Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Furniture Staining interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Furniture Staining Interview

Q 1. What types of wood stains are you familiar with (e.g., oil-based, water-based, gel)?

Wood stains come in several varieties, each with its own characteristics and applications. The three most common types are oil-based, water-based, and gel stains.

- Oil-based stains: These penetrate deeply into the wood, resulting in rich, vibrant colors and a durable finish. They offer excellent grain enhancement but require longer drying times and need mineral spirits for cleanup. Think of them as deeply moisturizing the wood.

- Water-based stains: These are easier to clean up (soap and water!), dry faster, and are generally less odorous than oil-based stains. They penetrate well, but might not offer the same depth of color as oil-based stains. They’re a good all-around choice.

- Gel stains: These are thicker than oil-based or water-based stains, which makes them ideal for vertical surfaces as they don’t run as easily. They provide excellent coverage and are great for hiding imperfections, but they can be more difficult to work with and may not penetrate as deeply.

Choosing the right stain type depends on the project, the type of wood, and your personal preference. For example, I might choose oil-based for a fine piece of mahogany furniture where deep penetration and rich color are desired, while a water-based stain might be more suitable for a quick project on pine.

Q 2. Explain the process of preparing wood for staining.

Proper wood preparation is crucial for a successful staining project. It’s like prepping your canvas before painting a masterpiece! The process typically involves these steps:

- Cleaning: Remove any dust, dirt, grease, or old finish with a suitable cleaner. I often use a tack cloth followed by a light sanding.

- Sanding: Sanding smooths the wood surface, allowing for better stain penetration and a more even finish. I usually start with a coarser grit (like 120-grit) and progressively move to finer grits (like 220-grit) for a super smooth surface. The direction of the sanding should follow the wood grain.

- Filling imperfections: Fill any gaps, holes, or knots with wood filler and allow it to dry completely. Sand this smooth once dry.

- Raising the grain: Applying water to the wood before staining will raise the grain. This allows you to sand it down for an extremely smooth finish, preventing a blotchy final result. Let it dry completely after sanding again.

Thorough preparation ensures a uniform stain application and a professional-looking result. Skipping steps leads to uneven color, poor penetration, and a less-than-satisfying finish.

Q 3. How do you achieve a consistent stain color across a large piece of furniture?

Achieving consistent color across a large piece requires careful planning and execution. Think of it like painting a wall – you wouldn’t just slap on paint in random patches!

- Work in sections: Divide the project into smaller, manageable sections. This prevents the stain from drying before you can blend it properly.

- Maintain a wet edge: When staining, try to keep a wet edge. This means overlapping each stroke to prevent lap marks and ensures a smooth transition between sections.

- Use consistent pressure: Apply the stain with even pressure using whichever method you choose (brush, rag, spray).

- Test your stain: Always test your stain on a scrap piece of the same wood to see how it absorbs. This helps determine how much stain to apply and how long to leave it on.

- Work quickly and efficiently: If you’re using a product with a short open time, you will need to work even faster to achieve a consistent color.

By following these steps, you can minimize variations and achieve a professional, uniform finish on even the largest furniture pieces. Remember: practice makes perfect!

Q 4. What are the different methods for applying wood stain?

Several methods can be used to apply wood stain, each with its own advantages and disadvantages.

- Brushing: This is a common method for applying stain, especially for detailed work. A good quality brush with soft bristles helps to avoid streaks. I use this often for intricate furniture pieces.

- Wiping: Using rags or cloths allows for better control and is good for achieving a more natural, less uniform finish. Great for rustic or distressed looks.

- Spraying: Spraying provides a very even finish, especially for large surfaces, but requires specialized equipment (HVLP sprayers are excellent) and proper ventilation.

- Padding: Using a foam pad, similar to a sponge roller, for stain application is another option for even application. This can be good for achieving a smoother finish than with a brush and reduces streaks.

The best method depends on the desired finish and the scale of the project. For example, I might use a brush for a detailed antique dresser and spraying for a large dining table. Experimentation with smaller projects will help you choose what works best for you!

Q 5. Describe your experience with various staining techniques (e.g., wiping, brushing, spraying).

My experience encompasses all three primary stain application methods: wiping, brushing, and spraying.

- Wiping: I find wiping especially useful for achieving a more subtle, natural finish. The control it offers is unmatched for distressing techniques or highlighting wood grain.

- Brushing: Brushing offers excellent control for detailed work and getting stain into tight areas. This is my go-to method for most projects due to its versatility.

- Spraying: Spraying is best for large, flat surfaces where a consistent, even finish is crucial. It can save time and effort on large pieces, but requires precision and attention to ventilation and overspray.

