Unlock your full potential by mastering the most common Concrete Block Bonding interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Concrete Block Bonding Interview

Q 1. Describe the different types of concrete block bonds.

Concrete block bonds refer to the pattern in which blocks are laid to create a strong and aesthetically pleasing wall. Several types exist, each offering different structural and visual characteristics. The choice depends on factors like the wall’s height, load-bearing requirements, and desired appearance.

- Running Bond: This is the simplest, where blocks are stacked directly on top of each other in a continuous horizontal row. It’s straightforward but offers less structural strength than other methods.

- Stack Bond: Blocks are stacked vertically, creating a visually striking but structurally weaker wall unless reinforced. It’s often used for non-load-bearing partition walls.

- Common Bond: A combination of headers (blocks laid horizontally) and stretchers (blocks laid vertically). This provides a better balance of strength and aesthetics. Headers are typically placed every fifth or sixth course for strength.

- English Bond: Similar to common bond but with alternating headers and stretchers in each course, creating a more visually complex pattern. It’s strong but more time-consuming to lay.

- Flemish Bond: Alternating headers and stretchers in each course, but with headers and stretchers offset to create a visually pleasing and strong pattern. This bond is the most labor-intensive but yields a beautiful, robust wall.

Choosing the right bond is critical for the wall’s structural integrity and longevity. For instance, a tall, load-bearing wall would necessitate a stronger bond like English or Flemish, while a low, non-load-bearing partition wall might suffice with a running or stack bond.

Q 2. Explain the importance of proper mortar mixing for block bonding.

Proper mortar mixing is paramount for successful block bonding. The mortar acts as the glue, transferring loads and ensuring the structural integrity of the wall. Incorrect mixing can lead to weak joints, reduced strength, and even wall failure.

The ideal mortar mix has the right consistency – not too wet (which leads to slumping and weak joints) nor too dry (which makes it difficult to spread and bond effectively). It should be workable yet hold its shape. The exact mix ratio will vary depending on the manufacturer’s recommendations and project specifics, often involving cement, lime, and sand.

Think of it like baking a cake; you wouldn’t use random ingredients or inconsistent measurements. Similarly, consistent mortar mixing is crucial for a strong and durable block wall. A poorly mixed mortar is like using weak glue, compromising the entire structure’s integrity. I always follow the manufacturer’s instructions meticulously and use a mortar mixer for consistency, avoiding inconsistencies in the mix that a manual approach might introduce.

Q 3. What are the key considerations for laying blocks in different weather conditions?

Weather conditions significantly impact block laying. Extreme temperatures and precipitation can affect the mortar’s setting time, strength, and the overall quality of the work. Appropriate adjustments are essential to maintain quality and safety.

- Hot Weather: In hot, dry conditions, the mortar can dry out too quickly, preventing proper bonding. Using a water spray to keep the blocks and mortar moist is crucial. Shade structures and working during cooler parts of the day are also important.

- Cold Weather: Freezing temperatures can damage the setting mortar. Using frost-resistant mortar and covering newly laid blocks to protect them from frost is vital. Using a heated mortar mixing system is advisable. The rate of work may need to slow down to allow time for proper setting.

- Rainy Weather: Rain can wash away the mortar, leading to poor bonding and structural weakness. It’s essential to avoid laying blocks during heavy rain and use tarps to cover the work area.

Ignoring these considerations can lead to a weakened structure that’s susceptible to damage or even failure. The project timeline might also be extended due to weather interruptions.

Q 4. How do you ensure vertical and horizontal alignment during block laying?

Maintaining accurate vertical and horizontal alignment is crucial for a structurally sound and aesthetically pleasing block wall. This requires careful planning and the use of appropriate tools.

For horizontal alignment, I use a spirit level regularly across each course of blocks. A string line, stretched taut between end points, also acts as a reliable guide for horizontal accuracy. For vertical alignment, I use a plumb bob or a laser level to check that each block is precisely vertical. A combination of checking and adjusting each block as it’s laid, and using these tools, ensures a straight wall with minimal imperfections.

Imagine building a tower of blocks – if the base isn’t straight, the whole tower will eventually wobble. Likewise, maintaining perfect alignment throughout the wall’s construction prevents future structural issues and contributes to a professional finish. This starts with creating a perfectly leveled base. Any irregularities are corrected before any blocks are laid, creating a firm and level foundation upon which to build.

Q 5. Describe your experience with different types of blocklaying tools.

Over the years, I’ve become proficient with various blocklaying tools, each serving a unique purpose. The right tools significantly enhance efficiency and precision.

- Mortar Board and Trowel: Essential for mixing and applying mortar. I prefer a stiff-bladed trowel for precise mortar application.

- Level: Crucial for maintaining horizontal alignment. I carry a long level, along with a smaller one for finer adjustments.

