Warning: search_filter(): Argument #2 ($wp_query) must be passed by reference, value given in /home/u951807797/domains/techskills.interviewgemini.com/public_html/wp-includes/class-wp-hook.php on line 324

Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Food Handler’s Certification interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Food Handler’s Certification Interview

Q 1. What are the four critical control points for food safety?

The four critical control points for food safety are crucial steps in preventing foodborne illnesses. Think of them as the four pillars holding up safe food handling. They are:

- Purchasing/Receiving: Ensuring food is obtained from reputable sources and is stored properly upon arrival. This includes checking for signs of spoilage or damage and verifying temperatures.

- Storage: Maintaining proper temperatures (refrigeration or freezing) and preventing cross-contamination in storage areas. Imagine your fridge as a highly organized system, separating raw meats from ready-to-eat foods.

- Preparation: Following safe food handling practices during cooking preparation, like thorough handwashing, preventing cross-contamination, and cooking to the correct internal temperature. This stage is all about minimizing risks before the food hits the heat.

- Cooking/Serving: Cooking food to the correct internal temperature to kill harmful bacteria and serving food promptly at the right temperature to prevent bacterial growth. This ensures that the food is safe to eat.

Each of these points requires careful attention to detail. A lapse in any one of them can compromise the safety of the food.

Q 2. Explain the temperature danger zone for food.

The temperature danger zone is the range of temperatures where bacteria multiply most rapidly. This is typically between 41°F (5°C) and 135°F (57°C). Think of it as the ‘danger zone’ because bacteria thrive within this range, potentially causing foodborne illnesses. Keeping food outside of this range is crucial for safety.

For example, leaving cooked chicken at room temperature for several hours within the danger zone will allow harmful bacteria to multiply rapidly to unsafe levels, potentially leading to food poisoning. Imagine that bacteria are having a party in the food – they have a great time and multiply exponentially within this temperature range.

Q 3. How long can potentially hazardous foods be left at room temperature?

Potentially hazardous foods should not be left at room temperature for more than two hours. This limit is crucial because, within this timeframe, the temperature encourages bacteria growth. After two hours, the risk of foodborne illness significantly increases. In warmer environments (above 90°F or 32°C), this time limit is reduced to just one hour.

Imagine a picnic on a hot summer day. If you leave your potato salad out for more than two hours, the bacteria will have plenty of time to multiply, leading to potential illness.

Q 4. Describe proper handwashing techniques.

Proper handwashing is fundamental to preventing the spread of foodborne illnesses. It’s a simple yet incredibly effective measure. Here’s a step-by-step guide:

- Wet your hands with warm water.

- Apply soap and lather thoroughly for at least 20 seconds (sing the ‘Happy Birthday’ song twice!).

- Scrub all surfaces of your hands, including between fingers and under your nails.

- Rinse thoroughly under warm running water.

- Dry your hands using a clean towel or air dryer.

Remember to wash your hands frequently, especially after using the restroom, handling raw food, touching your face, or coughing/sneezing. It’s a simple habit that can make a huge difference.

Q 5. What are the symptoms of foodborne illness?

Symptoms of foodborne illness vary depending on the causative agent (bacteria, virus, or parasite) and the individual’s immune system, but common symptoms include:

- Nausea

- Vomiting

- Diarrhea

- Stomach cramps

- Fever

- Chills

- Headache

- Muscle aches

If you experience these symptoms after eating, it’s crucial to seek medical attention. Don’t hesitate to contact your doctor, especially if the symptoms are severe or persistent.

Q 6. How do you prevent cross-contamination?

Cross-contamination occurs when harmful bacteria from one food source transfer to another. Preventing it requires careful attention to detail. Here are key strategies:

- Separate raw and cooked foods: Use different cutting boards, utensils, and containers. Imagine having dedicated tools for raw meat, and another set for ready-to-eat salads.

- Wash hands frequently: Especially after handling raw food.

- Clean and sanitize surfaces: Use hot, soapy water and a sanitizing solution to clean cutting boards and other surfaces after handling raw food. This is critical to eliminate bacteria left behind.

- Refrigerate foods promptly: Store cooked and raw foods separately at the correct temperatures.

- Avoid cross-contact: Prevent raw meat juices from dripping onto other foods. Ensure proper wrapping and storage of meats.

By following these guidelines diligently, you can significantly reduce the risk of cross-contamination and maintain food safety.

Q 7. What is the proper way to thaw frozen food?

There are three safe methods for thawing frozen food:

- Refrigerator thawing: This is the safest method. Place the food in the refrigerator and allow it to thaw slowly. This ensures even thawing and minimizes bacterial growth. Plan ahead as this method takes time, often overnight for larger items.

- Cold water thawing: Submerge the food in cold water, changing the water every 30 minutes to maintain a cold temperature. This method is faster than refrigerator thawing but still minimizes bacterial growth, as the water temperature stays below the danger zone.

- Microwave thawing: Use the defrost setting on your microwave. Cook the food immediately after thawing as it won’t be evenly thawed, and some parts might be in the danger zone.

Never thaw food at room temperature, as this drastically increases the risk of bacterial growth within the danger zone.

Q 8. Explain the importance of proper food storage.

Proper food storage is crucial for preventing foodborne illnesses and maintaining food quality. It involves protecting food from contamination and ensuring it’s kept at the correct temperature to inhibit the growth of harmful bacteria.

- Temperature Control: Refrigerate perishable foods promptly at 40°F (4°C) or below. Think of your refrigerator as a safe haven for food – keeping it cold slows bacterial growth significantly. Freezing at 0°F (-18°C) or below halts bacterial growth altogether.

- First-In, First-Out (FIFO): Older food should always be used before newer food. Imagine your refrigerator as a conveyor belt; the food that arrived first is the food that should be used first.

- Packaging and Wrapping: Store food in airtight containers to prevent cross-contamination and preserve freshness. Raw meat should be stored on lower shelves to prevent dripping onto other food items.

- Proper Location: Avoid storing food directly on the floor or near areas that could harbor pests. Think about how you organize your home pantry – you want everything easily accessible, but also clean and organized.

For example, imagine a restaurant that fails to refrigerate its chicken properly. Bacteria could rapidly multiply, causing food poisoning in customers, leading to potential health risks and damage to the restaurant’s reputation.

Q 9. What are the different types of foodborne pathogens?

Foodborne pathogens are microorganisms that can cause illness when consumed. There are many types, but some of the most common include:

- Bacteria: Salmonella (often found in poultry and eggs), E. coli (often found in undercooked ground beef and contaminated produce), Listeria (can grow even at refrigerator temperatures), and Staphylococcus aureus (often found in improperly handled food).

- Viruses: Norovirus (highly contagious and often spread through contaminated food or surfaces) and Hepatitis A (transmitted through contaminated food and water).

- Parasites: Toxoplasma gondii (found in undercooked meat) and Giardia lamblia (found in contaminated water).

- Fungi: Certain molds and yeasts can produce toxins that cause illness.

Understanding these pathogens allows food handlers to implement preventive measures, such as cooking food to safe internal temperatures and practicing good hygiene.

Q 10. How do you clean and sanitize food contact surfaces?

Cleaning and sanitizing food contact surfaces is a two-step process that’s vital for preventing cross-contamination.

- Cleaning: Remove visible dirt and debris. This usually involves washing the surface with hot, soapy water, often using a detergent designed for food service. Imagine scrubbing away all the residue from a dirty plate – the goal is to get it visibly clean.

- Sanitizing: Kills or reduces the number of harmful microorganisms remaining on the surface. This is typically done using a sanitizing solution, such as a bleach solution (follow manufacturer’s instructions carefully!) or a commercial sanitizer. Think of this step as giving the surface a final disinfecting bath to eliminate any lingering bacteria.

After cleaning and sanitizing, allow the surface to air dry. Using a clean, dry towel could reintroduce contaminants. This whole process is crucial to ensuring all surfaces used in food preparation are safe and clean.

Q 11. Describe the proper use of a thermometer in food preparation.

A food thermometer is a crucial tool for ensuring food is cooked to a safe internal temperature, killing harmful bacteria. Proper use involves:

- Calibrating the Thermometer: Check the thermometer’s accuracy regularly, often by immersing it in ice water (should read 32°F/0°C). Regular calibration ensures accurate readings.

- Inserting the Thermometer Properly: Insert the thermometer into the thickest part of the food, avoiding bone or fat. The thermometer needs to be inserted into the heart of the food to get a true temperature reading.

- Waiting for a Stable Reading: Don’t remove the thermometer until the temperature has stabilized. A fluctuating reading might indicate the food is still cooking.

- Knowing Safe Temperatures: Be aware of the minimum safe internal temperatures for different foods (e.g., 165°F/74°C for poultry, 160°F/71°C for ground meats). These temperatures are set to destroy harmful bacteria.

For instance, undercooked chicken can harbor Salmonella, which could make someone extremely ill. A food thermometer ensures the chicken reaches a safe temperature.

Q 12. What are the guidelines for receiving and storing food deliveries?

Receiving and storing food deliveries properly is essential for maintaining food safety. The process should include:

- Checking Temperatures: Verify that refrigerated and frozen foods are at the correct temperatures upon delivery. Use a thermometer to check these temperatures against safe thresholds.

- Inspecting Food Condition: Examine food for any signs of damage, spoilage, or tampering. Look for dents, tears, or unusual smells and appearances.

- Proper Storage: Store food promptly according to its temperature requirements. This is critical; do not leave foods at room temperature for extended periods.

- Maintaining Documentation: Keep records of food deliveries, including the supplier, date, and temperature readings. This allows for tracing potential problems.

Imagine a delivery of frozen fish arrives with a noticeably high temperature. This indicates potential spoilage, necessitating prompt rejection and action.

Q 13. How do you identify and handle spoiled food?

Identifying and handling spoiled food involves recognizing visual and sensory cues.

- Visual Clues: Look for mold growth, discoloration, unusual texture changes (e.g., slimy or sticky), or signs of pest infestation.

- Sensory Clues: Check for off-odors or unpleasant smells and tastes. Even a subtle change can indicate spoilage.

If food shows signs of spoilage, it should be discarded immediately. Do not taste test spoiled food to determine if it is still safe; when in doubt, throw it out. Spoiled food can harbor harmful bacteria and cause illness.

For example, if you see mold growing on bread or cheese, discard it immediately. Even a small amount of mold can spread, rendering the entire food unsafe for consumption.

Q 14. What is your understanding of FIFO (First-In, First-Out) inventory system?

FIFO, or First-In, First-Out, is an inventory management system where the oldest items are used first. This prevents food spoilage and reduces waste. Imagine a grocery store shelf – products with the earliest expiration dates are placed at the front to ensure they get used first. This system can be applied to all food items.