I’ve learned that mastering each technique requires practice and an understanding of the specific characteristics of the stain being used and the wood type. It is important to adjust your application technique based on the stain and project.

Q 6. How do you handle wood grain variations during staining?

Wood grain variations are a natural characteristic, and they can significantly impact how the stain is absorbed. It’s all part of the beauty of natural wood!

The key is to work with the grain, not against it. This means applying stain in the direction of the grain to ensure even penetration and minimize blotchiness. For example, applying stain across the grain can leave dark streaks in some areas. The best approach depends on the wood type and stain; some woods, like oak, are more prone to uneven absorption. Pre-treating the wood with a wood conditioner can help to even out absorption, reducing the appearance of blotchiness.

Often, embracing the natural variations rather than fighting them leads to a more authentic and attractive finish. Think of it like the unique character of a fingerprint – it adds to the overall appeal!

Q 7. What are the common problems encountered during staining, and how do you troubleshoot them?

Several issues can arise during staining. Here are some common problems and solutions:

- Uneven color: This often stems from inadequate preparation (poor sanding, uneven application, insufficient pre-treatment) or using the wrong type of stain for the wood. Solution: Proper preparation is key! Use a wood conditioner if necessary, and always apply stain evenly, maintaining a wet edge.

- Blotchiness: Certain wood types absorb stain unevenly. Solution: Use a wood conditioner to pre-treat the wood before applying stain; this helps even out absorption. Wiping stains, applied in thin coats, help minimize blotchiness.

- Streaking: Usually caused by uneven application of stain or using a brush with harsh bristles. Solution: Practice maintaining a wet edge and using proper application techniques. A high quality brush with soft bristles will help minimize streaks.

- Dust nibs: Dust particles settling on the wet stain before it dries. Solution: Work in a clean, dust-free environment. Use a tack cloth or vacuum to remove any debris.

Careful attention to detail and understanding wood’s properties are essential for preventing and resolving these problems. Remember that practice and patience will improve your results over time.

Q 8. How do you select the appropriate stain color for a project?

Selecting the right stain color is crucial for a successful project. It involves considering the wood type, the desired aesthetic, and the overall design scheme. Think of it like choosing paint for a room – you wouldn’t use a bright red in a bedroom meant for relaxation!

First, I analyze the wood’s natural color and grain. A lighter wood like maple will take stain differently than a darker wood like walnut. The grain pattern itself can also influence how the stain looks; a very open grain might show more variation. Then I consider the project’s purpose and surroundings. A rustic farmhouse table might benefit from a warm, honey-toned stain, while a sleek, modern coffee table might suit a darker, ebony finish. I often test stain samples on scrap wood pieces, applying multiple coats to see how the color develops. Natural lighting versus artificial lighting also plays a significant role in color perception. Finally, I discuss options with the client, presenting them with swatches and test pieces under various lighting conditions to ensure they’re completely satisfied with the final color choice.

Q 9. Explain the importance of proper ventilation when working with stains.

Proper ventilation is paramount when working with wood stains and finishes because many contain volatile organic compounds (VOCs) – these are chemicals that evaporate easily and can be harmful when inhaled. Imagine trying to bake a cake in a sealed oven – it wouldn’t turn out well, and you’d likely feel the effects of the heat! Similarly, inadequate ventilation when staining can lead to headaches, dizziness, and respiratory problems.

To ensure proper ventilation, I always work in a well-ventilated area, preferably outdoors or in a space with powerful exhaust fans. If working indoors, I open windows and doors and use fans to draw fresh air in and fumes out. I also wear a respirator to filter out any airborne particles or VOCs. This commitment to safety is non-negotiable for me and for the longevity of my projects. Remember, a well-ventilated workspace protects both your health and the quality of your work.

Q 10. What safety precautions do you take when using wood stains and finishing products?

Safety is my top priority. When working with wood stains and finishes, I always follow these precautions:

- Wear appropriate personal protective equipment (PPE): This includes safety glasses, gloves (nitrile is recommended for stain resistance), and a respirator.

- Work in a well-ventilated area: As discussed earlier, this is crucial for reducing exposure to VOCs.

- Follow product instructions carefully: Each stain and finish has specific instructions for application, drying time, and cleanup. Ignoring these can lead to uneven results or health risks.

- Use proper cleanup procedures: Many stains are flammable; dispose of rags properly to prevent spontaneous combustion. Never pour stains or solvents down the drain; use appropriate containers and disposal methods.

- Store materials safely: Keep all stains and finishes securely stored away from children and pets in a cool, dry place.

I also make sure to thoroughly wash my hands after completing the staining process, and to clean my tools immediately to prevent build-up and maintain proper tool care.

Q 11. Describe your experience with different types of sealers and topcoats.

