Preparation is the key to success in any interview. In this post, we’ll explore crucial Familiar with Materials Science Principles interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Familiar with Materials Science Principles Interview

Q 1. Explain the difference between crystalline and amorphous materials.

The key difference between crystalline and amorphous materials lies in the arrangement of their atoms or molecules. Crystalline materials exhibit a highly ordered, repeating three-dimensional atomic arrangement extending over large distances. Think of it like a perfectly stacked box of oranges – each orange (atom) has a specific, predictable location relative to its neighbors. This long-range order leads to distinct crystallographic planes and directions. Examples include metals like iron, table salt (NaCl), and quartz (SiO2). In contrast, amorphous materials lack this long-range order. Their atoms are arranged randomly, like a pile of oranges dumped haphazardly. This disordered structure results in isotropic properties (properties are the same in all directions), and they often lack sharp melting points. Common amorphous materials include glass, rubber, and many polymers.

Imagine trying to cut a perfectly ordered crystal versus a random pile of sand. The crystal will likely cleave along specific planes due to its ordered structure, whereas the sand will fracture irregularly. This difference in atomic arrangement significantly impacts material properties, such as strength, hardness, and optical characteristics.

Q 2. Describe the different types of bonding found in materials (ionic, covalent, metallic, etc.).

Materials are held together by various types of chemical bonds, each influencing their properties dramatically. Let’s explore the most common:

- Ionic Bonding: This involves the electrostatic attraction between oppositely charged ions. One atom loses electrons (becoming a positively charged cation) and another gains electrons (becoming a negatively charged anion). The strong coulombic forces create high melting points and hardness. Table salt (NaCl) is a classic example, with Na+ and Cl– ions held together by ionic bonds.

- Covalent Bonding: Here, atoms share electrons to achieve a stable electron configuration. This sharing creates strong, directional bonds. Diamond, with its strong carbon-carbon covalent bonds, exemplifies exceptional hardness and high melting point. Many polymers also rely heavily on covalent bonds.

- Metallic Bonding: This type of bonding is found in metals. Valence electrons are delocalized, forming a ‘sea’ of electrons surrounding positively charged metal ions. This electron sea allows for good electrical and thermal conductivity, malleability (ability to be shaped), and ductility (ability to be drawn into wires). Copper and aluminum are prime examples.

- Van der Waals Bonding: This is a weaker type of bonding arising from temporary fluctuations in electron distribution, creating weak attractive forces. It’s crucial in the structure of some polymers and explains the properties of noble gases.

- Hydrogen Bonding: A special type of dipole-dipole interaction that occurs when a hydrogen atom is bonded to a highly electronegative atom (like oxygen or nitrogen). It plays a vital role in the properties of water and many biological molecules.

The type of bonding present dictates a material’s overall characteristics. For instance, a material with predominantly ionic bonding will be brittle, while one with metallic bonding will be ductile.

Q 3. What are the main mechanical properties of materials and how are they measured?

Mechanical properties describe a material’s response to applied forces. Key mechanical properties include:

- Tensile Strength: The maximum stress a material can withstand before breaking under tensile (pulling) load. Measured using a tensile testing machine, which pulls a sample until it fails, recording the force and elongation.

- Yield Strength: The stress at which a material begins to deform plastically (permanently). This is crucial for designing structures that won’t permanently deform under load. Also measured via tensile testing.

- Hardness: Resistance to indentation or scratching. Measured using various hardness tests (Rockwell, Brinell, Vickers), which involve indenting the material with a known force and measuring the indentation size.

- Ductility: Ability to deform plastically before fracture. Often quantified as percent elongation in tensile testing.

- Brittleness: Tendency to fracture with little to no plastic deformation. Opposite of ductility.

- Toughness: Ability to absorb energy before fracture. It represents a combination of strength and ductility.

- Fatigue Strength: Resistance to failure under cyclic loading. Measured by applying repeated stress cycles until failure.

- Creep Resistance: Ability to resist deformation under sustained load and elevated temperature. Measured by applying a constant load at a high temperature and monitoring deformation over time.

These properties are vital in engineering design, ensuring materials are chosen based on their ability to withstand expected stresses and environmental conditions. For instance, a bridge must possess high tensile strength and fatigue resistance.

Q 4. Explain the concept of stress and strain.

Stress and strain are fundamental concepts in mechanics, describing how materials respond to applied forces. Stress is the internal force per unit area within a material caused by an external force. Think of it as the material ‘fighting back’ against the applied load. It’s calculated as:

Stress (σ) = Force (F) / Area (A)

The unit is usually Pascals (Pa) or MPa (megapascals). Strain is the measure of deformation in response to stress. It’s the change in length divided by the original length:

Strain (ε) = Change in length (ΔL) / Original length (L)

Strain is dimensionless. The relationship between stress and strain is often represented by a stress-strain curve, which graphically shows how a material behaves under different load levels. The slope of the linear portion of the curve gives the Young’s modulus (a measure of stiffness).

