Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Bridge Design Criteria interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Bridge Design Criteria Interview

Q 1. Explain the role of AASHTO LRFD in bridge design.

AASHTO LRFD, or the American Association of State Highway and Transportation Officials Load and Resistance Factor Design, is the prevailing design standard for bridges in North America. It’s a limit states design method, meaning it focuses on preventing failure modes rather than relying solely on allowable stresses. Instead of using a single safety factor applied to all loads and resistances, LRFD uses load factors to increase the design loads and resistance factors to reduce the predicted resistances, accounting for uncertainties inherent in both. This ensures a higher degree of safety by incorporating probabilistic approaches. Think of it like this: instead of building a bridge strong enough to withstand a specific load with a single safety buffer, LRFD statistically calculates the likelihood of various loads and potential weaknesses, resulting in a more reliable and efficient design.

In practice, LRFD involves calculating the load effects (moments, shears, etc.) for various load combinations, multiplying them by load factors, and then comparing these factored effects to the factored resistances of the bridge members. If the factored resistance exceeds the factored effects, the design is deemed acceptable. This method allows for more efficient use of materials while maintaining a high level of safety and reliability.

Q 2. Describe the different types of bridge loadings and their significance.

Bridge loadings are categorized into several types, each representing different forces acting on the structure. Understanding these is crucial for a safe and efficient design.

- Dead Loads: These are permanent loads, including the weight of the bridge structure itself (deck, beams, girders, etc.), and any permanently attached elements.

- Live Loads: These are variable loads, primarily from vehicles (trucks, cars, buses) and pedestrians. AASHTO LRFD specifies design live load models to represent the variability and intensity of traffic. These models often include multiple lane loadings, representing the worst-case scenario of heavily loaded trucks distributed across the bridge deck.

- Environmental Loads: These include wind, snow, ice, temperature effects (causing expansion and contraction), and even the effects of water pressure (for bridges spanning water bodies). These loads vary significantly depending on geographic location and climate.

- Dynamic Loads: These loads reflect the dynamic effects of moving vehicles, braking, and acceleration. They add to the live loads and are important in evaluating the vibrational response of the bridge.

- Seismic Loads: These are forces due to earthquakes, demanding specific design considerations to ensure the bridge’s stability and prevent collapse. The intensity of seismic loading depends on the bridge’s location and the local seismic zone.

The significance lies in accurately predicting the combined effect of all these loads to ensure the bridge’s structural integrity and prevent failure under various conditions. Each load type plays a part in the overall safety assessment and informs the choice of materials, dimensions, and structural configuration.

Q 3. How do you account for seismic design considerations in bridge design?

Seismic design is paramount in regions prone to earthquakes. Bridges must be designed to withstand ground shaking without collapse or significant damage. This involves several crucial aspects:

- Seismic Hazard Analysis: This determines the expected ground motion intensity at the bridge site based on geological data, historical earthquake records, and probabilistic seismic hazard assessments. The output often involves acceleration response spectra, providing information about the expected ground shaking at different frequencies.

- Structural Analysis: The bridge structure needs to be analyzed for seismic loads using sophisticated dynamic analysis techniques. Finite element models are frequently used to simulate the bridge’s response under seismic excitation, considering soil-structure interaction and the dynamic properties of the bridge materials.

- Design for Ductility and Energy Dissipation: Seismic design aims to enable the bridge to deform significantly under seismic loads without collapsing. This requires designing for ductility (the ability of the materials and structure to undergo large deformations without fracturing) and incorporating energy dissipation mechanisms (e.g., using ductile detailing in reinforced concrete structures, employing energy-absorbing devices like dampers).

- Foundation Design: The foundation plays a crucial role in seismic performance. The foundation must be capable of transferring seismic forces to the ground effectively, while mitigating the potential for liquefaction and soil instability.

Ignoring seismic design in seismically active areas can have catastrophic consequences, leading to structural failure and loss of life. Therefore, seismic considerations are not merely an addition to the design but are integrated throughout the design process, from site selection and geotechnical investigations to structural detailing and material selection.

Q 4. What are the key factors influencing the selection of bridge materials?

The choice of bridge materials is a complex decision influenced by numerous factors. The primary considerations include:

- Strength and Durability: The material must possess sufficient strength to resist the anticipated loads and exhibit long-term durability to withstand environmental factors (weathering, corrosion, etc.).

- Cost-Effectiveness: The initial cost of materials, along with the cost of fabrication, construction, and long-term maintenance, needs to be considered. Different materials have significantly different costs.

- Availability and Workability: The material should be readily available in the region, and its properties should allow for efficient construction and fabrication techniques.

- Aesthetic Considerations: The chosen materials can significantly impact the bridge’s visual appeal and integration with the surrounding environment. Sustainability and environmental impacts are also increasingly important.

- Specific Project Requirements: Factors like the span length, loading conditions, site accessibility, and the required service life influence material selection. For example, high-strength concrete is often preferred for long spans due to its high compressive strength.