My experience encompasses a wide range of sealers and topcoats, each offering unique properties. I select them based on the project’s requirements and the desired final finish.

For example, I often use water-based polyurethane for its low-odor and easy cleanup. It’s a good all-around choice for many projects. For durability, I might opt for oil-based polyurethane, which offers excellent protection against wear and tear but has a longer drying time and a stronger odor. For a more natural look, I’ll sometimes use a shellac or a wax finish, providing a smoother feel and a subtle sheen. Choosing the right topcoat depends heavily on the client’s expectations: Do they prioritize durability, ease of maintenance, or a specific aesthetic?

I’ve also worked with specialized sealers like dewaxed shellac for use as a barrier coat before applying other finishes. This prevents the underlying stain from bleeding through and ensures a smooth and uniform final result. Each project presents its own challenges and requires a thoughtful assessment of the available options to achieve the best possible outcome.

Q 12. How do you ensure the longevity and durability of your stain job?

Ensuring longevity and durability involves a multi-faceted approach, starting with proper wood preparation. This includes sanding to achieve a smooth surface, filling any cracks or imperfections, and cleaning the wood to remove dust and debris.

The stain itself plays a critical role; I usually apply multiple thin coats rather than one thick coat. This allows for better penetration and a more even color. The choice of sealer and topcoat is also critical, as these provide long-term protection against scratches, moisture damage, and UV degradation. I carefully follow the manufacturer’s instructions regarding drying times between coats. Finally, regular maintenance, such as dusting and occasional cleaning, plays a role in preserving the finish. For example, for high-traffic areas, I might suggest using coasters to protect the surface from water rings or scratches. It’s not just about the application; it’s about giving my clients advice on preserving the work long term.

Q 13. What is your experience with color matching and custom stain blending?

Color matching and custom stain blending are frequent parts of my work. I’ve developed a keen eye for color and a strong understanding of how different stains interact. It’s almost an art form. I often start with a base stain and then carefully add tints or other stains to achieve the precise shade the client desires. It’s a bit like mixing paints, but with much more nuance due to the nature of wood absorption.

For example, a client might bring in a sample of fabric or a paint chip as inspiration. I’ll then experiment with different stain combinations on test pieces, carefully adjusting the ratios until I achieve a near-perfect match. This process involves patience and precision, as even small adjustments can significantly impact the final color. Digital color matching tools can be helpful but often need adjustments based on the specific wood’s response to the stain.

Q 14. How do you address imperfections or blemishes in the wood before staining?

Addressing imperfections before staining is essential for a professional-looking finish. Ignoring blemishes can lead to an uneven stain and a less-than-desirable result. Think of it like applying makeup – you wouldn’t apply foundation directly over a pimple without first addressing it!

My process starts with a thorough inspection of the wood. I use wood filler to repair any cracks or gaps, ensuring it’s the same color or tone as the surrounding wood. After the filler dries, I sand the area smooth. For minor scratches or dents, I might lightly sand the entire surface to create a consistent texture. Then, I clean the wood thoroughly to remove dust and debris, using a tack cloth for the final wipe down. This careful preparation is crucial; it guarantees a beautiful and even stain application and prevents uneven color or absorption.

Q 15. What is your experience with antique or distressed furniture finishing?

Antique and distressed furniture finishing is a specialized area requiring a deep understanding of both wood and finishing techniques. It’s not just about applying stain; it’s about recreating history or suggesting age and wear. My experience encompasses various techniques, including the use of glazes to add depth and shading, dry brushing to highlight textures, and the application of crackle medium for a truly antique look. I’ve worked on pieces ranging from 18th-century tables to mid-century modern dressers, carefully assessing each piece’s existing finish and potential before determining the most appropriate approach. For instance, a heavily lacquered piece might require stripping before distressing, while a piece with a good original finish may only need subtle enhancements. Each project demands a unique approach that blends artistic sensibilities with preservation principles.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with different types of wood and their staining properties.

Different woods react to stains in unique ways. Hardwoods like oak, cherry, and walnut have distinct grain patterns and densities that influence stain absorption. Oak, for example, often has a closed grain, leading to a more uniform stain, while walnut’s open grain can create a more dramatic effect. Softwoods like pine and fir are less dense and can absorb stains more readily, sometimes unevenly. This can be exploited for specific effects, but requires careful control. Understanding these differences is critical. I might use a pre-stain conditioner on softwoods to even out absorption, while a wood with a naturally rich color might only require a toner to enhance its natural beauty. My experience covers a wide range, from the reddish hues of mahogany to the lighter tones of maple and birch. I always test the stain on a hidden area first to avoid surprises.

Q 17. What tools and equipment are essential for efficient furniture staining?