Applying FIFO is straightforward. When receiving new food deliveries, place newer items behind older ones. When preparing food, use the older items first to minimize waste and ensure freshness. Regular stock rotation using FIFO can significantly reduce the risk of food spoilage and potential foodborne illnesses.

Q 15. Explain the importance of personal hygiene in food handling.

Personal hygiene is paramount in food handling because it directly impacts food safety. Our hands, hair, and clothing can harbor bacteria, viruses, and other pathogens that can easily contaminate food, leading to foodborne illnesses. Think of it like this: your hands are constantly touching surfaces, and if you don’t wash them properly, you’re essentially transferring those germs to the food you’re preparing.

- Handwashing: Frequent and thorough handwashing is crucial, especially after using the restroom, handling raw meat, and touching potentially contaminated surfaces. We should use soap and warm water for at least 20 seconds, scrubbing thoroughly between fingers and under fingernails.

- Clean Clothing: Wearing clean clothing, including hair restraints, prevents hair and other debris from falling into food. Think about how a stray hair can easily end up in a salad or soup.

- Proper Wound Care: Any open wounds must be covered with a waterproof bandage to prevent contamination. Imagine the potential spread of bacteria from an uncovered cut while preparing food!

- Avoiding Touching Face: It’s important to avoid touching your face, especially eyes, nose, and mouth, to prevent the transfer of germs from your hands to your face, and then potentially to food.

Following these simple steps significantly reduces the risk of foodborne illnesses and ensures the food is safe for consumption. Maintaining good personal hygiene is not just a best practice but a legal requirement in most food service establishments.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you prevent pests from contaminating food?

Preventing pest contamination requires a multi-pronged approach focusing on sanitation, exclusion, and monitoring. Pests are attracted to food sources, warmth, and moisture, so eliminating these attractants is key.

- Sanitation: Regular cleaning is fundamental. This includes wiping down surfaces, sweeping floors, and properly storing food in sealed containers to prevent attracting insects or rodents. Think of it like cleaning your home – the cleaner it is, the less appealing it becomes to pests.

- Exclusion: Preventing pests from entering is equally vital. This involves sealing cracks and holes in walls and floors, using screens on windows and doors, and ensuring that garbage is disposed of properly in sealed containers. A common example is ensuring proper sealing of food storage areas.

- Monitoring: Regularly inspecting the premises for signs of pest activity is crucial for early detection. This might include checking for droppings, gnaw marks, or live pests. Early identification allows for quicker intervention and prevents widespread contamination.

- Professional Pest Control: In severe cases, professional pest control is necessary. They use specialized techniques to eliminate existing infestations and prevent future problems. This is particularly important if you identify a rodent problem.

A comprehensive pest control program combines these strategies to create a hygienic environment where food is safe from contamination. Failing to implement this can result in serious health risks and legal repercussions.

Q 17. What is your experience with different food preparation techniques?

My experience encompasses a wide range of food preparation techniques, from basic knife skills to more advanced culinary methods. I’m proficient in various cooking methods, including:

- Basic Knife Skills: Dicing, mincing, julienning, and other precise cutting techniques are essential for consistent food preparation and presentation. I can quickly and safely chop various vegetables and meats.

- Various Cooking Methods: I’m experienced with sautéing, grilling, roasting, braising, poaching, steaming, and deep-frying. Each technique requires a different understanding of heat control and timing.

- Baking and Pastry Skills: My knowledge extends to baking bread, cakes, and pastries. This includes understanding doughs and batters, proper oven temperatures, and proofing techniques.

- Food Preservation: I’m familiar with methods like canning, freezing, and pickling, which extend the shelf life of food and reduce waste.

I’m also adept at following recipes accurately and adapting them to different dietary needs and preferences, while always adhering to food safety standards. My culinary skills are always evolving, and I am constantly learning new and more efficient methods.

Q 18. How do you handle food allergies in a food service setting?

Handling food allergies requires meticulous attention to detail and a proactive approach. It’s about preventing cross-contamination and ensuring the safety of customers with allergies.

- Clear Communication: Thorough communication with customers is crucial. We need to clearly understand their allergies and dietary restrictions when taking orders. Asking clarifying questions is vital to prevent any misunderstandings.

- Ingredient Knowledge: A deep understanding of ingredients and potential allergens is critical. I need to be able to identify potential cross-contamination risks and ensure all ingredients are handled appropriately.

- Designated Preparation Areas: In some cases, designating separate preparation areas for allergen-free items minimizes cross-contamination risk. This prevents even indirect contact between foods.

- Allergen Training: Regular training on food allergies and allergen awareness is crucial for all staff members to ensure everyone understands their roles in preventing contamination. For instance, specific attention should be given to training on how to clean equipment thoroughly between preparing dishes with allergens and allergen-free dishes.

- Clear Labeling: All dishes containing potential allergens need to be clearly labeled in accordance with regulations.

Proper management of food allergies is not just about avoiding illness; it’s about ensuring a safe and inclusive dining experience for everyone.

Q 19. Describe your understanding of food labeling requirements.

Food labeling requirements are crucial for consumer safety and informed decision-making. Labels provide information about the ingredients, nutritional content, and potential allergens in food products. These requirements are largely regulated by government agencies such as the FDA (in the USA) and similar bodies in other countries.

- Statement of Identity: The label must clearly state the name of the food product.

- Net Weight or Volume: The label must clearly state the net weight or volume of the food product.

- Ingredient List: Ingredients must be listed in descending order of weight, with allergens clearly identified (e.g., milk, eggs, soy, wheat, peanuts, tree nuts, fish, shellfish).

- Nutrition Facts Panel: This panel provides information about the calories, fat, carbohydrates, protein, and other nutrients in a serving of the food.

- Manufacturer Information: The label must include the name and address of the manufacturer, packer, or distributor.

Understanding these requirements ensures that I can accurately interpret labels and select the right ingredients for safe food preparation. It also helps me communicate effectively with customers about the ingredients in the food they are consuming.

Q 20. Explain the importance of following proper recipe instructions.

Following recipe instructions precisely is essential for food safety, quality, and consistency. Deviations from the recipe can compromise the final product’s safety, taste, and texture.

- Ingredient Measurements: Accurate ingredient measurements are critical. Using incorrect amounts can alter the taste, texture, and even the safety of the food. For example, too much baking soda in a cake can make it taste bitter.

- Cooking Times and Temperatures: Following cooking times and temperatures as directed ensures the food is cooked to a safe internal temperature, killing harmful bacteria. Undercooked meat, for example, can cause foodborne illness.

- Cooking Methods: Adhering to the specified cooking methods ensures that the food is prepared correctly and safely. Different methods require different techniques, and deviating from the method could drastically affect the outcome. For example, deep frying requires careful control of the oil temperature.

- Order of Operations: The order in which ingredients are added is often crucial for the final product’s quality. Following the steps in order will ensure the proper texture and flavor.

By following recipes precisely, we ensure consistent results and minimize the risk of errors that could affect the food’s safety or quality. It’s a testament to professionalism and a commitment to providing high-quality food.

Q 21. How do you maintain a clean and organized work area?

Maintaining a clean and organized workspace is fundamental to food safety and efficiency. It prevents cross-contamination and facilitates smooth workflow.

- Cleaning as You Go: This approach prevents the accumulation of dirt and debris. Cleaning as you use ingredients and equipment helps maintain a consistent level of hygiene.

- Designated Storage Areas: All ingredients and equipment should have designated storage areas. This will eliminate clutter and help with quick identification of items.

- Regular Deep Cleaning: Regular deep cleaning of equipment and surfaces is crucial to remove any accumulated grease, grime, and bacteria. This involves using appropriate cleaning agents and following sanitation procedures.

- Proper Waste Disposal: Waste should be disposed of properly in designated containers. This helps prevent attracting pests and maintaining a clean environment.

- Organization System: Developing a system for organizing ingredients and equipment is essential for efficiency and to prevent confusion. This might involve labeling containers and shelves.

A clean and organized workspace not only improves safety but also boosts productivity and reduces stress in a busy kitchen environment. It contributes to a professional image and ensures a positive work environment.

Q 22. Describe a situation where you had to address a food safety issue.

During my time as a sous chef at a bustling Italian restaurant, we experienced a power outage during a particularly busy Friday night. Our walk-in refrigerator, relying on a backup generator, started to show signs of elevated temperature. This immediately triggered my food safety protocols. I immediately began assessing the situation.

First, I checked the temperature of the refrigerator using a calibrated thermometer. It was slowly rising above the safe 41°F (5°C) mark. Secondly, I systematically moved all perishable items—meats, seafood, dairy—to our backup cooler, prioritizing those closest to their expiration dates and those most susceptible to spoilage. Thirdly, I contacted our manager and the building maintenance to resolve the power issue. Finally, we discarded any items that had reached unsafe temperatures and meticulously documented all actions taken, including temperatures and times, for our food safety records. This incident highlighted the importance of having a robust contingency plan and the need for regular equipment maintenance to prevent such situations.

Q 23. How do you ensure that all food is cooked to the proper internal temperature?

Ensuring food is cooked to the proper internal temperature is paramount to preventing foodborne illnesses. We use calibrated thermometers regularly to check internal temperatures. Different foods have different safe minimum internal temperatures. For example, poultry must reach 165°F (74°C), while ground beef needs 160°F (71°C), and fish should reach 145°F (63°C). We train staff thoroughly on how to use thermometers correctly. Inserting the thermometer into the thickest part of the food is crucial for an accurate reading, and we avoid touching the pan or other surfaces with the thermometer to avoid contamination. We also employ visual cues – poultry should be cooked until it’s no longer pink and juices run clear, though these cues should never be relied upon in isolation from the thermometer.

Beyond individual checking, we maintain regular calibration schedules for our thermometers to ensure accuracy and maintain detailed logs of these calibrations. The kitchen also uses time-temperature indicators (TTIs) on high-volume items that visually indicate whether the product has been cooked safely within a set time frame. The combination of thermometers, TTIs and staff training gives us a robust approach to temperature control.

Q 24. What are your strengths and weaknesses related to food safety and handling?

One of my greatest strengths in food safety is my proactive approach. I’m not content just to follow regulations; I actively look for ways to improve our procedures. For example, I implemented a new system for storing and rotating inventory based on FIFO (First-In, First-Out) to minimize waste and reduce the risk of spoilage.

An area for improvement for me is delegating tasks effectively, especially during peak hours. While I can handle high-pressure situations myself, I sometimes find it challenging to ensure everyone follows the same rigorous standards. To address this, I’m focusing on improving my communication and training skills to empower my team and to foster a collaborative approach towards food safety.

Q 25. What is your experience with different food service equipment?

