Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Fit and Pattern Adjustment interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Fit and Pattern Adjustment Interview

Q 1. Explain the difference between a sloper and a block.

Both slopers and blocks are foundational pattern pieces used as the base for designing garments, but they differ significantly in their level of detail and intended use. Think of a sloper as a perfectly fitted, basic shell and a block as a slightly more complex and adaptable template.

- Sloper: A sloper is a basic, close-fitting pattern piece representing the body’s shape. It’s created from precise body measurements, essentially a two-dimensional representation of your individual body. It’s highly personalized and lacks design elements like seam allowances or ease. It’s the starting point, akin to a blank canvas.

- Block: A block is a more developed base pattern. It includes standard seam allowances and ease (extra fabric for comfort and movement), and can often incorporate basic design features like darts or shoulder shaping. Blocks can be based on slopers but can also be purchased as standardized sizes. It’s closer to a ready-to-use template, with more features already in place.

In essence, a sloper is a truly custom foundation, while a block is a more versatile, ready-to-use starting point. I often use slopers when creating garments for clients with unique body shapes, ensuring a perfect fit. For mass production or designs where slight variations in fit are acceptable, a block offers a more efficient approach.

Q 2. Describe your experience with different pattern grading methods.

My experience encompasses various pattern grading methods, each with its own advantages and disadvantages. I’m proficient in both manual and digital grading techniques.

- Manual Grading: This traditional method involves physically manipulating the pattern pieces using rulers, curves, and other tools. It’s ideal for smaller scale production runs or when fine-tuning adjustments are necessary. For example, I’ve successfully graded a client’s perfectly fitted sloper manually to accommodate various sizes, ensuring consistency in the design across the size range.

- Digital Grading: Utilizing specialized software like Optitex or Gerber Accumark is my preferred method for larger-scale projects. This automated process allows for precise grading and efficient scaling of patterns across numerous sizes. I find this especially useful when working with complex designs or when speed and accuracy are paramount. For instance, in my previous role, I used digital grading to efficiently produce a comprehensive size range for a new line of jackets, drastically reducing turnaround time.

I can seamlessly adapt between both methods depending on project demands, ensuring optimal results and efficiency.

Q 3. How do you identify and correct a ‘pulling’ issue in a garment?

A ‘pulling’ issue occurs when a garment feels tight or strained in specific areas, often due to insufficient ease or poorly balanced pattern construction. Identifying and correcting it involves a systematic approach.

- Identify the Area: Carefully examine the garment on the wearer to pinpoint the exact location of the pull. Note whether it’s across the bust, across the back, or another area. Is it only noticeable in certain movements?

- Analyze the Cause: Is the pulling due to lack of ease (too little fabric for comfort), a too-small size, an improperly placed dart, or ill-fitting seams? Sometimes, the fabric itself can contribute; stiff fabrics are more prone to pulling issues.

- Implement Corrections: If the issue is lack of ease, you can add width or length to the pattern pieces. If it’s a dart problem, you may need to reposition or reshape the dart. For seams, adjusting the seam allowance or reshaping the seamline can solve the problem. A muslin, a test garment made from inexpensive fabric, is invaluable at this stage. I often make a muslin first to avoid costly mistakes on expensive fabrics.

- Refine and Test: Once adjustments are made, create a new muslin or make the alterations directly to the final garment, and test again for a comfortable fit. Iterate this process until the garment fits properly.

For example, I once encountered a pulling issue across the back of a dress. By adding a small back shoulder adjustment and increasing the width of the back panel slightly, the issue was resolved.

Q 4. What are the key measurements you consider when fitting a garment?

Accurate measurements are fundamental to good fit. The key measurements I consider vary depending on the garment but generally include:

- High Bust/Bust/Underbust: Essential for tops, dresses, and jackets to ensure proper fit across the chest.

- Waist: Defines the waistline and crucial for skirts, trousers, and fitted garments.

- Hip: Important for bottoms, dresses, and coats to accommodate the lower body.

- Shoulder Width: Determines the width of shoulders and is vital for accurate sleeve placement.

- Back Width: Measures across the back and aids in proper back panel shaping.

- Sleeve Length: Crucial for sleeves of any length.

- Full Bicep: Used for sleeves fitting snugly around the biceps.

- Height and Posture:While not direct body measurements, they inform overall proportions and help adjust the length and balance of the garment.

