The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Fixture and Tool Design interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Fixture and Tool Design Interview

Q 1. Explain the difference between a jig and a fixture.

While both jigs and fixtures guide and support workpieces during manufacturing processes, they differ significantly in their primary function. A jig is primarily used to guide tools, ensuring accurate and repeatable machining operations. Think of it as a template that ensures the tool follows a specific path. A fixture, on the other hand, primarily holds the workpiece securely in place, allowing for multiple operations to be performed on it. It’s the workpiece’s secure and stable base during manufacturing.

Example: Imagine drilling several precisely-spaced holes in a metal plate. A jig would guide the drill bit to each location, ensuring consistent spacing and depth. A fixture would securely hold the plate in place while the jig guides the drill. If the operation involved additional steps like milling or tapping after drilling, the same fixture could be used, changing only the tool, but if the jig changed even slightly, the accuracy of the subsequent drilling operation could be lost.

Q 2. Describe your experience with various CAD/CAM software for fixture design.

I have extensive experience with various CAD/CAM software packages, including SolidWorks, AutoCAD, NX, and Mastercam. My proficiency extends beyond basic modeling to encompass advanced techniques like tolerance analysis, finite element analysis (FEA), and simulation of fixture performance. In SolidWorks, for example, I regularly utilize its simulation tools to verify the strength and stability of fixture designs under various loading conditions, helping prevent costly errors during production. Mastercam is essential for generating the CNC code necessary to machine the fixture components themselves. Using NX I routinely use the design review tools to collaborate with other engineers and stakeholders on the designs, enhancing effective communication during the design process.

I find that the choice of software depends on the project’s complexity and the client’s preferences. However, my familiarity with various platforms allows me to adapt quickly to any project’s needs.

Q 3. What are the key considerations for designing a fixture for high-volume production?

Designing a fixture for high-volume production demands a focus on efficiency, robustness, and ease of use. Key considerations include:

- Simplicity: The fixture should be straightforward to load and unload, minimizing downtime. Complex mechanisms increase the risk of failure and reduce efficiency.

- Durability: The materials and construction must withstand the rigors of continuous use, with minimal wear and tear.

- Cost-effectiveness: While ensuring quality, the materials and manufacturing process should be cost-effective for large-scale production.

- Maintainability: Regular maintenance should be easy to perform, and parts should be easily replaceable if necessary.

- Ergonomics: The fixture’s design should prioritize operator safety and comfort.

- Repeatability: Precise location of the workpiece is crucial, which is critical for consistent results and interchangeable tooling.

Example: In a high-volume automotive assembly line, a simple, robust fixture holding a car door during welding is far more effective than a complex one. The focus should be on quick clamping, consistent positioning, and minimal wear over tens of thousands of cycles.

Q 4. How do you ensure the accuracy and repeatability of a fixture?

Accuracy and repeatability are paramount in fixture design. I employ several strategies to ensure these qualities:

- Precise machining: Fixture components are machined to tight tolerances using CNC equipment, minimizing variations and inaccuracies.

- High-quality materials: Using materials with low thermal expansion coefficients and high dimensional stability is crucial for long-term accuracy.

- Redundant clamping: Employing multiple clamping points distributes the clamping force evenly across the workpiece, preventing distortion and ensuring consistent part location.

- Fixture design verification: Using CAD software, I can verify the design’s accuracy by simulating the clamping process and checking for potential interference. Finite Element Analysis (FEA) could be performed to predict stress levels on critical components.

- Regular calibration and inspection: Periodic inspection and calibration of the fixture are crucial for maintaining accuracy over time.

Example: When designing a fixture for precision drilling, I use hardened steel components machined to within 0.001 inches of tolerance. Multiple, evenly-spaced clamps, along with precision locating pins, prevent the part from shifting during operation.

Q 5. Explain your process for designing a fixture for a complex part.

Designing a fixture for a complex part requires a systematic approach:

- Part analysis: Thoroughly analyze the part’s geometry, features, and tolerances to identify critical areas for clamping and locating.

- Clamping strategy: Develop a clamping strategy that minimizes part distortion and ensures stability during machining operations. This may involve a combination of different clamping mechanisms.

- Locating strategy: Define locating points on the part to ensure consistent and repeatable positioning. This often involves locating pins, bushes, and other precision locating devices.

- Design and modeling: Use CAD software to create a 3D model of the fixture, incorporating the clamping and locating elements.

