Are you ready to stand out in your next interview? Understanding and preparing for Boiler Tools Techniques interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Boiler Tools Techniques Interview

Q 1. Describe your experience with different types of boiler tools.

My experience encompasses a wide range of boiler tools, from fundamental cleaning equipment to sophisticated diagnostic instruments. This includes:

- Mechanical Cleaning Tools: I’m proficient in using various types of tube cleaners, including rotary brushes, air-driven cleaners, and hand-held scrapers for removing scale and deposits from boiler tubes. I understand the importance of selecting the appropriate tool for different tube sizes and deposit types.

- Chemical Cleaning Tools: I have extensive experience in applying and managing chemical cleaning solutions, including selecting appropriate chemicals based on the type of deposit and boiler material. This includes proper safety precautions during chemical handling and disposal.

- Inspection Tools: My expertise extends to using advanced inspection tools such as borescopes, ultrasonic thickness gauges, and eddy current testers to assess the condition of boiler tubes, drums, and other components. This allows for proactive maintenance and prevents catastrophic failures.

- Instrumentation and Monitoring Tools: I’m adept at using various pressure gauges, thermometers, and water level indicators for monitoring boiler operation and identifying potential problems. Furthermore, I have experience using data acquisition systems to monitor boiler parameters and analyze trends.

For instance, I once had to deal with a particularly stubborn scale buildup in a high-pressure boiler. Using a combination of air-driven rotary brushes and a specialized chemical cleaning agent, I successfully removed the scale without damaging the tubes, ensuring the boiler’s continued safe and efficient operation.

Q 2. Explain the process of boiler tube cleaning.

Boiler tube cleaning is a critical process for maintaining boiler efficiency and preventing failures. The process generally involves these steps:

- Preparation: The boiler must be safely shut down and depressurized. Appropriate safety procedures, including lockout/tagout, must be strictly adhered to.

- Access: Access to the boiler tubes is gained, often requiring the removal of manholes or handholes. The area must be properly ventilated.

- Cleaning Method Selection: The appropriate cleaning method is chosen depending on the type of deposit (scale, sludge, etc.) and the tube material. Methods can include mechanical cleaning (e.g., using brushes, scrapers), chemical cleaning (using acids or other solvents), or a combination of both.

- Cleaning Execution: The selected method is carefully executed, ensuring thorough cleaning of all tubes. Regular inspection is vital to monitor progress and avoid damage to the tubes.

- Inspection: After cleaning, a thorough inspection is performed to ensure all deposits have been removed and that the tubes are not damaged. Tools like borescopes may be used for visual inspection.

- Rinsing and Drying: After mechanical cleaning, the tubes are thoroughly rinsed to remove any residual cleaning agents. The boiler is then dried before recommissioning.

- Reassembly: The boiler is reassembled, and all safety checks are performed before restarting the system.

Think of it like cleaning a clogged artery – failure to remove the buildup leads to decreased performance and potential catastrophe.

Q 3. What safety precautions are necessary when working with boiler tools?

Safety is paramount when working with boiler tools. Precautions include:

- Lockout/Tagout Procedures: Always follow strict lockout/tagout procedures to prevent accidental energization of the boiler system during maintenance.

- Personal Protective Equipment (PPE): Wear appropriate PPE, including safety glasses, gloves, respirators, and hearing protection. The specific PPE will depend on the task and the tools being used.

- Confined Space Entry Procedures: If working in confined spaces (e.g., inside the boiler drum), follow strict confined space entry procedures, including atmospheric monitoring and rescue plans.

- Hot Work Permits: If performing hot work (e.g., welding), obtain the necessary hot work permits and follow all safety guidelines.

- Chemical Handling Safety: When using chemical cleaning agents, follow the manufacturer’s safety data sheets (SDS) and wear appropriate PPE to prevent skin and respiratory irritation or burns.

- Proper Tool Usage: Always use tools correctly and avoid force that may damage the boiler components.

Ignoring these precautions can lead to serious injury or even fatalities. Safety is not just a guideline; it’s a non-negotiable requirement.

Q 4. How do you identify and troubleshoot common boiler problems?

Identifying and troubleshooting common boiler problems requires a systematic approach. I typically use a combination of visual inspection, data analysis, and diagnostic tools. Common problems include:

- Scale Buildup: Detected through reduced efficiency, overheating, or pressure drops. Solution involves chemical or mechanical cleaning.

- Tube Leaks: Identified through visual inspection, pressure testing, or leak detection dyes. Repair involves patching or tube replacement.

- Water Level Issues: Detected through low or high water levels. Causes may include feedwater pump failures or valve malfunctions. Solutions involve addressing the root cause of the issue.

- Corrosion: Detected through visual inspection and metallurgical testing. Solutions may involve chemical treatment of the water or replacement of corroded components.

- Burner Malfunctions: Identified through incomplete combustion, low flame, or unusual noise. Requires checking fuel supply, ignition system, and burner components.

For example, I once encountered a boiler with unexpectedly low steam production. Through systematic analysis of pressure and temperature data, coupled with a visual inspection, I determined that the problem was due to significant scale buildup within the tubes. Implementing a chemical cleaning procedure resolved the issue, restoring the boiler’s efficiency.

Q 5. Describe your experience with boiler inspection and maintenance.

My experience with boiler inspection and maintenance is extensive. It involves regular inspections to detect potential problems early on, as well as planned maintenance to prevent failures. This includes:

- Visual Inspection: Regular visual inspection of the boiler, piping, and associated equipment for signs of wear, corrosion, leaks, or damage.

- Non-Destructive Testing (NDT): Performing NDT methods such as ultrasonic testing or radiographic testing to assess the integrity of boiler tubes and other components.

- Pressure Testing: Conducting pressure tests to identify leaks or weaknesses in the boiler system.

- Water Analysis: Regular analysis of boiler water chemistry to monitor water quality and prevent scale formation or corrosion.

- Scheduled Maintenance: Performing scheduled maintenance tasks, such as cleaning, lubrication, and component replacement, based on manufacturer’s recommendations.

