Preparation is the key to success in any interview. In this post, we’ll explore crucial Floor Preparation and Smoothing interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Floor Preparation and Smoothing Interview

Q 1. Describe the different methods for preparing concrete floors for coating.

Preparing concrete floors for coating involves several crucial steps to ensure a durable and aesthetically pleasing finish. Think of it like preparing a canvas before painting a masterpiece – you wouldn’t start without prepping the surface! The methods vary based on the existing floor condition and the type of coating to be applied. Common methods include:

- Cleaning: Thoroughly removing dirt, dust, grease, oil, and other contaminants using appropriate methods like sweeping, vacuuming, and pressure washing. This is the foundation of any successful floor preparation.

- Grinding: Using diamond grinders to remove imperfections, level the surface, and increase its porosity for better adhesion. This can range from light profile grinding to aggressive scarifying, depending on the needs.

- Shot Blasting: A more aggressive method than grinding, using high-velocity steel shot to profile the concrete and remove laitance (a weak layer of cement paste on the surface). Ideal for extremely rough surfaces or when creating very high-porosity profiles.

- Acid Etching: Using a dilute acid solution to chemically etch the surface, increasing its porosity and improving bonding for coatings. Care must be taken to ensure proper ventilation and safety precautions.

- Repairing: Addressing any cracks, holes, or spalls using appropriate patching compounds. It’s vital to ensure these repairs are fully cured before proceeding.

The specific combination of these methods will depend on the project requirements.

Q 2. What are the key factors to consider when selecting a floor smoothing technique?

Choosing the right floor smoothing technique depends on several key factors. Imagine selecting the right tool for a specific job – a hammer wouldn’t be ideal for screwing in a screw! Here’s what to consider:

- Existing Floor Condition: Is the floor heavily damaged, slightly uneven, or relatively smooth? This dictates the level of intervention needed.

- Desired Level of Smoothness: Different applications have varying smoothness requirements. A high-gloss epoxy coating demands a much smoother surface than a simple paint finish.

- Type of Coating: The coating material itself will influence the necessary level of preparation. Some coatings are more forgiving of minor imperfections than others.

- Budget: Different smoothing techniques have varying costs, impacting the overall project budget.

- Time Constraints: Some methods are quicker than others. A tight deadline might influence the choice of technique.

- Environmental Concerns: Consider the dust generation and potential for noise pollution, especially in occupied spaces.

Balancing these factors ensures the selection of an efficient and cost-effective smoothing method.

Q 3. Explain the process of diamond grinding and its applications.

Diamond grinding is a powerful floor preparation technique that uses specialized grinding machines fitted with diamond-impregnated abrasive segments. Think of it like sanding, but on a much larger and more powerful scale. The process involves progressively using finer grit diamond segments to achieve the desired surface profile and smoothness. The process typically involves:

- Initial Grinding: Using coarser grit segments to remove significant imperfections, laitance, and contaminants.

- Intermediate Grinding: Switching to medium grit segments to further refine the surface and level any remaining irregularities.

- Final Grinding: Employing fine grit segments for a smooth and polished finish, ready for coating.

Applications: Diamond grinding is widely used in various settings, including:

- Commercial settings: Preparing floors for epoxy coatings in warehouses, retail spaces, and industrial facilities.

- Residential settings: Smoothing concrete floors in garages, basements, and workshops before applying coatings.

- Industrial applications: Preparing concrete surfaces for specialized coatings with high abrasion and chemical resistance.

The versatility of diamond grinding makes it a preferred method for a wide range of floor preparation projects.

Q 4. How do you ensure proper moisture mitigation before floor preparation?

Moisture mitigation is crucial before floor preparation, especially when applying coatings sensitive to moisture vapor. High moisture levels can cause blistering, delamination, and other coating failures. Think of it as preventing a foundation crack in your paint job!

Here’s how to ensure proper moisture mitigation:

- Moisture Testing: Conducting thorough moisture testing using methods like in-situ probes or calcium chloride tests to determine the moisture content of the concrete slab.

- Moisture Vapor Retarders (MVRs): Applying MVRs to the slab if moisture levels are too high. These are specialized membranes that restrict moisture vapor transmission.