- Plumb Bob and/or Laser Level: These are indispensable for checking and maintaining vertical alignment throughout the process.

- Line Level: Essential for maintaining a straight line, particularly over longer distances.

- Rubber Mallet: A gentler alternative to a hammer, minimizing the risk of damaging blocks.

- Block Cutter: Necessary for cutting blocks to fit specific dimensions, often using a masonry saw, which requires appropriate safety measures.

- Measuring Tape and Square: Ensure accurate measurements are taken before any cutting or laying of blocks.

My experience has taught me that the right tools not only improve the quality of work but also enhance safety and efficiency on the job site. Having a well-maintained toolbox ensures the successful completion of any blocklaying project. It’s not just about having the tools, but knowing how to use each one effectively.

Q 6. How do you ensure proper leveling and plumbness of a block wall?

Ensuring a level and plumb block wall requires continuous monitoring and adjustment throughout the construction process. Neglecting this can lead to structural instability and aesthetic imperfections.

I begin by establishing a perfectly level foundation. Then, using a level and plumb bob at regular intervals (usually after each course or every few blocks), I meticulously check for deviations. I use a line level to ensure the wall remains straight over its entire length. Any deviations are corrected immediately using shims or adjustments to the mortar bed. This continuous monitoring throughout the building process ensures a stable and visually appealing wall. The foundation is crucial, and any unevenness in the base will quickly be multiplied as the wall increases in height. Early detection of issues saves both time and resources, as small problems can snowball quickly if not addressed promptly.

Q 7. What are the safety precautions you take when working with concrete blocks?

Safety is my top priority when working with concrete blocks. These are heavy materials, and careless handling can lead to serious injuries. Therefore, I always adhere to stringent safety protocols.

- Personal Protective Equipment (PPE): I always wear safety glasses, gloves, and steel-toed boots. A hard hat is also essential, particularly when working at heights.

- Lifting Techniques: I use proper lifting techniques to avoid strain or injury. Never lift loads beyond my capacity, using mechanical assistance where necessary.

- Handling Blocks Safely: I ensure blocks are stacked carefully and securely to prevent them from falling. I take extra care when transporting blocks or working at heights.

- Work Area Safety: The work area should be kept clean and free of obstructions to prevent accidents. Proper lighting is also important, especially in low-light conditions.

- Fall Protection: When working at heights, I always use appropriate fall protection equipment, such as harnesses and safety lines.

Regular safety checks and awareness contribute to a safe work environment. This not only protects me but also my colleagues and those around the worksite. Safety is an integral part of every project I undertake.

Q 8. How do you handle different types of block imperfections?

Handling block imperfections is crucial for ensuring the structural integrity and aesthetic appeal of a concrete block wall. Imperfections can range from minor surface blemishes to significant cracks or voids. My approach is multifaceted and depends on the severity and type of imperfection.

- Minor imperfections: Surface blemishes like small chips or discoloration are usually acceptable and can often be addressed with careful mortar application, ensuring a smooth finish. I might use a slightly richer mortar mix in these areas to fill minor gaps.

- Significant imperfections: Larger cracks or voids require more attention. For cracks, I would assess the cause (e.g., damaged block during handling). Minor cracks can sometimes be filled with epoxy resin before laying the block, ensuring proper bonding. For larger cracks or damaged blocks, replacement is necessary. Voids can often be filled with grout, ensuring it’s properly compacted and cured.

- Compromised blocks: Blocks with significant damage compromising structural integrity are always replaced. Safety is paramount, and using a damaged block risks weakening the entire structure.

Throughout this process, careful documentation of imperfections and remediation strategies is crucial for future reference and quality control.

Q 9. Describe your experience with various concrete block sizes and shapes.

My experience encompasses a wide range of concrete block sizes and shapes, including standard rectangular blocks, various thicknesses (e.g., 6 inches, 8 inches, 12 inches), and specialized shapes designed for corners, arches, or specific architectural features. I’ve worked with blocks manufactured from different concrete mixes, each with varying properties affecting their handling and bonding characteristics. For example, the density and porosity of the block impact the amount of mortar needed for optimal bonding and the required curing time.

Working with non-standard shapes requires meticulous planning and precision in cutting and fitting blocks to ensure a smooth, structurally sound wall. I’ve often had to adapt my techniques to ensure compatibility between different sizes and shapes, sometimes even creating custom mortar mixes to achieve optimal bonding in unusual configurations.

Q 10. How do you manage the challenges of working with irregular surfaces?

Irregular surfaces present unique challenges in concrete block bonding, requiring careful planning and skilled execution. The key is to achieve a consistent bond while maintaining the structural integrity of the wall.

- Preparation: Thorough surface preparation is paramount. This includes cleaning the surface to remove debris, loose material, and any contaminants that could hinder adhesion. In some cases, this might involve applying a bonding agent to improve adhesion to the substrate.