Taking these measurements accurately, using appropriate measuring techniques, is crucial for producing a successful pattern and a well-fitting garment. I always double-check measurements to ensure consistency and accuracy.

Q 5. How do you adjust a pattern for ease and comfort?

Ease and comfort are paramount in garment construction. Adjusting a pattern for ease involves adding extra fabric to the pattern pieces. The amount of ease depends on the garment type, fabric, and personal preference.

- Ease: This refers to the extra fabric added beyond the body measurements for comfort and movement. Types of ease include:

- Ease for comfort: Small extra amount of fabric added throughout the garment to allow freedom of movement and ease of wear.

- Ease for design: Sometimes added to specific areas to create a particular design element (a gathered sleeve or a full skirt).

- Design Ease: Incorporated intentionally to create fullness or drape in the garment, for example, a full skirt or gathered sleeves.

I typically add ease to areas such as the bust, waist, and hip to allow for comfortable movement. The amount of ease varies; a snug-fitting garment may have minimal ease while a loose-fitting garment needs more. I also consider the fabric’s drape and stretch; stretchy fabrics require less ease compared to stiff fabrics. For example, I would add less ease for a close-fitting dress in stretch jersey than for a loose-fitting blouse in cotton.

Q 6. Explain the process of creating a muslin.

Creating a muslin, or a test garment, is a vital step in the pattern-making process. It allows you to check the fit and make adjustments before cutting into expensive fabrics. The process is quite straightforward:

- Choose Fabric: Select a cheap, lightweight fabric like muslin or calico that closely resembles the drape of your final fabric in terms of weight and weave type.

- Cut the Pattern: Cut out all pattern pieces according to the instructions. Add seam allowances before cutting for this step.

- Assemble the Muslin: Sew the muslin together using basic seams. Don’t worry about perfect finishing; the aim is to check the fit.

- Fit the Muslin: Try on the muslin and carefully assess the fit. Identify areas that are too tight, too loose, or need adjustments in shape.

- Mark Adjustments: Make notes or use pins directly on the muslin to indicate where adjustments are needed. Use the fitting process to mark the necessary changes, adding or removing fabric.

- Unpick and Adjust: Take off the muslin, and carefully unpick any seams where adjustments are needed. Then adjust the pattern pieces based on your notes.

- Repeat as Needed: Repeat this process until the muslin fits well, and always remember to test it on the same body form you’ll be using the end garment on.

Creating a well-fitted muslin saves time, money, and frustration in the long run. It’s one of the most critical steps I undertake in creating professionally-fitting garments. I’ve saved many hours and material costs this way over my career.

Q 7. Describe your experience with different fabric types and how they impact pattern adjustments.

Fabric type significantly impacts pattern adjustments. Different fabrics have varying degrees of drape, stretch, and weight. These characteristics must be accounted for to achieve a well-fitting garment.

- Drape: Fabrics with good drape, like silk or rayon, will hang differently than stiff fabrics like linen or denim. Pattern adjustments may be needed to account for the way the fabric will fall. For example, a pattern for a flowing silk skirt will require more ease to accommodate the drape.

- Stretch: Stretchy fabrics like jersey or spandex require less ease than non-stretch fabrics. The pattern may even need to be adjusted to incorporate the stretch, to accommodate the way it will move on the body.

- Weight: Heavy fabrics like wool or velvet will require more support, possibly through interfacing or design adjustments. They will also hang differently than lighter fabrics.

For instance, if I’m designing a dress in heavy brocade, I would need to account for its weight and structure, likely adding support features like boning or strategically placed interfacing. Conversely, a lightweight silk dress would require adjustments for its drape and flow.

I always take into account the specific fabric properties when adjusting patterns. My experience spans working with a wide variety of materials, and I am adept at making the necessary alterations based on the chosen material. It’s something I always consider critically and something I feel is essential for good quality garment construction.

Q 8. How do you handle fit issues related to different body types?

Addressing fit issues across diverse body types requires a nuanced understanding of body measurements and how they translate into garment construction. It’s not a one-size-fits-all approach; instead, I utilize a combination of techniques. For example, a person with broad shoulders might require adjustments to the shoulder slope and width of the pattern, possibly involving a shoulder adjustment technique such as raising the shoulder point or widening the back shoulder. Someone with a full bust will need adjustments to the bust dart placement and depth to ensure a smooth fit and prevent pulling or gaping. Conversely, a person with a swayback might require adjustments to the lower back, possibly adding length or shaping the curve of the lower back seam to accommodate the body’s natural curvature.

