Preparation is the key to success in any interview. In this post, we’ll explore crucial Engineered Hardwood Flooring Installation interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Engineered Hardwood Flooring Installation Interview

Q 1. What are the key differences between solid and engineered hardwood flooring?

The core difference between solid and engineered hardwood lies in their construction. Solid hardwood planks are made entirely from a single piece of wood, running the full thickness. This makes them incredibly durable and allows for multiple refinishes over their lifetime. Think of it like a sturdy, all-wood table. Engineered hardwood, conversely, is a multi-layered product. It typically features a top layer of real wood veneer, bonded to a core of plywood or other engineered wood materials. This construction offers greater stability, making it better suited for areas with fluctuating humidity or where subfloors might not be perfectly level. It’s like a high-quality, durable laminate floor but with a real wood surface. While it can be refinished, the number of times is generally limited by the thickness of the wear layer.

In short: Solid hardwood is more durable and refinishable but less stable; engineered hardwood is more stable and often more affordable but has fewer refinishing options.

Q 2. Explain the process of acclimating hardwood flooring.

Acclimation is crucial for preventing expansion and contraction of the hardwood after installation. This process involves storing the flooring in the room where it will be installed, in its original packaging, for a minimum of 72 hours, but ideally 5-7 days, at the final temperature and humidity of that room. This allows the wood to adjust to the ambient conditions, minimizing the chances of warping, cupping, or other problems after installation. Imagine taking a cold drink out of the refrigerator – you wouldn’t want to instantly drink it; it needs time to come to room temperature. Hardwood flooring is the same. Failure to acclimate properly is a common cause of installation failures.

Q 3. Describe different methods for installing engineered hardwood (e.g., nail-down, glue-down, floating).

Engineered hardwood offers several installation methods, each with its own advantages and disadvantages:

- Nail-down: This traditional method involves nailing the planks directly to the subfloor. It’s ideal for stable subfloors and offers excellent long-term stability. However, it requires more skill and can be noisy.

- Glue-down: The planks are adhered directly to the subfloor using construction adhesive. This results in a very stable and quiet floor but requires a perfectly level subfloor. It is also more difficult to repair individual planks if damaged.

- Floating: This method uses a cushioned underlayment, and the planks are clicked or glued together, creating a floating floor that isn’t attached to the subfloor. This is a great option for uneven subfloors and offers sound insulation. However, it’s typically not as durable as nailed-down or glued-down installations.

The choice of method depends on factors like subfloor condition, desired level of sound insulation, and the installer’s experience.

Q 4. What types of underlayment are suitable for engineered hardwood, and when would you choose each?

Several underlayments are suitable for engineered hardwood, each providing specific benefits:

- Foam underlayment: This is a common choice for floating installations, offering excellent sound and thermal insulation and cushioning underfoot. It’s relatively inexpensive and easy to install.

- Cork underlayment: Provides superior sound insulation and moisture resistance compared to foam. It’s a more sustainable option, but slightly more expensive.

- Rubber underlayment: Offers excellent durability and moisture resistance, ideal for areas prone to moisture or high traffic. It can be more expensive than foam or cork.

The selection depends primarily on the installation method (floating installations usually require underlayment) and the specific needs of the project, considering factors such as budget, moisture concerns, and desired level of comfort and sound insulation.

Q 5. How do you calculate the amount of hardwood needed for a room, accounting for waste?

Calculating hardwood needs requires accurate measurements and accounting for waste. First, measure the length and width of each room to get the square footage. Add the square footage of all rooms. Then, add 10-15% for waste, depending on the complexity of the room’s shape, cuts around obstacles, and the installer’s experience. More complex layouts requiring many cuts will lead to more waste. For example, a room measuring 10ft x 12ft equals 120 square feet. Adding 10% waste, you would need approximately 132 square feet of hardwood. Always round up to the nearest box quantity, as hardwood is sold in boxes of specific square footage.

