Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Dowel Insertion interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Dowel Insertion Interview

Q 1. Explain the different types of dowels used in woodworking.

Dowels are cylindrical wooden pins used to join two pieces of wood. Several types exist, each suited to different applications and aesthetic preferences:

- Wooden Dowels: These are the most common, available in various diameters and lengths. They’re readily available and relatively inexpensive, offering good strength for many applications. The choice of wood type (e.g., hardwood for strength, softwood for easier insertion) depends on the project.

- Plastic Dowels: Often used for less demanding applications or where moisture resistance is crucial. They are stronger than wood in compression, but can be brittle.

- Metal Dowels: Used in situations requiring exceptional strength or where durability is paramount, often in outdoor furniture or heavier construction.

- Bamboo Dowels: A sustainable alternative offering a unique aesthetic and good strength properties.

The selection depends largely on the project’s requirements, the type of wood being joined, and the desired final look.

Q 2. Describe the process of accurately measuring and marking dowel locations.

Precise dowel placement is paramount for a strong and visually appealing joint. Here’s a detailed process:

- Determine Dowel Placement: Plan the joint’s layout, considering both strength and aesthetics. Mark the centerlines of the joint on both pieces of wood.

- Choose Dowel Diameter: Select a dowel diameter appropriate for the wood thickness and the joint’s strength requirements. As a general rule, the dowel diameter should be approximately one-third to one-half the thickness of the thinnest piece of wood being joined.

- Use a Dowel Jig (Highly Recommended): This ensures accurate spacing and alignment. Drill guide holes using the jig, ensuring the bits are perfectly aligned. The jig’s bushings act as guides for the drill bit, preventing wandering and ensuring consistency.

- Mark Dowel Centers: Carefully mark the center points for the dowel holes on both workpieces, following the jig’s alignment markings.

- Drill Pilot Holes: Drill pilot holes in both workpieces at the marked locations, using a drill bit slightly smaller than the dowel diameter to prevent splitting.

- Drill Dowel Holes: Using a drill bit the exact diameter of the dowel, drill the dowel holes to the correct depth. Consistent depth is essential for a flush joint.

Using a quality dowel jig is crucial to achieve accurate and consistent results. Without one, reliance on meticulous hand-marking and extremely careful drilling is critical but far less accurate.

Q 3. What are the advantages and disadvantages of using dowels for joining?

Dowel joints offer several advantages, but also have limitations:

- Advantages:

- Strength: Provides strong, reliable joints, particularly when using a sufficient number of dowels.

- Ease of Use: Relatively simple to create, even for beginners, especially with a dowel jig.

- Aesthetics: Creates a clean, neat joint, ideal for visible surfaces.

- Versatility: Can be used with a wide range of wood types and thicknesses.

- Disadvantages:

- Limited Strength (compared to other methods): Not as strong as mortise and tenon joints or other more complex joinery.

- Glue Dependence: Dowel joints rely entirely on glue for their strength; a poor glue joint renders the dowels ineffective.

- Potential for Misalignment: Without proper tools and technique, dowel alignment can be challenging.

It’s crucial to carefully weigh these factors when deciding whether dowel joints are appropriate for a particular project.

Q 4. How do you ensure accurate alignment of dowels during insertion?

Accurate dowel alignment is essential. The use of a high-quality dowel jig is the most effective method. However, even with a jig, attention to detail is crucial:

- Cleanliness: Ensure the dowel holes are free from wood dust or debris that could interfere with alignment.

- Precise Drilling: Use sharp bits and drill at a consistent speed and pressure to avoid creating oversized or misaligned holes.

- Proper Glue Application: Use a thin, even layer of glue on both the dowels and the inside of the holes to ensure proper adhesion and prevent gaps.

- Careful Insertion: Gently tap the dowels into place, using a mallet and a soft block of wood to avoid damaging them.

- Clamping: Use appropriate clamps to hold the workpieces firmly together while the glue dries, ensuring perfect alignment.

In the absence of a dowel jig, extreme care and possibly the use of alignment tools like a combination square will be necessary to achieve accurate alignment. The risk of error is greatly increased in this case.

Q 5. What types of dowel jigs are you familiar with?

