The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Dowel Machine Troubleshooting interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Dowel Machine Troubleshooting Interview

Q 1. Describe your experience troubleshooting common dowel machine malfunctions.

Troubleshooting dowel machine malfunctions requires a systematic approach. My experience encompasses a wide range of issues, from simple adjustments to complex repairs. I’ve worked on various models, becoming adept at identifying the root cause of problems like inconsistent dowel depth, inaccurate placement, and machine jams. This involves a thorough understanding of the machine’s mechanics, including the drill mechanism, feed system, and clamping mechanism. For example, I once resolved a recurring issue of inconsistent dowel depth by identifying a worn-out drill bit, leading to a significant improvement in production quality and a reduction in wasted materials. Another instance involved diagnosing a problem with the dowel feeding mechanism, which I traced back to a loose screw causing inconsistent feed, ultimately leading to a simple solution with a tightened screw.

Q 2. Explain the process for diagnosing a dowel machine’s jamming issue.

Diagnosing a dowel machine jam is a process of elimination. First, I would ensure the machine is safely turned off and unplugged. Then, I would carefully inspect the area where the jam is occurring. This often involves checking for:

- Obstructions: Wood chips, dust, or foreign objects can easily clog the dowel feed system or the drill mechanism.

- Material Issues: Using wood that’s too hard, too wet, or contains knots can also cause jams. The dowel material itself might be poorly manufactured leading to irregular shapes.

- Mechanical Problems: A worn-out or damaged feed mechanism, a binding clamp, or a misaligned drill bit can all contribute to jamming.

Once the source is identified, the solution depends on the cause. Simple obstructions are usually easily removed. More complex issues might require adjustments, part replacements, or even a complete system overhaul. Think of it like unclogging a drain – you need to identify what’s blocking the flow before you can clear it.

Q 3. How would you identify and resolve issues with dowel alignment?

Dowel alignment problems usually stem from issues with the jig, the dowel insertion mechanism, or even the workpiece itself. To identify the problem, I start by visually inspecting the dowel placement against the workpiece. Are the holes misaligned? Is the dowel consistently off-center?

- Jig Alignment: A misaligned jig is the most frequent cause. This needs careful recalibration or potentially replacement.

- Mechanism Wear: The mechanism that inserts or guides the dowel might be worn, causing inaccuracies. Careful inspection and potentially replacement of worn parts is necessary.

- Workpiece Imperfections: Variations in the workpiece, such as warped boards or inconsistent drilling, can also affect alignment. Precise clamping and proper material selection are crucial.

Resolving alignment problems usually involves readjusting the jig, repairing or replacing worn parts of the dowel insertion mechanism, or ensuring the workpiece is properly prepared and clamped. Accurate measurements and careful adjustments are key to resolving this type of problem.

Q 4. What are the common causes of dowel breakage during operation?

Dowel breakage during operation usually indicates a problem with either the dowel itself, the machine’s operating parameters, or the wood being joined.

- Dowel Quality: Defective or brittle dowels are prone to breakage. Using high-quality, properly sized dowels is essential.

- Excessive Force: Incorrect drilling parameters, such as using too much force or too high a speed, can easily break dowels.

- Wood Density/Moisture Content: Extremely hard or wet wood can put excessive strain on the dowels, causing them to break. Using appropriate wood and properly conditioning it is important.

- Drill Bit Condition: A dull or damaged drill bit can create oversized holes, leading to loose dowels and potential breakage.

Addressing dowel breakage requires careful attention to these factors. Using higher quality dowels, adjusting the machine’s settings, and ensuring the wood is properly prepared are crucial steps.

Q 5. Describe your experience with preventative maintenance on dowel machines.

Preventative maintenance is crucial for extending the life and ensuring the accuracy of a dowel machine. My approach involves a regular schedule of inspections and cleaning, along with periodic lubrication and replacement of worn parts. I focus on these key areas:

- Regular Cleaning: Removing wood chips, dust, and debris prevents jams and ensures smooth operation. This includes cleaning the drill mechanism, the feed system, and the clamping mechanism.

- Lubrication: Regular lubrication of moving parts reduces friction and wear, prolonging the life of the machine. This is particularly important for the drill mechanism and the feed system.

- Part Inspections: Regularly inspecting parts for wear and tear, such as the drill bit, the feed rollers, and the clamping mechanism, helps identify potential problems before they cause major malfunctions.