My process involves detailed measurements, careful analysis of fit issues on a muslin (a test garment), and targeted pattern adjustments. I often use slopers (basic blocks) as a foundation, adapting them according to the individual’s measurements and body shape. For instance, if a client has a prominent abdomen, I would add fullness to the front bodice below the bust to accommodate that area, and possibly also reduce the waist dart to create a smoother fit.

Q 9. What software or CAD systems are you proficient in for pattern making?

I’m proficient in several industry-standard CAD systems for pattern making, including Optitex and Lectra. My experience with these systems allows me to efficiently create and manipulate patterns, grade them across multiple sizes, and generate technical design specifications. I find Optitex particularly useful for its intuitive interface and advanced grading capabilities, while Lectra excels in managing complex pattern libraries and automating production processes. Beyond CAD, I’m also comfortable using industry-standard software for illustration and digital design, like Adobe Illustrator and Photoshop, to create clear and concise technical drawings.

Q 10. How do you interpret technical sketches and specifications?

Interpreting technical sketches and specifications is crucial for accurate pattern making. I approach this systematically, starting with a thorough review of the design intent. This includes studying the silhouette, understanding the intended drape and volume, and analyzing the specific construction details. I pay close attention to all measurements, seam allowances, and markings indicated on the sketch. Any ambiguities are clarified with the designer before proceeding.

For example, if a sketch depicts a princess seam dress, I’ll carefully note the angle and placement of the seams, the type of neckline, and any special features like darts or gathers. I will then measure and translate these elements into the actual pattern pieces, ensuring proportions and measurements are accurate. This process requires a strong understanding of garment construction principles and an ability to visualize the 2D pattern pieces as a 3D garment.

Q 11. How do you ensure consistency in pattern grading across different sizes?

Maintaining consistency in pattern grading is paramount for producing a well-fitting garment across a range of sizes. I achieve this through the use of specialized grading software within my CAD systems. These programs allow me to define grading rules based on industry standards or client-specific requirements. For example, I can specify that the bodice width increases by a certain increment per size while the length increases proportionally. This ensures a consistent balance of fit and proportion across all sizes.

Beyond software, I also perform manual checks to ensure the graded patterns maintain the original design’s proportions and aesthetic. This includes visual inspection and reviewing key measurements at various points throughout the grading process. Regular quality control procedures are critical in this step to ensure consistent and accurate results and minimize errors.

Q 12. Explain your experience with different types of closures and how they impact pattern design.

Different closure types significantly impact pattern design. The choice of closure dictates the shape and construction of the garment’s opening and influences other design elements. For example, a zipper closure often requires a seam allowance to accommodate its width and may necessitate a specific facing or interfacing construction. The zipper location also affects the placement of other design details like darts or pockets. Similarly, a button closure demands allowance for buttonholes and often influences the style and shape of the placket, which needs to be integrated into the pattern accurately. A hook-and-eye closure, on the other hand, is less intrusive and may be suitable for more delicate fabrics and simpler garment designs.

In my experience, I’ve worked with a wide range of closures, including zippers (invisible, center-back, side), buttons, hooks and eyes, snaps, and toggles. Each type presents unique challenges, and my pattern design must accommodate those challenges to ensure a functional and aesthetically pleasing outcome. For instance, when designing a coat with a double-breasted closure, I carefully consider the overlap, button placement, and the necessary shaping to ensure a flattering and well-fitting garment.

Q 13. Describe your approach to problem-solving when encountering fit issues.

My approach to problem-solving with fit issues is methodical and iterative. I start by carefully analyzing the problem on a muslin. Pinning, pulling, and assessing the garment on a dress form or the client helps me identify specific areas of tightness or looseness. I record these observations precisely, noting the exact location and extent of the problem – for example, ‘tightness across the upper back, 1 inch reduction needed’.

Next, I translate these observations into pattern adjustments. This often involves easing, shifting, or adding/reducing seam allowances. For complex adjustments, I might make small, incremental changes, testing each adjustment on a new muslin until the fit is satisfactory. Throughout this process, I maintain detailed documentation of every adjustment made so I can easily replicate the changes or modify them for future projects. I consider the fabric’s drape and characteristics throughout the process as they affect the final fit.

Q 14. How do you document pattern adjustments and modifications?

