Unlock your full potential by mastering the most common Experience in a High-Volume Warehouse Environment interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Experience in a High-Volume Warehouse Environment Interview

Q 1. Describe your experience working in a high-volume warehouse environment.

My experience in high-volume warehouse environments spans over seven years, encompassing roles from warehouse associate to team lead. I’ve worked in facilities processing thousands of orders daily, demanding speed, accuracy, and meticulous organization. This involved managing a diverse range of products, from small electronics to large furniture, requiring adaptability and a strong understanding of efficient workflow processes. I’ve consistently exceeded performance targets in fast-paced environments, contributing significantly to overall warehouse productivity and order fulfillment.

For example, during peak season at my previous role, we handled a 40% increase in order volume. By implementing a streamlined picking strategy and proactively addressing potential bottlenecks, we managed to maintain on-time shipping rates while significantly reducing errors. This involved close collaboration with my team, effectively delegating tasks and providing ongoing support to ensure everyone remained productive and engaged.

Q 2. What warehouse management systems (WMS) are you familiar with?

I’m proficient in several Warehouse Management Systems (WMS), including Manhattan Associates WMS, Blue Yonder, and Fishbowl Inventory. My experience with these systems goes beyond simply using the interface; I understand their underlying logic and can troubleshoot effectively. I’m comfortable configuring settings, generating reports, and utilizing data analysis to improve warehouse operations. For instance, in my previous role, I used Manhattan Associates WMS to identify and eliminate a recurring issue with inaccurate inventory counts, leading to a 15% reduction in fulfillment errors.

Understanding the nuances of each WMS allows me to adapt quickly to new systems and contributes to a seamless transition between different warehouse environments.

Q 3. Explain your experience with inventory control and cycle counting.

Inventory control and cycle counting are crucial aspects of efficient warehouse management. My experience includes implementing and managing cycle counting procedures, utilizing both manual and automated methods. I understand the importance of accurate inventory data for efficient order fulfillment and minimizing stockouts. I’ve trained teams on proper cycle counting techniques, emphasizing accuracy and consistency. For example, I developed a new cycle counting schedule based on product velocity, which improved the accuracy of our inventory data by 10% while reducing the time spent on cycle counting by 15%. This involved analyzing historical data and identifying patterns to optimize the process.

Furthermore, I’m skilled at investigating discrepancies and resolving inventory issues, leveraging WMS data and physical audits to ensure accurate stock levels.

Q 4. How do you prioritize tasks in a fast-paced warehouse setting?

Prioritizing tasks in a fast-paced warehouse requires a structured approach. I typically utilize a combination of urgency and importance to determine task order. I leverage the WMS to identify the most time-sensitive orders and allocate resources accordingly. For instance, orders with expedited shipping requirements will take precedence over standard orders. Additionally, I consider factors like product availability, staffing levels, and potential bottlenecks to optimize workflow. I employ techniques like the Eisenhower Matrix (urgent/important) to visually prioritize tasks and delegate effectively to my team.

This helps prevent delays and ensures timely order fulfillment, even during periods of high volume. For example, during a sudden surge in orders due to a promotional sale, I swiftly prioritized urgent orders, effectively managing resources to meet the deadline and avoid impacting customer satisfaction.

Q 5. Describe your experience with order fulfillment processes.

My experience with order fulfillment is extensive. I’m proficient in all aspects of the process, from receiving and putaway to picking, packing, and shipping. I’ve managed order fulfillment teams, optimizing processes to ensure accuracy and efficiency. I’m familiar with various fulfillment methods, including single-order picking, batch picking, and wave picking, adapting my approach based on the specific needs of the operation. For instance, I implemented a wave picking strategy that improved picking efficiency by 20% and reduced order fulfillment time by 15%. This involved careful planning and analysis of order patterns to group similar orders for efficient processing.

Understanding the entire fulfillment cycle allows me to anticipate potential problems and proactively address them, leading to smoother operations and improved customer satisfaction.

Q 6. How do you ensure accuracy and efficiency in picking and packing orders?

Ensuring accuracy and efficiency in picking and packing requires meticulous attention to detail and a structured approach. I implement quality control checks at each stage, using barcode scanners and WMS confirmation screens to verify accuracy. I’ve trained teams on proper picking and packing techniques, emphasizing the importance of following established procedures and adhering to quality standards. Moreover, I regularly review metrics such as picking accuracy and packing errors to identify areas for improvement and implement corrective actions.

For example, we introduced a double-checking system for high-value items, reducing packing errors by 8%. This involved assigning a second team member to verify the contents of each package before it’s shipped.

Q 7. What is your experience with different types of warehouse equipment (forklifts, conveyor systems, etc.)?

I possess extensive experience operating various types of warehouse equipment, including forklifts (certified to operate both sit-down and stand-up units), pallet jacks, conveyor systems, and order pickers. I’m familiar with safety procedures and regularly comply with all relevant regulations. I understand the proper maintenance and care of this equipment and can identify potential issues proactively. For instance, I successfully implemented a preventive maintenance program for our forklift fleet, resulting in a 25% reduction in downtime due to equipment malfunction.