Example: Room area = 150 sq ft, Waste = 15%, Total needed = 150 + (150 * 0.15) = 172.5 sq ft. Round up to the nearest box quantity to ensure you have enough.

Q 6. Explain the importance of proper moisture content in hardwood flooring installation.

Proper moisture content is paramount. Hardwood expands and contracts with changes in humidity. If the wood is too dry when installed, it may shrink and gap. If it’s too moist, it may expand and buckle. Ideal moisture content is generally between 6-8% for hardwood flooring. This is best measured with a moisture meter and checked both in the wood and in the subfloor. A significant moisture difference can lead to installation failures. Remember, acclimation helps to mitigate this issue but doesn’t eliminate the need for checking moisture levels.

Q 7. What tools and equipment are essential for installing engineered hardwood?

Essential tools and equipment include:

- Measuring tape: For accurate room measurements.

- Moisture meter: To check moisture content of the wood and subfloor.

- Hand saw or circular saw: For cutting planks.

- Power miter saw: Highly recommended for precision cutting, especially angles.

- Hammer and nails (or flooring nailer): For nail-down installation.

- Construction adhesive: For glue-down installation.

- Rubber mallet: For tapping planks together during floating installation.

- Pull bar or tapping block: To ensure planks interlock properly.

- Spacer blocks: To maintain consistent expansion gaps.

- Knee kicker: For easier installation of large planks.

- Safety Glasses and Hearing Protection: Essential for safety.

The specific tools will vary depending on the chosen installation method.

Q 8. How do you handle uneven subfloors before installing engineered hardwood?

Uneven subfloors are the enemy of a beautiful, long-lasting hardwood floor. Before laying any engineered wood, achieving a level surface is paramount. Think of it like building a house – you wouldn’t start constructing walls on a shaky foundation! We use several methods to address this.

- Self-leveling compound: For minor imperfections and dips, a self-leveling compound is a quick and effective solution. It’s poured over the subfloor and self-levels, creating a smooth, even surface. This is ideal for smaller areas or where the unevenness is relatively consistent.

- Plywood underlayment: For more significant unevenness, plywood underlayment is the preferred method. We’ll carefully assess the subfloor, identifying high and low spots. Then, we’ll install sheets of plywood, screwing them securely to the subfloor to level out the surface. It’s crucial to ensure proper acclimation of the plywood to the environment before installation to minimize expansion and contraction issues.

- Concrete grinding or patching: In cases where the subfloor is concrete, grinding down high spots or patching low spots with concrete repair might be necessary. This is generally a more involved process requiring specialized tools and often necessitates professional concrete work.

Regardless of the method, a final check with a level is crucial before installing the engineered hardwood to ensure a perfectly flat surface, ensuring the longevity and beauty of the final floor.

Q 9. Describe your experience with various hardwood flooring finishes (e.g., polyurethane, oil).

Hardwood flooring finishes significantly impact the floor’s durability, appearance, and maintenance. I have extensive experience with both polyurethane and oil finishes.

- Polyurethane: Polyurethane is a durable, protective finish that’s highly resistant to scratches, stains, and water damage. It’s available in various sheens, from matte to high-gloss, offering a wide range of aesthetic options. It’s a great choice for high-traffic areas. A downside is that scratches, while less likely, are more difficult to repair. I frequently use water-based polyurethane for its lower VOCs (volatile organic compounds), making it a healthier option for installers and homeowners.

- Oil finishes: Oil finishes, such as tung oil or UV-cured oil, offer a more natural look and feel, enhancing the wood’s grain and color. They are easier to repair minor scratches and scuffs compared to polyurethane. However, they require more maintenance – regular oiling is needed to maintain their water resistance and overall protection. Oil finishes are excellent for a rustic or natural aesthetic. For extremely high-traffic areas, oil may not be the optimal choice.

The choice between polyurethane and oil depends entirely on the client’s preferences, budget, and the intended use of the space. I always discuss the pros and cons of each option with my clients to help them make an informed decision.