I follow a preventive maintenance schedule to minimize downtime and ensure safe, efficient boiler operation. A well-maintained boiler is not just cost-effective but also crucial for ensuring worker safety and minimizing environmental impact.

Q 6. What are the different types of boiler feedwater systems?

Different types of boiler feedwater systems are designed to deliver treated water to the boiler at the required pressure and temperature. Common types include:

- Direct-Contact Feedwater Heaters: These systems heat the feedwater using steam directly in a mixing chamber. They are simple but less efficient than other types.

- Surface-Contact Feedwater Heaters: These systems use heat exchangers to transfer heat from steam to feedwater without direct contact. This type is more efficient and minimizes contamination risks.

- Deaerating Feedwater Heaters: These heaters remove dissolved gases (oxygen and carbon dioxide) from the feedwater before it enters the boiler, preventing corrosion.

- Closed-Loop Feedwater Systems: These systems recycle condensate back to the boiler, reducing the amount of makeup water needed and improving efficiency.

- Open-Loop Feedwater Systems: These systems use makeup water directly from a source, requiring more extensive water treatment.

The choice of system depends on factors such as boiler size, capacity, water quality, and overall efficiency requirements.

Q 7. Explain the function of boiler safety valves.

Boiler safety valves are crucial safety devices that protect the boiler from overpressure. If the boiler pressure exceeds a predetermined limit, the safety valve automatically opens, releasing steam to reduce pressure and prevent a potentially catastrophic explosion. Key functions include:

- Pressure Relief: The primary function is to rapidly release steam when the boiler pressure exceeds the set pressure, preventing dangerous overpressure.

- Safety Protection: They act as a final safety barrier against boiler explosions, protecting personnel and equipment.

- Pressure Control: While not their primary function, they help maintain boiler pressure within safe operating limits.

Regular testing and maintenance of safety valves are crucial to ensure they function correctly in an emergency. Think of them as the boiler’s emergency escape hatch – ensuring it’s properly maintained is vital for preventing a disastrous situation.

Q 8. How do you maintain boiler water chemistry?

Maintaining boiler water chemistry is crucial for preventing scale buildup, corrosion, and other issues that can lead to boiler failure. It involves regularly monitoring and adjusting the chemical composition of the water within the boiler to optimal levels. This is achieved through a multi-pronged approach:

Regular Testing: We use test kits to monitor key parameters such as pH, alkalinity, conductivity, and dissolved oxygen. These tests help us identify potential problems early on. For example, low alkalinity can lead to corrosion, while high alkalinity can contribute to scale formation.

Chemical Treatment: Based on the test results, we add chemicals like oxygen scavengers (to remove corrosive oxygen), phosphates (to prevent scale), and other treatments as needed to maintain the water chemistry within the manufacturer’s recommended range. The specific chemicals and their dosages depend on the boiler type and water source. I’ve had experience working with both high-pressure and low-pressure boilers, each requiring a slightly different approach.

Blowdown: Regular blowdown is essential to remove accumulated solids and contaminants. This process is described in more detail in a later answer.

Water Treatment: Pretreatment of the feedwater is crucial. This often involves filtration and softening to remove impurities before they enter the boiler. In one instance, we implemented a pre-treatment system that drastically reduced scale formation and extended the boiler’s lifespan.

Proper water chemistry management is not just about following a procedure; it’s about understanding the underlying chemistry and its impact on the boiler’s operation. It requires a proactive approach with regular monitoring and adjustments to ensure optimal performance and longevity.

Q 9. What is your experience with boiler combustion controls?

My experience with boiler combustion controls spans several years, encompassing both analog and digital systems. I am proficient in troubleshooting and maintaining various control systems, ensuring optimal combustion efficiency and safety. This includes understanding and adjusting parameters like air-fuel ratio, oxygen levels, and flue gas temperature.

For example, I once worked on a boiler experiencing fluctuating flame stability. Through careful analysis of the combustion control system data, I identified a malfunctioning air flow sensor. Replacing the sensor resolved the issue, significantly improving combustion efficiency and reducing fuel consumption.

My expertise extends to preventative maintenance, including calibrating sensors, inspecting safety interlocks, and performing routine checks to ensure the system operates within safe and efficient parameters. I’m familiar with various control strategies, including PID control, and understand how to optimize these systems for specific boiler types and fuel sources. A strong understanding of combustion principles is crucial in this role, as it allows for fine-tuning the system to minimize emissions and maximize efficiency.

Q 10. How do you perform a boiler blowdown?

A boiler blowdown is a critical process that removes dissolved and suspended solids, along with other impurities, from the boiler water. This prevents scale formation, corrosion, and maintains optimal boiler water chemistry. It’s like regularly cleaning a teapot to prevent sediment buildup.

The process typically involves:

Identifying the Blowdown Valves: Locate the surface blowdown and bottom blowdown valves. Surface blowdown removes surface impurities, while bottom blowdown removes sediment.

Opening the Valves: Open the appropriate valve slowly and carefully to prevent sudden pressure drops or water hammer. This is crucial to prevent damage to the boiler system.

Monitoring the Blowdown: Observe the blowdown process to ensure impurities are being removed effectively. The blowdown water should initially be cloudy and then become clearer.

Closing the Valves: Once the water is clear, slowly close the blowdown valve.

The frequency of blowdown depends on various factors, including boiler operating pressure, water quality, and the type of boiler. I’ve developed a schedule based on continuous monitoring of water chemistry which has significantly improved our boiler’s efficiency and longevity.

Q 11. Describe your experience with boiler welding and fabrication.

My experience in boiler welding and fabrication is extensive, covering various welding processes such as shielded metal arc welding (SMAW), gas metal arc welding (GMAW), and gas tungsten arc welding (GTAW). I’m proficient in working with different boiler materials like carbon steel, stainless steel, and various alloys.

Safety is paramount in this field, and I adhere strictly to all safety protocols, including proper personal protective equipment (PPE) and safety procedures. I have a deep understanding of weld quality inspection techniques, including visual inspection, non-destructive testing (NDT), and other methods to ensure the structural integrity of the repairs and fabrications.