- Allowing Sufficient Drying Time: Providing ample time for the concrete to dry naturally, often several weeks or even months, depending on factors like slab thickness, ambient conditions, and concrete composition.

- Dehumidification: Using dehumidifiers to accelerate the drying process in enclosed spaces.

- Ventilation: Improving air circulation to encourage moisture evaporation.

Proper moisture testing and mitigation are essential for long-term coating success.

Q 5. What are the different types of self-leveling compounds and their uses?

Self-leveling compounds (SLCs) are crucial for achieving a perfectly smooth and level floor surface. They are essentially pourable mixtures that self-level under their own weight, filling in imperfections and creating a smooth base for coatings. Different types exist, categorized by their properties and applications:

- Cement-based SLCs: These are common, cost-effective options suitable for various applications. They offer good strength and durability but have a longer drying time.

- Gypsum-based SLCs: These are faster-drying than cement-based options, making them ideal for quicker turnaround projects. They are usually less durable than cement-based options and better suited for indoor applications.

- Polymer-modified SLCs: These incorporate polymers to improve their properties, such as strength, durability, and flexibility. They often offer faster drying and better crack resistance.

- Epoxy-based SLCs: These provide exceptional durability and chemical resistance, ideal for demanding industrial settings. They are more expensive and require careful application.

The choice depends on the project requirements, such as the desired drying time, durability, and budget constraints.

Q 6. Describe the safety precautions necessary when operating floor grinding equipment.

Operating floor grinding equipment requires strict adherence to safety procedures to prevent accidents and injuries. It’s not just about the tools; it’s about protecting yourself and others.

- Personal Protective Equipment (PPE): Always wear appropriate PPE, including safety glasses, respirators (to prevent inhaling dust), hearing protection, and sturdy work boots.

- Machine Operation: Ensure you are properly trained on the operation of the grinding equipment and follow manufacturer’s instructions.

- Dust Control: Implement dust collection systems, such as HEPA vacuum systems, to minimize dust generation and improve air quality. Consider using dust suppressants.

- Emergency Procedures: Be prepared for emergencies and have a clear understanding of emergency shut-off procedures. Know the location of first-aid kits and emergency contacts.

- Work Area Safety: Ensure the work area is adequately lit, well-ventilated, and free of obstacles to prevent tripping hazards.

- Proper Maintenance: Regularly inspect and maintain the equipment to prevent malfunctions. Replace worn-out parts promptly.

Following these safety protocols is non-negotiable for the safe and efficient operation of floor grinding equipment. Remember: safety is paramount!

Q 7. How do you identify and repair cracks in a concrete floor?

Identifying and repairing cracks in a concrete floor is crucial for maintaining its structural integrity and preventing further damage. Early detection and proper repair prevent costly problems down the line.

Identification: Cracks should be inspected for their type, size, width, and location. This helps determine the appropriate repair method. Some common types include:

- Hairline cracks: Thin cracks with minimal width.

- Map cracks: Network of interconnected cracks.

- Shrinkage cracks: Cracks resulting from concrete shrinkage during curing.

- Settlement cracks: Cracks caused by underlying foundation issues.

Repair: Repair methods depend on the crack type and severity. For smaller cracks, methods include:

- Epoxy injection: Filling cracks from below with epoxy resin for structural strengthening.

- Crack sealing: Filling cracks with specialized crack sealants that adhere well to concrete. This is mostly a cosmetic fix.

For larger cracks or structural damage, more extensive repairs might be needed, involving demolition and replacement of the damaged section of concrete. Professional assessment is recommended for significant cracks.

Q 8. What are the common causes of floor imperfections and how can they be addressed?

Floor imperfections arise from various sources, impacting the final look and durability of the floor. Common culprits include cracks, chips, uneven surfaces, adhesive residue, and ingrained dirt. Addressing these issues requires a tailored approach.

- Cracks and Chips: These can be repaired using epoxy or concrete patching compounds, ensuring a smooth transition. The choice of material depends on the crack’s size and location. For example, hairline cracks might only require filling, while larger ones might need more extensive repair.

