Are you ready to stand out in your next interview? Understanding and preparing for Garage Door Opener Installation interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Garage Door Opener Installation Interview

Q 1. Explain the different types of garage door openers (belt drive, chain drive, screw drive).

Garage door openers come in three primary drive types: belt drive, chain drive, and screw drive. Each offers a different balance of performance, noise level, and cost.

- Belt Drive: These openers use a rubber belt to lift the door. They’re known for their quiet operation, making them a popular choice for homes where noise is a concern. Think of it like a smooth, quiet conveyor belt moving your garage door.

- Chain Drive: The most common and often the most affordable type, chain drive openers use a metal chain to lift the door. They’re generally more durable but can be significantly louder than belt drives. The sound is similar to a bicycle chain.

- Screw Drive: These openers use a threaded steel rod that rotates to lift the door. They are powerful and reliable, but can be noisy, especially older models. Imagine a jack lifting a car; that’s similar to the mechanical action of a screw drive opener.

The best type for you will depend on your budget, noise sensitivity, and the weight of your garage door.

Q 2. Describe the safety features of modern garage door openers.

Modern garage door openers prioritize safety, incorporating features like:

- Automatic Reverse: If the door encounters an obstruction while closing, it automatically reverses to prevent injury or damage. This is crucial for protecting children and pets.

- Rolling Code Technology: This prevents unauthorized access by constantly changing the radio frequency code used by the remote. It’s like a constantly changing password for your garage door.

- Safety Sensors: Infrared beams are positioned near the bottom of the door. If these beams are interrupted during closing, the door reverses. This is a critical safety feature preventing accidents.

- Force Limiting System: This prevents the door from closing with excessive force, which could damage the door or cause injury.

- Pressure Sensors: Some newer models use pressure sensors to detect resistance while closing and reverse accordingly.

Regular maintenance and ensuring these features are functioning correctly are vital for ensuring the safety of your family and property.

Q 3. How do you troubleshoot a garage door opener that doesn’t respond to the remote?

Troubleshooting a non-responsive garage door opener requires a systematic approach. Here’s how to proceed:

- Check the Remote’s Batteries: This is the most common culprit. Replace the batteries in your remote and try again.

- Check the Remote’s Programming: Ensure your remote is properly programmed to your opener. Consult your opener’s manual for instructions on how to reprogram the remote.

- Check the Opener’s Power Supply: Make sure the opener is plugged into a working electrical outlet and the circuit breaker hasn’t tripped.

- Check the Opener’s Circuit Board: Inspect for any visible damage or loose connections on the opener’s circuit board. If you’re comfortable with basic electronics, you could check for power at the board itself.

- Test the Wall Button: If the wall button works, the problem likely lies with the remote or its programming. If the wall button doesn’t work, the issue is with the opener itself.

- Check the Antenna Connection (if applicable): Ensure the antenna is securely connected to the opener.

- Check Safety Sensors: Blocked or misaligned safety sensors are a common reason why the door won’t close. Clean and realign the sensors.

If none of these steps resolve the issue, it’s best to call a qualified garage door technician.

Q 4. What are the common causes of a garage door opener malfunction?

Garage door opener malfunctions stem from several sources:

- Worn-out Parts: Over time, components like the belt, chain, or gears wear down, leading to malfunctions.

- Broken Springs: Extension and torsion springs are under tremendous tension and can break, rendering the opener unable to lift the door.

- Power Supply Issues: Problems with the electrical outlet or circuit breaker can prevent the opener from functioning.

- Remote Control Problems: Dead batteries or programming issues can render the remote useless.

- Safety Sensor Problems: Misaligned, dirty, or damaged safety sensors can prevent the door from closing.

- Faulty Motor: A burned-out or damaged motor is a serious problem that requires replacement.

- Track Misalignment: A misaligned track can hinder the movement of the door and stress the opener’s components.

