Warning: search_filter(): Argument #2 ($wp_query) must be passed by reference, value given in /home/u951807797/domains/techskills.interviewgemini.com/public_html/wp-includes/class-wp-hook.php on line 324

Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Garage Door Panel Replacement interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Garage Door Panel Replacement Interview

Q 1. What types of garage door panels are most commonly replaced?

The most commonly replaced garage door panels are those made of steel, primarily because steel doors are the most prevalent type. Within steel panels, raised-panel styles are frequently replaced due to their susceptibility to dents and damage from impacts. Aluminum panels are also common, although less so than steel, and fiberglass panels are replaced occasionally, usually due to cracking or severe impact damage. Wood panels, while visually appealing, are prone to weathering and require more specialized repair or replacement.

Q 2. Describe the process of removing a damaged garage door panel.

Removing a damaged garage door panel is a delicate process requiring care to avoid further damage to the door or injury. First, disconnect the garage door opener to prevent accidental movement. Next, carefully remove any decorative hardware or trim around the damaged section. Then, using the appropriate tools (we’ll discuss those in a later question), you’ll need to detach the panel from the adjacent panels and the door’s track system. This often involves removing hinges and rollers depending on the type of panel and door construction. Always work slowly and methodically; rushing increases the risk of damage. Remember to support the adjacent panels to prevent them from shifting or falling as you work.

Q 3. How do you measure for a replacement garage door panel?

Accurate measurement is crucial for a proper fit. You shouldn’t just measure the damaged panel. Instead, measure the opening for the panel, not the panel itself. This is because the panel sits within the framework of the door section. Use a steel tape measure to obtain precise measurements of the height and width of the space where the panel will be installed. Take multiple measurements at different points along the opening to ensure consistency. Pay close attention to any slight variations in the size of the opening to account for potential irregularities in the garage door’s construction. A slight variance from standard panel sizes is fairly common and shouldn’t be cause for alarm; experienced installers are able to manage that.

Q 4. What tools are essential for accurate garage door panel replacement?

Having the right tools is critical for a professional and safe replacement. Essential tools include:

- A sturdy ladder to safely access the garage door.

- A claw hammer to carefully remove old panels.

- Screwdrivers (Phillips and flathead) to remove screws and hinges.

- Pliers for removing stubborn fasteners.

- A tape measure for accurate measurements of the opening.

- Safety glasses to protect your eyes from flying debris.

- Work gloves for protection.

- Possibly a cordless drill for faster removal and installation of screws.

Additionally, having a helper can significantly assist in the process, especially when handling heavier panels.

Q 5. Explain the different methods for securing a new garage door panel.

Securing a new garage door panel typically involves using the existing hinges and brackets. The method varies based on the garage door’s design. Many steel sectional doors use a system of hinges and rollers that connect each panel. For these, you simply attach the new panel to the existing hinges using screws. Some panels might use clips or other fastening systems. It’s critical to follow the manufacturer’s instructions for the specific panel being installed and ensuring the fasteners are appropriately tightened to prevent looseness or movement during operation. The aim is to have the panel firmly secured but not over-tightened, which could damage it.

Q 6. How do you identify and address panel alignment issues after installation?

Panel alignment issues are noticeable through gaps between panels, a crooked appearance, or difficulty closing or opening the door. Identifying the problem usually involves visually inspecting the panels and checking the spacing between them. Addressing misalignment typically involves loosening the screws securing the panel, adjusting its position to fit correctly within the frame, and then retightening the screws. If misalignment is severe, there may be underlying issues with the track system or the garage door’s frame, which might necessitate more extensive adjustments or repairs. If you’re unsure about how to address it, calling a professional is strongly recommended.

Q 7. What are the common causes of garage door panel damage?

Garage door panel damage arises from a variety of causes: collisions with vehicles, impacts from falling objects, rust due to exposure to the elements, strong winds, or general wear and tear over time. Improper installation can also lead to long-term issues such as warping or cracking. Consider the local climate; intense sun and fluctuating temperatures can contribute to panel degradation. Neglecting routine maintenance may also worsen existing damage or lead to new issues.

Q 8. How do you handle a situation where a replacement panel doesn’t fit perfectly?

A perfect fit is crucial for both aesthetics and functionality. If a replacement panel doesn’t fit, the problem usually stems from slight variations in manufacturing or minor warping of the existing door frame. We first assess the discrepancy. Is it a matter of a few millimeters, or a more significant gap? For minor discrepancies, careful adjustment is often sufficient. This might involve using shims – thin, wedge-shaped pieces of wood or metal – to create a snug fit between the panel and its adjacent sections. These are placed strategically at the top and bottom, or the sides, and carefully hammered in until the panel sits perfectly flush. For more pronounced mismatches, the panel might need minor trimming. This requires precise measurements and specialized tools to prevent damage. We always aim for the least invasive solution, prioritizing the integrity of the panel and the overall door structure. I recently had a situation where a steel panel was slightly too wide. Instead of trimming the panel itself, which risked damaging the finish, I very carefully adjusted the adjacent panels using shims, achieving a near-perfect result without altering the new panel.

