Are you ready to stand out in your next interview? Understanding and preparing for Chimney Liner Installation interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Chimney Liner Installation Interview

Q 1. What types of chimney liners are you familiar with (e.g., flexible, rigid, stainless steel)?

Chimney liners are crucial for safe and efficient venting of combustion appliances. I’m familiar with several types, each with its own strengths and weaknesses. The most common include:

- Flexible Liners: These are typically made of stainless steel and are highly adaptable to chimneys with bends or irregularities. They’re easier to install in challenging situations but might not be as durable as rigid liners in the long term.

- Rigid Liners: These liners are usually made of clay tile, metal (stainless steel is most common), or cast iron. They offer excellent strength and durability but require a more precise fit and are challenging to install in chimneys with complex shapes.

- Stainless Steel Liners: This is a very popular choice, encompassing both flexible and rigid types. Stainless steel offers excellent corrosion resistance, making it ideal for many applications. Different grades of stainless steel offer varying levels of corrosion resistance and heat tolerance, necessitating careful selection based on the appliance and chimney conditions.

The choice between these types depends heavily on the specific chimney’s condition and the type of appliance being vented.

Q 2. Describe the process of measuring a chimney for liner installation.

Accurately measuring a chimney for liner installation is critical for a successful and safe installation. The process involves several steps:

- Visual Inspection: Begin with a thorough visual inspection of the chimney from the top down, using a camera if necessary, to identify any obstructions, damage, or unusual shapes.

- Measuring the Height: Determine the total height of the chimney liner from the appliance connection point to the chimney top. Use a measuring tape and account for any bends or offsets.

- Measuring the Diameter: Measure the inside diameter of the chimney flue at several points. Use a flexible measuring tool that can navigate bends. The smallest diameter will determine the maximum liner size.

- Determining the Chimney Shape: Document the chimney shape – straight, with bends, offsets, or other complexities. Sketching a diagram is often helpful.

- Checking for Obstructions: Carefully note the location and type of any obstructions, like bird nests or debris. This information is crucial for planning the installation strategy.

Precise measurements are essential to avoid gaps that can compromise safety or create a poor draft. I always double-check my measurements to prevent costly mistakes.

Q 3. How do you determine the appropriate liner diameter and material for a specific chimney?

Choosing the right liner diameter and material is crucial for safety and efficiency. The diameter must be slightly smaller than the flue’s interior diameter to ensure a proper fit. This leaves enough space for sealant and prevents the liner from becoming lodged. The material choice depends on factors like:

- Appliance Type: Different appliances have different venting requirements; a wood-burning stove will require a liner with a higher heat tolerance than a gas fireplace.

- Fuel Type: Gas appliances usually require different liners than wood or oil burning appliances.

- Chimney Condition: A damaged or deteriorated chimney may necessitate a more robust liner.

- Local Codes and Regulations: Always check and adhere to local building codes and regulations.

For example, a gas appliance might use a smaller diameter liner than a wood-burning appliance with a larger vent opening. A chimney with significant deterioration might require a rigid liner rather than a flexible one, for enhanced structural support.

I always consult manufacturer recommendations and relevant codes to ensure the liner is appropriate for the specific application. In cases of doubt, seeking a second opinion from a qualified expert is always prudent.

Q 4. Explain the importance of proper chimney liner sealing and how it’s achieved.

Proper sealing of the chimney liner is paramount for safety and efficiency. Unsealed gaps allow dangerous combustion byproducts to leak into the home, while gaps can compromise draft and lead to smoke backflow. Sealing is achieved using high-temperature sealant, specifically designed for chimney applications.

The sealant is applied to all joints and connections between liner sections, and between the liner and the chimney’s interior. Common areas for sealing include connections of liner sections, the connection at the top of the chimney, and the connection to the appliance.

The type of sealant used should be compatible with the liner material and able to withstand the temperatures generated by the appliance. A properly sealed liner creates a gas-tight system, ensuring safe and effective venting.