Common bridge materials include steel, reinforced concrete, prestressed concrete, and timber. The selection process involves a detailed comparison of different materials based on these factors, often resulting in a trade-off between cost, performance, and aesthetics. For example, steel offers high strength-to-weight ratios but may require significant corrosion protection, while concrete offers durability but may be more expensive for very long spans.

Q 5. Explain the process of bridge design from conceptual design to construction drawings.

Bridge design is a multi-stage process involving numerous disciplines. Here’s a breakdown:

- Conceptual Design: This initial stage involves defining the project scope, identifying potential alignment alternatives, selecting preliminary structural types, conducting preliminary geotechnical investigations, and evaluating environmental impacts. Several design alternatives may be explored.

- Preliminary Design: The selected conceptual design is further refined. Preliminary structural analysis is performed, detailed design calculations are initiated, and preliminary material quantities are estimated. At this stage, preliminary cost estimates are also developed.

- Final Design: This stage involves detailed design calculations, final material selection, and detailed structural drawings. Shop drawings are developed for fabrication, and the design is reviewed for compliance with relevant codes and standards (like AASHTO LRFD).

- Construction Drawings: These are detailed plans, sections, and specifications required by the construction team. They include information about the location, geometry, dimensions, materials, construction methods, and quality control measures. These are essential for the contractor to build the bridge accurately.

- Construction Administration: This phase involves overseeing the bridge’s construction, ensuring compliance with the design plans and specifications. This involves regular inspections and addressing any issues that may arise during construction.

Each stage requires close collaboration among engineers, designers, contractors, and other stakeholders. The entire process demands meticulous attention to detail, adherence to codes, and robust quality control to ensure the bridge’s safety, functionality, and longevity.

Q 6. How do you assess the structural integrity of an existing bridge?

Assessing the structural integrity of an existing bridge involves a comprehensive evaluation of its condition and capacity. This process often includes:

- Visual Inspection: A thorough visual examination is the first step to identify visible signs of distress, such as cracks, spalling, corrosion, and settlement. This is often done by experienced bridge inspectors using specialized equipment.

- Non-Destructive Testing (NDT): NDT methods, such as ultrasonic testing, ground-penetrating radar, and magnetic particle inspection, are used to evaluate the internal condition of the bridge elements without causing damage. This helps to detect internal flaws or deterioration not visible on the surface.

- Load Testing: In some cases, controlled load tests are conducted to measure the actual load-carrying capacity of the bridge members. These tests provide quantitative data about the bridge’s strength and stiffness.

- Analytical Evaluation: Structural analysis is conducted to evaluate the bridge’s response to different load combinations, incorporating the information obtained from the inspection and testing. This may involve finite element modeling to simulate the bridge’s behavior under various scenarios.

- Material Testing: Samples of concrete or steel may be taken and tested in a laboratory to determine their material properties and assess the extent of degradation due to aging or environmental factors.

The results from these assessments are used to determine the bridge’s remaining service life, identify needed repairs or rehabilitation measures, and establish load restrictions if necessary. This ensures public safety and extends the bridge’s useful lifespan. The process must follow established protocols and standards for bridge inspection and assessment.

Q 7. Describe the various types of bridge foundations and their suitability.

Bridge foundations are crucial for transferring the bridge’s loads safely to the underlying soil or rock. The choice of foundation type depends heavily on the soil conditions, the magnitude of the loads, and the depth to bedrock.

- Shallow Foundations: These foundations transfer loads to the upper soil strata. Examples include spread footings (individual supports under columns or piers), combined footings (multiple supports connected together), and raft foundations (a large slab supporting the entire structure). Shallow foundations are suitable for relatively strong, shallow soils.

- Deep Foundations: These transfer loads to deeper, stronger soil or rock strata. Examples include piles (vertical elements driven into the ground), drilled shafts (large-diameter holes filled with concrete), and caissons (large, watertight structures sunk into the ground). Deep foundations are necessary for weak or soft soils, or when large loads need to be supported.

- Special Foundations: These include foundation types specifically suited to challenging situations, such as floating foundations for bridges built on water bodies, and specialized solutions for expansive or collapsible soils.

Suitability assessment involves extensive geotechnical investigations, including soil borings, laboratory testing, and in-situ measurements. The foundation design should ensure sufficient capacity to resist settlement, bearing pressure, and other potential failure modes, ensuring the long-term stability and safety of the bridge.

Q 8. Explain the importance of scour analysis in bridge design.

Scour analysis is absolutely critical in bridge design because it assesses the potential for erosion around bridge foundations. Erosion, or scour, can undermine the foundations, leading to instability and ultimately, bridge collapse. Imagine a river slowly washing away the soil beneath a bridge pier – that’s scour. We need to understand how much erosion is likely to occur so we can design foundations that are deep enough and strong enough to resist it.

