Unlock your full potential by mastering the most common Cabinet Finishing interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Cabinet Finishing Interview

Q 1. What types of wood finishes are you familiar with (e.g., lacquer, polyurethane, shellac)?

I’m highly proficient in various wood finishes, each with unique properties and applications. My experience encompasses:

- Lacquer: Known for its fast drying time and durable, hard finish. I often use lacquer for projects demanding a smooth, high-gloss finish, especially on kitchen cabinets where durability is paramount. It’s ideal for a professional look but requires a clean, dust-free environment for optimal results.

- Polyurethane: Offers excellent protection against scratches and water damage, making it a popular choice for high-traffic areas. I frequently select polyurethane for its versatility; it can be applied in various sheens, from satin to high-gloss. Water-based polyurethanes are becoming increasingly popular due to their lower VOCs (Volatile Organic Compounds).

- Shellac: A natural resin finish prized for its beautiful amber tone and ability to build a deep, lustrous finish. While offering good protection, shellac is less durable than lacquer or polyurethane and requires more maintenance. I might choose shellac for a more traditional or antique look, but I’d advise clients on its limitations compared to other options.

- Oil-based finishes: These offer deep penetration into the wood, enhancing its natural beauty. They are more forgiving of imperfections but take longer to cure and require more maintenance.

The choice of finish depends greatly on the client’s preferences, budget, and the intended use of the cabinets. I always discuss the pros and cons of each option before making a decision.

Q 2. Describe your experience with different spraying techniques (e.g., HVLP, airless).

Spraying techniques are critical for achieving a smooth, even finish. I’m experienced with both HVLP (High Volume Low Pressure) and airless spray systems:

- HVLP: This system atomizes the finish using a large volume of air at low pressure. It’s known for producing a fine, even spray with minimal overspray, resulting in less waste and a cleaner finish. I prefer HVLP for delicate work and when achieving a perfectly smooth surface is paramount.

- Airless: This system utilizes higher pressure to atomize the finish. It’s faster and covers larger areas quickly, making it efficient for large-scale projects. However, it requires more skill to control, and there’s a higher risk of runs and drips if not handled properly. I use this method strategically for larger pieces and base coats, where speed and coverage are prioritized.

My expertise allows me to select the best technique for each job, optimizing for speed, quality, and minimizing material waste. I regularly maintain and calibrate my spraying equipment to ensure optimal performance.

Q 3. How do you prepare cabinet surfaces for finishing?

Proper surface preparation is the cornerstone of a beautiful, long-lasting finish. It’s a multi-step process:

- Cleaning: The cabinets must be thoroughly cleaned to remove dust, grease, or any other contaminants. I use a tack cloth or a lightly damp cloth for this.

- Repairing: Any imperfections, such as dents, scratches, or gaps, need to be filled and sanded smooth using appropriate wood filler.

- Sanding: Starting with coarser grit sandpaper (e.g., 120-grit) and progressively moving to finer grits (e.g., 220-grit or higher), the surfaces are sanded smooth and even. This is crucial for ensuring a flawless finish. I always sand in the direction of the wood grain to avoid scratches.

- Priming (if necessary): Some woods or stains require a primer to ensure uniform color and adhesion. I select primers based on the substrate and the topcoat.

This meticulous preparation ensures a superior final finish and prevents problems down the line. Think of it as building a strong foundation for a house – you wouldn’t skip the foundation steps!

Q 4. What safety precautions do you take when working with finishes?

Safety is my top priority. When working with finishes, I always:

- Work in a well-ventilated area: Many finishes release VOCs that can be harmful if inhaled. I always use appropriate respirators and ensure adequate ventilation.

- Wear appropriate personal protective equipment (PPE): This includes gloves, safety glasses, and a long-sleeved shirt to protect my skin and eyes from the finish.

- Follow manufacturer’s instructions: Each finish has specific safety precautions that must be followed meticulously. I always refer to the Safety Data Sheet (SDS).

- Proper disposal of waste: Leftover finishes and cleaning materials are disposed of according to local regulations.

- Fire safety: Many finishes are flammable and should be handled with care away from open flames.

Ignoring these precautions can lead to serious health issues or accidents. My commitment to safety is unwavering.

Q 5. Explain the process of sanding and prepping cabinet doors for finishing.

Sanding and prepping cabinet doors is a critical step in achieving a professional finish. It’s a process of refinement:

- Initial sanding: Begin with a coarser grit sandpaper (e.g., 100-grit) to remove any major imperfections, followed by a finer grit (e.g., 150-grit). Always sand with the grain to prevent cross-grain scratches.

