Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Boiler Start-up and Shutdown interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Boiler Start-up and Shutdown Interview

Q 1. Describe the pre-start checks you perform before initiating a boiler startup.

Before starting a boiler, a thorough series of pre-start checks is crucial to ensure safe and efficient operation. Think of it like pre-flight checks for an airplane – you wouldn’t take off without them! These checks are designed to identify any potential issues that could lead to malfunction or danger.

- Water Level Check: Verify the boiler water level is within the acceptable range. Low water can cause overheating and damage, while excessive water can lead to inefficiencies and potential water hammer.

- Fuel Supply Check: Ensure adequate fuel supply (gas, oil, or coal) is available and the supply lines are free from obstructions. A lack of fuel will obviously prevent startup.

- Air Supply Check (for Air/Fuel Boilers): Confirm proper air supply to the combustion chamber. Insufficient air leads to incomplete combustion, reducing efficiency and emitting harmful pollutants.

- Pressure Gauge Check: Check all pressure gauges (steam, water, fuel) for proper functionality and zero readings. Inaccurate readings can compromise safety and efficiency.

- Safety Valve Check: Inspect the safety valves to ensure they are functioning correctly and are not blocked or obstructed. These are critical for preventing dangerous pressure buildup.

- Water Treatment Check: Confirm that the boiler water chemistry is within the recommended range. Improper water treatment can cause scaling, corrosion, and other problems.

- Electrical Systems Check: Inspect electrical connections, wiring, and controls to make sure everything is properly connected and functioning. Electrical issues can lead to malfunctions or even fires.

- Visual Inspection: Conduct a thorough visual inspection of the boiler and its surroundings for any signs of damage, leaks, or corrosion. This often catches subtle problems before they become major issues. Think of it as a general ‘once-over’ to identify anything out of the ordinary.

Q 2. Explain the sequence of events during a typical boiler startup procedure.

The boiler startup sequence is a carefully orchestrated process. Each step must be followed precisely to ensure safe and efficient operation. Skipping steps or rushing the process can have serious consequences.

- Initial Checks: Perform all pre-start checks as outlined above.

- Water Filling: Slowly fill the boiler with treated water, checking the level frequently. Avoid rapid filling to prevent thermal shock.

- Air Venting: Open air vents to purge any trapped air from the system. This is essential for proper water circulation and prevents overheating.

- Ignition (Fuel Firing): Light the burners (or ignite the fuel source) and gradually increase the heat input. Observe the flame pattern and adjust controls as needed for efficient combustion.

- Pressure Increase: Allow the steam pressure to rise gradually to the operating pressure. This prevents thermal stress and allows the boiler to heat uniformly.

- Load Increase: Once the operating pressure is reached, gradually increase the steam load by opening the steam valves slowly.

- Monitoring and Adjustment: Continuously monitor all parameters (pressure, temperature, water level, fuel consumption) and make adjustments as necessary to maintain optimal operating conditions.

Q 3. What safety precautions are critical during boiler startup and shutdown?

Safety is paramount during boiler startup and shutdown. A moment’s lapse in safety procedures can have catastrophic consequences. This is not something to take lightly.

- Lockout/Tagout (LOTO): Implement LOTO procedures before performing any maintenance or repair work on the boiler. This prevents accidental startup while someone is working on the equipment.

- Personal Protective Equipment (PPE): Wear appropriate PPE, including safety glasses, gloves, and heat-resistant clothing. Boiler operations involve high temperatures and pressures, so proper protection is non-negotiable.

- Emergency Shutdown Procedures: Ensure that all personnel are familiar with the emergency shutdown procedures and know where the emergency shutoff valves are located.

- Ventilation: Ensure adequate ventilation to prevent the buildup of carbon monoxide and other harmful gases. Carbon monoxide is odorless and deadly.

- Pressure Relief Devices: Ensure the pressure relief valves are regularly inspected and tested to confirm their functionality. These are your last line of defense against over-pressurization.

- Water Treatment: Maintain proper boiler water chemistry to prevent corrosion and scaling. Corrosion can weaken boiler components and lead to leaks or failures. Scaling reduces efficiency and can cause overheating.

- Regular Inspections: Conduct regular inspections of the boiler and its components to identify and address any potential problems before they escalate into major incidents.