- Calibration Checks: Periodically checking and adjusting the machine’s alignment and settings ensures accuracy and consistency.

Think of it as regular car maintenance – preventative measures are far more cost-effective than emergency repairs.

Q 6. How do you troubleshoot electrical problems in a dowel machine?

Troubleshooting electrical problems requires caution and a basic understanding of electrical safety. I always start by ensuring the machine is unplugged. Then, I systematically check the following:

- Power Supply: Verify the power supply is functioning correctly and the voltage matches the machine’s specifications.

- Wiring: Inspect all wiring and connections for any loose wires, damaged insulation, or corrosion. A multimeter is used to check continuity and voltage.

- Motor: Check the motor for any signs of damage or overheating. This may involve listening for unusual noises or checking the motor temperature.

- Control Panel: Inspect the control panel for any loose buttons, damaged switches, or malfunctioning components.

- Safety Devices: Verify that safety devices such as emergency stops and circuit breakers are functional.

I only proceed if I have the necessary electrical knowledge and safety precautions are in place. If unsure, I always consult an appropriately qualified electrician.

Q 7. How do you interpret error codes displayed on a dowel machine?

Interpreting error codes requires consulting the machine’s manual. Each code typically corresponds to a specific malfunction. The manual will provide a detailed description of the error and suggested troubleshooting steps. Some common error codes might indicate:

- Motor Failure: A specific code might appear if the motor overheats or fails.

- Sensor Malfunction: Error codes can indicate problems with sensors that monitor various aspects of the machine’s operation, like the feed system or the clamp.

- System Overload: A code may indicate that the machine is overloaded beyond its capacity.

Systematic troubleshooting based on the error code, along with a thorough examination of the machine’s components, usually leads to the source of the problem. Always refer to the machine’s documentation for the most accurate interpretation of error codes.

Q 8. Explain the importance of lubrication in dowel machine maintenance.

Lubrication is absolutely crucial for dowel machine maintenance. Think of it like oiling the joints of your body – without it, things would grind to a halt and break down quickly. Proper lubrication reduces friction between moving parts, preventing wear and tear, extending the lifespan of the machine, and ensuring smooth, consistent operation.

- Reduced Friction: Lubricants create a thin film between surfaces, minimizing metal-on-metal contact and reducing the heat generated during operation. This prevents premature wear of components like bushings, bearings, and spindles.

- Improved Accuracy: Reduced friction leads to improved accuracy in dowel placement. A well-lubricated machine produces more consistent and precise dowels.

- Increased Efficiency: A well-lubricated machine runs smoother, leading to increased production speeds and reduced downtime due to malfunctions.

- Extended Lifespan: By mitigating wear and tear, lubrication significantly increases the operational life of the dowel machine, saving you money on costly repairs and replacements.

In practice, this means following the manufacturer’s lubrication schedule meticulously. This usually involves using the correct type and amount of lubricant at specific points on the machine. Neglecting lubrication can lead to catastrophic failures, potentially resulting in expensive repairs or even a complete machine replacement.

Q 9. How do you handle a situation where a dowel machine is producing faulty dowels?

Faulty dowels point to a problem somewhere in the process. My approach is systematic, starting with the simplest possibilities and progressing to more complex issues.

- Examine the Dowels: Start by carefully inspecting the faulty dowels. Are they too short, too long, broken, or improperly sized? This gives immediate clues to the source of the problem.

- Check the Feed Mechanism: If the dowels are the wrong size, investigate the feed mechanism. Are the guides worn, misaligned, or jammed? This could be causing inconsistent dowel feeding.

- Inspect the Cutting Tools: Dull or damaged cutting tools (bits) are a common culprit. Examine the bits for wear, chipping, or misalignment. Dull bits produce inaccurate, splintered dowels. Replace or resharpen as needed.

- Check for Vibration: Excessive vibration can lead to inaccurate cutting. Check for loose components, worn bearings, or imbalance in the rotating parts. Addressing vibration issues often involves tightening bolts or replacing worn parts.

- Review Material Quality: The quality of the wood itself can impact the results. Inspect the wood stock for knots, inconsistencies, or moisture content variations. Using consistent, quality wood is essential for consistent results.

- Inspect the Clamp Mechanism: If the dowels are not properly seated or are loose, review the clamp mechanism. Ensure the clamps are applying consistent pressure and are properly aligned.

Troubleshooting involves a mix of visual inspection, testing, and knowledge of the machine’s mechanics. Sometimes, it’s necessary to systematically test each component until the root cause is identified. Maintaining a detailed log of troubleshooting helps to track progress and prevent repeated issues.