Throughout my career, I’ve gained extensive experience with a wide range of food service equipment, including ovens (conventional, convection, and pizza), ranges, grills, fryers, steamers, refrigerators (walk-in and reach-in), freezers, slicers, mixers, and dishwashers. I’m proficient in using and maintaining this equipment according to safety regulations. I understand the importance of regular cleaning and sanitation of all equipment to prevent cross-contamination and maintain optimal functionality. I’m also familiar with the safety features of each piece of equipment, such as emergency shut-off switches and proper handling procedures to prevent injuries. I’m comfortable troubleshooting minor equipment malfunctions and know when to call for professional maintenance.

Q 26. How do you stay up-to-date on current food safety regulations?

Staying current on food safety regulations is an ongoing process. I regularly consult the FDA Food Code and the local health department’s guidelines. I also subscribe to industry publications and participate in food safety workshops and online courses to stay abreast of new developments and best practices. Actively engaging in professional organizations provides access to the latest information and allows networking with other professionals in the field, leading to continuous learning and sharing of best practices.

Q 27. What steps do you take to prevent food waste?

Preventing food waste is crucial, both economically and environmentally. My approach is multi-pronged. Firstly, we utilize precise portioning techniques and careful inventory management using FIFO (First-In, First-Out) to minimize overstocking. Secondly, we create detailed prep lists to avoid purchasing excessive amounts of ingredients. Thirdly, we creatively repurpose leftovers into other menu items or donate surplus food to local shelters. Finally, we meticulously record food waste, helping us analyze patterns and areas where we can improve inventory control and reduce our environmental impact.

Q 28. Describe your experience with food preparation under time constraints.

Working in high-volume restaurants necessitates efficient food preparation under time constraints. I’ve developed a systematic approach that prioritizes tasks, ensuring the most time-sensitive preparations are handled first. This involves detailed prep work done well in advance, especially during less busy hours, and a strong focus on organization and teamwork. Effective communication with kitchen staff is crucial, and having a shared understanding of tasks and priorities helps streamline the process during rushes. I maintain a calm demeanor under pressure and prioritize food safety even when working quickly. Experience has taught me that proper planning and a calm, organized approach are key to successfully managing food preparation under time constraints.

Key Topics to Learn for Food Handler’s Certification Interview

- Foodborne Illness Prevention: Understanding the causes, transmission, and prevention of common foodborne illnesses. Think about how you would handle a situation where you suspect contaminated food.

- Personal Hygiene Practices: Mastering proper handwashing techniques, glove usage, and maintaining a clean work environment. Consider how you would explain the importance of these practices to a new employee.

- Temperature Control: Knowing safe temperature ranges for storing and cooking various food types. Be prepared to discuss how you would monitor and address temperature deviations.

- Food Storage and Handling: Understanding FIFO (First-In, First-Out) principles, proper labeling, and preventing cross-contamination. Practice explaining how you would organize a refrigerator for optimal food safety.

- Cleaning and Sanitizing Procedures: Knowing the difference between cleaning and sanitizing, and the correct procedures for various surfaces and equipment. Prepare to describe your approach to cleaning a spill involving raw meat.

- Pest Control: Understanding strategies for preventing pest infestations and maintaining a clean, pest-free environment. Be ready to explain how you would handle a pest sighting in the workplace.