- Simulation and analysis: Perform simulations to assess the fixture’s performance and identify potential issues. FEA can be invaluable here.

- Prototyping and testing: Create a prototype and test it thoroughly with the actual part to ensure it meets all requirements and identify any design flaws.

- Final design and documentation: Refine the design based on the testing results, and create detailed drawings and specifications for manufacturing.

Example: For a complex die-cast aluminum part, I might employ a combination of pneumatic clamps, hydraulic wedges, and multiple locating pins to ensure secure and repeatable positioning during machining. The simulation of this process will show stress points, possible clamping issues, and validate the design’s ability to hold the part to specification

Q 6. Describe your experience with different types of clamping mechanisms.

My experience encompasses a wide range of clamping mechanisms, including:

- Toggle clamps: Simple, cost-effective, and ideal for applications requiring quick clamping and release.

- Hydraulic clamps: Provide high clamping force and are suitable for large or heavy workpieces.

- Pneumatic clamps: Offer fast clamping cycles and precise control of clamping force, often used in automated systems.

- Cam clamps: Simple, reliable, and offer adjustable clamping force.

- Magnetic clamps: Ideal for ferrous materials and allow for quick and easy clamping.

- Screw clamps: Simple but provide substantial holding power. The design may employ a hand wheel for convenience or a powered wrench for increased speed and automation.

The choice of clamping mechanism depends heavily on the application, including the size and weight of the workpiece, the required clamping force, cycle time requirements, and budget constraints. I always consider factors such as ergonomics and the potential for operator safety during my selection.

Q 7. How do you select appropriate materials for fixture construction?

Material selection for fixture construction is critical for ensuring its durability, accuracy, and cost-effectiveness. Factors to consider include:

- Strength and rigidity: The material must be strong enough to withstand the clamping forces and resist deformation during use.

- Wear resistance: High wear resistance is essential for extending the fixture’s lifespan, especially in high-volume applications.

- Machinability: The material should be easily machined to precise tolerances using standard equipment.

- Corrosion resistance: In environments where corrosion is a concern, a material with good corrosion resistance is necessary.

- Cost: The material cost should be balanced against its performance characteristics.

Common materials include:

- Steel (various grades): Excellent strength, rigidity, and machinability, making it a popular choice for many fixture applications.

- Aluminum: Lighter and less expensive than steel, but with lower strength and rigidity. A good choice where weight is a concern.

- Cast iron: Good damping capacity and dimensional stability, often used for large or heavy-duty fixtures.

- Plastics (various types): Can be used for less demanding applications, offering lighter weight and potentially lower cost.

The final selection depends heavily on the application requirements and constraints. For example, a high-speed, high-volume operation might necessitate a hardened steel fixture for maximum durability. However, a prototyping application might use a less durable material for cost and convenience reasons.

Q 8. How do you handle design changes during the fixture development process?

Design changes are inevitable in fixture development. My approach focuses on proactive communication and robust design practices. First, I ensure a clear understanding of the initial design requirements through thorough documentation and collaboration with stakeholders. This includes creating a comprehensive design review process with clearly defined change management procedures.

When a change request arises, I assess its impact on the existing design using tools like tolerance stack-up analysis (discussed later) and FEA. This allows for quick identification of potential problems, such as increased manufacturing costs or functional limitations. The change request is then evaluated for feasibility and cost-effectiveness. Depending on the complexity, I may create a revised design, prototype, and conduct further testing to validate the changes’ impact. Finally, all relevant parties are notified of the changes, and updated documentation is distributed.

For example, I once worked on a welding fixture where the design of the part changed midway through the project. By meticulously assessing the impacts on the fixture’s clamping mechanisms and the part’s positioning, I was able to adapt the design with minimal delays and cost overruns. The key is to be flexible, organized, and proactive in communicating all changes.

Q 9. What are the common types of tooling used in manufacturing?

Manufacturing tooling encompasses a wide range of instruments and equipment. Common types include:

- Cutting tools: These remove material from a workpiece. Examples include drills, milling cutters, taps, and dies. The choice depends heavily on the material being machined and the desired surface finish.

- Forming tools: These shape materials without removing material. Examples include punches and dies for stamping, injection molds for plastics, and forging dies for metals. The design of these tools is crucial for achieving the desired shape and dimensional accuracy.