Q 9. What safety precautions should be taken during garage door panel replacement?

Safety is paramount. Before starting any work, disconnect the garage door opener. This prevents accidental movement during the replacement process. We also use safety glasses to protect our eyes from potential debris, and work gloves to prevent cuts and scrapes. For heavier panels, using a helper can greatly reduce strain and the risk of injury. The garage door should be properly supported while the old panel is being removed and the new one is being installed. This usually involves using sturdy supports or rollers to prevent accidental falls. Never work under a partially disassembled garage door; always ensure it’s properly secured before starting or stopping any work.

Q 10. Describe your experience with different panel materials (e.g., steel, wood, fiberglass).

I’ve worked extensively with steel, wood, and fiberglass panels, each offering unique properties. Steel panels are durable and relatively inexpensive, offering excellent resistance to dents and scratches. However, they can dent on impact and rust over time if not properly maintained. Wood panels provide a more aesthetically pleasing, classic look, but require regular maintenance such as painting or staining to prevent rot and damage from moisture. They are also more susceptible to dents and warping. Fiberglass panels offer a good compromise; they’re durable, relatively lightweight, and resistant to dents and rust. They also mimic the look of wood without the maintenance. The choice depends heavily on the client’s budget and aesthetic preferences, as well as the local climate. For example, in humid climates, fiberglass might be a superior choice over wood to prevent rot. In areas with harsh weather, steel’s durability would be highly beneficial.

Q 11. How do you determine the correct panel size and type for a specific garage door?

Determining the correct panel size and type involves careful measurement and identification of the existing door. First, we measure the height and width of the existing panel. This ensures the new one is appropriately sized to fit seamlessly. Next, we examine the existing panel to determine the material (steel, wood, fiberglass) and its style. Some panels have raised or recessed designs, and the replacement must match that style. We also check for any unique features, such as insulation, windows, or decorative trim. If the original manufacturer is known, finding a direct replacement is ideal. Otherwise, we match the panel based on the dimensions and style. Incorrect sizing and type will result in a poor fit and may compromise the balance and functionality of the entire garage door.

Q 12. What are the signs of a damaged garage door panel requiring replacement?

Several signs indicate the need for panel replacement. Visible cracks, significant dents, or holes are clear indicators of damage. If a panel is severely dented, it can affect the overall structural integrity of the door and may not close properly. Paint peeling or significant rust on a steel panel is another sign. Also, if a panel has suffered water damage, which can lead to rot in wood panels or weakening of other materials, it must be replaced. If a panel is significantly damaged, it can also impact the door’s insulation properties, leading to increased energy costs.

Q 13. Explain the process of insulating a replacement garage door panel.

Insulating a replacement panel can significantly improve the energy efficiency of the garage. Many panels come with built-in insulation, often polyurethane foam. For panels without insulation, we typically add rigid foam insulation board to the inside of the panel. The board is cut precisely to fit the panel’s dimensions. We use a high-quality adhesive designed for this application to ensure secure bonding. A protective covering, such as a thin sheet of plywood or a similar material, is often affixed over the insulation to improve its structural stability and to prevent damage to the foam. The outer finish of the panel is then restored (if necessary) to maintain a consistent aesthetic appearance.

Q 14. How do you repair minor damage to a garage door panel before replacement?

Minor damage, such as small dents or scratches, can sometimes be repaired before full panel replacement. For small dents in steel panels, we might use a dent puller or a combination of heat and pressure to gently coax the dent back into shape. For scratches, touch-up paint is often sufficient. Wood panels might need minor sanding and refinishing to restore their appearance. For fiberglass panels, minor scratches can be addressed with specialized fiberglass repair kits. However, if the damage is extensive, compromising the structural integrity of the panel or impacting its weather resistance, replacement is the best solution. It’s always better to prioritize safety and functionality over temporary repairs.

Q 15. What are your troubleshooting skills for common garage door panel problems?

Troubleshooting garage door panel problems starts with a systematic approach. I begin by visually inspecting the entire door system, looking for obvious damage like dents, cracks, or loose hardware. Then, I’ll test the door’s operation manually to identify whether the issue is with the panels themselves, the tracks, the springs, or the opener.

For example, if a panel is sagging, it could indicate a problem with the rollers, hinges, or the panel itself. If the door is binding, it might be due to misaligned tracks or damaged rollers. If the door won’t open or close at all, the problem could be with the opener, safety sensors, or a broken spring (a very dangerous situation that should be left to professionals). I use a combination of visual inspection, manual testing, and sometimes specialized tools to pinpoint the exact cause of the malfunction. Once the problem is identified, the appropriate solution can be applied, which might involve simple repairs like tightening screws or replacing damaged components.

- Dents and Cracks: Often repairable with fillers and paint, or panel replacement.

- Loose Hinges: Tighten or replace hinges.

- Broken Rollers: Replace the damaged rollers.

- Bent Tracks: Straighten or replace sections of the track.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is the difference between sectional and roll-up garage doors in terms of panel replacement?