- Uneven Surfaces: Grinding and polishing are frequently used to level the surface and create a consistent profile. The extent of grinding depends on the severity of the unevenness.

- Adhesive Residue: This can be removed using specialized solvents or mechanical methods such as scraping or grinding. The choice of method depends on the type of adhesive.

- Ingrained Dirt: Thorough cleaning, potentially including pressure washing, is crucial before any surface treatment. This ensures proper adhesion of coatings.

Identifying the root cause of the imperfection is vital for choosing the most effective solution. A simple crack might require just filling, whereas extensive damage might require a complete overlay.

Q 9. Explain the importance of proper surface profiling before applying coatings.

Proper surface profiling is paramount before applying coatings because it ensures the coating adheres correctly, promoting longevity and preventing premature failure. Think of it like painting a wall – you wouldn’t paint over a bumpy, uneven surface and expect a flawless finish. Similarly, a poorly profiled floor will lead to an uneven coating, potentially cracking or peeling.

Profiling provides a consistent surface for the coating to bond with, maximizing adhesion. It also creates an ideal surface roughness (profile), which ensures proper mechanical bonding.

Ignoring this crucial step can lead to costly rework, as the coating will not last and might fail prematurely, potentially leading to safety hazards.

Q 10. How do you determine the appropriate level of floor smoothness for a given application?

The required level of floor smoothness depends entirely on the intended application and the type of coating being used. For example, a high-gloss epoxy floor in a showroom needs significantly smoother surface preparation than a concrete floor in a warehouse.

Smoothness is often measured using a profilometer which determines the average surface profile (as per ISO standards). This instrument measures the height variations on the surface, allowing us to specify the level of smoothness required. For example, a low-traffic area might only require a profile of 0.2 mm whereas high-traffic area might only accept 0.05mm profile.

We use industry standards and the coating manufacturer’s recommendations to determine the acceptable profile and thus define the grinding process to ensure its achievement.

Q 11. What are the different types of floor coatings and their suitability for various applications?

There’s a wide range of floor coatings available, each with its own unique properties and best-suited application:

- Epoxy Coatings: Excellent chemical resistance, durability, and aesthetic appeal. Ideal for industrial settings, healthcare facilities, and high-traffic areas.

- Polyurethane Coatings: Offers good abrasion resistance and flexibility. Suitable for both indoor and outdoor applications, including garages and warehouses.

- Acrylic Coatings: Cost-effective option for moderate-traffic areas. Provides a good level of protection but is less durable than epoxy or polyurethane.

- Solvent-Based Coatings: Generally offer greater hardness and chemical resistance, but require careful ventilation during application. Suitable for high-traffic and high-demand areas.

- Water-Based Coatings: Environmentally friendly, low odour options with relatively easy application. Typically used for lower-traffic applications and where environmental concerns are paramount.

Selecting the appropriate coating depends on factors like anticipated foot traffic, chemical exposure, aesthetic requirements, and budget considerations.

Q 12. Describe your experience with shot blasting and its applications in floor preparation.

Shot blasting is a powerful surface preparation technique that uses high-velocity steel shot to remove contaminants and create a textured profile on concrete surfaces. It’s particularly effective for removing old coatings, laitance (weak surface layer on newly poured concrete), and other surface imperfections.

In my experience, shot blasting provides a superior profile compared to grinding for certain applications – improving concrete’s bonding strength. It’s especially valuable in situations where a highly textured surface is needed to enhance coating adhesion. I’ve utilized this method extensively in industrial floor projects, often preparing the substrate for epoxy coatings where exceptional bonding is essential.

However, it’s important to note that shot blasting generates significant dust and noise, demanding stringent safety precautions. This necessitates careful planning and adherence to all health and safety regulations.

Q 13. How do you manage dust and debris during floor grinding and polishing operations?

Dust and debris control is paramount during floor grinding and polishing, protecting both workers’ health and the quality of the finished floor. We employ a multi-pronged approach:

- HEPA Vacuum Systems: High-efficiency particulate air (HEPA) vacuums are indispensable, capturing almost all dust particles generated during grinding and polishing. We use vacuums specifically designed for this purpose and ensure regular filter changes.

