Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Framing square utilization interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Framing square utilization Interview

Q 1. Explain the different components of a framing square.

A framing square, also known as a carpenter’s square, is a versatile tool with two arms, typically made of steel. The longer arm, called the blade, is usually 24 inches long, while the shorter arm, the tongue, is 16 inches long. The intersection of these arms forms a right angle (90 degrees). Both the blade and tongue are marked with various scales and markings crucial for various carpentry tasks, including those related to roof framing, stair building, and general layout work. The markings include inches, fractions of inches, and specialized scales for calculating rafter lengths and angles.

Q 2. Describe how to use a framing square to find the center of a board.

Finding the center of a board with a framing square is straightforward. Simply align one edge of the square with the edge of the board. Then, measure the width of the board using the square’s markings. Divide the width by two. Mark this midpoint on the board. Repeat this process on the opposite edge. Finally, draw a straight line connecting these two midpoints; this line marks the exact center of the board. For example, if the board is 8 inches wide, you’d mark 4 inches from each edge.

Q 3. How do you use a framing square to lay out common rafters?

Laying out common rafters involves determining the length and angle cuts needed. You’ll use the framing square’s scales, usually the ‘rise’ and ‘run’ measurements determined by the roof pitch. The ‘rise’ is the vertical distance from the top plate to the peak of the roof, and the ‘run’ is the horizontal distance from the top plate to the center of the rafter. These values are inputted into a rafter table or calculated directly on the square using its scales and the Pythagorean theorem. Then, you transfer these measurements to your lumber to mark your cuts.

Q 4. Explain the process of using a framing square to cut common rafters with a given rise and run.

Cutting common rafters with a given rise and run uses the framing square’s ability to translate these measurements into the necessary angles and lengths. Let’s say you have a rise of 6 inches and a run of 12 inches per foot. You’d find the 6-inch mark on one arm of the square and the 12-inch mark on the other. This creates the angle of your rafter’s cut. Using the Pythagorean theorem (a² + b² = c²), you can calculate the rafter’s length (c). Mark this length on your lumber, and then use the framing square to accurately make the cuts for both the plumb cut (the vertical cut) and the bird’s mouth cut (the cut that sits on the top plate).

Example: Rise = 6, Run = 12; Length = √(6² + 12²) = 13.4 inches (per foot of run)Q 5. How do you use a framing square to determine the length of hip and valley rafters?

Determining the length of hip and valley rafters is more complex than common rafters due to their angled orientation. You’ll need to use the framing square in conjunction with the Pythagorean theorem and consider the roof’s pitch and the angle of the hip or valley. You can use specialized scales or tables on the square, or you can use a rafter calculator, considering both the common rafter length and the diagonal measurement created by the hip/valley’s angle. This calculation ensures that the hip/valley rafter fits accurately at its intersections.

Q 6. Describe how to use a framing square to find the length of a jack rafter.

A jack rafter is a shorter rafter that spans between a hip or valley rafter and a common rafter. Determining its length involves calculating the horizontal and vertical distances it covers. The framing square helps in transferring these measurements to your lumber, ensuring accurate cuts. You would measure the common rafter length and the spacing between common rafters, and then use these to find the corresponding jack rafter length based on its position on the roof.

Q 7. What are the different scales on a framing square and how are they used?

Framing squares feature various scales to aid in different calculations. The most common scales are inches and fractions of inches for general measurements. But the square also often includes scales for finding rafter lengths based on the roof pitch (rise and run). Other specialized scales may include board feet calculations, octagon scales, and even scales for determining the lengths and angles of other structural elements. Mastering these scales allows for quick and accurate calculations on the job site, minimizing the need for separate calculators or tables. Remember to always check your square’s markings to ensure you are using the right scale for your current task.

Q 8. Explain the concept of a ‘rise and run’ in relation to roof framing.

In roof framing, ‘rise’ and ‘run’ define the slope or pitch of the roof. Think of it like a staircase. The rise is the vertical distance from the top of the wall plate to the peak of the roof (the height of the step). The run is the horizontal distance from the outside edge of the wall plate to the center point of the roof (the length of the step). The ratio of rise to run determines the roof’s angle.

For example, a 4/12 roof has a rise of 4 inches for every 12 inches of run. This ratio is crucial for calculating rafter lengths and ensuring proper roof structure.