Q 10. How do you address expansion and contraction gaps in hardwood flooring installations?

Expansion and contraction are inherent properties of wood, influenced by changes in temperature and humidity. Failing to account for this can lead to buckling, cupping, or gaps in the flooring. This is where proper installation techniques are vital.

We always maintain expansion gaps around the perimeter of the room, and around fixed objects. The gap size varies based on the type of wood and the climate, but generally, we aim for a gap of about 1/4 to 3/8 of an inch. This space allows the wood to expand and contract freely without causing damage. We use expansion strips – thin strips of foam or similar material – to maintain this gap. These strips are placed against walls and other obstacles before the flooring installation begins.

Remember, ignoring expansion gaps is a recipe for disaster! A seemingly small oversight can lead to significant and costly repairs.

Q 11. What are common problems encountered during hardwood flooring installation, and how do you solve them?

Several common problems can occur during hardwood flooring installation. I’ve seen them all, and here are some of the most frequent issues and their solutions:

- Uneven subfloor: As discussed earlier, this is tackled with self-leveling compound, plywood underlayment, or concrete repair.

- Improper acclimation: Wood needs time to adjust to the room’s temperature and humidity before installation. Failure to acclimate can lead to warping. We always ensure the wood is acclimated for at least 72 hours before installation.

- Improper nailing or gluing: Incorrect fastening can result in loose planks or damaged wood. We use the appropriate nailing pattern or adhesive based on the type of subfloor and hardwood.

- Poorly cut planks: Precise cuts are essential for a clean and professional finish. We use precision tools, like a miter saw or circular saw, and take careful measurements to ensure all cuts are accurate. If there are mistakes, using wood filler, and sanding properly help eliminate them.

- Gaps between planks: This can be caused by improper acclimation or insufficient expansion gaps. The problem will usually resolve itself as the wood acclimates to the room’s conditions. If that’s not enough, wood filler may be necessary.

Problem-solving in this field requires a keen eye for detail, patience, and a thorough understanding of wood’s properties.

Q 12. How do you ensure the proper alignment and spacing of hardwood planks?

Maintaining proper alignment and spacing is crucial for a visually appealing and structurally sound floor. We employ several techniques to ensure this:

- Snap lines: We use snap lines to create straight lines across the floor, which serve as guides for the planks. This ensures that the rows are straight and parallel.

- Spacers: Small spacers, typically made of plastic, are placed between planks to maintain consistent spacing. This is crucial for accommodating expansion and contraction.

- Careful measurements and cutting: Precise measurements and cuts are essential for a perfect fit. We use measuring tapes and marking tools to ensure accuracy and double-check our measurements before making any cuts.

- Checking alignment regularly: Throughout the installation, we regularly check the alignment and spacing using a square and level to ensure that the floor is installed correctly.

Consistency is key to a visually pleasing result. We treat each plank with care to avoid misalignments, and our rigorous checking process eliminates most issues at the source.

Q 13. Explain the process of installing hardwood flooring around obstacles (e.g., doors, pipes).

Installing around obstacles requires careful planning and precise cutting. We typically use a combination of techniques:

- Precise measurements: We meticulously measure the area around the obstacle, such as a doorway or pipe, to create a precise template for the cuts.

- Jigsaw or coping saw: We use a jigsaw or coping saw to carefully cut the planks to fit around the obstacle. This requires skill and patience to ensure a clean, accurate cut without damaging the surrounding planks.

- Wood filler: After the cuts are made, wood filler is used to seamlessly blend any gaps or imperfections, creating a professional finish.

- Pre-cutting: If possible, we may pre-cut the planks to fit around obstacles before installing them, optimizing the fit and minimizing waste.

Working around obstacles takes meticulous planning and skilled execution. It’s a crucial aspect that distinguishes an amateur from a professional installation.

Q 14. Describe your experience working with different types of hardwood species.