Documenting pattern adjustments is crucial for consistency and reproducibility. My approach involves a combination of visual and written documentation. I meticulously annotate my patterns directly, using colored markers or tailor’s chalk to indicate adjustments, and I make notations in the margins detailing the nature and extent of each change (e.g., ‘added 1/2 inch to center back seam below waist’).

I also maintain a detailed digital record of all modifications, often using a spreadsheet or a dedicated pattern-making software’s database. This database includes information such as the initial pattern size, the client’s measurements, a description of the adjustments made, the date of the modification, and sketches or images showing the changes. This comprehensive documentation allows me to easily reproduce adjustments for the same client in the future or adapt them for similar projects.

Q 15. What is your experience with pattern making for different garment styles (e.g., dresses, pants, jackets)?

My experience in pattern making spans a wide range of garment styles. I’m proficient in drafting and adjusting patterns for dresses, encompassing various silhouettes from A-line to fit-and-flare, and incorporating details like princess seams, darts, and different necklines. With pants, I’m comfortable working with various fits – from slim-leg trousers to wide-leg palazzo pants, understanding the nuances of crotch curves, inseams, and rise adjustments. Jacket construction is another area of expertise, where I’ve worked extensively on tailored jackets, blazers, and more casual styles, understanding the complexities of shoulder construction, sleeve caps, and collar shaping. In each case, my approach involves a thorough understanding of the desired style, fit, and fabric drape, and this informs every step of the pattern-making process.

For example, when designing a princess seam dress, I meticulously consider the placement of seams to create a flattering silhouette, ensuring that they align with the body’s natural curves. Similarly, when constructing tailored pants, my expertise lies in precisely calculating the crotch curve to ensure a comfortable and well-fitting garment. The ability to adapt patterns to various body types and styles is crucial, and I’ve developed a strong foundation in this area.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain your experience with industrial sewing machines.

I possess extensive experience operating a variety of industrial sewing machines, including but not limited to straight stitch machines, overlock (serger) machines, coverstitch machines, and buttonhole machines. My skills extend beyond basic operation; I’m adept at adjusting stitch length, tension, and pressure to achieve precise and consistent seams suitable for diverse fabrics. I understand the maintenance requirements for these machines and can troubleshoot minor issues efficiently, minimizing downtime.

For instance, I know how to adjust the differential feed on an overlock machine to prevent stretching on delicate fabrics or how to optimize tension for neat, flat seams on heavier materials. I’m also skilled in using specialized sewing machine attachments like gathering feet and zipper feet to enhance efficiency and accuracy in garment construction. This proficiency ensures a smooth and efficient workflow in the production process.

Q 17. How do you work with fit models to achieve the desired fit?

Collaborating with fit models is an integral part of achieving the perfect fit. My approach involves careful communication, meticulous observation, and a methodical process of adjustment. Before any fitting, I ensure clear communication with the fit model about the desired fit and the areas needing special attention. During the fitting, I observe how the garment drapes on the body, noting any pulling, gaping, or areas of excess fullness. I meticulously mark these discrepancies directly on the garment.

I then translate these markings to the pattern, making precise adjustments. This might involve easing seams, taking in or letting out darts, or making adjustments to the shoulder or neckline. The process is iterative, often involving multiple fittings to achieve the desired outcome. For example, if the shoulder seam is pulling, I might slightly raise the armscye (armhole) on the pattern to provide more ease. I carefully document each adjustment made, ensuring consistency and enabling me to reproduce the refined fit effectively for future garments.

Q 18. How do you handle discrepancies between the pattern and the final garment?

Discrepancies between the pattern and the final garment can arise from various sources, including inaccuracies in pattern drafting, fabric choice, or even sewing techniques. My approach to resolving such discrepancies involves a systematic investigation. I first examine the garment carefully to identify the precise location and nature of the problem. I then compare the finished garment to the original pattern pieces, checking for any distortions or inconsistencies.

For example, if the sleeve cap is puckering, I might check for errors in the pattern’s sleeve cap construction or the fabric’s inherent stretch. I might use a grading ruler to ensure the pattern pieces are true to scale. Once the source of the problem is identified, I make targeted adjustments to the pattern, addressing the issue specifically. This might involve re-drafting parts of the pattern or adjusting seam allowances. This meticulous approach allows for continuous improvement and refinement of the patterns, minimizing discrepancies in future productions.

Q 19. What is your approach to quality control in pattern making and fitting?