This broad experience allows me to effectively manage and utilize warehouse resources, contributing to overall efficiency and operational safety.

Q 8. How do you handle discrepancies in inventory counts?

Inventory discrepancies are a common challenge in high-volume warehouses. Addressing them requires a systematic approach combining preventative measures with reactive solutions. My process begins with rigorous cycle counting, regularly verifying a sample of inventory against our system records. This helps identify minor discrepancies early, preventing them from snowballing. For larger discrepancies, I employ a multi-step process:

- Isolation: Pinpoint the affected area(s) to narrow down the search. This might involve checking specific shelves, bins, or even particular product batches.

- Investigation: Examine potential causes. This could include data entry errors, misplacement of items, damage leading to unnoticed loss, or even theft. I would analyze picking lists, receiving documents, and warehouse management system (WMS) logs for clues.

- Reconciliation: Conduct a thorough physical count of the affected inventory. This usually involves multiple team members to ensure accuracy.

- Documentation: Carefully document the findings, including the discrepancy, the cause (if determined), and corrective actions taken. This is critical for tracking trends and improving processes.

- Corrective Action: Implement solutions to prevent future occurrences. This might involve improved training for staff on data entry or implementing better inventory control measures like stricter bin organization and improved labelling.

For example, in my previous role, we discovered a significant discrepancy in a particular pallet of electronics. Through investigation, we found that a labeling error had caused the system to misattribute the pallet’s contents, leading to incorrect inventory numbers. We corrected the system records, updated the labels, and implemented a more rigorous label verification process to prevent this from happening again.

Q 9. How do you maintain safety standards in a busy warehouse environment?

Maintaining safety in a busy warehouse is paramount. It’s not just about compliance; it’s about fostering a culture of safety. My approach involves several key strategies:

- Regular Safety Training: Mandatory, recurring training on topics like forklift operation, proper lifting techniques, hazard identification (e.g., fire safety, electrical hazards), and emergency procedures is crucial. We also conduct refresher courses periodically.

- Proactive Hazard Identification and Mitigation: Regular inspections of the warehouse facility are critical. This includes checking for things like damaged flooring, inadequate lighting, obstructed walkways, and potential slip hazards. We use checklists to systematically assess and address these issues.

- Strict Adherence to Safety Regulations and Policies: This includes enforcing the use of Personal Protective Equipment (PPE), such as safety shoes, high-visibility vests, and safety glasses. We ensure that all employees understand and follow all safety protocols.

- Clear Communication and Reporting: A system for reporting near misses and accidents, coupled with immediate investigation and corrective action, is essential. Open communication is crucial, encouraging employees to voice concerns without fear of reprisal.

- Ergonomic Considerations: We strive to optimize workstation design and implement measures to reduce repetitive strain injuries. This can include proper shelving heights, comfortable seating, and use of lifting aids.

In one instance, we noticed an increase in minor slips and falls. After investigating, we discovered that a section of the flooring needed repair. Immediate action was taken to fix the floor, preventing further accidents.

Q 10. Describe your experience with receiving and shipping procedures.

Receiving and shipping are core functions in a high-volume warehouse, demanding accuracy and efficiency. My experience encompasses all aspects, from verifying incoming shipments against purchase orders to preparing and dispatching outgoing orders. Here’s a breakdown:

- Receiving: This includes physically checking the quantity and condition of received goods against the accompanying documentation (e.g., packing slips, invoices). Discrepancies are immediately noted and reported. We utilize a barcode scanning system to expedite this process and ensure accurate recording in the WMS. Damaged goods are carefully documented with photos and notes.

- Put-away: Efficiently storing received goods in designated locations based on WMS instructions is key. Proper organization ensures easy retrieval during order fulfillment.

- Shipping: Order picking is a critical step, ensuring accuracy in selecting the correct items in the correct quantities. We use various methods, including pick-to-light systems and voice-directed picking, to optimize speed and accuracy. Orders are then packed, labeled, and dispatched using appropriate shipping methods (e.g., courier, freight). Accurate tracking numbers are generated and recorded.

In my previous role, we implemented a new WMS that streamlined the entire receiving and shipping process, reducing processing time by 15% and improving order accuracy significantly.

Q 11. How do you manage deadlines and meet production targets in a high-pressure environment?

Managing deadlines and production targets in a high-pressure environment demands strong organizational skills and strategic prioritization. My approach is based on:

- Prioritization: Using techniques like the Eisenhower Matrix (urgent/important) helps in prioritizing tasks effectively. This allows for focusing on the most critical tasks first.

- Resource Allocation: Effective allocation of personnel and equipment is key to optimizing workflow and meeting targets. This involves understanding team strengths and weaknesses, and assigning tasks accordingly.

- Real-time Monitoring and Adjustment: Continuously monitoring progress against deadlines allows for early identification of potential delays. This enables proactive adjustments to schedules or resource allocation to stay on track.

- Communication and Collaboration: Open and constant communication with team members and supervisors ensures everyone is informed about progress and potential challenges. Teamwork is crucial in handling unexpected issues.

- Problem-Solving: A proactive approach to problem-solving is vital. By anticipating potential issues and developing contingency plans, disruptions can be minimized.