I’ve been involved in various projects, from minor repairs to significant modifications, always prioritizing safety and code compliance. One project I’m particularly proud of involved repairing a section of a high-pressure boiler that had sustained significant damage due to corrosion. The repair required meticulous welding techniques and extensive post-weld inspection to ensure the structural integrity of the boiler. We successfully completed the repair without any safety incidents and the boiler has been operating efficiently ever since.

Q 12. What is your experience with different types of boiler fuels?

My experience encompasses various boiler fuels, including natural gas, fuel oil (both light and heavy), and biomass. Each fuel type presents unique challenges and requires a different approach to combustion control and safety.

Natural gas, for instance, requires precise air-fuel ratio control for optimal efficiency and minimal emissions. Fuel oil, on the other hand, necessitates careful handling and storage due to its flammability and potential for contamination. Biomass fuel presents its own set of challenges, including managing ash content and ensuring consistent fuel quality.

I understand the specific requirements for each fuel type, including appropriate burner adjustments, emission control strategies, and safety protocols. This experience allows me to adapt to different situations and optimize boiler operation for diverse fuel sources, maximizing efficiency and minimizing environmental impact. My experience with these different fuels also extended to the necessary safety protocols and regulations associated with their handling and storage.

Q 13. How do you handle boiler emergencies?

Handling boiler emergencies requires a calm, methodical approach. My training emphasizes prioritizing safety and mitigating potential damage. The first step is always to secure the area and ensure the safety of personnel. This often involves shutting down the boiler or isolating the affected section, depending on the nature of the emergency.

Next, I would assess the situation to identify the cause of the emergency. This might involve checking pressure gauges, temperature indicators, and safety systems. Depending on the specific situation, this might entail inspecting for leaks, checking fuel supply, or investigating any unusual sounds or vibrations. I have experience handling various boiler emergencies, including low water level alarms, pressure surges, and fuel supply interruptions.

Once the cause is identified, I would implement the appropriate corrective actions, which could include restoring fuel supply, repairing leaks, or adjusting system parameters. A thorough investigation following the emergency is also critical to determining root causes and implementing preventative measures to avoid similar occurrences in the future. Documentation is essential for tracking these events and learning from them.

Q 14. Explain the process of boiler start-up and shutdown.

The boiler start-up and shutdown procedures are crucial for safety and equipment longevity. These processes are highly dependent on the boiler type and design. However, some general principles apply:

Start-up: This typically involves pre-operational checks such as inspecting fuel lines, checking water levels, and verifying the functionality of safety systems. Next, the ignition sequence is initiated, and the burner is lit. The boiler gradually heats up, and water pressure is increased slowly while carefully monitoring temperatures and pressures. During start-up, it is crucial to observe the boiler for any unusual behavior or sounds.

Shutdown: The shutdown procedure is equally important and typically involves gradually reducing the fuel supply, and allowing the boiler to cool down at a controlled rate. The process also includes lowering the pressure in a controlled manner and checking all parameters before deeming the boiler fully shut down. This ensures that the boiler cools down evenly to prevent thermal shock, which could damage the system.

Detailed procedures are usually provided by the boiler manufacturer and must be strictly followed. It is vital to perform regular maintenance and inspections to ensure safe and efficient boiler operation. This includes regular cleaning, inspections of critical components, and calibrations of instrumentation. I always prioritize thorough documentation and adherence to safety protocols during both start-up and shutdown processes.

Q 15. Describe your experience with boiler pressure testing.

Boiler pressure testing is a crucial safety procedure ensuring the integrity of the boiler system. It involves pressurizing the boiler beyond its normal operating pressure with water or air (depending on the boiler type and testing requirements) to identify any leaks or weaknesses in the pressure vessels, tubes, welds, or fittings. I have extensive experience conducting these tests, adhering strictly to safety protocols and relevant codes such as ASME Section I.

My process involves a careful pre-test inspection, isolating the boiler from the system, and then slowly increasing the pressure while monitoring it with calibrated pressure gauges. I meticulously document all readings, noting any unusual sounds or pressure drops. Post-test, a thorough visual inspection is done to identify any visible leaks or defects. I’ve worked on various boiler types, from small industrial units to large power plant boilers, and successfully identified several potential failure points during pressure tests, preventing costly repairs and potential accidents.

For example, during a pressure test on a fire-tube boiler, we detected a small leak in a weld near the rear tube sheet. This was successfully repaired before the boiler was returned to service, preventing a potentially hazardous rupture later on. The documentation from the pressure test is critical for insurance purposes and demonstrates our commitment to safety.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is your experience with boiler automation systems?

My experience with boiler automation systems spans several years and various technologies. I’m proficient in understanding and working with programmable logic controllers (PLCs), supervisory control and data acquisition (SCADA) systems, and distributed control systems (DCS) commonly used in modern boiler plants. I’ve worked with systems from various manufacturers, including Siemens, Allen-Bradley, and Schneider Electric.

My work involves troubleshooting automation issues, programming PLC logic for optimal boiler control, configuring SCADA interfaces for monitoring and controlling various boiler parameters (like pressure, temperature, fuel flow), and integrating different automation systems to ensure seamless operation. I understand the importance of safety interlocks and alarm systems within the automation setup to prevent malfunctions and ensure safe operation.

For instance, I once helped optimize the fuel-air ratio control logic on a large industrial boiler using a PLC. By fine-tuning the PID control parameters, we achieved a significant reduction in fuel consumption and improved boiler efficiency. The system also included an automatic safety shutdown function if any parameter deviated beyond acceptable limits.

Q 17. How do you interpret boiler instrument readings?

Interpreting boiler instrument readings is paramount for efficient and safe boiler operation. I’m experienced in reading and interpreting data from a wide range of instruments, including pressure gauges, temperature sensors (thermocouples, RTDs), flow meters, level indicators, and flue gas analyzers. My understanding includes the principles of operation for each type of instrument and how the readings correlate with boiler performance.