- Holding tools (fixtures): These secure the workpiece during machining or assembly. They must be designed to hold the part securely while allowing for accurate machining or assembly. This is where my expertise lies.

- Measuring tools: These ensure dimensional accuracy. Examples include calipers, micrometers, and CMMs (Coordinate Measuring Machines). Proper measurement tools are critical for quality control and process validation.

- Assembly tools: These assist in assembling components. Examples range from simple hand tools like screwdrivers to complex robotic systems.

The selection of appropriate tooling is critical for manufacturing efficiency and product quality. A poorly chosen tool can lead to defects, increased production time, and higher costs.

Q 10. Explain your understanding of tolerance stack-up analysis in fixture design.

Tolerance stack-up analysis is crucial in fixture design because it predicts the cumulative effect of individual component tolerances on the overall accuracy of the fixtured workpiece. Imagine building a tower of blocks—if each block is slightly off, the final height will be significantly different from the intended height. Similarly, small tolerances in fixture components can accumulate and result in a final product outside acceptable specifications.

In fixture design, we use tolerance stack-up analysis to determine the allowable tolerances for each component. This is typically done using statistical methods or worst-case scenario calculations. For example, if a fixture needs to locate a part to within 0.1mm, we must consider all aspects that contribute to the location, including the dimensions of the fixture itself, the locating pins, and the part’s own tolerances. We then determine how tightly the fixture needs to be designed and fabricated to meet this final requirement.

Software tools can significantly aid in this process. We can input the dimensions and tolerances of each component, and the software will calculate the overall tolerance stack-up, highlighting areas where tolerances are too large and requiring adjustments to the fixture design or component specifications.

Q 11. How do you ensure the safety of a fixture during operation?

Fixture safety is paramount. My design process incorporates several safety features from the outset:

- Ergonomics: Fixtures should be designed to be easy and safe to use. This involves considering factors such as reach, weight, and hand clearance.

- Guards and enclosures: Moving parts or sharp edges should be guarded to prevent injuries. Interlocks can ensure that the fixture cannot operate unless guards are in place.

- Emergency stops: Easily accessible emergency stop buttons should be incorporated to allow immediate shutdown in case of an emergency.

- Material selection: Materials should be chosen for strength and durability, but also for their resistance to corrosion, wear and tear, and potential hazards such as sparks or breakage.

- Risk assessment: A thorough risk assessment is crucial. This identifies potential hazards and helps develop control measures to mitigate risks. This can include using simulations or virtual prototypes to identify potential failure points.

For instance, in a fixture designed for high-pressure applications, I would incorporate safety features such as pressure relief valves and robust containment systems to prevent potential leaks or explosions.

Q 12. Describe your experience with DFMA (Design for Manufacturing and Assembly).

DFMA (Design for Manufacturing and Assembly) is a critical methodology that I extensively utilize. It focuses on designing products that are easy and cost-effective to manufacture and assemble. This involves considering factors such as material selection, part simplification, assembly methods, and tooling requirements from the initial design phase. A key aspect of DFMA is minimizing the number of parts, simplifying assembly operations, and using standardized components where possible. I always aim to reduce the manufacturing complexity and cost and reduce assembly times and associated costs

In my previous role, I applied DFMA principles to redesign a complex assembly fixture. By simplifying the fixture’s components and modifying the assembly sequence, we reduced the number of parts by 40%, assembly time by 30%, and manufacturing costs by 25%. This resulted in significant time and cost savings for the company.

Q 13. How do you manage multiple fixture design projects simultaneously?

Managing multiple fixture design projects simultaneously requires a structured approach and strong organizational skills. I employ project management techniques such as:

- Prioritization: Identifying and prioritizing projects based on urgency, impact, and resource availability is crucial. This involves creating a schedule and a clear work breakdown structure.

- Resource allocation: Effectively allocating time, personnel, and other resources across multiple projects ensures efficient workflow.

- Communication: Maintaining clear and consistent communication with stakeholders across all projects is vital for resolving conflicts and ensuring everyone is aligned.

- Project tracking software: Using software tools to track project progress, deadlines, and milestones allows for effective monitoring and timely interventions.

- Regular review meetings: Scheduling regular meetings helps to review progress, address challenges, and make necessary adjustments.

Think of it as conducting an orchestra; each project is a different instrument, and you must coordinate them to create a harmonious result. Effective prioritization and clear communication are key to success.

Q 14. What is your experience with Finite Element Analysis (FEA) in fixture design?

