Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Floor Maintenance and Repair interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Floor Maintenance and Repair Interview

Q 1. Describe your experience with different types of floor finishes.

My experience encompasses a wide range of floor finishes, from the classic elegance of hardwood to the modern practicality of vinyl and tile. I’ve worked extensively with various types of hardwood finishes, including polyurethane (water-based and oil-based), varnish, shellac, and even more traditional methods like wax. With vinyl, I’m familiar with sheet vinyl, luxury vinyl plank (LVP), and luxury vinyl tile (LVT), each requiring different maintenance techniques. My expertise also extends to ceramic and porcelain tiles, understanding the importance of proper sealing and cleaning for these surfaces. For example, I recently completed a project refinishing a historic home’s hardwood floors using a traditional shellac finish, which required meticulous preparation and application to achieve a durable and authentic look. Conversely, I regularly work with LVP installations, prioritizing ease of cleaning and durability for busy family homes. Each finish presents unique challenges and rewards; understanding their properties is key to successful installation and long-term maintenance.

Q 2. What are the common causes of floor damage and how do you address them?

Floor damage stems from various sources. Heavy furniture can cause dents and scratches in hardwood. Excessive moisture leads to warping, cupping, and buckling in wood and damage to grout in tile. Abrasive cleaning methods can dull the finish on any floor type. High-traffic areas naturally show more wear and tear. Spills and stains, if not addressed promptly, can cause permanent discoloration. For example, a red wine spill left unattended on hardwood can permanently stain the wood. Addressing these issues requires a tailored approach. Dents can often be repaired with steam or wood filler. Moisture damage might require extensive repairs or even replacement. Proper cleaning techniques are essential for preventive maintenance. In cases of severe damage, professional repairs, such as sanding and refinishing, might be necessary.

Q 3. Explain your process for sanding and refinishing hardwood floors.

Sanding and refinishing hardwood floors is a meticulous process. It begins with a thorough assessment of the floor’s condition, identifying any significant damage that needs to be addressed prior to sanding. Next, I thoroughly clean the floor to remove any debris, dirt, or old finish. Then, I use a progressive sanding process, starting with coarser grit sandpaper and gradually moving to finer grits to achieve a perfectly smooth surface. This usually involves several passes with different grit sizes. Each pass removes a thin layer of wood. Once the sanding is complete, I carefully inspect the floor for imperfections. Finally, I apply the chosen finish, whether it’s polyurethane, varnish, or another type. This may involve multiple coats with drying time between each application. This whole process demands precision and patience; rushing can lead to uneven finishes and other problems. For example, I recently refinished a floor where a prior DIY attempt had left gouges in the wood. This required more aggressive sanding and extra care during the finishing process to achieve a satisfactory result.

Q 4. How do you determine the appropriate cleaning method for various floor types?

Choosing the right cleaning method depends heavily on the floor type. Hardwood floors, for example, require gentle cleaning methods, such as sweeping or using a slightly damp mop. Avoid excessive moisture, which can damage the wood. Tile floors, on the other hand, are typically more resistant to moisture and can be cleaned with more vigorous methods. Vinyl floors are relatively low-maintenance but should be cleaned using appropriate products that won’t damage the finish. Always check the manufacturer’s instructions for specific floor types. For example, never use harsh chemicals like bleach on hardwood floors, as it can damage the wood and its finish. A wrong choice of cleaning product or method can permanently damage any type of flooring, leading to costly repairs.

Q 5. What safety precautions do you take when working with floor cleaning chemicals?

Safety is paramount when working with floor cleaning chemicals. I always wear appropriate personal protective equipment (PPE), including gloves, eye protection, and sometimes a respirator, depending on the product. I ensure adequate ventilation in the work area, often using fans to circulate the air and remove fumes. I carefully read and follow the manufacturer’s instructions on the product label, paying close attention to dilution ratios and safety precautions. I never mix different chemicals together, as this can create hazardous reactions. I also make sure to store chemicals properly, away from children and pets, and in their original containers with clear labels. Furthermore, I educate my clients about proper handling and storage of any chemicals I may use on their floors.

Q 6. Describe your experience with repairing cracks and chips in ceramic tile.

Repairing cracks and chips in ceramic tile depends on the severity of the damage. Small chips can often be filled with epoxy-based fillers specifically formulated for tile repair. Larger cracks may require more extensive work, sometimes involving removing and replacing damaged tiles. Matching the existing tile color and texture is crucial for a seamless repair. Proper preparation of the surface before applying the filler is also key to preventing future issues. For instance, I once repaired a kitchen tile floor where a large chip had been left unattended for years. Careful removal of loose material and application of a colored epoxy filler made the repair nearly invisible. This involved using a color-matched filler to achieve a near-perfect match, paying close attention to blending the repair seamlessly with the surrounding tiles.

Q 7. How do you handle repairs to damaged grout?