- Circuit Board Failure: The electronic control board can malfunction due to power surges, age, or component failure.

Regular maintenance and inspections can help identify and prevent many of these issues.

Q 5. How do you diagnose and repair a broken garage door opener spring?

Diagnosing and repairing a broken garage door spring is extremely dangerous and should only be attempted by qualified professionals. These springs are under immense tension, and a broken spring can cause serious injury. Never attempt this repair yourself.

However, if you must identify the problem for a professional, you can look for:

- Visible breakage: Look for snapped or visibly damaged sections of the spring.

- Door imbalance: One side of the door might be lower than the other, indicating a problem with one of the springs.

- Unusual noises: Listen for unusual sounds coming from the springs or the garage door mechanism.

A professional will accurately assess the spring type, tension, and size needed for a safe and effective replacement.

Q 6. Explain the process of installing a new garage door opener.

Installing a new garage door opener is a multi-step process:

- Disconnect the Old Opener: Begin by disconnecting the old opener from the power supply, and detaching it from the garage door track and the door itself.

- Prepare the Mounting Bracket: Securely attach the new opener’s mounting bracket to the garage ceiling following the manufacturer’s instructions.

- Install the Opener Motor: Mount the opener motor onto the bracket.

- Connect the Opener to the Power Supply: Connect the opener to a dedicated circuit and ensure proper grounding.

- Attach the Opener Arm to the Garage Door Trolley: Carefully attach the opener arm to the trolley mechanism on the garage door.

- Adjust the Travel Limits: Program the opener to adjust the door’s travel limits, ensuring the door opens and closes fully without binding.

- Install and Program the Remote Control: Install batteries and program your remotes to your new opener, following the manufacturer’s instructions.

- Test the System: Thoroughly test the opener, ensuring it works smoothly and safely.

Always consult the manufacturer’s instructions for your specific opener model. If you’re not comfortable with any part of this process, it’s advisable to hire a qualified professional.

Q 7. What safety precautions do you take when working with garage door openers?

Safety is paramount when working with garage door openers. Here are some vital precautions:

- Disconnect the Power: Always disconnect the opener from the power supply before performing any work.

- Use Appropriate Tools: Use the correct tools for the job and ensure they’re in good working condition.

- Wear Protective Gear: Wear safety glasses, gloves, and sturdy footwear.

- Never Work Under the Door: Avoid working directly under the door while it’s in operation or even if you’ve disconnected the power. The door may still move unexpectedly.

- Follow Manufacturer Instructions: Adhere strictly to the manufacturer’s instructions for installation, maintenance, and troubleshooting.

- Seek Professional Help When Needed: Don’t hesitate to seek professional help for tasks beyond your skillset, especially working with springs or complex electrical components.

- Proper Disposal of Waste: Dispose of old parts and materials responsibly.

By following these precautions, you’ll significantly reduce the risk of injury or damage.

Q 8. How do you adjust the force settings on a garage door opener?

Adjusting the force settings on your garage door opener is crucial for safety and smooth operation. It prevents the door from opening too easily (posing a security risk) or closing with excessive force (potentially causing damage or injury). The process varies slightly depending on the brand and model, but generally involves locating the force adjustment screws on the opener’s motor unit.

These screws are usually labeled with ‘+’ and ‘-‘ symbols indicating increase and decrease in force. Think of it like adjusting the volume on a stereo – you want the perfect balance. Start by setting the force to its lowest setting. Then, operate the door several times, gradually increasing the force until the door opens and closes reliably without jerking or struggling. The opener’s manual provides detailed instructions specific to your model. Never exceed the maximum force setting indicated in the manual. It’s safer to err on the side of slightly less force.

Example: On many LiftMaster openers, you’ll find the force adjustment screw near the motor unit. Turn it clockwise to increase force and counter-clockwise to decrease.

Q 9. Describe the process of programming a garage door opener remote.