I’m familiar with several types of dowel jigs:

- Self-Centering Dowel Jigs: These are the most common, offering simple and accurate hole placement. They typically use bushings to guide the drill bits.

- Multi-Hole Dowel Jigs: These jigs allow for the simultaneous drilling of multiple dowels in a single operation, increasing efficiency.

- Adjustable Dowel Jigs: Allow for customization of dowel spacing and hole depth, offering greater flexibility for various applications.

- Handheld Dowel Jigs: Smaller, more portable, and ideal for smaller projects or intricate work.

The choice of jig depends on the scale and complexity of the project, as well as personal preference. The self-centering type is a strong starting point for most home woodworkers.

Q 6. Describe your experience using various dowel insertion tools.

My experience encompasses various dowel insertion tools:

- Hand Drills: Provide good control for precise drilling, particularly in tight spaces.

- Drill Presses: Offer greater accuracy and consistency, particularly for larger-scale projects or when drilling multiple dowels.

- Dowel Drivers: Specialized tools that simplify dowel insertion, reducing the risk of damage.

- Mallets: Essential for gently tapping dowels into place after initial insertion, avoiding splitting or damage.

The appropriate tools depend on the job’s complexity and scale. A drill press generally provides better accuracy and consistency in my professional work, but a hand drill and mallet are vital for more intricate or on-site projects.

Q 7. How do you handle misaligned or broken dowels during assembly?

Misaligned or broken dowels during assembly can be frustrating, but are often manageable:

- Misaligned Dowels: If slightly misaligned, gentle tapping with a mallet and careful adjustment might suffice. For significant misalignment, you may need to remove the dowels (using a dowel extractor if necessary), re-drill the holes, and insert new dowels. Ensure the surfaces are clean before applying glue and reinserting.

- Broken Dowels: Broken dowels typically require removal, re-drilling, and replacing with new dowels. A small chisel can help break up stubborn dowel fragments that have broken off in the hole.

Prevention is always better than cure. Carefully following the aforementioned processes for accurate drilling and alignment will dramatically reduce the likelihood of these problems. Using good quality dowels also increases the likelihood of a successful joint.

Q 8. What safety precautions do you take when using dowel insertion tools?

Safety is paramount when working with dowel insertion tools. Before starting any project, I always ensure I’m wearing appropriate safety glasses to protect my eyes from flying wood chips or splinters. Hearing protection is also crucial, especially when using power tools like drill presses. I always make sure the work area is well-lit and free from clutter to prevent tripping hazards. Furthermore, I always unplug power tools before making adjustments or cleaning them. Finally, I double-check the alignment of the dowel jig and workpiece to prevent accidental slips or injuries. Think of it like this: you wouldn’t drive a car without a seatbelt; likewise, you shouldn’t operate dowel insertion tools without proper safety precautions.

- Wear safety glasses.

- Use hearing protection.

- Maintain a clean and well-lit workspace.

- Unplug power tools before maintenance.

- Double-check jig alignment.

Q 9. Explain the importance of proper glue application in dowel joining.

Proper glue application is the backbone of a strong and durable dowel joint. The glue acts as the primary bonding agent, transferring the stress from one piece of wood to the other. Insufficient glue leads to weak joints susceptible to failure under stress. Conversely, excessive glue can squeeze out, creating a messy finish and possibly weakening the joint by interfering with proper alignment. Think of it like mortar in bricklaying – the right amount is critical for stability. I aim for a thin, even bead of glue along the entire length of the dowel and the corresponding hole, ensuring complete coverage. This ensures maximum surface area contact and a strong bond.

Q 10. How do you determine the appropriate glue type for a given project?

Choosing the right glue depends heavily on the type of wood, the intended use of the project, and the environment it will be exposed to. For interior projects with hardwoods like oak or maple, I often use a PVA (polyvinyl acetate) wood glue, known for its strong bond and water resistance. For exterior projects or applications requiring higher water resistance, I opt for a polyurethane glue, which offers exceptional strength and durability, even in damp conditions. For very porous woods like balsa wood, I might use a thin-bodied glue to facilitate better penetration and bonding. I always refer to the glue manufacturer’s recommendations for application and drying time to ensure optimal performance.