Quality control is paramount in pattern making and fitting. My approach incorporates checks at every stage of the process. It begins with the initial pattern drafting, where I meticulously review the pattern for accuracy and consistency using various grading and measuring tools. During the first muslin (test garment) fitting, I meticulously observe the fit, making adjustments as necessary. After each adjustment, I double-check my measurements and markings to prevent introducing new errors.

Throughout the sewing process, I maintain high standards of craftsmanship, ensuring accurate seam construction, precise finishing, and careful attention to detail. The final garment is subjected to a rigorous inspection, verifying that the fit aligns with the design specifications and that the garment is free from defects. I use checklists and detailed documentation to track each step of the process. This multifaceted approach helps ensure a consistently high-quality end product.

Q 20. Describe your experience with pattern alterations based on fit sessions.

My experience with pattern alterations based on fit sessions is extensive and crucial to my pattern-making expertise. After each fitting, I meticulously document all adjustments. This documentation forms the basis for refining the pattern, ensuring that subsequent garments fit consistently and accurately. The changes are carefully recorded, not only numerically (e.g., ‘add 1/2 inch at the waist’) but also with detailed descriptions (e.g., ‘ease the center back seam to remove pulling’).

I utilize different techniques for alterations depending on the type of fit issue. For example, if a garment is too tight across the bust, I’ll adjust the dart placement or add fullness using a technique such as a slash and spread. If the garment is too long, I’ll adjust the pattern length accordingly. The ability to accurately interpret the feedback from the fit session and effectively translate that feedback into pattern adjustments is what truly separates a skilled pattern maker from an average one. This iterative process of fitting and adjustment leads to a consistently well-fitting garment.

Q 21. Explain your experience using a digital pattern-making system.

I am proficient in using various digital pattern-making systems, including [mention specific software if comfortable, otherwise replace with generic examples, e.g., Adobe Illustrator, Lectra Modaris]. My skills include creating base patterns, grading patterns for different sizes, manipulating pattern pieces, and generating various pattern markings and notations. The digital environment offers significant advantages, such as precision, repeatability, and the capacity for rapid prototyping and iteration. This allows for quick adjustments and efficient pattern manipulation compared to traditional manual methods.

For instance, using digital software, I can quickly adjust a pattern’s grading to create a size range efficiently, or I can easily make small adjustments to the pattern pieces without having to physically redraw or cut the pattern. The ability to seamlessly integrate digital pattern-making techniques with traditional pattern-making skills is a great asset in this field.

Q 22. How do you ensure the accuracy of your pattern grading?

Accurate pattern grading hinges on meticulous attention to detail and a solid understanding of body proportions. It’s not simply enlarging or reducing a base pattern; it’s about maintaining the design’s integrity across size ranges. I use a combination of methods to ensure accuracy. Firstly, I utilize professional grading software, which helps maintain consistent proportions across different sizes. This software allows for precise adjustments to key measurements, like the bust, waist, and hip, ensuring the garment fits correctly across size ranges. Secondly, I always create a test garment in the target size range to check the fit and make necessary adjustments. This physical testing allows me to identify and correct any anomalies the software may not have caught. Finally, I meticulously check my work against industry standards and grading rules, which help ensure that the finished product meets professional standards. Think of it like baking a cake – the recipe is the base pattern, but you still need to check the oven temperature (software) and taste-test the cake (test garment) to ensure it’s perfect.

Q 23. What are some common fit issues you encounter and how do you resolve them?

Common fit issues I encounter include pulling across the bust or back, gaping at the neckline, sleeve cap issues (bunching or pulling), and length discrepancies. Resolving these issues requires a systematic approach. For example, if there’s pulling across the bust, I might need to add width to the bust area of the pattern, potentially adjusting the dart placement or adding a princess seam for better shaping. Gaping at the neckline often points to a need for adjustment in the neckline curve itself, perhaps reducing the depth of the neckline. Sleeve cap issues usually involve refining the sleeve cap height and easing, adjusting the sleeve head circumference to fit the armhole correctly. Length discrepancies are easily solved with a simple adjustment to the length lines of the pattern piece. Each adjustment is a small alteration in the pattern, requiring attention to detail and the ability to visualize the impact of each adjustment on the garment’s final fit. The process often involves multiple fittings, with small adjustments made after each fitting until the desired fit is achieved.

Q 24. How do you manage time effectively during pattern making and fitting processes?