Programming a garage door opener remote is usually a straightforward process. Most modern openers use a ‘learn’ button method. This involves putting the opener into ‘learning’ mode by pressing and holding a specific button on the opener’s motor unit (often labeled ‘Learn’ or a similar term). Consult your opener’s manual to determine this process exactly for your opener. Then, within a short time frame (usually 30 seconds), you press and hold the button on your new remote. The opener will usually signal that the remote is programmed successfully with a flashing light or a clicking sound.

Important Note: Before you start, always clear any existing remotes from your opener’s memory if needed; this ensures there is no interference. The process for this is usually described in the instruction manual of the garage door opener and differs by brand.

Example: Many Chamberlain/LiftMaster openers use a ‘Learn’ button that blinks when in programming mode. You press and hold the button on your new remote, and the light will usually stay on to confirm programming.

Q 10. What are the different types of garage door tracks and how do they affect opener installation?

Garage door tracks come in several types, primarily differing in their curvature. These affect opener installation because they dictate the path the door takes as it opens and closes. The most common types are:

- Standard Track: Features a slight curve, the most commonly found in residential installations and simple to install.

- High-Lift Track: Allows for higher door openings and better headroom in garages. Installation requires careful alignment to ensure smooth operation.

- Vertical Lift Track: These systems lift the door straight up and are useful when there is limited side wall space. The installation process is more complex and requires precise measurements and attention to detail.

The track type directly impacts the opener’s mounting position and the required adjustments for proper alignment. Incorrect track choice or improper installation can result in binding, noisy operation, or even damage to the door or opener. Always select the appropriate track type for the existing door and garage configuration.

Q 11. How do you handle a customer complaint regarding a faulty garage door opener?

Handling customer complaints effectively is crucial for maintaining a positive reputation. My approach involves several key steps:

- Active Listening: I carefully listen to the customer’s description of the problem without interruption, letting them fully explain their experience.

- Information Gathering: I ask clarifying questions to understand the specific issue, including when the problem started, the symptoms, and any attempts made to resolve it. This could include a detailed description of the sounds from the opener.

- Troubleshooting: I systematically troubleshoot the problem using standard diagnostics to identify the cause. This might involve checking power, the opener’s settings, the garage door’s alignment, and the condition of the tracks and springs.

- Solution Proposal: Based on my diagnosis, I propose a solution which may include repair, replacement of components, or even a full opener replacement, carefully explaining the reasoning and cost to the customer.

- Follow-Up: After completing the repair or replacement, I always follow up with the customer to ensure their satisfaction and address any lingering concerns. A quick phone call or email can go a long way.

Example: One time, a customer reported their door opening and closing erratically. Upon inspection, I found a small obstruction on the track, leading to misalignment. Once the obstruction was cleared and the door was realigned, the issue resolved.

Q 12. What tools and equipment are essential for garage door opener installation?

Essential tools and equipment for garage door opener installation vary, but here’s a comprehensive list:

- Screwdrivers (Phillips and flathead): For securing various components.

- Drill with various drill bits: For pilot holes and fastening.

- Socket wrench set: For working with bolts and nuts on different components.

- Measuring tape and level: Essential for precise measurements and alignment.

- Safety glasses and gloves: Protect yourself from falling debris or sharp edges.

- Ladder or step stool: For safe access to higher areas.

- Wire strippers/cutters: For working with electrical wiring.

- Voltage tester: Ensure power is off before working on electrical components.

- Extension cord: For access to power outlets.

- Owner’s manual: Essential for following manufacturer’s guidelines.

Beyond these basic tools, specialized tools might be needed depending on the specific opener and situation. Always prioritize safety and use appropriate safety gear.

Q 13. How do you ensure the proper alignment of a garage door during installation?

Proper alignment is paramount for safe and smooth operation. Misalignment can lead to premature wear, noisy operation, binding, and even safety hazards. I achieve this through a series of checks and adjustments:

- Track Alignment: The tracks should be perfectly plumb (vertical) and level (horizontal). I use a level to check this and adjust the track mounting brackets as needed.