For example, when building a garden bench for outdoor use, I would absolutely choose a polyurethane glue. For a fine piece of furniture used indoors, PVA would usually suffice.

Q 11. What are the common causes of dowel joint failure?

Dowel joint failures typically stem from a few key issues. Insufficient glue application, as discussed earlier, is a common culprit. Improper alignment of the dowels and corresponding holes can also lead to weak points and eventual failure. Using dowels that are too short or too thin for the load they need to bear can cause problems. Furthermore, using wood that is too wet or damaged can compromise the integrity of the joint. Finally, applying excessive clamping pressure during the curing process can crush the wood around the dowel, resulting in a weak joint. Think of it like building a house on a cracked foundation – the structure won’t last long.

Q 12. How do you troubleshoot problems encountered during dowel insertion?

Troubleshooting dowel insertion problems often involves a systematic approach. If a dowel is proving difficult to insert, I first check for obstructions in the hole – perhaps a wood chip or dust. If the dowel is binding, I might slightly adjust the alignment of the jig or the workpiece. If the glue is causing problems, I ensure it’s applied evenly and not excessively thick. If the dowel is breaking, I might need to use a larger diameter dowel or reduce the insertion force. I always check for alignment issues and ensure the holes are appropriately sized and aligned. If a joint is failing after assembly, I would assess the glue usage and check for any signs of wood damage or poor alignment.

Sometimes, it’s a process of elimination – carefully inspecting each step of the process to identify the source of the problem.

Q 13. Describe your experience with different types of wood and their suitability for dowel joining.

My experience working with various wood types has shown that hardwoods like oak, maple, and cherry are ideal for dowel joining due to their strength and density. They provide a good grip for the glue and hold the dowels securely. Softwoods like pine and fir can also be used, but they require more attention to detail, as they are more prone to splitting and may require pre-drilling pilot holes. Wood with significant grain variations or knots should be approached with caution, as these irregularities can impact dowel alignment and joint strength. I’ve found that properly seasoning the wood before joining is essential, regardless of the species, to minimize shrinkage and ensure a consistent, durable joint. The choice of wood will directly impact the type of glue and clamping technique I’ll use.

Q 14. How do you ensure consistent dowel insertion depth?

Consistent dowel insertion depth is crucial for a strong and visually appealing joint. I use dowel jigs to ensure accurate alignment and depth. These jigs provide precisely sized bushings that guide the drill bit, guaranteeing consistent depth for all the holes. Alternatively, I can use a drill stop collar on the drill bit to regulate depth. For manual insertion, I mark the desired depth on the dowel itself to serve as a visual guide. Regardless of the method, I always double-check the depth before inserting the dowel to avoid potential problems. Consistent depth ensures that the dowels are fully seated and the glue has sufficient contact surface area, preventing the joints from being weak or unstable.

Q 15. What are some alternative methods for woodworking joints, and when would you prefer them over dowels?

Dowels are a fantastic way to create strong, hidden joints, but they aren’t always the best choice. The ideal joint depends heavily on the project’s requirements for strength, aesthetics, and speed of assembly. Several alternatives exist, each with its own strengths and weaknesses.

- Mortise and Tenon: This classic joint offers exceptional strength and is ideal for furniture and structural applications. It’s more time-consuming than dowels, however.

- Biscuit Joints: These use thin, oval-shaped biscuits to join two pieces of wood. They’re fast and relatively strong, suited for applications where strength isn’t paramount, like cabinet construction. They’re less strong than dowels or mortise and tenon.

- Pocket Hole Joints: Created using a jig and special screws, these joints are quick and strong, excellent for projects where you don’t want to see screws on the surface.

- Glue Blocks/Splices: For larger surfaces, edge gluing blocks or splicing can provide immense strength but is very visible.

I’d prefer alternatives to dowels when:

- Extreme Strength is Required: Mortise and tenon joints or well-executed glue blocks are superior in high-stress situations.

- Aesthetics are Crucial: Visible joints like mortise and tenon can be aesthetically pleasing in certain applications. Dowels, while hidden, can still show minor imperfections.

