Warning: search_filter(): Argument #2 ($wp_query) must be passed by reference, value given in /home/u951807797/domains/techskills.interviewgemini.com/public_html/wp-includes/class-wp-hook.php on line 324

Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Demolition Planning interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Demolition Planning Interview

Q 1. Explain the different demolition methods and their applications.

Demolition methods are chosen based on factors like building size, materials, location, and budget. There’s no one-size-fits-all approach.

- Manual Demolition: This involves hand tools and careful dismantling, ideal for historic buildings or structures with intricate features. Think of meticulously removing ornate stonework from a Victorian mansion – safety and precision are paramount.

- Mechanical Demolition: This utilizes heavy machinery like excavators, cranes, and wrecking balls. It’s faster and more cost-effective for large structures but requires careful planning to avoid collateral damage. Imagine demolishing a large apartment complex; this method is both efficient and powerful.

- Explosive Demolition: This method uses controlled explosions for large structures or when access is limited. It’s highly specialized, requiring expert knowledge and permits. The implosion of a skyscraper is a prime example – precise charges are needed to ensure the structure falls within a defined area.

- Hydraulic Demolition: This uses high-pressure hydraulic tools for controlled dismantling, reducing noise and vibration compared to mechanical methods. It is frequently used in urban settings or close to existing structures.

The choice of method is a critical decision that needs careful assessment of all influencing factors. A thorough site survey and risk assessment are essential before determining the most appropriate and safest method.

Q 2. Describe your experience with demolition sequencing and scheduling.

Demolition sequencing and scheduling is like creating a complex choreography. Each step depends on the previous one, ensuring safety and efficiency. My experience involves:

- Detailed Site Analysis: This involves creating a 3D model of the structure, identifying structural weaknesses, and mapping out utility lines. This is crucial for safe and efficient planning.

- Logical Sequencing: We start with disconnecting utilities (electricity, gas, water), followed by removing hazardous materials, and progressing through a sequence of demolition that minimizes risks to workers and the surrounding environment. For instance, the top floors of a building are often demolished first, to prevent debris from affecting lower levels.

- Resource Allocation: This includes coordinating the machinery, personnel, and permits. We use critical path method (CPM) scheduling to understand and manage task dependencies and critical paths within the project.

- Contingency Planning: Unexpected issues arise. We plan for delays caused by weather, unforeseen structural issues, or equipment failures and include this planning in the schedule.

In a recent project, we used a Gantt chart to visualize the schedule and track progress, and daily safety meetings and daily work logs ensured everyone was informed about daily tasks and safety measures.

Q 3. How do you ensure site safety during demolition operations?

Site safety is paramount. It’s not just about following regulations; it’s about creating a safety culture. My approach includes:

- Comprehensive Safety Plan: This includes risk assessments, emergency response procedures, and worker training. It outlines every safety precaution to avoid incidents.

- Site Security: Perimeter fencing, security personnel, and access control are vital to prevent unauthorized entry. Proper signage and lighting are necessary for night work.

- Personal Protective Equipment (PPE): Hard hats, safety glasses, high-visibility clothing, and appropriate footwear are mandatory. This is not optional; it’s a must-have for all personnel on-site.

- Regular Inspections: Daily inspections of the site, equipment, and procedures are vital to quickly identify and address potential hazards.

- Worker Training: All workers must receive comprehensive training on safe demolition practices and the use of equipment. Regular refresher training and safety talks are necessary.

For example, on a recent project, we implemented a ‘Stop Work Authority’ policy, where any worker could stop work if they identified a safety issue without fear of reprisal.

Q 4. What are the key considerations for environmental protection during demolition?

Environmental protection is crucial during demolition. It’s about minimizing the impact on air, water, and soil. My approach involves:

- Dust Suppression: Water sprays, barriers, and enclosed demolition methods help reduce dust generation and air pollution. Air quality monitoring might be needed depending on the site and project.

- Waste Management: Proper segregation of demolition waste – recyclable materials, hazardous materials, and general waste – is crucial. Recycling and waste reduction targets are set during the planning stage and are closely monitored.

- Water Management: Preventing runoff contamination, managing storm water, and controlling erosion are vital. We usually implement measures like silt fences and erosion control mats.