- Door Alignment: The garage door itself should be square and aligned within the tracks. I check for any gaps or misalignment between the door sections and the tracks. Adjustment might involve loosening the hinges and realigning the sections.

- Roller Alignment: Each roller should move smoothly within the track. I check for any binding or obstructions, cleaning or lubricating as needed.

Any misalignment is corrected using appropriate adjustments as detailed in the opener’s instruction manual. A slight misalignment might seem insignificant, but it can cause serious issues down the line.

Q 14. Explain the importance of regular maintenance for garage door openers.

Regular maintenance is vital for extending the lifespan of your garage door opener, ensuring safe operation, and preventing costly repairs. Think of it as a regular car checkup—preventative care is much cheaper and more convenient than emergency repairs. Here’s what should be included:

- Lubrication: Lubricating moving parts such as hinges, rollers, and tracks with a suitable lubricant minimizes friction and noise.

- Inspection: Regularly inspect the opener for any loose parts, damaged components, or signs of wear. Check the tension springs for any signs of stress or damage. Note that work with garage door springs should be left to a professional.

- Cleaning: Cleaning the tracks and rollers of any debris prevents binding and ensures smooth operation.

- Tightening: Regularly check and tighten all bolts and screws to ensure everything is secure and stable.

- Safety Check: Regularly check the safety sensors to ensure they are aligned and functioning correctly. This is crucial for preventing accidents.

- Force Adjustment: Periodically check and adjust the force settings as needed to maintain optimal performance and safety.

By adhering to a regular maintenance schedule, you significantly reduce the risk of breakdowns and keep your family safe.

Q 15. What are the common problems associated with older garage door openers?

Older garage door openers often suffer from wear and tear, leading to several common problems. Think of it like an old car – the parts eventually start to fail.

- Weak Motor: The motor may struggle to lift the door, resulting in slow opening and closing or complete failure.

- Failing Springs: Garage door springs are under immense tension. Over time, they weaken, break, or become dangerously unbalanced, leading to inconsistent operation or even dangerous snapping.

- Malfunctioning Sensors: The safety sensors, crucial for preventing accidents, can become misaligned, dirty, or damaged, causing the door to reverse unexpectedly or fail to operate at all.

- Worn Gears and Chains/Belts: The mechanical parts of the opener wear down, leading to noisy operation, jerky movement, and eventual failure.

- Remote Control Issues: Older remotes may have weak batteries or damaged internal components, resulting in unreliable operation.

- Electrical Problems: Wiring can fray, connections can loosen, and components within the opener can fail due to age and use.

Regular maintenance, including lubrication and inspection of key components, can extend the lifespan of an older opener and prevent many of these issues.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you troubleshoot a garage door that opens or closes too slowly?

A garage door opening or closing too slowly usually points to a problem with the motor, the springs, or possibly the opener’s chain or belt. Let’s troubleshoot it step-by-step:

- Check the Springs: Broken or weakened springs significantly reduce lifting power. If the springs are visibly damaged or the door feels unusually heavy, call a professional immediately – this is a dangerous situation.

- Inspect the Motor and Chain/Belt: Examine the motor for any signs of overheating (it might feel unusually hot). Check the chain or belt for wear, slack, or any obstructions. A slipping or damaged chain/belt will reduce efficiency.

- Lubricate Moving Parts: Apply a garage door lubricant to the moving parts (chain, hinges, rollers) to reduce friction and improve the door’s movement. Don’t over-lubricate!

- Check the Power Supply: Ensure the opener is receiving sufficient power. Check the circuit breaker or fuse box. A low voltage could cause sluggish operation.

- Test the Limit Switches: These switches tell the opener when to stop. If they are misaligned, it might cause the door to stop too early or continue moving slowly, trying to reach the incorrect position.