The process involves several steps: First, we analyze the hydraulic characteristics of the waterway, considering factors like water velocity, flow depth, sediment type, and the presence of any obstructions. Then, we use specialized software and empirical methods to predict the potential scour depth. Finally, we design the foundation to extend below the predicted scour depth, often incorporating protective measures like scour countermeasures (e.g., riprap, collars, or sheet piling) to further mitigate the risk.

For example, during the design of a bridge over a highly erosive river, we might discover a predicted scour depth of 10 meters. This would necessitate a foundation design that extends at least 12-15 meters below the riverbed to provide a sufficient safety margin. Ignoring scour analysis in such a situation would be incredibly risky.

Q 9. How do you incorporate environmental considerations into bridge design?

Environmental considerations are paramount in modern bridge design. We strive to minimize the impact of the bridge on its surroundings throughout its entire lifecycle. This involves a holistic approach encompassing several key aspects.

- Habitat Protection: We assess the potential impact on aquatic and terrestrial ecosystems, aiming to minimize disruption to wildlife habitats and migration routes. This might involve designing bridges with minimal impact on riparian zones or implementing mitigation measures to offset any unavoidable habitat loss.

- Water Quality: We carefully consider potential impacts on water quality, such as sediment pollution during construction or the potential for chemical leaching from bridge materials. This includes implementing best management practices during construction to minimize erosion and selecting environmentally friendly materials.

- Air Quality: We account for emissions from construction equipment and transportation during the bridge’s lifespan, aiming to minimize air pollution through the use of efficient equipment and encouraging the use of public transport.

- Visual Impact: The aesthetic impact of the bridge on the surrounding landscape is carefully considered. Designs are often tailored to integrate seamlessly with the existing environment, minimizing visual intrusion.

- Noise Pollution: We evaluate the potential for noise pollution from traffic on the bridge, implementing noise-reducing barriers or design features if necessary.

For instance, in a sensitive wetland area, we might opt for a shorter span bridge to reduce the overall footprint on the ecosystem, and employ specialized construction techniques to prevent damage to vegetation. Environmental impact assessments (EIAs) are a crucial part of the process, guiding decision-making and ensuring compliance with regulations.

Q 10. What are the common failure modes of bridges and how can they be prevented?

Bridges can fail in various ways, often due to a combination of factors. Understanding these failure modes is essential for designing robust and safe structures.

- Foundation Failure: Scour, as discussed earlier, is a major culprit. Other causes include inadequate bearing capacity of the soil, settlement, and seismic activity.

- Material Failure: Fatigue cracking due to repeated stress cycles, corrosion of steel elements, and deterioration of concrete due to environmental exposure are common issues. Proper material selection, detailed design, and corrosion protection are vital.

- Structural Failure: Overloading beyond the design capacity, design flaws, and inadequate detailing can all lead to structural failure. Detailed analysis and rigorous quality control are necessary.

- Impact Damage: Collisions with vehicles or objects can cause significant damage, particularly to bridge components like piers and abutments.

Prevention strategies encompass careful site investigation, appropriate material selection, robust structural design incorporating safety factors, comprehensive analysis of potential loads and stresses, and regular inspection and maintenance to detect and address any developing problems. For example, designing for fatigue involves using appropriate load factors, selecting high-strength materials, and employing effective corrosion protection.

Q 11. Describe your experience with bridge software (e.g., SAP2000, ETABS).

I have extensive experience with various bridge analysis and design software packages, including SAP2000 and ETABS. I’ve utilized these tools across multiple projects, from small pedestrian bridges to complex long-span highway structures. My proficiency extends beyond simple modeling; I’m comfortable performing advanced analyses such as nonlinear dynamic analysis, seismic analysis, and time-history analysis to evaluate the structural performance under various loading conditions.

In SAP2000, for instance, I routinely create detailed 3D models, define material properties, apply loads (dead, live, seismic, etc.), and run analyses to obtain stress, displacement, and other key results. I’m skilled in post-processing results to identify critical sections and potential areas of concern. Similarly, in ETABS, I leverage its powerful features for efficient modeling and analysis of complex bridge geometries and loading scenarios. The software output allows for optimized design based on accurate stress distribution.

For a recent project involving a cable-stayed bridge, I employed SAP2000’s nonlinear capabilities to model the cable behavior accurately, ensuring that the design adequately addressed potential cable sag and other nonlinear effects.

Q 12. Explain your understanding of bridge detailing and drafting standards.

My understanding of bridge detailing and drafting standards is thorough. I’m familiar with AASHTO (American Association of State Highway and Transportation Officials) standards, as well as other relevant codes and specifications depending on the project’s location and scope. These standards govern every aspect of bridge drawings, from the representation of structural elements and dimensions to reinforcement detailing and fabrication specifications.

Good detailing is crucial for ensuring the safe and efficient construction of a bridge. Ambiguous or poorly detailed drawings can lead to costly errors and delays during construction. I meticulously follow established standards to create clear, concise, and unambiguous drawings that leave no room for misinterpretation by contractors. This includes detailing reinforcement bars, embedments, connections, and other critical aspects with precision, incorporating proper dimensions, tolerances, and symbols.

