Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Furniture Troubleshooting interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Furniture Troubleshooting Interview

Q 1. Describe your experience diagnosing common furniture malfunctions.

Diagnosing furniture malfunctions requires a systematic approach combining visual inspection, physical testing, and understanding of materials and construction techniques. My experience spans years of working with various furniture types, from antique pieces requiring delicate handling to modern designs using innovative materials. I’ve tackled everything from loose joints and wobbly legs to damaged upholstery and broken mechanisms. I begin by carefully examining the piece, noting any visible damage or wear. Then I perform a series of tests to pinpoint the source of the problem. For instance, a squeaking chair might indicate loose screws or worn-out joints, while a sagging sofa suggests issues with the internal frame or springs. This combined approach allows me to quickly and accurately diagnose the problem and propose an effective solution.

For example, I once diagnosed a seemingly simple wobbly table as having a cracked leg hidden beneath the veneer. A quick visual inspection wouldn’t have revealed it, but by carefully examining the table’s stability and applying pressure to different points, I was able to pinpoint the exact location of the damage, leading to a successful repair.

Q 2. How do you troubleshoot a wobbly table?

Troubleshooting a wobbly table involves identifying the unstable leg(s) and then addressing the root cause. This usually involves tightening loose screws or adjusting the leg’s height. Begin by turning the table upside down. Inspect the legs and the connecting points for looseness. Tighten any screws using a screwdriver, ensuring they are securely fastened. If the problem persists, the issue may be uneven floor surfaces or a damaged leg. For uneven surfaces, use shims (small, thin pieces of wood or felt) to level the legs. You can place these under the shorter legs to raise them to the same height as the others. If a leg is damaged, it may need repair or replacement.

Think of it like balancing a four-legged stool – if one leg is even slightly shorter, the whole thing wobbles. The same principle applies to tables.

Q 3. Explain your process for repairing a damaged chair leg.

Repairing a damaged chair leg depends on the nature and extent of the damage. Minor cracks or splinters can often be repaired with wood glue and clamps. Clean the damaged area thoroughly, apply glue liberally, and clamp the pieces firmly together, allowing it to dry completely. For more significant damage, such as a broken leg, you may need to use wood filler to rebuild the broken section, followed by sanding and refinishing to match the existing finish. In some cases, replacing the leg entirely might be the best option, especially if the damage is extensive or the leg is made of a rare or hard-to-match wood. Matching the wood type and finish is crucial for a seamless repair.

Imagine fixing a broken bone; you’d use a cast to hold it together while it heals. Wood glue and clamps act as a similar ‘cast’ for broken chair legs.

Q 4. What tools and equipment are essential for furniture troubleshooting?

Essential tools for furniture troubleshooting vary depending on the specific task, but a basic toolkit should include:

- Screwdrivers (Phillips and flathead, various sizes)

- Wrench set

- Hammer

- Pliers

- Wood glue

- Clamps

- Sandpaper (various grits)

- Wood filler

- Measuring tape

- Level

- Shims

- Safety glasses

More specialized tools may be needed for upholstery repair or intricate woodworking repairs. For example, staple removers are essential for upholstery work, while specialized wood carving tools might be necessary for antique restoration. Always prioritize safety and use appropriate protective gear when working with tools.

Q 5. How do you identify different types of wood and their common problems?

Identifying different types of wood is crucial for effective furniture repair, as each type has unique properties and is prone to specific problems. Visual inspection, smell, and even feel can provide clues. Hardwoods like oak and maple are known for their durability but are susceptible to cracking if not properly treated. Softwoods like pine and fir are more prone to dents and scratches. Identifying the wood type helps determine the appropriate repair method; for example, repairing a crack in oak requires a different approach than fixing a dent in pine. Furthermore, understanding the wood’s grain direction is essential when making repairs to avoid further damage.

For instance, oak often has a pronounced grain pattern, while pine is typically more uniform. Recognizing these differences helps in selecting the appropriate wood filler or replacement wood to ensure a visually appealing and structurally sound repair.

Q 6. What are the common causes of upholstery damage?

Upholstery damage can stem from various causes, including:

- Wear and Tear: Daily use, particularly in high-traffic areas, leads to fabric abrasion, fraying, and seam separation.

- Spills and Stains: Liquids, food, and other substances can stain and damage fabric, especially if not cleaned promptly.

- Pet Damage: Scratches, tears, and embedded hair are common problems caused by pets.

- Improper Cleaning: Using harsh chemicals or abrasive cleaning methods can damage the fabric and its underlying structure.

- Sun Exposure: Prolonged exposure to sunlight can cause fading and weakening of the fabric.

Understanding these causes enables preventative measures, such as using protective covers, prompt stain removal, and regular professional cleaning.

Q 7. How do you repair a torn fabric on a sofa?

Repairing a torn fabric on a sofa depends on the size and location of the tear. Small tears can often be repaired with fabric glue and patching. For larger tears, professional upholstery repair may be necessary. If the tear is small and inconspicuous, you can carefully align the torn edges, apply fabric glue, and then cover the repair area with a fabric patch of similar color and texture. This method requires careful attention to detail to ensure a seamless repair. For more significant damage, including rips or tears along seams, professional help is often necessary as it involves more complex stitching and potentially replacing sections of fabric.