Think of it like sealing a window – any gaps allow drafts and leakage. Similarly, gaps in a chimney liner can have serious consequences.

Q 5. What safety precautions are essential during chimney liner installation?

Safety is my top priority during any chimney liner installation. Essential precautions include:

- Fall Protection: Working at heights requires harnesses, safety lines, and adherence to fall protection standards.

- Respiratory Protection: Chimneys often contain dust and debris; using respirators is vital to protect against inhalation hazards.

- Proper Tools and Equipment: Using the correct tools (e.g., proper ladders, safety gear, appropriate lifting equipment) reduces the risk of accidents.

- Fire Safety: Taking precautions to prevent fires, especially during cutting or welding operations, is crucial.

- Working with a Partner: Never work alone, especially at heights; a partner offers immediate assistance in case of an accident.

- Awareness of Environmental Hazards: Birds’ nests or other debris within the chimney can pose unexpected challenges.

Regular safety checks and adherence to established safety protocols are vital to minimize risk and ensure a safe working environment for myself and others involved.

Q 6. How do you identify and address potential obstacles during liner installation (e.g., obstructions, bends)?

Encountering obstacles during liner installation is common. These obstacles might include obstructions, bends, or sections of the chimney that are too narrow or damaged. Addressing these requires careful planning and specialized techniques.

- Obstructions: Obstructions like bird nests or debris are removed before liner installation begins, often with specialized tools and cameras. Severely damaged sections may require repair or rebuilding.

- Bends: Flexible liners are designed to navigate bends, but the process requires careful maneuvering to avoid kinks or damage. Rigid liners may necessitate the use of specialized components to negotiate tight bends.

- Narrow or Damaged Sections: Damaged sections may necessitate repair or even chimney reconstruction. If the flue is too narrow, the installation may not be feasible without resizing the chimney.

A thorough pre-installation inspection is essential to identify potential obstacles and develop a suitable strategy. In some cases, creative solutions may be necessary, such as using specialized liner sections or employing additional support structures.

One memorable instance involved a bird nest blocking almost half the flue. We carefully removed it, taking precautions to prevent debris from falling further down the chimney.

Q 7. What are the common causes of chimney liner failure?

Chimney liner failure can stem from several causes, impacting both safety and efficiency.

- Corrosion: Exposure to moisture, condensation, and corrosive gases can cause liners, especially those made of less resistant materials, to corrode over time.

- High Temperatures: Exceeding the liner’s temperature rating can lead to damage or failure, especially important with wood-burning appliances.

- Improper Installation: Incorrect sizing, poor sealing, or inadequate support can lead to premature liner failure. This underscores the significance of accurate measurements and professional installation.

- Buildup of Creosote: Creosote buildup can restrict airflow and cause overheating, leading to liner damage. Regular chimney cleaning is essential to prevent this.

- Physical Damage: Impact from objects falling down the chimney or settling of the chimney structure can damage the liner.

Regular inspections and maintenance are key to preventing liner failure. Early detection of problems can often prevent major and costly repairs.

Q 8. Describe your experience with different liner installation methods.

Chimney liner installation involves several methods, each chosen based on the chimney’s condition and the appliance being vented. The most common are flexible liners and rigid liners. Flexible liners, typically made of stainless steel, are inserted into the existing chimney flue. This method is versatile and suitable for chimneys with minor imperfections. We use a specialized insertion tool to carefully navigate bends and ensure a smooth, even installation. Rigid liners, usually ceramic or stainless steel, require more precise measurements and fitting. They are often preferred for severely damaged chimneys or when a more robust and durable solution is necessary. This installation often involves creating a mortar bed to secure the liner in place. In some cases, a combination of both methods might be employed, for example, using rigid liners in the lower section of the chimney where temperatures are highest and flexible liners higher up. I have extensive experience with all these methods and have successfully installed liners in various chimney types, from masonry to prefabricated metal chimneys.