Q 4. How do you monitor boiler water levels during startup and operation?

Boiler water level monitoring is a critical aspect of safe and efficient boiler operation. Think of it as the vital signs of the boiler.

- Water Level Gauges: Most boilers use water level gauges (glass or electronic) to directly indicate the water level in the boiler drum. These should be checked frequently, especially during startup and shutdown.

- Remote Indicators: Modern boilers often incorporate remote indicators, providing visual displays in the control room or at a central location.

- High/Low Level Alarms: Many boilers are equipped with high and low water level alarms to alert operators to abnormal conditions. This acts as an early warning system.

- Regular Checks: Frequent visual checks of the water level gauges should be supplemented by reviewing the data from remote indicators and alarm systems.

- Calibration: Periodic calibration of water level gauges and sensors is essential to ensure accurate readings. Without calibration, the readings could be inaccurate and lead to issues.

Q 5. What are the common causes of boiler water level fluctuations?

Fluctuations in boiler water levels can stem from several causes. Understanding these causes is crucial for effective troubleshooting.

- Excessive Steam Demand: A sudden increase in steam demand can cause a temporary drop in water level as more water is converted into steam.

- Feedwater Issues: Problems with the feedwater system, such as a malfunctioning pump or control valve, can cause inconsistencies in water supply and water level fluctuations.

- Leaks: Leaks in the boiler or piping systems will lower the water level gradually or suddenly depending on the severity of the leak.

- Water Hammer: Rapid changes in water flow, sometimes called ‘water hammer’, can cause temporary disturbances in the water level.

- Blowdown: Improper boiler blowdown can cause unexpected water level changes. This is a procedure for removing impurities from the boiler water.

- Faulty Level Sensors/Gauges: Incorrect readings from faulty sensors or gauges can lead to perceived fluctuations that are not actually present.

Q 6. Explain the importance of maintaining proper steam pressure during operation.

Maintaining proper steam pressure is crucial for efficient and safe boiler operation. Steam pressure is the lifeblood of many industrial processes. Insufficient or excessive steam pressure can seriously affect productivity and safety.

- Process Requirements: Different industrial processes require different steam pressures. Maintaining the correct pressure ensures the process runs efficiently and effectively.

- Equipment Protection: Maintaining proper steam pressure protects equipment and processes from damage caused by either insufficient or excessive steam.

- Energy Efficiency: Proper steam pressure ensures efficient energy utilization, as deviations cause inefficiencies and energy waste.

- Safety: Maintaining pressure within the designed range prevents dangerous over-pressurization conditions that could lead to boiler failure and injury.

Think of it like the fuel gauge in your car – you need to keep the pressure within a safe and optimal range to maintain efficient operation and prevent damage.

Q 7. Describe the procedures for handling a boiler trip during operation.

A boiler trip (sudden shutdown) is a serious event requiring a well-defined procedure. The focus is on safe shutdown and troubleshooting.

- Immediate Actions: Immediately secure the fuel supply, stop the firing, and isolate the boiler from the steam distribution system. Safety is the first priority.

- Investigate the Cause: Determine the cause of the trip by analyzing the alarms, logs, and other available data. This is crucial for preventing future trips.

- Safety Checks: Before proceeding, ensure the boiler has cooled down sufficiently to allow safe access for inspection and repair. Safety is paramount.

- Repair or Maintenance: Address the identified cause of the trip. This may involve replacing or repairing faulty components.

- Restart: Once repairs are complete and all safety checks are passed, follow the established startup procedure to restart the boiler.

- Documentation: Thoroughly document the trip event, including the cause, corrective actions taken, and lessons learned. This helps prevent future occurrences.

Q 8. What are the signs of a malfunctioning boiler safety valve?

A malfunctioning boiler safety valve can be a serious safety hazard. Several signs indicate a problem. The valve might be leaking steam continuously, even when the boiler pressure is well below the set pressure. This is a clear indication of a faulty valve seat or internal mechanism. Another sign is that the valve fails to lift and relieve pressure when the boiler pressure exceeds the setpoint. This can lead to dangerously high pressures, potentially causing a catastrophic boiler explosion. You might also notice evidence of water dripping or weeping from the valve, suggesting a seal failure. Regular inspection and testing are crucial to prevent such failures. Imagine a situation where a safety valve sticks – the pressure builds uncontrollably, risking a major incident. That’s why we pay such close attention to these valves’ functionality.