Think of sewing a button back onto a shirt – it’s a straightforward fix for minor damage. Larger tears might require a more extensive repair, like replacing a ripped sleeve.

Q 8. Describe your experience with furniture refinishing techniques.

Furniture refinishing is a multi-step process that can dramatically transform a piece. My experience encompasses various techniques, from simple cleaning and polishing to complete stripping and re-staining. I’m proficient in various finishes, including lacquer, varnish, shellac, and milk paint, each requiring a different approach. For example, stripping old varnish requires careful use of chemical strippers, followed by meticulous sanding to achieve a smooth surface. Applying a new finish demands precision and patience, ensuring even coats and avoiding drips or runs. I often utilize techniques like glazing and distressing to achieve specific aesthetic effects, matching the original piece’s style or creating a unique, custom look. I’ve worked on everything from antique grandfather clocks requiring delicate handling to modern dining tables needing a vibrant new color.

- Stripping: Using chemical strippers and sanding to remove old finishes.

- Sanding: Progressively using finer grits of sandpaper to achieve a smooth surface.

- Priming: Applying a primer to ensure proper adhesion of the new finish.

- Finishing: Applying multiple thin coats of chosen finish (lacquer, varnish, etc.), followed by sanding between coats for a smooth, even finish.

- Distressing: Using techniques like sanding, hammering, or applying glaze to create a worn or aged look.

Q 9. How do you address scratches and dents on wood furniture?

Addressing scratches and dents on wood furniture depends on the severity of the damage and the type of wood. Minor scratches can often be buffed out with a wood polish or filled with a wood filler that matches the wood tone. Deeper scratches might require more involved repair, potentially using wood putty and then carefully sanding and staining to blend the repair seamlessly with the surrounding area. For dents, wood filler is a good starting point. For more significant dents, I might use a technique called steam-raising to carefully swell the wood fibers and reduce the dent’s visibility. After filling or raising, the surface needs careful sanding and refinishing to match the existing finish. I always test any product in an inconspicuous area first to ensure color matching.

- Minor Scratches: Wood polish, scratch repair kits.

- Deeper Scratches: Wood filler, sanding, staining, and finishing.

- Dents: Wood filler, steam-raising (for deeper dents), sanding, and finishing.

Q 10. Explain your process for repairing a broken drawer slide.

Repairing a broken drawer slide involves careful assessment of the damage. If the slide is simply detached, reattaching it might be a simple fix with wood glue or screws, depending on the construction. If the slide is broken, replacing it is often the best solution. I would first identify the type and size of the slide to ensure I get the right replacement. Installation involves careful alignment to ensure smooth drawer operation. If the damage is to the drawer itself (e.g., a broken dovetail joint), more extensive repairs involving woodworking techniques might be required. I would use appropriate glue (like wood glue or epoxy, depending on the materials) for re-joining the broken parts, clamping firmly until the glue cures completely.

- Assessment: Determine the extent of the damage (detached or broken).

- Replacement: Order appropriate replacement drawer slides (if broken).

- Reattachment: Use appropriate glue or screws to reattach (if detached).

- Installation: Carefully align and install replacement slides.

- Wood Repair: If drawer is damaged, repair broken joints with glue and clamps.

Q 11. How do you determine the best glue type for a specific furniture repair?

Choosing the right glue is crucial for successful furniture repair. The best glue depends on the materials being joined and the type of stress the joint will endure. For wood-to-wood joints, wood glue is typically the best option, offering strong bonding and a good level of flexibility. For materials like metal or plastic, epoxy glue often provides superior adhesion. For delicate repairs, a less aggressive adhesive like white glue may be preferable. I always consider the glue’s drying time and its compatibility with the finish to avoid unwanted reactions or discoloration. For example, using epoxy on a highly porous wood might create problems. I often keep a variety of glues on hand for different repair scenarios.

- Wood-to-Wood: Wood glue (provides a strong and flexible bond).

- Metal/Plastic: Epoxy glue (offers excellent adhesion to various materials).

- Delicate Repairs: White glue (less aggressive, suitable for delicate materials).

Q 12. How do you handle a situation where you cannot fix a furniture piece?

There are situations where a furniture piece is beyond repair. This might involve extensive structural damage, irreparable wood rot, or significant insect infestation. In such cases, honesty and transparency with the client are crucial. I would explain the extent of the damage and why repair isn’t feasible. I would offer alternative solutions, such as suggesting a replacement piece, recommending a professional furniture restoration specialist (if the damage is restorable), or helping the client find a creative repurposing solution for the damaged piece. My goal is always to provide the best possible outcome for the client, even if that means accepting that some pieces simply can’t be repaired.

Q 13. What safety precautions do you take during furniture repair?