For example, on a recent project, a homeowner was experiencing creosote buildup and chimney drafts. After a thorough inspection, we opted for a flexible stainless steel liner due to the minimal damage to the existing flue. It provided a secure and efficient venting system, eliminating the creosote problem. Conversely, another project involved a chimney with significant cracking; a rigid ceramic liner was installed after carefully repairing the damaged sections of the chimney, creating a completely reliable and safe venting system.

Q 9. How do you ensure the proper draft within a chimney after liner installation?

Proper draft is crucial for safe and efficient appliance operation. After liner installation, we meticulously check the draft to ensure it’s within the manufacturer’s specifications. We use a draft gauge to measure the pressure difference between the inside and outside of the chimney. An inadequate draft can lead to incomplete combustion, producing carbon monoxide and other dangerous byproducts. Conversely, excessive draft can cause excessive fuel consumption and potentially damage the appliance. Several factors influence draft, including chimney height, flue diameter, and the liner’s smoothness and integrity. We address issues by checking for blockages, ensuring proper chimney cap ventilation, and adjusting the flue diameter if necessary. For example, if the draft is too low, we might need to clean any obstructions or even consider a taller chimney cap. If the draft is too strong, we might examine the flue diameter or appliance configuration.

Q 10. What are the building codes and regulations related to chimney liner installation in your area?

Building codes and regulations concerning chimney liner installation vary by location, but there are common themes. In my area, we must adhere strictly to the International Residential Code (IRC) and local ordinances. These regulations cover aspects like liner materials, clearances between the liner and the chimney, firestopping methods, and the inspection process. Codes usually specify minimum liner diameter requirements based on the appliance’s BTU output. All our installations are documented and meet local codes; I regularly attend continuing education courses to stay updated on code changes and best practices.

Q 11. How do you inspect a chimney for damage before liner installation?

Before liner installation, a thorough chimney inspection is critical. This typically involves a visual inspection using a video camera to check for cracks, spalling, deterioration, blockages (like bird nests or debris), and any other damage to the existing chimney structure. We assess the chimney’s overall stability and identify areas that might affect liner installation or future performance. We look for signs of water damage, which can indicate leaks and potential structural issues. This detailed inspection allows us to plan the installation effectively and address any potential problems beforehand, ensuring the long-term functionality and safety of the chimney system.

Q 12. What tools and equipment are necessary for chimney liner installation?

Chimney liner installation requires specialized tools and equipment. For flexible liners, we use insertion tools, often motorized, to guide the liner through the flue. For rigid liners, we need measuring tools, cutting tools, mortar, and possibly scaffolding for higher sections. Safety equipment is paramount, including harnesses, ropes, and fall protection. Other essential tools include: a level, a plumb bob, cleaning brushes, a vacuum cleaner for debris removal, a camera inspection system to check the chimney’s interior, and a draft gauge to check the chimney’s draft after installation. Safety is paramount, and we always use appropriate personal protective equipment (PPE) including gloves, safety glasses, and respirators.

Q 13. Describe your experience with working at heights.

I have extensive experience working at heights. Safety is my top priority, and I am fully certified and trained in fall protection techniques. I’m proficient in using various types of harnesses, lifelines, and anchors to ensure safety during installation. I’m always aware of weather conditions and environmental factors that might affect safety at heights. I regularly inspect my equipment, making sure it’s in perfect working condition, and I strictly adhere to all safety protocols and procedures.

Q 14. How do you handle unexpected issues or complications during installation?

Unexpected issues during installation are sometimes unavoidable. For example, we might encounter unexpected blockages or damage to the chimney that wasn’t detected during the initial inspection. In such cases, we have a problem-solving strategy. This involves careful assessment of the issue, using our expertise to determine the best course of action, and communicating openly with the client about potential changes or delays. We’re adept at adapting to unforeseen circumstances while maintaining safety and quality. I always have a contingency plan to handle such issues, and I prioritize communication with the client throughout the process to keep them informed. For instance, if we uncover significant damage during installation, we’ll stop the work, re-evaluate the situation, and provide a detailed cost estimate for any necessary repairs before continuing.

Q 15. What is your understanding of chimney fire prevention and mitigation?