For example, during a peak season rush, we faced a significant order backlog. By re-allocating personnel to the most critical areas and implementing overtime strategically, we managed to clear the backlog within the stipulated timeframe, exceeding our initial target.

Q 12. How do you handle customer returns and damaged goods?

Handling customer returns and damaged goods requires a structured process to ensure efficiency and customer satisfaction. My approach involves:

- Inspection and Documentation: Carefully inspecting returned goods to determine the reason for return (e.g., damaged, defective, wrong item). This involves detailed documentation, including photos and descriptions of the condition. We ensure alignment with return policies.

- Processing Returns: This includes updating the WMS to reflect the return, processing refunds or exchanges, and determining whether the returned item can be resold (after potential refurbishment). Damaged items might require disposal according to relevant regulations.

- Quality Control: Analyzing the reasons for returns can help identify issues with products or processes. This information is valuable for feedback loops to improve product quality and reduce future returns.

- Customer Communication: Maintaining clear and timely communication with customers throughout the return process is critical for ensuring satisfaction and maintaining a positive brand image. Regular updates regarding the status of the return are provided.

For instance, we once experienced a significant increase in returns of a particular product due to a manufacturing defect. By carefully tracking the reasons for returns and communicating with the supplier, we were able to address the issue effectively, minimizing further returns and restoring customer confidence.

Q 13. Explain your experience with warehouse layout and organization.

Warehouse layout and organization are crucial for efficient operations. My experience includes working with various layouts, from block stacking to more advanced systems. Effective organization involves:

- Strategic Product Placement: Frequently accessed items should be easily reachable, reducing travel time for pickers. This is often based on the principles of the Pareto principle (80/20 rule), placing high-demand items in readily accessible locations.

- Clear Aisleways and Traffic Flow: Maintaining clear and wide aisleways to prevent congestion is crucial for safe and efficient movement of equipment and personnel. One-way systems or designated lanes can further improve flow.

- Efficient Racking Systems: The selection of appropriate racking systems (e.g., pallet racking, shelving, cantilever racking) depends on the type and volume of goods stored. Proper use of vertical space optimizes storage capacity.

- Zone Picking: Dividing the warehouse into zones for picking can improve efficiency by reducing travel time for pickers. It ensures that each picker only works within a designated area.

- Proper Labeling and Identification: Clear labeling of bins, shelves, and aisles is crucial for easy navigation and accurate product location. We utilize barcode scanning and WMS integration to improve accuracy and reduce errors.

In a previous role, we redesigned the warehouse layout to incorporate zone picking and a more efficient racking system. This resulted in a 20% improvement in order picking efficiency.

Q 14. How do you improve efficiency in warehouse operations?

Improving warehouse efficiency requires a multi-faceted approach. My experience includes implementing several strategies:

- Process Optimization: Continuously analyzing warehouse processes to identify bottlenecks and inefficiencies is essential. Lean principles (e.g., eliminating waste, streamlining processes) can guide improvement efforts. Time and motion studies can help pinpoint areas for improvement.

- Technology Integration: Utilizing technology, such as WMS, barcode scanners, RF guns, and automated guided vehicles (AGVs), significantly enhances efficiency and accuracy. Real-time data provides valuable insights for decision-making.

- Cross-Training and Skill Development: Investing in employee training to enhance their skills and cross-train them in multiple areas increases flexibility and reduces reliance on specific individuals.

- Inventory Management: Implementing effective inventory control strategies, including cycle counting and ABC analysis (prioritizing inventory management for high-value items), minimizes stockouts and excess inventory.

- Performance Monitoring and KPIs: Regularly monitoring key performance indicators (KPIs) like order fulfillment rate, picking accuracy, and storage capacity utilization helps identify areas needing attention and track progress.

For instance, we implemented a voice-directed picking system which improved order picking speed by 18% and reduced errors significantly.

Q 15. Describe your problem-solving skills in a warehouse setting.

In a high-volume warehouse, problem-solving is less about individual incidents and more about identifying and addressing systemic issues. My approach is always data-driven, starting with identifying the problem’s root cause rather than just treating the symptoms. For instance, if we experienced a surge in late orders, I wouldn’t just blame individual workers. I’d analyze picking data, shipping times, and potentially even software glitches to determine if there were bottlenecks in the process. One time, we saw a significant increase in picking errors. Instead of reprimanding the pickers, I analyzed the warehouse layout and discovered that poorly placed items were leading to confusion. A simple reorganization, based on frequency of picking, dramatically reduced errors. My problem-solving method follows a cyclical process: identify the problem, gather data, analyze the data, implement a solution, monitor the results, and refine the solution as needed.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you manage a team of warehouse workers?

Managing a team in a high-volume warehouse requires a blend of strong leadership, clear communication, and a focus on teamwork. I believe in leading by example, setting high standards, and empowering my team to achieve them. My approach includes regular team meetings to discuss challenges, celebrate successes, and solicit feedback. I use a variety of motivational techniques, focusing on recognizing individual contributions and fostering a positive and collaborative work environment. For example, I established a system of ‘Employee of the Month’ awards based on performance metrics and peer nominations to acknowledge both individual and team efforts. Training and development are crucial too; I regularly organize training sessions on new technologies and safety protocols to ensure the team remains efficient and safe.