Safety is paramount in furniture repair. I always wear appropriate safety gear, including safety glasses to protect my eyes from flying debris during sanding, dust masks to prevent inhaling wood dust, and gloves to protect my hands from chemicals and sharp objects. When using power tools, I ensure they are properly maintained and used according to the manufacturer’s instructions. I work in a well-ventilated area, especially when using chemical strippers or stains. I also properly dispose of hazardous materials like chemical strippers according to local regulations. Careful planning and preparation are essential to minimizing risks.

- Safety Glasses: Protect eyes from flying debris.

- Dust Mask: Prevent inhalation of wood dust.

- Gloves: Protect hands from chemicals and sharp objects.

- Ventilation: Work in a well-ventilated area when using chemicals.

- Proper Tool Use: Follow manufacturer instructions for power tools.

Q 14. How do you maintain your tools and equipment?

Maintaining my tools and equipment is essential for efficient and safe work. After each use, I clean my tools thoroughly, removing any sawdust, glue residue, or paint. I regularly sharpen my hand tools, such as chisels and sandpaper, to ensure they perform optimally. Power tools require regular maintenance, including checking cords for damage, ensuring blades are sharp and properly secured, and lubricating moving parts as needed. I store my tools in a well-organized manner to prevent damage and ensure easy accessibility. A regular maintenance schedule ensures my tools remain in top condition, ready for any repair challenge.

- Cleaning: Thoroughly clean tools after each use.

- Sharpening: Regularly sharpen hand tools.

- Maintenance: Perform regular maintenance on power tools.

- Storage: Store tools in a well-organized manner.

Q 15. Describe a challenging furniture repair you successfully completed.

One of the most challenging repairs I tackled involved a 19th-century Victorian writing desk with extensive damage to its intricate inlay work. Several pieces of the inlaid wood were missing, and the surrounding areas were cracked and loose. The challenge wasn’t just the repair itself, but preserving the antique’s historical integrity. My approach was multi-faceted:

- Careful Assessment: I meticulously documented the damage, photographing each detail and creating sketches to plan the repairs.

- Wood Selection: Finding a matching wood species for the inlay was crucial. I sourced a similar piece of hardwood, carefully matching its color and grain pattern as closely as possible.

- Repair Techniques: I used a combination of techniques including careful wood gluing with specialized adhesive, inlaying the new pieces, and stabilizing the surrounding cracked areas with consolidants and Japanese wood repair methods. Fine-grained sanding and finishing were essential to ensure a seamless blend.

- Finishing: Matching the existing finish was another critical step. I used traditional shellac and carefully applied several thin coats to achieve a consistent finish that blended seamlessly with the original.

The result was a restoration that preserved the desk’s historical value and its aesthetic beauty. The repair was virtually invisible, demonstrating the importance of careful planning and the application of diverse repair techniques.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are some common mistakes to avoid in furniture repair?

Common mistakes in furniture repair often stem from a lack of planning and improper technique. Here are a few key errors to avoid:

- Using the wrong adhesive: Different woods and materials require specific adhesives. Using an inappropriate adhesive can weaken the repair and lead to failure.

- Insufficient clamping: Proper clamping pressure is critical for a strong joint. Inadequate clamping can lead to gaps and weakened joints.

- Ignoring wood movement: Wood expands and contracts with changes in humidity. Ignoring this fact can cause repaired joints to fail over time. Consider using joinery techniques that accommodate this movement.

- Over-sanding: Sanding too aggressively can remove too much material, compromising the structural integrity of the piece or leaving a visible repair.

- Improper finishing: Applying too thick a coat of finish can result in a blotchy or uneven appearance. It’s always better to apply several thin coats instead of one thick coat.

For example, using wood glue on a water-damaged piece might cause the glue to not properly adhere. Similarly, applying an oil-based finish over a water-based one, might lead to incompatibility issues.

Q 17. How do you handle customer complaints regarding furniture repairs?

Handling customer complaints requires empathy, professionalism, and a commitment to finding a fair resolution. My approach involves the following steps:

- Active Listening: I carefully listen to the customer’s concerns, allowing them to fully explain the issue without interruption.

- Thorough Inspection: I perform a thorough inspection of the repaired furniture to identify the source of the complaint. Sometimes the complaint is legitimate, but other times it’s based on a misunderstanding.

- Transparent Communication: I clearly explain the findings of my inspection, outlining the potential causes of the problem and possible solutions. Technical language is avoided whenever possible.

- Fair Resolution: Depending on the nature of the complaint, the resolution might involve a minor repair, a partial refund, or a complete re-do of the work. The goal is always to satisfy the customer.

- Documentation: I maintain detailed records of all communications and actions taken to address customer complaints. This helps maintain accountability and consistency across all issues.

For instance, if a customer complains about a wobbly table leg, I would examine the leg joint, check the levelness of the floor, and assess whether the problem is a result of improper repair or a different structural issue. The appropriate solution would then be implemented based on my findings.

Q 18. What is your experience with different types of furniture joinery?

My experience encompasses a wide range of furniture joinery techniques. I’m proficient in both traditional and modern methods. Here are a few examples:

- Mortise and Tenon: A strong and classic joint, used extensively in traditional furniture making. I’m experienced in both through-tenons and blind-tenons.