Chimney fires are terrifying and devastating, but largely preventable. My understanding centers around the principle of proper venting and minimizing creosote buildup. Creosote, a byproduct of incomplete combustion, is highly flammable and accumulates within the chimney flue. Prevention strategies include regular chimney cleaning (at least annually, more frequently for high-use fireplaces), burning only dry, seasoned wood, ensuring adequate airflow to the fireplace, and installing a properly sized and functioning chimney liner.

Mitigation involves addressing existing risks. This starts with a thorough chimney inspection to identify potential hazards like cracks, blockages, or excessive creosote. If a chimney fire does occur, immediate action is crucial. Call the fire department immediately and never attempt to extinguish it yourself. After the fire is out, a professional chimney sweep should inspect the damage and assess the need for repairs, liner replacement, or other necessary work. A properly installed and maintained liner is a key component of both prevention and mitigation because it creates a smooth, fire-resistant pathway for smoke and gases, preventing creosote buildup on the chimney’s interior walls.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain your experience with different types of chimney construction materials.

I’ve worked with a variety of chimney construction materials throughout my career. Older chimneys are often made of masonry – brick, stone, or concrete blocks. These materials are durable but can deteriorate over time, leading to cracks and gaps that compromise safety and efficiency. I’ve also worked extensively with prefabricated metal chimneys, typically made of stainless steel. Stainless steel liners are known for their durability, corrosion resistance, and ability to withstand high temperatures. They’re often preferred for their smooth interior, which minimizes creosote buildup and makes cleaning easier. In some cases, I’ve encountered clay tile liners, which are more traditional but require careful handling and are more susceptible to damage. Finally, I have experience working with flexible chimney liners, which are particularly useful for repairing existing chimneys with irregular shapes or adapting to difficult installations.

Q 17. How do you ensure the liner is properly supported and secured?

Proper support and securement of a chimney liner is paramount to its longevity and effectiveness. The liner must be installed so it is fully supported along its entire length and can withstand the thermal expansion and contraction it experiences during use. This involves using appropriate supports depending on the liner material and chimney construction. For example, stainless steel liners often use support brackets attached to the interior walls of the chimney. These brackets must be spaced according to manufacturer’s recommendations to prevent sagging or buckling. Masonry supports may also be necessary in some cases to provide additional stability, especially in older chimneys. The top and bottom connections are critical, ensuring a tight seal to prevent leakage and maintain the integrity of the venting system. We often use specialized sealant and clamps to achieve a reliable, long-lasting connection.

Imagine it like a tightly strung cable – if it isn’t supported properly, it could sag or break. Similarly, an unsupported liner can become damaged or detach, compromising its function and even posing a fire hazard. A properly supported liner is crucial for maintaining a safe and efficient chimney system.

Q 18. How do you communicate effectively with clients and colleagues during an installation?

Effective communication is the cornerstone of any successful chimney liner installation. With clients, I begin by thoroughly explaining the process, addressing their concerns, and answering their questions in plain language. I provide detailed quotes, outlining all costs involved and clearly explaining the benefits of the installation. Regular updates throughout the process, along with clear explanations of any unforeseen issues, build trust and transparency. With colleagues, clear and concise communication is key. I follow established safety protocols and always maintain open communication on the worksite, ensuring everyone understands their roles and responsibilities.

For example, I once had a client concerned about the disruption caused by the installation. By clearly outlining the process timeline and addressing their concerns proactively, I allayed their fears and ultimately fostered a positive working relationship. This level of communication is essential for building strong client relationships and efficient teamwork.

Q 19. How do you maintain accurate records and documentation for chimney liner installations?

Maintaining accurate records and documentation is a crucial aspect of my work. For each installation, I create a detailed report which includes the client’s information, a description of the existing chimney, the type of liner used, the installation details, photos (before, during and after installation), and any other relevant information. This documentation provides a comprehensive record of the work performed and ensures that I can easily access the details if needed in the future. This information is crucial for warranty claims, future maintenance, and ensures compliance with relevant regulations and standards. I also maintain a database of my past projects which allows me to track my work history and analyse trends and issues.