- Intermediate sanding: Use progressively finer grits (e.g., 180, 220) to smooth out any remaining imperfections and create a consistently even surface. Pay special attention to edges and corners.

- Final sanding: A very fine grit (e.g., 320 or higher) produces a surface ready for finishing. Always check the surface with your hand to ensure there are no noticeable imperfections.

- Cleaning: Thoroughly clean the surface with a tack cloth to remove all sanding dust. This is crucial to prevent dust particles from being trapped under the finish.

Careful sanding ensures an even, smooth surface that will allow the finish to adhere properly. A smooth finish always looks more professional.

Q 6. How do you troubleshoot common finishing problems such as runs, drips, or orange peel?

Troubleshooting finishing problems requires experience and a systematic approach. Here’s how I address common issues:

- Runs and drips: These often result from applying too much finish at once or using improper spraying technique. The solution is to let the finish dry completely and then carefully sand down the runs using very fine sandpaper before reapplying a thin coat.

- Orange peel: This textured finish usually results from the finish drying too quickly or using an incorrect spraying technique. Reducing the distance between the spray gun and the surface, adjusting the air pressure (if applicable), or using a slower spraying technique often solves the problem.

- Dust nibs: These tiny imperfections are often caused by airborne dust particles settling on the wet finish. Again, thorough cleaning before application is key. A light sanding, if necessary, may help.

- Sagging: This occurs when the finish is too thick. It’s usually best to use a thinner coat and multiple applications.

In each case, careful diagnosis of the problem is critical. Sometimes, it’s simply a matter of adjusting spraying techniques, but other times, it may necessitate more extensive sanding and reapplication.

Q 7. What is your experience with color matching and stain blending?

Color matching and stain blending are essential skills for achieving the client’s vision. My experience includes:

- Color matching: I use color charts and spectrophotometers to accurately match existing colors or create custom blends. I always test the stain on scrap wood before applying it to the cabinets.

- Stain blending: This requires a keen eye for color and a systematic approach. I start by mixing small amounts of stain and testing the blend until the desired color is achieved. The process often requires multiple adjustments and refinements.

I’ve worked on projects where precise color matching was crucial – creating a bespoke finish to match existing woodwork in a historical home. The challenge lies not just in getting the correct color, but also in ensuring a consistent finish across all cabinet pieces. A consistent finish truly showcases professional expertise.

Q 8. How do you ensure a consistent finish across multiple cabinets?

Consistency in cabinet finishing is paramount for a professional look. It’s achieved through meticulous preparation and a controlled finishing process. Think of it like baking a cake – you need precise measurements and consistent technique to get the same result every time.

- Controlled Environment: Maintaining a consistent temperature and humidity in your workspace prevents variations in drying time and finish application.

- Batch Processing: Finish multiple cabinets using the same batch of stain or paint to minimize color variations. Thoroughly mix the finish before each application.

- Consistent Application Technique: Employ the same technique (spraying, brushing, wiping) with the same pressure and speed for each piece. Practice makes perfect here!

- Regular Calibration: If using spray equipment, calibrate the air pressure and fluid flow regularly to ensure a uniform spray pattern. A test piece before starting the actual project is a good idea.

- Sanding Between Coats: Consistent sanding between coats using the appropriate grit ensures a smooth, even surface for the next layer. This removes imperfections and creates an even base for the finish.

By following these steps, you can minimize variations and deliver a flawless, uniform finish across all your cabinets.

Q 9. What types of finishing equipment are you proficient with?

My expertise spans a range of finishing equipment, from traditional hand tools to advanced spray systems. I’m proficient in using:

- Spray Guns (HVLP, airless): I’m comfortable with both high-volume, low-pressure (HVLP) and airless spray systems, selecting the appropriate one based on the project’s needs and the finish being applied. HVLP offers better atomization and less overspray, while airless is faster for large projects.

- Brushes and Rollers: For smaller projects or detailed work, I utilize high-quality brushes and rollers, ensuring proper application and minimizing brush strokes. Choosing the right brush for the finish is crucial.

- Sanding Equipment: I’m skilled in using various sanding tools, including orbital sanders, belt sanders, and hand sanding blocks, to achieve the desired surface smoothness.

- Finishing Accessories: I’m also experienced with various finishing accessories, including tack cloths, respirators, and safety glasses, ensuring both quality and safety in the work environment.

My proficiency with this equipment allows me to select the optimal tools for each project, resulting in the best possible finish.

Q 10. Describe your experience with different types of wood and their finishing requirements.

Different woods have unique characteristics that influence their finishing requirements. For example, the porous nature of oak requires a different approach than the denser grain of maple.