- Dovetail Joints: A highly decorative and very strong joint, particularly suitable for drawers and casework. I’m comfortable with both through-dovetails and half-blind dovetails.

- Dowel Joints: A simpler joint, suitable for less-stressed applications. I understand how to use dowels effectively to create strong and accurate joints.

- Biscuit Joints: These use special biscuits or plates to create a strong, relatively easy-to-assemble joint suitable for many applications.

- Modern joinery: I am also experienced with using various fasteners such as screws, bolts, and cam locks, appropriate for modern furniture assembly and repair.

Understanding the strengths and weaknesses of each type of joint is key to selecting the appropriate technique for any given repair. For example, I would not use dowel joints for a heavy table leg, but they are appropriate for joining the back panels of a chair.

Q 19. How familiar are you with various furniture finishes?

My familiarity with various furniture finishes extends across a range of materials and techniques. I’m skilled in applying and repairing the following:

- Shellac: A traditional finish known for its durability and beauty. I understand the process of applying multiple thin coats for a smooth, even finish.

- Lacquer: A fast-drying finish with excellent hardness and clarity. I am skilled in spray application for large projects and brush application for small repairs.

- Varnish: Provides a durable and protective layer, available in both oil-based and water-based formulations. I can work with both types of varnishes.

- Oil finishes: These offer a more natural and less protective finish suitable for certain types of wood and applications. I understand the various types and their properties.

- Waxes: Used as a final protective layer for many finishes. I am skilled in applying and polishing waxes for a smooth surface and enhanced protection.

Knowing how to correctly identify the existing finish and match it with the correct type of repair is vital. Incorrect finishing can damage the piece, or lead to an unsightly finish.

Q 20. How do you ensure the structural integrity of a repaired furniture piece?

Ensuring the structural integrity of a repaired furniture piece is paramount. My approach involves a multi-stage process:

- Careful assessment of the damage: Identifying the cause of the damage is the first step. This includes assessing the type and extent of the damage, the materials involved, and any potential underlying weaknesses.

- Appropriate repair techniques: Selection of the correct repair technique is based on factors such as the type of joint, the materials used, and the level of stress that the joint will endure. This may involve reinforcing weak areas with additional supports or using specialized adhesives and clamps.

- Proper alignment and clamping: Precise alignment and adequate clamping pressure are crucial to ensure a strong and lasting repair. This is especially important for joints where wood movement is a factor.

- Testing the stability: After the repair, I thoroughly test the structural integrity of the piece. This includes checking for stability, strength, and overall functionality. Any weaknesses identified are addressed before the piece is considered complete.

- Preventive measures: Beyond the repair itself, I will suggest and discuss preventive measures with the client to reduce the risk of future damage. This might include environmental recommendations or specific care instructions.

For instance, when repairing a broken chair leg, I would not simply glue it back together, but I would assess the overall integrity of the joint and might reinforce it with dowels or other strengthening techniques to prevent future breakage.

Q 21. Describe your understanding of furniture assembly instructions.

My understanding of furniture assembly instructions extends beyond simply following the steps. I’m capable of interpreting complex diagrams and written instructions, adapting them as needed to overcome unexpected challenges. I also understand the logic behind the assembly sequence to identify and resolve issues efficiently.

I am familiar with different instruction formats, including those which utilize:

- Diagrams and illustrations: I can read and interpret both 2D and 3D diagrams effectively. I can also recognize common conventions and symbols used in these diagrams.

- Step-by-step written instructions: I can follow detailed written procedures and identify any ambiguities or inconsistencies within them. I can also understand the implied steps sometimes left out.

- Part lists and hardware specifications: I can match hardware to the correct parts and identify any missing or incorrect parts.

Furthermore, I’m able to troubleshoot assembly problems stemming from incomplete or incorrect instructions. My experience allows me to identify and correct problems arising from manufacturing defects or incomplete assembly. For example, I’ve had experience where instructions might have missing steps or unclear diagrams. In these cases, my knowledge of furniture joinery and assembly principles enables me to deduce the correct assembly sequence and rectify any problems.

Q 22. How do you troubleshoot problems with furniture hardware?

Troubleshooting furniture hardware begins with careful observation. First, identify the specific problem: is a drawer sticking, a door loose, a hinge broken, or are screws stripped? Then, systematically check the hardware itself. Are there any bent or broken parts? Are screws loose or missing? Is the alignment of the hardware correct? For sticking drawers, consider adjusting the drawer glides, cleaning out any debris, or applying wax to reduce friction. Loose doors often require tightening screws, while broken hinges usually necessitate replacement. Stripped screws might be remedied with wood glue and toothpicks for a temporary fix, or by using larger screws and wood filler for a more permanent solution.

For example, if a chair leg is wobbly, I’d first check if the screws connecting the leg to the chair’s frame are loose. Tightening them might solve the problem. If not, I’d look for cracks in the wood, which might require glue and clamps. If the screw holes are stripped, I’d consider using wood plugs to create new, stronger screw holes.