Consider stretching a rubber band. The force you apply creates stress within the rubber band, and the amount it stretches is the strain. Understanding stress and strain is crucial for predicting material behavior under load and designing safe and reliable structures.

Q 5. Describe different types of material failure (fatigue, creep, fracture).

Materials can fail in various ways, depending on the loading conditions and material properties:

- Fatigue Failure: This occurs due to repeated cyclic loading, even if the maximum stress is below the yield strength. Microscopic cracks initiate and propagate until final fracture. This is a common cause of failure in bridges, aircraft components, and machinery subjected to vibrations. Imagine repeatedly bending a paperclip – it will eventually break even if each bend doesn’t exceed its yield strength.

- Creep Failure: This is time-dependent deformation under sustained load, especially at elevated temperatures. The material gradually deforms until it eventually fails. This is a significant concern in high-temperature applications like power plant turbines and jet engines.

- Fracture: This involves the separation of a material into two or more pieces due to applied stress. Fracture can be brittle (sudden, without much plastic deformation) or ductile (with significant plastic deformation before fracture). The type of fracture depends on material properties and loading conditions. A brittle fracture might occur in glass, while a ductile fracture might occur in mild steel.

Understanding the different failure mechanisms is essential for designing components with appropriate safety factors and service life. Proper material selection and design considerations can mitigate these failure modes.

Q 6. What is the difference between tensile strength and yield strength?

Tensile strength and yield strength are both measures of a material’s strength under tensile loading, but they represent different aspects of its behavior:

- Tensile Strength: This is the maximum stress a material can withstand before it fractures. It indicates the material’s ultimate load-bearing capacity. It’s determined by the point at which the stress-strain curve peaks.

- Yield Strength: This is the stress at which the material starts to deform plastically (permanently). It’s the point at which the material undergoes a significant change in behavior, transitioning from elastic deformation (recoverable) to plastic deformation (permanent). It’s often found by the 0.2% offset method on the stress-strain curve.

The difference is crucial in engineering design. Yield strength ensures the component won’t undergo permanent deformation under service loads, while tensile strength ensures it won’t fracture. For instance, a structural component might need high yield strength to avoid permanent deformation, even if its tensile strength is higher than required.

Q 7. Explain the principles of phase diagrams.

Phase diagrams are graphical representations of the equilibrium relationships between different phases (solid, liquid, gas) of a material as a function of temperature, pressure, and composition (for multi-component systems). They are invaluable tools for understanding and predicting material behavior during processing and applications.

A simple binary phase diagram (two components) shows the regions of stability for different phases. Lines on the diagram represent phase boundaries, where phase transitions occur. For instance, the liquidus line separates the liquid phase from the liquid + solid regions, and the solidus line separates the solid phase from the liquid + solid regions. The eutectic point represents the lowest melting temperature for a given composition. The lever rule is a useful technique for calculating the relative amounts of each phase at a given temperature and composition.

Phase diagrams provide insights into various processes, such as alloy design, solidification, heat treatment, and phase transformations. For example, by understanding the phase diagram of a steel alloy, metallurgists can control the heat treatment process to achieve desired microstructures and properties (e.g., hardness, toughness).

In summary, phase diagrams provide a powerful means for understanding material behavior as a function of temperature and composition. This knowledge is directly applicable to material selection, processing, and performance prediction in countless engineering applications.

Q 8. What are the common methods for characterizing the microstructure of materials?

Characterizing the microstructure of materials involves techniques that reveal the arrangement of its constituent phases and features at a microscopic level. This is crucial for understanding a material’s properties and performance. Common methods include:

Optical Microscopy: Uses visible light to magnify the sample’s surface. Simple, inexpensive, and provides a general overview of the microstructure, revealing grain size, phase distribution, and surface defects. Think of it like using a magnifying glass, but much more powerful.

Scanning Electron Microscopy (SEM): Uses a focused beam of electrons to scan the sample’s surface. Offers much higher resolution than optical microscopy, revealing fine details like precipitates, grain boundaries, and surface morphology. It’s like using a super-powered microscope with incredible detail.

Transmission Electron Microscopy (TEM): A beam of electrons is transmitted through an ultra-thin sample. Provides the highest resolution, allowing visualization of individual atoms and crystal defects. This is the ultimate microscopic technique, allowing us to see materials at the atomic level.