Q 20. What is your experience with troubleshooting chimney liner problems?

Troubleshooting chimney liner problems requires a systematic approach. I start by carefully inspecting the entire system, looking for visible signs of damage or malfunction, such as leaks, cracks, or blockages. I listen for unusual sounds, such as whistling or rattling, which can indicate problems within the flue. Specialized equipment such as a camera inspection system can be used to visually assess the interior of the chimney, identifying potential problems in areas not easily accessible. The symptoms of problems can vary widely. For example, a downdraft in the fireplace can point to a problem with the chimney liner’s draft, possibly due to a blockage or improper installation. Addressing these issues may involve repairs, such as resealing gaps, or more extensive interventions, like replacing sections of the liner or addressing issues with the overall chimney structure.

Q 21. Describe your familiarity with different types of chimney caps and their importance.

Chimney caps are crucial for protecting the chimney from the elements and improving its overall performance. I’m familiar with various types, including those made from stainless steel, copper, and aluminum. Stainless steel caps are popular for their durability and resistance to corrosion. Copper caps offer a more aesthetically pleasing appearance, while aluminum caps are a more economical option. The choice of material depends on factors like the chimney’s location, climate, and budget. The primary importance of chimney caps is to prevent water, debris, and animals from entering the chimney. This prevents damage to the chimney structure, reduces the risk of leaks and blockages, and improves the efficiency and safety of the chimney system. A well-designed cap will also enhance the chimney’s draft, ensuring proper ventilation and smoke removal.

Q 22. How do you assess the structural integrity of a chimney before liner installation?

Assessing a chimney’s structural integrity before liner installation is crucial for safety and the longevity of the liner. It’s like checking the foundation of a house before building a new addition – you wouldn’t want the addition to collapse because the foundation is weak.

My assessment involves a thorough visual inspection, using tools like a high-powered flashlight and a camera to inspect hard-to-reach areas. I check for:

- Cracks or deterioration in the masonry: Significant cracks could indicate instability and potential for collapse. I’d note their size, location, and severity.

- Efflorescence (salt deposits): This often signals moisture intrusion, weakening the chimney structure. I’d investigate the source of the moisture.

- Loose bricks or mortar: These indicate areas of weakness that need repair before liner installation.

- Chimney crown condition: A damaged crown allows water penetration, leading to further damage. I carefully examine for cracks and missing mortar.

- Spalling (chipping or flaking of the brick): Spalling signifies deterioration and potential for further damage.

If I identify any significant structural issues, I’ll recommend a structural engineer’s evaluation before proceeding with the liner installation. Safety is always my top priority.

Q 23. What is your experience with using specialized chimney cleaning equipment?

I’m proficient in using a variety of specialized chimney cleaning equipment, including rotary brushes, vacuum systems, and specialized cameras. These tools are essential for ensuring the chimney is clean and free of obstructions before liner installation. Think of it like preparing a clean canvas before painting a masterpiece – a clean chimney ensures a proper liner fit and optimal performance.

For example, I regularly utilize a high-powered vacuum system to remove soot and debris from the flue. This is particularly important when dealing with older chimneys that may have accumulated significant buildup over time. The camera allows me to inspect the interior thoroughly, identifying any hidden obstructions or damage. Rotary brushes are excellent for dislodging stubborn creosote buildup. I always follow manufacturer’s safety guidelines and best practices when operating this equipment.

Q 24. How do you dispose of waste materials generated during liner installation?

Waste disposal during chimney liner installation is handled responsibly and in compliance with all local regulations. It’s vital to protect both the environment and public safety.

We meticulously separate waste materials into different categories: masonry debris, soot, and any other construction waste. Masonry debris is typically transported to a designated landfill or recycling facility. Soot is often disposed of as hazardous waste, following all applicable regulations. Other waste materials are disposed of according to local ordinances. We always obtain the necessary permits and follow safe handling procedures. I keep detailed records of disposal methods for auditing purposes.