Q 9. How do you calculate the length of rafters using the framing square?

The framing square’s ‘rafter table’ is your best friend for this. These tables provide pre-calculated values based on rise and run. You’ll find tables for different common rafter lengths and pitches.

Here’s how you typically use it:

- Determine the rise and run of your roof.

- Locate the appropriate table on your framing square. This usually involves finding the column matching your rise and the row matching your run.

- Find the intersection. The number at the intersection represents the length of the rafter per foot of run.

- Multiply by the run in your roof. This will give you the total rafter length. Remember to add extra for overhang!

Let’s say you have a 6/12 pitch roof with a run of 10 feet. You would find the value in the rafter table corresponding to 6 and 12, multiply that value by 10 feet, and you have your rafter length (plus overhang). Always double-check your calculations!

Q 10. Explain the difference between a steel and an aluminum framing square.

Both steel and aluminum framing squares serve the same purpose – assisting in construction layout and measurement – but they differ in durability and weight.

- Steel framing squares are incredibly durable and resistant to bending or damage. They’re the classic choice, favored for their robustness on tough job sites.

- Aluminum framing squares are lighter and easier to handle, making them preferable for extended use or overhead work. However, they’re more prone to bending under heavy pressure, potentially compromising accuracy.

The choice depends on personal preference and the job demands. For heavy-duty applications, the steel square is generally preferred; for portability and ease of use, aluminum might be a better fit. I personally have both in my tool kit!

Q 11. What are some common mistakes when using a framing square?

Common mistakes include:

- Incorrectly reading the rafter table: Double-checking your work is crucial, as misreading the table leads to inaccurate rafter lengths and potentially unsafe structures.

- Not accounting for overhang: Always add the necessary overhang to your calculated rafter length.

- Improperly marking cuts: Accurate marking is vital for a precisely fitting roof. Using a sharp pencil and ensuring proper alignment are essential.

- Ignoring the blade’s wear: Ensure the square is clean and undamaged before each use. Over time, wear can influence measurements.

I’ve seen many projects delayed or even compromised due to these seemingly small errors. Careful attention to detail is paramount.

Q 12. How do you maintain and care for a framing square?

Maintaining a framing square is simple but vital for accuracy.

- Regular cleaning: Wipe off any dirt or debris after each use.

- Inspect for damage: Check for bends, cracks, or wear on the blade. Replace if necessary.

- Proper storage: Store in a dry place, away from excessive heat or moisture. A tool case helps safeguard against damage and loss.

- Lubrication (optional): A light coating of oil can help prevent rust, especially on steel squares.

A well-maintained square is a reliable tool that you can trust time and again, and that pays dividends in efficient, accurate work.

Q 13. Describe how to use a framing square for marking angles.

The framing square’s markings make it ideal for marking angles. The square’s edges and the various markings on its face (like the rafter table) allow for precise angle transfer.

For example, to mark a 45-degree angle: Align one edge of the square along your workpiece, and mark along the other edge that creates the right angle to get the 45-degree angle. The square’s 45-degree markings can be directly used.

Other angles can be marked similarly by utilizing the different markings on the square, or by using trigonometry and the square’s inch markings if an uncommon angle is needed.

Many experienced framers often mark a common angle directly from the square onto a piece of wood, and then use this as a template to produce subsequent cuts.

Q 14. What safety precautions should be taken when using a framing square?

Safety is paramount when working with any tool, including a framing square.

- Wear appropriate safety glasses: This protects your eyes from potential debris during cutting or marking.

- Use caution when handling sharp edges: The square’s edges can be sharp; be mindful to avoid cuts and scrapes.

- Ensure proper footing and stability: Don’t reach or work from an unstable position.

- Keep the workspace clear: A cluttered workspace increases the risk of accidents.

I’ve seen firsthand how carelessness can lead to injuries, so always prioritize safety to ensure a safe and productive work environment.

Q 15. Explain how to use a framing square to create different angles.

The framing square’s versatility lies in its ability to create various angles. Its two arms, typically at a 90-degree angle, act as a base for creating other angles. Think of it as a highly accurate, easily portable protractor and ruler combined.

To create an angle, simply align one arm of the square with a reference line (like an edge of a board), then use the other arm to mark the desired angle. For example, to create a 45-degree angle, you’d use the markings on the square itself, often found on the tongue (the shorter arm). Many framing squares clearly mark common angles like 30, 45, and 60 degrees, but you can use trigonometry and measurements to create virtually any angle.