X-ray Diffraction (XRD): Uses X-rays to determine the crystal structure and phase composition of the material. It doesn’t directly show images, but provides information about the atomic arrangement. Think of it as a fingerprint of the material’s crystal structure.

The choice of method depends on the material and the specific information needed. For example, a quick assessment of grain size might use optical microscopy, while detailed analysis of defects would require TEM.

Q 9. Describe the process of heat treating metals.

Heat treating metals involves controlled heating and cooling processes to alter their microstructure and consequently their mechanical properties. This is a fundamental process in metallurgy used to enhance strength, ductility, and toughness. The process typically involves several stages:

Heating: The metal is heated to a specific temperature, often within a particular phase region, to allow for atomic diffusion and phase transformations.

Soaking: The metal is held at the temperature for a specific time to ensure that the desired phase changes or microstructure developments occur uniformly throughout the material.

Cooling: The metal is then cooled, often at a controlled rate (quenching or slow cooling), to solidify the new microstructure. The cooling rate significantly influences the final properties.

Examples of heat treatments:

Annealing: Relieves internal stresses and softens the metal, making it more ductile.

Quenching and Tempering: Used to harden steel. Quenching involves rapid cooling (often in water or oil), while tempering involves reheating to a lower temperature to reduce brittleness.

Normalizing: Improves the uniformity of the microstructure and mechanical properties.

The specific parameters – temperature, time, and cooling rate – are carefully chosen based on the metal’s composition and the desired properties.

Q 10. Explain the concept of diffusion in materials.

Diffusion in materials is the net movement of atoms or molecules from a region of higher concentration to a region of lower concentration. Think of it like sugar dissolving in water – the sugar molecules spread out until they’re evenly distributed. This process is driven by the second law of thermodynamics, aiming for a state of maximum entropy (disorder).

Several factors affect the rate of diffusion:

Temperature: Higher temperatures increase atomic mobility and diffusion rate. Think of how sugar dissolves faster in hot water.

Concentration Gradient: A steeper concentration gradient leads to faster diffusion. The greater the difference in concentration, the faster the movement.

Diffusion Coefficient (D): This material-specific parameter quantifies the diffusion rate. It’s temperature-dependent, often following an Arrhenius relationship (

D = D0exp(-Q/RT), where D0 is a pre-exponential factor, Q is the activation energy, R is the gas constant, and T is the absolute temperature).Material Structure: The crystal structure, grain boundaries, and defects in the material influence diffusion pathways and rates.

Diffusion plays a crucial role in many material processes, including heat treatments, sintering (powder metallurgy), and the growth of thin films.

Q 11. What are the main types of polymers and their properties?

Polymers are large molecules composed of repeating structural units called monomers. They’re classified into different types based on their structure and properties:

Thermoplastics: Can be repeatedly softened by heating and solidified by cooling. They are typically flexible and relatively easily processed. Examples include polyethylene (PE), polypropylene (PP), and polyvinyl chloride (PVC). Think of plastic bottles – you can melt them down and reshape them.

Thermosets: Undergo irreversible chemical changes upon heating, forming a cross-linked network structure. They are typically rigid and stronger than thermoplastics but are not easily recyclable. Examples include epoxy resins and vulcanized rubber. Think of the hardened resin in a fiberglass boat – it can’t be easily melted and reshaped.

Elastomers: Exhibit high elasticity and flexibility. They can be stretched significantly and return to their original shape. Examples include natural rubber and silicone rubber. Think of rubber bands – they can stretch and then return to their original form.

Polymer properties vary widely depending on their chemical structure, molecular weight, and processing conditions. Factors like strength, stiffness, flexibility, thermal resistance, and chemical resistance are important considerations for selecting the appropriate polymer for an application.

Q 12. How do you select materials for a specific application?

Material selection for a specific application is a crucial step in engineering design. It’s a multi-criteria decision-making process that considers various factors:

Required Properties: Identify the key properties needed (e.g., strength, toughness, corrosion resistance, electrical conductivity, thermal conductivity). This often involves understanding the application’s operating conditions and potential stresses.

Material Databases and Handbooks: Consult material property databases (e.g., MatWeb) and handbooks (e.g., ASM Handbook) to find suitable materials with the required properties.

Cost and Availability: Consider the material’s cost and whether it is readily available. A material might have excellent properties but be too expensive or difficult to obtain.

Manufacturing Processes: Consider the ease and cost of manufacturing using the selected material. Some materials are more easily formed, machined, or joined than others.

Environmental Considerations: Evaluate the material’s environmental impact throughout its life cycle (from production to disposal). Sustainability is becoming an increasingly important criterion.