My experience encompasses a wide variety of hardwood species, each with its unique properties and characteristics. This influences everything from installation techniques to maintenance advice.

- Oak (Red and White): Oak is a very popular choice due to its durability, beautiful grain pattern, and availability. Its hardness necessitates the use of appropriate tools and techniques during installation.

- Maple: Maple is known for its hardness and clean, light color. It’s very susceptible to dents and scratches, so careful handling is required during the installation and afterward.

- Walnut: Walnut boasts a rich, dark color and striking grain pattern. Its darker color often requires more attention to detail during installation to avoid highlighting inconsistencies.

- Cherry: Cherry offers a beautiful, warm reddish-brown hue that deepens with age. It’s relatively softer than oak or maple, requiring gentle handling. Understanding the wood’s character helps me advise the client on its maintenance needs, including the appropriate finish and cleaning methods.

Knowing the unique properties of different hardwood species is essential for successful installation and client satisfaction. It allows me to recommend the best practices for each specific type of wood, ensuring the longevity and beauty of the finished floor.

Q 15. What safety precautions do you take during hardwood flooring installation?

Safety is paramount in hardwood flooring installation. We begin by ensuring the work area is clean and free of obstacles to prevent trips and falls. This includes removing any clutter and securing loose wires or objects. We always wear appropriate safety gear, including safety glasses to protect our eyes from flying debris, hearing protection from the noise of power tools, and work gloves to protect our hands. Dust masks are crucial, especially when sanding, to prevent inhaling harmful particles. Proper ventilation is also essential, using fans to circulate the air and remove dust. Finally, we use caution when operating power tools, following all manufacturer’s safety guidelines and ensuring that all guards are in place. I’ve personally witnessed a near-miss with a nail gun, highlighting how crucial safety procedures are to prevent injuries. A misplaced foot could have had serious consequences, so maintaining vigilance is part of our daily routine.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you maintain the quality of your work throughout the installation process?

Maintaining quality begins with meticulous preparation. This involves carefully acclimating the wood to the environment to avoid expansion or contraction after installation. We check for moisture levels in the subfloor and ensure it’s perfectly level and clean. Then, we carefully plan the layout, minimizing waste and ensuring a visually appealing pattern. During installation, we use precision tools to cut and fit each piece precisely, taking extra care at doorways and transitions. We regularly check our work for gaps, inconsistencies, or issues. For instance, I once noticed a slight imperfection in a board mid-installation. By addressing it immediately, instead of hoping it would go unnoticed, we avoided a larger problem later. This proactive approach to quality control is essential for a professional finish. Every board is inspected, every seam is reviewed, and we don’t rush the process. It is better to slow down and do it right, than fast and regret it.

Q 17. What is your experience with different types of flooring adhesives?

I have extensive experience with various flooring adhesives, including moisture-cure urethane, pressure-sensitive, and water-based adhesives. The choice depends heavily on the subfloor material, the type of engineered hardwood, and the specific project requirements. Moisture-cure urethane is excellent for concrete subfloors and provides a strong, durable bond. Pressure-sensitive adhesives are suitable for quick installations, but require a very level subfloor. Water-based adhesives are environmentally friendly and low in VOCs, a factor often preferred by environmentally conscious clients. Each adhesive has its own application technique and open time, which I am well-versed in. For example, I once worked on a project with a particularly tricky subfloor, where a pressure sensitive adhesive would have failed. The selection of a moisture-cure urethane was critical to the project’s success. Careful adhesive selection is about understanding the specific constraints of each project and choosing accordingly.

Q 18. How do you troubleshoot squeaky floors in engineered hardwood installations?

Squeaky floors in engineered hardwood are often caused by loose boards, insufficient adhesive, or movement in the subfloor. Troubleshooting involves careful investigation. We start by identifying the location of the squeak, then gently tap on the boards to pinpoint the culprit. If the squeak is due to loose boards, we can often reinforce the connection with additional adhesive, applied precisely using a caulking gun. For squeaks caused by the subfloor, we may need to address underlying issues, like loose joists or unevenness. In more serious cases, it may be necessary to lift and re-secure the affected boards. I remember one project where a seemingly simple squeak turned out to be a result of a loose subfloor joist. Properly addressing the root cause, rather than simply attempting a quick fix, was essential to resolve the long-term issue.