Finite Element Analysis (FEA) is a powerful tool in fixture design, allowing for the simulation of real-world conditions. I use FEA to analyze stress, strain, and deformation in fixtures under various loading conditions, helping identify potential weaknesses or failure points before manufacturing. This prevents costly rework and ensures the fixture’s structural integrity and reliability. For example, I might use FEA to determine the optimal clamping force required to hold a part securely without causing damage, or to analyze the stresses in a fixture under high-cycle loading to ensure it can withstand long-term use.

I have extensive experience using various FEA software packages, and I am proficient in mesh generation, boundary condition definition, and result interpretation. In one project, FEA helped me identify a potential stress concentration point in a complex fixture design that wouldn’t have been obvious through traditional methods, enabling me to modify the design and prevent a potential failure in the field.

Q 15. How do you troubleshoot issues with existing fixtures?

Troubleshooting existing fixtures involves a systematic approach. First, I’d carefully document the problem: what’s failing, how frequently, and under what conditions? This includes gathering data like part rejection rates, cycle times, and operator observations. Then, I would visually inspect the fixture for wear, damage, or misalignment. This often reveals loose screws, worn clamping mechanisms, or damaged tooling. Next, I’d check the fixture’s setup parameters – are the locators correctly positioned? Are clamping forces adequate? Are there any interferences? If the issue persists, I might use measurement tools like dial indicators or CMMs to pinpoint dimensional inaccuracies. For example, if a part is consistently out of tolerance, measuring the fixture’s key dimensions can determine if the fixture itself is the root cause. Finally, I’d consider the machine and process parameters. Are there vibrations or thermal variations affecting the fixture’s performance? A thorough investigation often involves a combination of these methods to isolate the root cause, ensuring a robust solution.

For instance, I once worked on a fixture used in a high-speed milling operation where parts were consistently warped. Initial inspection showed minor wear on the clamping pads. However, further investigation revealed inconsistent clamping pressure due to a faulty pneumatic system. Addressing the pneumatic issue resolved the warping problem.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with GD&T (Geometric Dimensioning and Tolerancing).

Geometric Dimensioning and Tolerancing (GD&T) is crucial for ensuring part quality and fixture accuracy. My experience with GD&T encompasses interpreting and applying GD&T symbols and tolerances on engineering drawings. I understand the implications of different tolerances, including positional, form, orientation, and runout tolerances. I frequently use GD&T in fixture design to define the allowable variations in fixture components, ensuring the final part remains within the specified tolerances. This involves selecting appropriate tolerance zones for locating features, considering the impact of thermal expansion, and ensuring the fixture itself doesn’t introduce errors.

For example, when designing a fixture to hold a part for precise machining, I’d specify positional tolerances for the locating pins and clamping mechanisms, preventing variations in part placement that would lead to out-of-tolerance features. Understanding GD&T ensures the fixture’s dimensional accuracy directly contributes to consistent part quality.

Q 17. How do you ensure the cost-effectiveness of a fixture design?

Cost-effectiveness in fixture design is a balancing act between functionality and expense. I achieve this through several strategies. First, I carefully select materials, opting for readily available and cost-effective materials whenever possible without compromising strength or durability. I also explore different manufacturing processes to find the most economical option. For instance, using simpler machining methods like milling instead of more complex ones like EDM can reduce costs.

Modular design is also critical. Designing fixtures with interchangeable components allows for adaptation to different parts or variations, reducing the need for multiple, specialized fixtures. Finally, I prioritize simplicity in design. Overly complex designs increase manufacturing time and costs. A well-designed, straightforward fixture is usually the most cost-effective.

In a past project, by choosing a simpler design and readily available materials, I reduced fixture costs by 25% without affecting the quality of the parts produced.

Q 18. Explain your experience with different manufacturing processes (e.g., milling, turning, stamping).

My experience spans a wide range of manufacturing processes, including milling, turning, stamping, and more. Understanding these processes is fundamental to effective fixture design. For milling, I consider factors like cutting forces, chip removal, and fixture rigidity to prevent part deflection or chatter. With turning operations, I focus on work-holding stability to avoid vibrations and ensure smooth surface finishes. Stamping requires designing fixtures capable of withstanding high forces and preventing part deformation. Each process has its unique considerations, and my designs reflect that understanding. This includes selecting appropriate materials and designing fixtures that are compatible with the specific machine tools and automation equipment used in each process.