Often, a trade-off is required between different properties. For example, a high-strength material might be brittle, while a ductile material might be weaker. The selection process involves carefully weighing the relative importance of different properties.

Q 13. Explain the concept of material degradation and corrosion.

Material degradation encompasses any process that diminishes a material’s desirable properties over time. Corrosion is a specific type of degradation that involves the deterioration of a material due to chemical or electrochemical reactions with its environment. It often refers to the deterioration of metals, but other materials like polymers and ceramics can also degrade.

Corrosion Mechanisms:

Uniform Corrosion: Occurs evenly over the material’s surface. Think of rusting on a piece of iron left outside.

Galvanic Corrosion: Occurs when two dissimilar metals are in contact in an electrolyte. The more active metal corrodes preferentially. Think of a steel bolt in a brass plate exposed to seawater.

Pitting Corrosion: Localized corrosion resulting in the formation of small pits or holes. This can be difficult to detect and can cause catastrophic failures.

Crevice Corrosion: Occurs in confined spaces, such as crevices or under gaskets. Stagnant conditions within the crevice accelerate corrosion.

The severity of corrosion depends on factors like the material’s composition, the environment (presence of moisture, oxygen, electrolytes), and temperature.

Q 14. Describe different methods of corrosion prevention.

Corrosion prevention involves strategies to minimize or eliminate the deterioration of materials due to corrosion. Common methods include:

Protective Coatings: Applying a layer of paint, polymer coating, or metal plating (e.g., zinc galvanization) to create a barrier between the material and the environment. This is like giving the material a protective shield.

Corrosion Inhibitors: Adding chemicals to the environment to slow down corrosion reactions. These chemicals often react preferentially with the corrosive species or form a protective film on the metal’s surface.

Cathodic Protection: Using a sacrificial anode (a more active metal) to protect the main structure. The sacrificial anode corrodes preferentially, leaving the main structure unharmed. Think of this like a superhero sacrificing themselves to save the city.

Material Selection: Choosing corrosion-resistant materials for the application. For example, using stainless steel instead of mild steel in corrosive environments.

Design Modifications: Designing the structure to minimize crevices, stagnant areas, and other locations prone to corrosion.

The most appropriate corrosion prevention method depends on several factors, including the material, the environment, and the cost constraints. Often a combination of techniques is employed for optimal protection.

Q 15. What are composites and what are their advantages?

Composites are materials made from two or more constituent materials with significantly different physical or chemical properties that when combined, produce a material with characteristics different from the individual components. Think of it like a layered cake – each layer (constituent material) has its own unique properties, but together they create something entirely new.

Advantages of Composites:

- Enhanced Strength and Stiffness: Combining a strong, stiff material (e.g., carbon fibers) with a lightweight, flexible matrix (e.g., polymer resin) results in a composite that is both strong and lightweight, exceeding the properties of either material alone. This is crucial in aerospace and automotive applications.

- Tailored Properties: The properties of a composite can be precisely tailored by adjusting the type and amount of each constituent material and their arrangement. For instance, varying the fiber orientation can control the strength and stiffness in different directions.

- High Strength-to-Weight Ratio: This is a significant advantage in applications where weight is a critical factor, such as aircraft and spacecraft.

- Corrosion Resistance: Certain composites exhibit excellent resistance to corrosion, making them suitable for marine and chemical processing environments.

- Design Flexibility: Composites can be molded into complex shapes, which is advantageous for intricate designs.

Example: Fiberglass, a common composite, combines glass fibers with a polymer resin. The glass fibers provide strength, while the resin binds them together and protects them from environmental damage. This makes fiberglass ideal for boat hulls, car bodies, and other applications requiring strength and durability.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are some common ceramic materials and their applications?

Ceramic materials are inorganic, non-metallic solids formed by the action of heat. They are generally characterized by high hardness, high melting points, and brittleness. Their properties stem from strong ionic or covalent bonds.

Common Ceramic Materials and Applications:

- Alumina (Al2O3): Used in cutting tools, high-temperature applications, and as a substrate for electronic components due to its high hardness and wear resistance.

- Zirconia (ZrO2): Known for its high strength and toughness, it’s utilized in dental implants, cutting tools, and oxygen sensors.

- Silicon Carbide (SiC): A very hard material with high thermal conductivity, used in abrasive materials, high-temperature components (e.g., furnace linings), and semiconductor devices.

- Silicon Nitride (Si3N4): Possessing high strength and excellent high-temperature capabilities, it finds applications in high-performance engines and cutting tools.

- Glass: An amorphous (non-crystalline) ceramic material, extensively used in windows, containers, and optical fibers due to its transparency and formability.