Q 10. Describe your familiarity with different types of dowel machines.

My experience encompasses a range of dowel machines, from small, manual benchtop models to large, automated industrial units. I’m familiar with:

- Manual Dowel Machines: These simpler machines are typically hand-cranked or have a basic electric motor. They’re great for smaller workshops but have limitations on production volume and accuracy.

- Pneumatic Dowel Machines: These machines utilize compressed air to power the drilling and clamping mechanisms. They offer faster operation and greater precision compared to manual models. This is a common type I’ve worked with extensively.

- CNC Dowel Machines: These computer-numerically controlled machines provide high precision and repeatability, ideal for large-scale production runs and complex applications. I’ve helped integrate these systems into automated production lines.

- Combination Machines: Some machines combine doweling with other woodworking operations like drilling or mortising. Understanding the integrated systems of these machines is essential.

Each type presents unique troubleshooting challenges, requiring a thorough understanding of its specific mechanisms and components. My expertise allows me to quickly identify and resolve problems on various machine types.

Q 11. What safety precautions do you follow when troubleshooting dowel machines?

Safety is paramount when troubleshooting any machinery, especially power tools like dowel machines. My safety protocol includes:

- Lockout/Tagout: Before beginning any troubleshooting, I always disconnect the power source and apply a lockout/tagout device to prevent accidental startup. This is non-negotiable.

- Personal Protective Equipment (PPE): I always wear appropriate safety glasses, hearing protection, and work gloves. Depending on the task, dust masks or respirators might also be necessary.

- Machine Inspection: Before starting any work, I carefully inspect the machine for obvious hazards like loose parts, frayed wires, or leaking fluids.

- Proper Lifting Techniques: Dowel machines can be heavy. I always use proper lifting techniques to avoid injury when moving or adjusting components.

- Awareness of Moving Parts: I’m always mindful of moving parts and keep a safe distance while the machine is operating (even for brief tests).

- Trained Personnel: I only allow trained and authorized personnel to work on the dowel machines.

By following these procedures, I ensure a safe working environment and minimize the risk of accidents. Safety is not just a guideline; it’s a priority.

Q 12. How do you document troubleshooting procedures and findings?

Detailed documentation is essential for efficient troubleshooting and preventative maintenance. My process involves:

- Problem Description: A clear and concise description of the problem encountered, including symptoms, date, and time.

- Troubleshooting Steps: A chronological log of all steps taken, including inspections, adjustments, and part replacements. This also includes the testing methodology used.

- Findings: Detailed notes on all observations, measurements, and test results. Pictures or diagrams can be immensely helpful here.

- Solutions Implemented: A clear description of the implemented solutions, including part numbers and any adjustments made. This should clearly indicate what was successful in resolving the fault.

- Recommendations: Suggestions for preventative maintenance or further actions to prevent similar issues in the future.

I typically use a combination of digital and physical documentation. A digital log allows for easy sharing and searchability, while physical labels or markings on the machine can be helpful for quick identification of repairs or maintenance performed. This approach ensures that the information is readily available when needed, and that future maintenance is smoother.

Q 13. What is your experience with pneumatic systems in dowel machines?

Pneumatic systems are common in dowel machines, providing the power for the drilling and clamping actions. My experience includes troubleshooting a wide variety of pneumatic issues, including:

- Air Leaks: Identifying and repairing leaks in air lines, fittings, and cylinders using leak detection tools and replacement parts.

- Pressure Regulation: Adjusting and calibrating pressure regulators to ensure the proper operating pressure for the machine’s components. This is particularly important to avoid damage to components.

- Cylinder Issues: Diagnosing and repairing problems with pneumatic cylinders, such as worn seals, damaged piston rods, or air leaks. This requires understanding the cylinder’s mechanics.

- Valve Problems: Troubleshooting issues with pneumatic valves, such as sticking valves, faulty solenoids, or internal leaks. This often requires testing the valves and understanding their electrical and pneumatic interfaces.

- Air Compressor Issues: Working with and understanding the air compressor’s role in providing sufficient air pressure to the system. This includes troubleshooting issues such as low pressure and compressor malfunctions.

Understanding the principles of pneumatics, including pressure, flow, and the components involved, is essential for effectively troubleshooting these systems. I have a strong practical understanding of pneumatic systems and their application in dowel machines.