- Step 1: Identify the problem.

- Step 2: Inspect the hardware for damage or misalignment.

- Step 3: Address the issue by tightening, cleaning, adjusting, or replacing parts.

Q 23. What are some common issues with antique furniture?

Antique furniture presents unique challenges. Common issues include woodworm infestation (indicated by small holes and bore dust), loose joints due to age and wood shrinkage, damaged veneers, and worn finishes. Cracks and splits in the wood are also common, especially in pieces that have experienced significant temperature and humidity fluctuations. Furthermore, old glues may have failed, leading to structural instability. The age and material of the piece also influence the repair strategy, calling for careful consideration and often specialized techniques.

For instance, I once worked on a Victorian dresser with extensive woodworm damage. The treatment involved carefully removing affected areas, treating the wood with insecticide, and then filling the holes with appropriate wood filler and carefully matching the finish. Similarly, dealing with loose joints often involves reinforcing the joints using additional glue and dowels or replacing failed parts while matching original materials and joinery methods to maintain the furniture’s integrity.

Q 24. How do you approach the repair of veneer furniture?

Veneer repair demands precision and patience. The goal is to seamlessly integrate the repair into the existing veneer, making it practically invisible. Minor veneer chips can often be repaired with wood glue and clamping, carefully pressing the chip back into place. More significant damage, like larger cracks or missing sections, may require replacing the damaged section with a matching veneer patch. This involves careful removal of the damaged area, applying adhesive to the patch and the substrate, and then meticulously pressing it into place, ensuring consistent pressure to prevent air bubbles. Finally, the repair needs to be carefully sanded and finished to match the surrounding veneer.

For example, I’ve successfully repaired a veneer desk with a large crack by carefully lifting the edges, injecting adhesive beneath, and clamping it until dry. Once cured, the repaired area was carefully sanded smooth, and then refinished to blend seamlessly.

Q 25. What is your experience with repairing rattan or wicker furniture?

My experience with rattan and wicker furniture repair involves addressing broken strands, loose weaving, and structural instability. Broken strands require replacing with similar material, carefully weaving it into the existing structure. This often involves using a needle and specialized glue suitable for the material. Loose weaving can be tightened by carefully re-weaving or using appropriate glue to reinforce the structure. Structural issues may require reinforcement with additional materials, which needs to be unobtrusive and aesthetically pleasing. The repair process requires delicate handwork, patience, and a good understanding of the weaving techniques.

For instance, I repaired a wicker chair with a loose seat by carefully re-weaving loose strands and reinforcing the whole structure with natural fiber glue to maintain its original integrity and look.

Q 26. Explain your knowledge of different types of wood finishes (e.g., lacquer, polyurethane).

Different wood finishes offer unique properties. Lacquer dries quickly, is durable, and offers a high-gloss finish. It’s often used on higher-end pieces but can be more challenging to repair. Polyurethane is another popular choice, providing excellent durability and protection against water damage. It’s available in various sheens, from satin to high-gloss. Other finishes include shellac, varnish, and oil-based finishes, each with its own characteristics in terms of durability, application, and appearance. Understanding these differences is crucial for effective repair, as different finishes require different repair techniques.

For example, repairing scratches on a polyurethane-finished table might involve lightly sanding the affected area, applying touch-up polyurethane, and then sanding and polishing to restore the sheen. Lacquer repair, on the other hand, often requires more precise techniques and careful matching of the existing finish to avoid noticeable differences.

Q 27. How do you assess the overall condition of a furniture piece before starting a repair?

Assessing furniture condition begins with a thorough visual inspection. I check for cracks, splits, loose joints, damage to the finish, and any signs of insect infestation. I then examine the structure, testing the stability of joints and identifying any weak points. For upholstered pieces, I’d check the stuffing and fabric for wear and tear. The overall condition guides the repair plan; a simple repair for minor damage may be feasible, whereas extensive damage may require more complex interventions or might indicate the piece is beyond economical repair. Documenting the condition with photographs is essential, providing a record before, during, and after repairs.

For instance, before repairing a vintage armchair, I’d check the frame’s structural integrity by applying pressure to different points. I’d also examine the springs of the seat and the condition of the upholstery fabric to determine if a re-upholstery is required in addition to other structural repairs.

Q 28. What is your experience with using power tools for furniture repair?

I have extensive experience using various power tools for furniture repair. These include routers for creating intricate joinery, sanders for smoothing surfaces, and drills for creating holes with precision. Safety is paramount; I always wear appropriate safety gear, including eye protection, hearing protection, and a dust mask. I also ensure the tools are well-maintained and operated correctly. Power tools greatly increase efficiency and precision, particularly for tasks involving shaping, sanding, or creating complex joints. However, careful control and understanding of the tools’ capabilities are crucial to avoid damage to the furniture.

For example, when constructing a new leg for a table, I’d utilize a router to shape the leg, a sander to refine the surface, and a drill to create pilot holes for any needed screws. Each step is crucial and requires a thorough understanding of safety and tool operation.