In a recent inspection, we found a safety valve that had become corroded internally due to poor water treatment, causing it to leak constantly. This was swiftly rectified by replacing the faulty valve.

Q 9. How do you identify and address boiler burner malfunctions?

Boiler burner malfunctions can manifest in various ways, disrupting efficient and safe operation. One common issue is improper ignition, leading to repeated ignition attempts or flame failure. This often stems from problems with the ignitor, gas supply, or air-fuel mixture. You might observe yellow or smoky flames instead of the characteristic blue flame indicating incomplete combustion, signifying insufficient air or excess fuel. Another sign is unusual noises, such as loud popping or banging sounds from the burner, indicating instability or potential damage within the burner assembly. A consistently low flame or a complete lack of flame output is a serious issue, requiring immediate attention.

Troubleshooting these malfunctions involves systematically checking each component. This includes inspecting the ignitor for proper spark, verifying the gas pressure and fuel supply, checking the air intake for obstructions, and examining the burner nozzles for clogging or damage. A systematic approach and the right diagnostic tools are essential for quickly identifying and addressing the root cause.

For example, a recent incident involved a burner failing to ignite due to a clogged gas nozzle. A simple cleaning resolved the issue, highlighting the importance of regular maintenance.

Q 10. What are the indicators of low water level in a boiler?

Low water level in a boiler is a critical condition that can lead to serious damage or even an explosion. Indicators vary depending on the boiler type and its instrumentation but commonly include a low-water level alarm activating; this is a crucial safety feature. The water gauge glass, if fitted, might show a water level below the safe operating range. Some boilers incorporate low water level cutoff switches designed to automatically shut down the boiler should the level drop too low. A noticeable drop in boiler pressure despite consistent firing might indicate a water level problem, as the lack of sufficient water can’t absorb heat effectively.

Imagine a scenario where the boiler operates with a low water level for an extended period. The lack of water moderation leads to overheating of the boiler tubes, potentially causing them to warp or even fail. Regular monitoring of water levels is essential to prevent such a scenario.

Q 11. Describe the process for safely shutting down a boiler.

Safely shutting down a boiler is a critical procedure requiring adherence to strict protocols. The process is designed to prevent accidents and protect personnel and equipment. First, reduce the fuel supply to the burner in a controlled manner. Then, allow the boiler pressure to gradually decrease naturally. Open the vents or bleed valves to facilitate this process and ensure the safe release of steam or pressure. Once the pressure has dropped to a safe level, turn off all power to the boiler and its ancillary equipment, including pumps and fans. Finally, ensure all safety interlocks are engaged and the boiler is fully isolated from the fuel supply.

Each step is crucial and needs to be documented, emphasizing the importance of safe and systematic procedures. In one instance, we found an operator rushing the process which was a near miss and a violation of established protocols.

Q 12. What are the post-shutdown procedures you follow?

Post-shutdown procedures are equally important to ensure the boiler remains in a safe and stable condition until the next startup. This typically involves checking the boiler water level and ensuring that there are no leaks. A visual inspection is needed to check for any signs of damage, such as corrosion or overheating. Properly documenting the shutdown process is important for maintenance records. All gauges and instrumentation should be checked for proper readings and functionality. Finally, the boiler should be secured to prevent unauthorized access.

In a real-world example, we discovered a small leak during the post-shutdown inspection that was identified and addressed immediately. This prevented a much larger leak further down the line.

Q 13. How do you inspect a boiler after a shutdown?

Inspecting a boiler after a shutdown involves a thorough visual examination of all accessible components. This includes checking for any signs of leaks, corrosion, or damage to the boiler shell, tubes, and fittings. Inspect the burner assembly for any signs of wear or damage, checking for obstructions, debris or damage in the burner area. Carefully examine all safety devices, including the safety valves and pressure gauges, verifying their proper functioning. The documentation of all findings is crucial for maintenance planning and future operations.

Imagine trying to restart a boiler without a post-shutdown inspection. We could end up facing a significant problem if a minor leak or component failure isn’t detected and repaired before the next startup.