Q 19. How do you handle moisture damage in hardwood flooring?

Moisture damage in hardwood flooring is a serious issue, often leading to cupping, crowning, or even rot. The first step is to identify and address the source of the moisture. This might involve fixing leaks in plumbing or roofing, or addressing high humidity levels. Once the source is dealt with, the damaged boards need to be assessed. Minor damage might be reversible through sanding and refinishing. More severe damage, such as rot, necessitates board replacement. We always use a moisture meter to assess the damage, and never begin repairs without determining the root cause. I’ve had situations where clients thought it was just a minor problem, only to find that the water damage extended significantly beyond what was initially apparent. Proactive moisture control is very important; sometimes, installing a vapor barrier underneath the subfloor is essential to prevent future problems.

Q 20. What are your methods for finishing the edges of the flooring?

Finishing the edges of the flooring requires precision and attention to detail. We use a variety of tools and techniques, depending on the specific requirements of the project. For example, we might use a hand plane or router to create a custom finish on exposed edges, ensuring a seamless transition between the flooring and other surfaces. Alternatively, we might use specialized molding to cover the edges and provide a more decorative finish. Often, a combination of careful cuts and matching molding yields a beautiful and clean edge. I’ve had experience using different materials for molding, choosing materials that complement the flooring and the overall design of the room. The finished edges are integral to the overall aesthetic quality of the flooring installation.

Q 21. Describe your experience with installing hardwood on stairs.

Installing hardwood on stairs is a more complex task, requiring specialized skills and techniques. The process involves carefully measuring and cutting each tread and riser to ensure a precise fit. We use specialized stair nosing and other trim pieces to create a safe and aesthetically pleasing finish. Proper securing of the boards is critical to ensure longevity and prevent movement. We use appropriate adhesives and fasteners, and may employ different techniques for the different parts of the staircase. For instance, the stringers usually require a different approach than the treads and risers themselves. I have handled several stair projects, of varying complexity, and can confidently say that meticulous measurement and planning are essential to a successful outcome. Safety is also enhanced with proper planning and execution, making sure we don’t compromise safety for expediency.

Q 22. What are your preferred methods for cutting hardwood planks to fit?

Cutting hardwood planks precisely is crucial for a seamless installation. My preferred methods depend on the cut needed. For straight cuts, a circular saw with a fine-tooth blade designed for hardwood is my go-to. This ensures clean, accurate cuts minimizing splintering. For intricate cuts around doorways or obstacles, I use a jigsaw with a hardwood blade, controlling the speed for smooth results and preventing chipping. Finally, for angled cuts, a miter saw is invaluable, ensuring perfectly fitting pieces. Each saw requires careful setup – the correct blade, appropriate speed, and proper support to avoid errors. Think of it like a surgeon using different instruments for different procedures – each tool is specialized for a specific task.

- Circular Saw: Ideal for straight cuts across long planks.

- Jigsaw: Best for curves and intricate cuts around obstacles.

- Miter Saw: Essential for precise angled cuts, especially for baseboards and transitions.

Q 23. Explain your experience with using specialized tools for hardwood installation.

My experience with specialized tools is extensive. Beyond the saws mentioned, I’m proficient with a power planer for leveling uneven planks, a nail gun for efficient and secure fastening (always using the right nails for the wood type and thickness!), and a flooring tapping block to avoid damaging the surface during installation. I also utilize moisture meters to ensure the wood’s acclimation to the environment and prevent future problems. A good example is using a tapping block: it allows for even pressure distribution when tapping in planks, preventing dents or damage and creating a consistent, tight fit across the entire floor. This is far better than simply using a hammer directly.