- Mortar adjustment: Mortar consistency needs careful consideration. A slightly wetter mix may be needed to fill irregularities and ensure complete contact with the blocks. However, an excessively wet mix can weaken the bond.

- Block placement: Careful placement of blocks is crucial. This often involves adjusting the mortar bed to compensate for unevenness. Using wedges or shims might be needed to level blocks on uneven surfaces.

- Inspection and reinforcement: Frequent inspection during construction helps identify and address any inconsistencies early on. In some cases, additional reinforcement, like steel mesh, might be necessary to enhance stability on highly irregular surfaces.

For instance, when building a retaining wall against a sloped hillside, I’d meticulously prepare the base, ensuring it’s level in sections, using compacted gravel and creating stepped layers if necessary to accommodate the uneven terrain.

Q 11. Explain the process of installing lintel blocks.

Installing lintel blocks, which support the weight above openings like doors and windows, requires precision and careful consideration of structural loads. The process typically involves the following steps:

- Accurate measurement and planning: Precise measurements are essential to ensure the lintel block spans the opening correctly and provides adequate support.

- Preparing the opening: The opening needs to be properly sized and cleaned to receive the lintel block.

- Mortar bed preparation: A level and adequately sized bed of mortar is prepared to support the lintel block.

- Lintel block placement: The lintel block is carefully placed, ensuring it’s level and centered. Proper support is provided during placement to prevent it from shifting.

- Mortar application: Mortar is applied around the block, ensuring complete contact with the surrounding masonry units.

- Curing: The mortar is allowed to cure properly to develop its full strength.

- Support during construction: Temporary supports may be necessary to ensure that the lintel block doesn’t carry loads prematurely before the surrounding masonry is completed. This might involve using scaffolding or other appropriate means.

The specific type of lintel block used (e.g., reinforced concrete, steel) will also affect installation methods. Always consult the manufacturer’s specifications for the optimal installation procedure.

Q 12. How do you calculate the amount of mortar needed for a given project?

Accurately calculating mortar quantity is essential for efficient project management and cost control. There isn’t one single formula, as it depends on several factors:

- Block size and type: Different block sizes and shapes require varying amounts of mortar.

- Joint thickness: The thickness of the mortar joints significantly impacts the overall mortar volume. A thinner joint requires less mortar but may make alignment more difficult.

- Wall configuration: Complex wall designs with many openings or irregular shapes will require more mortar.

- Mortar wastage: Account for wastage due to cleanup, spillage and unusable mixes. Generally, adding a 5-10% buffer is recommended.

A common approach is to estimate the volume of mortar needed per unit area of wall. This can be calculated by multiplying the area of the wall by the joint thickness and the number of joints. This estimate is then adjusted based on the other factors described above. For example, if you’re working with standard blocks and a 3/8-inch joint, you can use readily available charts or online calculators that provide estimates for mortar consumption per cubic meter or square foot of wall. Always overestimate slightly to ensure you have enough material to complete the job.

Q 13. What are the common causes of cracking in concrete block walls and how to prevent them?

Cracking in concrete block walls can stem from several issues, often related to poor construction practices or inadequate design. Understanding the causes is vital for effective prevention.

- Settlement: Uneven foundation settlement can put significant stress on the wall, leading to cracking. Proper site preparation and foundation design are crucial.

- Shrinkage: As mortar dries, it shrinks, and if not managed correctly, this shrinkage can cause cracking. Using the appropriate mortar mix and ensuring proper curing are vital.

- Overloading: Exceeding the wall’s design load capacity can lead to cracking. Proper design and engineering calculations must be followed.

- Thermal expansion and contraction: Temperature changes cause the wall to expand and contract, which can lead to cracking, especially if there are restraints on movement. Appropriate expansion joints can mitigate this.

- Moisture movement: Moisture absorption and drying cycles can cause expansion and contraction, leading to cracking. Good waterproofing measures and proper drainage are essential.

- Poor workmanship: Issues like improper block placement, inadequate compaction of mortar, or insufficient support during construction can all lead to cracking.

Prevention involves careful planning, quality materials, and skilled execution. This includes proper site investigation, appropriate foundation design, use of high-quality materials, proper curing, and careful workmanship during construction. Regular inspection and timely repair of minor cracks are also essential to prevent the development of larger, more serious cracks.

Q 14. Describe your experience with different types of mortar.

My experience with different types of mortar is extensive, as the choice of mortar significantly affects the properties and performance of the concrete block wall. Each mortar type has different strengths and is suited for various applications.

- Type N Mortar: A general-purpose mortar suitable for most applications, offering a good balance of strength, workability, and water retention.

- Type S Mortar: A higher-strength mortar, suitable for applications requiring increased compressive strength, such as load-bearing walls in areas with high seismic activity.