Key Topics to Learn for Furniture Troubleshooting Interview

- Understanding Furniture Construction: Knowing the different materials (wood, metal, fabric, etc.), joinery techniques, and common manufacturing processes is fundamental. This allows you to diagnose issues more effectively.

- Common Furniture Problems and Their Causes: Develop a strong understanding of typical malfunctions like wobbly legs, drawer jams, broken hinges, fabric tears, and loose connections. Learn to identify the root cause, not just the symptom.

- Diagnostic Techniques: Master visual inspection, testing for stability and functionality, and using appropriate tools (screwdrivers, wrenches, measuring tapes) to pinpoint the problem area. This includes understanding how to safely disassemble and reassemble furniture components.

- Repair and Restoration Methods: Familiarize yourself with various repair techniques, including tightening screws, gluing, replacing parts, and fabric repair. Understanding appropriate adhesives and wood fillers is crucial.

- Safety Procedures: Highlight your knowledge of safe handling of tools and materials, workshop safety protocols, and the importance of following manufacturer guidelines.

- Preventive Maintenance: Discuss strategies for preventing common furniture problems, such as regular inspections, proper care instructions, and recommended cleaning methods.

- Customer Service and Communication: Demonstrate your ability to clearly communicate with clients, explain repair procedures, and manage expectations.