For example, a fixture for high-speed milling would differ significantly from one designed for a low-speed, high-precision turning operation, reflecting the different stresses and precision needs of each process. This understanding allows me to create robust and efficient fixtures for each application.

Q 19. How do you communicate technical information effectively to non-technical stakeholders?

Communicating technical information to non-technical stakeholders requires clear, concise language and visual aids. I avoid using technical jargon and instead opt for simple analogies or metaphors to explain complex concepts. Visual aids like diagrams, charts, and 3D models are highly effective in conveying design features and functionality. I tailor my communication style to the audience, focusing on the impacts relevant to their roles. For management, I emphasize the cost-effectiveness and time savings. For production staff, I highlight ease of use and maintenance.

Imagine explaining the intricacies of a clamping mechanism. Instead of delving into technical specifications, I might use the analogy of a vice grip, a universally understood clamping mechanism, to explain the fundamental principle of the more complex fixture. This ensures the message is understood and avoids confusion.

Q 20. What is your experience with design reviews and feedback incorporation?

Design reviews are an integral part of my design process. I actively participate in these reviews, presenting my designs and receiving feedback from engineers, manufacturing personnel, and quality control specialists. I find that diverse perspectives often identify potential issues or areas for improvement that I might have overlooked. I approach feedback constructively, considering all viewpoints and incorporating valuable suggestions into my designs. This iterative process significantly improves the final product, resulting in more robust and efficient fixtures.

For instance, in one project, a design review revealed a potential safety hazard that I hadn’t considered. The feedback led to a revised design that eliminated the risk, enhancing the safety and reliability of the fixture.

Q 21. How do you stay up-to-date with the latest advancements in fixture and tool design?

Staying current in fixture and tool design requires continuous learning. I regularly attend industry conferences and webinars to learn about new materials, manufacturing techniques, and design methodologies. I subscribe to industry publications and actively follow key players in the field. Additionally, I leverage online resources and professional networks to stay informed about the latest advancements. This proactive approach ensures my designs are cutting-edge, incorporating the latest innovations to create superior fixtures.

For example, keeping abreast of advancements in 3D printing technologies allows me to explore new approaches to fixture prototyping and manufacturing, potentially leading to cost savings and quicker turnaround times.

Q 22. Describe your experience with different types of tooling materials (e.g., steel, aluminum, plastics).

My experience spans a wide range of tooling materials, each chosen based on the specific application requirements. Steel, for instance, is a workhorse known for its high strength and durability. I’ve used various grades, from mild steel for less demanding applications to hardened tool steels like A2 and D2 for high-precision, high-wear tooling. The choice often hinges on the part material and the forces involved. For example, a fixture holding a delicate aluminum part would likely use softer steel to avoid damaging the workpiece. Aluminum, on the other hand, offers a great balance of strength and lightness, making it ideal for portable fixtures or those requiring quick setup and tear-down. However, its lower stiffness necessitates careful design considerations. Finally, plastics, such as high-performance polymers like PEEK or POM, find use in low-force applications, or where chemical resistance or electrical insulation is crucial. I’ve worked with plastic fixtures for electronic assembly, for example, where static discharge is a critical concern.

In one project, we were faced with choosing the material for a fixture used to hold complex automotive components during welding. The initial inclination was to use steel, given its robustness. However, the high heat involved necessitated exploring other options. We evaluated aluminum alloys, ultimately settling on a specific grade with excellent thermal conductivity and enhanced strength. This decision reduced warping and improved the fixture’s lifespan significantly, demonstrating the importance of material selection beyond mere strength.

Q 23. How do you handle design conflicts between functionality, cost, and manufacturability?

Balancing functionality, cost, and manufacturability in fixture design is a constant juggling act. I approach it systematically, employing a process of iterative refinement. It starts with clearly defining the functional requirements: what must the fixture do, and how accurately? This forms the baseline. Then, I explore various design options, evaluating their manufacturability – how easily and cost-effectively can they be produced? This includes assessing factors like material availability, machining complexity, and assembly time. Finally, I analyze the cost implications of each option, considering material costs, manufacturing processes, and potential tooling costs. This holistic view allows for informed decision-making.

For instance, a design might initially call for high-precision, complex castings. However, this can significantly increase costs and lead times. Through careful consideration, I might redesign the fixture to utilize simpler machined components or even weldments, reducing complexity and cost without compromising functionality. This might involve some compromises on accuracy, which are then carefully evaluated to ensure they are acceptable within the overall process tolerances.