- Type M Mortar: A high-strength, low-water-retention mortar, suited for severe exposure conditions, providing excellent durability. However, it’s less workable.

- Type O Mortar: A low-strength mortar suitable for non-load-bearing applications, where higher strength is not required. Often used for interior walls.

The choice depends on factors like the intended use of the wall, the expected environmental conditions, and the level of structural load. In some cases, I might even use specialized mortars, like those designed for specific bonding characteristics or improved water resistance. Understanding the properties of each type enables me to select the optimal mortar to ensure the long-term performance and durability of the concrete block wall.

Q 15. What is the importance of using proper reinforcement in concrete block walls?

Proper reinforcement in concrete block walls is crucial for enhancing their structural integrity and resistance to various loads, including wind, seismic activity, and gravity. Think of it like the steel skeleton in a human body; without it, the structure wouldn’t be able to withstand stresses and strains.

Reinforcement, typically steel bars or remesh, is embedded within the mortar joints and/or within cores of the blocks. This reinforcement works in conjunction with the concrete blocks to form a composite structural element. It significantly improves the wall’s tensile strength, preventing cracks and ensuring stability, particularly in taller walls or those subjected to lateral forces. Without adequate reinforcement, the wall may crack, buckle, or even collapse under these stresses.

For instance, in earthquake-prone zones, correctly placed reinforcement is absolutely critical for the wall to withstand the ground’s movement. The design of the reinforcement – the size, spacing, and layout of the bars – depends on the anticipated loads and local building codes. A structural engineer typically determines the necessary reinforcement based on detailed calculations.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the difference between running bond and stacking bond.

Running bond and stacking bond are two common patterns for laying concrete blocks. The difference lies primarily in how the blocks are arranged vertically. Imagine building a brick wall; the patterns are similar.

- Running Bond: This is the most common pattern. Each course (horizontal row) is offset by half a block length relative to the course below. This creates a staggered effect, resembling a continuous ‘run’ of blocks and greatly improving the wall’s strength and stability. It is significantly stronger than stacking bond, because the vertical joints are offset, preventing vertical cracking.

- Stacking Bond: In this pattern, the blocks in each course are aligned directly above those in the course below. This arrangement is simpler and faster to construct, but it’s considerably weaker than running bond. Think of it like stacking boxes; they won’t be as structurally sound and are more vulnerable to buckling.

While stacking bond might seem appealing due to its speed, it’s rarely used in load-bearing walls due to its susceptibility to failure under stress. Running bond is the preferred method in almost all construction applications involving structural walls.

Q 17. How do you ensure proper curing of concrete blocks?

Proper curing of concrete blocks is essential for achieving their designed strength and durability. It’s the process of maintaining adequate moisture and temperature conditions for the concrete to fully hydrate and gain strength. Think of it like letting a cake cool and set properly; a rushed process results in a less than ideal final product.

Curing typically involves keeping the blocks moist for a specific period, usually 7 to 28 days, depending on the type of block and ambient conditions. Methods include:

- Water Curing: Regularly spraying the blocks with water or submerging them in water.

- Membrane Curing: Covering the blocks with a moist curing compound or plastic sheeting to retain moisture.

- Steam Curing: Using steam in a controlled environment for faster curing (used primarily in block manufacturing).

Insufficient curing can lead to weak blocks prone to cracking and reduced lifespan. Therefore, adhering to the manufacturer’s recommended curing procedures is paramount to ensuring the long-term success of the project. Proper curing ensures that the blocks reach their full potential strength and durability, leading to a more stable and lasting structure.

Q 18. What are the common problems encountered during concrete block laying and their solutions?

Several common problems can arise during concrete block laying. Addressing these issues promptly is critical for preventing structural defects and ensuring a quality finished product.

- Uneven Mortar Joints: Inconsistent mortar thickness weakens the wall and affects its aesthetics. Solution: Use a consistent mortar-spreading technique and check frequently for uniformity. Employing a mortar line gauge can improve accuracy.

- Improper Block Placement: Misaligned blocks weaken the structure and compromise its appearance. Solution: Carefully check the alignment of each block using a level and adjust as needed.

- Insufficient Mortar: Lack of adequate mortar leads to poor bonding between blocks, reducing the wall’s strength. Solution: Ensure sufficient mortar is applied and distributed evenly between the blocks. The mortar should fully fill the joints and make good contact with the blocks.

- Cracking: Cracks can develop due to poor construction practices, shrinkage, or excessive loads. Solution: Prevention is key; proper reinforcement, consistent curing, and skilled workmanship can significantly minimize the risk of cracking. Cracks may also need to be repaired by approved methods if they do occur.

Experienced block layers anticipate these issues and employ techniques to prevent them. Thorough planning, careful execution, and regular quality checks are key to avoiding common problems during the laying of concrete blocks.

Q 19. Describe your experience with waterproofing concrete block walls.