Damaged grout can be repaired using grout color matching tools and careful filling techniques. For minor issues, you can sometimes simply clean out the old, damaged grout and replace it with new grout of the same color. Larger areas of damaged grout might require more extensive work, potentially involving cleaning the entire grout line before re-grouting. For effective and lasting repairs, you must use the appropriate tools for proper cleaning and application. Choosing the right grout and applying it correctly are vital to ensuring the success of your repair; a poorly done grout job will not last and will quickly degrade. Before starting, I always test the color on an inconspicuous area to ensure a perfect match, as this minimizes the impact of any minor color discrepancy.

Q 8. What are the different types of carpet and their maintenance requirements?

Carpet types vary greatly in fiber content, construction, and durability, each demanding a unique maintenance approach. Understanding these differences is crucial for proper care and longevity.

- Nylon: A strong, resilient fiber resistant to wear and stains. Regular vacuuming and occasional professional cleaning are usually sufficient. However, aggressive cleaning solutions can damage it.

- Polyester: Softer than nylon, it’s more prone to matting and crushing but resists staining well. Regular vacuuming with a low-pile setting and spot cleaning with appropriate solutions are key. Avoid excessive moisture.

- Olefin (Polypropylene): Highly stain-resistant and water-resistant, making it ideal for high-traffic areas. However, it’s less durable than nylon. Regular vacuuming and occasional cleaning with a solution designed for olefin are recommended.

- Wool: A luxurious natural fiber offering excellent resilience and insulation. It requires professional cleaning due to its sensitivity to harsh chemicals. Regular vacuuming with a good quality vacuum is a must.

For example, I once worked on a high-end home with wool carpets. Ignoring the manufacturer’s cleaning recommendations led to matting and discoloration. Proper maintenance, including professional cleaning every 12-18 months, is crucial for preserving its beauty and extending its lifespan.

Q 9. Explain your experience with carpet stretching and repair.

Carpet stretching and repair are essential for maintaining a carpet’s appearance and preventing further damage. My experience includes addressing issues like stretching, bunching, ripples, and seams coming apart.

For stretching, I utilize power stretchers to evenly distribute tension across the carpet, securing it to the tack strip. This requires careful measurement and technique to avoid damaging the fibers. For repairs, I’ve worked with patching damaged sections using matching carpet remnants and applying appropriate adhesive. Seam repairs involve carefully re-gluing and securing the seams. I’ve also addressed pet stains and tears using specialized repair kits and techniques.

One memorable project involved repairing a severely damaged carpet in a high-traffic office. The carpet was excessively worn, and the seams were separating. By carefully assessing the damage and using a combination of stretching, patching, and seam repair, I was able to restore the carpet’s appearance to a near-perfect state, saving the client significant expense compared to replacement.

Q 10. Describe your knowledge of various types of flooring adhesives.

Flooring adhesive selection depends critically on the flooring type and the subfloor’s condition. Choosing the wrong adhesive can lead to installation failures and costly repairs.

- Pressure-sensitive adhesives: These are easy to use and are suitable for certain types of flooring, such as vinyl sheet and some types of resilient flooring. They offer a good bond but are not suitable for heavy loads or high moisture areas.

- Water-based adhesives: These are environmentally friendly and commonly used for hardwood, laminate and some resilient floor coverings. They offer strong adhesion, but the drying time needs to be considered.

- Solvent-based adhesives: These adhesives provide excellent bonding strength but release strong fumes during application. They are usually employed for specialty flooring and require proper ventilation during and after installation.

- Epoxy adhesives: These provide extremely strong bonds, excellent resistance to moisture and chemicals, and are often selected for industrial settings, or where a very durable bond is necessary.

For example, using a pressure-sensitive adhesive for a hardwood floor would be a disastrous mistake, leading to loose planks and potential damage. Choosing the correct adhesive is paramount for a successful and long-lasting floor installation.

Q 11. How do you troubleshoot common problems with flooring installation?

Troubleshooting flooring installation problems requires a systematic approach. I start by identifying the specific issue, its location, and potential causes.

Common problems and solutions:

- Uneven subfloor: This leads to uneven flooring. Solution: Level the subfloor using self-leveling compound or other appropriate methods before installation.

- Poor adhesive application: Insufficient or uneven adhesive application results in loose tiles or planks. Solution: Carefully follow manufacturer’s instructions for adhesive application, ensuring complete coverage and correct drying time.

- Improper acclimation: Failure to acclimate flooring materials (especially hardwood) to the room’s temperature and humidity can cause expansion or contraction issues after installation. Solution: Follow manufacturer recommendations for acclimation prior to installation.

- Improper expansion gaps: Failure to leave proper expansion gaps around the perimeter of the room can lead to buckling. Solution: Leave adequate gaps according to the manufacturer’s specifications.

Recently, I encountered a situation where a newly installed hardwood floor was cupping. After careful investigation, I determined the problem stemmed from inadequate acclimation. By addressing the root cause, I was able to prevent further damage and successfully remedy the situation.