- Noise Control: Using quieter equipment and implementing noise mitigation strategies are vital, especially in densely populated areas. We might need to work during specific hours or implement sound barriers.

- Soil Contamination: Testing for soil contamination before demolition and proper handling of contaminated soil are crucial steps to prevent environmental damage. Remediation procedures might be necessary.

We aim for zero waste to landfill whenever practically possible, by prioritizing reuse, recycling, and recovery of materials.

Q 5. How do you manage hazardous materials during a demolition project?

Managing hazardous materials is a critical aspect, demanding strict adherence to regulations. My process includes:

- Identification and Assessment: A thorough assessment of the building to identify asbestos, lead paint, PCBs, and other hazardous materials is the first step. This often requires specialized testing and analysis.

- Permitting and Reporting: We obtain all necessary permits for handling hazardous waste and report to the relevant environmental agencies. This includes detailed plans for abatement or removal.

- Abatement Procedures: Qualified contractors following strict protocols are used for the safe removal and disposal of hazardous materials. The work is carefully monitored and documented.

- Disposal and Documentation: Hazardous materials are transported to licensed disposal facilities and appropriate documentation is maintained throughout the process, including chain of custody paperwork.

- Worker Protection: Workers involved in hazardous material handling must have specific training and wear specialized PPE.

For instance, in a recent project involving asbestos, we employed a certified asbestos abatement company and ensured all workers had the proper respiratory protection and decontamination procedures were followed meticulously.

Q 6. Describe your experience with demolition cost estimation and budgeting.

Accurate cost estimation is essential for project success. My process involves:

- Detailed Quantity Surveying: Accurately measuring the building and quantifying the materials and labor needed. This provides the foundation for the cost estimate.

- Material Pricing: Obtaining accurate prices from suppliers for all necessary materials, factoring in potential price fluctuations.

- Labor Costing: Estimating the labor costs based on the demolition method, crew size, and project duration. This incorporates wage rates, overtime, and potential delays.

- Equipment Costs: Estimating the costs of renting or owning the necessary equipment, considering fuel and maintenance.

- Contingency Budgeting: Allocating funds for unforeseen expenses and potential delays. This is critical to prevent cost overruns.

- Waste Disposal Costs: Estimating the costs for the disposal and transportation of demolition waste, taking into account the type and quantity of waste.

I use specialized software to create detailed cost breakdowns and track expenses throughout the project. We present our cost estimates transparently to clients, highlighting the assumptions and potential risks involved.

Q 7. How do you handle unexpected challenges or delays during demolition?

Unexpected challenges are inevitable. My approach focuses on proactive planning and a flexible mindset:

- Regular Monitoring: Closely monitoring progress, identifying potential issues early, and having a contingency plan to address delays and problems.

- Problem-Solving Team: Having a team of experts from different disciplines who can analyze issues, evaluate solutions, and implement effective strategies.

- Communication: Maintaining transparent and open communication with the client, contractors, and regulatory agencies to address unforeseen challenges promptly.

- Adaptation and Flexibility: Being able to adjust the plan and resources based on the circumstances and adapting to changing conditions is critical.

- Documentation: Thorough documentation of changes, delays, and solutions is vital for future reference and efficient problem resolution.

In one project, we discovered unexpected underground utilities, which required a change in demolition sequencing and a temporary halt in the project. Through effective communication and swift re-planning, we minimized the impact on the project timeline and budget.

Q 8. Explain your process for obtaining necessary permits and approvals.

Securing the necessary permits and approvals for a demolition project is a crucial first step, often involving a complex process that varies based on location and project specifics. It’s akin to navigating a detailed roadmap before embarking on a long journey.

- Initial Assessment: We begin by thoroughly assessing the site, identifying any potential environmental concerns (asbestos, lead paint), and understanding the building’s structural integrity. This informs our application.

- Permit Application: We then compile a comprehensive application, including detailed site plans, demolition plans, and a project timeline. This often requires surveying the site, taking detailed measurements and photography.

- Regulatory Submissions: This application is submitted to the relevant authorities – city planning departments, environmental agencies, and potentially historical preservation societies, depending on the building’s age and location. Each authority might have specific forms and requirements.