Waterproofing concrete block walls is crucial in many applications, particularly in basements, retaining walls, and areas prone to moisture ingress. I’ve had extensive experience implementing various waterproofing strategies depending on the specific needs of the project.

Methods I’ve employed include:

- Exterior Waterproofing: Applying a waterproof membrane to the exterior surface of the wall before backfilling. This creates a barrier preventing water from reaching the wall. This is the most effective method.

- Interior Waterproofing: Applying a waterproof coating or sealant to the interior wall surface. This is less effective and generally addresses only water already within the wall, but can still be of use in conjunction with other waterproofing measures.

- Waterproofing Admixtures in Mortar: Using specialized mortar admixtures that improve the water resistance of the block work itself. This is a preventative approach that enhances the structure’s intrinsic ability to resist moisture intrusion.

The choice of waterproofing method depends on factors like the wall’s location, exposure to moisture, and the overall building design. Thorough site assessments are necessary to identify the best approach. Careful attention to detail during the installation of any waterproofing system is crucial for its long-term effectiveness. Poorly installed waterproofing is more costly to fix later on.

Q 20. How do you manage waste materials during block laying?

Waste management during block laying is crucial for environmental responsibility and efficient site management. My approach emphasizes minimizing waste and responsibly disposing of what’s generated.

Strategies I consistently implement include:

- Accurate Material Estimation: Careful planning and precise calculations minimize material waste. This involves accurately estimating the number of blocks required for the project.

- Careful Handling of Blocks: Protecting blocks from damage during handling reduces the number of unusable ones.

- Efficient Mortar Mixing: Mixing only the amount of mortar needed at a time prevents wastage due to hardening or drying.

- Recycling and Disposal: Broken blocks and excess mortar are sorted for possible reuse or disposal following local regulations and environmental best practices. This includes separating recyclable materials from non-recyclable materials and ensuring that waste is disposed of at appropriate locations.

Waste reduction translates directly into cost savings and reduces the environmental impact of the project.

Q 21. What is your experience with different types of block finishes?

My experience encompasses a variety of concrete block finishes, each offering unique aesthetic and functional properties. The choice of finish depends on the project’s design requirements, budget, and the desired level of maintenance.

I’ve worked with:

- Stucco: A common and versatile finish offering excellent weather protection and aesthetic flexibility. It’s applied over a base coat and can be textured or smooth.

- Brick Veneer: A more expensive but aesthetically pleasing option offering enhanced durability and insulation. It’s bonded to the block wall in a running bond pattern.

- Paint: An economical choice offering a wide range of colors and finishes, but generally requires more frequent maintenance. It is important to select the right type of paint that will adhere well to the concrete block surface.

- Stone Veneer: A high-end option that enhances curb appeal and durability. It requires careful installation to maintain structural integrity.

- Exposed Aggregate: A rustic and unique look achieved by exposing the aggregate in the mortar mix. It requires careful control of the mortar mix during the application.

Each finish has its advantages and disadvantages, and the selection should be based on a thorough consideration of project specifics and client preferences.

Q 22. How do you inspect the quality of your completed blockwork?

Inspecting completed blockwork involves a multi-stage process focusing on both aesthetics and structural soundness. I begin with a visual inspection, checking for plumbness (vertical alignment), levelness (horizontal alignment), and straightness of the walls. I use a level and plumb bob to verify these aspects at regular intervals throughout the wall. I meticulously examine the mortar joints for consistency – they should be full, uniform, and properly tooled, ensuring proper bond between blocks. Any gaps, voids, or inconsistencies indicate potential structural weakness. Furthermore, I check for proper block alignment and the absence of cracked or damaged blocks. Finally, I assess the overall appearance, ensuring the wall is free of any significant blemishes or imperfections that could compromise its integrity or aesthetic appeal. Think of it like inspecting a brick wall; attention to detail is key.

For larger projects, I might employ more sophisticated tools like a laser level for greater accuracy, and I would document any findings with photographs or detailed notes. The aim is not only to ensure the work meets the specifications but also to identify any potential issues early on to prevent future problems.

Q 23. Explain your understanding of building codes and regulations related to blockwork.

Understanding building codes and regulations is paramount. My work always adheres to local, state, and national building codes, including those relating to masonry construction. These codes dictate crucial aspects of blockwork, such as the type of block allowed (e.g., compressive strength), the required mortar type, the allowable tolerances for plumbness and levelness, and the necessary reinforcement for specific applications. I am familiar with standards concerning wind load and seismic resistance, and I ensure all my work accounts for these factors. Codes also specify requirements for flashing and damp proofing to prevent water damage. For instance, I’m aware of the International Building Code (IBC) and local amendments, ensuring I’m using the most current and relevant regulations for every project. Non-compliance can lead to significant structural problems and legal ramifications, so staying updated on these codes is a critical part of my role.