- Examine the Track: Ensure the track is clean, straight and free of obstructions. Bents tracks or debris can impede smooth operation.

If the problem persists after these checks, it’s best to call a qualified garage door technician for a professional diagnosis and repair. Trying to fix a complex mechanical issue without proper training can be risky.

Q 17. Explain the different types of sensors used in garage door openers.

Modern garage door openers use several types of sensors, but the most critical are the safety sensors. These are usually infrared sensors that use beams of light to detect obstacles in the door’s path. Think of them as a sophisticated ‘stop’ button. If the beams are broken, the door will reverse to prevent accidents.

- Infrared (IR) Sensors: These are the most common safety sensors. One sensor transmits an infrared beam, and the other receives it. Any interruption, like a person or object, breaks the beam, triggering the reversal mechanism.

- Photoelectric Sensors: Similar to IR sensors, these use light to detect obstructions. However, they might use a visible or near-infrared light instead of infrared.

Some newer systems incorporate additional sensors for things like door position detection, which helps the opener know where the door is located. These might use different technologies, depending on the system and manufacturer.

Q 18. How do you test the safety sensors of a garage door opener?

Testing the safety sensors is a critical safety check. Here’s how you do it:

- Locate the Sensors: These are usually mounted near the bottom corners of the garage door opening, on either side of the door.

- Observe the LED Indicator Lights: Most sensors have tiny LED indicator lights. When functioning correctly, these lights should be lit. A blinking or unlit light signals a problem.

- Interrupt the Beam: Carefully place your hand, or a small object, in front of the sensors to interrupt the invisible beam of light. The garage door should immediately begin to reverse.

- Check Sensor Alignment: If the sensors are not aligned correctly, the door might not reverse properly. The sensors should be pointed at each other. Use a small straight edge or level to ensure precise alignment.

- Clean the Sensors: Dust, dirt or debris can obstruct the sensor beam. Gently clean them with a soft cloth.

If the door doesn’t reverse when you interrupt the beam or the LED lights aren’t working correctly, then you’ll need to troubleshoot further by checking wiring connections and potentially replacing the faulty sensors. If you are uncomfortable performing these steps, call a qualified technician.

Q 19. Describe the process of replacing a garage door opener motor.

Replacing a garage door opener motor is a more advanced task, best left to professionals unless you have significant experience with electrical work and mechanical systems. However, here’s a general overview:

- Safety First: Disconnect the power to the garage door opener at the breaker box.

- Remove the Old Motor: This often involves removing screws and disconnecting wires. Carefully note the wiring configuration before disconnecting any wires.

- Install the New Motor: Mount the new motor in the same location, securing it with screws.

- Connect the Wiring: Reconnect the wires according to the wiring diagram provided with the new motor and the original wiring configuration you noted earlier. It is crucial to connect the wires correctly.

- Test the Opener: Restore the power and carefully test the opener’s operation. If it runs smoothly, the job is done. If not, double check all connections.

Remember, this is a simplified description. Improper installation can lead to safety hazards and damage to the equipment. It’s recommended to consult the installation manual for your specific garage door opener model.

Q 20. How do you connect a garage door opener to a home automation system?

Connecting a garage door opener to a home automation system allows for convenient control and monitoring via smartphone apps, voice assistants, and other smart home devices. The process varies depending on the specific brands involved. Most modern openers offer Wi-Fi connectivity or use a separate module that connects to the opener and your home Wi-Fi network.

- Check Compatibility: Ensure your garage door opener is compatible with your chosen home automation system (e.g., SmartThings, HomeKit, Google Home).

- Install the Connecting Module (if necessary): Some openers require a separate Wi-Fi-enabled bridge or module to interface with the automation system.

- Follow the Manufacturer’s Instructions: Each opener and home automation system will have its own specific setup instructions. Carefully follow these steps, paying close attention to the specifics of your systems.