Q 17. What metrics do you use to measure warehouse performance?

Several key metrics are essential for tracking warehouse performance. These include:

- Order fulfillment rate: The percentage of orders picked, packed, and shipped accurately and on time.

- Inventory accuracy: The percentage of inventory items whose physical count matches the system record. Discrepancies indicate potential issues with receiving, putaway, or picking processes.

- Order cycle time: The time it takes to process an order from receipt to shipment. Reducing this time improves customer satisfaction and efficiency.

- Storage space utilization: This measures the efficiency of warehouse space usage. Maximizing space utilization helps minimize costs.

- Labor productivity: Units picked, packed, or shipped per labor hour. This reflects the overall efficiency of the warehouse team.

- Shipping cost per unit: Tracking this helps to optimize logistics and reduce expenses.

By regularly monitoring these metrics, we can identify areas for improvement and track the success of implemented changes.

Q 18. How do you stay updated on warehouse technology and best practices?

Staying updated on warehouse technology and best practices is critical in this fast-paced industry. I achieve this through a multi-pronged approach:

- Industry publications and websites: I regularly read industry magazines and visit websites to keep abreast of new technologies and trends.

- Industry conferences and seminars: Attending industry events allows networking with other professionals and learning about cutting-edge solutions.

- Vendor relationships: Maintaining strong relationships with warehouse equipment and software vendors keeps me informed about product updates and advancements.

- Online courses and certifications: I actively pursue online courses and certifications to deepen my understanding of warehouse management systems and best practices.

- Professional organizations: Membership in relevant professional organizations provides access to resources, networking opportunities, and industry insights.

Q 19. Describe your experience with inventory forecasting and demand planning.

My experience with inventory forecasting and demand planning involves using historical data, sales trends, and market analysis to predict future demand. I’ve worked with various forecasting models, including moving averages and exponential smoothing, to optimize inventory levels. For example, when we noticed a significant increase in demand for a particular product during a specific season, I used historical sales data to project demand for the following year, allowing for proactive measures like adjusting storage space, increasing staff, and pre-ordering products to avoid stockouts.

The accuracy of these predictions is crucial to avoid both overstocking (leading to increased storage costs and potential obsolescence) and understocking (leading to lost sales and dissatisfied customers). I regularly review and refine our forecasting models to improve accuracy and ensure our inventory aligns with actual demand.

Q 20. How do you handle peak seasons and increased order volumes?

Peak seasons require strategic planning and execution. We typically anticipate increased order volumes well in advance, focusing on several key strategies:

- Staffing: We hire temporary staff or utilize existing staff through overtime to handle the increased workload.

- Process optimization: We streamline our processes to maximize efficiency and minimize bottlenecks.

- Technology utilization: We leverage our warehouse management system (WMS) to its full potential, optimizing order routing and task assignments.

- Inventory management: We ensure sufficient inventory levels to meet anticipated demand.

- Communication: We communicate clearly with the team, customers, and suppliers throughout the peak season.

In one peak season, by implementing these strategies – particularly prioritizing order fulfillment based on urgency – we managed a 40% increase in order volume without compromising order accuracy or shipping times.

Q 21. Explain your experience with warehouse data analysis.

Warehouse data analysis is a cornerstone of efficient operations. My experience includes using data from our WMS and other sources to identify trends, pinpoint inefficiencies, and improve decision-making. For example, I use data visualization tools to identify bottlenecks in our processes, such as long wait times for certain tasks. I then use this information to make changes to improve workflow. Data analysis is also crucial for optimizing inventory levels. We use data to track product velocity, identify slow-moving items, and forecast future demand. I also track key performance indicators (KPIs) like those mentioned earlier, and analyze the data to identify areas where we can improve efficiency, reduce costs, and ultimately, improve customer satisfaction. This analysis allows us to be proactive rather than reactive in addressing potential problems and capitalizing on opportunities for improvement.

Q 22. How do you ensure the security of warehouse inventory?

Ensuring warehouse inventory security is paramount. It’s a multi-layered approach involving physical security, access control, and robust inventory management systems.

- Physical Security: This includes things like secure building access (e.g., keycard systems, surveillance cameras), well-lit areas, and regular security patrols. We also need to consider securing loading docks and preventing unauthorized vehicle access.

- Access Control: Strict protocols for employee access are crucial. This means assigning specific roles and responsibilities, limiting access to sensitive areas based on job function, and implementing a system for tracking who accesses what and when. Think of it like a high-security building – different keys for different rooms.

- Inventory Management Systems: A strong inventory management system (WMS) is the backbone of security. It allows us to track every item’s movement, location, and status from the moment it enters the warehouse until it leaves. Regular cycle counts and stock audits help to identify discrepancies and potential theft early on. A good WMS also integrates with security systems to log access to specific inventory zones.

- Employee Training and Accountability: Training employees on security protocols, emphasizing the importance of reporting suspicious activity, and having clear consequences for security breaches are fundamental. This fosters a culture of responsibility and reduces internal theft risks.