Q 12. What tools and equipment are essential for effective floor maintenance?

Effective floor maintenance requires a range of tools and equipment. The specific tools depend on the floor type, but some essentials include:

- Vacuum cleaner: A powerful vacuum with appropriate attachments is essential for removing loose dirt and debris from all floor types.

- Floor buffer/polisher: Used for polishing and buffing hard floors, especially those made of stone or hardwood.

- Wet/dry vacuum: Used for cleaning up spills and excess cleaning solutions, especially crucial when working with hard floors and tile.

- Floor cleaning solutions: Specialized cleaning solutions tailored to different floor types are essential to avoid damage.

- Mops and brushes: Various types of mops and brushes for different cleaning tasks and floor types.

- Scraper/putty knife: For removing stubborn adhesive or dirt residue.

- Protective gear: Gloves, safety glasses, and dust masks to protect against chemicals and dust.

The appropriate tools ensure efficient and effective cleaning, minimizing the risk of damage and maximizing the floor’s lifespan.

Q 13. How do you determine the appropriate type of sealant for a given floor?

Sealant selection depends heavily on the floor type, its intended use, and the environment it’s in. Different sealants offer varying levels of protection against moisture, chemicals, abrasion, and UV damage.

- Hardwood floors: Often sealed with polyurethane, which offers durability and protection against scratches and water. Different sheens are available.

- Stone floors: Sealants specifically designed for stone are necessary, offering protection against staining and etching. Penetrating sealers are often preferred for porous stones.

- Concrete floors: Sealants for concrete protect against staining, spalling, and dust. Epoxy sealants are common for high-traffic areas.

- Tile floors: Grout sealers prevent moisture and staining in grout lines. Some tile may need a specialized sealant.

For example, using a sealant designed for hardwood on a porous stone floor would be ineffective and could even damage the stone. Proper sealant selection is vital for preserving the beauty and longevity of the floor.

Q 14. Explain your experience with floor polishing and buffing techniques.

Floor polishing and buffing techniques are critical for maintaining the shine and luster of hard surface floors. These methods remove surface scratches and restore the floor’s original finish.

Polishing: Typically done using a floor polisher with a polishing pad, this process uses a fine abrasive to enhance the shine and luster. It’s often a final step after cleaning and buffing.

Buffing: Usually done before polishing, this involves using a buffer with a coarser pad to remove minor scratches and build up, leaving a smooth surface ready for polishing. It’s important to use the correct pads for each step and to avoid excessive pressure.

My experience includes working with various floor types, requiring different polishing and buffing techniques and products. For instance, marble floors require a gentler approach compared to more resilient materials. The selection of pads, speed, and polishing compound is crucial to avoid damaging the surface. Proper technique ensures a beautiful, long-lasting shine.

Q 15. What is your experience with concrete floor grinding and polishing?

Concrete grinding and polishing transforms dull, uneven concrete floors into smooth, aesthetically pleasing surfaces. My experience encompasses all phases, from initial assessment and surface preparation to the final polishing stages. This involves using specialized diamond-grinding tools of varying grits to progressively refine the concrete surface, removing imperfections and creating a highly polished finish. I’m proficient in selecting the appropriate grinding pads and techniques to achieve the desired level of sheen, whether it’s a matte, satin, or high-gloss finish. For instance, I once worked on a large warehouse where we needed to remove significant surface imperfections before applying a protective sealant. Careful grinding and multiple passes with different grit levels were crucial to ensuring a uniform, durable, and visually appealing final product.

The process also includes densifying the concrete, making it more resistant to staining and wear. This is achieved using specialized densifiers that penetrate the concrete’s pores, hardening and sealing the surface. I have extensive experience working with various densifiers and sealants, choosing the optimal product based on the specific requirements of the project and the client’s expectations. For example, in a food processing plant, we used a food-grade densifier to ensure hygiene and safety.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you prepare a floor for new flooring installation?

Preparing a floor for new flooring installation is critical for ensuring a long-lasting and aesthetically pleasing result. It involves several key steps that should not be overlooked. First, the existing floor must be thoroughly cleaned to remove any debris, dust, loose materials, or existing adhesive residue. This may involve sweeping, vacuuming, and potentially pressure washing depending on the type and condition of the subfloor. For example, I once had to remove old vinyl tiles using a scraper, which was painstaking but necessary to ensure the new tiles would adhere properly.

Next, the subfloor needs to be assessed for levelness. Any significant irregularities or unevenness must be addressed through leveling techniques, which might involve self-leveling compounds or the use of underlayment. Cracks or damage in the subfloor should be repaired using appropriate patching materials and techniques. Finally, the subfloor should be primed to enhance the adhesion of the new flooring. The type of primer selected depends on the new flooring material and the subfloor type; using an unsuitable primer can compromise adhesion and longevity.

Q 17. Describe your experience with epoxy floor coating installation.