- Oak: Oak’s open grain needs to be filled before finishing to prevent uneven color absorption. I typically use wood filler and then carefully sand it smooth before staining or painting.

- Maple: Maple’s dense, closed grain takes stain more evenly. It might require a sealer to prevent blotchiness.

- Cherry: Cherry wood darkens over time and requires careful selection of stain and finish to achieve the desired effect. A clear finish allows the natural color to develop, while a darker stain speeds the process.

- Softwoods (Pine, Fir): Softwoods often require a wood conditioner or a sanding sealer to create a uniform surface and prevent the finish from soaking into the wood unevenly.

I adjust my techniques depending on the wood type, considering its grain, porosity, and overall properties to achieve the best results. Experience has taught me how to handle these nuances effectively.

Q 11. How do you handle damaged or imperfect cabinet surfaces before finishing?

Handling imperfections before finishing is critical to achieving a professional result. It’s like prepping a canvas before painting a masterpiece.

- Repairing Damage: I use wood filler to repair dents and scratches, ensuring it’s completely level with the surrounding surface after drying and sanding.

- Filling Gaps: Wood glue and clamps are used to repair loose joints and gaps, ensuring a stable and solid base for finishing.

- Sanding: Multiple stages of sanding, progressing from coarser to finer grits, are essential for removing imperfections and achieving a smooth surface. This creates an even foundation for the finish to adhere to.

- Cleaning: Thorough cleaning using tack cloths removes any dust or debris that could compromise the adhesion of the finish.

These steps are essential to eliminate visual flaws and create a perfectly smooth surface for an exceptional finish.

Q 12. What are the advantages and disadvantages of different finish types?

Several finish types exist, each with its own set of advantages and disadvantages.

- Lacquer: Advantages: Fast drying time, durable, and produces a smooth finish. Disadvantages: Can be difficult to repair and may require multiple thin coats.

- Shellac: Advantages: Easy to repair, creates a warm tone, and is naturally breathable. Disadvantages: More sensitive to moisture and less durable than lacquer.

- Polyurethane: Advantages: Extremely durable, water-resistant, and comes in various finishes (gloss, satin, matte). Disadvantages: Longer drying time, more difficult to repair, and can yellow over time.

- Paint: Advantages: Excellent for hiding imperfections and readily available in various colors. Disadvantages: Less durable than many other finishes and often requires more coats for even coverage.

The choice of finish depends on the client’s preferences, budget, and the specific requirements of the project. For example, a high-traffic kitchen might benefit from the durability of polyurethane, while a delicate antique piece might be better suited to shellac.

Q 13. How do you maintain your finishing equipment?

Maintaining finishing equipment is crucial for consistent results and longevity. Regular maintenance prevents costly repairs and ensures optimal performance.

- Cleaning: After each use, I thoroughly clean spray guns and brushes using appropriate solvents. This prevents build-up of finish and ensures proper operation next time.

- Lubrication: Moving parts on spray guns and other equipment need regular lubrication to prevent wear and tear.

- Storage: I store equipment in a clean, dry environment to protect it from moisture and dust.

- Regular Inspection: I inspect equipment regularly for any damage or wear, addressing any issues promptly.

Proper maintenance isn’t just about prolonging the lifespan of the equipment, it directly impacts the quality of the finish. A well-maintained spray gun, for instance, produces a far superior finish compared to a neglected one.

Q 14. What are the industry standards for VOC compliance in cabinet finishing?

VOC (Volatile Organic Compound) compliance is a critical aspect of cabinet finishing. VOCs are released into the air during the drying process of many finishes and can be harmful to both the environment and the health of the workers.

Industry standards vary by location and are often regulated at the state or local level. However, common practices include:

- Using low-VOC or zero-VOC finishes: These finishes minimize the release of harmful chemicals, protecting the environment and worker health.

- Proper ventilation: Maintaining adequate ventilation in the workspace helps to reduce VOC concentrations. This is especially important when working with higher-VOC finishes.

- Following safety protocols: This involves wearing appropriate personal protective equipment (PPE) like respirators and eye protection.

- Proper disposal of waste: Adhering to local regulations for disposal of waste materials and solvents to prevent environmental contamination.

Staying informed about current regulations and choosing environmentally friendly finishes demonstrates professionalism and commitment to responsible practices.

Q 15. Describe your experience with different types of primers and sealers.

Primers and sealers are crucial in cabinet finishing, acting as the foundation for a durable and aesthetically pleasing finish. They prepare the wood surface, improving adhesion of subsequent coats and blocking stains or blemishes. My experience encompasses a wide range of products, categorized primarily by their chemical composition and intended function.