- Speed is a Priority: Biscuit joints and pocket hole joints are significantly faster than precise dowel insertion, particularly for larger projects.

Choosing the right joint type is a crucial decision that requires careful consideration of the project’s specifics.

Career Expert Tips:

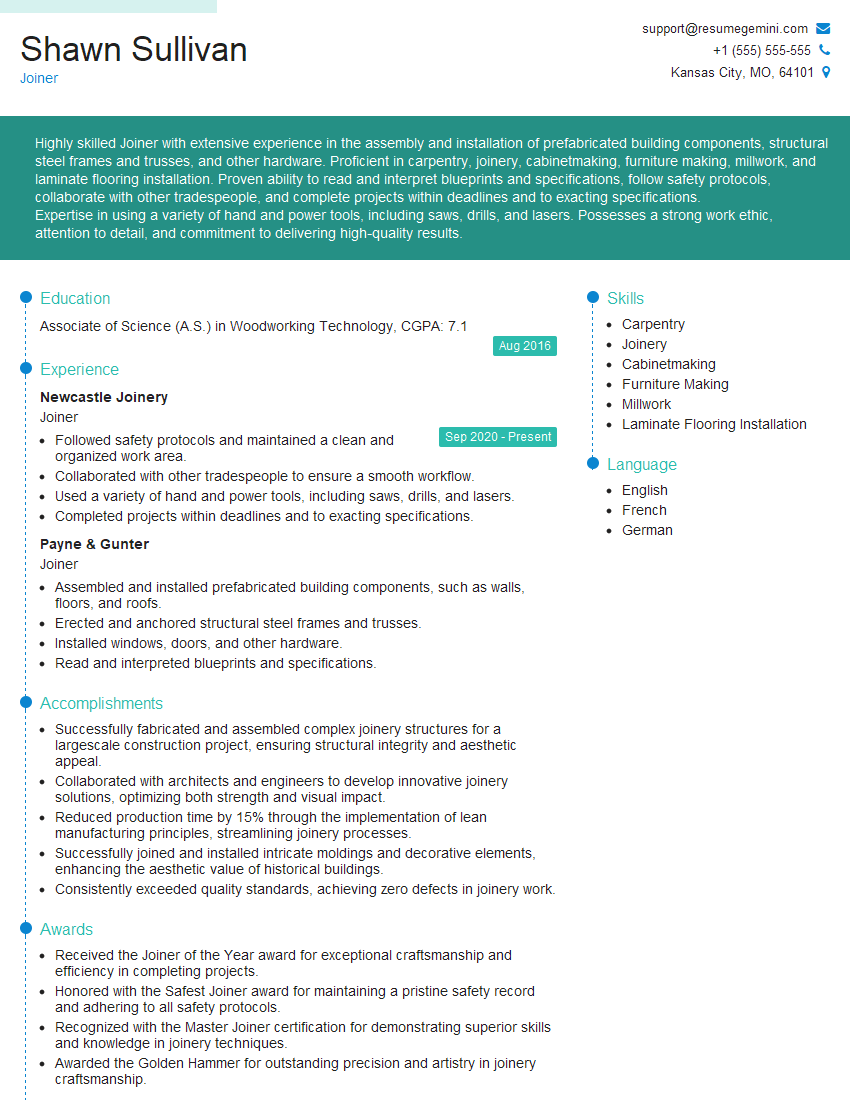

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience working with automated dowel insertion machines.

I have extensive experience operating automated dowel insertion machines, ranging from small benchtop models to larger, CNC-controlled systems. My experience includes programming machine settings for various dowel diameters and depths, ensuring accurate placement, and maintaining optimal machine performance. I’m proficient in troubleshooting common issues like misaligned jigs, faulty clamping mechanisms, and dowel jams. For instance, on a recent project involving a high-volume production run of chair legs, I programmed a CNC dowel insertion machine to precisely place six dowels per leg with incredible accuracy and speed, significantly improving efficiency compared to manual insertion.

I am also familiar with various safety protocols associated with these machines, emphasizing safe operating procedures and regular preventative maintenance to ensure both operational efficiency and worker safety.

Q 17. How do you maintain and clean dowel insertion equipment?