For instance, in my previous role, we implemented a two-factor authentication system for access to the warehouse management system, coupled with regular surprise audits, significantly reducing inventory discrepancies.

Q 23. What is your experience with warehouse automation technologies?

My experience with warehouse automation technologies is extensive. I’ve worked with various systems, from automated guided vehicles (AGVs) and conveyor systems to warehouse management systems (WMS) and radio frequency identification (RFID) technology.

- Automated Guided Vehicles (AGVs): I’ve overseen the implementation and maintenance of AGVs in a high-volume distribution center, which drastically improved the efficiency of material handling and reduced labor costs associated with transporting goods across the warehouse.

- Conveyor Systems: Experience with designing and managing conveyor belt systems for sorting, routing, and transporting products ensures smooth workflow and maximum throughput. I’ve optimized existing systems and implemented new ones to suit specific needs.

- Warehouse Management Systems (WMS): I am proficient in using and managing various WMS software, including data analysis and reporting. My expertise extends to streamlining processes within the WMS to optimize order fulfillment and inventory control.

- Radio Frequency Identification (RFID): Implementing RFID tagging and tracking systems allowed us to gain real-time visibility into inventory location and movement, improving accuracy and reducing manual tracking errors.

For example, I led a project to integrate a new WMS with our existing RFID system. This integration dramatically improved our inventory accuracy and order fulfillment speed, resulting in a 15% increase in productivity.

Q 24. How do you handle conflicts among warehouse staff?

Handling conflicts among warehouse staff requires a proactive and fair approach. My strategy focuses on open communication, active listening, and finding mutually agreeable solutions.

- Open Communication: Encouraging open dialogue and providing a safe space for employees to express their concerns is key. I make myself available to address issues promptly and facilitate discussions.

- Active Listening: I prioritize understanding each person’s perspective before offering solutions. This helps to de-escalate tension and build trust.

- Mediation and Facilitation: When necessary, I act as a mediator, guiding employees toward a resolution. This often involves identifying the root cause of the conflict and exploring collaborative solutions.

- Clear Expectations and Consequences: A well-defined code of conduct and clear expectations for behavior are crucial to prevent conflicts. This includes outlining appropriate responses to unacceptable behavior.

In one instance, a conflict arose between two team leads regarding workload distribution. By facilitating a discussion, listening to their concerns, and collaboratively creating a new workflow, I successfully resolved the conflict and improved team morale.

Q 25. What is your approach to training new warehouse employees?

Training new warehouse employees is a structured process designed to ensure they’re equipped to handle their responsibilities safely and efficiently.

- Onboarding Program: A comprehensive onboarding program includes a detailed overview of company policies, safety procedures, and warehouse layout. This sets a strong foundation for their role.

- Job-Specific Training: Hands-on training in their specific roles, whether it’s order picking, packing, or operating machinery, is crucial. This involves practical demonstrations and supervised practice.

- Mentorship and Shadowing: Pairing new employees with experienced staff for mentorship and shadowing allows them to learn from real-world examples and receive personalized guidance.

- Regular Feedback and Assessments: Continuous feedback and performance assessments are essential to identify areas for improvement and ensure they’re progressing satisfactorily. This also allows for timely adjustments to the training plan if needed.

For example, I developed a standardized training program that included interactive modules, simulated scenarios, and regular quizzes, resulting in faster onboarding and higher initial productivity for new hires.

Q 26. Describe a time you had to solve a complex problem in the warehouse.

One particularly challenging situation involved a major system outage during peak shipping season. Our WMS went down unexpectedly, bringing all operations to a standstill.

My approach involved these steps:

- Immediate Damage Control: First, I mobilized the team to manually process orders using backup systems and established temporary procedures. We prioritized urgent shipments.

- Troubleshooting and Diagnosis: Simultaneously, I worked with the IT department to identify the root cause of the outage. This involved analyzing system logs and working with vendors to diagnose the problem.

- Communication and Transparency: I maintained open communication with all stakeholders, including shipping carriers and clients, keeping them informed about the situation and providing realistic updates on the restoration timeline.

- Problem Resolution and System Restoration: We successfully isolated the issue, implemented a temporary fix, and worked to fully restore the system as quickly as possible. This involved data recovery and system optimization.

- Post-Incident Analysis: Once the system was back online, we performed a thorough post-incident analysis, identifying weaknesses in our backup systems and processes. This helped us prevent similar disruptions in the future.

We successfully minimized disruptions and maintained a high level of customer satisfaction, highlighting the importance of proactive planning, decisive action, and strong teamwork under pressure.

Q 27. How do you maintain good communication with other departments (e.g., shipping, receiving)?

Maintaining good communication with other departments is vital for smooth warehouse operations. I utilize a combination of methods for effective communication and collaboration.

- Regular Meetings: Scheduled meetings with representatives from shipping, receiving, and other relevant departments ensure alignment on key objectives, address pending issues, and foster collaborative problem-solving.

- Real-time Communication Tools: Utilizing instant messaging platforms, email, and collaborative tools facilitates quick responses and immediate updates on urgent matters.