Q 14. Explain the role of the combustion controls in boiler operation.

Combustion controls are the brains of the boiler operation, managing the air-fuel mixture to achieve efficient and clean combustion. They regulate the fuel supply and air intake, optimizing the combustion process to maintain the desired boiler temperature and pressure. These controls ensure safe operation by monitoring various parameters, including flame detection, gas pressure, air flow, and exhaust gas analysis. They also incorporate safety interlocks that shut down the system if any parameters fall outside the acceptable range, preventing unsafe conditions.

For example, if oxygen levels in the exhaust gas are too high, it indicates incomplete combustion and the controls will adjust the air-fuel ratio accordingly. Modern combustion control systems are increasingly sophisticated, employing advanced algorithms to optimize performance and minimize emissions.

Q 15. Describe different types of boiler fuel and their impact on startup and shutdown.

Boiler fuel selection significantly impacts startup and shutdown procedures. Different fuels have varying ignition characteristics, heating rates, and potential for residue buildup.

- Natural Gas: Clean-burning and easy to control, making startup relatively quick and shutdown straightforward. Minimal residue, simplifying post-shutdown cleaning.

- Fuel Oil: Requires preheating before ignition, leading to a longer startup time. Shutdown necessitates careful management to avoid residue solidification in the fuel lines. Different grades of oil (e.g., #2, #6) have different viscosities and require tailored procedures.

- Coal: Slowest startup due to the time needed for ignition and achieving stable combustion. Shutdown is also slow, requiring careful control to prevent overheating and damage to refractory linings. Significant ash residue requires regular cleaning.

- Biomass (wood chips, pellets): Similar to coal in terms of startup and shutdown times, requiring careful control to avoid smoldering and ensure complete combustion. Ash handling and residue management are crucial.

For example, in a power plant using fuel oil, we would preheat the oil to a specific temperature before initiating the burner sequence during startup. During shutdown, we’d circulate the oil to keep it fluid and prevent clogging.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure efficient fuel consumption during boiler operation?

Efficient fuel consumption hinges on optimizing combustion and minimizing energy losses. This involves a multi-pronged approach:

- Precise Air-Fuel Ratio Control: Using oxygen sensors and advanced control systems to maintain the optimal air-fuel ratio for complete combustion, minimizing unburnt fuel.

- Regular Maintenance: Clean burners, inspect for leaks, and maintain proper draft to ensure efficient heat transfer. A dirty burner will require excess fuel to achieve the desired heat output.

- Insulation and Heat Recovery: Minimizing heat loss through proper insulation of boiler components and implementing heat recovery systems to recapture waste heat. This significantly reduces fuel demand.

- Boiler Tuning and Optimization: Regular performance testing and adjustments to optimize operating parameters based on load demands. This might involve adjusting burner flame patterns or steam pressure setpoints.

- Load Management: Matching boiler output to actual demand. Avoiding unnecessary high-load operation saves substantial fuel.

Imagine a situation where a boiler’s insulation is compromised. This leads to increased heat loss, necessitating more fuel to achieve the target temperature, resulting in higher operating costs and reduced efficiency.

Q 17. What are the different types of boiler systems?

Boiler systems are categorized based on several factors, including fuel type, operating pressure, and design. Some common types include:

- Fire-Tube Boilers: Hot gases pass through tubes surrounded by water.

- Water-Tube Boilers: Water passes through tubes surrounded by hot gases (more common in large-scale applications).

- Packaged Boilers: Pre-assembled units, often gas-fired and suitable for smaller applications.

- Firetube Boilers (Horizontal Return Tubular): Commonly used in smaller industrial and commercial settings, this design features hot gases passing through tubes within a larger water-filled shell.

- Water-Tube Boilers (Babcock & Wilcox): A widely used design in power generation, featuring water circulating through tubes exposed to hot gases.

The choice of boiler system depends heavily on factors such as required steam capacity, fuel type, space constraints, and budget. For example, a large power plant would utilize a water-tube boiler because of its high steam production capacity, while a small factory might use a packaged fire-tube boiler for its ease of installation and cost-effectiveness.

Q 18. How do you handle emergency situations during boiler operation?