Efficient time management in pattern making and fitting is critical. I begin with detailed planning. This includes creating a realistic timeline for each step, from initial design to final fitting. I prioritize tasks, focusing on the most time-consuming aspects first. For instance, the initial pattern drafting is often the most time-intensive, so I dedicate ample time to this stage, ensuring accuracy at the outset to minimize later corrections. I also utilize time-saving techniques such as using pre-made pattern blocks for basic shapes whenever possible. During the fitting process, I work methodically, documenting all changes made to the pattern and keeping a detailed record of any findings. This not only saves time in subsequent fittings but also enables easy replication for future projects. Furthermore, I always take a break and come back to it with fresh eyes to spot mistakes. Finally, I streamline processes using techniques like slopers and pattern software. This approach ensures accuracy and efficiency, keeping projects on track and meeting deadlines effectively.

Q 25. Explain your experience with different types of seam finishes and their impact on the final fit.

Seam finishes significantly impact the final fit and drape of a garment. A poorly finished seam can cause bulk, distort the garment’s shape, or even alter the fit. My experience encompasses various finishes, including French seams (for a clean, professional look, particularly in fine fabrics), serged seams (for stretchy or woven fabrics where durability is a priority), and Hong Kong finishes (for clean, professional, and durable finishes inside the garment). The choice of seam finish depends on the fabric type and garment style. For example, French seams are ideal for light to medium-weight fabrics where a crisp, clean finish is important, but they are not suitable for heavy fabrics or knits. Conversely, serged seams are perfect for knit fabrics but may not be as aesthetically pleasing in finer fabrics. The impact on fit is noticeable; poorly executed finishes add bulk, which can distort the garment’s lines and negatively affect the fit, particularly in fitted garments. Careful execution of seam finishes is crucial for a professional and well-fitting garment.

Q 26. Describe your experience with creating patterns for plus-size garments.

Creating patterns for plus-size garments requires a nuanced understanding of body proportions and fit considerations specific to this size range. It’s not just about scaling up a standard pattern. I work with several variations in size blocks and understand that grading is more complex, needing adjustments in areas like the bust, shoulder, and back. The ease and fit need careful attention, often requiring more generous allowances to accommodate a wider range of body shapes and sizes. I prioritize using techniques that create a flattering and comfortable fit. This includes adjustments to seam lines, adding shaping darts in strategic locations, and implementing design details that enhance the garment’s aesthetics and support without restricting movement. For example, different back adjustments might be necessary compared to straight size garments, as well as adjustments for wider shoulders and a fuller bust, and often the addition of design details that balance the garment for better drape and flattering appearance. I approach this area with a deep understanding of inclusive design principles that value different body types.

Q 27. How do you adjust patterns to accommodate various fabric draping and stretch?

Fabric drape and stretch are crucial factors that directly influence pattern adjustments. For fabrics with significant drape (like silk or rayon), the pattern needs to account for the additional fullness the fabric will create. I might add extra ease to the pattern or adjust the design lines to complement the flow of the fabric. Conversely, with stiff fabrics (like linen), less ease is needed as the fabric holds its shape better. The same principle applies to stretch fabrics. Knit fabrics, for example, have a lot of stretch, so I will adjust the pattern to account for this, including using a more forgiving ease allowance in areas with stretch and adding ease to account for the recovery of the fabric after stretching. I often make muslins (test garments) in the chosen fabric before finalizing the pattern to see how the fabric behaves and make any necessary adjustments. This ensures the final garment fits and drapes as intended, regardless of the fabric type.

Q 28. Explain the importance of using appropriate tools and techniques in pattern making and fitting.

Appropriate tools and techniques are essential for accurate and efficient pattern making and fitting. Precision is key, and using high-quality tools aids in this. This includes using a sharp rotary cutter for clean cutting, accurate rulers and measuring tapes for consistent measurements, and a well-maintained sewing machine for accurate stitching. Beyond tools, techniques such as proper fabric handling (pressing, notching, marking), precise cutting, and methodical stitching are vital. For example, using French curves helps to create smooth, organic curves in patterns, avoiding abrupt angles that might lead to poor fit. Moreover, understanding grading techniques to maintain design integrity across sizes is essential. The correct selection and use of these tools and techniques is a defining factor between a professional, well-fitting garment and an amateur, ill-fitting garment. My proficiency in these areas guarantees efficiency and accuracy in my pattern making and fitting processes.

Key Topics to Learn for Fit and Pattern Adjustment Interview

- Understanding Basic Garment Construction: Grasping fundamental principles of sewing construction, seam allowances, and fabric properties is crucial for effective pattern adjustments.