Epoxy floor coating installation is a specialized process that requires precision and attention to detail. My experience includes all stages, from surface preparation to final curing. Before applying the epoxy, the concrete floor must be meticulously cleaned and primed to ensure optimal adhesion. The choice of primer is crucial; it should be compatible with both the concrete and the epoxy coating. Any cracks or imperfections in the concrete should be repaired before epoxy application to avoid issues later on.

The epoxy coating itself is applied in multiple layers, typically two or three, allowing each layer to cure completely before the next is applied. This multi-layer approach enhances durability and creates a seamless, visually appealing surface. I’m experienced in working with different types of epoxy coatings, including those with decorative flakes or quartz aggregates for added aesthetic value and slip resistance. For instance, I recently installed a high-performance epoxy coating in a mechanic’s garage, incorporating anti-slip additives for safety and a durable finish that could withstand chemicals and heavy equipment.

Proper curing is paramount; temperature and humidity must be controlled during the curing process to avoid imperfections or premature failure. I always follow the manufacturer’s recommendations meticulously to ensure the epoxy coating achieves its maximum performance and lifespan.

Q 18. Explain your understanding of floor leveling techniques.

Floor leveling is crucial for ensuring a smooth, level surface for new flooring installations or to correct existing unevenness. Several techniques exist, each suitable for different situations and levels of unevenness. For minor imperfections, a self-leveling compound may be sufficient. This is a pourable mixture that flows easily, self-levels, and dries to create a smooth surface. I often use this for smaller areas or when the unevenness is relatively minor. For larger areas or significant unevenness, I might employ techniques such as using a cement-based leveling compound or an underlayment. The selection depends on factors such as the severity of the unevenness, the type of flooring to be installed, and budget constraints.

Careful preparation is key. The existing floor must be thoroughly cleaned and primed before applying any leveling compound. The leveling compound must be mixed according to the manufacturer’s instructions to ensure proper setting and avoid cracking or other issues. I always ensure proper ventilation during the drying process, as some compounds emit fumes during curing.

Q 19. How do you assess the condition of a floor prior to repair or maintenance?

Assessing the condition of a floor before repair or maintenance involves a systematic approach. It starts with a visual inspection to identify obvious defects such as cracks, holes, stains, or loose tiles. This is followed by a more thorough assessment, which may involve using specialized tools. For example, a moisture meter can be used to detect moisture levels, which are crucial for diagnosing potential problems, such as water damage or inadequate subfloor drying. I also might use a level to check for unevenness and a hammer to tap on the floor to detect hollow sounds which could indicate delamination or other structural issues.

The assessment should also consider the type of flooring material. Different materials have varying strengths and weaknesses, and this information informs the choice of repair or maintenance strategy. The overall condition of the floor dictates the scope of work needed, informing the preparation of a detailed plan and quote for the client. The level of wear and tear and the intended use of the space both play a key role in making informed recommendations about the best course of action.

Q 20. What is your experience with water damage restoration related to floors?

Water damage restoration related to floors is a specialized area requiring prompt action to prevent further damage and protect the structural integrity of the building. My experience encompasses identifying the source of the water damage, assessing the extent of the damage to the floor structure, and executing the necessary repairs. This often involves removing affected flooring materials, allowing for complete drying, and then applying appropriate waterproofing and restoration techniques. In cases of severe damage, subfloor replacement may be necessary.

The process includes the use of moisture meters to monitor the drying process and ensure that the subfloor reaches a safe level of dryness before new flooring is installed. The choice of new flooring material should consider the potential for future water damage; moisture-resistant materials are usually preferred in areas prone to water leaks. In one instance, I worked on a kitchen where a burst pipe caused significant water damage to the wooden floor. We removed the damaged wood, thoroughly dried the subfloor using specialized equipment, and replaced it with a waterproof engineered wood floor, preventing future damage and restoring the functionality of the kitchen.

Q 21. Describe your experience working with different types of stone flooring.

I have significant experience working with various types of stone flooring, including marble, granite, limestone, slate, and travertine. Each stone has unique properties that influence how it’s installed, maintained, and repaired. For example, marble is known for its elegance but is susceptible to etching from acidic substances. Granite is harder and more resistant to scratches and stains. Understanding these properties is vital for providing the right care and maintenance recommendations.

My experience encompasses the installation of stone flooring, including the preparation of the subfloor, the proper setting of the stone tiles, and the application of grout and sealant. I am proficient in various installation methods, such as thin-set and thick-set, selecting the appropriate technique based on the stone type, the subfloor, and the desired result. Maintenance and repair of stone floors often involve cleaning, polishing, and repairing damaged areas using appropriate materials and techniques. I have experience with color matching and repairing chips and cracks in stone flooring to maintain its aesthetic appeal and structural integrity. For example, I recently restored a historic building’s marble floors, carefully repairing chipped edges and filling cracks using a color-matched epoxy filler before polishing the entire surface back to its former glory.

Q 22. How do you maintain and troubleshoot floor cleaning equipment?