Emergency situations require swift and decisive action. A structured approach is key:

- Identify the Emergency: Determine the nature and severity of the problem (e.g., low water level, flame failure, high pressure).

- Activate Emergency Procedures: Follow established protocols, including shutting down affected systems safely and alerting relevant personnel.

- Isolate the Problem: If possible, isolate the affected component to prevent further damage or escalation.

- Safety First: Prioritize the safety of personnel and equipment. Evacuate the area if necessary.

- Damage Assessment and Repair: Once the emergency is under control, conduct a thorough assessment of the damage and initiate repairs, possibly involving external experts.

- Root Cause Analysis: Investigate the root cause of the emergency to prevent recurrence. This often involves reviewing operational logs, conducting inspections, and analyzing data.

For instance, if a low-water level alarm sounds, we’d immediately shut down the boiler, investigate the cause (leak, pump failure, etc.), and refill the boiler before restarting—following established safety procedures throughout.

Q 19. What are the common causes of boiler scale buildup?

Boiler scale buildup is primarily caused by the precipitation of dissolved minerals in the boiler water as it is heated and evaporated. Common culprits include:

- Hardness Minerals: Calcium and magnesium salts, present in untreated water, form hard scale deposits on heat transfer surfaces.

- Silica: Dissolves in water and deposits as hard, glassy scale at high temperatures.

- Iron Oxide: Can form scale from corrosion of internal boiler components.

Imagine the effect of hard water in a kettle—the same principle applies to boilers, but on a much larger scale and with more severe consequences. The scale reduces heat transfer efficiency, leading to increased fuel consumption and potential overheating, and even equipment failure.

Q 20. Describe the measures you take to prevent boiler corrosion.

Preventing boiler corrosion is crucial for longevity and safety. Strategies include:

- Water Treatment: Employing chemical treatments (oxygen scavengers, pH control agents) to neutralize corrosive elements in the boiler water.

- Material Selection: Utilizing corrosion-resistant materials for boiler construction (e.g., stainless steel, special alloys).

- Regular Inspection and Maintenance: Conducting periodic inspections to detect and address early signs of corrosion.

- Proper Boiler Operation: Maintaining optimal water chemistry, avoiding overheating, and ensuring proper venting to minimize oxygen ingress.

- Deaeration: Removing dissolved oxygen from the feedwater to prevent oxygen-based corrosion.

For example, regularly monitoring the pH of the boiler water is critical. A low pH can lead to acidic corrosion, while a high pH can cause caustic corrosion. Maintaining the pH within the optimal range is essential for corrosion prevention.

Q 21. What is your experience with boiler water treatment?

I have extensive experience in boiler water treatment, encompassing various aspects such as:

- Water Analysis: Regularly analyzing boiler water samples to monitor key parameters like pH, dissolved solids, conductivity, and oxygen content.

- Chemical Treatment: Selecting and applying appropriate chemical treatments to control scale formation, corrosion, and microbiological growth.

- Blowdown Management: Implementing proper blowdown procedures to remove impurities and maintain water quality.

- Treatment System Operation and Maintenance: Overseeing the operation and maintenance of water treatment systems, including filters, softeners, and chemical injection systems.

- Troubleshooting Water Quality Issues: Diagnosing and resolving issues related to boiler water quality, such as scale buildup or corrosion.

In a previous role, I successfully resolved a recurring issue of boiler scale formation by optimizing the chemical treatment program and implementing a more effective blowdown strategy. This resulted in improved boiler efficiency and reduced maintenance costs.

Q 22. How do you interpret boiler performance data?

Interpreting boiler performance data involves analyzing key parameters to assess efficiency, identify potential issues, and optimize operation. This typically involves examining data from various instruments and gauges, comparing it to historical data and manufacturer specifications, and applying a methodical approach to interpretation.

Efficiency Parameters: We look at parameters like thermal efficiency (heat output vs. fuel input), combustion efficiency (how completely the fuel burns), and steam quality (dryness fraction of the steam). A lower-than-expected thermal efficiency, for example, might indicate scaling in the boiler tubes or inefficient burner operation.

Operational Parameters: Monitoring parameters such as steam pressure, feedwater temperature and flow rate, fuel consumption, and flue gas temperature helps assess the boiler’s load and stability. Sudden pressure fluctuations might point to issues in the feedwater system or a control valve malfunction.