- Configure the App: The app associated with your home automation system will guide you through the pairing process and setup of the garage door opener. You will typically need to input your home’s Wi-Fi password.

- Test the Connection: After setting up, thoroughly test the connection by controlling the garage door through your home automation app or voice assistant.

This is a general outline. The exact steps and specifics will depend greatly on the opener and home automation system chosen. Always consult manufacturer’s instructions and contact support if needed.

Q 21. How do you handle a situation where a garage door is jammed?

A jammed garage door can be frustrating and potentially dangerous. Here’s how to approach the situation:

- Assess the Situation: Determine the cause of the jam. Is the door obstructed? Are the tracks misaligned? Is there something wrong with the springs or the motor?

- Safety First: Never attempt to force a jammed door. Disconnect the power to the opener to prevent accidental movement.

- Manual Release: Most garage door openers have a manual release cord or lever. Locate and use this to disconnect the opener from the door, allowing you to manually lift or lower the door.

- Identify the Problem: Once the door is free, carefully inspect the tracks, rollers, springs, and other parts to identify the cause of the jam. Look for bent tracks, obstructions, or damaged components.

- Repair or Replace: Based on your assessment, repair the damaged parts or contact a professional garage door technician to address the problem. Attempting complex repairs without the right tools and experience can lead to further damage or injury.

If you are unsure about any part of this process, call a professional. A jammed door can indicate a serious issue that requires expert attention.

Q 22. What are the different types of lubricants used for garage door openers?

Choosing the right lubricant for your garage door opener is crucial for smooth, quiet operation and longevity. Different components require different lubricants. We generally avoid WD-40, as it’s a solvent and can actually damage certain parts over time.

Silicone-based sprays: These are excellent for lubricating the tracks and rollers. They’re relatively inexpensive, widely available, and leave a thin, non-sticky film that reduces friction. Think of it like applying a protective layer to prevent metal-on-metal grinding.

White lithium grease: This thicker grease is ideal for hinges and other moving parts that require more substantial lubrication. It’s more durable than silicone spray and offers better protection against corrosion. Imagine it as a strong shield against wear and tear in high-stress areas.

Dry graphite lubricant: This is perfect for the chain or belt drive system. Unlike oily lubricants that can attract dirt and grime, dry graphite provides excellent lubrication without creating a messy residue. It’s like a silent guardian, reducing friction without the mess.

Remember to always follow the manufacturer’s recommendations for lubrication. Over-lubrication can be just as detrimental as under-lubrication.

Q 23. Describe the proper way to dispose of old garage door opener parts.

Proper disposal of old garage door opener parts is essential for environmental safety and responsible recycling. Different components require different approaches.

Metal parts: These should be taken to a local scrap metal recycling center. This ensures responsible metal recovery and prevents unnecessary waste.

Plastic components: Many plastic parts can be recycled through your local curbside recycling program, but always check your local guidelines. Some plastics may require specialized recycling centers.

Electronic components: These often contain hazardous materials. Do not throw them in the regular trash. Instead, bring them to an e-waste recycling facility. Many municipalities offer free or low-cost e-waste drop-off locations.

Batteries: Remove any batteries from the unit before disposal. Batteries should be recycled separately at designated collection points or retailers.

It’s always best to check with your local waste management authority for specific guidelines and recommendations in your area.

Q 24. How familiar are you with different brands of garage door openers (e.g., LiftMaster, Chamberlain, Genie)?

I have extensive experience with major garage door opener brands, including LiftMaster, Chamberlain, and Genie. I’m familiar with their various models, from basic chain-drive openers to more sophisticated belt-drive and direct-drive systems. I understand their unique features, troubleshooting techniques, and common repair issues. For example, I know that LiftMaster often utilizes MyQ technology for smart home integration, while Chamberlain offers similar connectivity options under their brand.