- Body Measurement and Sizing: Learn how to accurately take body measurements and interpret standard size charts to identify areas needing adjustment.

- Pattern Alteration Techniques: Master techniques like full-bust adjustments, swayback adjustments, shoulder adjustments, and sleeve adjustments. Understand the practical application of these techniques on various garment types.

- Fabric Behavior and Drape: Analyze how different fabric types (e.g., wovens, knits) behave and impact the final fit. Learn to adjust patterns accordingly.

- Muslin Mock-ups and Fitting: Understand the importance of creating and fitting muslin mock-ups to identify and correct fit issues before cutting into the final fabric.

- Advanced Pattern Making Concepts: Explore advanced techniques like drafting slopers, manipulating darts, and creating design adaptations within the pattern.

- Problem-Solving and Troubleshooting: Develop the ability to diagnose fit problems, identify their root causes, and implement effective solutions.

- Understanding Different Fitting Methods: Become familiar with various fitting methods, such as the flat pattern method, the draping method, and the sloper method.

- Using Technology in Fit and Pattern Adjustment: Explore the use of CAD software and digital pattern making tools to enhance efficiency and precision.

Next Steps

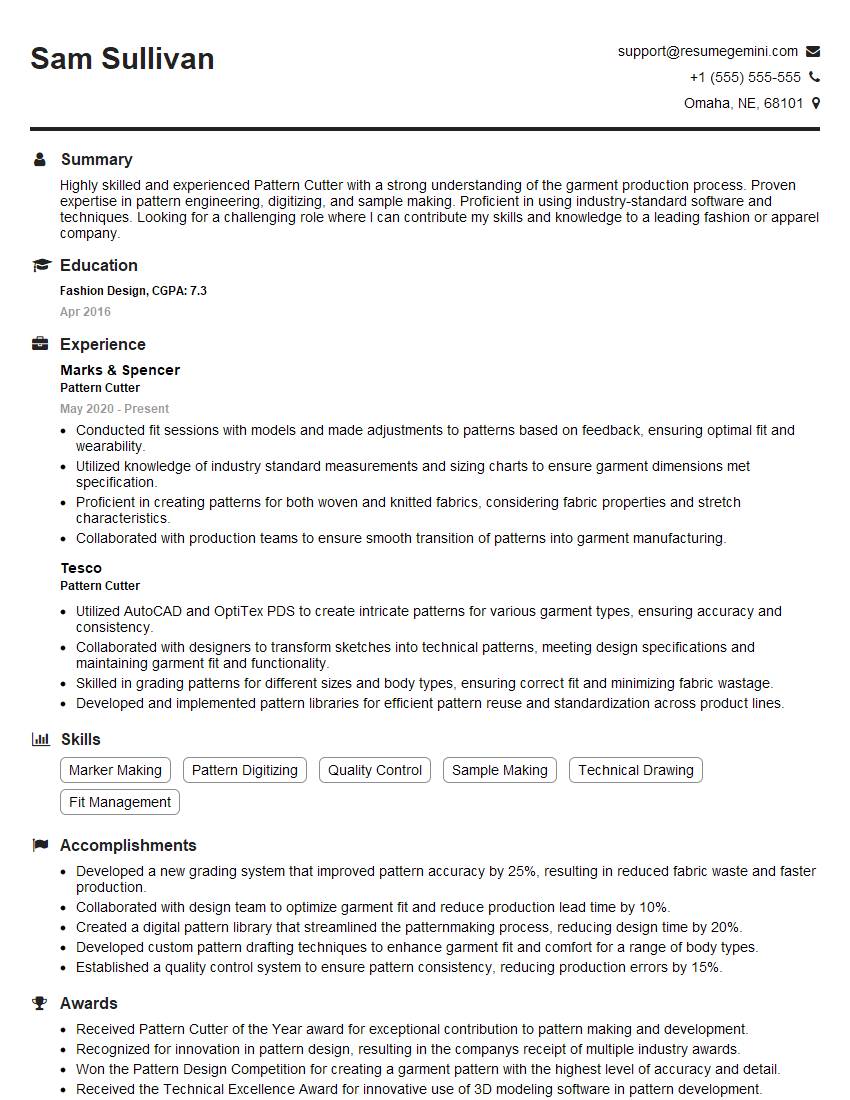

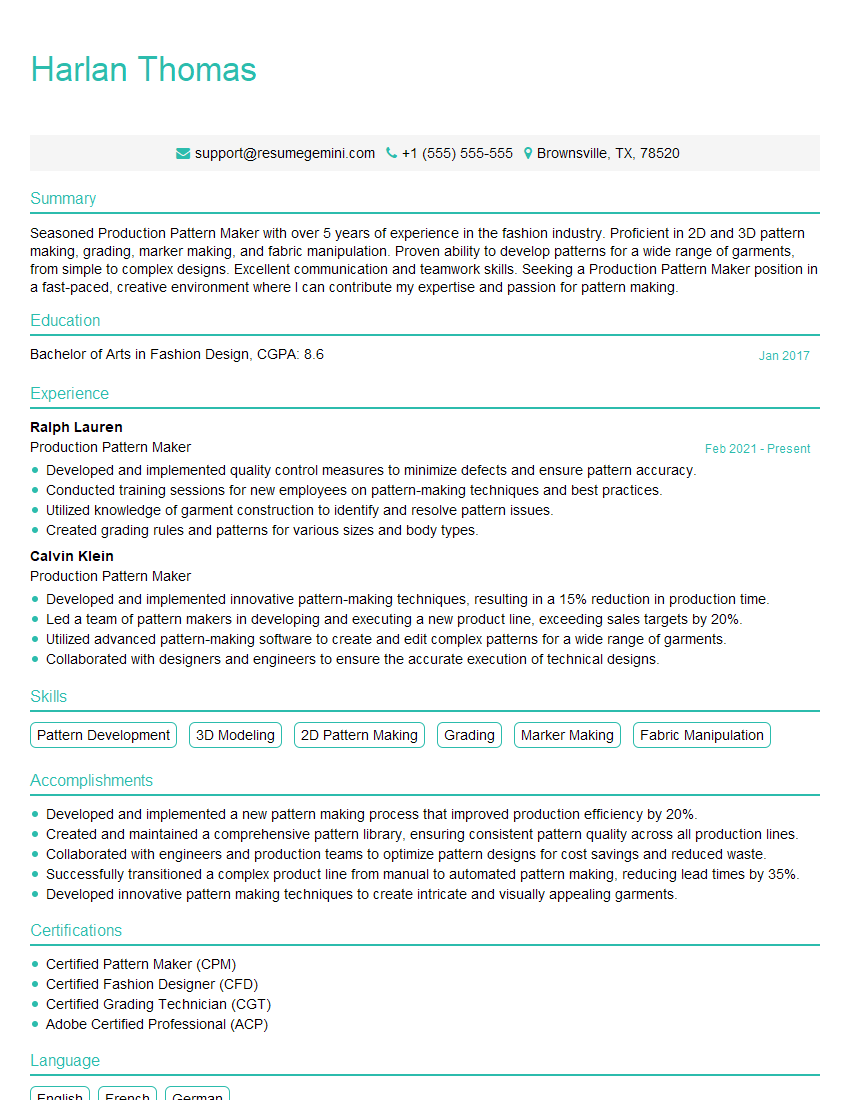