I understand how pressure gauges indicate steam pressure, temperature sensors show water and steam temperatures, flow meters measure feedwater and fuel flows, and level indicators show the water level in the boiler drum. Flue gas analyzers provide insights into combustion efficiency by measuring the concentration of oxygen (O2), carbon monoxide (CO), carbon dioxide (CO2), and other gases. Deviation from normal operating ranges indicates potential problems, like insufficient fuel, scaling, or combustion issues.

For example, a high CO reading in flue gas indicates incomplete combustion, suggesting a need for adjustment of the air-fuel ratio. Similarly, a low water level could indicate a problem with the feedwater pump, necessitating prompt attention. My ability to interpret these readings allows for proactive maintenance and prevents costly downtime or safety incidents.

Q 18. What are the common causes of boiler scaling and how do you prevent them?

Boiler scaling is a common problem caused by the deposition of mineral salts from the feedwater onto the boiler’s internal surfaces. These deposits reduce heat transfer efficiency, leading to decreased boiler efficiency, increased fuel consumption, and potentially overheating or tube failure. The primary causes include high water hardness (presence of dissolved calcium and magnesium salts) and high water alkalinity.

Prevention involves several strategies: First, using pretreatments like water softening or reverse osmosis to reduce the hardness and alkalinity of the feedwater is vital. Second, regular chemical cleaning of the boiler using specialized descaling chemicals removes existing scale. Third, monitoring water quality through regular water testing helps identify and rectify issues promptly. Finally, operating the boiler within its designed parameters and maintaining consistent water chemistry helps prevent excessive scaling.

We employ a combination of these strategies. We use water softeners in many facilities to control hardness. In some cases, where feedwater quality is particularly challenging, we integrate a sophisticated water treatment system involving a multi-stage process to achieve optimal water purity before it enters the boiler. Regular monitoring and timely interventions avoid costly repairs and ensure consistent boiler performance.

Q 19. Describe your experience with boiler refractory repair.

Boiler refractory repair is crucial for maintaining the integrity and efficiency of the boiler furnace. Refractory materials, resistant to high temperatures, line the furnace walls and protect them from the intense heat. Damage to the refractory can lead to heat loss, reduced efficiency, and even structural failure. My experience covers various repair techniques, from minor patching to major rebuilds.

I’m skilled in identifying the cause of refractory damage, which can range from thermal shock, erosion, spalling, or chemical attack. The repair process typically involves careful removal of damaged sections, cleaning the area, and applying new refractory material, followed by curing to ensure proper setting. I use specialized tools and techniques, ensuring the repaired area matches the original design and is properly insulated to maintain efficient heat transfer.

In one instance, I successfully repaired significant damage caused by a localized thermal shock in a large industrial boiler’s furnace wall. This repair prevented a much more extensive and costly replacement of a substantial portion of the refractory lining, ultimately saving the client considerable expense and downtime.

Q 20. What is your experience with boiler insulation and lagging?

Boiler insulation and lagging are essential for minimizing heat loss and improving boiler efficiency. Insulation materials, like fiberglass, mineral wool, or calcium silicate, reduce heat transfer to the surroundings. Lagging, the outer protective layer, usually metal cladding, protects the insulation and improves its durability.

My experience involves selecting appropriate insulation materials based on temperature and environmental conditions, installing insulation and lagging according to best practices, ensuring proper coverage and minimal gaps, and inspecting for any damage or deterioration over time. Effective insulation significantly reduces energy waste and improves the overall safety of the boiler system.

For example, I recently oversaw the re-lagging of several steam pipes in a process plant. The improved insulation resulted in a measurable reduction in steam loss, leading to a tangible improvement in overall plant efficiency and cost savings for the client. Proper insulation and lagging are crucial for both energy efficiency and personnel safety, preventing burns from hot surfaces.

Q 21. Explain your understanding of boiler efficiency and optimization.

Boiler efficiency refers to the percentage of heat input that is effectively converted into useful steam output. Optimization involves identifying and implementing strategies to maximize this efficiency. Factors influencing boiler efficiency include complete combustion, proper air-fuel ratio, minimal heat loss through insulation and lagging, efficient heat transfer, and minimizing blowdown losses.

Optimization strategies include regular maintenance, optimizing combustion controls, implementing air preheating, regular chemical cleaning to remove scale, and monitoring key parameters like flue gas composition, water quality, and steam pressure. Advanced techniques involve the use of economizers, air heaters, and feedwater heaters to recover waste heat.

I once assisted in a project where we implemented a comprehensive optimization program for a large industrial boiler. This included upgrading the burner system, improving insulation, and optimizing the boiler controls. The result was a significant increase in boiler efficiency, reducing fuel consumption by 15% and resulting in substantial cost savings for the facility. Continuous monitoring and adjustments are key to maintaining optimized boiler efficiency over time.

Q 22. How do you ensure compliance with boiler safety regulations?

Ensuring boiler safety compliance involves a multi-faceted approach. It begins with understanding and meticulously following all relevant local, regional, and national regulations. This includes regular inspections, thorough documentation, and adherence to strict operating procedures. For example, we must ensure that pressure relief valves are regularly tested and functioning correctly, as this is crucial for preventing catastrophic boiler explosions. We also maintain detailed logs of all maintenance activities, inspections, and any repairs conducted, making these records readily available for auditing purposes. Further, we conduct regular training for all personnel involved in boiler operation and maintenance to refresh their knowledge of safety procedures and emergency protocols. Think of it like a pilot constantly undergoing flight simulator training to handle unexpected situations; proactive safety measures are paramount.

Beyond regulatory compliance, we also implement a robust preventative maintenance program. This involves scheduled inspections, cleaning, and testing of critical components, such as tubes, pressure vessels, and safety devices. Identifying potential issues early, before they escalate into major problems, is key to avoiding costly downtime and ensuring continuous, safe operation.

Q 23. Describe your experience with different types of boiler burners.