My experience extends to understanding the differences in their safety mechanisms, such as photoelectric sensors and safety reverse systems, and how to properly install and maintain these critical safety components. This broad brand familiarity allows me to efficiently diagnose and repair a wide range of garage door opener malfunctions regardless of the manufacturer.

Q 25. What is your experience with troubleshooting electrical issues related to garage door openers?

Troubleshooting electrical issues is a significant part of my expertise. This involves diagnosing problems such as power outages, faulty wiring, malfunctioning limit switches, and problems with the opener’s control board. I am proficient in using multimeters to test voltage, continuity, and current in various parts of the system. A systematic approach is key.

For instance, I’ll start by checking the main power supply to the garage door opener to ensure power is reaching the unit. Then, I move to the wiring connections to identify any loose or damaged wires. If the problem persists, I’ll carefully examine the opener’s control board for any burned components or signs of damage. Safety is paramount; I always disconnect the power before working on any electrical components.

Q 26. What is your experience with working from heights?

Working from heights is something I’m completely comfortable with and handle safely. I’m fully trained in and adhere to all relevant safety procedures, including the use of proper fall protection equipment like harnesses and safety lines. I never take shortcuts. Before starting any work involving heights, I assess the work area thoroughly to identify potential hazards and plan accordingly. This includes securing a stable and properly positioned ladder or using a lift when necessary.

I understand that safety is not negotiable when working at heights. My experience has taught me the importance of following established safety protocols and using appropriate safety gear. Client safety is my top priority.

Q 27. Describe your experience with working independently and as part of a team.

I thrive in both independent and team-oriented environments. When working independently, I’m highly self-motivated and able to manage my time effectively to complete projects on schedule. I’m resourceful and adept at problem-solving, often finding creative solutions to unforeseen challenges. I’ve successfully managed numerous solo installations and repairs demonstrating my self-sufficiency.

Equally important is my ability to collaborate effectively within a team. I am a strong communicator and value teamwork. I readily share my expertise with colleagues, contribute to problem-solving discussions, and consistently support my team to achieve shared goals. My experience on larger projects has demonstrated my ability to work seamlessly as part of a larger installation team.

Q 28. What is your understanding of relevant safety regulations and codes for garage door installations?

I have a thorough understanding of all relevant safety regulations and codes pertaining to garage door installations. This includes familiarization with UL (Underwriters Laboratories) safety standards, local building codes, and any relevant OSHA (Occupational Safety and Health Administration) guidelines. These codes focus on preventing injury and property damage. They cover aspects like proper installation of safety sensors, ensuring sufficient clearance between the door and the ground, and safe electrical wiring practices.

Staying updated on these codes is an ongoing process. I regularly review updated regulations and industry best practices to ensure all my work adheres to the highest safety standards. Safety is not just a guideline for me; it’s a top priority in everything I do.

Key Topics to Learn for Garage Door Opener Installation Interview

- Safety Procedures: Understanding and adhering to all safety protocols during installation, including proper use of safety equipment and awareness of potential hazards.

- Types of Garage Door Openers: Familiarity with various opener types (belt drive, chain drive, screw drive, direct drive), their mechanisms, and appropriate applications for different garage door types and customer needs.

- Installation Process: Detailed knowledge of the complete installation process, from initial assessment and preparation to final testing and troubleshooting.

- Wiring and Electrical Connections: Understanding electrical schematics, proper wiring techniques, and safety considerations related to electrical work. Ability to troubleshoot electrical problems.

- Programming and Remote Control Setup: Knowledge of programming different opener models, pairing remotes, and troubleshooting common programming issues.

- Troubleshooting and Repairs: Ability to diagnose and repair common garage door opener malfunctions, such as malfunctioning remotes, broken springs (understanding limitations here), and noisy operation.

- Customer Service and Communication: Demonstrating excellent communication skills to clearly explain the installation process, address customer concerns, and build rapport.

- Code Compliance and Regulations: Awareness of relevant building codes and regulations pertaining to garage door opener installation in your area.