Mastering Fit and Pattern Adjustment is key to advancing your career in the fashion industry, opening doors to more specialized roles and higher earning potential. A strong resume is crucial for showcasing your skills and experience to potential employers. To maximize your job prospects, focus on creating an ATS-friendly resume that highlights your abilities effectively. ResumeGemini is a trusted resource that can help you build a professional and impactful resume, ensuring your qualifications shine. Examples of resumes tailored to Fit and Pattern Adjustment are available to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

hello,

Our consultant firm based in the USA and our client are interested in your products.

Could you provide your company brochure and respond from your official email id (if different from the current in use), so i can send you the client’s requirement.

Payment before production.

I await your answer.

Regards,

MrSmith

hello,

Our consultant firm based in the USA and our client are interested in your products.

Could you provide your company brochure and respond from your official email id (if different from the current in use), so i can send you the client’s requirement.

Payment before production.

I await your answer.

Regards,

MrSmith

These apartments are so amazing, posting them online would break the algorithm.

https://bit.ly/Lovely2BedsApartmentHudsonYards

Reach out at [email protected] and let’s get started!

Take a look at this stunning 2-bedroom apartment perfectly situated NYC’s coveted Hudson Yards!

https://bit.ly/Lovely2BedsApartmentHudsonYards

Live Rent Free!

https://bit.ly/LiveRentFREE

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?