The choice of ceramic material depends heavily on the required properties for a specific application. For instance, the extreme hardness of silicon carbide makes it suitable for grinding wheels, while the biocompatibility of zirconia makes it ideal for medical implants.

Q 17. Explain the principles of powder metallurgy.

Powder metallurgy is a metal fabrication process involving the compaction of metal powders into a desired shape, followed by sintering (heating below the melting point) to bond the particles together and create a solid part. It’s like building a sandcastle, but instead of sand, we use metal powder, and instead of water, we use heat.

Principles of Powder Metallurgy:

- Powder Production: Metal powders are produced through various methods, such as atomization, reduction of metal oxides, or electrolytic deposition. The powder characteristics (particle size, shape, and distribution) are crucial in determining the final properties of the part.

- Blending: If necessary, different metal powders or alloying elements are blended to achieve specific properties in the final product.

- Compaction: The metal powder is compacted under high pressure in a die to form a “green compact,” a pre-sintered part with the desired shape. The pressure is crucial in determining the density and strength of the green compact.

- Sintering: The green compact is heated in a controlled atmosphere to a temperature below the melting point of the metal. This causes the metal particles to bond together through diffusion, increasing the density and strength of the part. The sintering temperature, time, and atmosphere are critical parameters affecting the final properties.

- Finishing Operations: After sintering, the part may undergo various finishing operations, such as machining, heat treatment, or surface coating, to achieve the final desired dimensions and properties.

Advantages: Powder metallurgy allows the creation of complex shapes, precise dimensions, and materials with unique properties not easily achievable through traditional casting or forging methods.

Example: Powder metallurgy is widely used to produce self-lubricating bearings, porous filters, and parts with controlled porosity.

Q 18. What are nanomaterials and their unique properties?

Nanomaterials are materials with at least one dimension sized between 1 and 100 nanometers (a nanometer is one billionth of a meter!). This nanoscale size leads to unique properties that differ significantly from their bulk counterparts, due to the high surface area to volume ratio and quantum mechanical effects.

Unique Properties of Nanomaterials:

- Enhanced Mechanical Properties: Nanomaterials can exhibit significantly higher strength, stiffness, and ductility compared to their bulk counterparts.

- Improved Catalytic Activity: The high surface area enhances their catalytic activity, making them useful in chemical reactions.

- Tunable Optical Properties: The optical properties of nanomaterials (color, absorbance, etc.) can be tuned by controlling their size and shape.

- Enhanced Electrical Conductivity: Some nanomaterials exhibit significantly better electrical conductivity than their bulk forms.

- Unique Magnetic Properties: Nanomaterials can exhibit different magnetic behaviors than their bulk forms, leading to applications in magnetic storage and sensors.

Example: Carbon nanotubes, cylindrical structures of carbon atoms, possess exceptional strength and electrical conductivity, making them promising materials for electronics and composites.

Q 19. Describe different methods for synthesizing nanomaterials.

Numerous methods exist for synthesizing nanomaterials, each with its own advantages and limitations:

- Top-Down Approaches: These methods involve breaking down larger materials into nanoscale components. Examples include:

- Ball Milling: Using high-energy ball milling to grind bulk materials into nanoparticles.

- Lithography: Precisely patterning nanoscale features on a substrate.

- Bottom-Up Approaches: These methods involve assembling atoms or molecules into nanoscale structures. Examples include:

- Chemical Vapor Deposition (CVD): Deposition of nanomaterials from a gaseous precursor onto a substrate.

- Sol-Gel Method: Synthesis of nanoparticles from a sol (colloidal suspension) that is then converted into a gel.

- Electrospinning: Producing nanofibers by electrically charging a polymer solution.

- Chemical Reduction: Reducing metal salts in solution to form metal nanoparticles.

The choice of synthesis method depends heavily on the desired nanomaterial, its desired properties, and the scale of production. For example, CVD is often used for producing high-quality carbon nanotubes, while the sol-gel method is suitable for producing various types of metal oxide nanoparticles.

Q 20. Explain the concept of material sustainability.

Material sustainability focuses on developing and using materials in a way that minimizes environmental impact throughout their entire lifecycle – from extraction of raw materials to end-of-life management. This involves considering factors like energy consumption, resource depletion, waste generation, and toxicity.

Key aspects of material sustainability include:

- Life Cycle Assessment (LCA): Evaluating the environmental impacts of a material throughout its entire lifecycle.

- Design for Environment (DfE): Designing products and processes to minimize environmental impacts.

- Recyclability and Reusability: Designing materials that can be easily recycled or reused at the end of their service life.

- Renewable Resources: Utilizing renewable resources to reduce reliance on finite resources.

- Bio-based Materials: Employing materials derived from renewable biological sources.