Next Steps

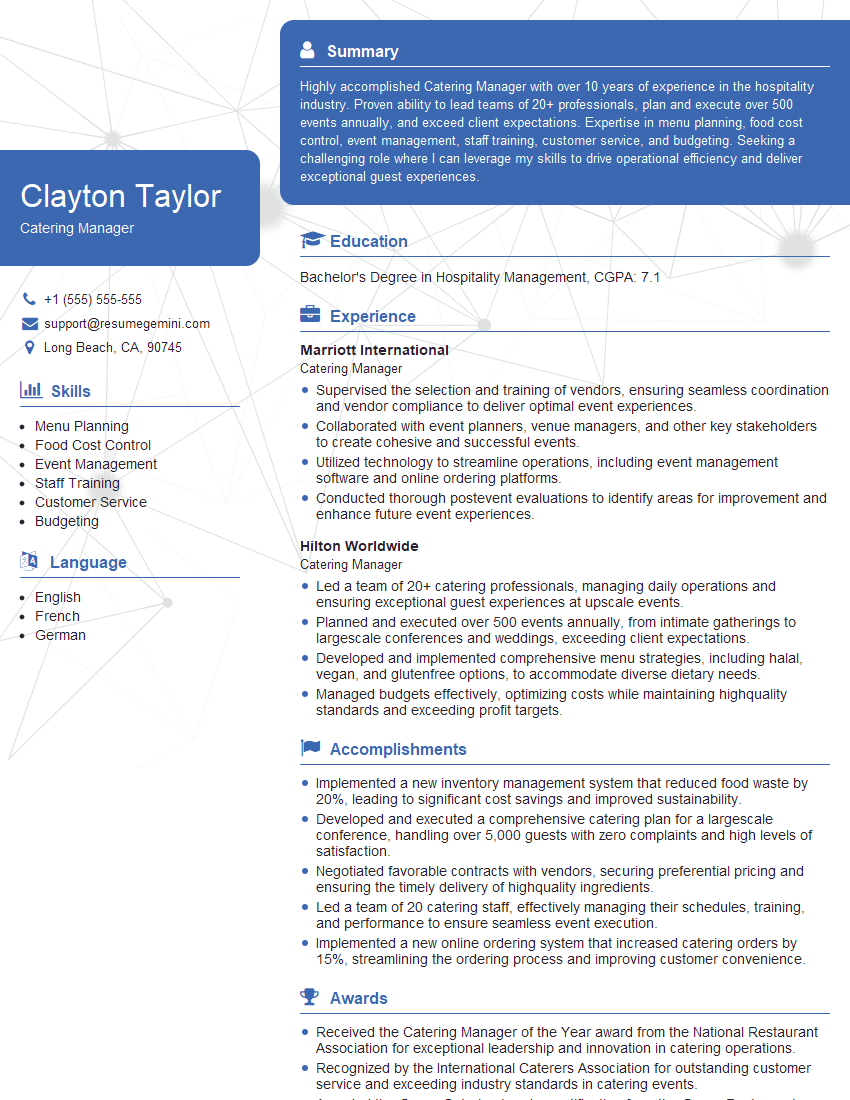

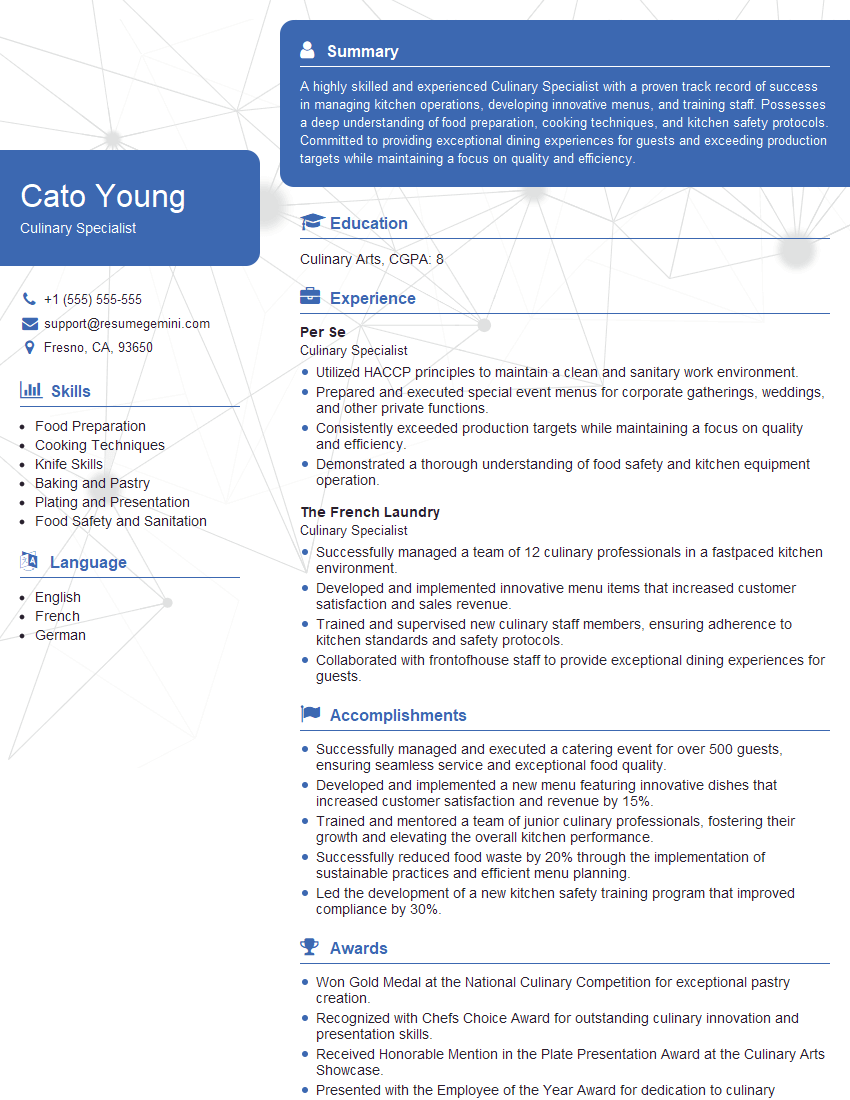

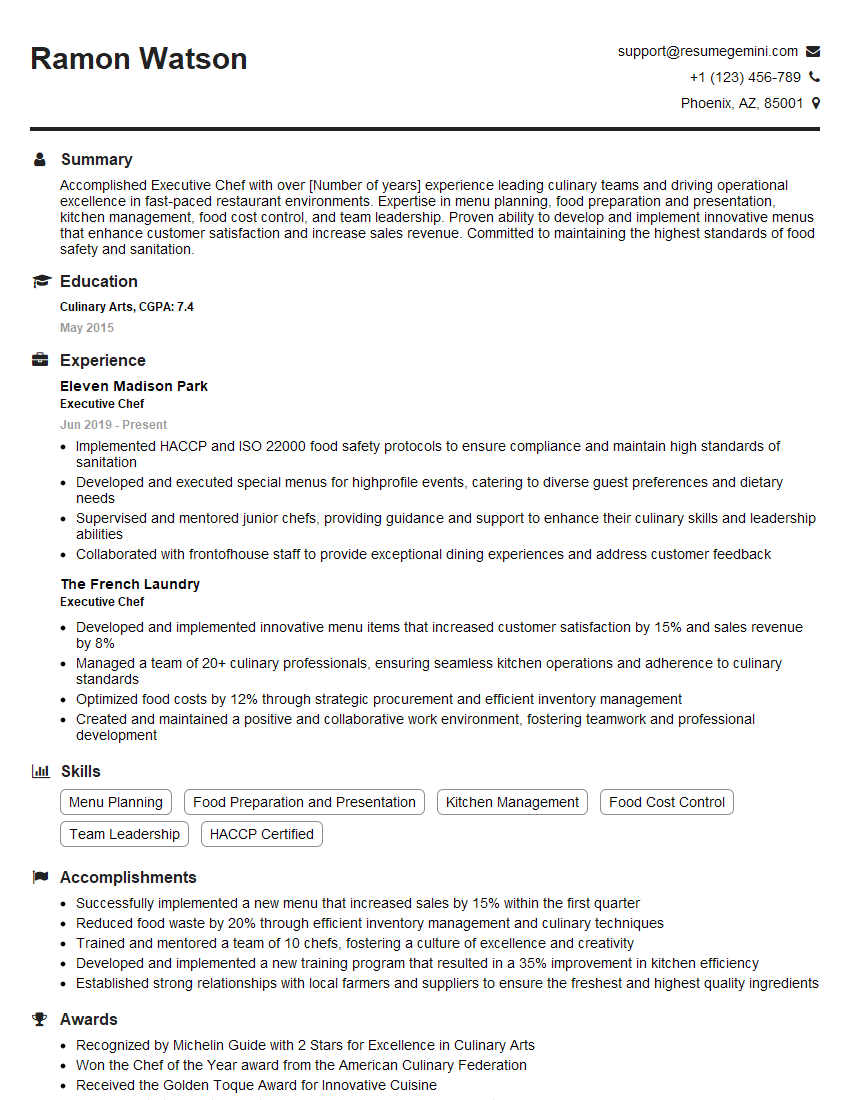

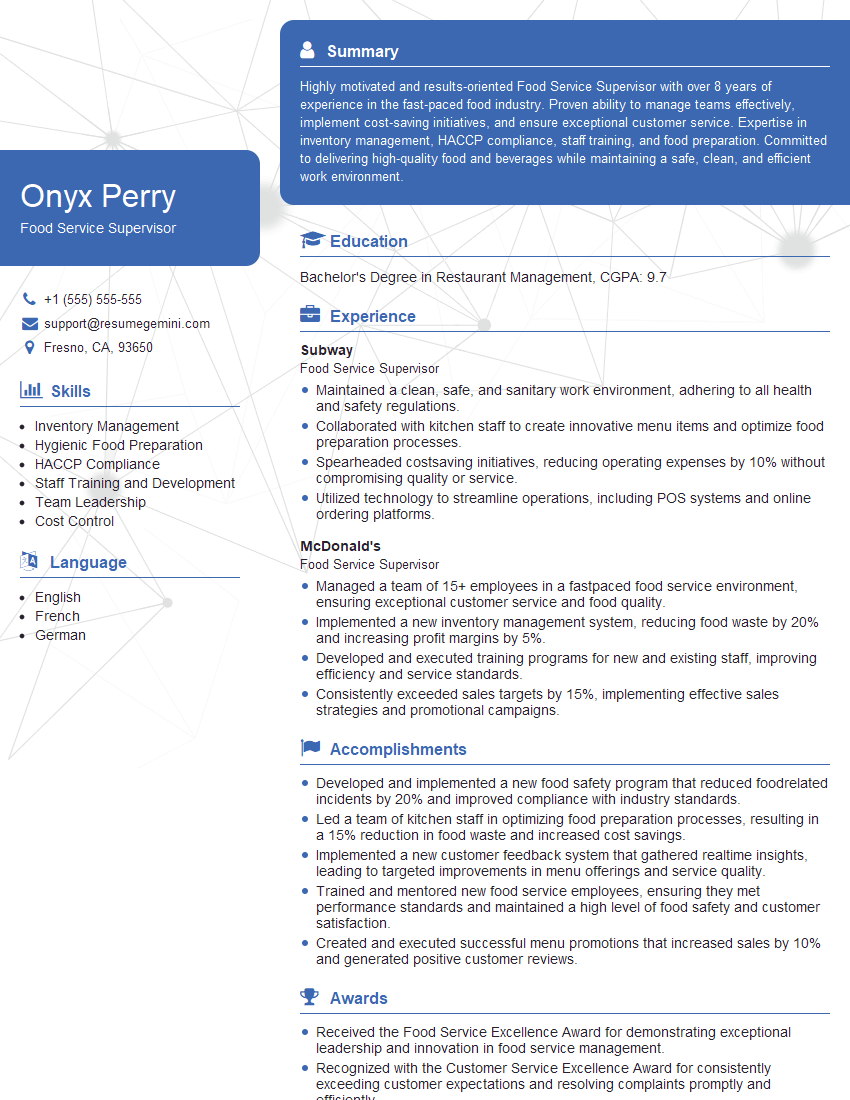

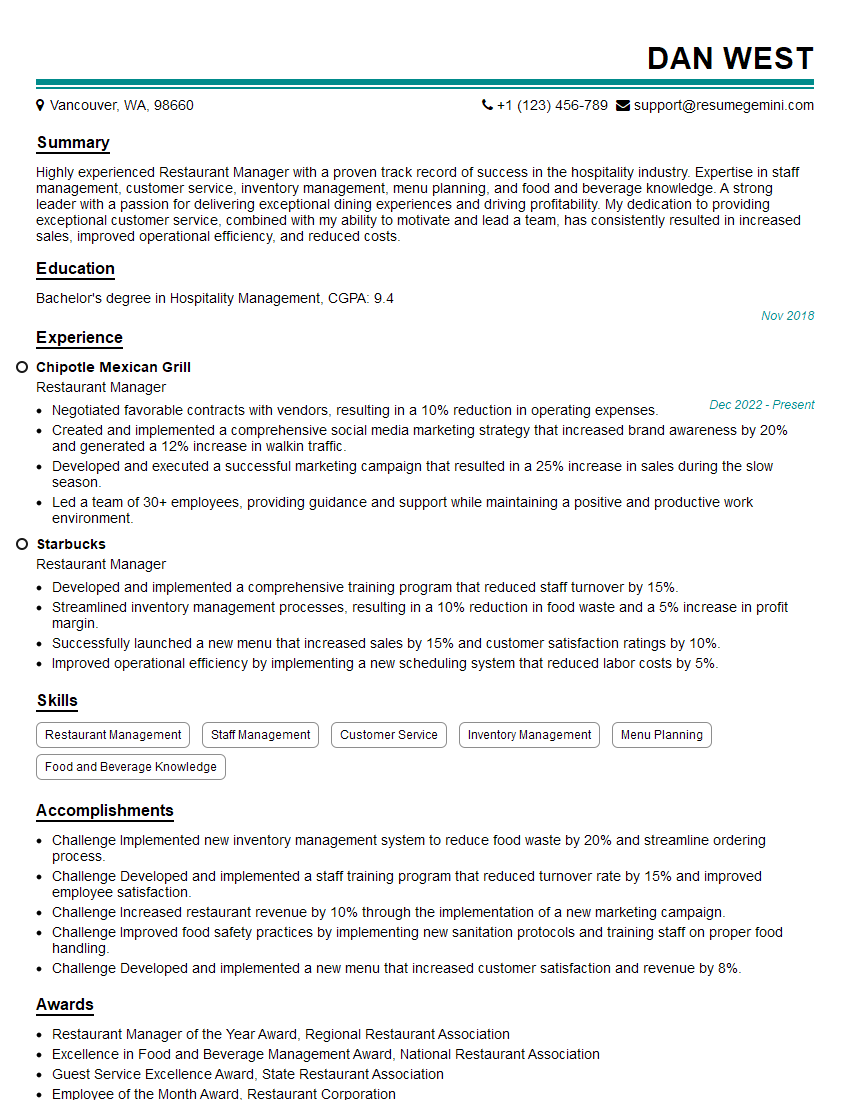

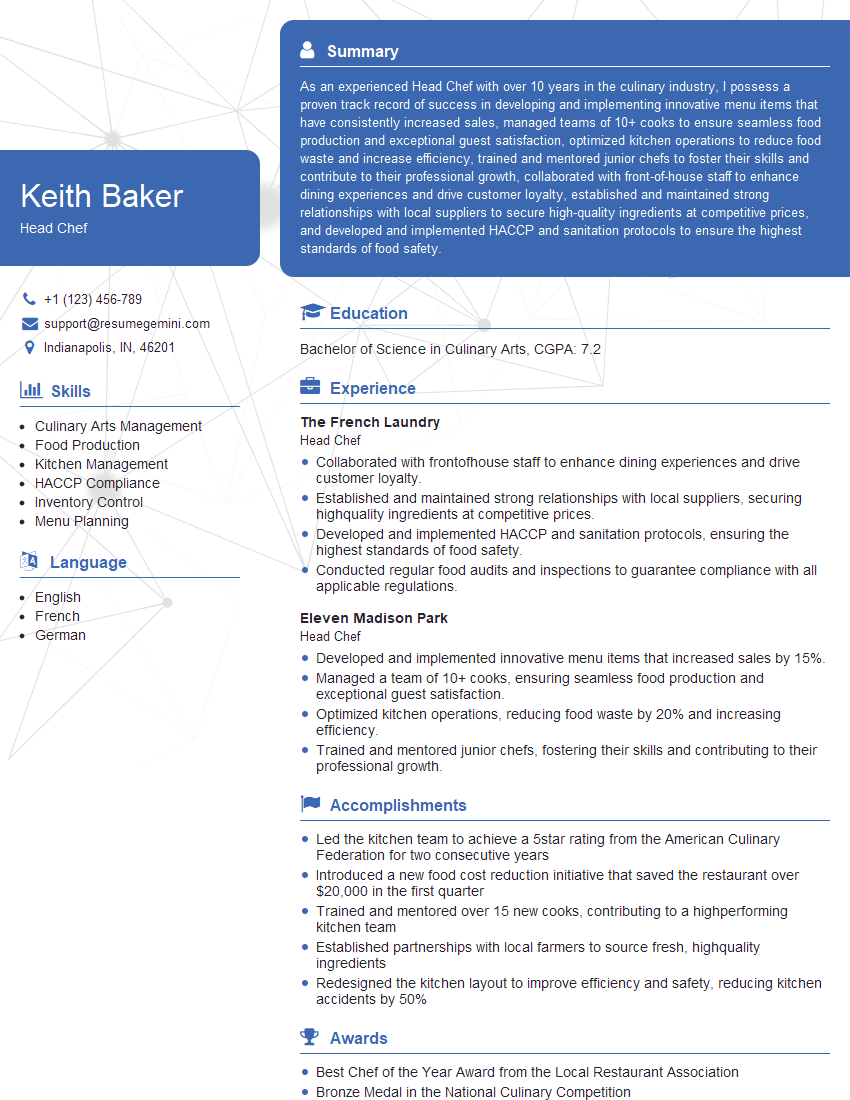

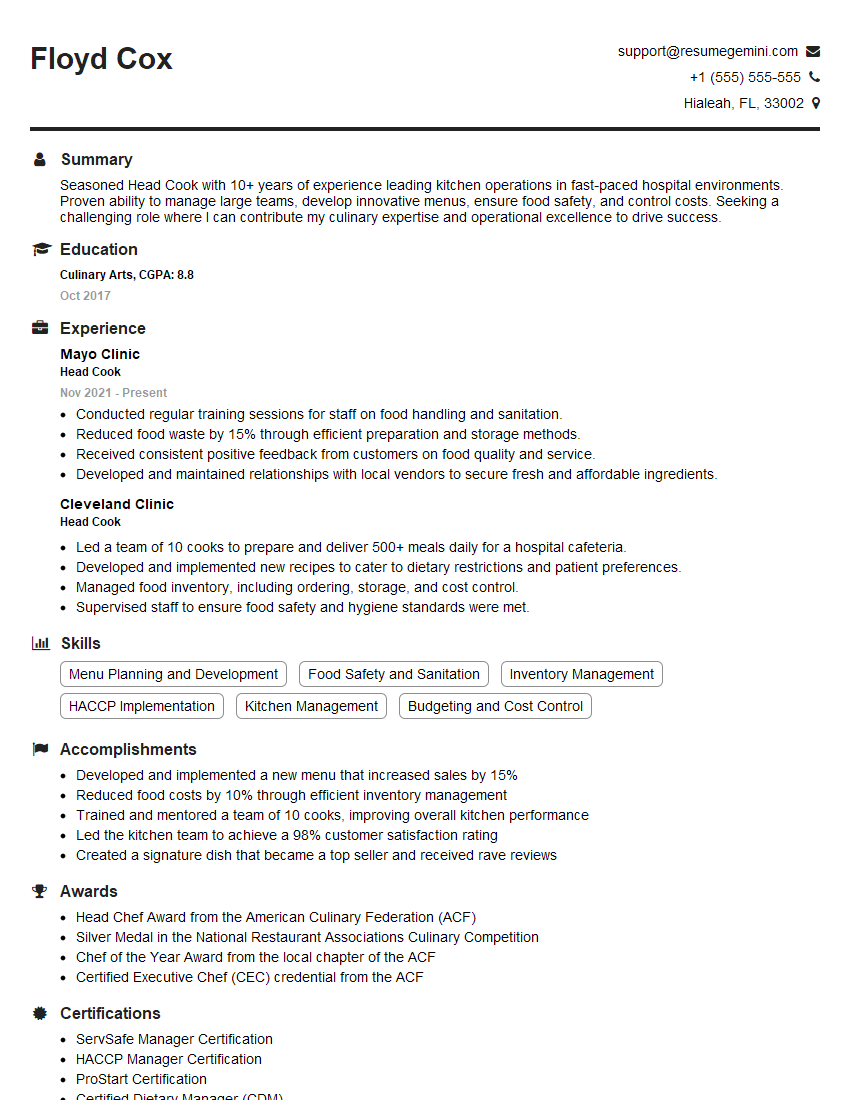

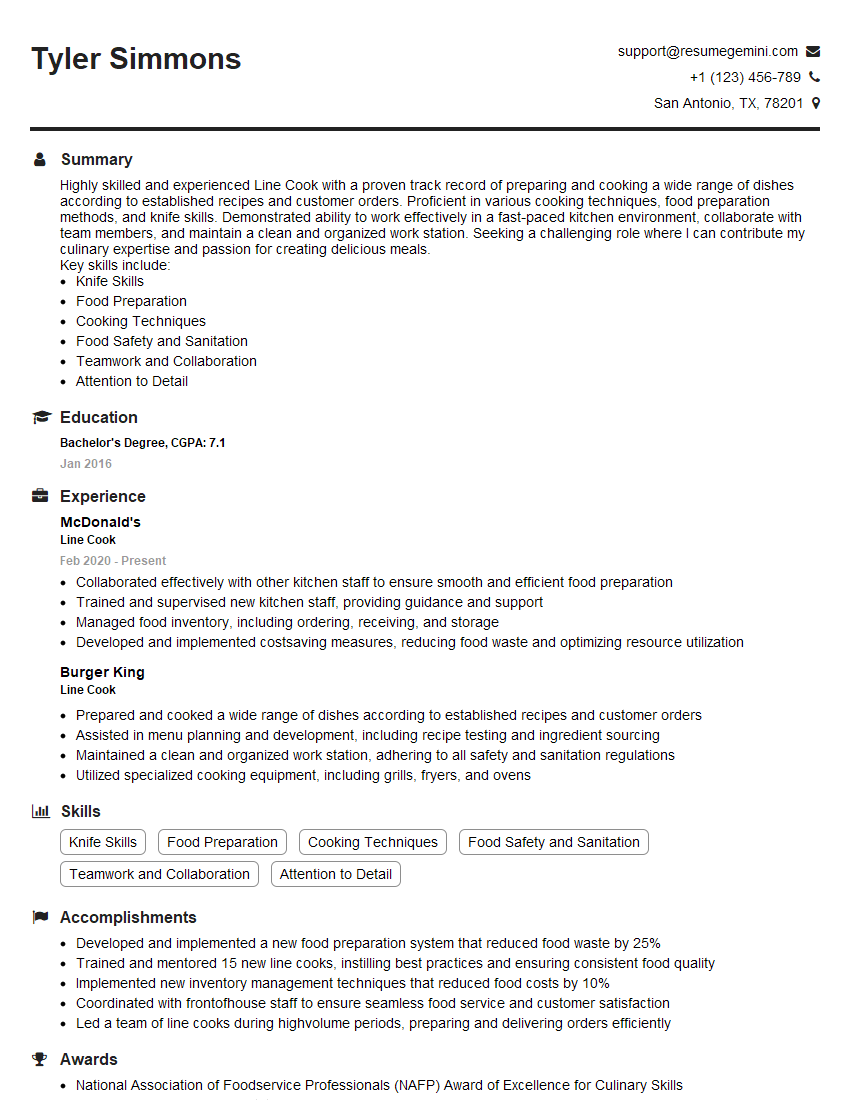