Q 25. Describe your approach to quality control during a chimney liner installation.

My approach to quality control is multifaceted, aiming for a perfectly installed liner that will provide decades of reliable service. Think of it like building a high-rise – every step requires meticulous attention to detail.

My quality control measures include:

- Pre-installation inspection: A thorough assessment of the chimney’s condition, as already discussed.

- Accurate liner measurements and selection: Ensuring the correct liner size and type for the chimney’s dimensions and application.

- Careful installation techniques: Following manufacturer’s instructions precisely to avoid liner damage or misalignment.

- Regular inspection during installation: Checking for proper alignment and seal integrity at every stage.

- Post-installation inspection: Using a camera to verify the liner’s proper placement and integrity. This includes checking for any gaps or damage.

- Documentation: Maintaining detailed records of the entire process, including photos and measurements, for future reference.

This multi-step process minimizes errors and ensures a high-quality installation.

Q 26. How do you stay up-to-date with the latest advancements and best practices in chimney liner installation?

Staying current in this field requires continuous learning. The industry is constantly evolving with new materials, techniques, and safety regulations. I actively participate in:

- Industry association memberships: Joining professional organizations that provide continuing education and networking opportunities.

- Manufacturer training: Attending training sessions offered by chimney liner manufacturers to stay updated on product advancements and installation best practices.

- Trade publications and online resources: Regularly reviewing industry journals, websites, and online forums for new information.

- Conferences and workshops: Attending industry events to learn from experts and network with other professionals.

This commitment to ongoing education ensures I consistently use the latest, most effective methods and materials.

Q 27. What is your experience with working in confined spaces?

I have extensive experience working in confined spaces, including chimneys. This requires specialized training and adherence to strict safety protocols. Safety is paramount. It’s not just about the physical demands; it’s about awareness and preparedness.

Before entering any confined space, I always:

- Assess the environment: Checking for hazardous gases, oxygen levels, and structural stability.

- Use appropriate safety equipment: This includes harnesses, respirators, and fall protection gear.

- Have a spotter: Someone who remains outside the chimney to monitor my progress and provide assistance if needed.

- Communicate regularly: Maintaining constant communication with the spotter to relay any issues or concerns.

My experience and adherence to safety protocols allow me to perform work efficiently and safely in these challenging environments.

Q 28. Describe a challenging chimney liner installation project and how you overcame the obstacles.

One particularly challenging project involved installing a liner in a very old, narrow, and severely deteriorated chimney. The existing flue was partially collapsed in sections, and there was significant creosote buildup. The narrow diameter made maneuvering the liner extremely difficult.

To overcome these obstacles, we first carefully stabilized the unstable sections of the chimney using specialized bracing and epoxy repair. We then used a flexible liner with a small diameter, carefully guiding it through the narrow sections using specialized insertion tools. We also employed a powerful industrial vacuum system to remove the creosote buildup to ensure a clean surface for the liner. The project required meticulous planning, careful execution, and close teamwork, but we successfully installed the liner without incident, restoring the chimney to safe and functional operation.

Key Topics to Learn for Chimney Liner Installation Interview

- Chimney System Assessment: Understanding chimney structure, identifying damage, and assessing suitability for liner installation. This includes recognizing different chimney materials and their limitations.

- Liner Selection and Sizing: Choosing the appropriate liner material (stainless steel, flexible, etc.) and diameter based on chimney dimensions and appliance requirements. Practical application involves calculations and understanding safety regulations.

- Installation Techniques: Mastering various installation methods, including top-down, bottom-up, and flexible liner insertion. This requires understanding tools, safety precautions, and troubleshooting common challenges.

- Code Compliance and Safety Regulations: Familiarity with local building codes, fire safety regulations, and industry best practices related to chimney liner installation. This ensures safe and legal installations.

- Troubleshooting and Problem Solving: Identifying and resolving common installation problems, such as liner kinks, improper sealing, and clearance issues. This includes understanding the cause-and-effect relationship of installation errors.