Example: Developing biodegradable plastics from renewable resources like corn starch reduces reliance on petroleum-based plastics and minimizes landfill waste. Similarly, designing products for easy disassembly and material separation facilitates recycling and resource recovery.

Q 21. What are some common material testing techniques?

Many material testing techniques exist to characterize the properties of materials. The choice of technique depends on the specific properties of interest and the type of material being tested.

Common Material Testing Techniques:

- Tensile Testing: Measures the material’s strength, ductility, and elastic modulus by applying a uniaxial tensile load.

- Compression Testing: Determines the material’s compressive strength and deformation behavior under compressive loads.

- Hardness Testing: Assesses the material’s resistance to indentation, using techniques like Rockwell, Brinell, or Vickers hardness tests.

- Impact Testing: Evaluates the material’s resistance to fracture under impact loading, often using Charpy or Izod tests.

- Fatigue Testing: Determines the material’s resistance to failure under cyclic loading.

- Creep Testing: Measures the material’s deformation under constant stress at elevated temperatures.

- Fracture Toughness Testing: Assesses the material’s resistance to crack propagation.

- Non-destructive testing (NDT): Techniques like X-ray diffraction, ultrasonic testing, and magnetic particle inspection used to detect internal flaws without damaging the material.

These tests provide essential data for material selection, quality control, and design optimization. For example, tensile testing is crucial for ensuring that a structural component meets the required strength and ductility, while fatigue testing is essential for designing parts that will withstand repeated loading cycles.

Q 22. How do you interpret material test results?

Interpreting material test results involves a systematic approach that goes beyond simply reading the numbers. It requires understanding the test methodology, the material’s properties, and the context of the application. First, I carefully examine the raw data, looking for outliers or anomalies that might indicate experimental errors. Then, I analyze the data in relation to the material’s expected behavior, based on its composition and processing. For instance, if I’m evaluating tensile strength, I would consider the yield strength, ultimate tensile strength, and elongation at break. Low yield strength might indicate poor processing or an unsuitable material choice, while low elongation suggests brittleness. I also consider the statistical significance of the results, using standard deviations and confidence intervals to determine the reliability of the measurements. Finally, I correlate the results with the intended application. A material might have excellent tensile strength but be unsuitable for a specific application due to poor corrosion resistance or inadequate fatigue life. Ultimately, the interpretation should provide a comprehensive assessment of the material’s suitability for its intended purpose.

For example, if a polymer shows significantly lower impact strength than expected, I would investigate potential reasons: Was the material improperly processed (e.g., insufficient curing)? Are there impurities present? Is the testing environment (temperature, humidity) affecting the results? This systematic approach ensures that the conclusions drawn from material tests are accurate, reliable, and valuable for making informed decisions.

Q 23. Discuss the importance of material selection in product design.

Material selection is paramount in product design; it directly impacts performance, cost, durability, and environmental impact. The wrong material choice can lead to product failure, increased manufacturing costs, and even safety hazards. The selection process typically begins with identifying the critical performance requirements. For example, a component might require high strength, corrosion resistance, or specific thermal properties. Then, I consider a range of potential materials that meet these requirements, weighing their relative advantages and disadvantages. This often involves trade-offs – a stronger material might be more expensive or heavier, while a lighter material might sacrifice strength. Factors such as manufacturability, availability, and recyclability also play important roles. Life cycle assessment (LCA) is frequently employed to evaluate the environmental impact of different materials, considering energy consumption, emissions, and waste generation throughout the product’s life. Software tools such as CES EduPack can assist in this process by providing comprehensive material property databases and aiding comparative analyses.

Imagine designing a bicycle frame. Steel offers a good balance of strength and cost, but aluminum is lighter, while carbon fiber offers superior strength-to-weight ratio but is more expensive. The choice depends on the intended use (e.g., racing, commuting), target market, and budget.

Q 24. Explain the role of materials science in addressing environmental challenges.

Materials science plays a crucial role in addressing environmental challenges by enabling the development of sustainable materials and technologies. One major area is the development of biodegradable and compostable polymers to replace conventional plastics, reducing plastic waste and pollution. Another is the design of high-efficiency solar cells using novel materials to harness renewable energy. Materials science also contributes to improving energy storage technologies (e.g., advanced battery materials) and creating more energy-efficient building materials to reduce carbon emissions. Furthermore, the development of sustainable manufacturing processes, such as additive manufacturing (3D printing), reduces waste and improves resource utilization. The focus is shifting towards circular economy principles, where materials are designed for recyclability and reuse, minimizing their environmental footprint throughout their entire life cycle. Research into lightweight, high-strength materials reduces fuel consumption in transportation. The development of efficient water filtration membranes using nanomaterials contributes to clean water access.