- Communication and Follow-Up: Constant communication with the regulatory bodies is essential. This ensures any questions or concerns are addressed promptly and efficiently, avoiding delays. We meticulously track all submissions and follow up on pending approvals.

- Permit Issuance: Once all requirements are met, we receive the necessary permits, which are legally binding documents authorizing the commencement of demolition.

For example, on a recent high-rise demolition project in downtown Chicago, we needed to secure permits from the city’s Department of Buildings, the Environmental Protection Agency for asbestos abatement, and the Department of Transportation for street closures. This involved several months of meticulous paperwork and communication.

Q 9. Describe your experience with demolition project documentation and reporting.

Demolition project documentation and reporting is crucial for accountability, legal compliance, and future reference. It’s like keeping a meticulously detailed logbook of a ship’s journey – crucial for understanding every aspect of the voyage.

- Pre-Demolition Documentation: This includes site surveys, structural assessments, asbestos reports, and utility disconnect plans. We use high-resolution photography and 3D laser scanning to document the site’s existing condition.

- During Demolition Documentation: Daily logs record progress, equipment used, and any safety incidents. We often employ time-lapse photography to visually document the process. This allows us to verify compliance, track expenses and also identify any deviation from the project plan.

- Post-Demolition Documentation: This encompasses waste removal certificates, site cleanup reports, and ‘as-built’ drawings reflecting the final state of the site. We meticulously ensure all waste is disposed of according to regulations.

- Reporting: Regular progress reports are issued to clients, highlighting achievements, challenges, and any changes in the project plan. This is presented using charts, graphs, and concise written reports.

In a recent project, our detailed documentation was crucial when a previously unknown underground utility line was discovered. Our accurate records allowed us to quickly adapt the demolition plan and notify the utility company, preventing a costly and potentially hazardous incident.

Q 10. How do you ensure compliance with relevant safety regulations and codes?

Safety is paramount in demolition, and compliance with all relevant regulations and codes is non-negotiable. Think of it as the foundation upon which the entire project is built. A weak foundation risks collapsing the entire structure.

- Safety Training: All personnel receive comprehensive safety training before starting any work. This includes OSHA regulations, specific demolition hazards, and emergency procedures.

- Risk Assessments: We conduct thorough risk assessments identifying potential hazards, including falling debris, equipment malfunctions, and exposure to hazardous materials. These assessments inform our safety plan.

- Safety Plans: Our detailed safety plans outline mitigation strategies for identified risks, specifying personal protective equipment (PPE), work procedures, and emergency response plans.

- Site Supervision: Experienced safety officers monitor work progress, ensuring compliance with safety protocols. This includes regular inspections and daily safety meetings.

- Incident Reporting: A robust system for reporting and investigating any incidents, no matter how minor, is in place. This data informs continuous improvement in our safety procedures.

For instance, on a recent project, our pre-emptive identification of potential asbestos contamination led us to implement rigorous abatement procedures, protecting both workers and the surrounding environment. This proactive approach prevented any potential health risks and ensured regulatory compliance.

Q 11. What software or tools do you use for demolition planning and management?

Technology plays a vital role in efficient and safe demolition planning and management. It’s like having a sophisticated GPS system guiding us through every stage of the demolition process.

- AutoCAD: For creating detailed demolition plans, including site surveys, demolition sequences, and as-built drawings.

- Revit: For 3D modeling, allowing for improved visualization of the demolition process and identification of potential conflicts.

- Project Management Software (e.g., MS Project, Primavera P6): For scheduling, resource allocation, cost tracking, and progress monitoring.

- 3D Laser Scanning: For precise site surveying and as-built documentation. This ensures accurate measurements and aids in planning.

- Specialized Demolition Software: Several software packages offer specific tools for demolition sequencing, waste management, and safety planning.

We leverage these tools to create dynamic, adaptable plans, enabling us to adjust to unforeseen circumstances during the demolition process, and to accurately track progress, costs and resources.

Q 12. Describe your experience with risk assessment and mitigation in demolition projects.

Risk assessment and mitigation are fundamental to successful demolition projects. It’s like carefully calculating the risks before embarking on a challenging mountain climb, ensuring every precaution is taken.