Q 24. Describe your experience working with different types of foundations for block walls.

My experience encompasses various foundation types for block walls. I’ve worked with poured concrete footings, which are common for most projects and provide a stable base. These are usually poured according to specific dimensions and reinforced with rebar. I’ve also worked with spread footings, typically for lighter structures or in areas with stable soil conditions. For more challenging soil conditions, I’ve used pile foundations – this involves driving piles into the ground to create a strong, deep foundation before building the block wall. The choice of foundation depends on soil analysis, the height and load of the wall, and local building codes. A proper foundation is essential, as it distributes the load of the wall effectively to prevent settlement and cracking. Ignoring this can result in serious structural issues down the line.

Q 25. How do you handle changes in project plans or specifications?

Handling changes in project plans requires careful communication and adaptability. First, I ensure I fully understand the nature of the change, obtaining clarified specifications from the architect or project manager. I then evaluate the impact of the change on the existing work, considering factors like materials, schedule, and cost. If significant changes are needed, I’ll immediately inform the relevant stakeholders and get their approval. If necessary, I will update any relevant drawings or plans and will ensure all team members are informed about the alteration. I maintain clear documentation of all changes, which helps to prevent misunderstandings and streamline the process. This approach emphasizes clear communication and proactive problem-solving to mitigate any disruptions.

Q 26. How do you ensure the structural integrity of a concrete block wall?

Ensuring structural integrity is a top priority. Several key steps are essential: using high-quality concrete blocks with sufficient compressive strength; employing the correct type and amount of mortar to ensure a strong bond; ensuring proper block placement, alignment, and leveling; incorporating reinforcement where needed, especially in taller walls or areas prone to seismic activity; and applying proper construction techniques to minimize stress points. Consider the analogy of building a brick tower: each block must be perfectly placed, and mortar acts as the glue; reinforcement is like internal supports ensuring stability. Neglecting these measures can lead to instability and even collapse. Regular inspections and quality control checks throughout the construction process are crucial to identifying and addressing potential issues.

Q 27. Describe a time you had to solve a problem on a blocklaying project.

On a recent project, we encountered unexpected soil instability during the excavation for the foundation. The initial plan relied on spread footings, but the soil proved too soft. I immediately flagged the issue to the supervisor, and we collaboratively reviewed the geotechnical report. We determined that spread footings were unsuitable and needed to switch to pile foundations. This required a change order and additional time, but it prevented any future structural problems. Instead of proceeding without addressing the problem, we adapted our approach, ensuring the wall would be safe and stable. The project took slightly longer, but the focus on long-term structural integrity ensured a successful outcome.

Q 28. What are your strengths and weaknesses as a concrete block layer?

My strengths include meticulous attention to detail, a thorough understanding of building codes and construction techniques, and excellent problem-solving skills. I’m highly skilled in maintaining accurate measurements and alignment, leading to structurally sound and aesthetically pleasing walls. I also value teamwork and clear communication with colleagues and clients. My weakness, if I had to choose one, would be my tendency to be a perfectionist, sometimes leading to slower progress. I’m actively working on improving my time management skills to balance quality and efficiency without compromising safety or standards. I believe self-awareness is key and I strive to continuously improve in all aspects of my work.

Key Topics to Learn for Concrete Block Bonding Interview

- Mortar Selection and Mixing: Understanding different mortar types (Type N, S, M), their properties, and appropriate mixing techniques for optimal bond strength.

- Block Laying Techniques: Mastering proper techniques for laying concrete blocks, including bed joint thickness, head joint alignment, and achieving plumb and level walls.

- Bond Patterns and Configurations: Familiarity with various bond patterns (running bond, stack bond, common bond) and their structural implications, selecting the appropriate pattern for specific project needs.

- Reinforcement and Structural Considerations: Understanding the role of reinforcement in concrete block walls, including the placement and types of reinforcement (rebar, wire mesh) to enhance structural integrity.

- Adhesive Bonding Methods: Knowledge of adhesive bonding techniques for concrete blocks, their advantages and disadvantages compared to traditional mortar methods, and appropriate applications.

- Quality Control and Inspection: Understanding methods for ensuring the quality of the bond, including visual inspection, testing for bond strength, and addressing common defects like voids or weak mortar joints.

- Environmental Factors and Considerations: Recognizing how weather conditions (temperature, humidity) can affect the bonding process and implementing appropriate mitigation strategies.

- Troubleshooting and Problem-Solving: Ability to identify and resolve common issues encountered during concrete block bonding, such as efflorescence, cracking, or uneven settling.

- Safety Procedures and Regulations: Understanding and adhering to all relevant safety regulations and procedures related to working with concrete blocks and mortar.

- Tools and Equipment: Familiarity with the various tools and equipment used in concrete block bonding, including trowels, levels, plumb bobs, and mixers.