My experience encompasses a wide range of boiler burners, including:

- Gas Burners: I’m proficient in working with both atmospheric and forced draft gas burners, including those using natural gas, propane, and other fuel gases. Troubleshooting issues such as flame instability, incomplete combustion, and proper air-fuel mixture adjustment is routine. For instance, I once resolved a flame instability issue in a large industrial boiler by meticulously adjusting the gas pressure regulator and ensuring proper air intake.

- Oil Burners: I’m experienced with both atomizing and rotary cup oil burners. This includes understanding the intricacies of fuel oil viscosity, atomization pressure, and maintaining optimal combustion efficiency. I’m familiar with troubleshooting issues relating to nozzle clogging, improper atomization, and soot buildup.

- Combination Burners: I have worked with boilers capable of using multiple fuel sources – often gas and oil – giving flexibility in fuel choice based on availability and cost. This requires a detailed understanding of the switching systems and ensuring seamless transition between fuels.

Understanding the unique characteristics of each burner type, and how their design impacts combustion efficiency and emissions, is critical for ensuring optimal boiler performance and reducing operational costs.

Q 24. What is your experience with boiler water treatment chemicals?

My experience with boiler water treatment chemicals is extensive, covering various aspects including chemical selection, dosing, and monitoring. The goal is always to maintain optimal water chemistry to prevent scale formation, corrosion, and other water-related issues that can damage the boiler and reduce efficiency. This involves a deep understanding of water analysis and interpreting the results to determine the appropriate chemical treatment strategy.

I’m familiar with a range of chemicals, including:

- Oxygen Scavengers: Used to reduce dissolved oxygen in boiler water, preventing corrosion.

- Scale Inhibitors: Preventing the formation of mineral deposits (scale) on heat transfer surfaces.

- Corrosion Inhibitors: Protecting boiler metal from corrosive attack.

- pH Adjusters: Maintaining the water’s pH within the optimal range for preventing corrosion and scale.

For example, in one instance, we noticed increased corrosion rates in a boiler despite seemingly appropriate water treatment. By carefully analyzing the water chemistry and investigating operational parameters, we discovered a leak introducing oxygen into the system. Correcting this leak, in conjunction with adjusting the oxygen scavenger dosage, immediately solved the problem.

Q 25. How do you diagnose and repair boiler leaks?

Diagnosing and repairing boiler leaks requires a systematic approach. First, we need to pinpoint the exact location of the leak. This often involves visual inspection, using specialized tools like ultrasonic leak detectors to identify subtle leaks, especially in hard-to-reach areas. Once the leak is located, determining its cause is critical; it could be due to corrosion, erosion, or mechanical failure.

Repair methods vary depending on the severity and location of the leak. Minor leaks might be repairable through welding or patching, while more extensive damage might necessitate replacing sections of piping or other components. In some cases, we may employ specialized techniques such as brazing or using high-temperature sealant to make repairs.

The entire process emphasizes safety. Before starting any repair, we always isolate the affected section of the boiler and ensure the system is depressurized and cooled down to prevent further damage or injury. We document the repair process meticulously, including details of the leak, the repair method used, and any relevant observations.

Q 26. Explain the function of boiler economizers and air preheaters.

Boiler economizers and air preheaters are crucial components that enhance boiler efficiency and reduce fuel consumption. They both function by recovering waste heat that would otherwise be lost to the atmosphere, effectively preheating the feedwater (economizer) or combustion air (air preheater).

- Economizers: These devices preheat the boiler feedwater using the hot flue gases exiting the boiler. This reduces the amount of heat needed to raise the feedwater temperature to the desired level, improving overall thermal efficiency. Think of it as preheating the water before it even reaches the boiler, saving energy and fuel.

- Air Preheaters: These preheat the combustion air using the heat from the flue gases. By introducing hotter air into the combustion chamber, the combustion process becomes more efficient, leading to improved heat transfer and reduced fuel consumption. The hotter the air, the more complete the combustion process.

Both economizers and air preheaters are instrumental in modern boiler systems designed to maximize efficiency and minimize environmental impact. Their proper operation and maintenance are vital for optimal boiler performance.

Q 27. What is your experience with boiler control systems troubleshooting?

Troubleshooting boiler control systems involves a systematic approach that combines technical expertise with problem-solving skills. It starts with understanding the control system’s architecture, including sensors, actuators, and the control logic itself. The first step is always to identify the problem, often through careful observation, review of alarm logs, and analysis of operational data.

For instance, if we observe a boiler consistently failing to reach its set temperature, we might check the following:

- Sensor Readings: Are the temperature sensors providing accurate readings? A faulty sensor could lead to incorrect control signals.

- Actuator Function: Is the fuel valve responding correctly to the control signals? Is there a mechanical issue preventing proper fuel delivery?

- Control Logic: Are there any errors or glitches in the control program? This might require reviewing the control system’s programming and potentially making adjustments.

Advanced control systems often incorporate diagnostics tools that aid in troubleshooting. These tools can highlight potential issues, providing valuable insights into the problem’s root cause. Thorough documentation of the troubleshooting process and any changes implemented is crucial for future reference.

Q 28. Describe your experience with non-destructive testing methods for boilers.

Non-destructive testing (NDT) methods play a crucial role in ensuring the structural integrity of boilers. These techniques allow us to evaluate the condition of boiler components without causing damage. This is vital for identifying potential flaws, such as cracks, corrosion, or erosion, before they lead to catastrophic failures.

My experience includes using several NDT methods:

- Ultrasonic Testing (UT): This method uses high-frequency sound waves to detect internal flaws in metal components. It’s particularly useful for detecting cracks and other subsurface defects.

- Radiographic Testing (RT): This involves using X-rays or gamma rays to create images of the internal structure of boiler components. It’s effective for identifying flaws such as welds, corrosion, and other internal defects.

- Magnetic Particle Testing (MT): This is used to detect surface and near-surface cracks in ferromagnetic materials. A magnetic field is applied, and magnetic particles are used to visualize any discontinuities.