Safety Parameters: Data from safety devices, such as pressure relief valves, low water fuel cut-off systems, and flame detectors, are crucial for ensuring safe operation. Frequent activation of safety devices warrants investigation and may indicate a serious problem.

Example: If we observe a consistent drop in thermal efficiency coupled with increased fuel consumption and higher flue gas temperatures, we might suspect fouling or scaling within the boiler tubes, necessitating cleaning or chemical treatment.

Q 23. Describe your experience with boiler automation systems.

My experience with boiler automation systems spans various platforms, from basic Programmable Logic Controllers (PLCs) to sophisticated Distributed Control Systems (DCS). I’m proficient in configuring, programming, and troubleshooting these systems. This includes experience with:

PLC Programming: I’ve used various PLC platforms (e.g., Allen-Bradley, Siemens) to automate functions like fuel control, feedwater regulation, and safety interlocks. For example, I’ve implemented logic to automatically adjust the fuel input based on steam demand, ensuring efficient and stable operation.

DCS Integration: I’ve worked with DCS systems to monitor and control multiple boilers within a plant, optimizing overall steam production and energy efficiency. These systems allow for centralized monitoring and control, improving responsiveness and reducing manual intervention.

SCADA Systems: I’m familiar with Supervisory Control and Data Acquisition (SCADA) systems for remote monitoring and control, providing real-time data visualization and alarm management capabilities. This is crucial for maintaining continuous oversight, even from a remote location.

In one project, I successfully migrated an older PLC-based system to a modern DCS, significantly enhancing the boiler’s control and monitoring capabilities, resulting in improved efficiency and reduced downtime.

Q 24. Explain the use of different boiler instruments and gauges.

Boiler instruments and gauges are essential for monitoring critical parameters and ensuring safe and efficient operation. They provide real-time data on various aspects of the boiler’s performance.

Pressure Gauges: Indicate steam pressure and water pressure, crucial for maintaining safe operating parameters and preventing overpressure.

Temperature Gauges: Measure feedwater temperature, steam temperature, and flue gas temperature, providing insights into heat transfer efficiency and combustion.

Flow Meters: Monitor feedwater flow rate, fuel flow rate, and air flow rate, ensuring proper fuel-air ratio and preventing operational issues.

Level Indicators: Indicate water level in the boiler drum, preventing low-water conditions which can lead to severe damage.

Safety Valves: Pressure relief valves that automatically open to prevent overpressure, protecting the boiler from catastrophic failure. Their proper functioning is critical.

Oxygen Analyzers: Measure oxygen content in flue gases, indicating combustion efficiency. High oxygen levels suggest inefficient combustion.

Example: A sudden drop in water level as indicated by the level indicator, coupled with a high steam pressure reading, might indicate a leak in the boiler or a problem with the feedwater pump, requiring immediate attention.

Q 25. How do you ensure compliance with boiler safety regulations?

Ensuring compliance with boiler safety regulations is paramount. This requires a multi-faceted approach encompassing regular inspections, maintenance, operator training, and meticulous record-keeping.

Regular Inspections: Conducting regular inspections in accordance with local codes and regulations (e.g., ASME Boiler and Pressure Vessel Code) is critical to identify potential hazards and prevent accidents.

Preventative Maintenance: Implementing a robust preventative maintenance program ensures that all safety-critical components are in good working order. This includes regular checks of safety valves, pressure gauges, and other critical instrumentation.

Operator Training: Thoroughly training operators on safe operating procedures, emergency response protocols, and regulatory compliance is essential for preventing accidents. Operators should be able to recognize and respond to abnormal situations effectively.

Documentation: Meticulous record-keeping, including inspection reports, maintenance logs, and operator training records, is essential for demonstrating compliance during audits.

Example: We ensure all our safety valves are regularly tested and certified to meet regulatory requirements, with the test results properly documented and filed.

Q 26. Describe your experience with boiler maintenance and repair procedures.

My experience encompasses all aspects of boiler maintenance and repair, from routine inspections to major overhauls. I am familiar with various boiler types and their specific maintenance requirements.