Oil-based primers: These offer excellent adhesion and are often used on porous woods like pine or fir. They tend to have a longer drying time but provide a robust base for topcoats. For example, I’ve successfully used oil-based primers on knotty pine cabinets to prevent resin bleeding through the final finish.

Water-based primers: Environmentally friendly and low in VOCs (Volatile Organic Compounds), water-based primers are becoming increasingly popular. They dry quickly and offer good adhesion, particularly on hardwoods. I frequently use these on cherry and maple cabinets due to their quick drying times, allowing for faster turnaround.

Shellac-based sealers: Shellac provides a very hard, protective layer that’s excellent at sealing knots and preventing stains from bleeding through. It’s a traditional choice, and I use it when working on antique restoration projects or when superior stain blocking is needed. The amber tint can be a benefit or a drawback depending on the final finish, something I discuss with clients upfront.

Stain-blocking primers: Specifically formulated to prevent bleed-through from tannins and other wood components, these primers are indispensable when working with woods like redwood or cedar. I’ve used these on many projects, where they proved vital in achieving a consistent, even final colour.

The choice of primer or sealer depends heavily on the type of wood, the desired finish, and environmental considerations. I always carefully assess these factors before selecting the most appropriate product for each project.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you handle rush orders or tight deadlines in cabinet finishing?

Handling rush orders requires meticulous planning and efficient execution. My strategy involves a three-pronged approach: prioritizing tasks, optimizing workflow, and leveraging my team’s expertise (where applicable).

Prioritization: I immediately assess the order’s specifics, identifying critical steps that cannot be delayed. This might involve focusing on completing the priming and sealing stages quickly to allow for parallel processes like sanding and color matching.

Workflow Optimization: I meticulously plan each step of the finishing process, minimizing downtime between tasks. This may involve using faster-drying products or adjusting the spray application technique for improved efficiency. For example, I might use a higher-pressure spray gun to reduce the number of passes needed for a consistent coat.

Teamwork: In larger projects, I coordinate with my team (if applicable), assigning tasks based on individual strengths and ensuring smooth transitions between stages. Clear communication and diligent monitoring are key.

While speed is essential, maintaining quality is paramount. I never compromise on proper surface preparation or the application of coats, even under pressure. A rushed job will always show, and that is something I refuse to allow.

Q 17. What is your understanding of different sheen levels (e.g., matte, satin, gloss)?

Sheen levels describe the amount of light reflected by the cabinet finish. Different sheens create varying aesthetic effects, ranging from a subtle matte finish to a high-gloss shine.

Matte (or Flat): Reflects minimal light, resulting in a low-luster, velvety appearance. It’s ideal for a more understated, traditional look and can help conceal minor imperfections.

Satin: Offers a soft, subtle sheen with a slightly reflective surface. It strikes a balance between matte and gloss, providing elegance without being overly shiny. It’s a very popular choice due to its versatility.

Semi-gloss: Shows a noticeable shine with more reflectivity than satin, making it easy to clean. It’s a practical choice for high-traffic areas like kitchen cabinets.

Gloss: Highly reflective, providing a mirror-like shine. While visually striking, gloss emphasizes any surface imperfections, requiring flawless preparation. It’s a great option when a bold, modern look is desired.

Understanding sheen levels is crucial for meeting client expectations. I always discuss the various options with clients, showing samples to help them visualize the final look and choose the best sheen for their project and their style preference.

Q 18. How do you clean your spray equipment after use?

Cleaning spray equipment immediately after use is vital to prevent paint buildup and ensure the equipment’s longevity. My cleaning process is precise and consistent, involving a multi-step approach.

Initial Flush: I begin by flushing the system with the appropriate thinner or cleaner recommended for the specific type of finish I used (e.g., lacquer thinner for lacquer finishes, water for water-based finishes). This removes most of the wet paint.

Detailed Cleaning: I then disassemble any removable parts of the spray gun (e.g., needles, cups, and air caps), cleaning each component thoroughly with the thinner or cleaner. I use brushes and appropriate cleaning rags to remove any stubborn residue.

Rinsing: After cleaning, I thoroughly rinse all parts with the solvent or water until completely clean. I will repeat this process several times until any trace of paint is gone.

Lubrication: For air-operated spray guns, I lubricate moving parts as per the manufacturer’s instructions.

Reassembly and Storage: I carefully reassemble the spray gun, ensuring all parts are properly seated. I store the equipment in a clean, dry place to prevent rust and corrosion.

Proper cleaning prevents clogs, ensures consistent spray patterns in future projects, and extends the lifespan of my equipment, saving money in the long run.