- Water Misting Systems: These systems effectively suppress dust generation during grinding. The fine water mist binds to dust particles, preventing their release into the air.

- Containment Systems: In some cases, we use containment systems such as plastic sheeting and sealing to minimize dust spread beyond the work area.

- Personal Protective Equipment (PPE): Workers always wear respirators, safety glasses, and appropriate clothing to protect themselves from dust inhalation and other hazards.

Regular monitoring of dust levels is crucial to ensure we’re maintaining a safe and clean working environment.

Q 14. What are the different types of floor grinding equipment and their advantages/disadvantages?

Several types of floor grinding equipment are available, each with its own set of advantages and disadvantages:

- Handheld Grinders: These are smaller and more versatile, ideal for smaller projects or hard-to-reach areas. However, they are less efficient than larger machines for large surface areas.

- Walk-Behind Grinders: More powerful and efficient than handheld grinders, suitable for medium to large projects. Operator skill is essential to control evenly.

- Ride-on Grinders: Highly productive for large-scale projects, these machines offer high speed and efficiency but require a skilled operator and significant space for maneuverability.

- Planetary Grinders: These machines use multiple grinding heads, enabling very high-speed surface preparation and increased efficiency. They are suitable for larger projects where a uniform finish is crucial.

The selection of the right equipment depends on the size of the project, the desired level of smoothness, the budget, and the operator’s skill level.

Q 15. How do you ensure the proper adhesion of coatings to prepared floor surfaces?

Proper adhesion of coatings to prepared floor surfaces is paramount for a durable and long-lasting finish. It all starts with a clean, dry, and properly profiled substrate. Think of it like painting a wall – you wouldn’t expect good adhesion if the wall was dusty, greasy, or covered in flaking paint. Similarly, the floor needs to be optimally prepared.

- Cleaning: Thorough cleaning is crucial. This often involves mechanical methods like shot blasting or diamond grinding to remove old coatings, contaminants, and laitance (a weak layer of cement paste on concrete surfaces). Chemical cleaning may also be necessary to remove stubborn stains or residues.

- Profiling: The surface needs the correct profile to provide mechanical interlocking for the coating. This can range from a smooth, polished surface for some coatings, to a more textured profile achieved through grinding or blasting to improve adhesion for others, especially epoxy coatings. The correct profile is determined by the type of coating and substrate.

- Moisture Management: Excessive moisture can significantly compromise adhesion. Moisture meters are used to assess moisture content before proceeding. If moisture levels are too high, specialized primers or delay tactics may be employed to allow for proper drying before coating application.

- Priming: Primers act as an intermediary between the substrate and the final coating. They enhance adhesion, improve the coating’s flow and leveling, and can also offer added protection against moisture intrusion. The choice of primer is critical and depends on the type of substrate and coating.

For instance, on a concrete floor with residual oil stains, we’d first use a degreaser, then mechanically profile the surface with a diamond grinder, and finally apply a suitable epoxy primer before the final epoxy coating. Ignoring any of these steps significantly increases the risk of coating failure – peeling, blistering, or delamination.

Career Expert Tips:

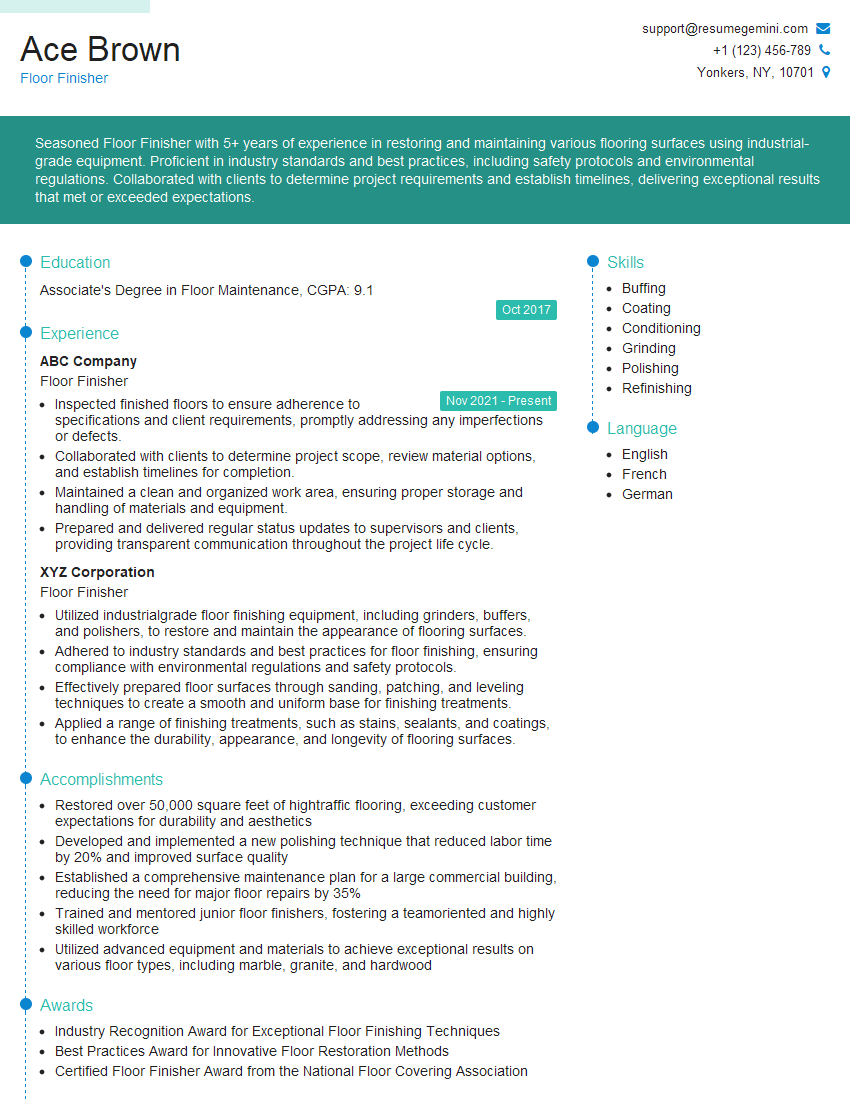

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with epoxy floor installations.

I have extensive experience with epoxy floor installations, encompassing various applications and substrates. From high-performance industrial floors in manufacturing facilities to aesthetically pleasing decorative floors in commercial settings, I’ve worked on a wide range of projects.

- System Selection: My experience includes selecting the appropriate epoxy system – self-leveling, broadcast flake, quartz, or other specialized systems – based on the specific requirements of the project, including anticipated loads, chemical resistance, aesthetic considerations and budget.

- Surface Preparation: I ensure meticulous surface preparation, which is critical for the success of any epoxy installation. This involves assessing the existing floor condition, selecting the right methods for cleaning and profiling, and managing moisture content to optimize adhesion.

- Installation Techniques: My expertise covers all aspects of the installation process, from the precise mixing and application of epoxy components to ensuring proper curing conditions. I’m proficient in using various tools and techniques, including trowels, squeegees, and specialized broadcast equipment.

- Troubleshooting: I have successfully addressed various challenges encountered during epoxy installations, such as pinholes, fisheyes, or uneven surfaces, by identifying the root cause and implementing corrective measures.

One memorable project involved installing a chemical-resistant epoxy floor in a pharmaceutical manufacturing plant. Meeting stringent hygiene and chemical resistance requirements demanded meticulous attention to detail throughout the entire process. We used a specialized epoxy with superior chemical resistance and followed a strict cleaning and surface preparation protocol to ensure a flawless, long-lasting installation.

Q 17. What is your experience with different types of concrete?

My experience spans various types of concrete, each with unique properties affecting floor preparation and finishing:

- Standard Concrete: This is the most common type and requires typical preparation, involving cleaning, grinding, and potentially crack repair depending on the condition.

- High-Strength Concrete: This type is denser and harder, demanding more aggressive grinding techniques to achieve the desired profile for optimum coating adhesion.

- Polymer-Modified Concrete: These concretes offer enhanced strength and durability, but preparation may require specialized techniques to avoid damaging the surface. Sometimes, less aggressive methods like shot blasting are preferred.