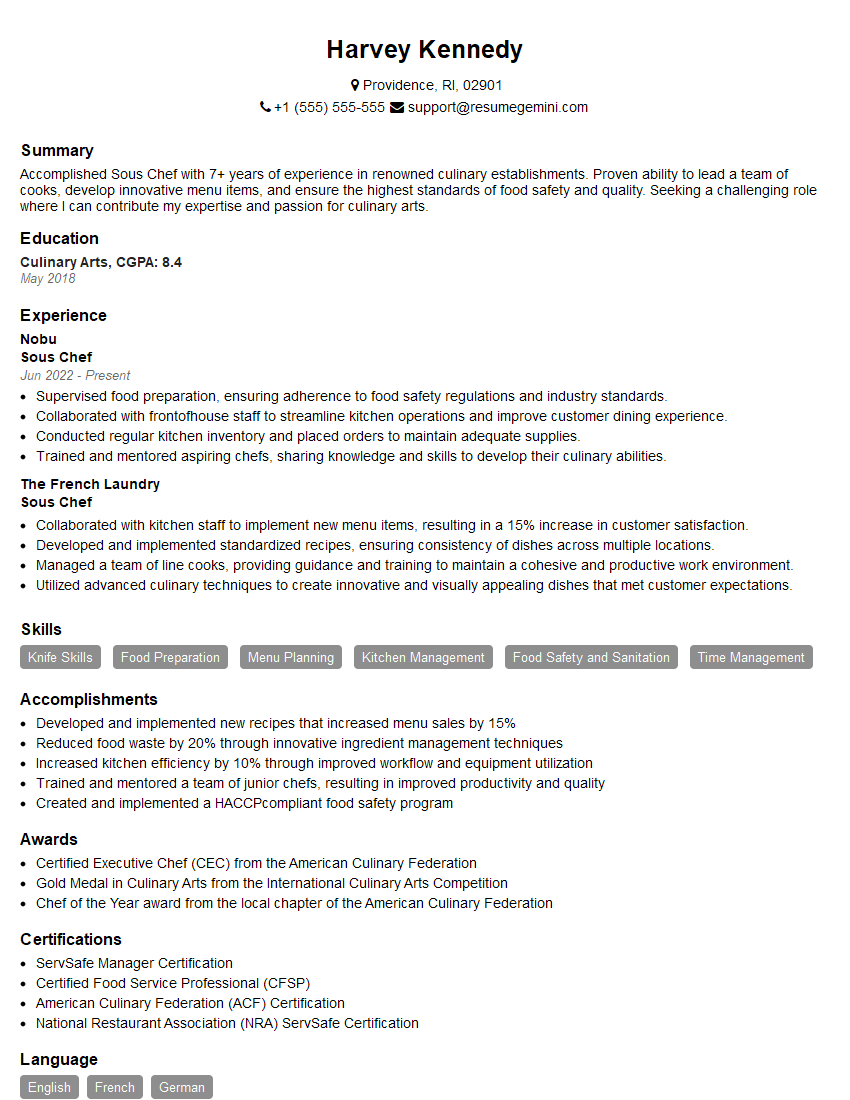

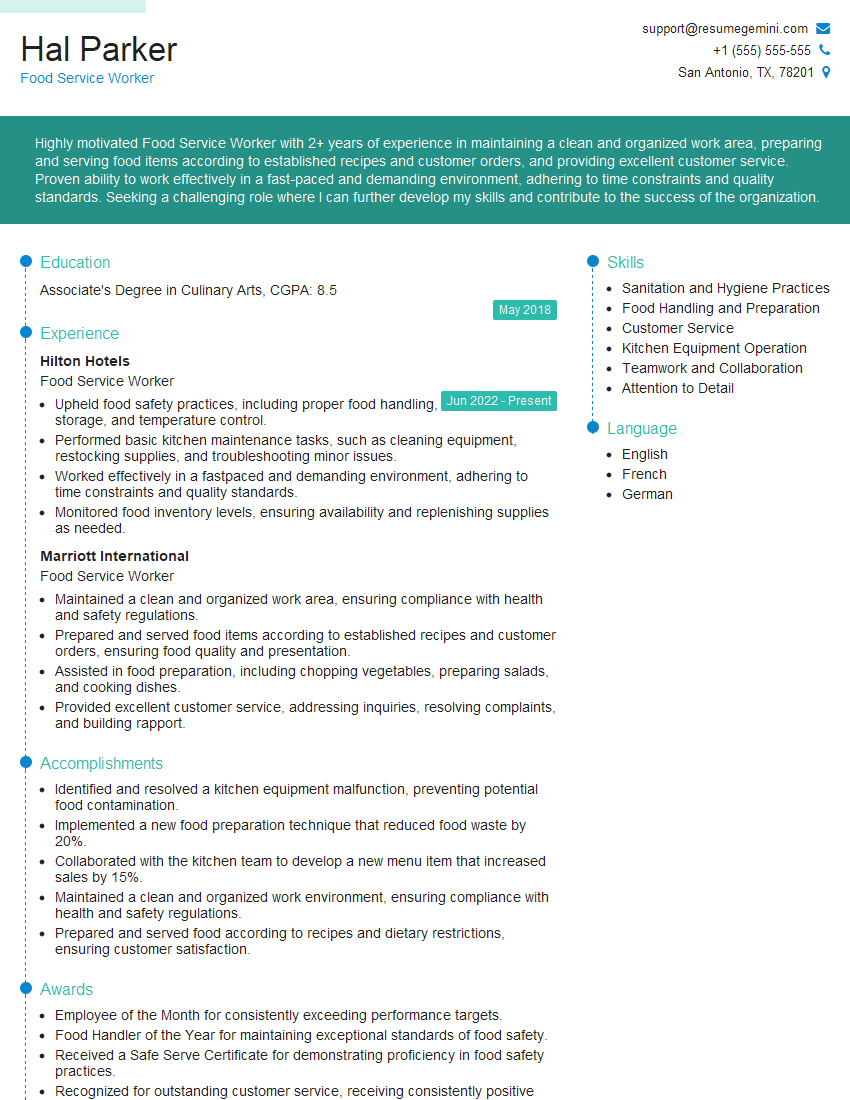

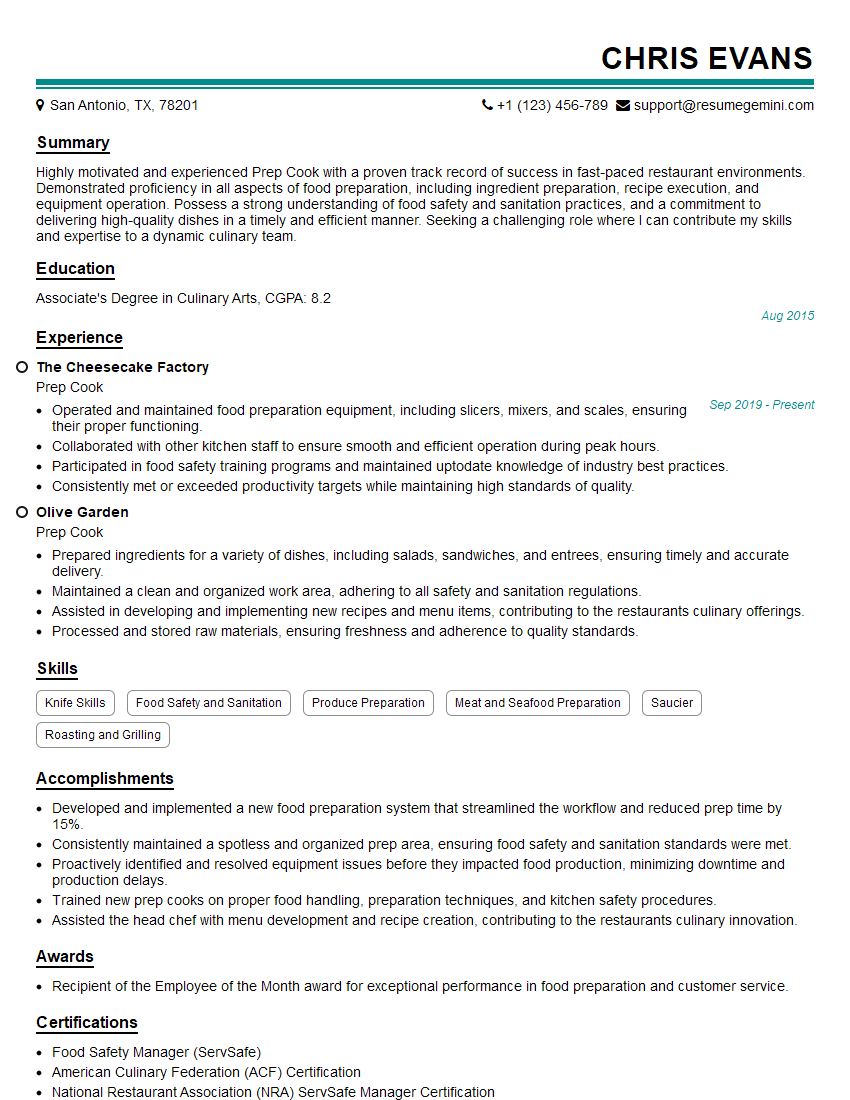

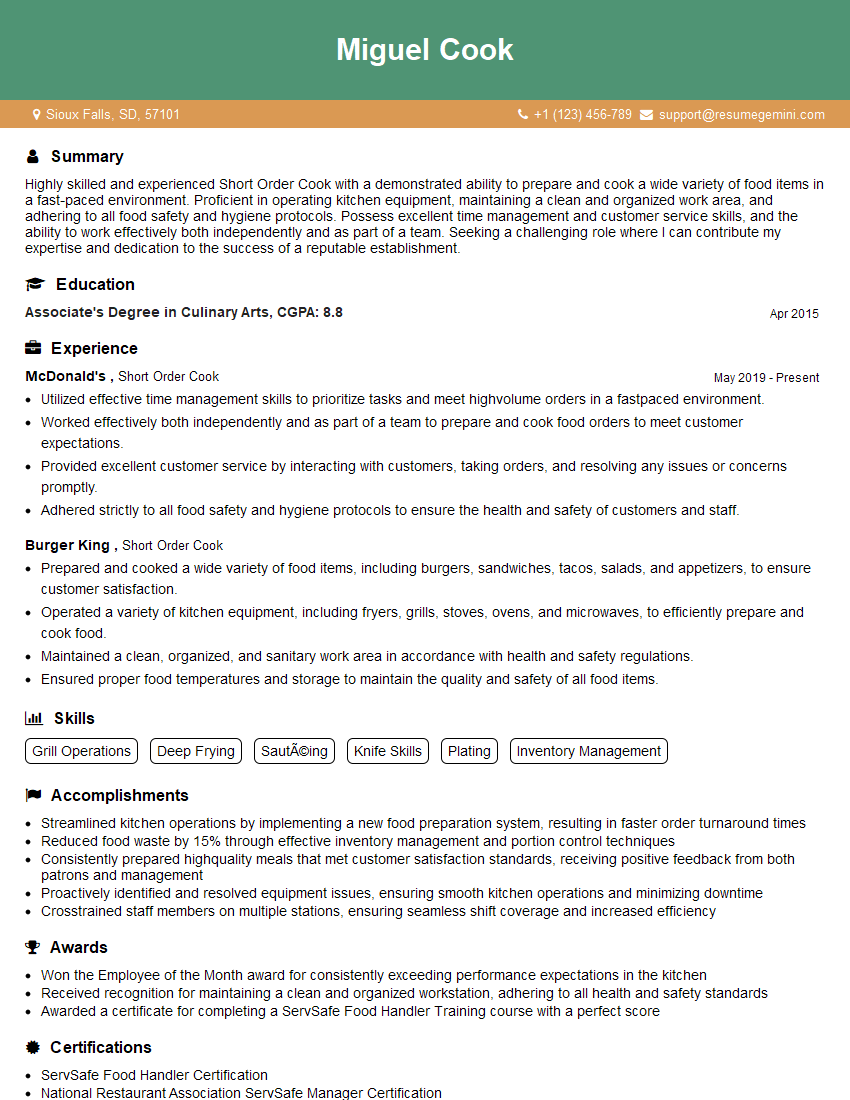

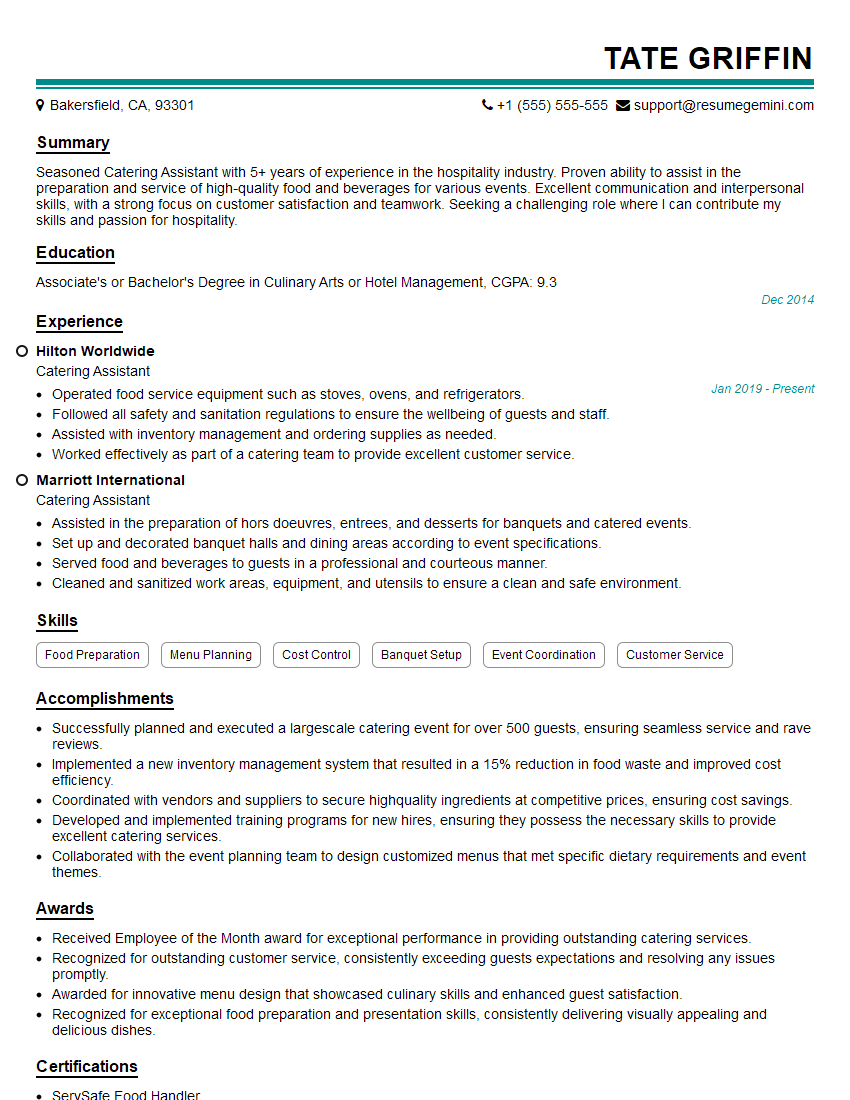

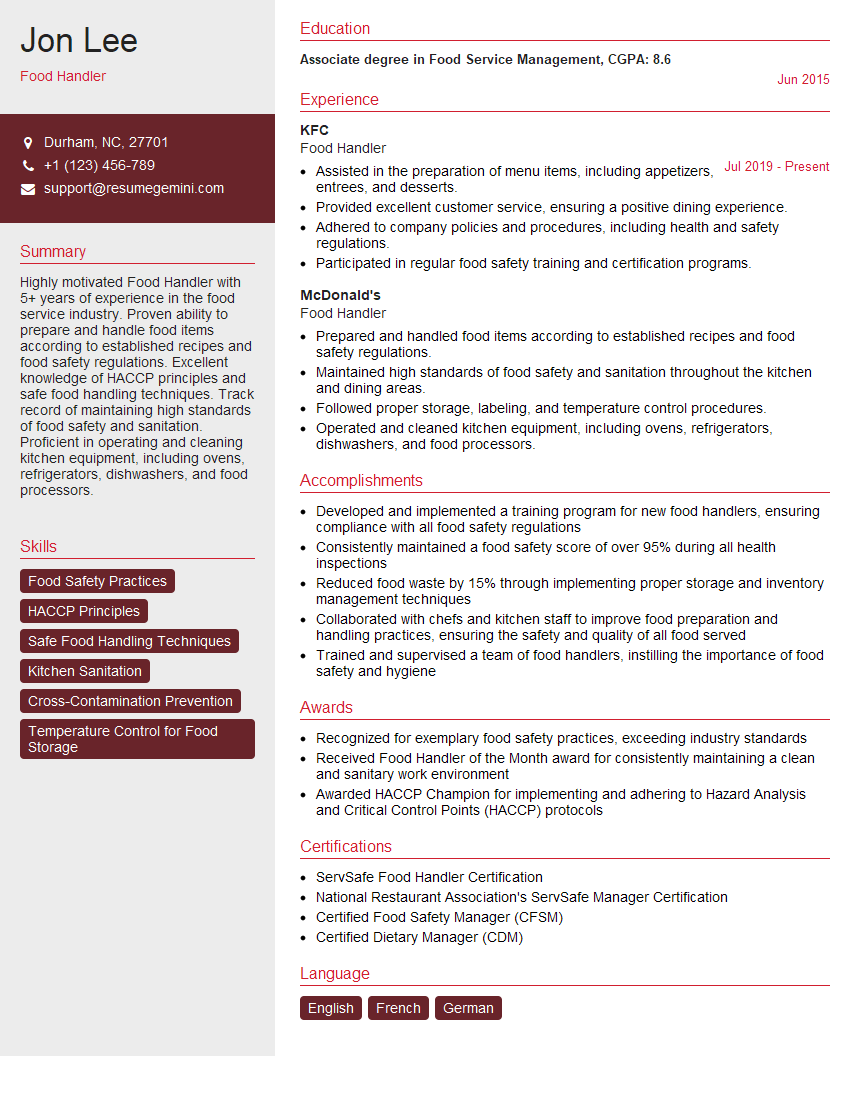

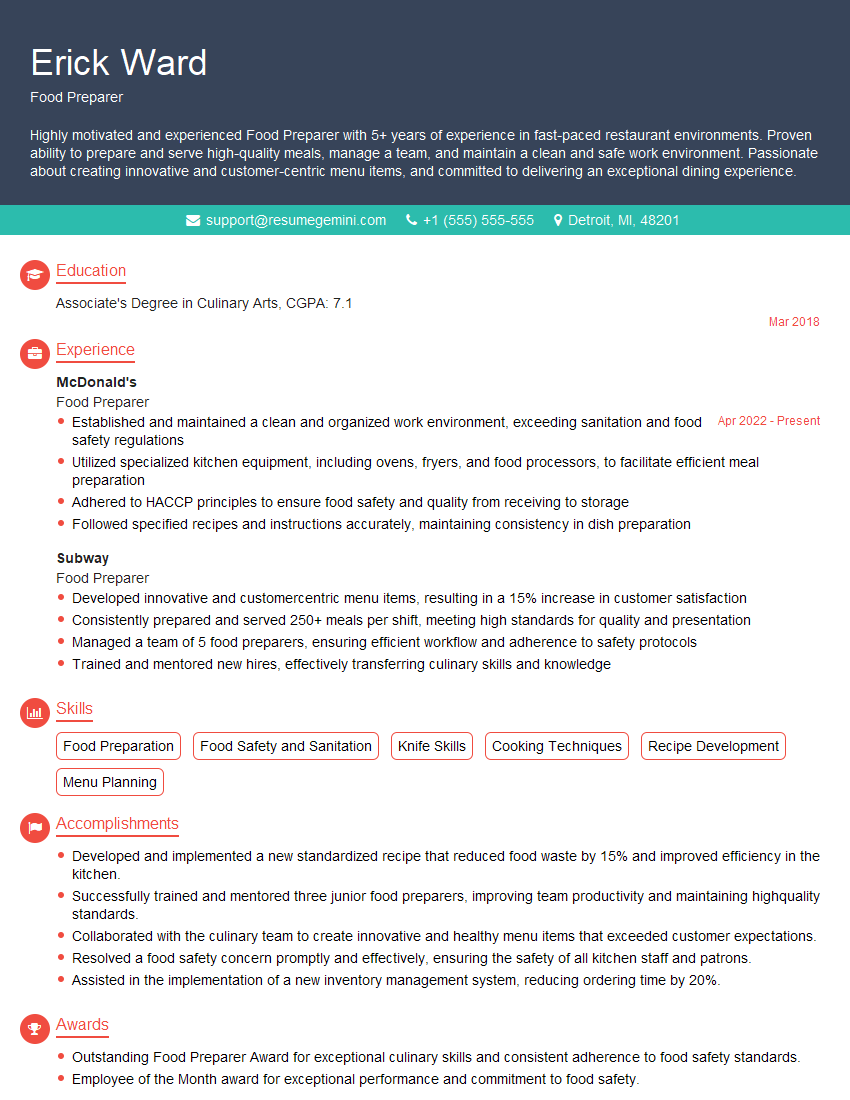

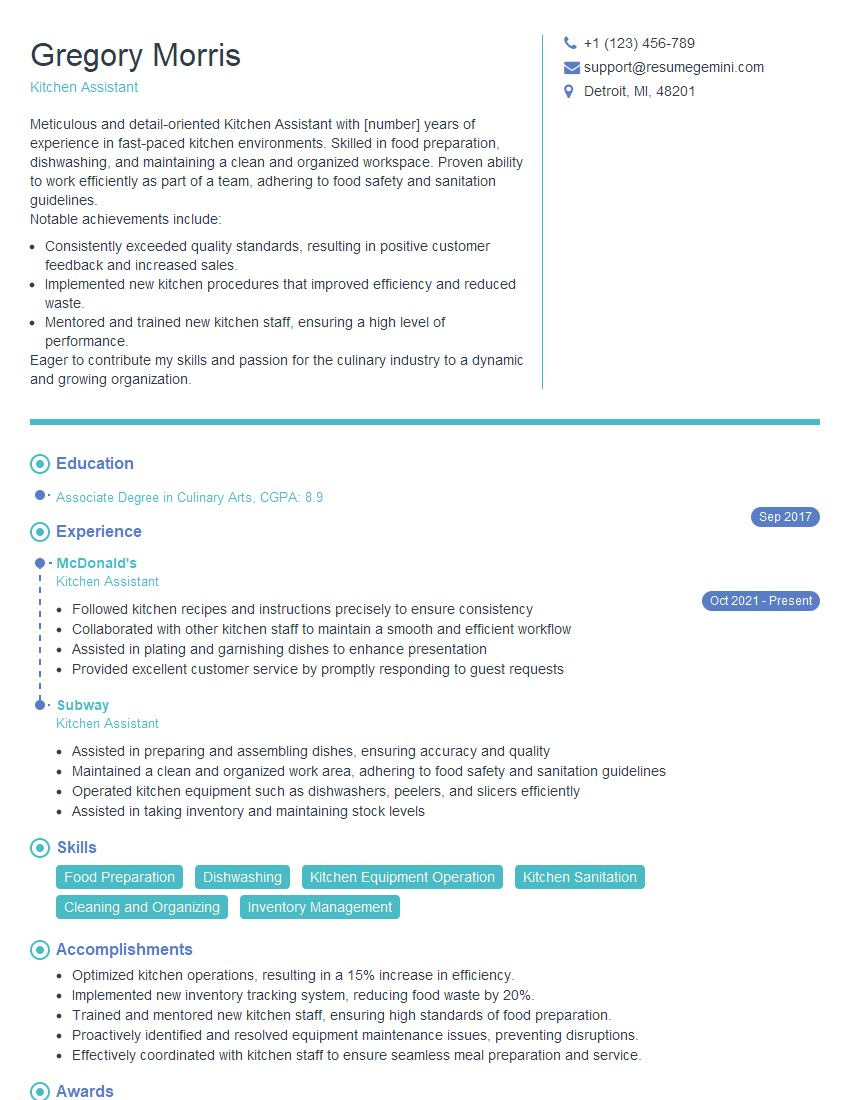