- Liquid Penetrant Testing (PT): This method is used to detect surface cracks in non-porous materials. A dye penetrant is applied, and excess is removed, revealing any surface cracks when a developer is applied.

The choice of NDT method depends on several factors, including the type of material, the expected type of defect, and the accessibility of the component. Regular NDT inspections are essential for ensuring the long-term safety and reliability of boilers.

Key Topics to Learn for Boiler Tools Techniques Interview

- Boiler System Components & Operation: Understanding the intricacies of boiler systems, including combustion processes, water treatment, and safety mechanisms. This includes knowledge of different boiler types and their applications.

- Troubleshooting and Diagnostics: Practical experience in identifying and resolving common boiler malfunctions, using diagnostic tools and techniques. This involves analyzing symptoms, identifying root causes, and implementing effective solutions.

- Boiler Maintenance and Repair: Knowledge of preventative maintenance procedures, routine inspections, and repair techniques for various boiler components. This includes understanding safety regulations and best practices.

- Safety Procedures and Regulations: A comprehensive understanding of relevant safety protocols, regulations, and best practices related to boiler operation and maintenance. This is crucial for ensuring a safe working environment.

- Instrumentation and Control Systems: Familiarity with the instrumentation and control systems used in boiler operations, including pressure gauges, temperature sensors, and automated control systems. Understanding how these systems work and how to interpret their readings is essential.

- Fuel Systems and Combustion Efficiency: Knowledge of different fuel types used in boilers (gas, oil, etc.) and optimizing combustion efficiency for optimal performance and reduced emissions. This includes understanding burner adjustments and efficiency calculations.

- Water Treatment and Chemistry: Understanding the importance of water treatment in preventing scaling and corrosion within the boiler system. This includes knowledge of various water treatment chemicals and techniques.

- Blueprint Reading and Technical Drawings: Ability to interpret boiler schematics, blueprints, and technical drawings to understand system layout and component specifications.