- Hazard Identification: This involves identifying potential hazards, such as structural instability, hazardous materials, and nearby utilities. We use checklists and site inspections to identify potential problems.

- Risk Evaluation: We assess the likelihood and severity of each identified hazard, determining the potential impact on workers, the public, and the environment.

- Mitigation Strategies: Based on our risk evaluation, we develop strategies to mitigate identified hazards. This could involve specialized equipment, protective measures, or alternative demolition methods.

- Emergency Preparedness: Contingency plans address potential emergencies, such as equipment failures or unforeseen structural issues. This ensures a quick and safe response to any unexpected events.

- Continuous Monitoring: Throughout the project, we continuously monitor and reassess risks, adapting our mitigation strategies as needed. This is crucial for ensuring worker safety and project success.

For example, on a recent project involving a structure with suspected asbestos, our risk assessment led to the implementation of a strict asbestos abatement plan, using specialized equipment and protective measures, ensuring worker safety and environmental compliance.

Q 13. How do you coordinate with other trades and contractors during demolition?

Coordinating with other trades and contractors is essential for a seamless demolition process. Think of it as conducting a well-orchestrated symphony – every instrument (contractor) must play its part in harmony.

- Pre-Construction Meetings: We hold regular meetings with all stakeholders, including utility companies, subcontractors, and the client, to clarify roles, responsibilities, and schedules. This ensures everyone is on the same page.

- Communication Protocols: Clear communication channels are established, using regular updates, emails, and on-site meetings to share information and address any issues promptly.

- Scheduling Coordination: We carefully schedule demolition activities to minimize conflicts with other trades and ensure smooth transitions between different phases of the project. This helps maintain progress without disruptions.

- Safety Coordination: Collaborating with other contractors on site-specific safety plans ensures a unified approach to safety, reducing risks and maximizing worker protection.

- Progress Monitoring: We actively monitor the progress of other contractors to identify potential delays or conflicts, enabling proactive adjustments to the overall project schedule.

For instance, on a large-scale project, coordinating the demolition with the subsequent excavation and groundwork was critical. Careful scheduling and regular communication with the excavation contractor ensured a smooth transition between the two phases, preventing any delays or cost overruns.

Q 14. Explain your approach to quality control and assurance in demolition.

Quality control and assurance in demolition ensures the project meets the specified standards, adheres to safety regulations, and achieves the desired outcome. It is like rigorously testing every component of a complex machine before use, ensuring seamless operation.

- Pre-Demolition Inspection: We perform a thorough inspection of the site before demolition begins, verifying the accuracy of plans and identifying any unexpected conditions.

- Material Management: We implement a system for tracking and managing materials and waste, ensuring proper disposal or recycling, following environmental regulations.

- Progress Monitoring: Regular inspections during demolition ensure compliance with approved plans and safety protocols, ensuring work is done according to standards.

- Safety Audits: Regular safety audits identify areas for improvement in safety practices and ensure compliance with all relevant regulations.

- Post-Demolition Inspection: A final inspection confirms the site has been cleaned, restored, and meets all regulatory requirements, ensuring the successful completion of the project.

For example, meticulous quality control during a recent historical building demolition resulted in the successful salvage of reusable architectural elements. This not only added value to the project but also ensured responsible material management.

Q 15. Describe your experience with demolition of different building types (e.g., residential, commercial, industrial).

My experience spans a wide range of demolition projects, encompassing residential, commercial, and industrial buildings. Each type presents unique challenges. Residential demolition often involves smaller structures, potentially with intricate interior layouts and varying material compositions. This requires meticulous planning to minimize disruption to surrounding properties. Commercial projects, like office buildings or shopping malls, are usually larger and more complex, frequently incorporating specialized materials and structural elements. Detailed structural assessments are crucial before initiating demolition to ensure safety and prevent unexpected collapses. Industrial demolition presents the most significant challenges, often involving hazardous materials like asbestos or heavy machinery. Careful planning, specialized equipment, and adherence to stringent safety protocols are absolutely paramount. For instance, I oversaw the demolition of a large textile mill, where we had to safely manage the removal of significant asbestos-containing materials before proceeding with the main demolition phase. This involved meticulous pre-demolition surveys, specialized abatement procedures, and rigorous monitoring.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you manage waste and debris generated during demolition?