For example, research into bio-based polymers derived from renewable resources (like plants) offers a sustainable alternative to petroleum-based plastics. Similarly, the development of self-healing materials reduces the need for frequent replacements, extending product lifespan and minimizing waste.

Q 25. Describe your experience with materials modeling and simulation software.

I have extensive experience with various materials modeling and simulation software packages, including Abaqus, COMSOL Multiphysics, and Materials Studio. My expertise extends to utilizing these tools for a wide range of applications, from predicting material behavior under various loading conditions to designing novel materials with desired properties. In Abaqus, for example, I’ve performed finite element analysis (FEA) to simulate the stress and strain distribution in complex geometries under different loading scenarios, such as tensile testing or impact simulations. This allows for virtual prototyping and optimization of designs before physical testing, saving time and resources. With COMSOL Multiphysics, I’ve modeled multi-physics phenomena, such as coupled thermal-mechanical behavior or fluid-structure interactions, offering a more realistic representation of real-world scenarios. Materials Studio has been instrumental in designing and analyzing the structure and properties of new materials at the atomic level, enabling the exploration of different compositions and processing methods to optimize performance. I’m proficient in scripting and automating simulations for high-throughput calculations, allowing for efficient exploration of large parameter spaces.

For instance, I used Abaqus to simulate the fracture behavior of a ceramic component under impact loading, identifying potential failure points and optimizing the design to improve its resilience. This prevented costly failures during physical testing and allowed for a more robust final design.

Q 26. How do you stay updated on the latest advancements in materials science?

Staying updated in the rapidly evolving field of materials science requires a multifaceted approach. I regularly read peer-reviewed journals such as Nature Materials, Advanced Materials, and Science, focusing on areas relevant to my work. I attend international conferences and workshops to learn about the latest research findings and network with other professionals. I actively participate in online communities and forums, such as those on ResearchGate and LinkedIn, engaging in discussions and sharing knowledge. I also subscribe to relevant newsletters and online resources that provide updates on new publications, technologies, and industry trends. Furthermore, I regularly review patents and technical reports to stay abreast of emerging technologies and potential applications. This combined approach ensures I maintain a comprehensive understanding of the latest advancements and their potential impact on my work.

Q 27. Describe a time you had to troubleshoot a materials-related problem.

During a project involving the development of a new composite material for aerospace applications, we encountered unexpected brittleness in the final product. Initial testing revealed lower-than-expected impact strength. My troubleshooting process involved a systematic investigation. First, we reviewed the material composition and processing parameters, looking for deviations from the specifications. We found that a slight variation in the curing temperature had occurred during production. We then conducted further tests under controlled conditions, varying the curing temperature systematically. This revealed a strong correlation between curing temperature and impact strength. Through microscopic analysis (SEM), we observed microstructural defects that were more prevalent at lower curing temperatures, explaining the brittleness. We adjusted the curing process to ensure consistent temperature control and implemented quality control measures to prevent future occurrences. The problem was resolved, and the improved material met the required specifications. This experience highlighted the importance of meticulous process control and the value of a systematic troubleshooting approach.

Q 28. Explain your understanding of material safety data sheets (MSDS).

Material Safety Data Sheets (MSDS), now often referred to as Safety Data Sheets (SDS), are crucial documents that provide comprehensive information on the hazards and safe handling of chemical substances and mixtures. They are vital for ensuring workplace safety and environmental protection. An SDS typically includes information on the material’s identity, chemical composition, physical and chemical properties, health hazards, flammability, reactivity, and first aid measures. It also outlines safe handling procedures, personal protective equipment (PPE) requirements, storage recommendations, and spill response procedures. Understanding and adhering to the information provided in an SDS is paramount for anyone working with hazardous materials. Ignoring this information can lead to serious health risks and environmental damage. I’m familiar with the Globally Harmonized System of Classification and Labelling of Chemicals (GHS), which is the international standard for SDS creation and provides a consistent format for this critical information worldwide.

For example, before working with a particular solvent, I always consult its SDS to understand its flammability, toxicity, and recommended PPE. This ensures I work safely and responsibly, protecting myself and the environment.

Key Topics to Learn for a Materials Science Principles Interview

- Atomic Structure and Bonding: Understand the relationship between atomic structure, bonding types (ionic, covalent, metallic, van der Waals), and material properties like strength, ductility, and electrical conductivity. Consider how these concepts influence material selection for specific applications.

- Mechanical Properties and Testing: Familiarize yourself with concepts like stress, strain, elasticity, plasticity, fracture toughness, and fatigue. Understand common mechanical testing methods (tensile, compression, hardness tests) and how to interpret the results. Be prepared to discuss the relationship between microstructure and mechanical behavior.