Q 14. Explain the process for replacing worn dowel machine parts.

Replacing worn dowel machine parts is a crucial aspect of maintenance, ensuring continued accuracy and longevity. The process generally follows these steps:

- Identify the Worn Part: Thoroughly inspect the machine to pinpoint the specific part needing replacement. This often involves detailed visual inspection, sometimes alongside testing to confirm a component has failed.

- Source the Replacement Part: Locate the correct replacement part, ensuring it’s compatible with your dowel machine model. Use the manufacturer’s part number for accurate sourcing.

- Disconnect Power and Secure the Machine: Always disconnect the power supply and employ lockout/tagout procedures before starting any part replacement.

- Remove the Worn Part: Carefully remove the worn part following the machine’s manual or schematic diagrams. This often involves removing fasteners, disconnecting air lines, or other procedures.

- Install the New Part: Carefully install the new part, ensuring proper alignment and secure fastening. Refer to the manufacturer’s instructions or diagrams.

- Reconnect Power and Test: Reconnect the power supply and carefully test the machine’s operation. Inspect the machine for proper functioning of all components.

- Document the Replacement: Document the part replacement, including the date, part number, and any observations made during the process. This keeps detailed records for future maintenance or troubleshooting.

Remember: When dealing with complex machines, always consult the manufacturer’s manual for detailed instructions and safety precautions. Improper part replacement can lead to further damage or injury.

Q 15. How do you prioritize maintenance tasks on multiple dowel machines?

Prioritizing maintenance on multiple dowel machines requires a systematic approach. I typically use a combination of methods, including a criticality analysis and a planned maintenance schedule. The criticality analysis considers factors like machine age, production importance, and recent repair history. Machines crucial for high-volume production or with a history of frequent breakdowns get top priority.

For instance, a machine producing critical components for a time-sensitive project would be prioritized over a machine used for less urgent orders. The planned maintenance schedule is then created, based on manufacturer recommendations and my own observations. This schedule outlines preventative maintenance tasks (lubrication, cleaning, inspections) and their frequency. I also utilize a computerized maintenance management system (CMMS) to track tasks, automate reminders, and generate reports. This allows for proactive maintenance and reduces downtime.

- Criticality Analysis: Prioritize machines based on impact on production.

- Planned Maintenance Schedule: Develop a routine for preventative maintenance tasks.

- CMMS System: Leverage software for tracking and automation.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you troubleshoot problems related to dowel feed mechanisms?

Troubleshooting dowel feed mechanism issues involves a methodical approach. I start by visually inspecting the entire mechanism, looking for obvious problems like jams, broken parts, or misalignments. Then, I’ll check the feed motor for proper operation and the power supply. If there’s still a problem, I will check the sensors to ensure they are correctly detecting dowels and triggering the feed mechanism.

For example, if the dowels are jamming, I’ll check the dowel magazine for obstructions, ensure proper dowel orientation, and inspect the feed rollers for wear and tear or misalignment. If the feed mechanism is not starting, I’ll check for electrical issues at the motor and the control system. Sometimes, I use a multimeter to measure the voltage and current supplied to the motor to rule out power issues.

Understanding the specific design of the feed mechanism is key; some systems are pneumatic, others mechanical or even robotic. Diagnosis will vary based on the technology involved.

Q 17. What are the common causes of excessive noise or vibration in a dowel machine?

Excessive noise or vibration in a dowel machine usually indicates a problem with bearings, drive components, or loose parts. I begin by identifying the source of the noise – is it a high-pitched whine, a grinding sound, or a rhythmic thump? This helps isolate the problem area.

A high-pitched whine might point to a failing bearing, while a grinding sound could mean metal-on-metal contact. A rhythmic thump could suggest a problem with the machine’s drive mechanism, such as unbalanced components. I’ll then systematically check each potential source: bearings, belts, gears, and motor mounts. I use vibration sensors to pinpoint the exact location of the problem and measure the vibration level quantitatively. Loose bolts or fasteners are also common culprits. Regular lubrication also helps reduce noise and vibration. It is important to always shut down and secure the machine before performing any inspection.

Q 18. Describe your experience working with PLC controllers on dowel machines.

I have extensive experience working with PLC (Programmable Logic Controller) controllers on dowel machines. I’m proficient in reading and modifying PLC programs, troubleshooting PLC-related issues, and using programming software to diagnose and resolve problems.