For example, I’m meticulous about detailing reinforcement in concrete elements, ensuring proper spacing, cover, and lapping to prevent cracking and ensure adequate strength. I also understand and apply the concepts of detailing for cast-in-place, precast, and pre-stressed concrete elements. This careful attention to detail is vital for building a structurally sound and durable bridge.

Q 13. How do you handle design changes during the construction phase of a bridge project?

Handling design changes during construction is a common challenge in bridge projects. It requires a systematic approach to ensure that any changes are properly documented, reviewed, and implemented without compromising safety or delaying the project.

The process typically involves the following steps:

- Formal Change Request: Any proposed change, no matter how small, must be initiated through a formal change request process. This ensures that all stakeholders are aware of the change and have the opportunity to review it.

- Impact Assessment: A thorough assessment is required to determine the impact of the proposed change on the structural integrity, schedule, and cost of the project. This might involve re-analyzing the design using software like SAP2000 or ETABS.

- Review and Approval: The change request is reviewed and approved by the relevant authorities, including the design engineer, construction manager, and potentially the client.

- Documentation: All changes are meticulously documented, including the reason for the change, its impact on the project, and the approvals obtained. This documentation is essential for legal and insurance purposes.

- Implementation: The change is implemented by the construction team, adhering to all safety protocols and quality control procedures.

For instance, if a subsurface condition discovered during excavation differs from the initial geotechnical report, we would initiate a formal change request to modify the foundation design, ensuring the updated design adequately addresses the new conditions. This process ensures transparency and accountability, minimizing risks and disputes.

Q 14. Explain your experience with bridge inspection and maintenance.

I have significant experience with bridge inspection and maintenance, recognizing that it’s critical for ensuring the long-term safety and serviceability of bridge structures. Regular inspections, whether visual or more in-depth, help identify potential problems early on, allowing for timely repairs and preventing catastrophic failures.

My experience encompasses both visual inspections, where I systematically assess the condition of various bridge components – decks, beams, girders, piers, abutments – looking for signs of cracking, corrosion, spalling, or other damage, and more detailed inspections involving non-destructive testing methods like ultrasonic testing or ground-penetrating radar to identify internal flaws.

I understand the importance of developing and implementing a robust maintenance plan, tailored to the specific needs of the bridge. This might involve regularly scheduled inspections, preventative maintenance activities like painting or crack sealing, and major repairs or rehabilitation projects as needed. For example, if significant corrosion is detected on a steel bridge, we would develop a plan to address the issue, potentially involving cleaning, repainting, or even replacing affected elements.

Proper documentation of inspection findings is crucial, forming the basis for developing effective maintenance plans and communicating the bridge’s condition to stakeholders.

Q 15. Describe your understanding of different bridge types (e.g., beam, arch, suspension).

Bridges are categorized into various types based on their structural systems. The primary classifications include beam, arch, suspension, and cable-stayed bridges, each with unique characteristics and applications.

- Beam Bridges: These are the simplest type, employing horizontal beams supported by piers or abutments. Think of a simple overpass – that’s likely a beam bridge. They’re suitable for shorter spans and moderate loads. Variations include girder bridges (using multiple parallel beams) and simple span bridges (single beam).

- Arch Bridges: These utilize curved arches to transfer the load to abutments. The arch’s shape is crucial in creating compression, allowing it to efficiently span larger distances. The iconic Sydney Harbour Bridge is a well-known example of a steel arch bridge. Their strength stems from the efficient compression forces within the structure.

- Suspension Bridges: These are designed for exceptionally long spans. A roadway is suspended from cables, which in turn are anchored to towers. The Golden Gate Bridge is a prime example. The weight is transferred to the towers and then to the anchorages via huge cables.

- Cable-Stayed Bridges: These are similar to suspension bridges, but the roadway is supported by cables directly connected to towers. This differs from suspension bridges where the cables are anchored on either side and the weight is suspended.

The choice of bridge type depends on factors such as span length, terrain, material availability, cost, and aesthetic considerations. Each type has strengths and weaknesses which are considered during design.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure compliance with relevant building codes and regulations?

Compliance with building codes and regulations is paramount in bridge design. My approach involves a multi-stage process:

- Identifying Applicable Codes: This first step involves determining which codes are relevant, based on the bridge’s location, type, and intended use. This might include national standards such as AASHTO (American Association of State Highway and Transportation Officials) LRFD (Load and Resistance Factor Design) bridge design specifications, or regional regulations.

- Detailed Design Checks: Each element of the design – from the foundation to the superstructure – is meticulously checked against the code requirements. Software tools and structural analysis techniques are used to verify that the design meets or exceeds all safety factors and load capacity limits.

- Documentation and Reporting: Thorough documentation of all design calculations, analysis, and code compliance checks is essential. This forms part of the submission package to the relevant authorities for approval.

- Peer Review and Audits: Independent review by other experienced bridge engineers is often part of the process to ensure that the design adheres to best practices and satisfies all regulatory requirements. This provides added assurance of safety and quality.