- Colored Concrete: Requires careful preparation to avoid damaging the existing color and ensure the new coating is compatible with the existing finish.

- Degraded Concrete: Damaged or deteriorated concrete needs thorough assessment before preparation. This may involve repairing significant cracks, spalling, or other defects before proceeding to cleaning and profiling.

Understanding the specific characteristics of each concrete type is crucial for selecting appropriate preparation methods and ensuring the longevity of the final floor finish. For example, attempting to grind a high-strength concrete floor with inadequate equipment can damage the grinding tools and leave an unsatisfactory surface. Conversely, using overly aggressive methods on a polymer-modified concrete floor can damage the surface.

Q 18. Explain the importance of proper ventilation during floor preparation and finishing.

Proper ventilation during floor preparation and finishing is crucial for worker safety and the quality of the finished product. Many materials used, such as epoxy resins, solvents, and sealers, release volatile organic compounds (VOCs) that can be harmful if inhaled in high concentrations. Adequate ventilation removes these harmful fumes and prevents them from building up to dangerous levels.

- Worker Safety: VOCs can cause various health problems, including headaches, nausea, dizziness, and respiratory issues. Sufficient ventilation minimizes worker exposure and protects their health.

- Coating Quality: Insufficient ventilation can slow down curing, leading to the formation of bubbles or other defects in the coating. Proper airflow ensures faster and more effective curing, resulting in a higher-quality finish.

- Fire Prevention: Some materials are flammable, and proper ventilation reduces the risk of fire hazards associated with fumes accumulating near ignition sources.

In practice, this often involves using industrial-grade exhaust fans, opening doors and windows, and possibly using specialized ventilation equipment based on the project’s scale and materials used. Neglecting proper ventilation is a significant safety and quality risk, potentially leading to costly rework or even health complications for the workers involved. Always adhere to all safety guidelines and relevant OSHA regulations.

Q 19. What are your troubleshooting skills regarding floor preparation issues?

Troubleshooting floor preparation issues requires a systematic approach. I begin with a thorough visual inspection to identify the problem’s nature and severity. Then, I use a combination of testing and analysis to pinpoint the root cause.

- Identifying the Problem: Is the issue poor adhesion, surface imperfections, unevenness, or something else?

- Root Cause Analysis: What caused the problem? Was it improper cleaning, inadequate profiling, moisture issues, or incorrect material selection?

- Testing and Measurement: Moisture meters, pull-off tests, and other testing methods are used to gather data and support the diagnosis.

- Corrective Actions: Based on the diagnosis, I implement appropriate corrective measures, which may include additional cleaning, profiling, or application of repair materials.

For instance, if I encounter poor adhesion of a coating, I might investigate the moisture content of the substrate, the cleanliness of the surface, and the compatibility of the primer and coating. If excessive moisture is found, I would employ drying techniques or specialized primers before re-applying the coating. If the problem is surface contamination, thorough cleaning and proper profiling would be necessary before proceeding.

Q 20. Describe your experience working with different types of sealers and their applications.

My experience includes working with various types of sealers, each suited for specific applications and substrates:

- Epoxy Sealers: Excellent chemical resistance and durability, often used as a base coat under epoxy coatings or as a standalone sealer for high-traffic areas.

- Acrylic Sealers: Offer good water resistance and are often used on interior concrete floors, providing a more aesthetic finish.

- Urethane Sealers: Known for high abrasion and chemical resistance, often utilized in industrial environments.

- Penetrating Sealers: These sealers soak into the concrete, reducing dust and improving moisture resistance. They’re commonly used on porous concrete floors.

The application method also varies depending on the sealer type. Some are applied by roller or brush, while others require specialized equipment. Selecting the right sealer is critical, as an improper choice can result in poor performance or even compromise the longevity of the floor finish. For example, using an acrylic sealer in a chemical-processing facility would be inappropriate due to its limited chemical resistance.

Q 21. How do you handle unexpected issues or problems during a project?

Handling unexpected issues requires a calm and methodical approach. My first step is to assess the situation and identify the problem. Then, I communicate clearly with the client, outlining the issue and potential solutions. Following this, I develop a plan to mitigate the problem, focusing on minimizing disruption and ensuring project completion.