For example, I’ve used PLC programming to optimize the production cycle, improve machine efficiency, and implement safety features. When a machine malfunctions, I use the PLC’s diagnostic tools to identify the source of the problem and to correct the fault by adjusting parameters or replacing faulty components. My experience extends to various PLC brands and programming languages, such as Ladder Logic and Structured Text. Understanding PLC programs allows for advanced troubleshooting and preventative maintenance.

Q 19. Explain the process for calibrating a dowel machine for accurate dowel length.

Calibrating a dowel machine for accurate dowel length is crucial for consistent product quality. The process usually involves adjusting the machine’s stopping mechanism. This could be a mechanical stop, a sensor-based system, or a combination of both. I start by setting the desired dowel length using the machine’s control panel. Then, I run a small test batch of dowels and measure their length using a precise measuring instrument. I compare the measured length with the set length and adjust the stopping mechanism accordingly, using the machine’s calibration procedures – often involving fine-tuning screws or adjusting sensor positions.

This process is iterative; I repeatedly test and adjust until the measured dowel length consistently meets the specified tolerance. Accurate calibration requires meticulous attention to detail and the use of calibrated measuring tools to ensure accuracy. Regular calibration is essential to maintain consistent dowel length over time.

Q 20. How do you handle emergency situations involving dowel machine malfunctions?

Handling emergency situations requires quick thinking and a structured approach. My first priority is always safety. I immediately shut down the machine using the emergency stop button and secure the area to prevent further injury or damage. Then, I assess the situation, identifying the nature and extent of the malfunction. I follow established safety protocols, which include notifying supervisors, relevant personnel, and potentially emergency services if necessary.

Depending on the problem, I might attempt immediate repairs if it’s safe and within my skillset. Otherwise, I’ll document the issue thoroughly, including photographs and notes, and contact qualified maintenance personnel or the manufacturer for assistance. The goal is to minimize downtime and ensure the safe return to operation.

Q 21. What is your experience with hydraulic systems in dowel machines?

My experience with hydraulic systems in dowel machines includes troubleshooting leaks, diagnosing hydraulic pump malfunctions, and performing routine maintenance. Hydraulic systems are commonly used for clamping mechanisms or for powering certain parts of the dowel cutting process. I’m familiar with hydraulic schematics and troubleshooting techniques, which involve checking fluid levels, pressure, and identifying leaks.

For instance, if a hydraulic clamp fails to operate properly, I’ll check the hydraulic fluid level, inspect the hydraulic lines for leaks, and assess the condition of the hydraulic pump and valves. I also use specialized tools like pressure gauges to test the hydraulic system’s performance and identify potential issues. Safety is paramount when working with hydraulic systems; I always follow proper safety protocols to prevent injuries.

Q 22. How do you determine the root cause of recurring dowel machine problems?

Pinpointing the root cause of recurring dowel machine problems requires a systematic approach. It’s like being a detective; you need to gather clues and eliminate possibilities. I begin by meticulously documenting the problem: When does it occur? What are the exact symptoms (e.g., broken dowels, inaccurate placement, machine jamming)? What are the operating conditions at the time (speed, feed rate, material type)?

Next, I perform a visual inspection, checking for obvious issues such as worn bits, misaligned components, loose fasteners, or debris buildup. I then move to more detailed checks, testing individual components like the feed mechanism, drilling unit, and clamping system. This often involves using diagnostic tools (discussed in Question 4). If the problem persists, I may systematically replace suspected faulty parts, one at a time, to isolate the culprit. Data logging, if available on the machine, is invaluable in identifying trends and patterns.

For instance, if dowels are consistently breaking, I’d first check the bit sharpness and the dowel material’s properties. If the dowels are misaligned, the problem likely lies within the clamping or feed system. A systematic approach ensures that we don’t jump to conclusions and that we address the underlying issue, rather than just the symptoms.

Q 23. Describe your experience with different types of dowel joining techniques.

My experience encompasses a wide range of dowel joining techniques. I’m proficient with both traditional and more advanced methods. Traditional methods involve using a simple dowel jig and hand-drilling, which is suitable for smaller-scale projects and requires precise hand-eye coordination. However, for mass production, automated dowel machines are essential. These machines utilize various techniques:

- Fixed-center drilling: The most common type, where the machine drills holes at a fixed distance apart.

- Self-centering jigs: These jigs automatically align the workpieces, improving consistency and accuracy.

- CNC-controlled systems: For complex shapes and high precision, CNC machines offer ultimate control and programmability. This allows for intricate dowel patterns and reduces waste.