- Tools and Equipment: Familiarity with the tools and equipment necessary for efficient and safe garage door opener installation.

- Maintenance and Preventative Care: Understanding of routine maintenance procedures to extend the lifespan of garage door openers and educating customers on preventative measures.

Next Steps

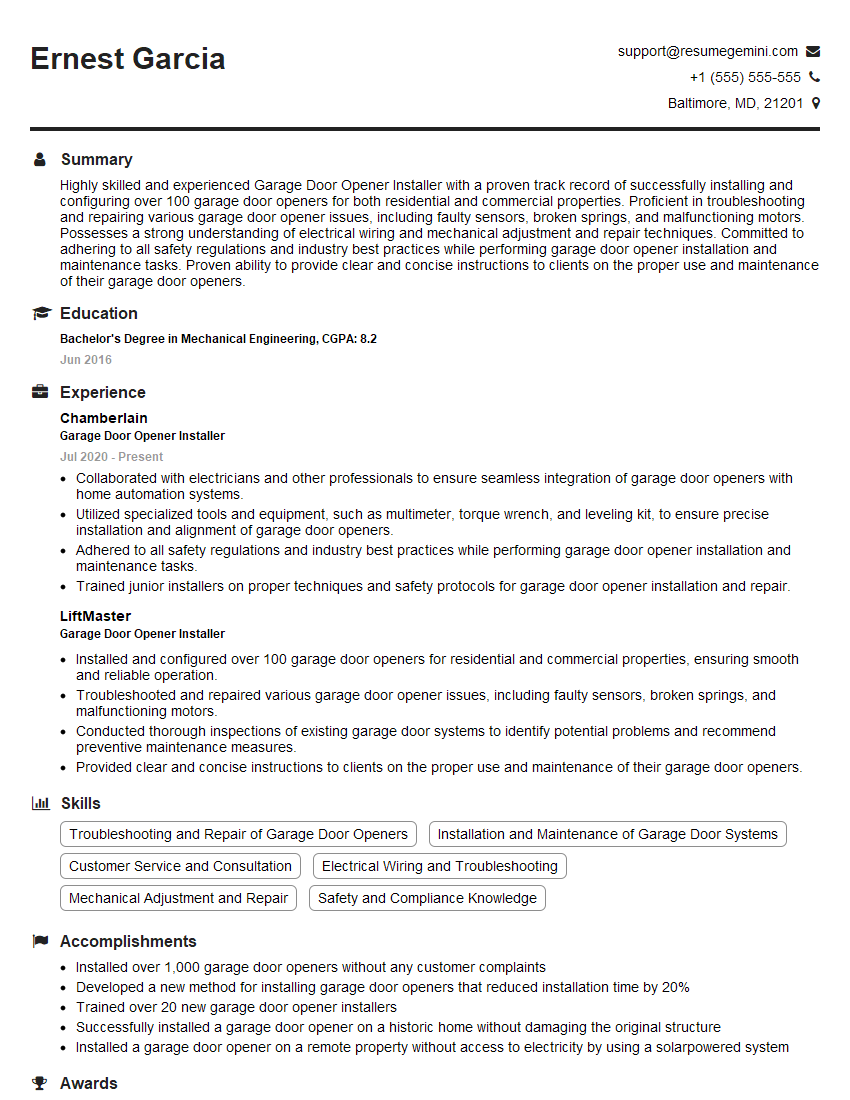

Mastering garage door opener installation opens doors to a rewarding career with excellent growth potential. This skill is highly sought after, and demonstrating proficiency through a well-crafted resume is crucial. Creating an ATS-friendly resume significantly increases your chances of landing an interview. To enhance your resume and showcase your expertise effectively, we highly recommend using ResumeGemini. ResumeGemini provides a user-friendly platform to build professional resumes, and we offer examples of resumes tailored specifically to the Garage Door Opener Installation field to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?