Next Steps

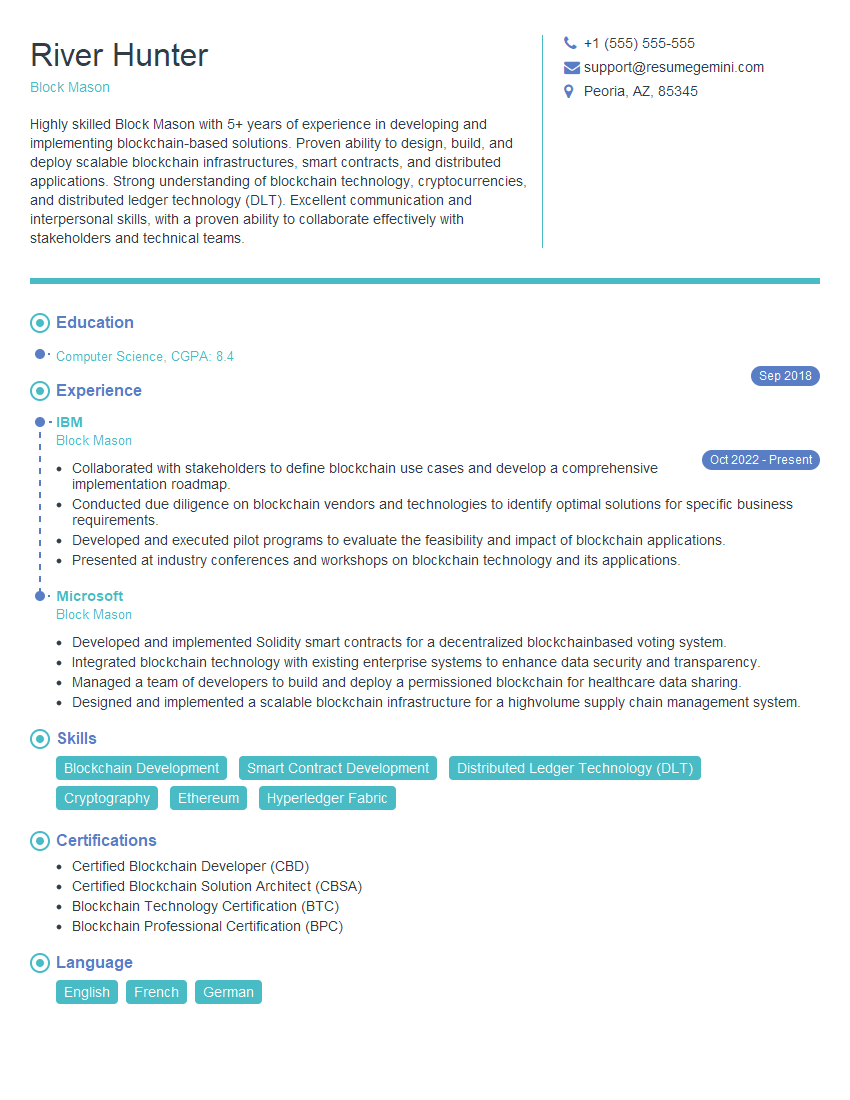

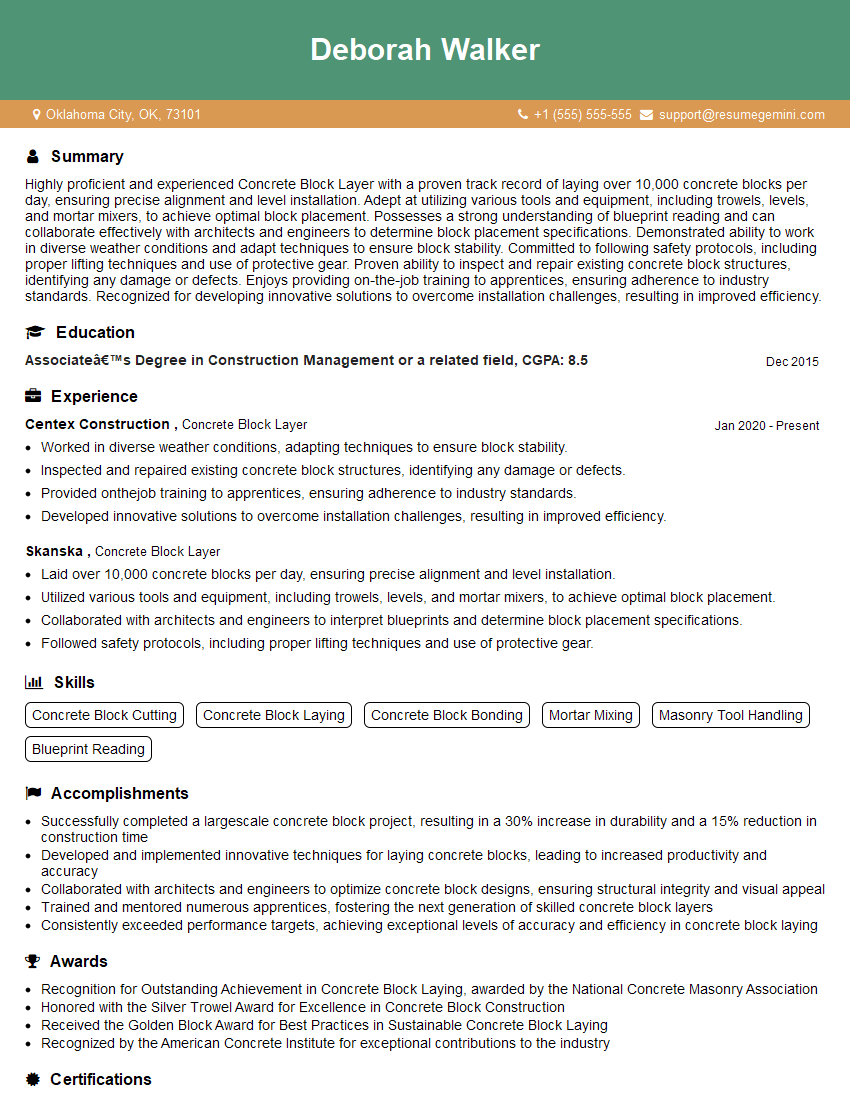

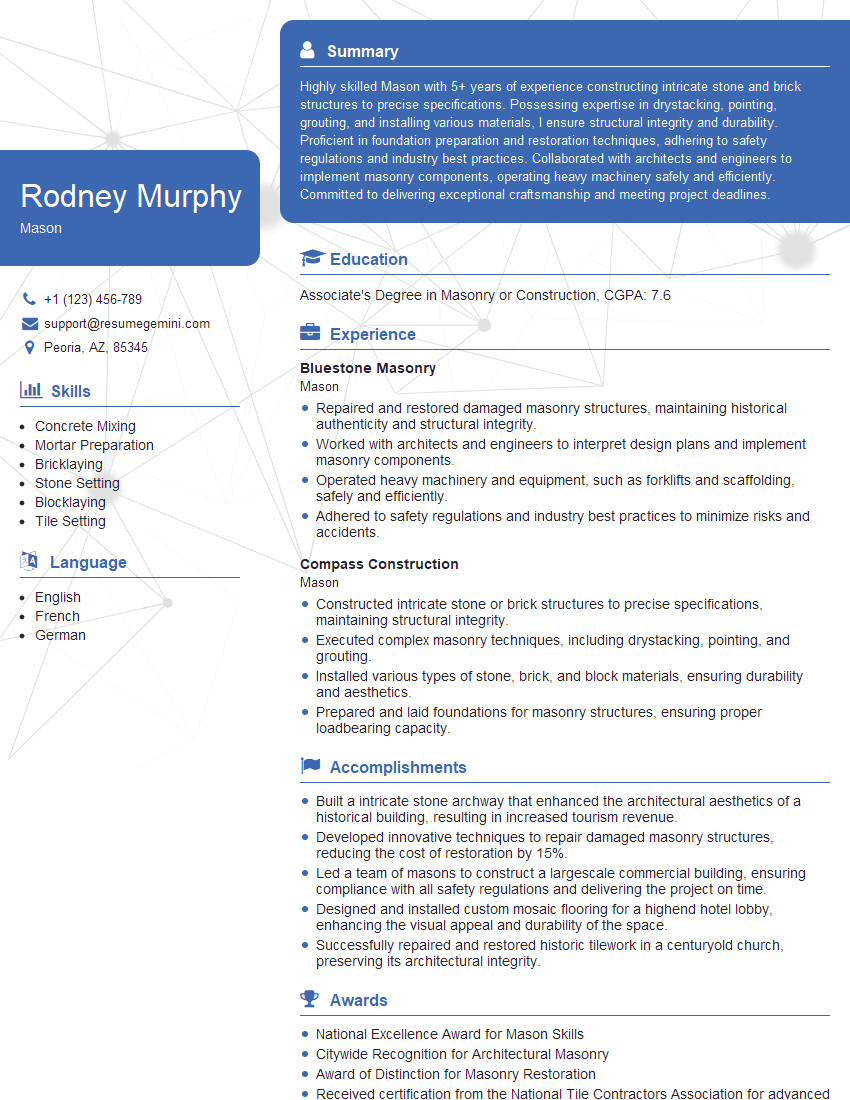

Mastering concrete block bonding opens doors to rewarding careers in construction, offering opportunities for advancement and specialized skills development. A strong understanding of these techniques is highly valued by employers. To significantly boost your job prospects, create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional resume that stands out. We provide examples of resumes tailored to Concrete Block Bonding to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?