Throughout the entire process, meticulous record-keeping and adherence to standardized procedures are critical. Ignoring even minor code requirements can have catastrophic consequences.

Q 17. What are your approaches to managing risks and uncertainties in bridge design?

Risk and uncertainty management is crucial in bridge design, where failure can have severe consequences. My strategies include:

- Probabilistic Analysis: This involves incorporating uncertainties in material properties, loads, and construction techniques through probabilistic models. This provides a clearer picture of the potential risks rather than simply relying on deterministic models which only consider a singular load scenario.

- Sensitivity Analysis: Examining how sensitive the design is to variations in key parameters (like material strength or load magnitudes) allows us to identify critical areas needing extra attention. It highlights those parameters that might have a disproportionate impact on the bridge’s performance.

- Redundancy and Robustness: Designing with redundancy – meaning incorporating multiple load paths so that failure of one component doesn’t lead to complete collapse – is paramount. This provides an extra layer of safety.

- Risk Assessment and Mitigation: A formal risk assessment identifies potential hazards (e.g., seismic activity, scour, material defects) and outlines mitigation strategies. For example, detailed geotechnical investigations help minimize risks related to soil conditions.

- Regular Inspections and Monitoring: Even after construction, regular inspections and monitoring are essential to detect any deterioration or unexpected issues early on, thus preventing larger problems down the line.

These approaches help ensure that the bridge is designed to withstand foreseeable events and still function reliably and safely throughout its expected service life.

Q 18. Explain the difference between ultimate and serviceability limit states in bridge design.

Limit states define the boundaries of acceptable bridge performance. There are two primary categories:

- Ultimate Limit State (ULS): This refers to the conditions where the bridge structure might collapse or suffer significant damage. It deals with the structural capacity and strength, ensuring the bridge doesn’t fail under extreme loads such as an earthquake or extreme wind. The design must demonstrate adequate strength to avoid complete collapse.

- Serviceability Limit State (SLS): This focuses on the functional performance of the bridge under normal operating conditions. It considers aspects like excessive deflection (sagging or bending), cracking, vibrations, and overall usability. Even if the bridge doesn’t collapse, excessive vibration can be unacceptable and could fall under SLS.

Both limit states are essential. A bridge might be structurally sound (pass ULS) but still be unserviceable due to excessive vibration or deflection (fail SLS). The design must meet both to be considered safe and functional.

Q 19. How do you incorporate live load distribution in your bridge designs?

Live load distribution refers to how the weight of vehicles and other moving loads is spread across the bridge structure. Accurate live load distribution is crucial for determining the stresses and forces experienced by different bridge components. My approach involves:

- Influence Lines: These graphical tools help determine the maximum stress produced by a live load at a particular point within the structure as the load travels across the bridge. They are crucial for determining the maximum stress.

- Finite Element Analysis (FEA): Sophisticated FEA software models the bridge’s behavior under various live load scenarios, providing a detailed stress distribution and allowing for assessment of critical sections.

- Load Distribution Factors: AASHTO provides load distribution factors based on the bridge’s geometry, type, and material. These factors account for how loads are transferred between girders and beams within the bridge deck.

Accurate live load distribution ensures the bridge’s design incorporates sufficient capacity to handle expected traffic conditions. Underestimating this can lead to premature deterioration or failure.

Q 20. How do you consider fatigue and fracture in bridge design?

Fatigue and fracture are significant concerns in bridge design, particularly for steel structures subjected to repeated cyclic loading from traffic. My approaches to address these issues include:

- Fatigue Analysis: This involves assessing the bridge’s response to millions of cycles of stress over its lifetime. Stress range, mean stress, and number of cycles are all factored in. The goal is to ensure that the stress levels remain within acceptable limits to avoid fatigue failure.

- Fracture Mechanics: This discipline investigates the growth and propagation of cracks under stress. Design considerations include using materials with high fracture toughness and incorporating features to slow or stop crack growth. We analyze the possibility of crack initiation and propagation and ensure the structure has adequate tolerance before complete failure.

- Detailing for Fatigue Resistance: Careful detailing of welds, connections, and other critical areas helps minimize stress concentrations and improve fatigue resistance. For example, smooth transitions between structural elements reduce stress concentration and improve fatigue life.

- Material Selection: The selection of high-quality materials with suitable fatigue properties is essential. Regular material testing is performed to ensure the material complies with relevant standards.

Ignoring fatigue and fracture could lead to unexpected and potentially catastrophic failures, even with adequate capacity under static load.

Q 21. Explain your experience with geotechnical investigations for bridge projects.

Geotechnical investigations are fundamental to bridge design, as they provide essential information about the soil and rock conditions at the bridge site. My experience involves:

- Site Reconnaissance: Initial site visits to observe the terrain, geology, and hydrological conditions. This provides a preliminary understanding of potential issues.