Routine Maintenance: This includes cleaning boiler tubes, inspecting and repairing refractory linings, checking and cleaning burner components, and lubricating moving parts. Regular cleaning of the boiler tubes helps maintain optimal heat transfer and prevents efficiency loss.

Major Overhauls: I have participated in major overhauls, involving dismantling and inspecting internal components, replacing worn-out parts, and performing pressure testing to ensure the boiler’s integrity. This typically involves careful planning and coordination to minimize downtime.

Troubleshooting and Repair: I have successfully diagnosed and repaired a variety of boiler issues, ranging from minor leaks to complex combustion problems. For example, I once diagnosed a recurring burner flame instability issue by carefully analyzing combustion parameters and ultimately replacing a faulty igniter.

I am also proficient in using various diagnostic tools, such as thermal cameras and gas analyzers, to identify potential problems early and prevent major breakdowns.

Q 27. What are your troubleshooting skills related to boiler issues?

My troubleshooting skills are based on a systematic approach involving careful observation, data analysis, and methodical elimination of potential causes. This often involves a combination of theoretical knowledge and practical experience.

Data Analysis: I analyze data from various instruments and gauges to identify deviations from normal operating parameters. For instance, a sudden increase in flue gas temperature coupled with decreased steam pressure might point to a problem with the feedwater pump or a leak in the steam system.

Systematic Approach: I use a structured troubleshooting methodology to systematically eliminate potential causes. This might involve checking each component in a specific sequence or using diagnostic tools to pinpoint the problem.

Root Cause Analysis: I am skilled in performing root cause analysis to identify the underlying cause of a problem and prevent its recurrence. This often involves examining historical data, maintenance records, and operator logs.

Example: In one instance, a boiler experienced repeated trips due to low water level alarms. By analyzing the data and performing a thorough inspection, I discovered a leak in the feedwater piping, a problem that had been overlooked during previous inspections.

Q 28. How do you ensure efficient and safe boiler operations?

Ensuring efficient and safe boiler operations requires a holistic approach incorporating proper maintenance, operator training, and adherence to safety regulations. It’s about balancing performance with safety.

Preventative Maintenance: A robust preventative maintenance program is fundamental to prevent unexpected breakdowns and ensure long-term efficiency. This involves regular inspections, cleaning, and repairs.

Operator Training: Properly trained operators are crucial for safe and efficient operation. Training should cover all aspects of boiler operation, maintenance, and emergency procedures.

Data Monitoring and Analysis: Continuously monitoring key performance indicators (KPIs) and analyzing the data helps identify trends, anticipate potential problems, and optimize performance.

Compliance with Regulations: Adhering strictly to all relevant safety regulations and codes is non-negotiable. This includes regular inspections and certifications.

Emergency Preparedness: Having a well-defined emergency response plan in place is crucial for handling unexpected situations, minimizing potential damage and ensuring the safety of personnel.

In essence, it’s about creating a culture of safety and efficiency, where everyone understands their responsibilities and works together to maintain optimal boiler performance while adhering to the highest safety standards.

Key Topics to Learn for Boiler Start-up and Shutdown Interview

- Pre-Start-up Checks and Inspections: Understanding the importance of thorough pre-start checks, including water level, pressure testing, fuel supply verification, and safety system functionality. Practical application: Describe your experience in conducting these checks and identifying potential issues.

- Start-up Procedures: Mastering the sequential steps involved in safely initiating boiler operation, including burner ignition, flame stabilization, pressure build-up, and monitoring critical parameters. Practical application: Detail your experience following specific start-up procedures for different boiler types and sizes.

- Operational Monitoring and Control: Understanding the critical parameters to monitor during boiler operation (pressure, temperature, water level, fuel flow, etc.) and the actions required to maintain optimal performance and efficiency. Practical application: Explain your experience troubleshooting minor operational issues and adjusting parameters to meet desired output.

- Shutdown Procedures: Knowing the safe and efficient steps for shutting down a boiler, including the proper sequencing of actions to prevent damage and ensure safety. Practical application: Describe your experience performing safe shutdowns under various circumstances (planned maintenance, emergency situations).