Maintaining floor cleaning equipment is crucial for efficiency and longevity. It involves regular cleaning, proper storage, and timely repairs. Troubleshooting involves identifying the problem, isolating the cause, and implementing a solution.

- Regular Cleaning: After each use, empty and rinse all tanks and containers. Wipe down the machine’s exterior to remove dirt and debris. For auto-scrubbers, check and clean the brushes and squeegee regularly.

- Preventive Maintenance: Regularly check fluid levels (water, cleaning solution), belts, and brushes for wear and tear. Replace worn parts promptly. This proactive approach prevents larger, more costly repairs down the line. Think of it like changing your car’s oil – it’s preventative care.

- Troubleshooting: If a machine malfunctions, first check the obvious: power cord, water supply, solution dispensing system. Consult the machine’s manual for specific troubleshooting guides. For example, if your vacuum isn’t picking up, check for clogs in the hose or filter. If the auto-scrubber isn’t dispensing solution, check the solution tank and pump.

- Storage: Store equipment in a dry, secure location, away from extreme temperatures. This protects it from damage and extends its lifespan.

Following these steps will significantly extend the lifespan of your equipment, reduce downtime, and maintain a high standard of cleanliness.

Q 23. What are the common causes of floor squeaking and how do you fix them?

Floor squeaking is a common annoyance, often stemming from loose floorboards or insufficient lubrication between wood components. Addressing it requires careful diagnosis and targeted repair.

- Loose Floorboards: The most frequent cause is loose floorboards rubbing against each other. This can be easily identified by tapping the suspect area and noting the movement. Fixing it usually involves tightening the screws or nails securing the boards, or, in more serious cases, using construction adhesive to re-secure them.

- Insufficient Lubrication: Dry wood expands and contracts, leading to friction and squeaking. Applying a lubricating agent like talcum powder, dry graphite, or specialized floor lubricant into the gaps between floorboards can quiet the noise. A common method is to use a bellows or straw to direct the lubricant precisely.

- Worn-out Subfloor: In more advanced cases, the subfloor itself may be damaged or worn, causing the squeaking. This requires more extensive repair, potentially involving subfloor replacement. It’s important to investigate the extent of the damage before proceeding with any solutions.

Remember to test each fix before moving on to the next. Using a methodical approach will help you identify and efficiently address the underlying problem.

Q 24. How do you handle customer complaints related to floor maintenance?

Handling customer complaints effectively involves active listening, empathy, and a problem-solving approach. It’s crucial to take ownership of the issue and offer solutions promptly and professionally.

- Active Listening: Allow the customer to fully explain their complaint without interruption. Use phrases like ‘I understand your frustration’ to show empathy.

- Investigate the Issue: Thoroughly inspect the area of concern to understand the nature of the problem. Take photos or videos as necessary for documentation.

- Offer a Solution: Propose a reasonable solution, which might involve re-cleaning, repairing the damage, or offering compensation for the inconvenience. Be realistic and transparent about the timeline for resolution.

- Follow Up: Once the issue is resolved, follow up with the customer to ensure they are satisfied. This demonstrates your commitment to customer service and builds trust.

An example: If a customer complains about streaks left after a cleaning, I would apologize, examine the area, determine the cause (perhaps the wrong cleaning solution or technique), and re-clean the area using the correct method. I’d then follow up to ensure they’re satisfied with the results.

Q 25. What is your experience with different types of floor stripping and waxing?

Stripping and waxing floors is a common practice to restore shine and protect floor surfaces. Different floor types require specific approaches.

- Types of Strippers: There are various types of floor strippers, including water-based, solvent-based, and green strippers. Water-based strippers are generally safer and easier to use but may require multiple applications. Solvent-based strippers are more aggressive and effective on heavy wax buildup but require more caution due to their strong chemical composition. Green strippers are environmentally friendly options.

- Types of Wax: Wax options range from emulsion polishes (water-based) to self-glossing sealers and high-gloss acrylic finishes. Emulsion polishes are easier to apply and maintain, while high-gloss finishes offer a durable, high-shine finish. The choice depends on the floor type and the desired level of shine and protection.

- Application Process: The process generally involves thoroughly cleaning the floor, applying the stripper, letting it dwell, scrubbing to remove old wax, rinsing, and then applying the new wax in several thin coats. Each coat is allowed to dry before the next is applied.

My experience includes working with various floor types, from vinyl and terrazzo to hardwood and concrete, and utilizing different stripping and waxing techniques to achieve optimal results.

Q 26. Explain your knowledge of relevant health and safety regulations regarding floor maintenance.

Health and safety regulations concerning floor maintenance are paramount and vary by location. Compliance is critical to prevent injuries and maintain a safe work environment.

- Personal Protective Equipment (PPE): This includes gloves, eye protection, respirators (for working with strong chemicals), and safety footwear to protect against slips, trips, and falls.

- Chemical Handling: Following manufacturers’ instructions for dilution, application, and storage of cleaning and stripping chemicals is vital. Proper ventilation is crucial to prevent exposure to hazardous fumes.