Q 19. Explain your experience with repairing minor imperfections in a finished cabinet.

Repairing minor imperfections in a finished cabinet requires precision and attention to detail. The approach varies depending on the nature of the imperfection.

Minor Scratches: These are often addressed with a touch-up of paint or stain, carefully blended to match the surrounding area. A very fine-grit sandpaper can be used to smooth any irregularities before applying the touch-up.

Small Chips: These require filling the chip with a suitable wood filler, sanding smooth, and then applying a touch-up to match the finish.

Dings or dents: Depending on the depth, these may require wood filler, and then sanding and a finishing touch-up. For more significant damage, the affected area might need to be repaired with wood patching techniques before finishing.

I use specialized touch-up techniques, such as feathering or stippling, to ensure that the repairs are invisible, blending seamlessly with the existing finish. The success of these repairs hinges on careful color matching and the use of high-quality materials. Proper lighting is essential during these repairs to ensure a quality match.

Q 20. What is your experience with applying clear coats and topcoats?

Applying clear coats and topcoats provides protection and enhances the cabinet’s appearance. My experience includes working with various types, each offering unique properties.

Lacquer: Dries quickly, providing a hard, durable finish. It’s excellent for achieving a high-gloss shine but requires careful application to avoid runs or sags.

Polyurethane: Offers excellent durability and protection against scratches and moisture. It’s available in various sheens and is a popular choice for kitchen cabinets.

Varnish: Provides a protective layer with good clarity and durability. It’s often chosen for its ability to enhance the natural wood grain.

The application method involves multiple thin coats, allowing sufficient drying time between each coat to prevent runs and ensure proper adhesion. I carefully sand lightly between coats to create a smooth, even finish. The final coat is carefully inspected for flaws before final approval.

Q 21. How do you handle customer requests or revisions to a finish?

Handling customer requests and revisions is crucial for client satisfaction. My approach centers on clear communication, collaboration, and a commitment to exceeding expectations.

Open Communication: I encourage open communication throughout the project, regularly updating the client on progress and proactively addressing any concerns.

Detailed Review: When a revision is requested, I carefully review the request, ensuring I fully understand the client’s vision. I discuss potential challenges and solutions, providing realistic timelines and cost implications where necessary. I encourage open dialogue and will suggest alternatives, if they meet quality standards.

Collaborative Approach: I work closely with the client, offering options and suggestions while ensuring the final product aligns with their preferences and remains within the scope of the project. This may involve showing samples of different finishes or techniques.

Documentation: I maintain detailed records of all changes, approvals, and any adjustments made to the project scope.

I believe that proactive communication and a collaborative approach are key to resolving any disagreements and delivering a project that meets and surpasses the client’s expectations. Even if it means additional time or cost considerations, exceeding expectations builds customer trust and a great reputation.

Q 22. What methods do you use to ensure the longevity and durability of the finish?

Ensuring a durable and long-lasting finish on cabinets involves a multi-step process that begins even before the finish is applied. It’s about creating a solid foundation for the finish to adhere to and protecting it from environmental stressors.

- Proper Wood Preparation: This is paramount. It involves meticulously sanding the wood to a smooth surface, removing any imperfections or debris. This ensures good adhesion of the finish. I typically use multiple grits of sandpaper, progressing from coarser to finer grits, to achieve a flawless surface.

- Primer Application: A high-quality primer acts as a barrier between the wood and the topcoat, preventing staining and improving the overall finish’s durability. I select primers based on the wood species and the desired finish.

- Multiple Thin Coats: Rather than applying one thick coat, I always opt for multiple thin coats. This allows for better penetration and less chance of runs, drips, or unevenness. Each coat is allowed to dry thoroughly before the next is applied.

- Topcoat Selection: The type of topcoat greatly influences durability. For example, polyurethane is known for its hardness and scratch resistance, making it an excellent choice for kitchen cabinets. I consider factors like the cabinet’s location (high-traffic area or not) and the desired level of sheen when selecting a topcoat.

- Proper Curing Time: Allowing sufficient time for each coat to cure is critical. Rushing the process can result in a weak and less durable finish. I follow the manufacturer’s recommendations meticulously.

For example, I once worked on a project where the client wanted a super durable finish for their high-traffic kitchen. We used a high-quality polyurethane topcoat applied in multiple thin coats and allowed ample curing time, and the finish has held up exceptionally well for over five years now.

Q 23. How do you maintain a clean and organized work area?

A clean and organized workspace is crucial for efficiency and the quality of the finish. Chaos leads to mistakes and delays. My approach is based on a system of constant maintenance and a dedicated place for everything.