- Assessment: What exactly went wrong? What is the impact on the project timeline and budget?

- Communication: Keep the client informed, providing updates on the situation and proposed solutions. Transparency is key.

- Problem-Solving: Implement the most efficient and cost-effective solution. This may involve adjusting the schedule, sourcing alternative materials, or employing specialized techniques.

- Documentation: Meticulously document all changes, challenges, and solutions for future reference and learning.

Once, during an epoxy floor installation, we encountered unexpected subsurface moisture. Instead of proceeding, we immediately communicated the issue to the client, explained the potential implications, and proposed a solution involving a delay to allow the floor to dry and using a moisture-tolerant epoxy system. Open communication and proactive problem-solving prevented project delays and ensured client satisfaction.

Q 22. What are your experience with different types of resin flooring?

My experience with resin flooring encompasses a wide range of types, including epoxy, polyurethane, and methyl methacrylate (MMA) systems. Each type offers unique properties making them suitable for different applications. For example, epoxy resin is known for its exceptional chemical resistance and durability, making it ideal for industrial environments. Polyurethane resin, on the other hand, boasts superior flexibility and impact resistance, often preferred for areas with high foot traffic or potential for impact damage. MMA resin is renowned for its rapid curing time, making it perfect for projects with tight deadlines. I’ve worked extensively with all three, understanding their individual strengths and limitations, allowing me to recommend and execute the optimal choice for any given project. I’ve personally overseen projects involving heavy-duty industrial floors, sterile environments in healthcare settings, and aesthetically pleasing, high-traffic retail spaces, each requiring a specific resin system tailored to the demands.

Beyond the primary types, I also have hands-on experience with various colored and textured resin finishes, including metallic and quartz finishes that offer both functional and decorative advantages. This broad experience allows me to effectively consult with clients on the best resin choice to meet both their functional requirements and aesthetic preferences.

Q 23. How do you maintain your equipment to ensure optimal performance and safety?

Maintaining my equipment is paramount to ensuring both optimal performance and the safety of myself and others on the job site. My routine involves a meticulous cleaning process after every project, removing any residual material from grinders, polishers, and other tools. This prevents cross-contamination and ensures the equipment remains in top condition. Regular servicing and inspection are crucial; I carefully check for wear and tear on grinding discs, ensuring they are properly balanced to avoid vibrations that can lead to damage or injury. I also regularly check the functionality of safety features such as emergency stop buttons and dust extraction systems. Keeping accurate maintenance logs helps track servicing schedules and identify potential issues early on. For example, if I notice a grinder’s motor is starting to overheat, I address it promptly, preventing a potential breakdown in the middle of a project. This proactive maintenance approach ensures the longevity of the equipment and contributes to a safe and productive work environment.

Q 24. What quality control methods do you employ during floor preparation?

Quality control is integrated into every step of the floor preparation process. Before starting any work, I conduct a thorough site survey, meticulously documenting the existing floor condition, including assessing moisture levels, identifying cracks or other defects, and determining the necessary preparation steps. During the preparation phase, I employ various methods to ensure a level and smooth surface. This might involve diamond grinding to remove old coatings, scarification to prepare the substrate for better adhesion, and the use of laser leveling tools to achieve the required tolerances. Regular visual inspections are carried out throughout the process, and moisture meters are used to verify dryness. Photographs and detailed progress reports are consistently maintained to document each step and to provide evidence of the quality of our work. In one recent project, a slight irregularity was detected during our initial survey. By carefully addressing this beforehand, we avoided significant issues later in the project, ensuring the finished floor met the highest quality standards.

Q 25. How do you ensure the floor meets the specified tolerances and finishes?

Meeting specified tolerances and achieving the desired finish requires precise planning and execution. Laser leveling is instrumental in achieving accurate surface planarity, enabling us to meet tight tolerance requirements. We use calibrated equipment and regularly check measurements against project specifications. For finishes, we adhere strictly to the manufacturer’s guidelines for resin application, ensuring proper mixing ratios and curing times. After application, we use specialized polishing techniques to achieve the desired level of sheen and smoothness. Visual inspection, coupled with the use of straight edges and surface profile gauges, helps us confirm compliance with project specifications. Any deviations are immediately addressed before proceeding to the next step. A client recently required a highly polished floor for a showroom. By rigorously implementing our quality control measures, we not only met but exceeded their expectations, resulting in a stunning and exceptionally smooth final product.