Efficient furniture staining requires a well-equipped workspace. Essential tools include various brushes – natural bristle for oil-based stains, synthetic for water-based – and quality sanding tools such as orbital sanders and sanding blocks with different grits of sandpaper. A tack cloth is crucial for removing dust after sanding. Accurate stain application often requires lint-free rags and a spray bottle for water-based stains. Protective gear such as gloves, a respirator (especially for oil-based products), and safety glasses are non-negotiable for safety and health. I also use a variety of scrapers and steel wool for cleaning and prepping surfaces, as well as clamps for holding pieces together during the finishing process.

Q 18. How do you maintain your staining tools and equipment?

Maintaining staining tools is paramount for longevity and quality. Brushes should be thoroughly cleaned immediately after use, with appropriate solvents depending on the type of stain. Oil-based stains require mineral spirits, while water-based stains are cleaned with soap and water. Sandpaper is expendable, but sanding blocks should be cleaned regularly. I store my brushes in a designated area away from dust and moisture. Rags used for wiping stain should be disposed of properly, as they can spontaneously combust if improperly stored. Overall, cleanliness and careful organization are key to efficient maintenance.

Q 19. Describe your experience with large-scale furniture staining projects.

Large-scale projects require meticulous planning and execution. I’ve worked on projects involving dozens of chairs, sets of tables, and even entire room sets. In these instances, efficient workflow is critical. This includes setting up an assembly line-style system where different team members are responsible for preparation, sanding, staining, and finishing. Careful pre-planning, including precise measurements and material ordering, is essential to avoid delays. Proper staging and storage of materials are also crucial for an organized workspace. For example, recently I stained all the chairs for a banquet hall – having a dedicated team for each phase sped up the process significantly. Effective communication within the team is paramount for success.

Q 20. How do you manage your time and prioritize tasks during a staining project?

Time management is vital. I prioritize tasks based on deadlines and dependencies. For example, preparing the wood is always the first priority, followed by sanding and finally staining. Large projects are broken down into smaller, manageable tasks with clear timelines. I use project management tools to track progress and identify potential bottlenecks. A Gantt chart, for instance, can visually represent the timeline, assisting in maintaining efficiency and ensuring that each step is completed on schedule. This also helps with resource allocation.

Q 21. How do you handle unexpected challenges or issues during a project?

Unexpected challenges are inevitable. Whether it’s wood defects, uneven stain absorption, or a change in client requirements, adaptability is key. I’ve faced scenarios where a piece of wood was damaged during the sanding process. This required careful patching and refinishing. I address these issues by systematically assessing the problem, researching solutions, and employing the appropriate techniques to rectify the situation. Clear communication with the client is essential throughout the process, ensuring their understanding and buy-in to any changes in the plan.

Q 22. How familiar are you with different types of wood fillers and their application?

Wood fillers are crucial for achieving a smooth, professional finish on furniture. They come in various types, each suited for different needs. The most common include:

- Wood putty: An easily workable filler, often oil-based, suitable for smaller imperfections. It’s readily available and relatively inexpensive.

- Epoxy fillers: Excellent for larger gaps and cracks, offering exceptional strength and durability. They are often two-part systems that need to be mixed before application.

- Solvent-based fillers: These fillers shrink less than others during drying, making them ideal for larger repairs where shrinkage could be a problem. They’re often harder than putty and require more careful sanding.

- Paste wood fillers: These are easy to use, often water-based, and are ideal for smaller repairs. They are easily sanded once dry.

Application involves carefully cleaning the area to be filled, applying the filler slightly above the surface level to account for shrinkage, letting it dry completely, and then sanding it smooth to match the surrounding wood. The choice of filler depends on the size and nature of the imperfection and the type of wood being repaired. For example, I would use epoxy for a deep crack in a solid oak table but paste filler for a small knot hole in a pine dresser.

Q 23. What is your understanding of color theory as it relates to wood staining?

Color theory is fundamental to successful staining. Understanding the color wheel—primary, secondary, and tertiary colors—helps predict the outcome of mixing stains. For instance, adding a bit of a cool blue to a warm red stain can create a more sophisticated burgundy. Think of it like painting: mixing different stains, much like mixing paints, can create numerous unique shades. Knowing how undertones (the subtle hints of color beneath the surface) in the wood itself interact with the stain is key. For example, a yellow undertone in pine will drastically alter the final color compared to the same stain on maple with a more neutral undertone. I always test stains on scrap pieces of the same wood before applying them to the actual project to avoid surprises.

Considering the surrounding environment is also critical. A light stain will appear different in a brightly lit room than in a dimly lit one. Therefore, color perception plays an important role in selecting and testing stains. I often advise clients to consider the overall design of their room when choosing a stain color, to ensure a harmonious aesthetic.