Q 24. What are some common mistakes to avoid in fixture design?

Several common mistakes can derail even the best-intentioned fixture designs. One major pitfall is inadequate locating and clamping systems. Insufficient locating points can lead to inaccurate part positioning and inconsistent results. Similarly, improper clamping can cause workpiece distortion or damage, rendering the fixture useless. Another common error is neglecting to account for thermal expansion. If parts are heated or cooled during the process, differential expansion can cause misalignment, requiring careful thermal compensation in the fixture design. Ignoring ergonomic principles is another big issue; poorly designed fixtures can lead to operator fatigue and injury.

I once encountered a fixture where the clamping mechanism was poorly designed, resulting in inconsistent clamping force. This led to variations in the final product, causing significant rework and delays. To rectify this, I redesigned the clamping system to provide even and adjustable pressure distribution across the workpiece, significantly improving consistency and reducing production errors.

Q 25. Explain your understanding of ergonomic principles in fixture design.

Ergonomic principles are paramount in fixture design. A poorly designed fixture can lead to operator fatigue, repetitive strain injuries, and even workplace accidents. Key considerations include minimizing repetitive motions, optimizing reach distances, providing adequate support, and ensuring proper tool placement. For instance, tools should be easily accessible without excessive reaching or awkward postures. The fixture’s weight and overall size must be considered to minimize operator strain. Handles and controls must be properly positioned and sized for comfortable gripping. Furthermore, the operator’s line of sight should be unobstructed, facilitating clear vision of the work area.

In one project, we redesigned a fixture for assembling small electronic components. The original design required repetitive bending and twisting, leading to significant operator fatigue. By implementing ergonomic principles – optimizing reach, incorporating adjustable height settings, and redesigning the tool placement – we reduced operator strain and increased productivity. This resulted in a 20% increase in output and a significant reduction in reported workplace injuries.

Q 26. How do you validate the functionality and performance of a newly designed fixture?

Validating a newly designed fixture involves a multi-stage process. Initially, a thorough design review is conducted, involving simulations and stress analysis to assess its structural integrity and functionality. Following this, a physical prototype is built and rigorously tested. This often entails performing several trial runs, using the actual parts and process parameters. Dimensional checks are crucial, verifying that the fixture accurately positions and holds the workpiece. We might use Coordinate Measuring Machines (CMMs) to achieve high precision. We also monitor the fixture’s performance over extended periods to identify any potential issues like wear or deformation. Finally, the data gathered is carefully analyzed to make any necessary adjustments or modifications.

For example, in a recent project involving a large automotive part, we conducted finite element analysis (FEA) simulations to assess the fixture’s ability to withstand the clamping forces involved. The results of the FEA guided us in optimizing the fixture’s structure, ensuring it could withstand the applied loads without deformation. We then built and tested a prototype and continued adjustments until all performance criteria were met.

Q 27. Describe your experience with different types of locating and clamping systems.

My experience encompasses a broad range of locating and clamping systems. Locating systems, which define the part’s position, can range from simple pins and dowel pins for basic positioning, to more complex systems like three-plate fixtures and dedicated datum features for higher precision. Clamping systems vary considerably, including toggle clamps, cam clamps, pneumatic clamps, and hydraulic clamps. The choice depends on factors such as the workpiece geometry, material properties, required clamping force, cycle time, and overall system cost. For example, quick-release toggle clamps are ideal for applications requiring frequent fixture setup and tear-down, while hydraulic clamps offer precise and high clamping forces for robust applications.

In one project, we opted for a pneumatic clamping system for an automotive assembly fixture due to its speed, accuracy, and ability to provide consistent clamping pressure across multiple points. This eliminated the inconsistencies that were present with a previous manual clamping system, improving both part quality and production speed.

Q 28. How do you incorporate sustainability considerations into fixture design?

Sustainability is a growing concern in all aspects of engineering, and fixture design is no exception. I incorporate sustainability considerations through several key approaches: material selection, design for disassembly, and lifecycle assessment. Using recycled materials whenever possible is a key strategy. Selecting materials with high recyclability and low environmental impact is also crucial. Design for disassembly simplifies end-of-life processing, making it easier to reclaim valuable materials. Furthermore, a lifecycle assessment helps in evaluating the environmental impact of the fixture throughout its entire lifespan, from material extraction to disposal.