Maintaining and cleaning dowel insertion equipment is critical for ensuring accuracy and longevity. My routine includes:

- Regular Cleaning: After each use, I remove wood chips and dust from the machine using compressed air and a brush. I pay particular attention to the clamping mechanisms and dowel guides.

- Lubrication: Moving parts, especially those involved in the clamping mechanism and dowel feed system, require regular lubrication to prevent wear and tear. I use a high-quality machine oil specifically designed for woodworking equipment.

- Jig Inspection: The jigs that guide the dowels need to be regularly inspected for wear and tear. Any damage can compromise the accuracy of the dowel placement. I ensure they’re properly aligned and secure.

- Bit Sharpening/Replacement: The drilling bits will dull over time, impacting dowel insertion precision. I regularly assess the bits and replace or sharpen them as necessary. Dull bits can lead to splintering and inaccurate placement.

Following a thorough cleaning and maintenance schedule ensures the machine operates smoothly, leading to high-quality joints and extending the machine’s lifespan.

Q 18. How do you ensure the quality of the dowel joints you create?

Ensuring quality dowel joints involves meticulous attention to detail at every stage. Here’s my approach:

- Precise Drilling: Accurate drilling is paramount. I use a drill press with a jig to ensure perfectly aligned holes in both workpieces. A consistent depth is vital.

- Proper Glue Application: I use a suitable wood glue, applying a thin, even layer inside both holes. Too much glue can squeeze out and create a mess, while too little glue results in a weak joint.

- Firm Clamping: Secure clamping is crucial to maintain alignment while the glue dries. I apply clamps evenly to prevent warping or misalignment.

- Post-Assembly Inspection: After the glue has dried, I carefully inspect the joint for any signs of misalignment, gaps, or glue squeeze-out. I address any imperfections.

Regularly checking my tools and techniques ensures consistency, resulting in robust and visually appealing dowel joints.

Q 19. What is your experience with different types of dowel materials (wood, plastic, metal)?

My experience encompasses various dowel materials, each suited to different applications:

- Wooden Dowels: These are the most common and offer excellent strength and compatibility with most wood types. The choice of wood should ideally match the wood being joined. Birch is common for its strength and machinability.

- Plastic Dowels: These are suitable for applications where moisture resistance is key, such as outdoor projects or applications requiring water resistance. They are generally not as strong as wooden dowels.

- Metal Dowels: Metal dowels (often brass or steel) provide exceptional strength and are ideal for heavy-duty applications or when higher structural integrity is required. They are less common in general woodworking.

The choice of material is influenced by the project’s demands for strength, moisture resistance, and aesthetic considerations.

Q 20. How do you adapt your techniques for different sizes and types of dowels?

Adapting techniques for different dowel sizes and types is fundamental to successful joinery. I adjust my methods based on several factors:

- Dowel Diameter: I use appropriately sized drill bits and jigs for each dowel diameter. Smaller dowels require more precise drilling to avoid splitting the wood.

- Dowel Length: The depth of the drill holes must precisely match the dowel length. I carefully adjust the drill stop to achieve consistency. In the case of longer dowels, multiple dowels might be preferable to a single long dowel.

- Wood Type: Hardwoods require more careful drilling to prevent splitting than softwoods. I often use a slower speed and sharper drill bits for hardwoods.

- Joint Type: The type of joint (edge-to-edge, edge-to-face, etc.) determines the jig placement and the number of dowels required. This influences dowel placement and spacing.

Experience allows me to intuitively adjust my methods for optimal results regardless of dowel size, type, or the wood being joined. This also includes adapting techniques for different joint configurations.

Q 21. Describe a time you had to troubleshoot a difficult dowel insertion problem.

During a recent project constructing a large, intricate cabinet, I encountered a recurring issue where dowels were consistently binding halfway into the pre-drilled holes. Initial troubleshooting pointed to issues with the drill bits (wear and tear). However, replacing them did not fully solve the problem. I systematically investigated further, considering all possibilities.