- Safety Protocols and Emergency Procedures: Demonstrating a thorough understanding of safety regulations, emergency shutdown procedures, and the actions to take in case of malfunctions or accidents. Practical application: Explain how you have prioritized safety in your past roles and followed established protocols.

- Troubleshooting and Problem Solving: Developing the ability to identify, analyze, and resolve common boiler operation problems, demonstrating a practical understanding of the system’s mechanics and limitations. Practical application: Describe a situation where you successfully troubleshooted a boiler issue, outlining your problem-solving approach.

- Boiler Types and Variations: Understanding the differences between various boiler types (e.g., fire-tube, water-tube, etc.) and their specific start-up and shutdown requirements. Practical application: Describe experience working with different boiler types and how their operational procedures vary.

Next Steps

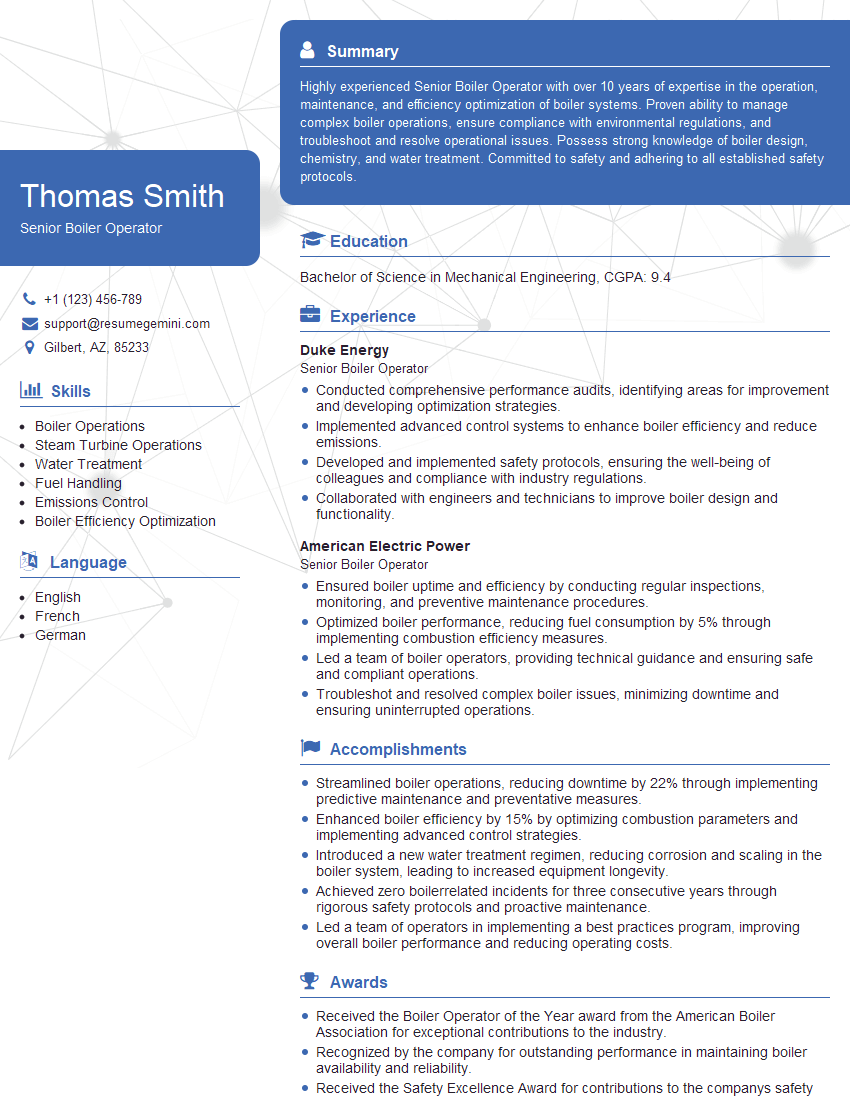

Mastering boiler start-up and shutdown procedures is crucial for career advancement in power generation, industrial settings, and related fields. It demonstrates your technical expertise, problem-solving abilities, and commitment to safety. To significantly improve your job prospects, create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource for building professional and impactful resumes. We provide examples of resumes tailored to the Boiler Start-up and Shutdown field, helping you showcase your qualifications to potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Live Rent Free!

https://bit.ly/LiveRentFREE

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?