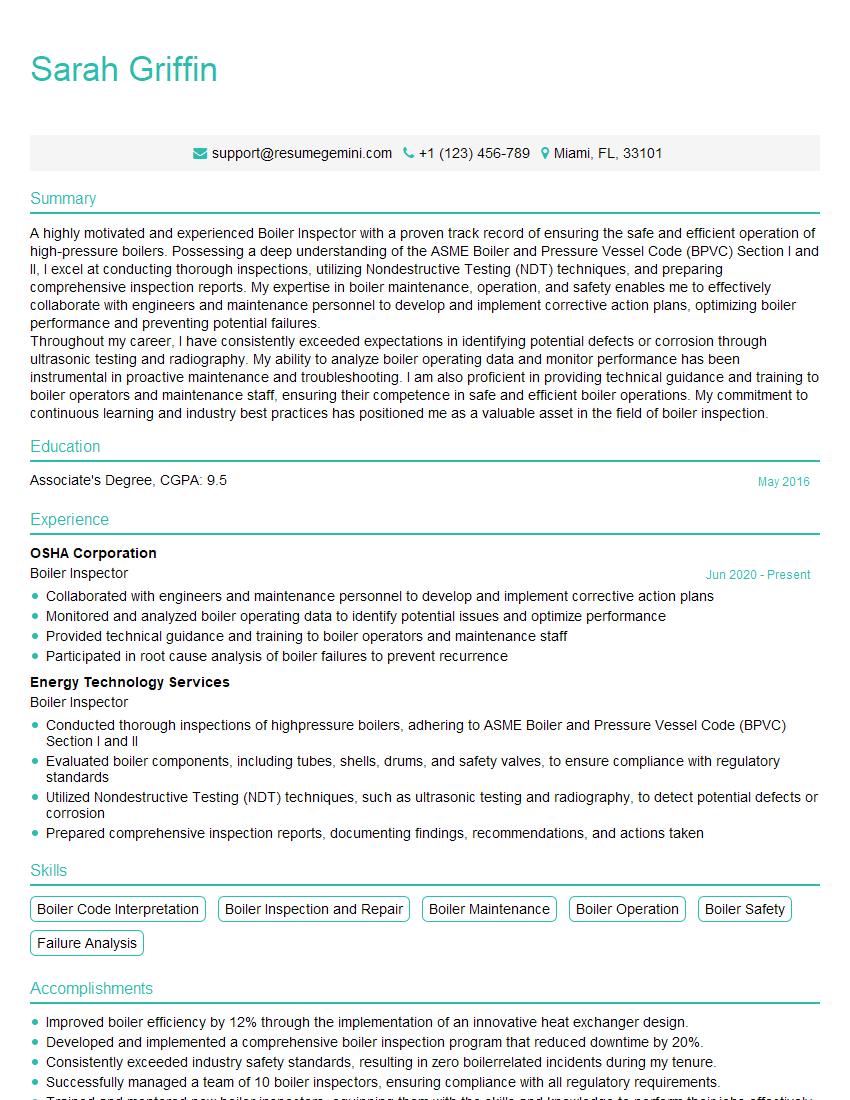

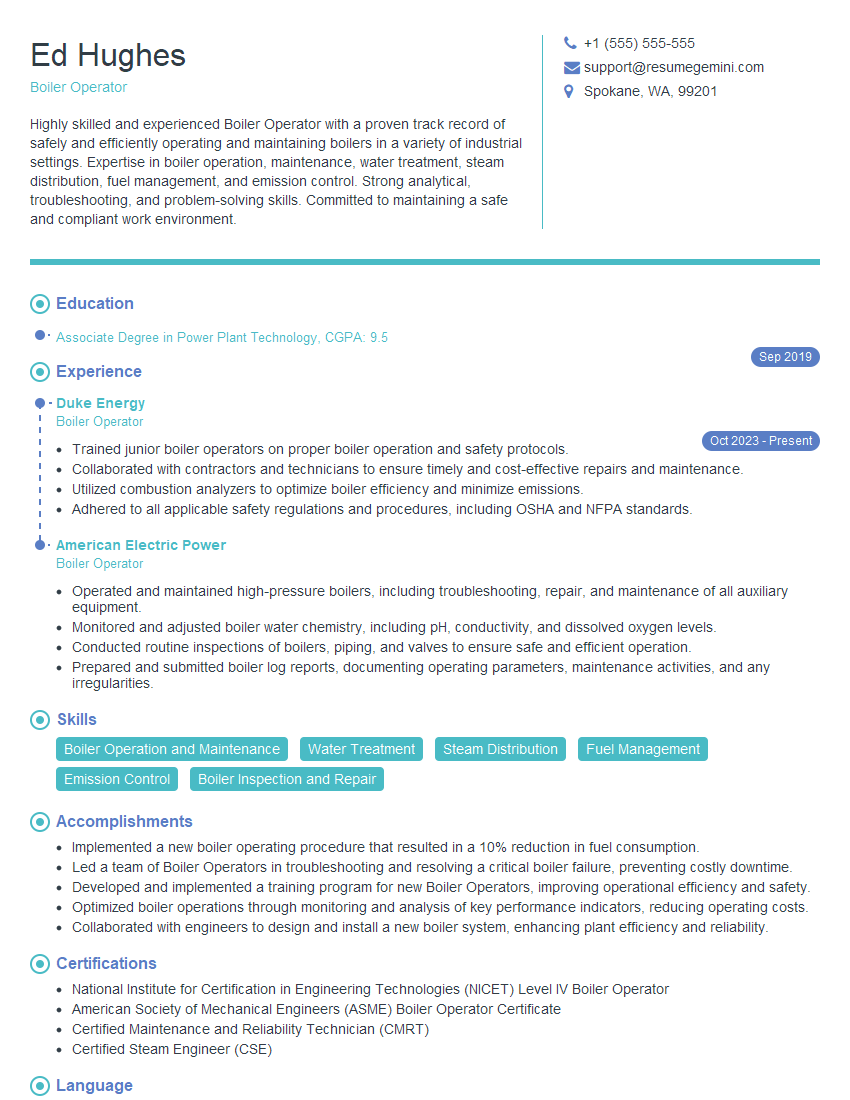

Mastering Boiler Safety Techniques opens doors to exciting career opportunities in a vital industry. To make the most of your expertise, a strong resume is crucial. An ATS-friendly resume increases your chances of getting noticed by recruiters. That’s where ResumeGemini comes in. ResumeGemini helps you craft a compelling, ATS-optimized resume that highlights your skills and experience effectively. We provide examples of resumes tailored to Boiler Safety Techniques to help you get started. Take the next step towards your dream career – build a winning resume with ResumeGemini today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

These apartments are so amazing, posting them online would break the algorithm.

https://bit.ly/Lovely2BedsApartmentHudsonYards

Reach out at [email protected] and let’s get started!

Take a look at this stunning 2-bedroom apartment perfectly situated NYC’s coveted Hudson Yards!

https://bit.ly/Lovely2BedsApartmentHudsonYards

Live Rent Free!

https://bit.ly/LiveRentFREE

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?