For example, I recently designed a fixture using recycled aluminum. This reduced the need for new material extraction, lowering the environmental impact. Moreover, the design was modular, facilitating easy disassembly and recycling of individual components at the end of the fixture’s useful life. The choice of aluminum also minimized the fixture’s overall weight, reducing the energy required for transportation and potentially leading to reduced carbon emissions in shipping.

Key Topics to Learn for Fixture and Tool Design Interview

- Design Principles: Understanding fundamental engineering principles like GD&T (Geometric Dimensioning and Tolerancing), material selection, and stress analysis as they apply to fixture and tool design.

- Fixture Design: Explore various fixture types (e.g., welding fixtures, machining fixtures, assembly fixtures), their applications, and the critical considerations for designing robust and efficient fixtures. This includes locating, clamping, and supporting workpieces.

- Tool Design: Gain a comprehensive understanding of different tooling methods (e.g., cutting tools, forming tools, stamping tools) and their design considerations, such as tool geometry, material selection, and wear mechanisms.

- Manufacturing Processes: Develop a strong understanding of relevant manufacturing processes such as machining, casting, forging, and welding, and how they influence fixture and tool design choices.

- CAD/CAM Software Proficiency: Showcase your expertise in relevant CAD/CAM software packages (e.g., SolidWorks, AutoCAD, Creo) used for designing and simulating fixtures and tools. Highlight your proficiency in creating detailed 2D and 3D models, including drawings and simulations.

- DFM (Design for Manufacturing): Demonstrate your ability to design fixtures and tools considering manufacturability, cost-effectiveness, and ease of assembly. This includes understanding tolerances, material costs, and manufacturing limitations.

- Problem-Solving and Troubleshooting: Be prepared to discuss your approach to problem-solving in fixture and tool design, including identifying potential issues, proposing solutions, and optimizing designs based on feedback and testing results.

- Safety and Ergonomics: Highlight your understanding of safety regulations and ergonomic principles in the design of fixtures and tools, focusing on operator safety and efficient work practices.