Q 24. How do you manage challenging installation sites (e.g., uneven floors, difficult angles)?

Uneven floors and difficult angles are common challenges. For uneven subfloors, I assess the severity. Minor imperfections can be addressed by using self-leveling compound, creating a perfectly smooth base. For more significant issues, I might need to install a subfloor, carefully following building codes for proper support and ensuring levelness. Difficult angles, like those around stairs or fireplaces, require precise measurements and careful cuts, often using a combination of jigsaw and miter saw cuts. Sometimes, strategically using transition strips helps to bridge between different flooring heights or angles, concealing any minor irregularities. Each situation requires careful planning and attention to detail.

For example, on a recent job with significant subfloor inconsistencies, we utilized a laser level to pinpoint high and low spots, ensuring consistent leveling across the entire area before installation.

Q 25. What is your understanding of building codes and regulations related to hardwood flooring installations?

Understanding building codes and regulations is paramount. This includes adhering to moisture content limits for wood, ensuring proper subfloor preparation, using appropriate adhesives and fasteners, and complying with safety regulations for power tools. I stay updated on local codes, frequently checking for revisions and ensuring my methods reflect current best practices. Failure to comply can lead to significant issues, including structural problems and liability concerns.

Q 26. How do you handle customer concerns or complaints during and after installation?

Addressing customer concerns is crucial. I prioritize open communication throughout the project. Any concerns that arise during installation are immediately discussed and addressed. If a problem occurs after installation, I thoroughly investigate the cause, whether it’s a manufacturing defect, an issue with the subfloor, or an unforeseen circumstance. My goal is to find a fair and effective solution, often including repairs or replacements as needed. Building a trusting relationship is key, allowing for open dialogue and the potential to resolve even the most difficult situations smoothly.

Q 27. Describe your experience with working in a team environment on flooring installation projects.

Teamwork is essential for efficient and high-quality installations. I’ve worked on many projects with teams of varying sizes, from small crews to larger teams. My role always involves clear communication, effective delegation, and collaboration to ensure each step is executed correctly and efficiently. I value a team where everyone contributes their skills and experience, working together to achieve a shared goal. This collaboration includes sharing tasks like preparing the subfloor, cutting planks and installing them as well as clean-up.

Q 28. What are your long-term career goals in the hardwood flooring industry?

My long-term goals involve continued professional development in the hardwood flooring industry. I aim to expand my knowledge of new materials, techniques, and technologies. I’d also like to contribute to the training and mentorship of aspiring installers, sharing my expertise to maintain high standards in the industry. Ultimately, I strive to be a recognized expert, contributing to the growth and improvement of professional hardwood flooring installation.

Key Topics to Learn for Engineered Hardwood Flooring Installation Interview

- Substrate Preparation: Understanding different subfloor types (concrete, plywood, etc.), moisture content testing, leveling techniques, and appropriate underlayment selection.

- Acclimation & Storage: Proper acclimation procedures for engineered hardwood, understanding the impact of humidity and temperature on wood expansion and contraction, and safe storage practices.

- Measurement & Layout: Accurate room measurement, creating efficient layout plans to minimize waste, and understanding different installation patterns (running bond, herringbone, etc.).

- Installation Techniques: Mastering various installation methods (nail down, glue down, floating), using appropriate tools and equipment, and understanding the importance of proper expansion gaps.

- Troubleshooting & Problem Solving: Identifying and resolving common installation issues such as squeaking floors, gapping, and uneven surfaces. Developing strategies for effective problem diagnosis and repair.

- Finishing Touches: Proper trimming and cutting techniques, installing transition strips, and achieving a professional finish around doorways and other obstacles.

- Safety Procedures: Understanding and adhering to safety regulations, proper use of power tools, and maintaining a clean and organized work area.

- Wood Species & Grades: Familiarity with different engineered hardwood species, their properties, and grading systems. Understanding the impact of wood type on installation and maintenance.