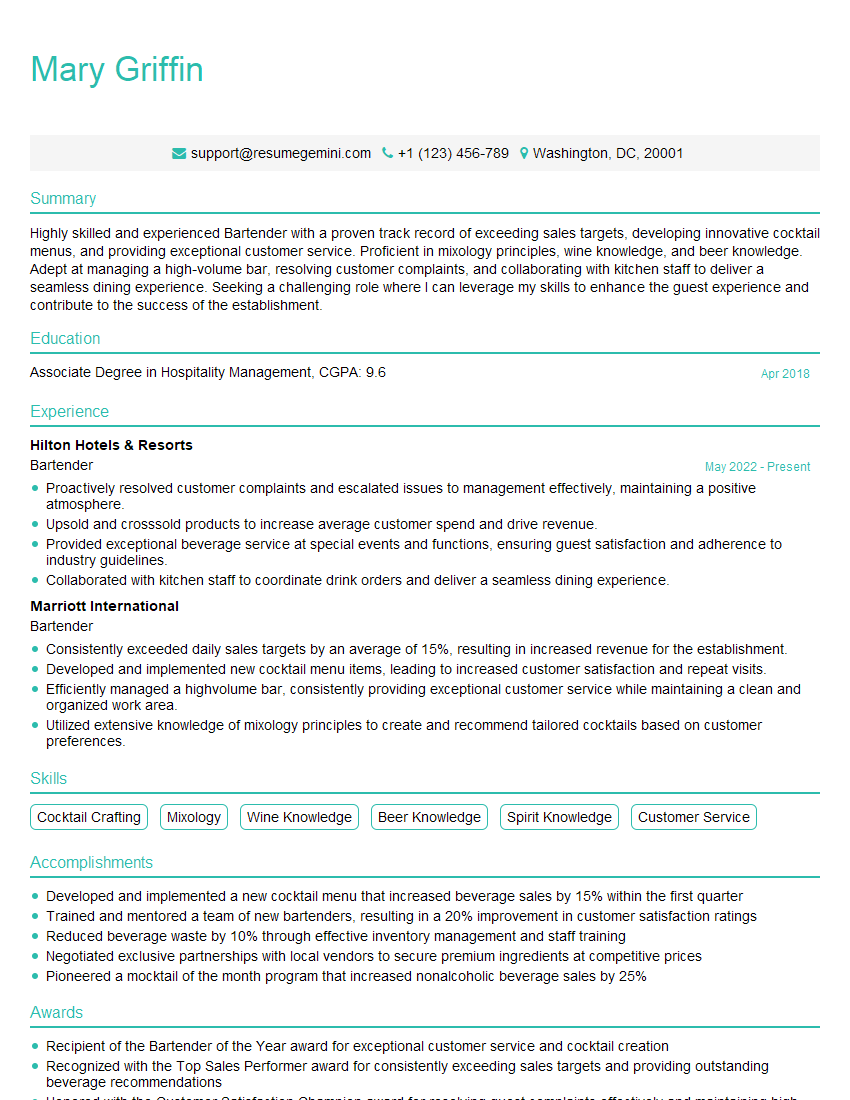

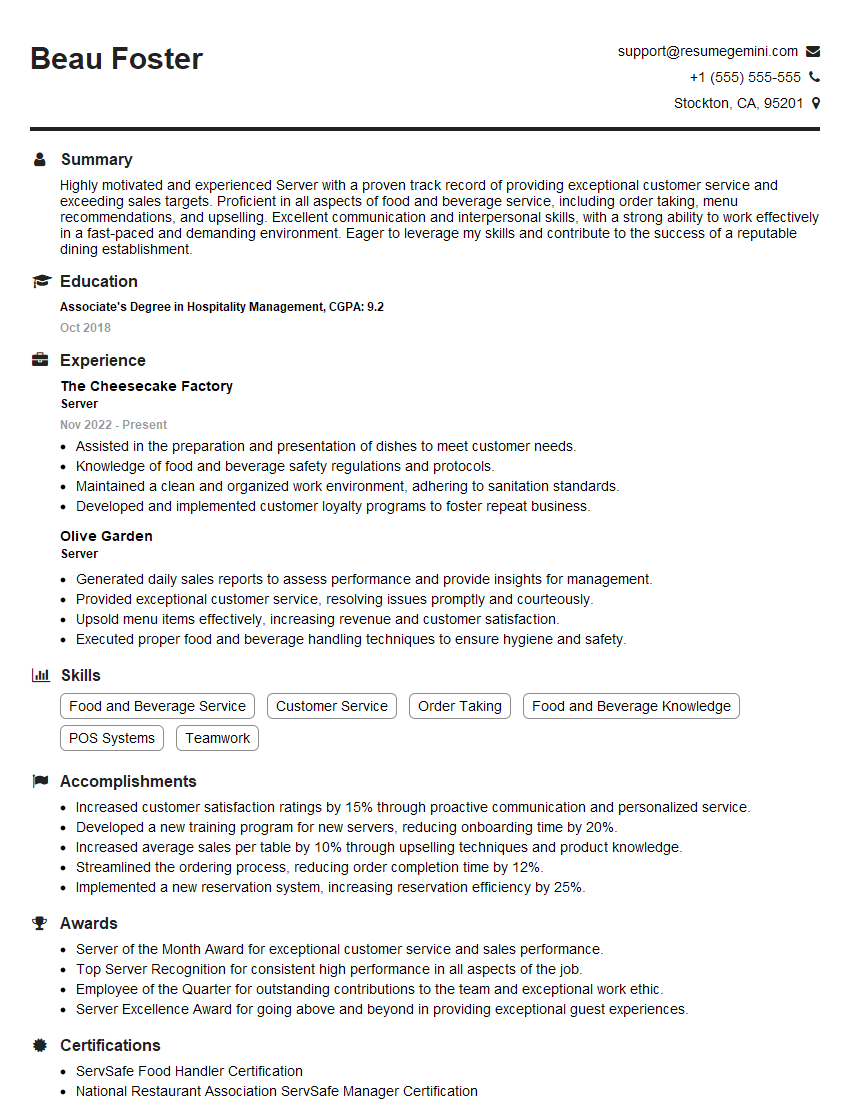

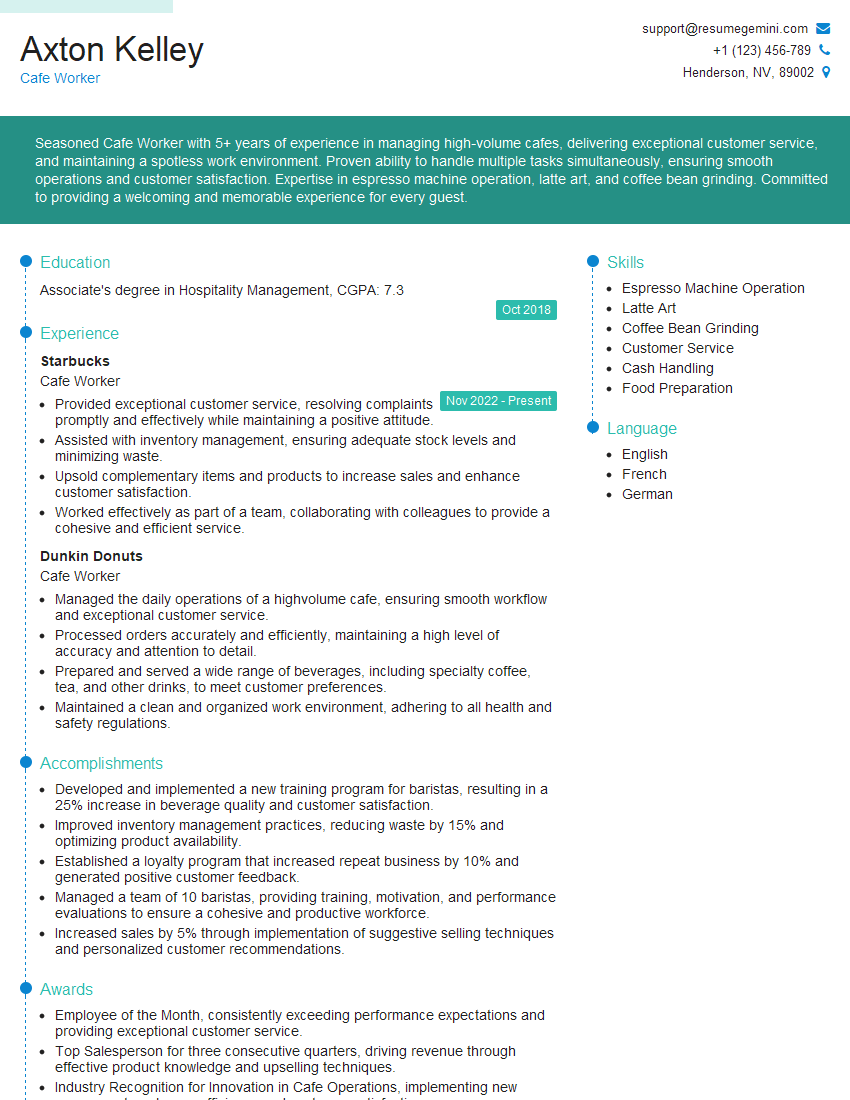

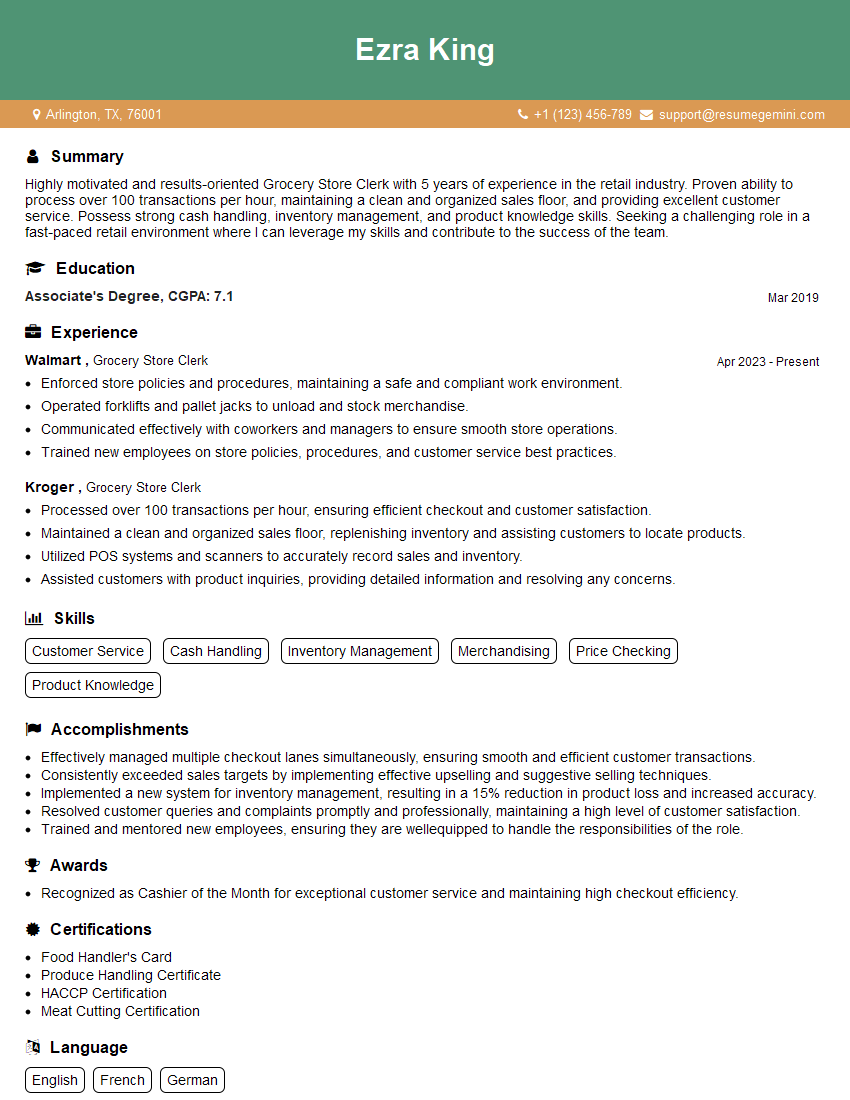

Mastering your Food Handler’s Certification opens doors to numerous opportunities in the food service industry, boosting your career prospects and earning potential. To make the most of your certification, create an ATS-friendly resume that showcases your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional and impactful resume. We offer examples of resumes tailored specifically to Food Handler’s Certification to guide you through the process. Invest in your future – craft a resume that highlights your qualifications and helps you land your dream job!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I represent a social media marketing agency that creates 15 engaging posts per month for businesses like yours. Our clients typically see a 40-60% increase in followers and engagement for just $199/month. Would you be interested?”

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?