- Example: Let’s say you need a 30-degree angle. Align one arm of the framing square with the edge of your lumber. Find the 30-degree mark on the tongue (usually clearly labeled), and make a mark along this line. Now you have a 30-degree angle clearly defined!

- Complex Angles: For angles not directly marked, you can use the square’s measurement markings alongside basic trigonometry (sine, cosine, tangent) to calculate and create more complex angles.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe how to accurately transfer measurements using a framing square.

Accurately transferring measurements with a framing square involves using its marked edges and right angle. It’s simpler than you might think. Think of it as a high-precision measuring and marking tool.

Method:

- Measure: Use the framing square’s tongue or blade to measure the distance you want to transfer.

- Mark: Carefully make a mark on the material at the measured point using a pencil.

- Transfer: Place the square against the reference point of the second material, aligning the square’s edge with the previously marked measurement.

- Mark again: Mark the transferred measurement on the second material using the other edge of the square as a guide.

Example: If you need to transfer a 12-inch measurement from one piece of lumber to another, measure 12 inches along one arm of your square and make a mark. Now place the square onto your new piece of lumber, aligning the edge with your reference point and mark the 12-inch point on your new lumber.

Q 17. How do you use a framing square to construct a stair stringer?

Constructing a stair stringer—the angled support for stairs—is a classic application of the framing square. It requires understanding rise (vertical height between steps), run (horizontal distance between steps), and the relationship between them.

The process utilizes the square’s markings (often including stair gauges) and involves transferring measurements from a layout to the lumber. This is best done with accurate measurements.

Step-by-step process:

1. Determine the rise and run of each stair step.

2. Use the framing square to layout the pattern using the rise and run numbers.

3. Transfer the pattern onto the wood that will become the stringer.

4. Cut along the traced lines.

5. Repeat for the other stringers.

Framing Square’s Role: The square assists in accurately transferring these rise and run measurements to create the precisely angled cuts necessary for the stair stringer’s construction.

Q 18. What are some alternative tools that can be used for similar tasks as a framing square?

While the framing square is incredibly versatile, other tools can accomplish similar tasks. The choices depend on the specific application.

- Speed Square: A smaller, more compact version, ideal for quicker tasks and marking angles.

- Protractor: For precise angle measurement and marking, although less convenient for transferring measurements.

- Combination Square: Offers a combination of measuring and marking capabilities, including a protractor head for angle work.

- Miter Saw with Adjustable Stops: For repetitive cuts at specific angles, ensuring consistency.

- Digital Angle Finder: For precise angle measurement, particularly useful in situations where accuracy is paramount.

The best alternative depends on the job’s complexity and the required precision.

Q 19. How can you determine the pitch of a roof using the framing square?

Determining roof pitch (the slope of a roof) using a framing square involves understanding the relationship between rise (vertical height) and run (horizontal distance). The framing square helps to translate these into common roofing terms.

Roof pitch is often expressed as a ratio (e.g., 4:12), meaning a 4-inch rise for every 12 inches of run. You can use the framing square’s markings or its ability to measure rise and run to find this ratio.

Method: Measure a representative section of the roof’s rise and run. Then, using the framing square, determine the ratio between these two measurements. This ratio translates directly into the roof’s pitch.

Q 20. Explain the use of the brace marks on a framing square.

Brace marks on a framing square are pre-marked measurements and angles that assist in the construction of common roof rafters. The marks provide quick reference points for cutting rafters to create the correct angles needed for supporting roofs.

How they work: These marks represent specific angles and lengths, eliminating the need for complicated calculations. By aligning the brace marks with a rafter’s dimensions, you get the precise cuts needed. They’re usually marked for various roof pitches.

Practical use: Using a framing square with brace marks saves time and effort. With correct identification and use, they are invaluable for quickly and accurately cutting rafters.

Q 21. What is the difference between a speed square and a framing square?

While both speed squares and framing squares are used for marking angles and measurements in carpentry, they have key differences:

- Size and Portability: Speed squares are smaller and more compact, making them ideal for one-handed use and portability. Framing squares are larger and more substantial, providing a longer measuring surface.