- Phase Diagrams and Transformations: Master the interpretation of phase diagrams (e.g., binary phase diagrams) and understand phase transformations (e.g., solidification, diffusion, phase transitions). Be able to predict microstructure evolution based on processing parameters.

- Crystallography and Microstructure: Understand crystal structures (BCC, FCC, HCP), crystallographic directions and planes, and the relationship between microstructure (grain size, grain boundaries, precipitates) and material properties. Be ready to discuss techniques for characterizing microstructure (e.g., microscopy).

- Diffusion and Mass Transport: Grasp the fundamentals of diffusion, Fick’s laws, and their applications in processes like heat treatments and doping of semiconductors. Be able to discuss factors influencing diffusion rates.

- Material Selection and Design: Develop your ability to select appropriate materials for specific applications based on required properties and constraints. Consider factors like cost, availability, and environmental impact.

- Defects in Materials: Understand different types of material defects (point defects, line defects, planar defects, volume defects) and their impact on material properties. Be able to discuss the role of defects in strengthening or weakening materials.

Next Steps

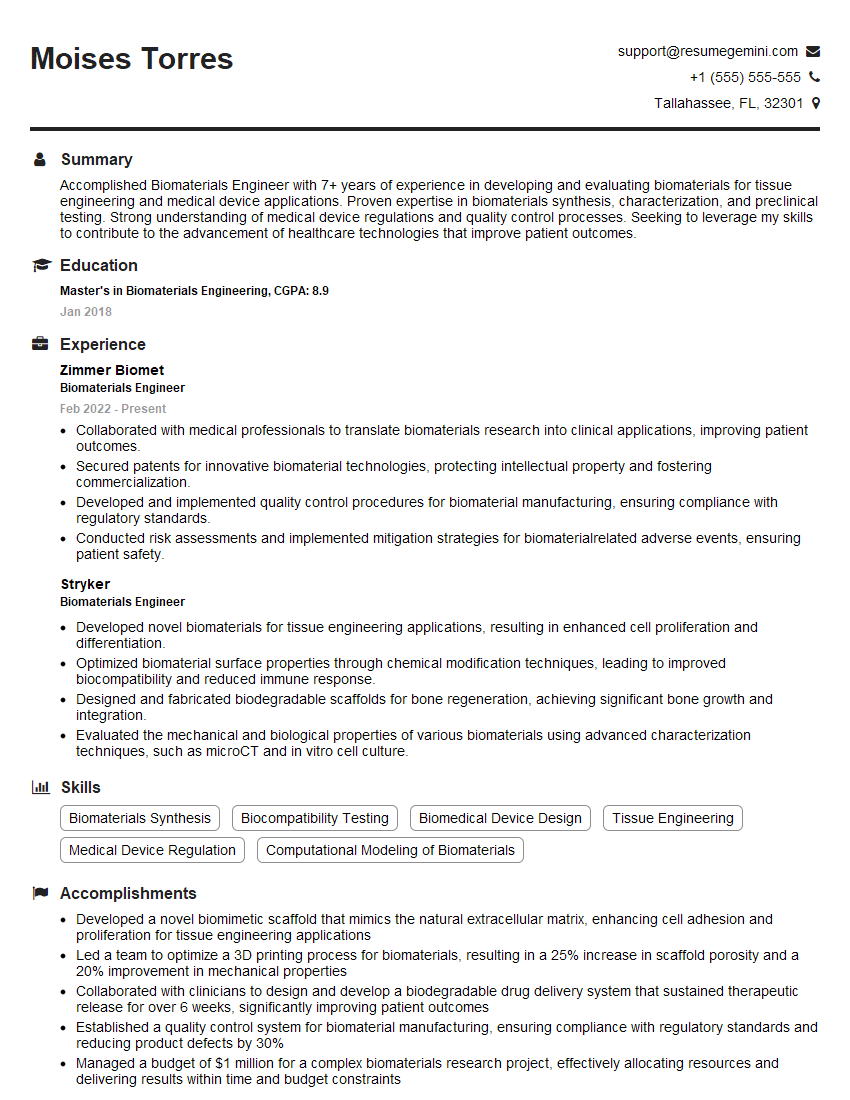

Mastering materials science principles is crucial for career advancement in various engineering and scientific fields. A strong understanding of these concepts opens doors to exciting opportunities and allows you to contribute meaningfully to innovative projects. To significantly enhance your job prospects, it’s essential to create a well-structured, ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to your specific experience. Examples of resumes tailored to showcasing expertise in Materials Science Principles are available through ResumeGemini, helping you present yourself in the best possible light to potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?