- Glue application systems: Many modern machines integrate automatic glue application systems for optimized joint strength and efficiency.

Understanding the strengths and limitations of each technique allows me to select the most appropriate method for a given project, taking factors such as production volume, accuracy requirements, and material properties into account.

Q 24. How do you ensure the quality and consistency of dowels produced by the machine?

Ensuring consistent dowel quality involves a multi-faceted approach. It starts with using high-quality materials—both the wood and the dowels themselves—and maintaining the machine to optimal standards. Regular preventative maintenance is crucial; this includes lubricating moving parts, checking for wear and tear on the bits and other components, and cleaning the machine to prevent debris buildup that could affect accuracy.

Process parameters play a vital role. The speed and feed rate of the machine must be correctly set based on the wood type and dowel diameter. Incorrect settings can lead to uneven holes, broken dowels, or damaged workpieces. Regular calibration checks ensure the machine is consistently producing dowels to the specified dimensions. Finally, quality control checks, involving regular sampling and measurement of the produced dowels, confirm that the process is within acceptable tolerances.

Think of it like baking a cake: using high-quality ingredients (materials), precise measurements (parameters), and a properly functioning oven (machine) are all necessary to ensure a consistently delicious result.

Q 25. What is your experience with using diagnostic tools on dowel machines?

I’m experienced in using a variety of diagnostic tools on dowel machines. This includes:

- Digital calipers and micrometers: For precise measurement of dowel diameter and hole spacing.

- Runout gauges: To detect bit wobble, a common cause of inaccurate holes.

- Vibration sensors: To identify excessive vibrations which might indicate worn bearings or other mechanical issues.

- Data loggers and monitoring systems (if available on the machine): To track key parameters (speed, feed rate, power consumption) over time and identify trends that might suggest developing problems.

Knowing how to interpret the data from these tools is just as important as using the tools themselves. For example, consistently high vibration readings could point to a worn-out bearing, which needs to be replaced to prevent further damage. The data-driven approach improves efficiency and reduces downtime.

Q 26. How would you train a new employee on dowel machine troubleshooting?

Training a new employee involves a phased approach, moving from theoretical understanding to practical application. I begin with a thorough explanation of the machine’s operation, safety procedures, and the different types of dowel joints. This includes a review of diagrams and manuals. Then, I would demonstrate the correct operation of the machine, highlighting key safety precautions. Next, they would shadow me while I troubleshoot a few routine issues, learning how to identify potential problems.

Hands-on practice is crucial. I would supervise the trainee while they operate the machine, gradually increasing the complexity of the tasks. Throughout the process, I’d provide constructive feedback and answer any questions. Regular assessments, involving troubleshooting simulated problems, are part of the training regimen to ensure competence and proficiency. The goal is to build confidence and competence, fostering the ability to independently diagnose and solve problems. I emphasize the importance of documenting procedures and findings for future reference.

Q 27. How do you stay updated on the latest technologies and best practices in dowel machine maintenance?

Staying updated in this field requires continuous learning. I regularly attend industry trade shows and workshops, where I learn about the latest advancements in dowel machine technology and best practices. I also subscribe to relevant industry publications and online forums. These resources keep me abreast of new developments, emerging trends, and improvements in machine design and maintenance techniques. Moreover, I actively seek out training opportunities offered by the machine manufacturers to enhance my knowledge and skills.

Furthermore, I participate in online communities and networks of professionals in the woodworking and manufacturing industries, exchanging experiences and knowledge. This network provides access to a wealth of information and allows me to learn from others’ successes and mistakes. Staying current ensures I can provide the best possible service and support.

Q 28. Describe a time you had to troubleshoot a complex dowel machine problem; what was your approach and the outcome?

One time, we experienced a recurring issue with a CNC-controlled dowel machine. The machine would occasionally produce dowels that were significantly shorter than the programmed length. Initially, we suspected a problem with the CNC controller itself. However, after meticulously checking the programming and the controller’s functionality, the issue persisted. We systematically checked each component, including the feed mechanism, the cutting head, and the clamping system.

It turned out to be a seemingly minor issue: a small amount of debris had accumulated in the feed mechanism, causing intermittent jamming and inconsistent dowel length. Once this debris was cleared and the mechanism properly lubricated, the problem was resolved. This incident highlighted the importance of thorough inspection, even of components that initially seem unlikely culprits. It also reinforced the value of systematic troubleshooting and the necessity of meticulous preventative maintenance to avoid these types of issues in the future. The outcome was a fully functioning machine with significantly reduced downtime.