- Markings: While both have angle markings, framing squares often include more detailed markings, including stair gauges, brace marks, and other specialized measurements. Speed squares tend to have more basic angle markings.

- Applications: Framing squares are suited for larger construction tasks and accurate measurement, while speed squares are more often used for faster tasks such as marking cuts on smaller pieces of wood.

Essentially, a speed square is a more specialized, smaller, and more portable version of the framing square, excellent for quick tasks, while the framing square is favored for more complex projects that require more versatile measurement capabilities. The framing square is often preferred for stair building. They are both invaluable tools in any carpentry toolbox.

Q 22. Describe how to use a framing square for marking octagons.

Marking octagons with a framing square leverages its ability to create accurate angles. You won’t find a direct octagon layout on the square, but we use its ability to find 45-degree angles repeatedly.

- Step 1: Establish your central point. This will be the center of your octagon.

- Step 2: Draw a starting line. From your central point, draw a straight line outwards – this will be one side of your octagon.

- Step 3: Use the square to mark 45-degree angles. Place one leg of the framing square along your starting line, and use the other leg to mark a 45-degree angle from the central point. This is crucial for achieving an octagon’s 135-degree interior angles.

- Step 4: Repeat for the remaining sides. Repeat Step 3, pivoting around the central point, to mark seven additional 45-degree angles. Ensure each line is the same length to ensure an accurate octagon.

- Step 5: Connect the lines. Connect the ends of your marked lines to create your octagon. You may need to use a combination square or speed square for the connection lines depending on the length and material.

This process requires careful measurement and precise angle marking, but the framing square is an indispensable tool for this task.

Q 23. How do you solve problems involving complex roof layouts using a framing square?

Complex roof layouts often involve multiple angles and intersecting planes. The framing square is invaluable for breaking down these complexities into manageable parts. Think of it as a geometric translator. It helps you convert abstract roof plans into practical cutting instructions.

Here’s how I approach complex roof layouts:

- Careful Plan Review: I start by meticulously reviewing the architectural plans to fully understand the roof’s geometry, including rafter lengths, angles, and hip/valley intersections.

- Breaking Down the Problem: I decompose the complex structure into simpler geometric shapes – triangles, rectangles, and trapezoids – easily workable with the framing square.

- Angle Calculation: Using the framing square’s various scales and markings (discussed in the next question), I determine the precise angles for each cut, especially for hips, valleys, and jack rafters. Trigonometry might be helpful, but most carpenters can handle this using the square.

- Layout on Lumber: I transfer those calculated angles to the lumber using the framing square, carefully marking each cut location. I double-check my measurements at every stage to minimize errors.

- Cutting and Checking: I execute each cut with precision. Dry fitting before assembly is essential to ensure proper alignment and avoid costly mistakes.

Remember: accuracy is paramount in roofing. A well-used framing square prevents mistakes and ensures a structurally sound roof.

Q 24. Can you explain the use of the various tables and markings found on the framing square?

The framing square is more than just a right angle; it’s a mini-toolbox of information. The most commonly used tables are those for:

- Rafter Lengths: These tables assist in calculating rafter lengths based on the desired roof pitch (slope). Usually, you’ll need to input the rise and run measurements to determine the correct length from the tables.

- Octagon Measurements: While not explicit, as explained earlier, the 45-degree markings facilitate the creation of octagons.

- Essex Board Measure: This is less common now with digital tools, but it was historically used to quickly estimate the amount of lumber needed for a project.

- Other Markings: Many framing squares include markings for common angles, such as 30, 45, and 60 degrees, facilitating various cuts.

Besides tables, the actual body of the square itself is marked with inches and fractional subdivisions for accurate measurements. The combination of these features makes it a versatile tool for any carpenter.

Q 25. Explain how to use a framing square to create accurate cuts for various joints.

The framing square’s strength lies in accurately transferring angles to lumber. Different joints require different angles. Let’s illustrate with some examples:

- Butt Joints: While simple, the framing square ensures the ends of the lumber are perfectly square for a strong, flush joint. It’s an ideal tool for setting up your cuts before using a saw.

- Miter Joints: For angled connections, such as picture frames or crown molding, the square helps create the precise angle needed. Using the appropriate angles (often 45 degrees) is critical for perfect joints. Use the square to mark the angle on the wood before cutting.