Waste management is a critical aspect of any demolition project. It’s not just about clearing debris; it’s about doing so responsibly and sustainably. My approach involves a multi-stage process: Firstly, a thorough waste audit is conducted before demolition begins to identify the types and quantities of materials expected. This allows us to plan for appropriate disposal or recycling methods. Secondly, during demolition, materials are segregated at the source. This often involves setting up multiple designated areas for different waste streams – concrete, wood, metal, etc. This maximizes recycling potential. Thirdly, we work with licensed waste haulers and recycling facilities to ensure all materials are handled in compliance with local regulations. For instance, we might use specialized crushers to reduce the volume of concrete waste, which then can be repurposed as aggregate in new construction. Finally, we maintain detailed records of waste disposal to ensure transparency and accountability. Proper documentation is key in demonstrating environmental responsibility.

Q 17. What is your experience with controlled demolition techniques?

Controlled demolition techniques are essential for projects in densely populated areas or when preserving adjacent structures is vital. My experience includes implementing various controlled demolition methods, including implosion using explosives, selective demolition using excavators and specialized attachments, and top-down demolition. The choice of method hinges on several factors like the building’s size, structural integrity, and proximity to other structures. Implosion is reserved for larger structures where a swift, controlled collapse is necessary. I was involved in the implosion of an obsolete water tower, where precision was paramount to avoid damage to surrounding infrastructure. Selective demolition, using machinery, is often preferred for smaller projects or for phased demolition, enabling controlled removal of sections. Top-down demolition involves dismantling a structure layer by layer from the top, offering greater precision and control, especially when dealing with complex internal structures. Each method requires rigorous planning, meticulous execution, and detailed safety protocols.

Q 18. How do you address potential asbestos or lead contamination during demolition?

Asbestos and lead contamination pose serious health risks, so addressing them is a top priority. Prior to any demolition, a thorough environmental survey is conducted to identify potential hazards. If asbestos or lead is found, we engage licensed abatement contractors to safely remove these materials. This involves strict adherence to regulations, including the use of specialized equipment, protective gear, and air monitoring to ensure worker and public safety. The process is meticulously documented, with air quality testing conducted before, during, and after abatement. The removed materials are disposed of according to regulatory guidelines at designated hazardous waste facilities. For example, in a recent school renovation, we encountered asbestos-containing insulation. Following a comprehensive abatement plan, we successfully removed the material, minimizing any risk to workers and the community.

Q 19. Describe your experience with structural assessments prior to demolition.

Structural assessments are fundamental to safe and efficient demolition. I collaborate closely with structural engineers to conduct thorough inspections, often employing non-destructive testing methods like ultrasound and ground penetrating radar. These assessments help identify structural weaknesses, potential hazards, and the most effective demolition strategy. The assessment report guides the demolition plan, specifying the sequence of demolition, necessary shoring or bracing, and potential risks. A detailed understanding of the building’s structural elements – load-bearing walls, foundations, and supporting columns – is crucial in determining the safest and most efficient demolition method. A poorly assessed structure can lead to significant delays, cost overruns, and even accidents. For instance, the discovery of unexpected structural instability during a demolition of an old warehouse required us to revise our plan and implement additional safety measures before continuing.

Q 20. How do you ensure the safety of adjacent structures during demolition?

Protecting adjacent structures is paramount. My approach involves a combination of engineering controls and meticulous planning. Before demolition begins, a detailed assessment of adjacent buildings is undertaken to identify vulnerabilities. This often includes checking foundations, analyzing proximity, and evaluating potential vibration impacts. Measures to mitigate these risks might include shoring up adjacent buildings, erecting protective barriers, installing vibration monitoring equipment, and carefully controlling demolition activities. The demolition sequence is designed to minimize vibrations and flying debris, and close monitoring occurs throughout the process. For example, during the demolition of a building next to a historical landmark, we implemented strict vibration monitoring and employed specialized demolition techniques to minimize any impact on the adjacent structure. Maintaining open communication with neighbors and obtaining necessary permits is also critical.