Next Steps

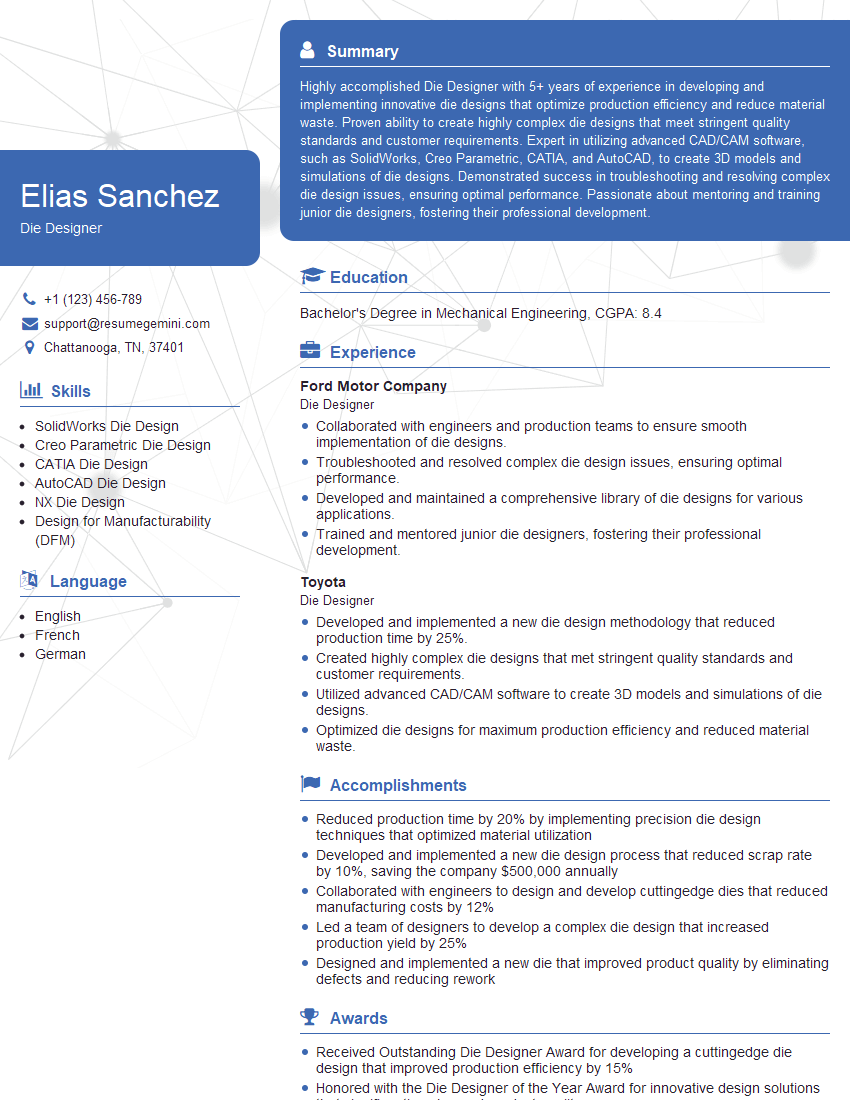

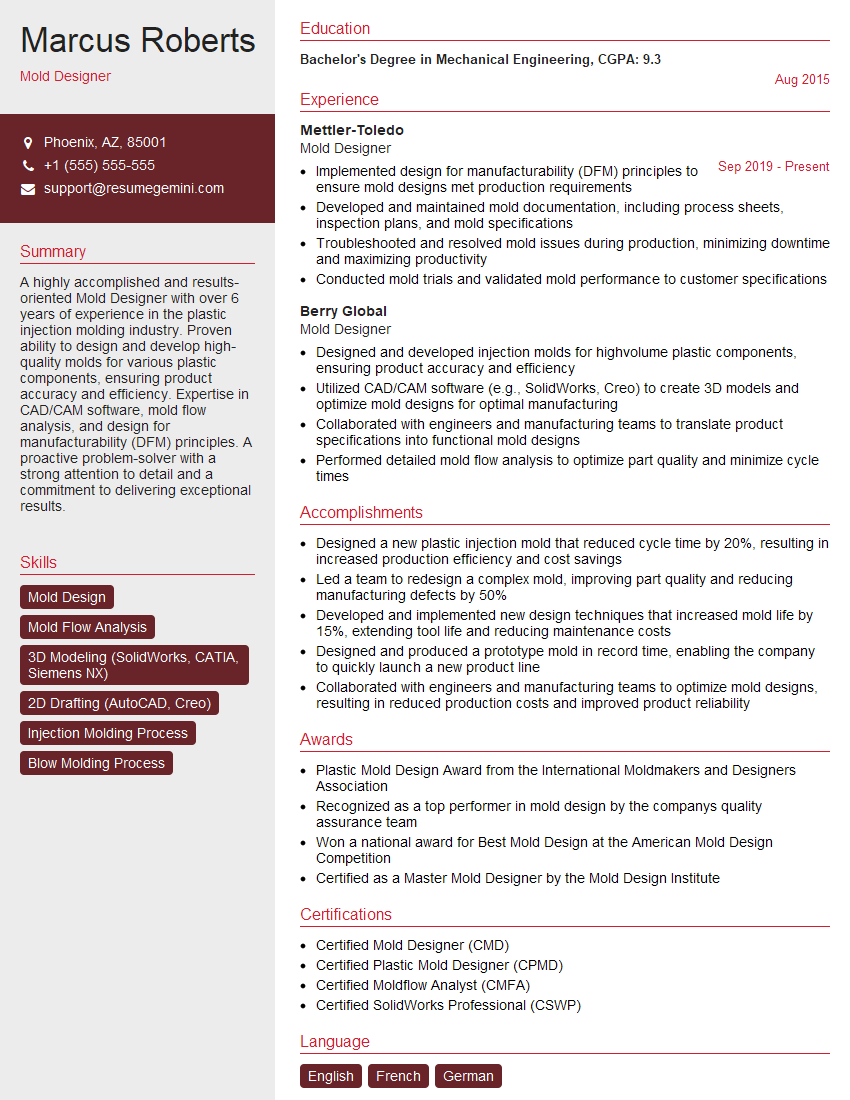

Mastering Fixture and Tool Design opens doors to exciting career opportunities with significant growth potential in manufacturing, automation, and engineering industries. A strong resume is your key to unlocking these opportunities. Building an ATS-friendly resume is crucial for getting your application noticed by recruiters. We highly recommend using ResumeGemini to craft a professional and effective resume that highlights your skills and experience. ResumeGemini offers examples of resumes specifically tailored to Fixture and Tool Design professionals, helping you present yourself in the best possible light to potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?