- Dovetail Joints: Although complex, the framing square’s accurate measurements are crucial for marking the tails and pins precisely. The square gives consistent angle guides for accurate layout.

- Half-Lap Joints: The square is used to mark both the lap and the shoulder cuts, ensuring they align perfectly when the two pieces are joined together. The square acts as a guide for marking the exact points of intersection.

In each case, the framing square provides a consistent and accurate reference point, ensuring clean, strong joints.

Q 26. How would you use a framing square to lay out a gable end?

Laying out a gable end involves establishing the correct angle of the rafters and ensuring they meet precisely at the peak. The framing square is vital here:

- Determine the Roof Pitch: This is crucial and determines the angle of your rafters. The plans will usually specify the pitch (e.g., 7/12), or you can use the plan to calculate this.

- Use Rafter Tables (if available): If your framing square has rafter tables, use the pitch and desired run (horizontal distance) to find the correct rafter length and angle.

- Mark the Rafter Angle: Use the framing square to mark the calculated angle on the lumber for each rafter. This ensures all rafters have the same angle, leading to a symmetric gable.

- Plumb Cut: The framing square is also used to ensure the plumb cut (the vertical cut at the top end of the rafter) is square and properly aligns with the ridgeboard. The square enables precise marking to help the rafter meet the ridgeboard correctly.

- Layout on Gable End: Transfer the measurements and angles to the gable end studs, aligning the top ends of the rafters to create a clean peak. The square helps ensure these alignment cuts are precisely at the right angle.

Without a framing square, achieving an accurately constructed gable end would be very difficult and time consuming.

Q 27. Describe a situation where you had to use a framing square to solve a complex problem on a job site.

On a recent renovation project, we were adding a dormer to an existing roof. The dormer had a complex intersection with the main roof, involving several different angles and planes. The framing square became invaluable in calculating and marking several key cuts.

The challenge was determining the exact angles for the various intersecting rafters and the fascia board around the dormer. Simply using a speed square, or relying on visual estimation, wouldn’t have provided the needed accuracy. Instead, we systematically used the framing square to mark each rafter’s angles to match the main roof’s pitch and the dormer’s pitch, while ensuring the proper intersection points. The square’s ability to define both angles and lengths allowed us to overcome the complex geometry, resulting in a seamless integration of the dormer with the existing roofline.

Without the precise measurement and angle transfer capabilities of the framing square, we would have struggled to achieve a structurally sound and aesthetically pleasing result. The entire project might have experienced considerable delays and rework.

Q 28. How would you explain the use of a framing square to someone with no carpentry experience?

Imagine a framing square as a really smart, super-accurate right-angle ruler. Carpenters use it to create perfect angles and measure lengths precisely in wood. It’s like a combination of a ruler, a protractor, and a specialized calculator all in one tool.

You see that right angle? That’s crucial for building strong, stable structures, like houses and sheds. The square also has markings that help carpenters quickly figure out things like how long to cut wood for a slanted roof or how to connect pieces of wood at an angle. It’s an indispensable tool that takes the guesswork out of carpentry, helping carpenters create strong, well-built constructions and avoiding mistakes that can weaken a structure. It ensures that everything lines up perfectly, resulting in structures that are both safe and visually appealing.

Key Topics to Learn for Framing Square Utilization Interview

- Understanding the Tool: Familiarize yourself with the different parts of a framing square and their functions. This includes the tongue, blade, and various markings.

- Common Calculations: Master calculations involving finding angles, determining rafter lengths, and calculating cuts for various joinery techniques. Practice using the square for both simple and complex cuts.

- Practical Applications: Understand how to use the framing square in various carpentry scenarios, including roof framing, wall framing, and stair construction. Be prepared to discuss specific examples.

- Reading the Markings: Become proficient in interpreting the various scales and markings on the framing square, such as the brace, octagon, and rafter scales. Practice using these scales to solve problems.

- Accuracy and Precision: Discuss the importance of accuracy and precision when using a framing square. Explain techniques for ensuring accurate measurements and cuts.

- Troubleshooting and Problem Solving: Be prepared to discuss common challenges encountered when using a framing square and how to overcome them. This might include dealing with imperfect lumber or complex angles.

- Safety Procedures: Understand and be able to discuss safe practices when handling and using a framing square, including proper storage and maintenance.

- Material Selection & its impact on Square Usage: Discuss how different materials influence the precision and accuracy of cuts made using the framing square.