- Slip and Trip Hazards: Maintaining a clean and dry work area, using warning signs and cones when necessary, and properly storing equipment are crucial in preventing accidents.

- Ergonomics: Using proper lifting techniques and taking breaks to prevent strain and injury is important, particularly for repetitive tasks such as stripping and waxing.

- Waste Disposal: Proper disposal of waste materials, according to local regulations, is crucial. This often involves separating chemical waste from other waste streams.

Adherence to these regulations is not just a matter of compliance; it is a demonstration of a commitment to the well-being of workers and customers.

Q 27. How do you manage your time and prioritize tasks effectively in a floor maintenance role?

Effective time management and task prioritization are key to success in floor maintenance. This often involves planning, organization, and efficient execution.

- Daily Planning: Beginning each day with a clear plan, prioritizing tasks based on urgency and importance. This could involve creating a schedule or using a task management app.

- Prioritization Matrix: Using a prioritization matrix (like Eisenhower Matrix) to categorize tasks based on urgency and importance helps focus on the most critical tasks first.

- Efficient Workflow: Organizing tools and supplies in advance to minimize wasted time during execution. This might involve prepping cleaning solutions or gathering necessary equipment ahead of time.

- Delegation: If working with a team, delegating tasks effectively can increase efficiency and allow everyone to focus on their strengths.

- Regular Review: Regularly reviewing schedules and adjusting plans as needed, to account for unexpected events or changes in priorities.

For example, in a busy office building, I would prioritize cleaning high-traffic areas before less-used areas. I’d also schedule more intensive tasks like floor stripping and waxing during off-peak hours to minimize disruption.

Q 28. Describe a challenging floor repair project you successfully completed.

One challenging project involved repairing extensive water damage to a hardwood floor in a historic building. The damage included significant warping, cupping, and mold growth.

- Assessment: The first step was a thorough assessment of the damage, including determining the extent of water penetration and the condition of the subfloor.

- Water Damage Mitigation: The affected area was thoroughly dried using specialized dehumidifiers. Mold was removed using appropriate cleaning solutions.

- Repair: Damaged boards were carefully removed and replaced with matching hardwood planks. Existing boards were sanded and refinished to match the new ones. The subfloor was inspected and repaired where necessary.

- Refinishing: Once all repairs were complete, the entire floor was sanded, stained, and sealed to restore its original beauty.

Successfully completing this project required expertise in water damage restoration, carpentry skills, and knowledge of hardwood floor refinishing techniques. It demonstrated the value of meticulous attention to detail and a systematic approach to complex repairs.

Key Topics to Learn for Floor Maintenance and Repair Interview

- Floor Cleaning Techniques: Understanding various cleaning methods for different floor types (hardwood, tile, carpet, etc.), including appropriate cleaning agents and equipment. Practical application: Describing your experience with strip and wax procedures, or deep carpet cleaning.

- Floor Repair & Restoration: Identifying and addressing common floor damage such as scratches, cracks, stains, and water damage. Practical application: Explaining your experience with wood floor refinishing, tile repair, or carpet patching.

- Floor Finishing & Sealing: Applying sealants and finishes to protect and enhance floor surfaces. Practical application: Detailing your experience with different types of finishes and their application methods, including safety precautions.

- Equipment Operation & Maintenance: Safe and efficient operation and maintenance of floor cleaning and repair equipment (buffers, vacuums, polishers, etc.). Practical application: Explaining your preventative maintenance routines and troubleshooting skills.

- Safety Procedures & Regulations: Adherence to safety protocols, including proper handling of chemicals and equipment. Practical application: Describing your experience with OSHA regulations and safety training.

- Estimating & Project Management: Accurately estimating project costs and timelines, and managing projects efficiently. Practical application: Explain your experience in planning and executing floor maintenance projects from start to finish.

- Customer Service & Communication: Effective communication with clients and colleagues, addressing concerns and ensuring client satisfaction. Practical application: Describing a situation where you exceeded customer expectations.