Q 21. What is your experience with using demolition equipment and machinery?

I have extensive experience operating and managing a variety of demolition equipment, including excavators, high-reach demolition machines, and specialized attachments like shears, crushers, and grapples. Understanding the capabilities and limitations of each piece of equipment is essential for safe and efficient demolition. Operator training and certification are strictly enforced on all my projects. Safety protocols are implemented for each piece of equipment, and regular maintenance checks are conducted. I also have experience utilizing controlled blasting techniques when necessary, always adhering to strict safety and licensing regulations. Proficiency with this equipment, combined with a comprehensive understanding of safe operating procedures, is essential for minimizing risks and maximizing efficiency throughout the demolition process.

Q 22. Explain your process for monitoring and controlling demolition noise and vibration.

Monitoring and controlling noise and vibration during demolition is crucial for minimizing disruption to the surrounding environment and ensuring compliance with regulations. My process begins with a thorough pre-demolition assessment, identifying sensitive receptors like nearby residences or businesses. This informs the selection of demolition techniques and the implementation of mitigation measures.

We employ various methods for monitoring. This includes using sound level meters to measure ambient noise levels before, during, and after demolition activities, comparing them against permitted limits set by local authorities. For vibration monitoring, we utilize geophones placed strategically around the site to record ground vibrations. These readings are continuously monitored, often remotely, and compared to predetermined thresholds. If limits are exceeded, we immediately adjust the demolition techniques, potentially slowing down the process or switching to less impactful methods like hydraulic demolition instead of explosives.

Mitigation strategies vary. These can include implementing noise barriers, using low-noise equipment, scheduling demolition work during less sensitive hours, and employing vibration dampening techniques like controlled blasting or the use of specialized equipment. Regular reporting and documentation of these monitoring results are essential, forming part of our compliance record.

Q 23. How do you handle potential conflicts or disputes during demolition?

Conflicts during demolition projects can arise from various sources, including neighbor disputes, contractor disagreements, or unforeseen site conditions. My approach involves proactive communication and conflict resolution strategies. Open and honest communication is key – we keep all stakeholders informed of the project progress, potential challenges, and how we plan to address them.

For example, if a neighbor complains about noise, we immediately investigate, review our monitoring data, and explain our mitigation strategies. We might offer alternative solutions, such as providing temporary relocation accommodations, or adjusting the demolition schedule. If the dispute escalates, we engage in mediation or arbitration, involving neutral third parties to help find a mutually acceptable solution. Thorough documentation of all communications and agreements is crucial in preventing escalation and supporting our position if legal action becomes necessary.

We also address potential contractor conflicts proactively through clear contractual agreements that define roles, responsibilities, and dispute resolution mechanisms. This includes outlining timelines, payment schedules, and procedures for resolving disagreements.

Q 24. Describe your experience with post-demolition site cleanup and restoration.

Post-demolition site cleanup and restoration is a critical phase that ensures safety and prepares the site for its intended future use. My experience encompasses all aspects, from debris removal and sorting to soil remediation and landscaping. Safety is paramount. We implement strict safety protocols to prevent injuries during the cleanup process, including proper personal protective equipment (PPE) and site security measures.

The cleanup process involves separating materials for recycling and disposal. Hazardous materials such as asbestos or lead-based paint are handled according to strict regulations, with licensed contractors and disposal facilities employed. We carefully document all waste materials generated and their disposal methods, complying with environmental regulations. Following the cleanup, the site is graded and prepared for its next phase, whether it’s construction, landscaping, or simply site restoration to its original condition.

For example, on a recent project involving a multi-story building, we developed a detailed waste management plan that resulted in over 80% of the demolition debris being recycled, significantly reducing landfill waste and environmental impact. The site was then restored, exceeding the client’s expectations for landscaping and site preparation.

Q 25. What is your understanding of demolition insurance and liability?

Demolition insurance and liability are critical aspects of any demolition project. A comprehensive insurance policy protects against financial losses resulting from accidents, injuries, property damage, or environmental contamination. The policy must cover general liability, workers’ compensation, and pollution liability, adequately protecting the project owner, contractors, and subcontractors.