Next Steps

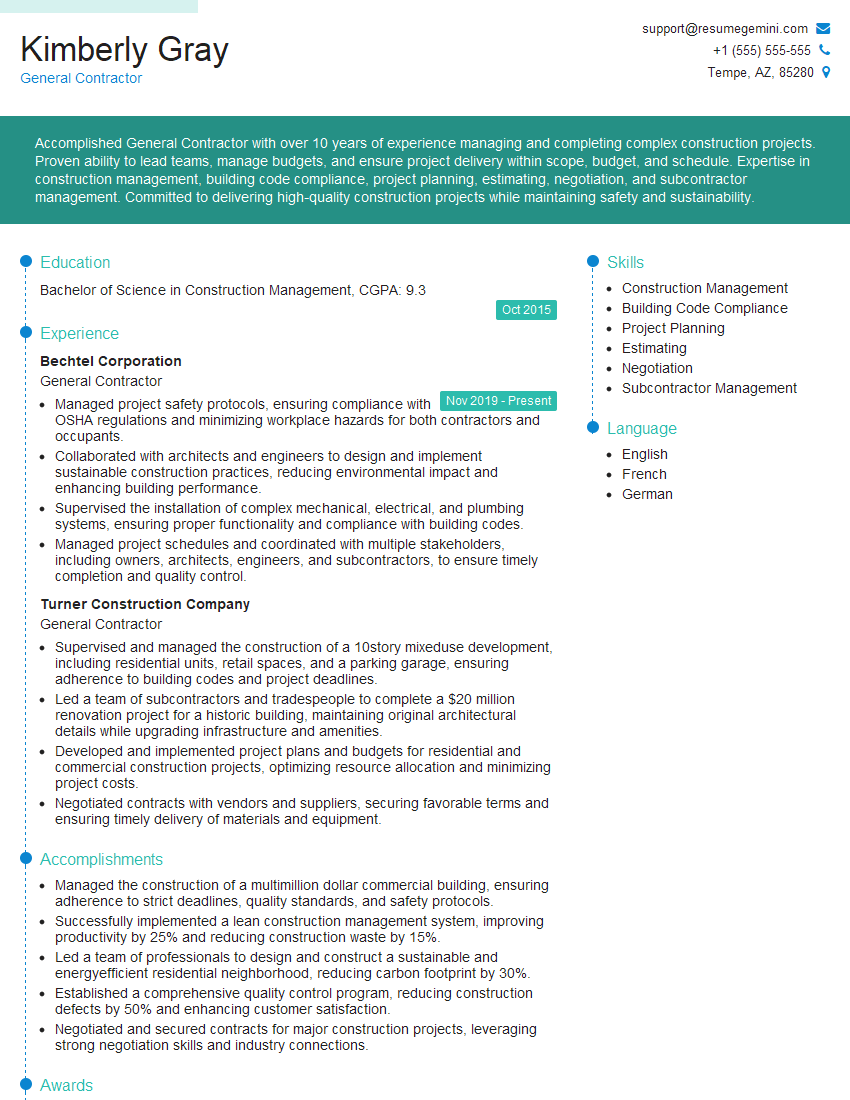

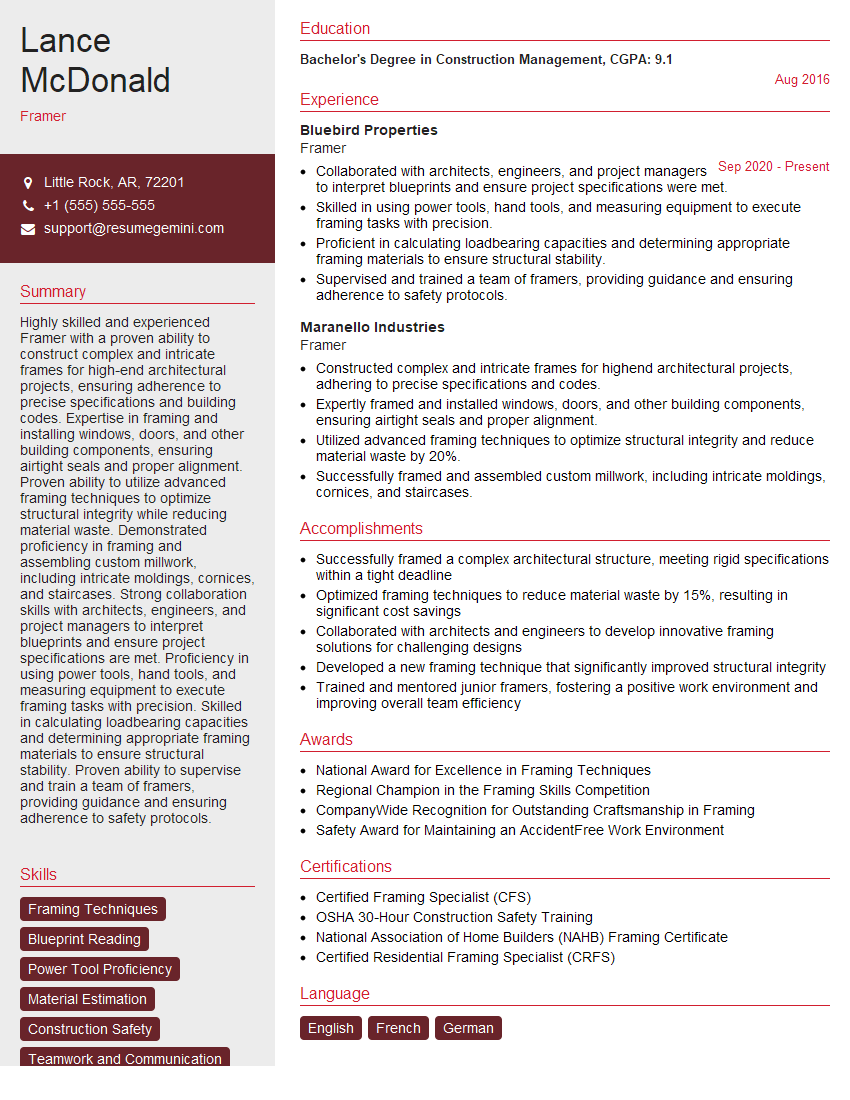

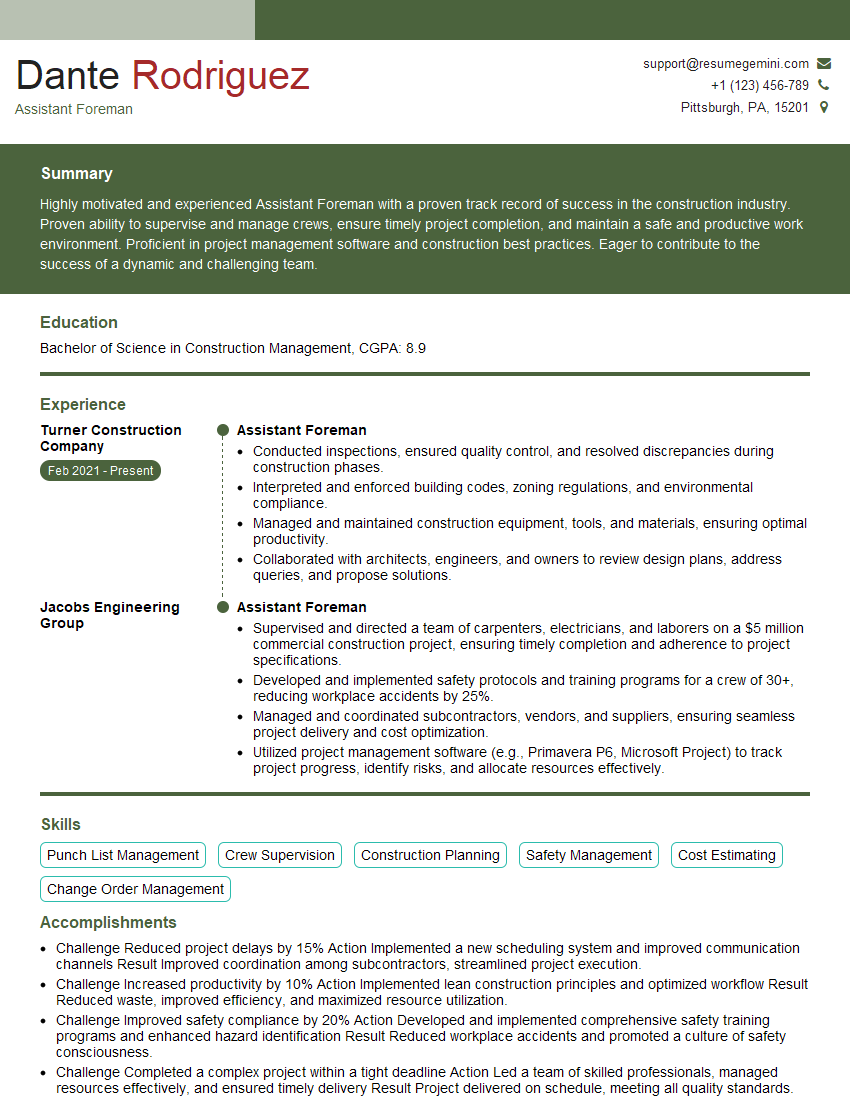

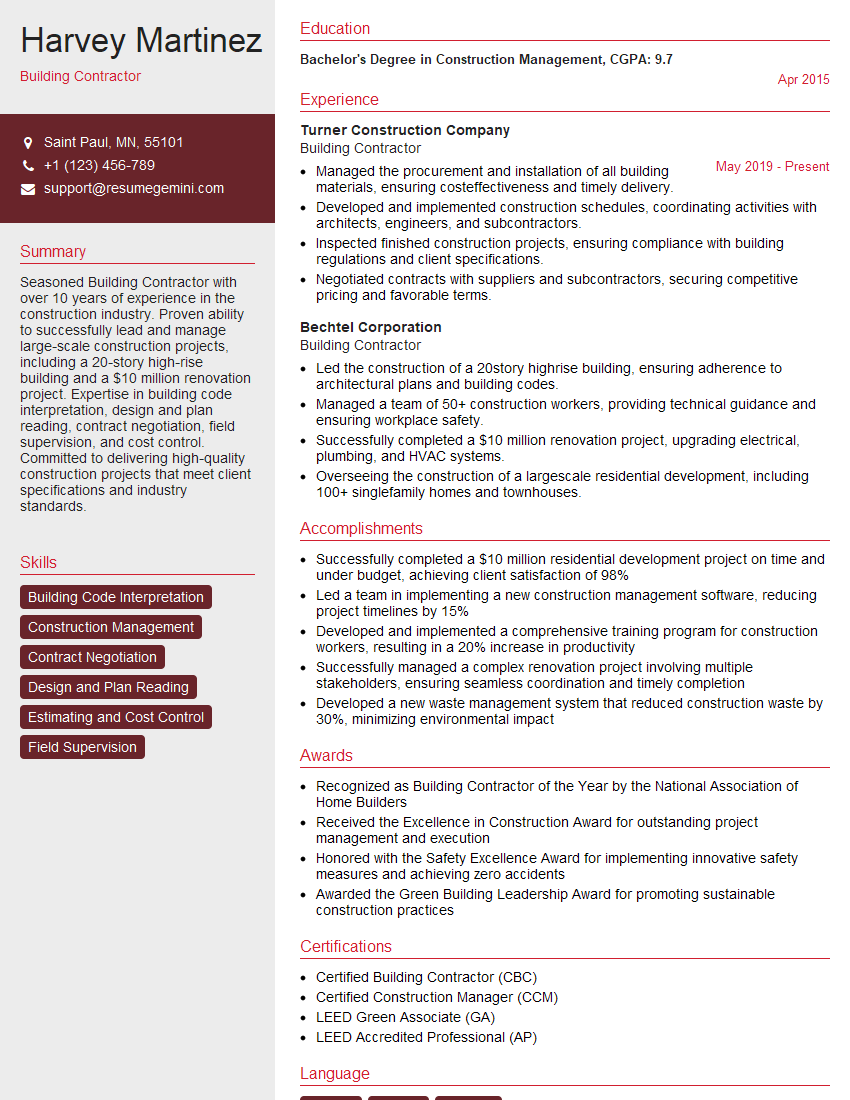

Mastering framing square utilization is crucial for career advancement in the construction and carpentry fields. Proficiency demonstrates precision, problem-solving skills, and a strong foundation in practical carpentry. To increase your job prospects, create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource to help you build a professional resume that stands out. Examples of resumes tailored to framing square utilization are available to guide you. Take the next step and build your winning resume today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?