- Data Sharing and Reporting: Regular reports on key metrics (inventory levels, order fulfillment rates, etc.) are shared to ensure everyone has visibility into warehouse performance and potential bottlenecks.

- Collaborative Platforms: Using shared platforms for tracking tasks, managing projects, and document sharing improves transparency and encourages team collaboration across departments.

For example, I implemented a daily communication system using a shared spreadsheet to track order fulfillment progress, ensuring both warehouse and shipping teams had a real-time view of shipments. This reduced delays and streamlined the entire shipping process.

Q 28. What are your salary expectations for this role?

My salary expectations for this role are in the range of [Insert Salary Range] annually. This is based on my experience, skills, and the responsibilities associated with this position. I am open to discussing this further based on the full details of the compensation package and benefits offered.

Key Topics to Learn for Experience in a High-Volume Warehouse Environment Interview

- Inventory Management: Understanding inventory control systems, cycle counting, stock rotation (FIFO/LIFO), and managing discrepancies. Practical application: Describe your experience with inventory software and how you ensured accuracy and efficiency.

- Order Fulfillment: Processes involved in picking, packing, and shipping orders accurately and efficiently. Practical application: Explain your strategies for optimizing picking routes and minimizing errors in a high-pressure environment.

- Warehouse Safety & Compliance: Adherence to safety regulations, proper use of equipment, and maintaining a safe work environment. Practical application: Detail your experience implementing or following safety protocols and your contributions to a safe workplace.

- Warehouse Technology & Systems: Familiarity with Warehouse Management Systems (WMS), RF scanners, conveyor systems, and other automated equipment. Practical application: Describe your experience using WMS software and how you leveraged technology to improve productivity.

- Teamwork & Communication: Effective collaboration with colleagues, supervisors, and other departments. Practical application: Give examples of how you successfully collaborated with team members to achieve shared goals under pressure.

- Problem-Solving & Troubleshooting: Identifying and resolving issues quickly and efficiently, such as order discrepancies, equipment malfunctions, or workflow bottlenecks. Practical application: Describe a challenging situation you faced in a warehouse setting and how you effectively resolved it.

- Productivity & Efficiency: Strategies for maximizing output and minimizing waste. Practical application: Explain how you contributed to improving productivity metrics in your previous role.