Liability extends to a range of potential issues. This includes damage to adjacent properties, injuries sustained by workers or members of the public, environmental violations, and delays or cost overruns. Understanding the scope of liability is vital. We ensure that all contractors carry adequate insurance coverage and that their certificates of insurance are regularly reviewed and updated.

Furthermore, we work closely with insurance brokers to select appropriate coverage, ensuring the policy limits are sufficient to cover potential losses. We also ensure our demolition plans minimize potential risks, making us proactive in mitigating potential liabilities.

Q 26. How do you communicate effectively with clients, stakeholders, and the team?

Effective communication is the backbone of successful demolition projects. My approach involves a multi-faceted strategy focusing on clarity, transparency, and proactive engagement.

With clients, we establish clear communication channels from the outset, including regular meetings, progress reports, and open forums for addressing concerns. We translate technical details into easily understandable language, avoiding jargon. With stakeholders like neighbors, we use a variety of methods – public meetings, newsletters, dedicated websites – to keep them informed and address their questions. This is vital for building trust and minimizing conflicts.

Internally, within the team, we leverage tools like daily huddles, progress tracking software, and open communication platforms to ensure seamless coordination. Clear roles, responsibilities, and decision-making processes are established to avoid misunderstandings and streamline operations. Open and constructive feedback is encouraged to foster a collaborative team environment.

Q 27. Describe a challenging demolition project and how you overcame the difficulties.

One challenging project involved demolishing a large, structurally unsound industrial building located near a busy highway. The primary difficulty lay in the building’s precarious condition, the proximity to the highway, and the need to minimize disruption to traffic flow. The risk of collapse was significant, requiring a meticulously planned and executed demolition strategy.

To overcome this, we first conducted a comprehensive structural assessment to determine the building’s weak points. We developed a phased demolition approach, starting with the least structurally sound areas, utilizing controlled implosion techniques for certain sections to minimize vibrations and debris. Simultaneously, we implemented a robust traffic management plan, coordinating with the highway authorities to minimize disruptions. This involved temporary lane closures and the use of traffic control personnel.

Throughout, rigorous safety measures were implemented, including protective barriers and worker training. Continuous monitoring of the demolition process, along with real-time adjustments to the plan, proved crucial to ensure both the safety of workers and the public, and to complete the project on time and within budget.

Q 28. How do you stay updated on best practices and new technologies in demolition?

Staying updated on best practices and new technologies in demolition is essential for maintaining professional competence and delivering efficient, safe, and environmentally sound projects. I actively engage in several strategies to achieve this.

I regularly attend industry conferences, workshops, and training sessions offered by professional organizations such as the National Demolition Association. These events provide insights into the latest technologies, safety regulations, and best practices. I also subscribe to industry journals and publications, keeping abreast of research findings and technological advancements. Online resources and professional networking platforms offer additional avenues for knowledge sharing and staying informed.

Furthermore, I actively seek opportunities to participate in project reviews and case studies to learn from the experiences of other professionals. Staying curious, researching new demolition technologies, and engaging in continued professional development are crucial for success in this dynamic field.

Key Topics to Learn for Demolition Planning Interview

- Demolition Methods & Selection: Understanding various demolition techniques (e.g., implosion, high-reach demolition, selective demolition) and factors influencing method selection (structural integrity, site constraints, environmental impact).

- Safety Planning & Risk Assessment: Developing comprehensive safety plans, identifying potential hazards (e.g., falling debris, asbestos, structural collapse), and implementing mitigation strategies. Practical application includes creating site-specific safety plans and conducting risk assessments.

- Sequencing & Methodology: Planning the demolition sequence to minimize risks and maximize efficiency. This includes understanding the order of demolition, equipment selection, and waste management strategies.

- Structural Analysis & Assessment: Understanding the structural elements of the building to be demolished and assessing their condition to determine appropriate demolition techniques. This includes evaluating load-bearing walls, foundations, and other critical structural components.

- Environmental Considerations & Permits: Familiarity with environmental regulations (e.g., asbestos abatement, hazardous waste disposal), obtaining necessary permits, and implementing environmentally responsible demolition practices.