Q 24. Explain your experience with using different types of sanding equipment and grits.

My experience with sanding equipment ranges from hand sanding (using different grades of sandpaper) to using orbital sanders, belt sanders, and random orbital sanders. The choice depends on the project’s scale and the surface area to be sanded. Hand sanding is perfect for detailed areas or intricate carvings; belt sanders are ideal for large flat surfaces needing quick removal of material; and random orbital sanders are excellent for smoothing and refining surfaces, minimizing swirl marks.

Regarding grits, I use a progression of grits, starting with coarser grits (e.g., 80-100 grit) for initial shaping and removal of significant imperfections, then gradually moving to finer grits (e.g., 150-220 grit) to achieve a progressively smoother finish. For a super fine finish, I might use grits as high as 320 or even higher, particularly before applying a clear coat. The correct sanding technique is as crucial as the equipment and grits: Too much pressure can damage the wood and create uneven surfaces. I always sand with the grain to avoid leaving scratches.

Q 25. What is your experience with finishing techniques other than staining (e.g., painting, lacquering)?

While staining is my specialty, I’m proficient in other finishing techniques. Painting is often used for a more dramatic color change or when the wood’s natural grain isn’t desired. I frequently use high-quality paints designed for furniture, ensuring proper surface preparation beforehand. Lacquering provides a protective and often high-gloss finish, enhancing the look of both stained and painted furniture. I’m also experienced with shellac, which offers a durable and amber-toned finish. The choice of finish depends on the client’s preferences, the type of wood, and the desired aesthetic.

For example, I recently completed a project where the client wanted a bright white finish on a set of kitchen cabinets. Staining wouldn’t have achieved the desired look, so painting with a high-quality, durable enamel paint was the perfect solution. The subsequent application of a clear lacquer provided additional protection and a beautiful shine.

Q 26. How do you ensure that the finished product meets the client’s expectations?

Client satisfaction is paramount. My process starts with a thorough consultation, where I discuss the client’s vision, their expectations, and the piece’s specific requirements. We discuss stain options, finishes, and any special requests. I always provide samples or mock-ups, demonstrating potential outcomes before proceeding with the actual project. Clear communication is vital. I keep the client updated throughout the process, showing photos and discussing any changes or potential issues. Once the project is completed, I perform a final quality check, ensuring that it’s free of imperfections and aligns with the client’s vision. I’m always open to addressing any concerns or making minor adjustments to guarantee complete satisfaction.

Q 27. How do you stay updated with the latest trends and techniques in furniture finishing?

Staying current in this field requires continuous learning. I subscribe to industry magazines, attend workshops and seminars, and actively participate in online forums and communities dedicated to furniture finishing. Following leading furniture makers and restoration experts on social media provides exposure to the newest techniques and products. Additionally, experimenting with new stains, finishes, and techniques in my own workshop allows me to stay ahead of the curve and refine my skillset. I also value feedback from clients, as this provides real-world insights into current trends and preferences.

Q 28. Describe a time you had to adapt your techniques to overcome a challenge during a staining project.

I once faced a challenging project involving a highly figured, highly porous piece of cherry wood. The stain was absorbing unevenly, resulting in blotchy areas. My initial approach, using a standard staining technique, wasn’t effective. To overcome this, I adapted my technique by pre-treating the wood with a wood conditioner. The conditioner helped to even out the wood’s porosity, enabling the stain to penetrate more uniformly. I followed this by applying thin, multiple coats of stain instead of one heavy coat, allowing each coat to dry thoroughly before applying the next. This layered approach resulted in a much more consistent and even finish, exceeding the client’s expectations.

Key Topics to Learn for Your Furniture Staining Interview

- Wood Species and Grain: Understanding different wood types (oak, cherry, maple, etc.), their grain patterns, and how they affect stain absorption and final appearance. Practical application: Knowing which stain to choose for optimal results on various woods.

- Stain Types and Application Methods: Familiarizing yourself with water-based, oil-based, and gel stains; understanding the pros and cons of each, and mastering different application techniques (brush, rag, spray). Practical application: Troubleshooting issues like uneven stain absorption or blotchiness.

- Preparation and Finishing: Mastering the crucial steps of sanding, cleaning, and prepping the wood surface for optimal stain penetration. Understanding different topcoats (lacquer, polyurethane, shellac) and their application methods. Practical application: Diagnosing and resolving common finishing problems like bubbling or uneven sheen.

- Color Theory and Mixing: Understanding color mixing principles to achieve desired shades and tones. Practical application: Creating custom stain blends to match specific client requests or project needs.

- Safety and Environmental Considerations: Understanding and adhering to safety protocols when handling stains, solvents, and finishing products. Knowing environmentally friendly options and disposal methods. Practical application: Maintaining a safe and clean workspace.