- Subsurface Exploration: This includes drilling boreholes to obtain soil samples and performing in-situ testing (like Standard Penetration Tests or cone penetration tests) to determine soil strength, density, and other engineering properties.

- Laboratory Testing: Soil samples are analyzed in a laboratory to determine their properties more precisely. This allows for better prediction of soil behavior under various conditions.

- Geotechnical Report: A comprehensive report summarizes the findings and provides recommendations for foundation design, considering factors like bearing capacity, settlement, and potential scour (erosion of soil around foundations). This report is the basis for all foundation design.

- Foundation Design: Based on the geotechnical report, I participate in the design of suitable foundations (e.g., piles, caissons, spread footings), ensuring stability and safety under anticipated loads.

I have worked on various bridge projects involving diverse soil conditions, from soft clays to hard rock. Proper geotechnical investigation is critical to prevent foundation failures, which can lead to significant cost overruns and safety risks. A seemingly small oversight can lead to massive problems later.

Q 22. Describe your understanding of hydraulic analysis for bridge designs.

Hydraulic analysis in bridge design is crucial for ensuring the safety and functionality of the structure, especially in areas prone to flooding or high water flow. It involves determining the forces exerted by water on the bridge piers, abutments, and the bridge deck itself. This assessment helps engineers design the bridge substructure to withstand these forces and prevent damage or collapse.

The process typically involves:

- Defining the hydraulic characteristics of the waterway: This includes determining the water levels (both normal and flood levels) and the flow velocities. Data from historical records, hydrological studies, and hydraulic modeling are used.

- Analyzing the bridge geometry: The bridge’s configuration, including pier locations, shapes, and the bridge’s overall alignment, significantly affects the flow pattern and forces exerted by the water. This involves understanding scour (erosion around bridge foundations) potential.

- Estimating hydrodynamic forces: Using computational fluid dynamics (CFD) models or empirical formulas, engineers calculate the pressure, drag, and lift forces acting on different parts of the bridge. These forces are then incorporated into the structural design.

- Designing for scour protection: Scour is a major threat. Measures like riprap (stone) placement, and the use of scour-critical designs around piers, are crucial to preventing erosion and foundation instability.

For example, during the design of a bridge spanning a river prone to flooding, a hydraulic analysis might reveal that the piers need to be designed to withstand significant uplift and drag forces during a 100-year flood event. This informs the selection of the appropriate foundation type and the overall pier design to ensure stability.

Q 23. How do you utilize finite element analysis in bridge design?

Finite Element Analysis (FEA) is an indispensable tool in modern bridge design. It’s a numerical method that divides the bridge structure into many small elements, allowing engineers to simulate the behavior of the structure under various loads and conditions. This provides detailed insights into stress, strain, and displacement throughout the structure, helping to optimize the design for strength, stiffness, and durability.

In practice, we use FEA software to:

- Analyze stress and strain distributions: FEA helps identify areas of high stress concentration, allowing for optimization of the structural members to avoid potential failure.

- Assess the effects of different loads: We can apply various loads such as dead loads (weight of the structure), live loads (traffic), wind loads, seismic loads, and thermal loads to see how the bridge responds.

- Model complex geometries: FEA is adept at handling complex bridge shapes and configurations, providing accurate results even for intricate designs.

- Evaluate different design alternatives: We can use FEA to compare the performance of several design options, leading to a cost-effective and efficient solution.

For instance, when designing a cable-stayed bridge, FEA is essential to accurately model the complex interaction between the cables, deck, and towers. The analysis ensures the overall structural integrity and stability of the bridge under various load scenarios.

Q 24. What are the key differences between prestressed and reinforced concrete bridge design?

Prestressed and reinforced concrete bridge designs differ significantly in how they handle tensile stresses. In reinforced concrete, steel reinforcement bars (rebar) are embedded to resist tensile stresses that develop in the concrete under load. In prestressed concrete, high-strength steel tendons are tensioned before the concrete is poured, creating a compressive stress that counteracts tensile stresses that arise from service loads. This allows for more slender and efficient bridge sections.

Here’s a comparison:

- Tensile Stress Resistance: Reinforced concrete relies on the bond between steel rebar and concrete to resist tension. Prestressed concrete uses initial compression to minimize or eliminate tensile stresses in the concrete.

- Crack Control: Prestressed concrete is more effective in controlling cracks due to the inherent compressive stress. Reinforced concrete is more susceptible to cracking under tensile stresses.

- Material Efficiency: Prestressed concrete often allows for the use of less material to achieve the same strength, resulting in lighter and potentially more economical structures. However, the specialized equipment required for prestressing does increase initial costs.

- Durability: While both types can be durable, prestressed concrete’s reduced cracking can enhance long-term durability and reduce the risk of corrosion of reinforcement.

- Span Length: Prestressed concrete is generally favored for longer spans due to its increased strength and reduced need for substantial reinforcement.

Imagine a long-span bridge: prestressed concrete would likely be more economical and efficient than using reinforced concrete which would require significantly more rebar for the same load capacity.