- Maintenance and Inspection: Understanding post-installation procedures, including inspections and maintenance recommendations to ensure long-term functionality and safety of the installed liner.

- Understanding Different Appliance Types and their Liner Requirements: Knowing the specific needs of various fuel types (wood, gas, oil) and how they influence liner selection and installation.

Next Steps

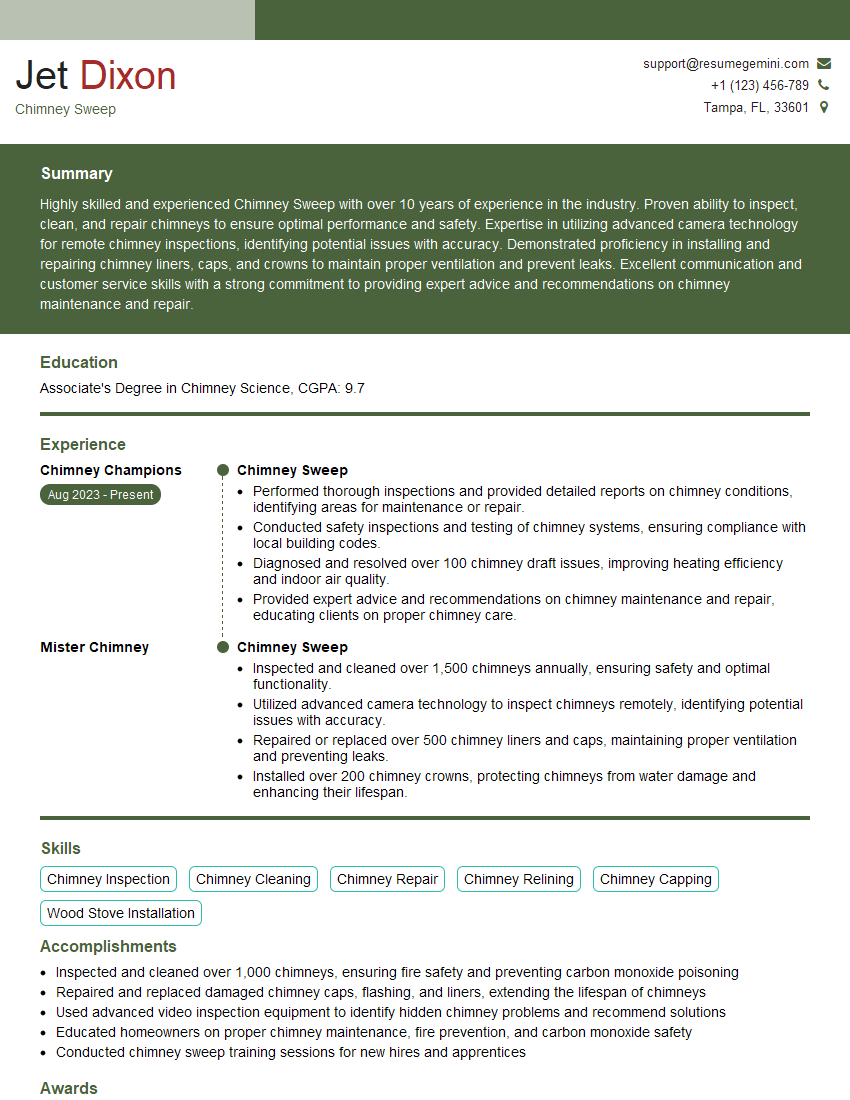

Mastering Chimney Liner Installation opens doors to a rewarding career with excellent growth potential. Demand for skilled technicians is high, offering opportunities for advancement and specialization. To stand out, create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource to help you build a professional and impactful resume that gets noticed by employers. We provide examples of resumes tailored to Chimney Liner Installation to guide you in creating a winning application.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Take a look at this stunning 2-bedroom apartment perfectly situated NYC’s coveted Hudson Yards!

https://bit.ly/Lovely2BedsApartmentHudsonYards

Live Rent Free!

https://bit.ly/LiveRentFREE

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?