Next Steps

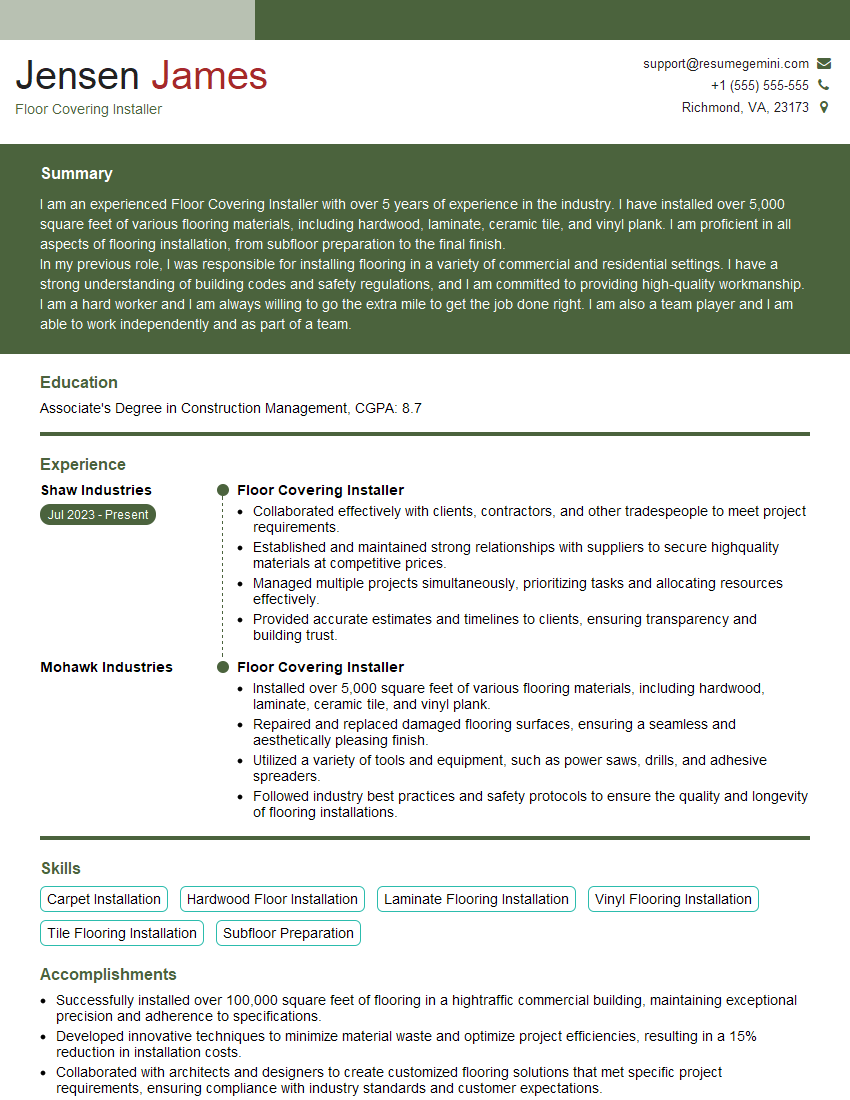

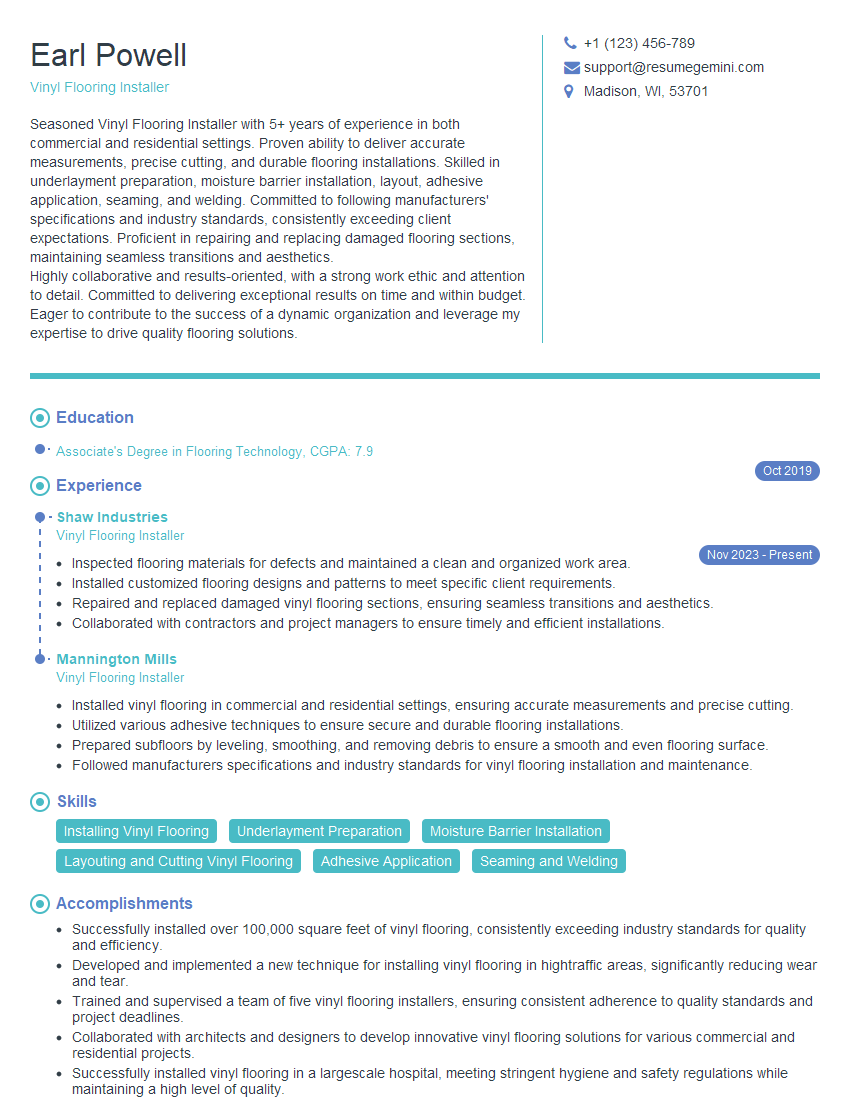

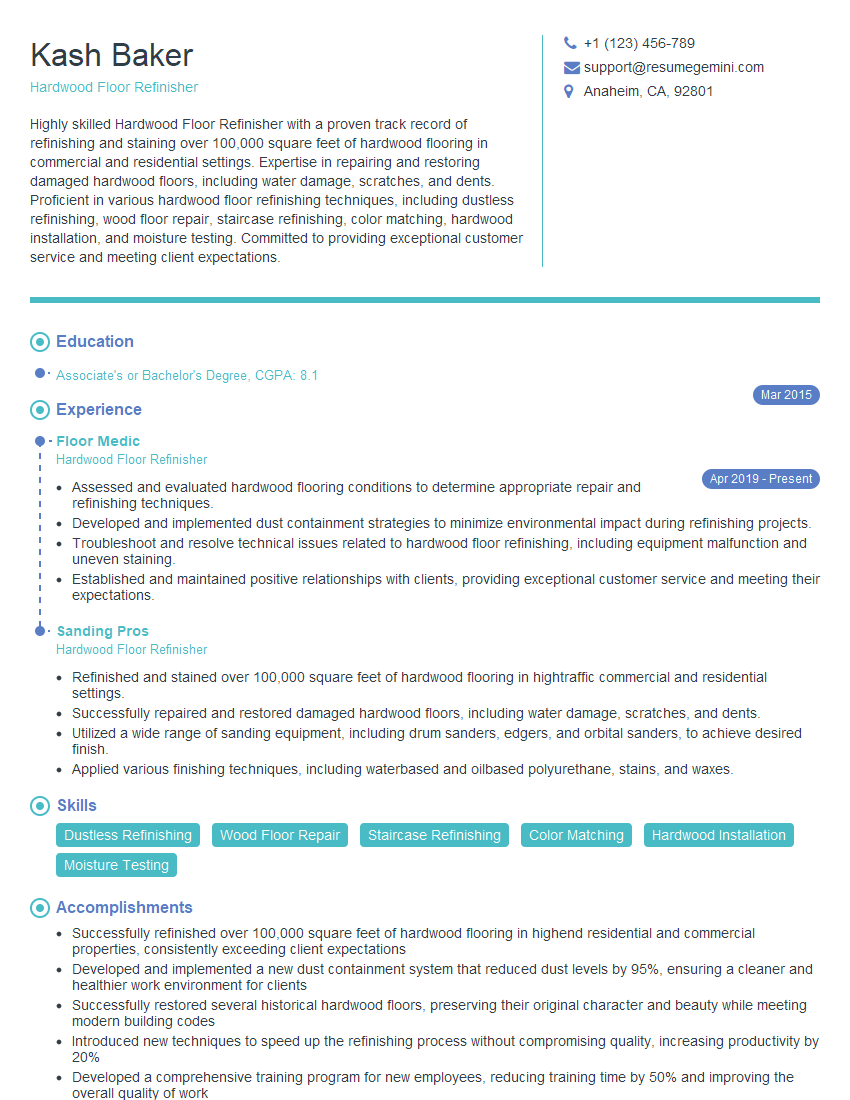

Mastering Floor Maintenance and Repair opens doors to a rewarding career with excellent growth potential. Advancement opportunities abound, from crew lead to supervisor and beyond, offering increased responsibility and earning potential. To maximize your job prospects, it’s crucial to present yourself effectively. Creating an ATS-friendly resume is key to getting your application noticed by recruiters. ResumeGemini is a trusted resource to help you build a professional, impactful resume that highlights your skills and experience. Examples of resumes tailored specifically to Floor Maintenance and Repair are available to guide you. Take the next step towards your dream career today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

hello,

Our consultant firm based in the USA and our client are interested in your products.

Could you provide your company brochure and respond from your official email id (if different from the current in use), so i can send you the client’s requirement.

Payment before production.

I await your answer.

Regards,

MrSmith

hello,

Our consultant firm based in the USA and our client are interested in your products.

Could you provide your company brochure and respond from your official email id (if different from the current in use), so i can send you the client’s requirement.

Payment before production.

I await your answer.

Regards,

MrSmith

These apartments are so amazing, posting them online would break the algorithm.

https://bit.ly/Lovely2BedsApartmentHudsonYards

Reach out at [email protected] and let’s get started!

Take a look at this stunning 2-bedroom apartment perfectly situated NYC’s coveted Hudson Yards!

https://bit.ly/Lovely2BedsApartmentHudsonYards

Live Rent Free!

https://bit.ly/LiveRentFREE

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?