Q 25. Explain your familiarity with different types of bridge bearings and their functions.

Bridge bearings are critical components that transfer loads from the superstructure (bridge deck and girders) to the substructure (piers and abutments) while allowing for thermal expansion, contraction, and settlement. Different bearing types cater to specific needs.

Common types include:

- Fixed bearings: Restrict both horizontal and rotational movement. They’re usually placed at one end of the bridge to prevent longitudinal movement.

- Expansion bearings: Allow for longitudinal movement due to temperature changes, typically using sliding plates or elastomeric pads.

- Pot bearings: Use a pot filled with a viscous fluid to accommodate vertical and rotational movements while restraining horizontal movement.

- Roller bearings: Allow for substantial longitudinal movement using rollers. Often used in bridges with significant thermal expansion or seismic considerations.

- Elastomeric bearings: Made from layers of rubber and steel plates. They provide flexibility and dampen vibrations while restraining some movements.

Choosing the right bearing depends on several factors including span length, traffic loads, expected temperature changes, seismic activity, and available space. A long bridge with significant temperature variations might require expansion bearings at multiple points along the bridge’s length to prevent stress buildup and cracking of the structure.

Q 26. Describe your experience working with bridge construction contractors.

My experience working with bridge construction contractors has been extensive and collaborative. Effective communication and a strong understanding of construction practices are vital for successful bridge projects. I’ve worked closely with contractors throughout all stages of a project from the initial planning and design review to the construction phase and final inspection.

This collaboration includes:

- Design review meetings: I participate in regular meetings to discuss the design’s constructability, ensuring that the design is feasible and can be implemented safely and efficiently. This often leads to design improvements that simplify construction.

- Shop drawing review: I meticulously review shop drawings (detailed construction plans) to ensure that the materials and construction methods comply with the design specifications and contract requirements.

- Construction site visits: Regular site visits allow me to observe the construction progress, address any issues that arise during construction, and ensure that the work is being performed according to the approved plans.

- Conflict resolution: Inevitably, challenges occur. Experience in mediating disputes and finding solutions acceptable to both the contractor and the owner is critical for project success.

A successful project relies on building a strong relationship with contractors, fostering open communication, and a shared commitment to quality and safety. One memorable project involved resolving a unforeseen geological issue during construction; by working closely with the contractor, we developed a creative solution that minimized project delays and cost overruns.

Q 27. How do you ensure the sustainability and environmental impact of your bridge designs?

Sustainability and environmental impact are paramount in modern bridge design. We strive to minimize the ecological footprint of our projects throughout their entire lifecycle, from construction to demolition. This encompasses several strategies:

- Material selection: Prioritizing the use of recycled and locally sourced materials reduces transportation emissions and environmental impact.

- Energy-efficient design: Incorporating features that reduce energy consumption during construction and operation, such as energy-efficient lighting and optimized structural design to minimize material use.

- Waste minimization: Implementing strategies to reduce waste generation during construction, and prioritizing recyclable materials.

- Minimizing impacts on water and air quality: Implementing construction practices that reduce sediment runoff, air emissions, and noise pollution.

- Habitat protection and restoration: Minimizing the impact on surrounding ecosystems during construction and incorporating measures to protect or restore natural habitats.

- Lifecycle assessment: Conducting a comprehensive lifecycle assessment (LCA) to evaluate the environmental impact of the bridge throughout its entire life cycle, identifying opportunities to reduce its carbon footprint and other environmental impacts.

For example, designing a bridge to use less concrete reduces carbon emissions related to cement production. Utilizing recycled steel for reinforcement further minimizes the environmental impact.

Q 28. Describe your understanding of the lifecycle cost analysis of a bridge.

Lifecycle cost analysis (LCCA) is a critical aspect of bridge design. It considers all costs associated with a bridge over its entire lifespan, not just the initial construction costs. This comprehensive approach helps optimize designs for long-term economic efficiency.

LCCA involves estimating and comparing costs across the project lifecycle, including:

- Initial construction costs: Material, labor, and equipment costs.

- Maintenance costs: Regular inspections, repairs, and rehabilitation work over the bridge’s lifespan.

- Replacement costs: Costs associated with replacing the bridge at the end of its design life.

- Operational costs: Costs associated with bridge operation and management, such as lighting, safety inspections, and snow removal.

- Environmental costs: Consideration of environmental impact and any associated costs.

By considering these costs holistically, we can make informed decisions about the design, materials, and construction methods that provide the best value for money over the long term. For example, selecting materials with higher initial costs but lower maintenance needs might lead to a lower overall lifecycle cost compared to cheaper materials requiring more frequent and costly repairs.

Key Topics to Learn for Bridge Design Criteria Interview

- Loads and Load Combinations: Understanding dead loads, live loads (vehicles, pedestrians, etc.), environmental loads (wind, snow, seismic), and how to combine them according to relevant codes (e.g., AASHTO, Eurocodes).

- Material Properties and Behavior: Familiarize yourself with the properties of common bridge materials (concrete, steel, timber) and their behavior under different load conditions. This includes understanding stress-strain relationships and material failure modes.