- Designated Areas: I have specific areas for sanding, staining, finishing, and cleanup. This prevents cross-contamination and keeps materials organized.

- Regular Cleanup: After each step, I immediately clean my tools and workspace. This prevents dried finishes from accumulating and interfering with subsequent steps. I use appropriate solvents and rags for cleaning.

- Storage System: All materials, tools, and finishes are stored in clearly labeled containers and racks. This makes it easy to find what I need when I need it. I use color-coded labels to further enhance organization.

- Waste Disposal: Proper disposal of hazardous waste, such as solvents and used rags, is vital. I adhere strictly to all safety regulations and disposal procedures.

Maintaining a clean workspace is not just about tidiness; it’s a safety measure. A cluttered workspace is a dangerous workspace. It reduces the risk of accidents and enables me to focus on producing high-quality work.

Q 24. What is your experience with cabinet finishing in different wood species?

My experience spans a wide range of wood species, each requiring a unique approach to finishing. The key is understanding the characteristics of each wood—its porosity, density, and grain pattern—to achieve the desired outcome.

- Hardwoods (Oak, Maple, Cherry): These woods generally accept stain well and offer a beautiful finish. However, careful sanding is essential to achieve a smooth surface. I often use pre-catalyzed lacquers or polyurethane for a durable finish on these hardwoods.

- Softwoods (Pine, Fir): Softwoods are more porous and require more attention to filling any gaps or imperfections before staining or finishing. I may use wood filler to achieve a smooth surface. A durable finish is essential to protect these softer woods.

- Exotic Woods (Walnut, Mahogany): Exotic woods often have unique grain patterns and colors that require careful handling to enhance their beauty. I focus on highlighting the natural grain using appropriate stains and finishes, often using oil-based finishes for a richer look.

For instance, I recently completed a project using reclaimed oak. The wood had some variations in color, which I enhanced using a clear coat with a slight amber tint to emphasize the natural variations and give it a warm, antique look.

Q 25. Describe your troubleshooting skills related to finish defects (e.g., blistering, cracking).

Troubleshooting finish defects is a crucial skill. My approach involves systematic investigation to pinpoint the cause and implement the appropriate solution.

- Blistering: Often caused by insufficient drying time between coats or applying finish over a damp surface. The solution is to sand down the affected area, allowing it to dry completely, and reapplying the finish properly.

- Cracking: Can result from applying thick coats, using an incompatible finish, or inadequate surface preparation. Addressing the underlying cause is key, which may involve sanding and refinishing the entire piece.

- Runs and Sags: Typically occur when applying too much finish at once. The solution is to lightly sand the affected area after it dries completely and reapply thin coats to avoid further sagging.

- Orange Peel: Caused by spraying with too much pressure, improper gun setup or high viscosity finish. Proper adjustment of spray equipment and the correct thinner for the finish is crucial.

For example, I once encountered a cabinet with severe blistering. Through careful investigation, I determined the underlying cause was insufficient drying time. I successfully remedied the issue by carefully sanding the blisters, allowing adequate drying time, and reapplying multiple thin coats of finish, resulting in a smooth, flawless result.

Q 26. How do you manage your time and prioritize tasks in a busy cabinet shop?

Time management is essential in a busy cabinet shop. I employ a combination of strategies to prioritize tasks and maintain efficiency.

- Project Planning: I carefully review each project’s specifications, materials, and timeline before starting. This allows me to create a realistic schedule and identify potential bottlenecks.

- Prioritization: I prioritize tasks based on deadlines and urgency. Critical tasks are addressed first to meet deadlines effectively.

- Task Batching: I group similar tasks together (e.g., sanding all the cabinet doors at once). This improves efficiency by minimizing setup and cleanup time.

- Regular Check-ins: Throughout the day, I conduct brief check-ins to ensure I am on track and to adjust my schedule if necessary. This prevents unforeseen delays.

Utilizing a digital project management tool for tracking progress and deadlines is invaluable. This ensures smooth coordination and prevents miscommunication, ultimately saving valuable time.

Q 27. What are your strengths and weaknesses as a cabinet finisher?

My strengths lie in my meticulous attention to detail, my ability to troubleshoot finish defects effectively, and my broad experience across various wood species and finishes. I’m also a dedicated and reliable worker who takes pride in the quality of my craftsmanship.

A potential area for development is delegation. While I excel at handling the entire finishing process myself, learning to delegate certain tasks effectively would allow me to manage even larger volumes of work.

Q 28. What are your salary expectations?

My salary expectations are commensurate with my experience and skillset, ranging from [Insert Lower Bound] to [Insert Upper Bound] annually. This is based on my research of industry standards and my confidence in my abilities to contribute significantly to your team.