After careful inspection, I discovered that the wood’s moisture content had varied slightly between the different sections of the cabinet sides. This resulted in dimensional changes between the parts to be joined, creating a slight misalignment that was causing the binding issue. The solution was to lightly sand and plane the misaligned sections of the cabinet side to ensure perfect alignment before dowel insertion. After implementing this adjustment, the dowel insertion process became smooth and consistent. This incident emphasized the importance of material consistency and thorough inspection of all aspects of a project to prevent unexpected complications.

Q 22. How do you ensure the strength and durability of a dowel joint?

The strength and durability of a dowel joint hinge on several key factors. Think of it like building a strong bridge – you need a solid foundation and proper construction techniques. Firstly, accurate hole alignment is paramount. Even a slight misalignment can significantly weaken the joint. Secondly, the dowel material itself must be of high quality and appropriate for the application, often matching the wood species for optimal expansion and contraction properties. Thirdly, proper glue application is critical. A good quality wood glue, applied liberally and evenly, ensures maximum surface contact between the dowel and the wood, maximizing bond strength. Finally, sufficient clamping pressure during curing is essential to maintain alignment and prevent movement before the glue sets completely. Insufficient clamping can result in a weak joint, prone to failure.

For example, in furniture making, using high-quality hardwood dowels and a robust clamping system are vital for joints that can withstand daily use for many years. In contrast, a poorly executed dowel joint in a less demanding application might still hold, but its lifespan and load-bearing capability would be severely compromised.

Q 23. What are the different methods for pre-drilling holes for dowels?

Pre-drilling for dowels employs several methods, each with its strengths and weaknesses. The choice depends on the project’s scale and precision requirements.

- Manual Drilling: This involves using a hand drill and drill bits sized to the dowel diameter. It’s suitable for smaller projects where precision isn’t paramount, offering excellent control and flexibility. However, it can be time-consuming and requires a steady hand to achieve consistent hole depth and alignment.

- Drill Press: A drill press offers superior accuracy and repeatability. Using jigs to guide the drill bit ensures perfectly aligned holes, essential for larger projects and those requiring high-strength joints. This is a far more efficient method for production work or where numerous identical joints are required.

- Doweling Jig: This specialized jig simplifies the process, ensuring accurate hole placement and depth, even for multiple dowels. These jigs are particularly useful for those less experienced with precise drilling and are widely available for various dowel diameters.

For instance, for a one-off chair repair, manual drilling might suffice. However, creating ten identical cabinet doors would necessitate using a drill press or doweling jig to guarantee consistent quality and efficiency.

Q 24. How do you deal with variations in wood density when inserting dowels?

Variations in wood density directly impact dowel insertion and joint strength. Denser wood requires more force for insertion, and a slightly undersized dowel might be needed to avoid splitting. Conversely, less dense wood might require a slightly larger dowel or increased glue application to ensure a tight fit. The key is to pre-drill pilot holes slightly smaller than the dowel’s diameter and then use a slightly larger bit for the final hole to account for wood density variations. This avoids splitting the wood while still allowing a tight-fitting joint. The pilot hole acts as a guide for the final hole and prevents the bit from wandering.

For example, working with hard maple will demand more careful pre-drilling than working with softer pine. Always test the pre-drilling technique on scrap wood of the same species before proceeding to the actual project piece. Observing the wood’s response to the drilling process is vital for a successful dowel insertion.

Q 25. What experience do you have working with various wood species and their specific requirements for dowel insertion?

My experience spans a wide range of wood species, from hardwoods like oak, maple, and walnut to softwoods like pine and fir. Each species presents unique challenges related to dowel insertion. Hardwoods, being denser, require more precise pre-drilling to prevent splitting. Softer woods, while easier to work with, are more susceptible to crushing during the process. I’ve developed techniques tailored to each species. For example, when working with highly figured hardwoods like curly maple, I employ a smaller pilot hole to prevent tear-out and carefully use a sharp drill bit to minimize splitting. This allows me to maintain control and precision during the dowel insertion.

Understanding the grain direction is crucial, preventing the dowel from splitting the wood, particularly along the grain. My experience includes working with exotic hardwoods that demand more specialized handling due to their hardness and density, requiring extra care to avoid cracking during the process.

Q 26. Explain your understanding of the relationship between dowel diameter and joint strength.