- Structural Analysis Techniques: Mastering methods like statically determinate and indeterminate analysis, influence lines, and finite element analysis (FEA) is crucial for evaluating bridge structures’ performance.

- Design Codes and Standards: Thorough knowledge of relevant design codes and standards is essential. Understand the requirements for load factor design, limit states design, and serviceability limit states.

- Foundation Design: Gain a solid understanding of different foundation types (e.g., piles, caissons, spread footings) and their suitability for various soil conditions and bridge types.

- Construction Methods and Sequencing: Familiarity with common bridge construction methods and their impact on design considerations is valuable. Understand the implications of staging and construction sequencing on structural behavior.

- Sustainability and Environmental Considerations: Understand current trends in sustainable bridge design, including the use of environmentally friendly materials and minimizing the environmental impact of construction.

- Bridge Types and Their Suitability: Develop a comprehensive understanding of different bridge types (beam, girder, arch, suspension, cable-stayed) and their applications based on span length, site conditions, and other factors.

- Structural Detailing and Connections: Be prepared to discuss common structural details and connections, paying attention to aspects like shear connections, moment connections, and detailing for fatigue resistance.

- Problem-Solving and Design Optimization: Develop your ability to approach design problems systematically and creatively. Be prepared to discuss methods for optimizing designs to meet performance requirements while minimizing cost and environmental impact.

Next Steps

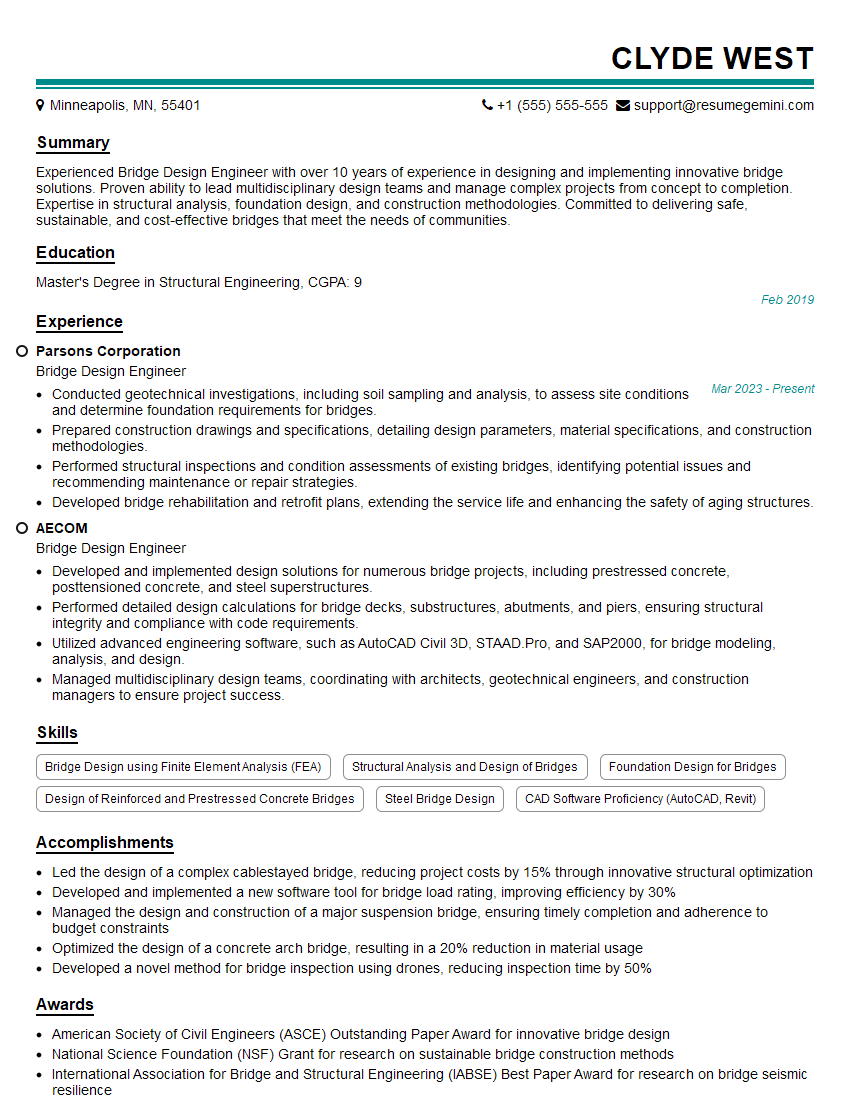

Mastering Bridge Design Criteria is vital for career advancement in structural engineering, opening doors to challenging and rewarding projects. An ATS-friendly resume is crucial for getting your application noticed by recruiters. To significantly enhance your job prospects, we highly recommend using ResumeGemini to craft a compelling resume tailored to the specific requirements of Bridge Design Criteria roles. Examples of resumes optimized for these positions are available to help guide you through the process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?