Next Steps

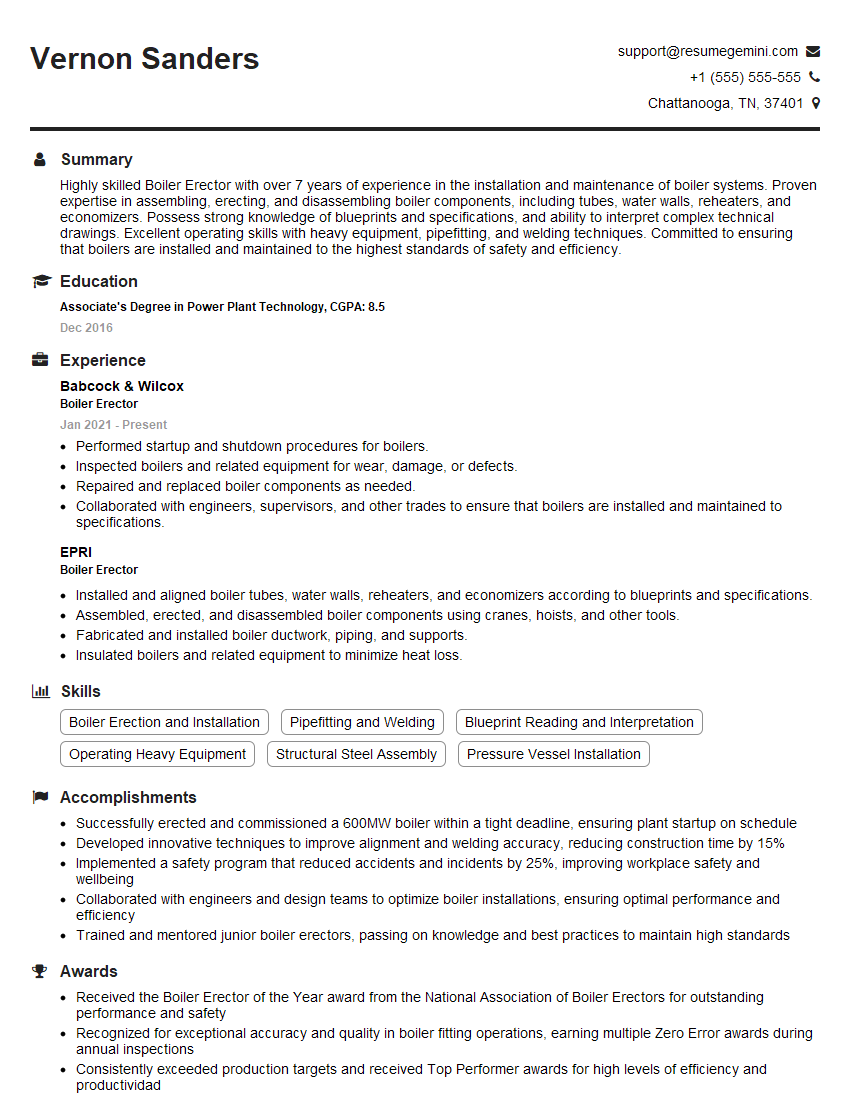

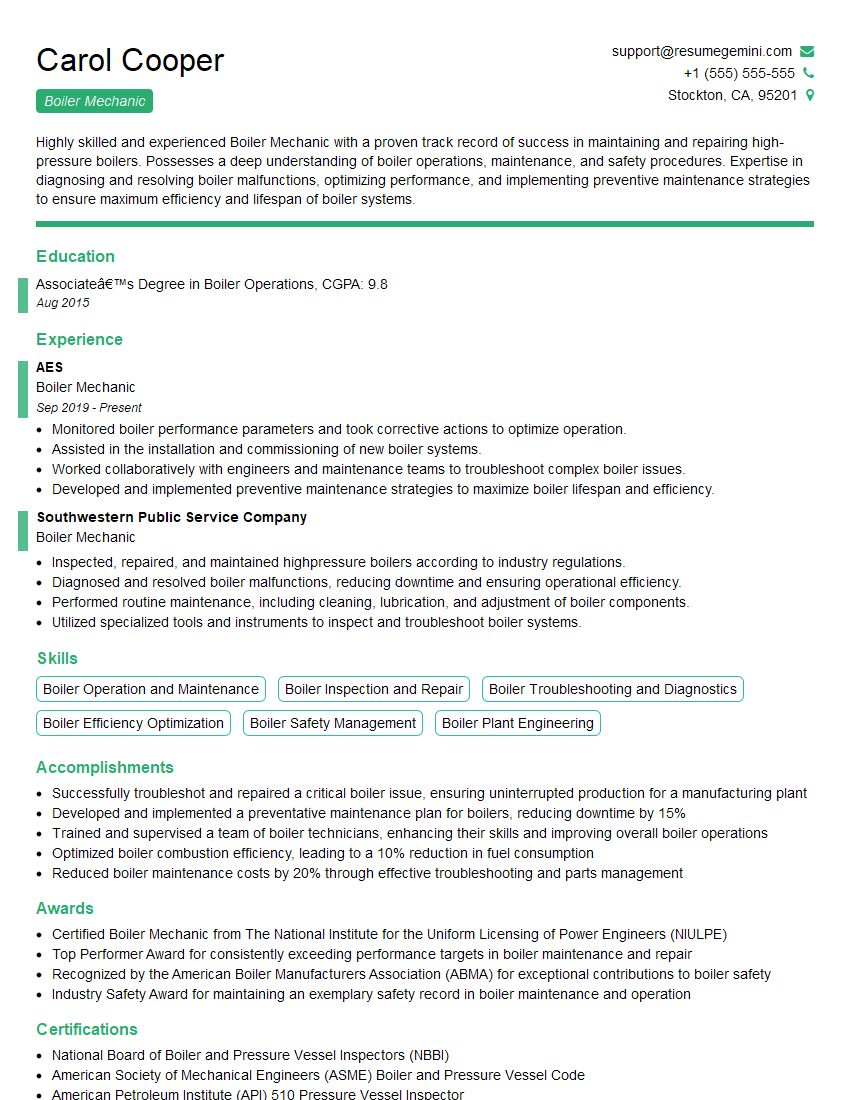

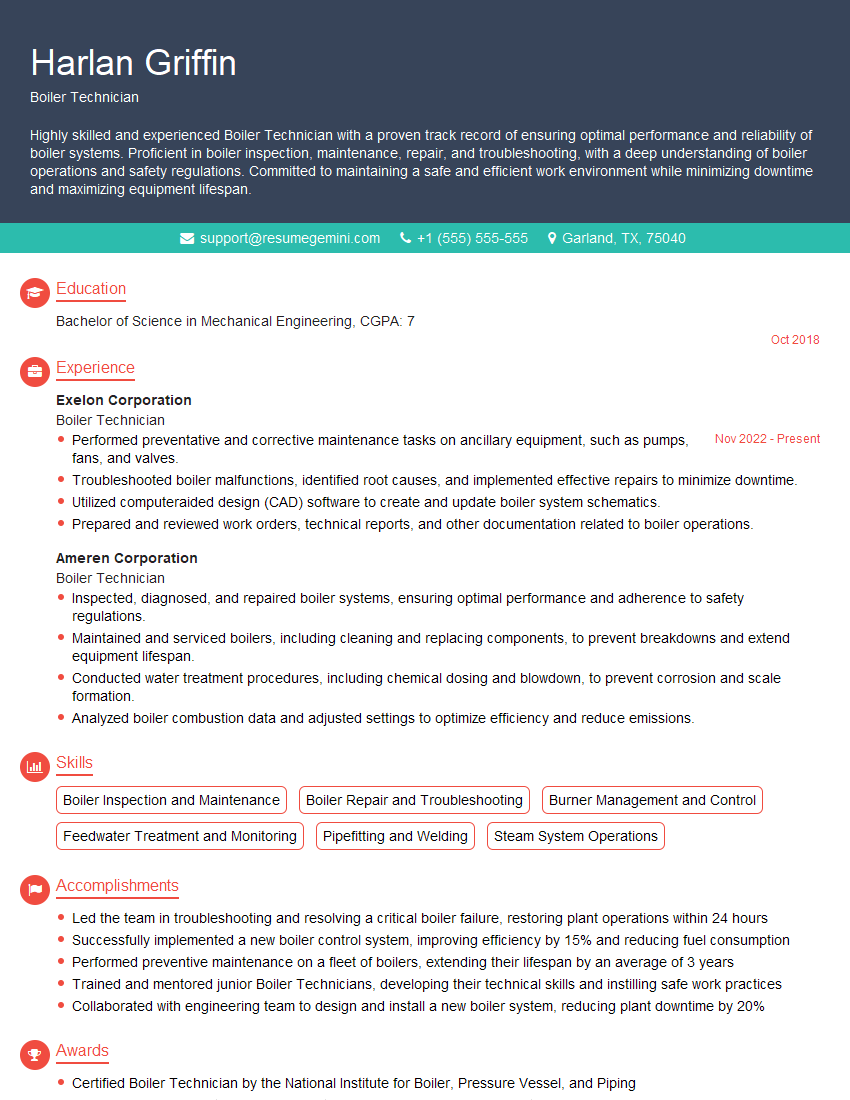

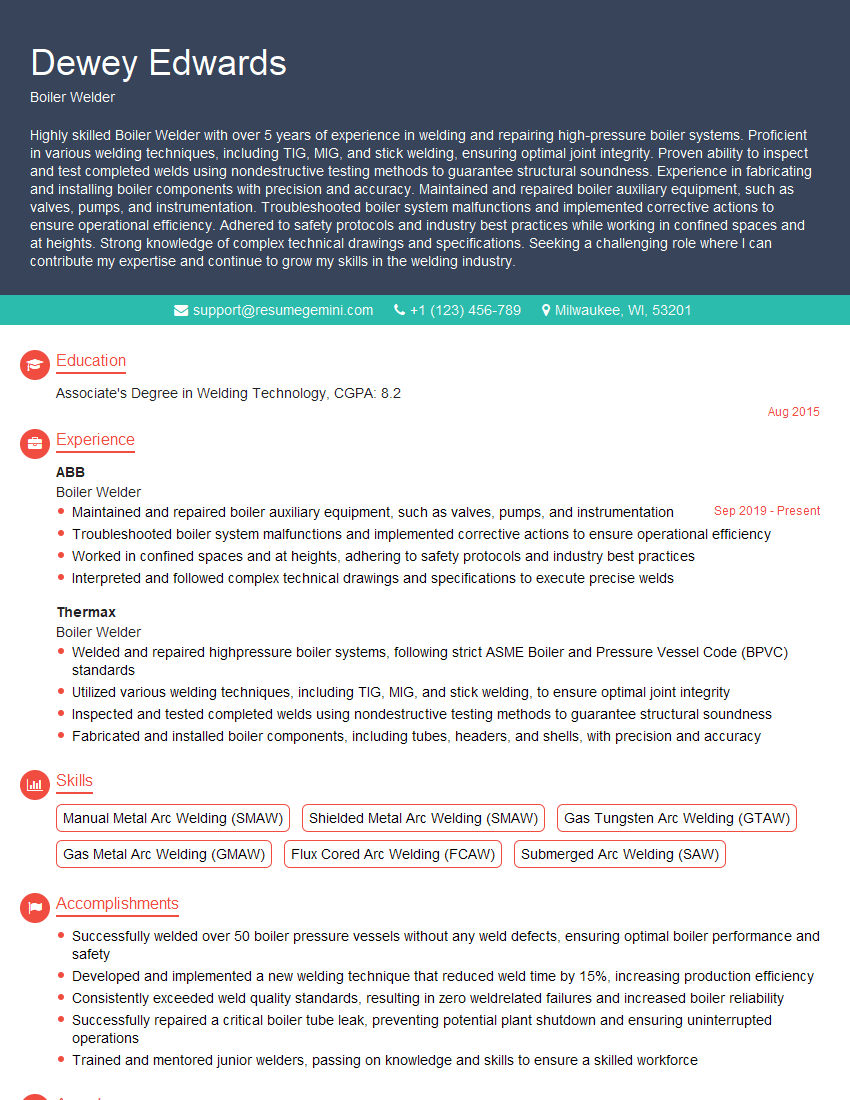

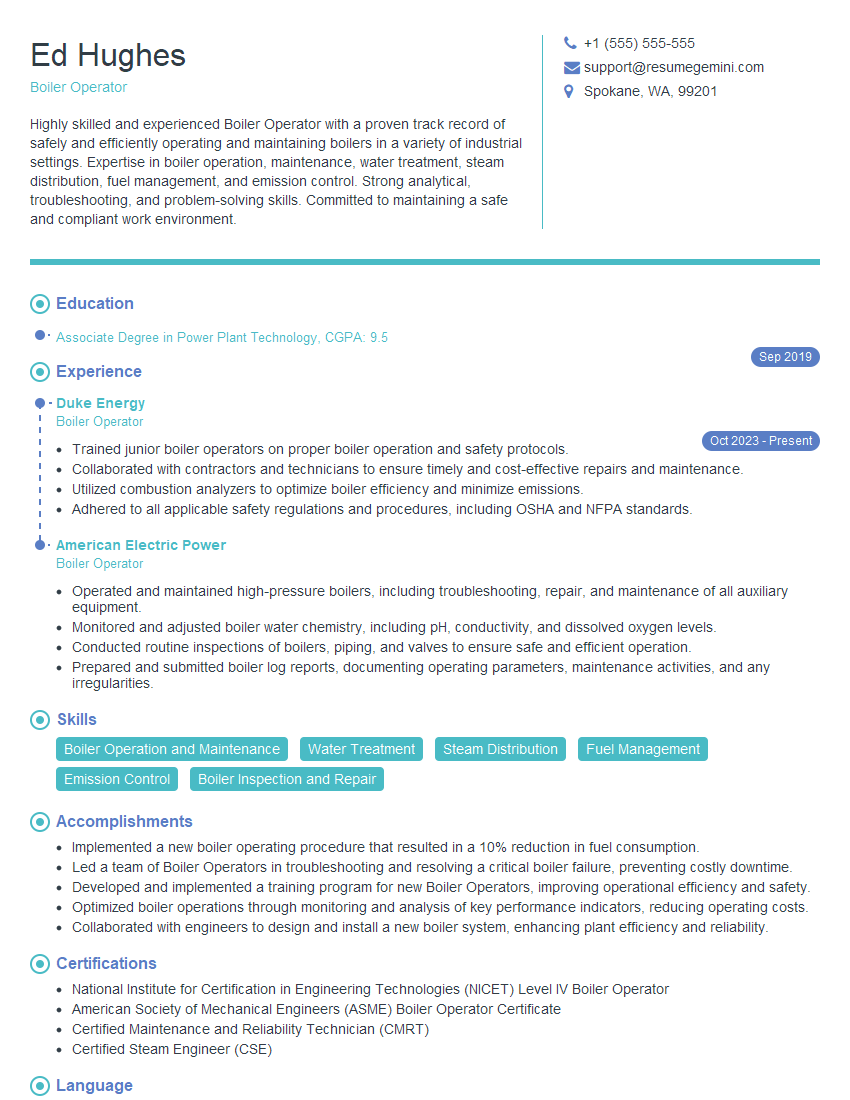

Mastering Boiler Tools Techniques is crucial for career advancement in the power generation, industrial, and HVAC sectors. A strong understanding of these techniques opens doors to higher-paying roles with increased responsibility. To significantly boost your job prospects, focus on creating an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional and impactful resume. We provide examples of resumes tailored to Boiler Tools Techniques to guide you through the process. Invest time in crafting a strong resume – it’s your first impression on potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Take a look at this stunning 2-bedroom apartment perfectly situated NYC’s coveted Hudson Yards!

https://bit.ly/Lovely2BedsApartmentHudsonYards

Live Rent Free!

https://bit.ly/LiveRentFREE

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?