Key Topics to Learn for Dowel Machine Troubleshooting Interview

- Understanding Dowel Machine Mechanics: Gain a thorough understanding of the mechanical components, their functions, and interrelationships within a dowel machine. This includes feed systems, drilling mechanisms, clamping systems, and ejection mechanisms.

- Troubleshooting Common Dowel Machine Issues: Learn to identify and diagnose common problems such as jams, misaligned dowels, inaccurate drilling depth, broken parts, and insufficient clamping pressure. Practice applying systematic troubleshooting methodologies.

- Preventive Maintenance Procedures: Familiarize yourself with routine maintenance tasks, lubrication schedules, and safety protocols to prevent breakdowns and extend the lifespan of the machine. Understanding preventative maintenance is crucial for efficiency and safety.

- Electrical and Control Systems: Develop a working knowledge of the electrical systems powering the machine, including motors, sensors, and control panels. Understand basic troubleshooting of electrical faults and safety procedures.

- Hydraulic Systems (if applicable): If the dowel machine uses hydraulics, understand the principles of hydraulic pressure, fluid flow, and common hydraulic system issues. Learn how to identify leaks and diagnose hydraulic malfunctions safely.

- Safety Protocols and Procedures: Demonstrate a strong understanding of relevant safety regulations and procedures for operating and maintaining a dowel machine. This includes lockout/tagout procedures and personal protective equipment (PPE) usage.

- Data Analysis and Reporting: Learn how to collect and analyze data related to machine performance, downtime, and maintenance. Be prepared to discuss how you’d use this data to improve efficiency and reduce issues.