Next Steps

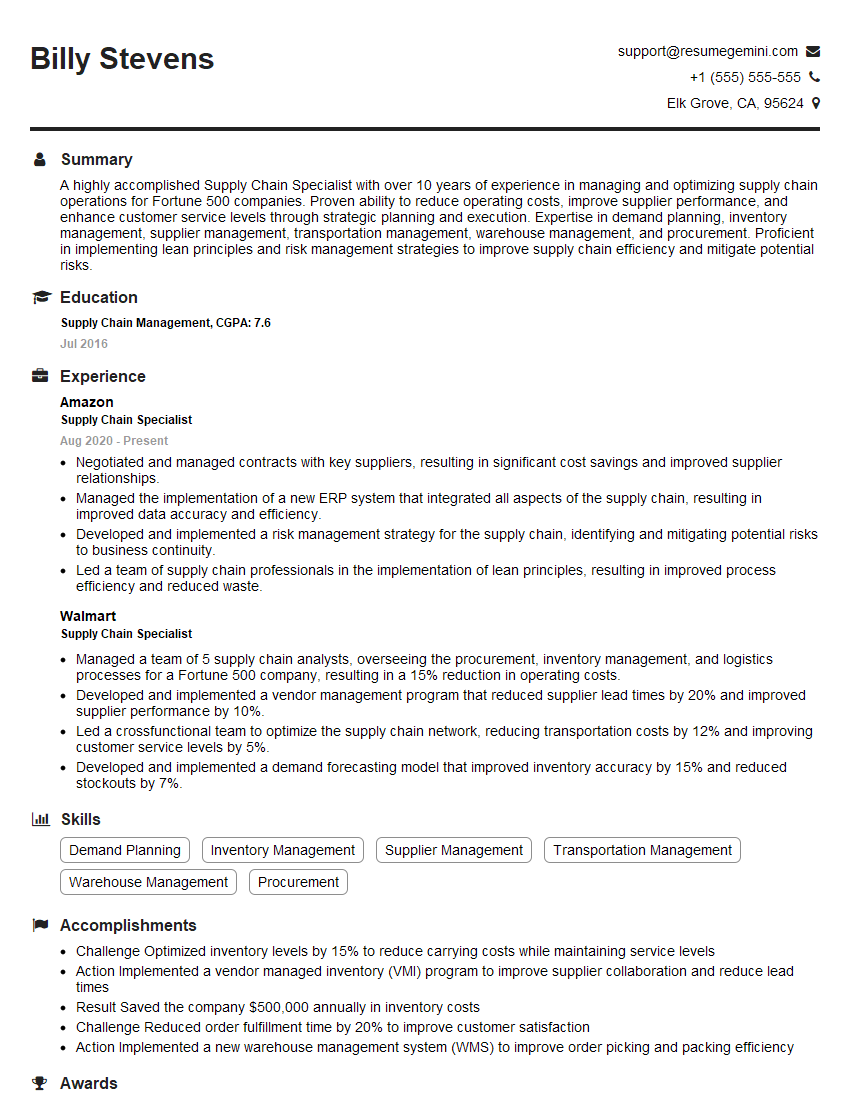

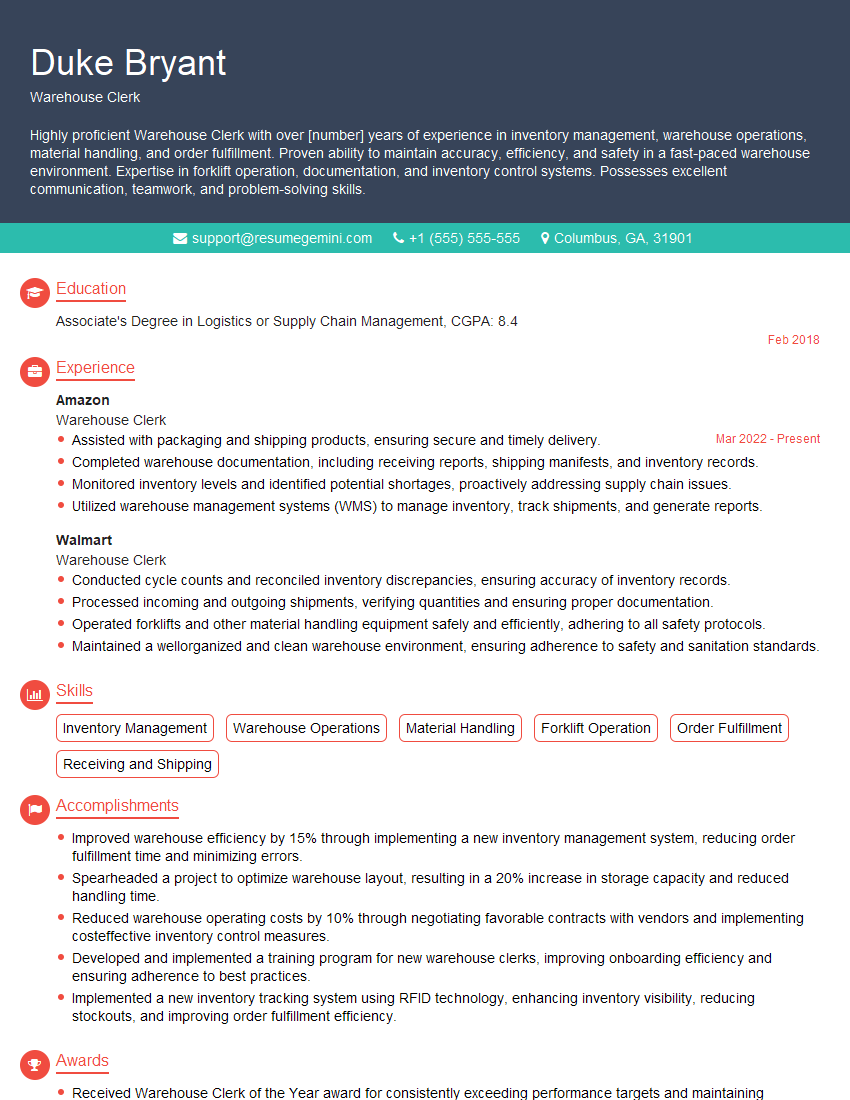

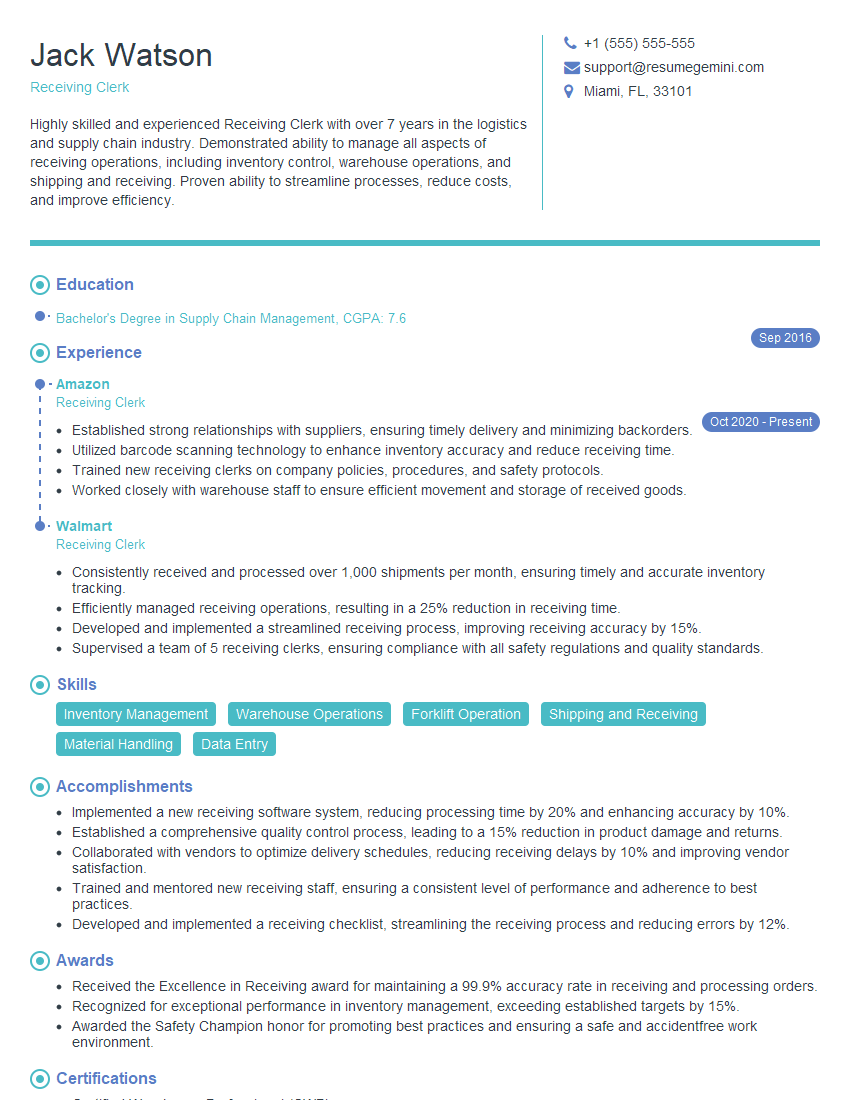

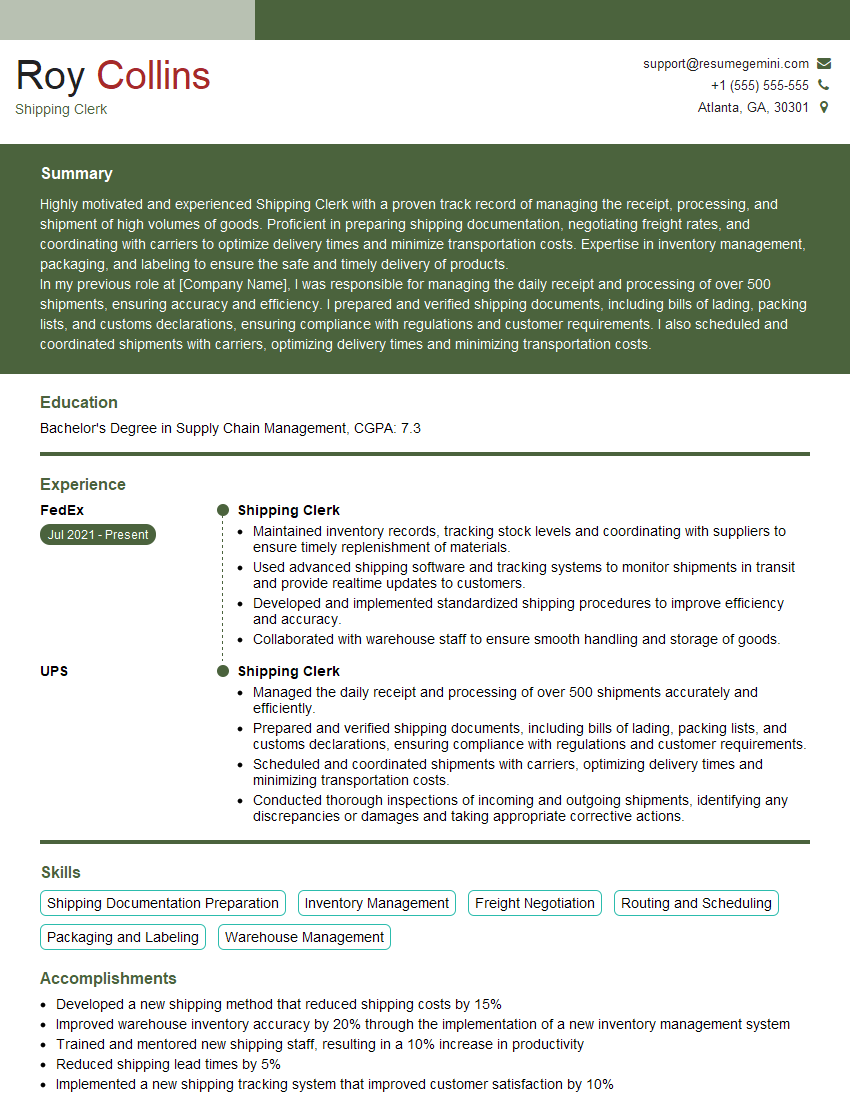

Mastering the skills and knowledge related to high-volume warehouse environments is crucial for career advancement in logistics, supply chain management, and related fields. A strong understanding of these areas demonstrates valuable experience and positions you for success in competitive job markets. Creating an ATS-friendly resume is essential for getting your application noticed by recruiters. ResumeGemini is a trusted resource to help you build a professional and effective resume that highlights your accomplishments and skills. We provide examples of resumes tailored to high-volume warehouse experience to guide you in crafting a compelling application that showcases your expertise.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Live Rent Free!

https://bit.ly/LiveRentFREE

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?