- Troubleshooting and Problem Solving: Developing the ability to identify and resolve common issues encountered during the staining process, such as uneven color, blotching, or other imperfections. Practical application: Demonstrating your ability to think critically and find solutions to unexpected challenges.

Next Steps

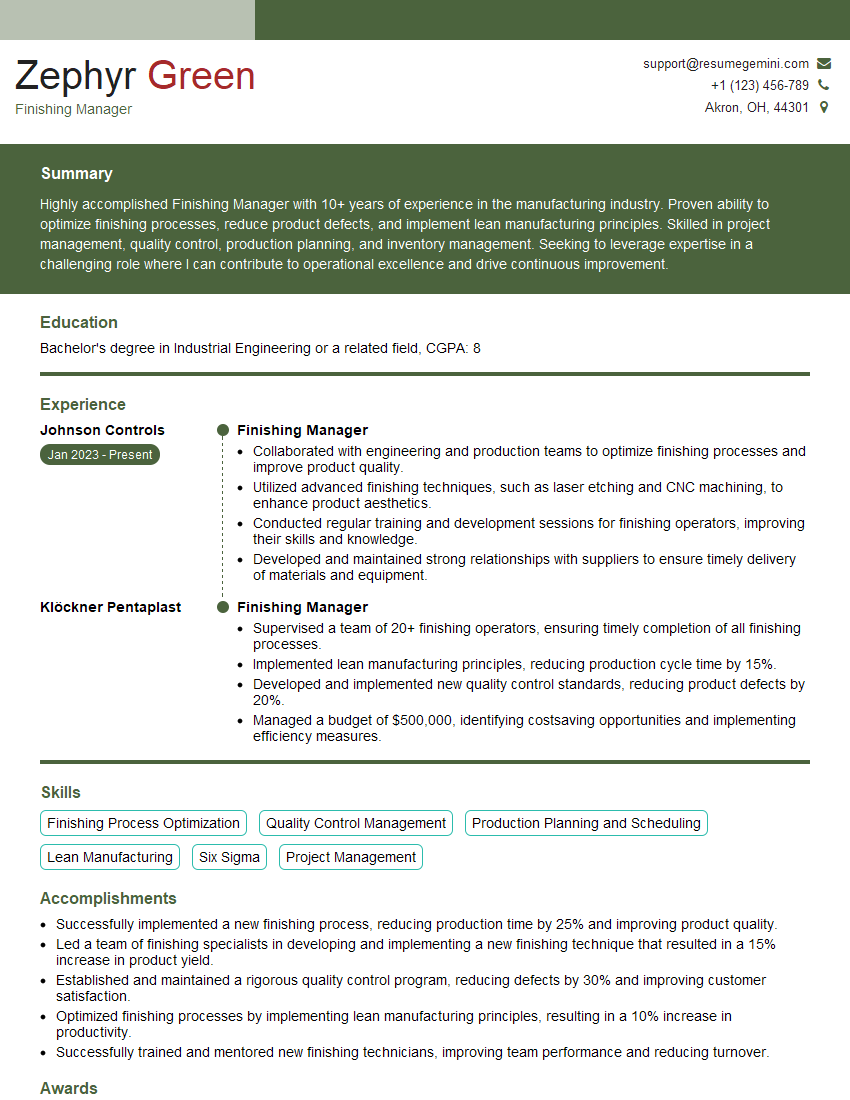

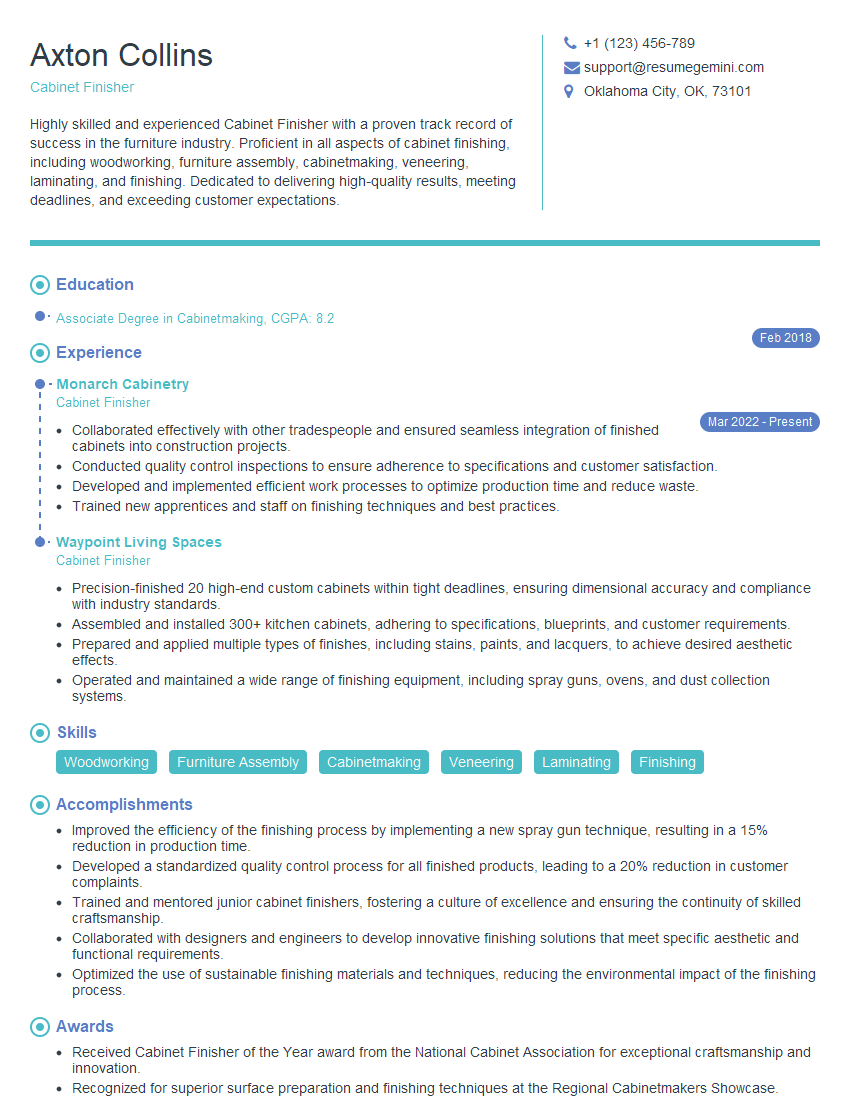

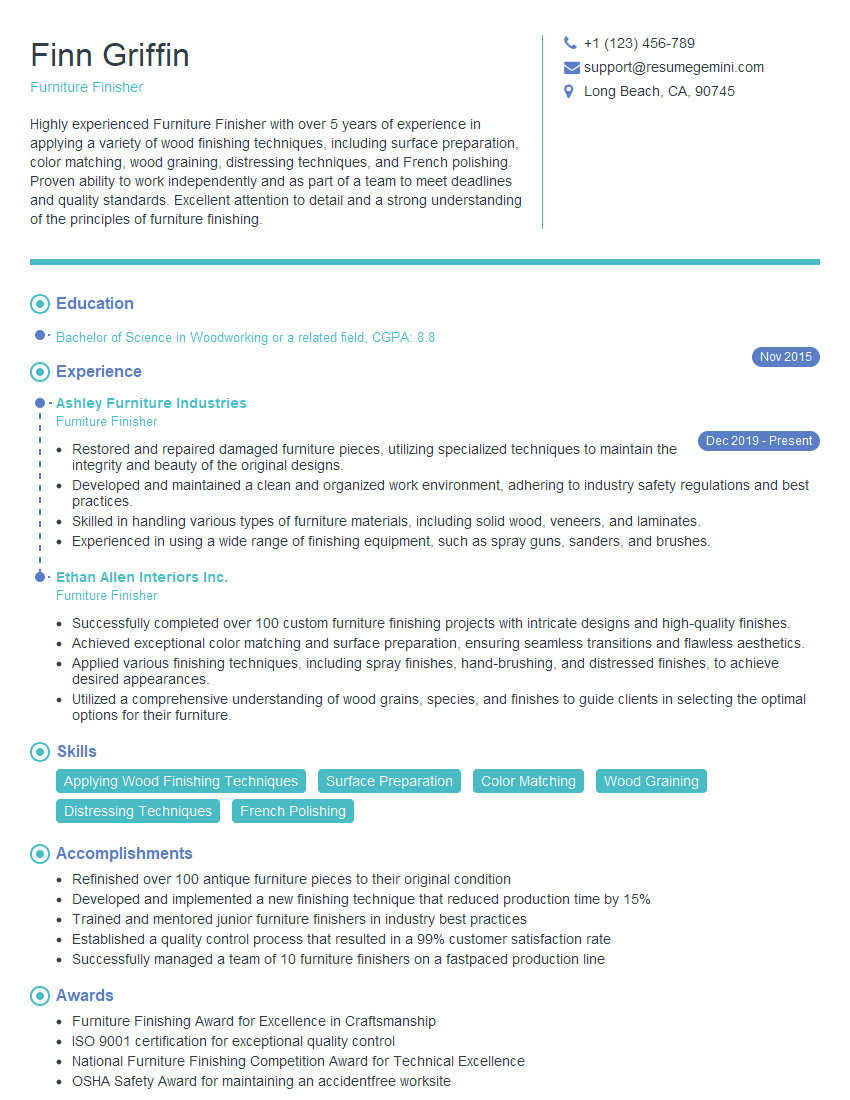

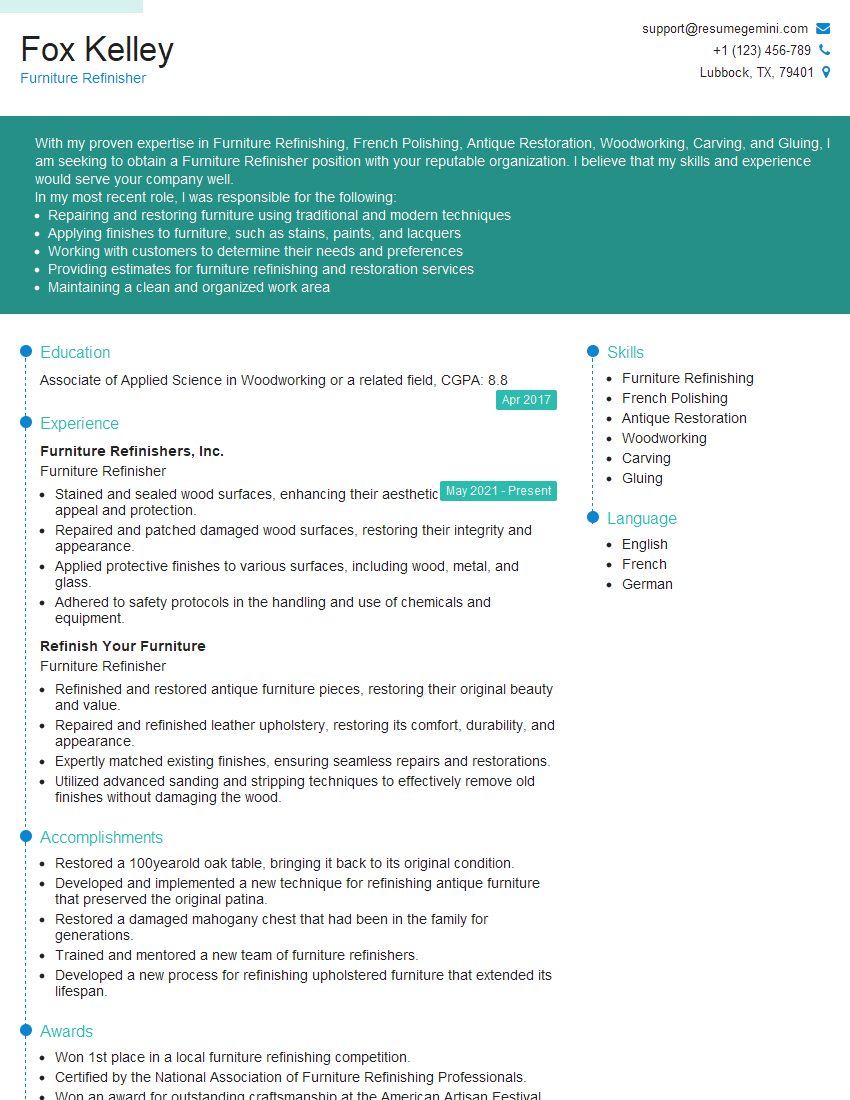

Mastering furniture staining opens doors to exciting career opportunities in woodworking, restoration, and custom furniture creation. To maximize your job prospects, a strong and ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you craft a compelling resume tailored to highlight your skills and experience in furniture staining. Examples of resumes specifically designed for furniture staining professionals are available to guide you. Invest time in building a professional resume—it’s a vital step in securing your dream job.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

hello,

Our consultant firm based in the USA and our client are interested in your products.

Could you provide your company brochure and respond from your official email id (if different from the current in use), so i can send you the client’s requirement.

Payment before production.

I await your answer.

Regards,

MrSmith

hello,

Our consultant firm based in the USA and our client are interested in your products.

Could you provide your company brochure and respond from your official email id (if different from the current in use), so i can send you the client’s requirement.

Payment before production.

I await your answer.

Regards,

MrSmith

These apartments are so amazing, posting them online would break the algorithm.

https://bit.ly/Lovely2BedsApartmentHudsonYards

Reach out at [email protected] and let’s get started!

Take a look at this stunning 2-bedroom apartment perfectly situated NYC’s coveted Hudson Yards!

https://bit.ly/Lovely2BedsApartmentHudsonYards

Live Rent Free!

https://bit.ly/LiveRentFREE

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?