Next Steps

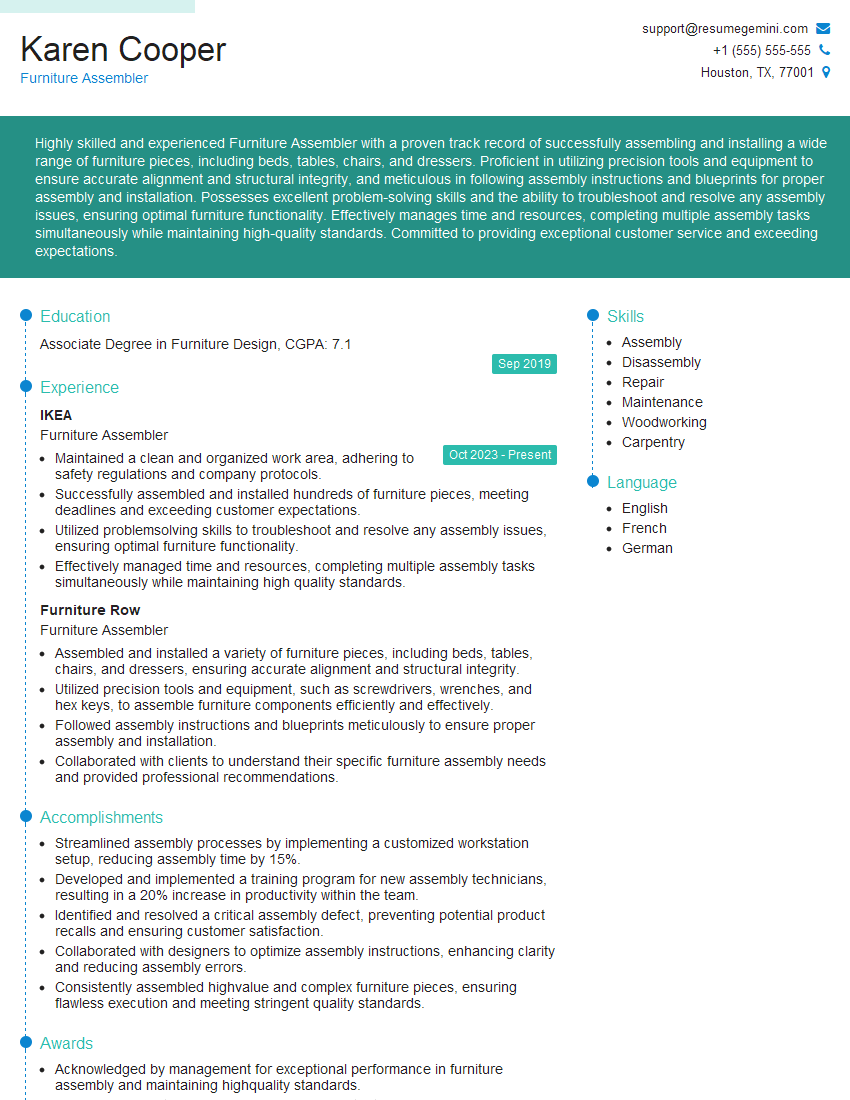

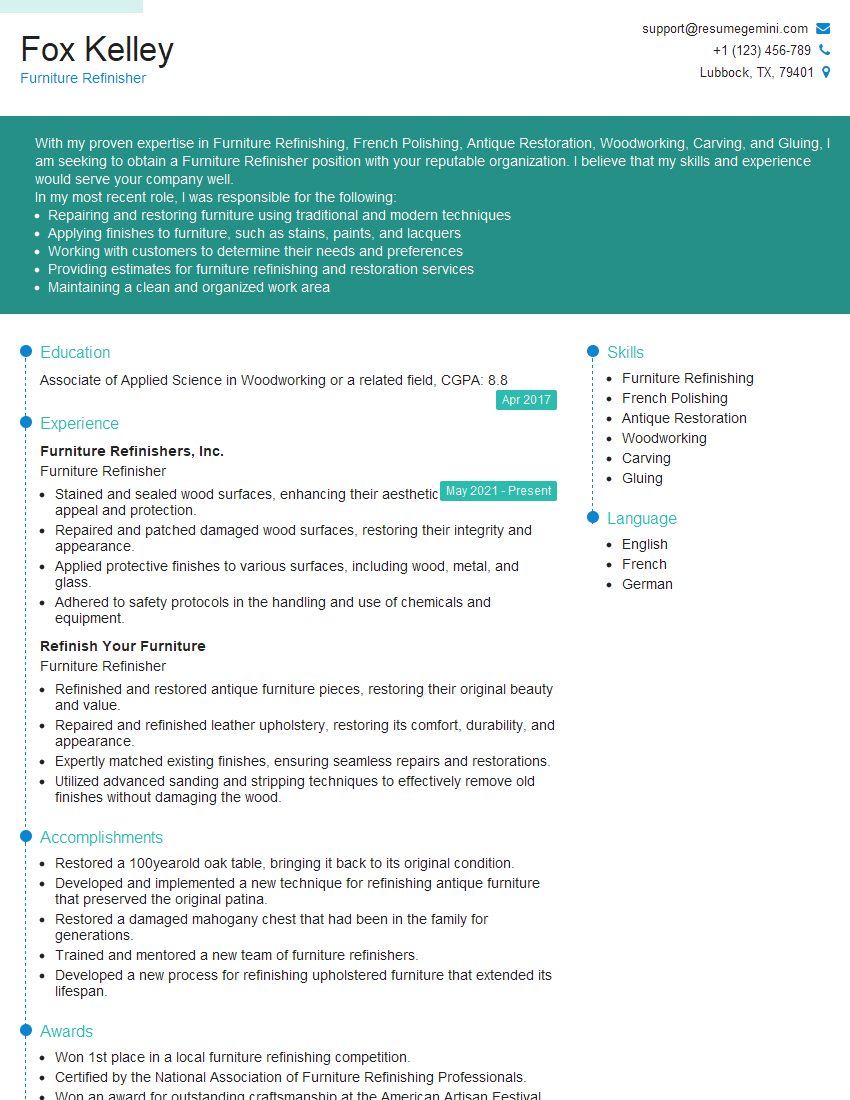

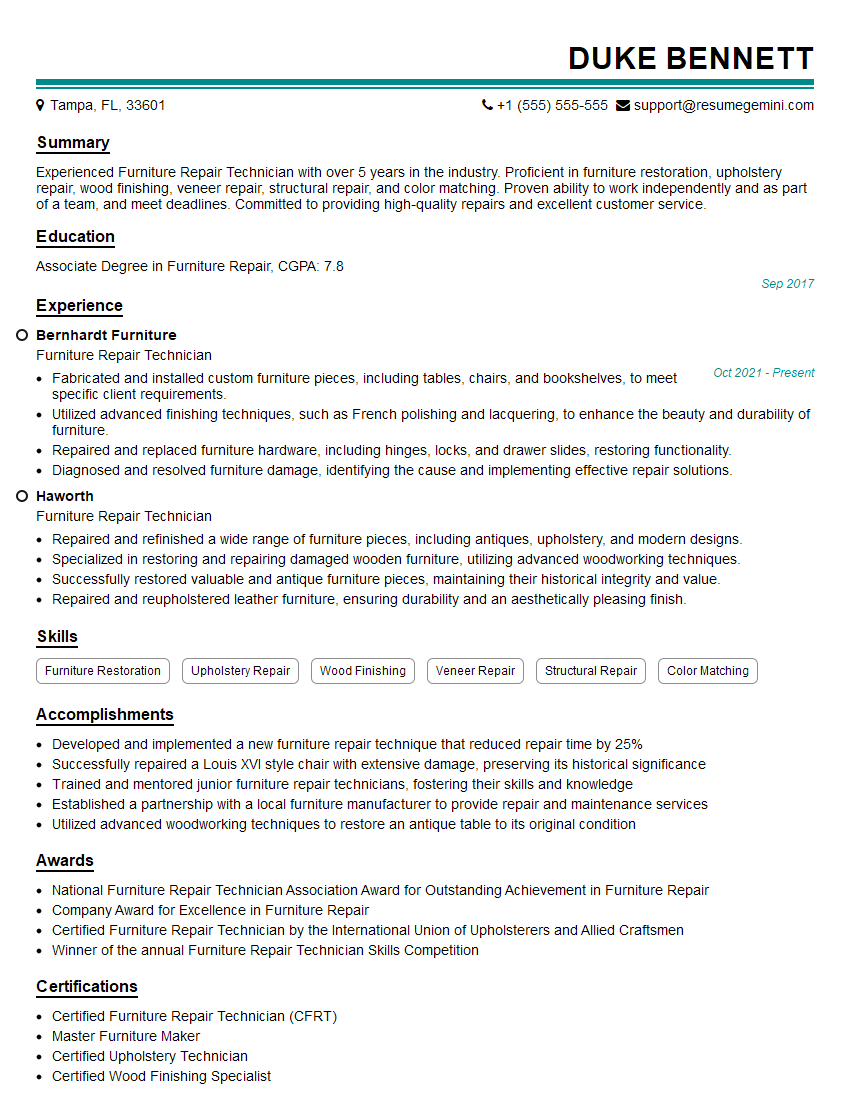

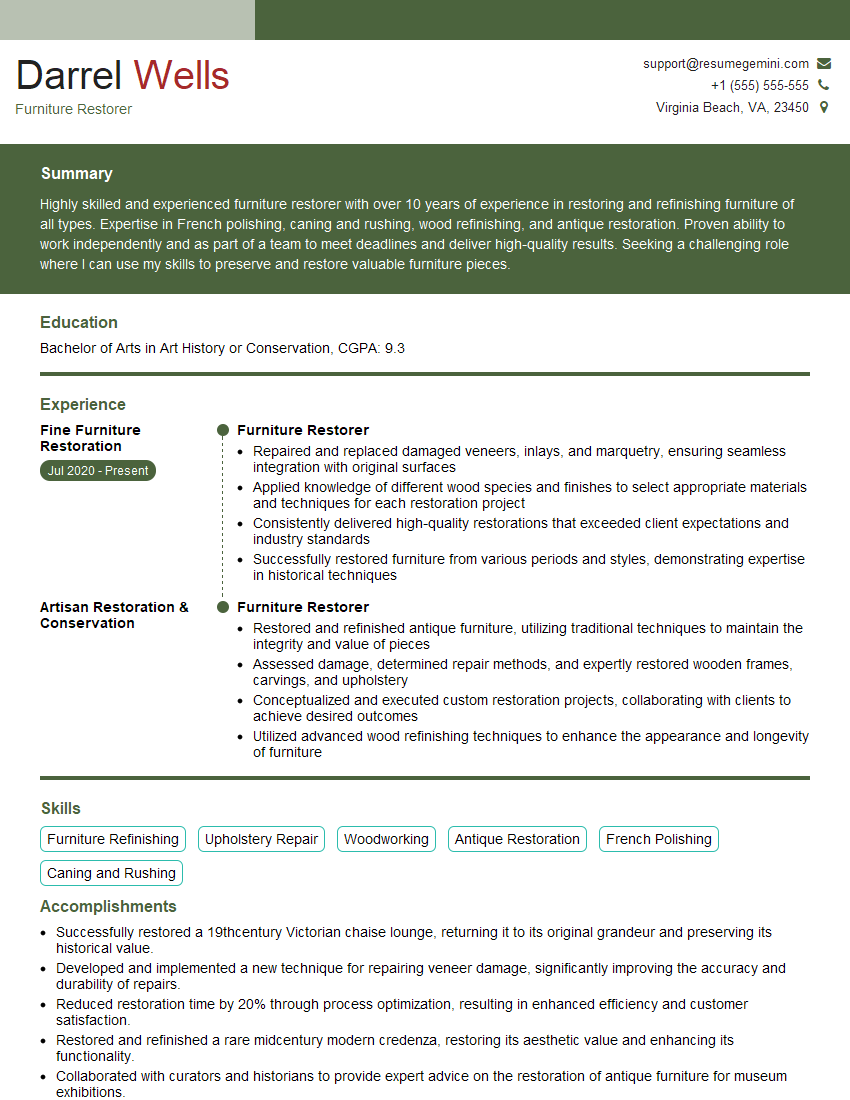

Mastering furniture troubleshooting opens doors to rewarding careers with excellent growth potential. As a skilled troubleshooter, you’ll be a valuable asset to any furniture retailer, repair shop, or even manufacturing company. To significantly boost your job prospects, it’s essential to create an ATS-friendly resume that highlights your skills and experience effectively. We strongly encourage you to leverage ResumeGemini to build a professional resume that stands out. ResumeGemini offers a user-friendly platform and provides examples of resumes tailored to the Furniture Troubleshooting field, ensuring your application makes a strong first impression.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

hello,

Our consultant firm based in the USA and our client are interested in your products.

Could you provide your company brochure and respond from your official email id (if different from the current in use), so i can send you the client’s requirement.

Payment before production.

I await your answer.

Regards,

MrSmith

hello,

Our consultant firm based in the USA and our client are interested in your products.

Could you provide your company brochure and respond from your official email id (if different from the current in use), so i can send you the client’s requirement.

Payment before production.

I await your answer.

Regards,

MrSmith

These apartments are so amazing, posting them online would break the algorithm.

https://bit.ly/Lovely2BedsApartmentHudsonYards

Reach out at [email protected] and let’s get started!

Take a look at this stunning 2-bedroom apartment perfectly situated NYC’s coveted Hudson Yards!

https://bit.ly/Lovely2BedsApartmentHudsonYards

Live Rent Free!

https://bit.ly/LiveRentFREE

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?