Key Topics to Learn for Your Cabinet Finishing Interview

- Wood Species & Properties: Understanding the characteristics of various wood types (e.g., oak, maple, cherry) and their impact on finishing techniques and durability.

- Surface Preparation: Mastering sanding techniques, filling imperfections, and ensuring a smooth, even surface for optimal finish adhesion. This includes understanding different grits and their application.

- Finishing Techniques: Proficiency in various finishing methods, including staining, sealing, lacquering, and applying topcoats. Understanding the differences in sheens and their application.

- Finishing Materials: Knowledge of different types of stains, sealers, lacquers, and their properties (e.g., water-based vs. oil-based). Understanding the chemical interactions and potential compatibility issues.

- Troubleshooting & Problem Solving: Identifying and resolving common finishing issues such as drips, runs, uneven color, and poor adhesion. This includes understanding the root cause of such problems.

- Health & Safety: Familiarity with safety regulations and procedures related to handling finishing materials and equipment (e.g., proper ventilation, PPE use).

- Application Methods: Understanding and being able to discuss different application techniques, including spraying, brushing, and wiping. This includes considerations of material viscosity and environmental conditions.

- Color Matching & Custom Finishes: Experience in mixing and matching colors to achieve specific results and understanding techniques for creating custom finishes.

- Finishing Equipment: Familiarity with various finishing tools and equipment, including spray guns, sanders, and other relevant tools. Understanding proper maintenance and cleaning.

- Quality Control: Understanding the importance of quality control measures throughout the finishing process to ensure a high-quality, durable finish.