Next Steps

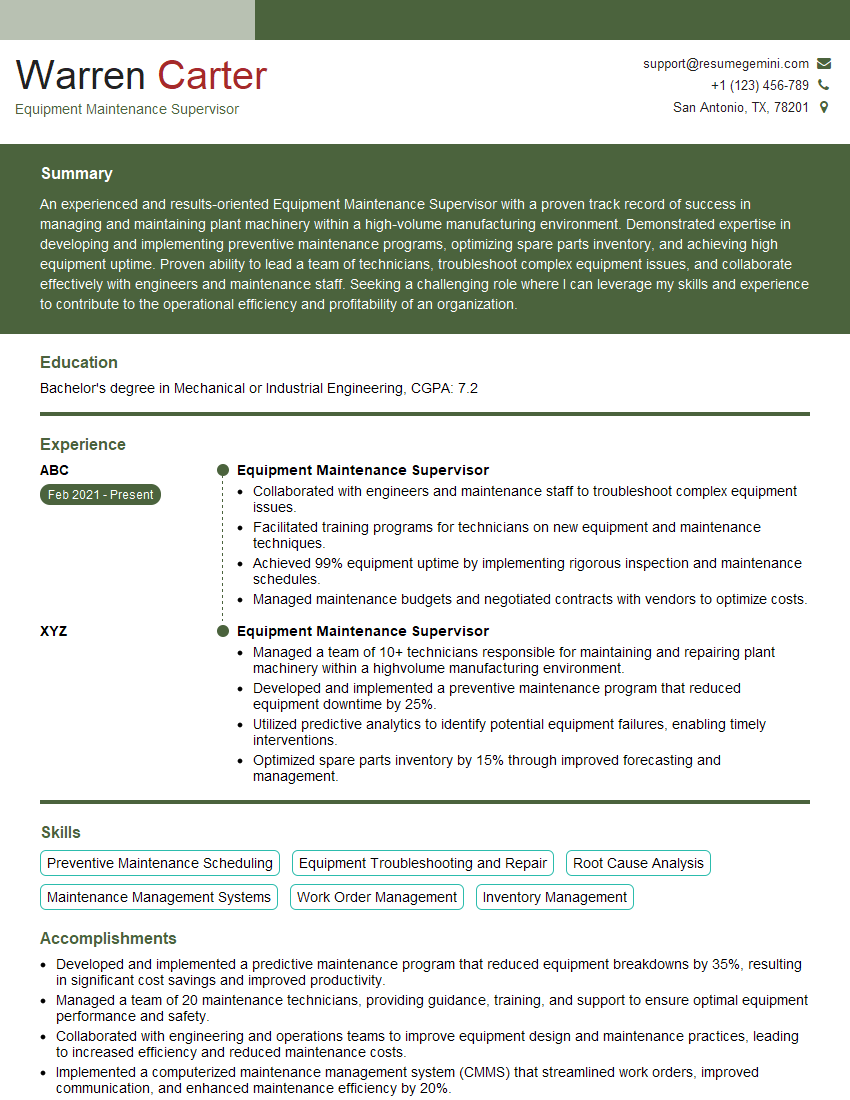

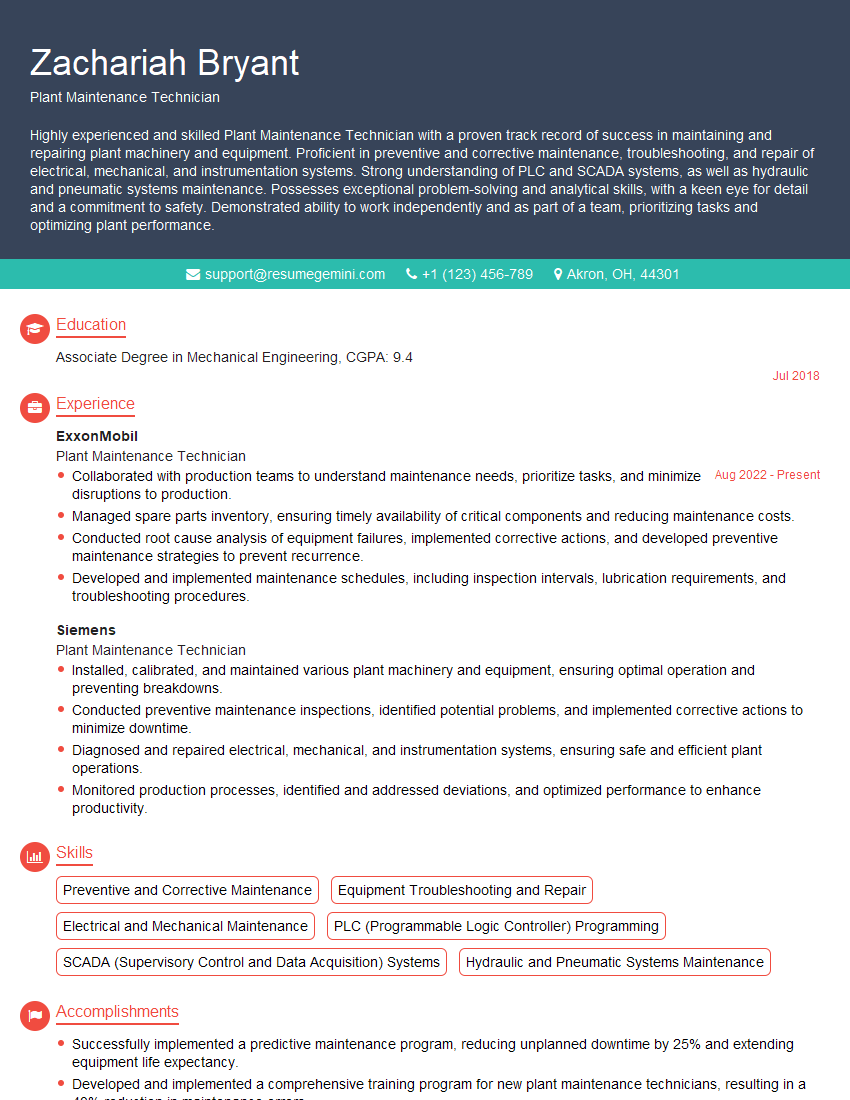

Mastering dowel machine troubleshooting is a valuable skill that significantly enhances your career prospects in manufacturing and woodworking industries. It demonstrates your problem-solving abilities, technical expertise, and commitment to efficiency and safety. To maximize your job search success, it’s crucial to create a compelling and ATS-friendly resume that highlights your skills and experience. ResumeGemini is a trusted resource that can help you build a professional resume tailored to your specific experience. Examples of resumes tailored to Dowel Machine Troubleshooting are available to help guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

These apartments are so amazing, posting them online would break the algorithm.

https://bit.ly/Lovely2BedsApartmentHudsonYards

Reach out at [email protected] and let’s get started!

Take a look at this stunning 2-bedroom apartment perfectly situated NYC’s coveted Hudson Yards!

https://bit.ly/Lovely2BedsApartmentHudsonYards

Live Rent Free!

https://bit.ly/LiveRentFREE

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?