- Tools and Equipment: Demonstrating knowledge of essential tools (measuring tapes, saws, nail guns, etc.), their proper use, and maintenance.

Next Steps

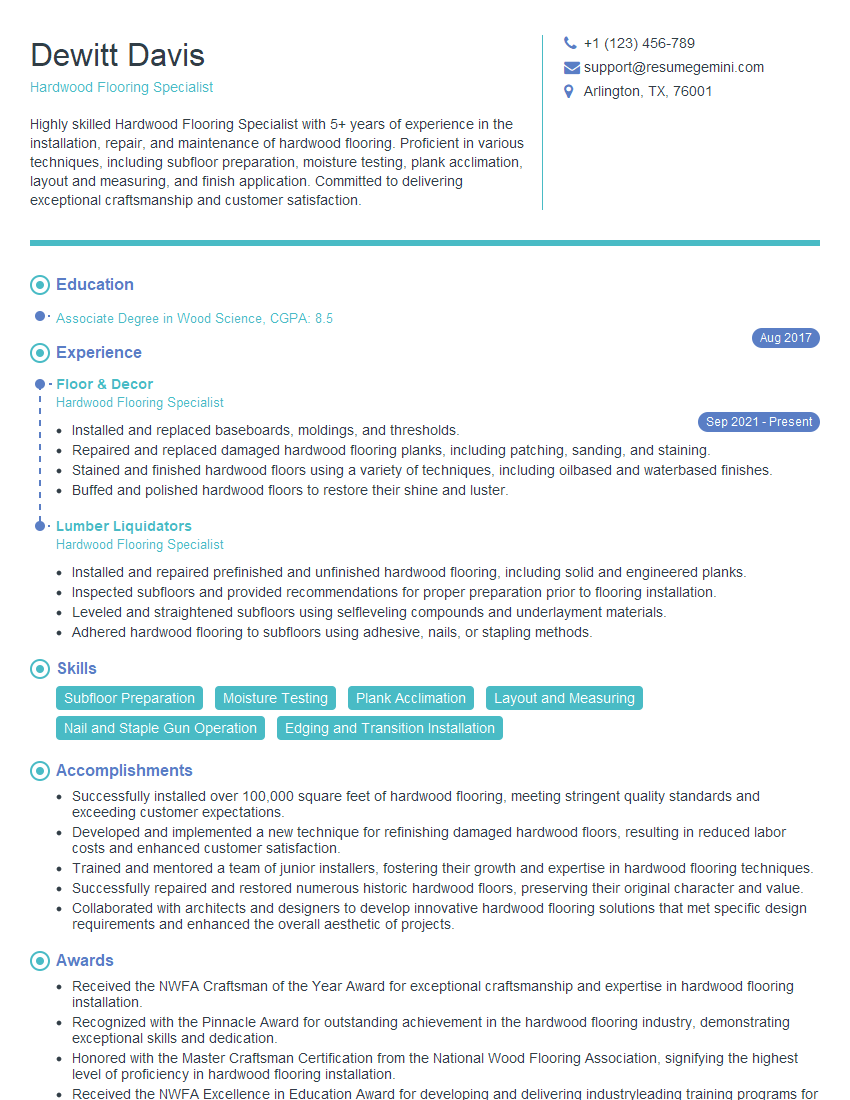

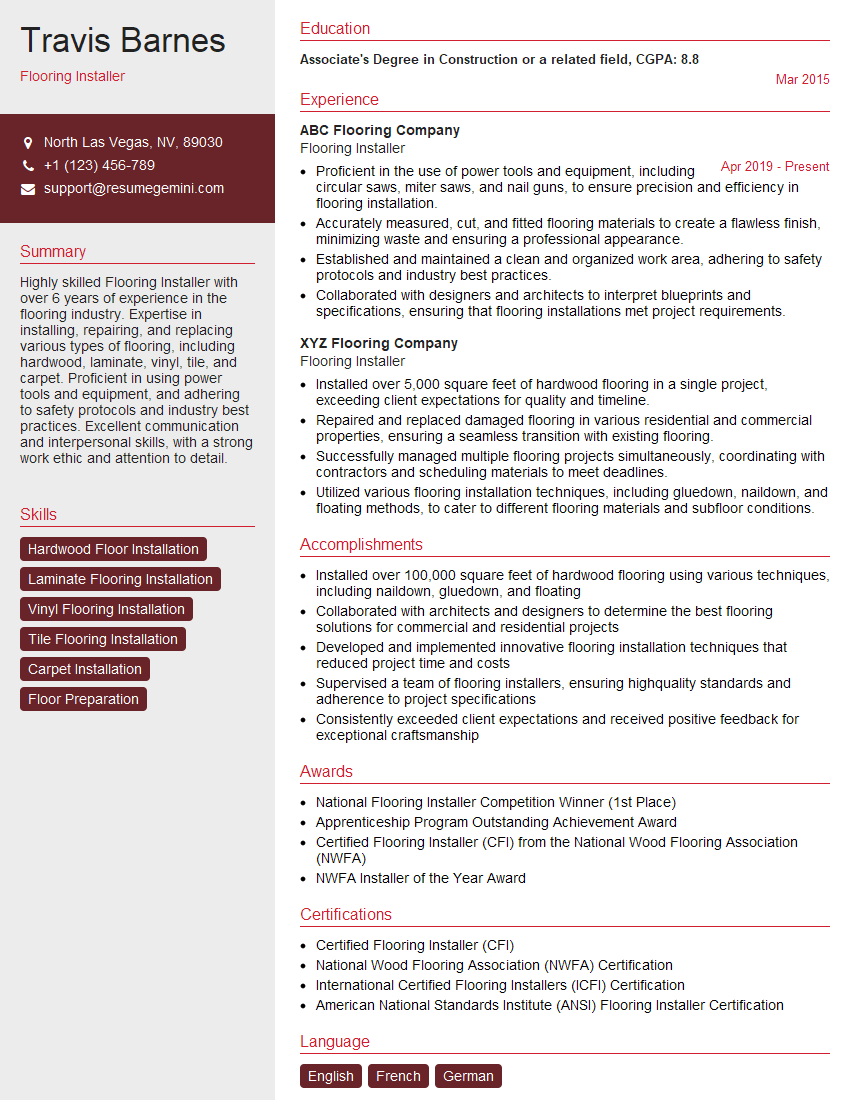

Mastering engineered hardwood flooring installation opens doors to rewarding careers with excellent growth potential. Your expertise in this skilled trade will make you a highly sought-after professional. To maximize your job prospects, it’s crucial to present your skills effectively. Creating an ATS-friendly resume is key to getting your application noticed by recruiters and hiring managers. We recommend using ResumeGemini to build a professional and impactful resume that showcases your abilities. ResumeGemini provides examples of resumes tailored specifically to engineered hardwood flooring installation to guide you through the process. Take the next step towards your dream career today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

hello,

Our consultant firm based in the USA and our client are interested in your products.

Could you provide your company brochure and respond from your official email id (if different from the current in use), so i can send you the client’s requirement.

Payment before production.

I await your answer.

Regards,

MrSmith

hello,

Our consultant firm based in the USA and our client are interested in your products.

Could you provide your company brochure and respond from your official email id (if different from the current in use), so i can send you the client’s requirement.

Payment before production.

I await your answer.

Regards,

MrSmith

These apartments are so amazing, posting them online would break the algorithm.

https://bit.ly/Lovely2BedsApartmentHudsonYards

Reach out at [email protected] and let’s get started!

Take a look at this stunning 2-bedroom apartment perfectly situated NYC’s coveted Hudson Yards!

https://bit.ly/Lovely2BedsApartmentHudsonYards

Live Rent Free!

https://bit.ly/LiveRentFREE

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?