Next Steps

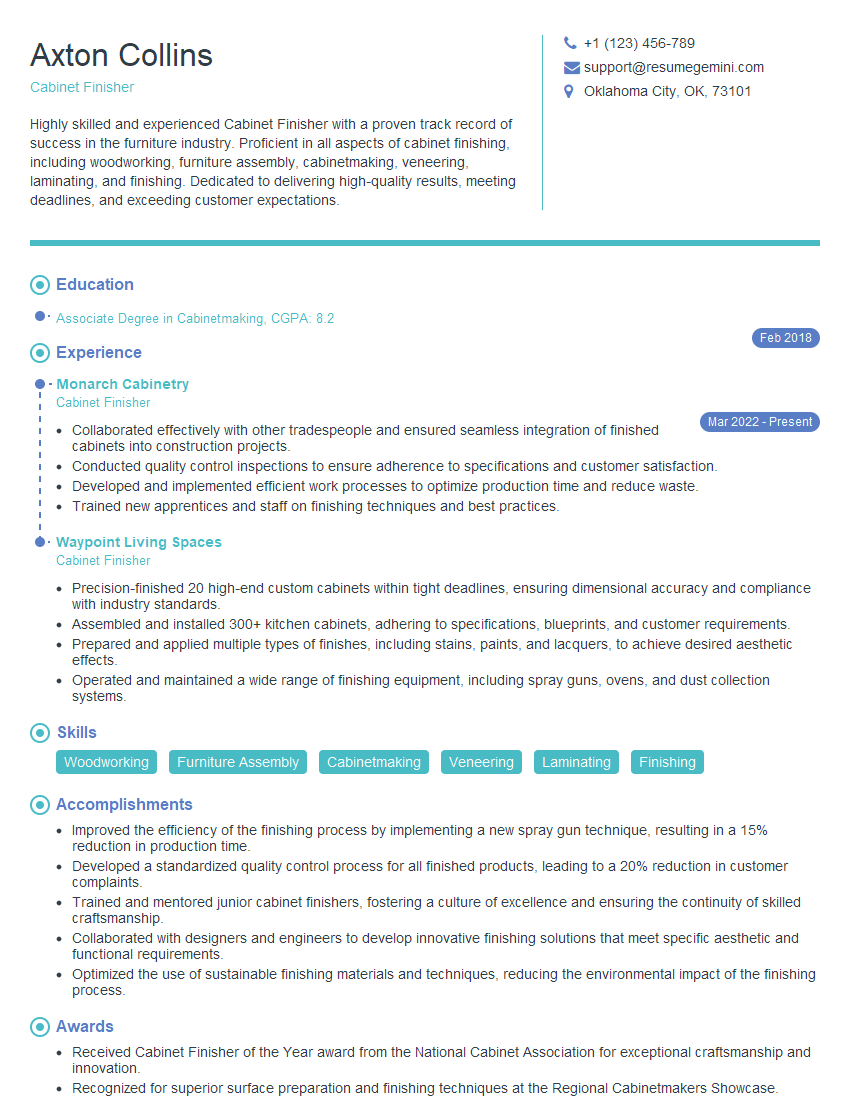

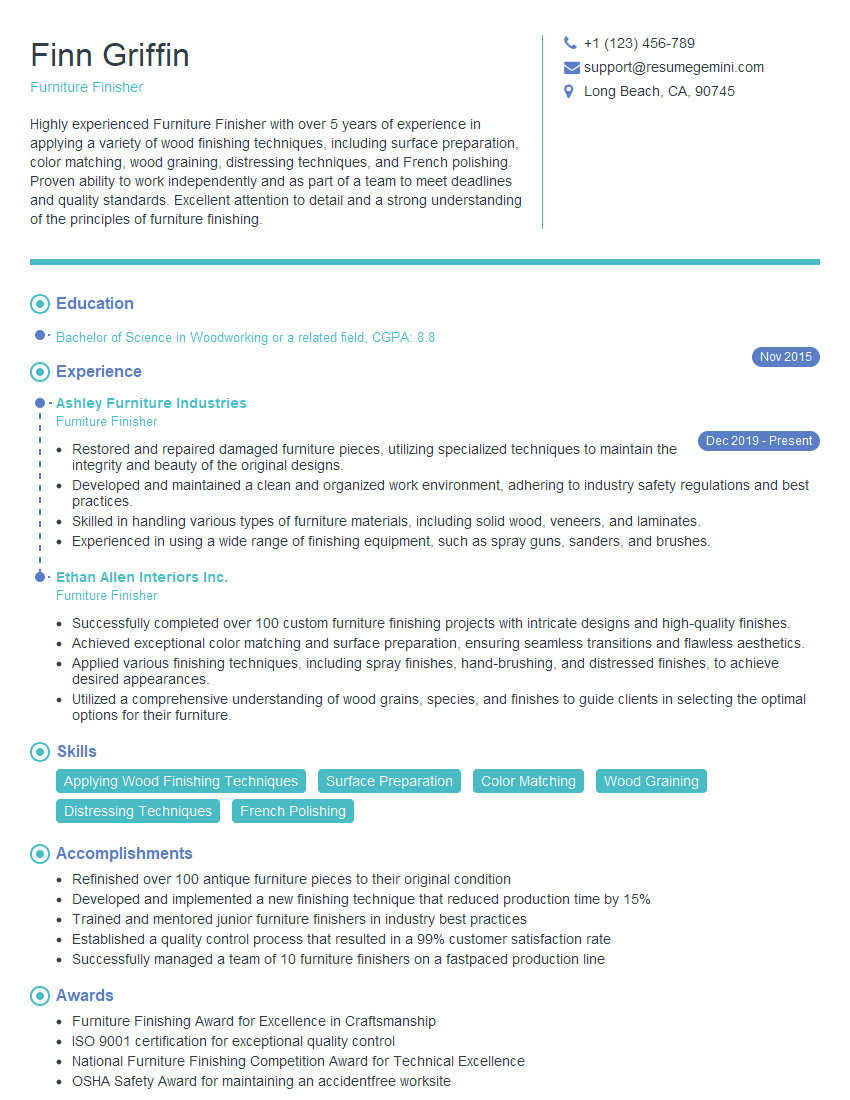

Mastering cabinet finishing techniques significantly enhances your career prospects in the woodworking industry, opening doors to higher-paying roles and specialized projects. To maximize your chances of landing your dream job, creating an ATS-friendly resume is crucial. This ensures your application gets noticed by recruiters and hiring managers. We highly recommend using ResumeGemini to build a professional and impactful resume. ResumeGemini provides a user-friendly platform and offers examples of resumes tailored to cabinet finishing positions to help you craft a compelling application.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

hello,

Our consultant firm based in the USA and our client are interested in your products.

Could you provide your company brochure and respond from your official email id (if different from the current in use), so i can send you the client’s requirement.

Payment before production.

I await your answer.

Regards,

MrSmith

hello,

Our consultant firm based in the USA and our client are interested in your products.

Could you provide your company brochure and respond from your official email id (if different from the current in use), so i can send you the client’s requirement.

Payment before production.

I await your answer.

Regards,

MrSmith

These apartments are so amazing, posting them online would break the algorithm.

https://bit.ly/Lovely2BedsApartmentHudsonYards

Reach out at [email protected] and let’s get started!

Take a look at this stunning 2-bedroom apartment perfectly situated NYC’s coveted Hudson Yards!

https://bit.ly/Lovely2BedsApartmentHudsonYards

Live Rent Free!

https://bit.ly/LiveRentFREE

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?