Q 26. Describe your experience with project planning and scheduling related to floor preparation.

Project planning and scheduling are crucial for successful floor preparation. I begin by carefully reviewing project specifications, identifying the scope of work, and estimating the required materials and labor. A detailed schedule is then created, outlining each phase of the project, including site preparation, surface grinding, priming, resin application, and final polishing. This schedule accounts for potential delays and allows for flexibility. I utilize project management software to track progress, manage resources, and maintain communication with the project team. For example, in a recent large-scale project, we anticipated potential material delivery delays. We proactively built contingency time into the schedule, enabling us to complete the project on time despite the unforeseen circumstances.

Q 27. How do you communicate effectively with clients and other professionals on a project?

Effective communication is vital to a successful project. I maintain open communication with clients from the initial consultation to project completion. Regular updates are provided, including progress reports, photographs, and addressing any concerns promptly. Clear and concise language is used, avoiding technical jargon when possible. With other professionals on the project, such as architects or contractors, I collaborate using shared online platforms for documentation and scheduling, ensuring transparency and efficiency. A recent project involved close coordination with a construction manager. Regular meetings and clear communication ensured a seamless integration of our floor preparation work with the overall construction timeline.

Q 28. What are your long-term career goals in the field of floor preparation and smoothing?

My long-term career goals include further developing my expertise in specialized resin flooring systems and advanced floor preparation techniques. I aspire to become a recognized leader in the industry, sharing my knowledge and experience through mentorship and training. I aim to contribute to the advancement of sustainable flooring solutions, promoting environmentally friendly products and practices. Ultimately, I envision establishing a reputation for delivering exceptional quality, exceeding client expectations, and contributing to the advancement of the floor preparation and smoothing field.

Key Topics to Learn for Floor Preparation and Smoothing Interview

- Subfloor Assessment and Repair: Understanding different subfloor types (concrete, wood, etc.), identifying defects (cracks, moisture issues, unevenness), and selecting appropriate repair techniques.

- Moisture Mitigation: Methods for detecting and addressing moisture problems in subfloors, including the use of moisture meters and vapor barriers. Practical application: Explaining your experience with dealing with high-moisture situations and preventing future issues.

- Surface Preparation Techniques: Detailed knowledge of grinding, sanding, patching, and priming techniques for various floor coverings (e.g., tile, hardwood, epoxy). Practical application: Describing your experience with different tools and materials used in surface preparation and your ability to choose the right method for a specific project.

- Self-Leveling Compounds: Understanding the properties of self-leveling compounds, their application methods, and troubleshooting potential problems like air bubbles or uneven setting. Practical application: Explaining your experience mixing, pouring, and finishing self-leveling compounds to achieve a perfectly smooth surface.

- Floor Covering Compatibility: Knowledge of the requirements for different floor coverings and how subfloor preparation needs to be tailored to ensure proper adhesion and longevity. Practical application: Describing your experience preparing subfloors for specific floor coverings like vinyl, ceramic tile, or hardwood.

- Health and Safety Regulations: Understanding and adhering to relevant safety regulations, including the use of personal protective equipment (PPE) and proper handling of chemicals. Practical application: Demonstrating your commitment to a safe work environment.

- Troubleshooting and Problem-Solving: Ability to identify and solve common problems encountered during floor preparation and smoothing, such as uneven surfaces, cracking, or delamination. Practical application: Providing specific examples of problems you’ve encountered and how you successfully resolved them.

Next Steps

Mastering floor preparation and smoothing is crucial for career advancement in the construction and flooring industry. It demonstrates a high level of technical skill and attention to detail, leading to greater responsibility and higher earning potential. To maximize your job prospects, it’s essential to create a professional and ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource to help you build a compelling resume that showcases your abilities in this specialized field. We provide examples of resumes tailored to Floor Preparation and Smoothing to guide you in creating a standout application.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?