The relationship between dowel diameter and joint strength is directly proportional – larger diameter dowels generally result in stronger joints, given proper execution. However, this relationship isn’t linear. Increasing the dowel diameter excessively might lead to wood splitting, negating any strength gains. The optimal dowel diameter depends on the wood’s species, density, and the overall dimensions of the joint itself. Too small a dowel might not provide sufficient glue surface area, leading to a weak joint. A proper dowel size offers maximum surface contact for the glue, providing the strongest bond.

Think of it like building a wall – using larger bricks (dowels) creates a stronger structure, but if the bricks are too big, they may not fit together properly. The balance between appropriate dowel size and overall joint design is key for optimal strength.

Q 27. How do you ensure a consistent level of quality control in dowel insertion processes?

Quality control in dowel insertion involves several crucial steps. Firstly, it starts with meticulous pre-drilling using appropriate tools and techniques. A drill press or a high-quality doweling jig is usually necessary to maintain consistent hole depth and alignment. Secondly, consistent glue application is essential; using a glue dispenser ensures an even and ample amount of adhesive in each hole. Thirdly, proper clamping pressure is vital – too little pressure results in an insecure joint, whereas excessive pressure may lead to wood deformation or crushing of the dowel. Finally, after the glue has cured, a visual inspection ensures that all dowels are flush with the wood surface, indicating a successful join.

In my work, I routinely implement these quality control measures, including regular checks of tools and equipment to ensure their continued accuracy and efficiency. I also maintain detailed records of my projects, noting any challenges encountered and adjustments made to the process. This allows for continuous improvement and reduces error rates.

Q 28. How do you handle different types of wood grain when inserting dowels?

Different wood grains necessitate adjusting dowel insertion techniques. Straight grain is generally easiest to work with, while figured or highly textured grain requires more care to prevent splitting. Pre-drilling becomes even more critical in these situations, possibly requiring multiple pilot holes before the final dowel hole, or even using a smaller diameter dowel. The grain direction should always be considered when determining hole placement, and often, working with the grain can help reduce the risk of tear-out or splitting. Additionally, softer woods with less pronounced grain may still present problems if the dowel is too large or forced in.

For example, when working with birdseye maple, its complex grain pattern necessitates using a slightly smaller dowel and even more careful pre-drilling to avoid splitting the wood. Experience and careful observation are key to handling various grain patterns effectively.

Key Topics to Learn for Dowel Insertion Interview

- Types of Dowels: Understanding different dowel materials (wood, metal, plastic), sizes, and their applications in various joining techniques.

- Joint Design and Preparation: Analyzing joint strength, appropriate dowel placement, and accurate hole drilling techniques for optimal results. This includes understanding different joint types and their suitability for dowel insertion.

- Drilling Techniques and Precision: Mastering the use of drilling equipment to ensure accurate hole alignment, depth, and diameter, minimizing error and maximizing joint strength.

- Glue Selection and Application: Understanding the properties of various wood glues and their compatibility with different dowel materials. This also includes proper glue application techniques for strong and durable joints.

- Troubleshooting and Problem-Solving: Identifying and resolving common issues such as misaligned holes, broken dowels, and inadequate glue penetration. Developing effective strategies for quality control.

- Safety Procedures and Best Practices: Adhering to safety regulations when using power tools and handling materials. Following best practices for efficient and accurate dowel insertion.

- Material Science Considerations: Understanding the properties of the materials being joined (wood types, density, moisture content) and how these affect dowel insertion and joint strength.

- Automation and Technology: Familiarity with automated dowel insertion systems (if applicable to the specific role) and their advantages and limitations.

Next Steps

Mastering dowel insertion techniques is crucial for career advancement in various fields, including woodworking, manufacturing, and construction. A strong understanding of these principles demonstrates practical skills and problem-solving abilities highly valued by employers. To significantly increase your job prospects, focus on crafting an ATS-friendly resume that highlights your relevant skills and experience. ResumeGemini is a trusted resource that can help you build a professional and impactful resume, ensuring your application stands out. Examples of resumes tailored to Dowel Insertion expertise are available through ResumeGemini to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Live Rent Free!

https://bit.ly/LiveRentFREE

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?