- Cost Estimation & Budgeting: Preparing accurate cost estimates, including labor, materials, equipment, and permits. Understanding different costing methods and factors influencing project budget.

- Project Management & Communication: Managing the demolition project effectively, including scheduling, resource allocation, and communication with stakeholders (clients, contractors, regulatory bodies).

- Waste Management & Recycling: Developing a plan for managing demolition waste, including sorting, recycling, and disposal, in compliance with relevant regulations.

Next Steps

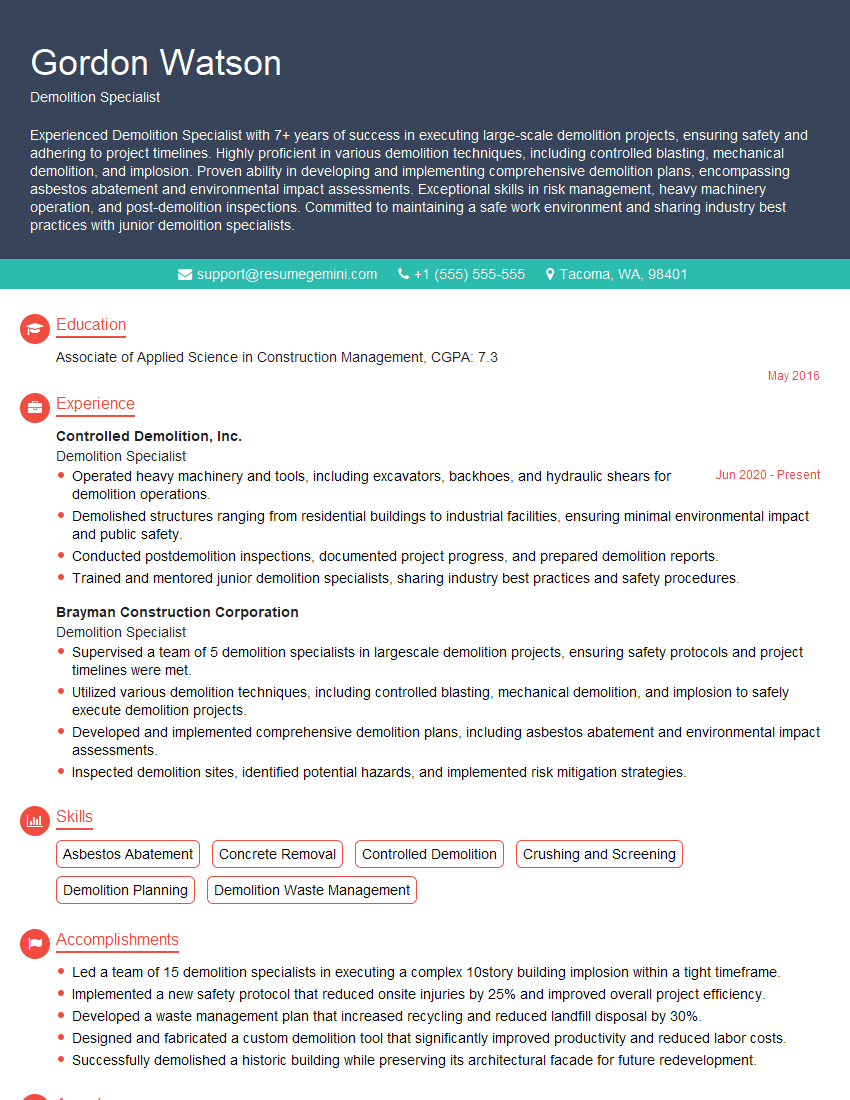

Mastering Demolition Planning is crucial for career advancement in the construction industry, opening doors to senior roles with increased responsibility and earning potential. An ATS-friendly resume is key to getting your application noticed. To significantly enhance your job prospects, we strongly recommend using ResumeGemini to build a professional and effective resume. ResumeGemini provides tools and resources to help you craft a compelling narrative showcasing your skills and experience. Examples of resumes tailored to Demolition Planning are available to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I represent a social media marketing agency that creates 15 engaging posts per month for businesses like yours. Our clients typically see a 40-60% increase in followers and engagement for just $199/month. Would you be interested?”

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?