Sectional and roll-up garage doors differ significantly in their panel replacement processes. Sectional doors, the most common type, consist of individual panels connected by hinges and rollers running along tracks. Replacing a panel involves removing the damaged panel and carefully installing a new one, ensuring proper alignment and connection to the adjacent panels. This is a relatively straightforward process for experienced technicians. Roll-up doors, on the other hand, are made of a single, large sheet of material that rolls up around a drum. Panel replacement in roll-up doors is significantly more complex, often involving replacing entire sections of the material rather than individual panels. This requires specialized tools and a more in-depth understanding of the door’s mechanism.

Think of it like this: replacing a panel in a sectional door is like replacing a single tile in a mosaic; replacing a panel in a roll-up door is more akin to replacing a section of a large tapestry, often requiring more extensive work.

Q 17. Explain your experience with different types of garage door hardware.

My experience encompasses a wide range of garage door hardware, from standard to high-end components. I’m proficient with various types of hinges, rollers, springs (extension and torsion), tracks, cables, and safety sensors. I’ve worked with both residential and commercial-grade hardware, understanding the nuances in durability and functionality. For instance, I’ve installed heavy-duty rollers for high-traffic garages and quieter, self-lubricating rollers for residential settings. I’m familiar with various spring types and their appropriate installation techniques. Knowing the differences and strengths of each is crucial for ensuring the longevity and safe operation of the garage door.

I’ve also dealt with various brands and manufacturers of hardware, ensuring I’m able to source and install replacement parts effectively. Proper hardware selection is critical, and I prioritize safety in every installation.

Q 18. How do you ensure the proper functioning of the garage door opener after panel replacement?

After replacing a garage door panel, ensuring the proper functioning of the garage door opener is paramount. I start by checking the opener’s travel limits. These limits determine how far the opener will move the door, and they need to be adjusted precisely to account for the new panel’s dimensions. Incorrect limits can cause the door to not fully open or close, or even lead to damage. I then test the door’s operation multiple times, checking for smooth and complete opening and closing cycles.

Next, I thoroughly check the safety sensors, located near the bottom of the door frame. These sensors prevent the door from closing if an object is in its path. I ensure they are aligned correctly and functioning properly, using a simple test by breaking the sensor beam. The door should reverse immediately when the beam is interrupted. Finally, I test the emergency release cord to confirm the door can be manually opened and closed. This multi-step process guarantees smooth and safe operation after the panel replacement.

Q 19. How do you handle customer concerns or complaints during the installation process?

Handling customer concerns is a vital aspect of my job. I believe in proactive communication, keeping customers informed throughout the process. Before commencing any work, I clearly explain the procedure, the estimated time required, and any potential unforeseen issues. During the process, I encourage open dialogue, answering questions and addressing any concerns immediately.

If a complaint arises, I listen carefully, empathize with the customer’s frustration, and work towards a resolution. This may involve re-examining my work, offering additional services, or finding a mutually agreeable compromise. Ultimately, my goal is to ensure customer satisfaction and build trust. A positive experience fosters referrals and establishes a solid reputation.

For example, if a customer complains about a slight misalignment, I would carefully check my work and make any necessary adjustments, explaining the process and ensuring they are satisfied with the outcome. This proactive approach shows respect and professionalism.

Q 20. What are some common mistakes to avoid during garage door panel replacement?

Avoiding mistakes during garage door panel replacement requires careful attention to detail. One common mistake is not properly aligning the new panel with existing panels. This can lead to gaps, misalignment, or even binding. Another mistake is failing to adequately lubricate the rollers and hinges. This can cause excessive friction and premature wear. Over-tightening screws can also damage the panels or the hardware. Conversely, under-tightening screws can lead to loose components and potential safety hazards.

Finally, overlooking safety precautions, such as not properly supporting the door during panel replacement, is a significant mistake. Remember, garage door springs are under extreme tension and can cause serious injury if handled improperly. Always prioritize safety and, if unsure about any aspect of the process, seek assistance from a qualified professional.

Q 21. Describe your experience working with different types of garage door tracks.

My experience with garage door tracks encompasses various types, including standard, heavy-duty, and curved tracks. Standard tracks are common in residential settings, while heavy-duty tracks are used for larger and heavier doors. Curved tracks are found in garages with limited space or unusual layouts. I understand the nuances of each track type and know how to properly align and adjust them. Misaligned tracks are a frequent cause of garage door malfunctions, from binding to complete operational failure. Repairing or replacing a track segment usually requires precision and careful alignment to ensure smooth door operation.

I’ve encountered various materials used in track construction, such as steel and aluminum, each having its strengths and weaknesses. For example, steel tracks are more durable but prone to rust, while aluminum tracks are lighter and corrosion-resistant but might bend more easily under stress. Understanding these differences is critical for selecting and installing the right track for the specific application.

Q 22. How do you manage your time and prioritize tasks during a panel replacement job?

Efficient time management is crucial for any garage door panel replacement job. I approach each project with a structured plan. First, I thoroughly assess the situation, noting the number of panels needing replacement, their condition, and the type of garage door. This allows me to accurately estimate the time needed. Then, I prioritize tasks based on urgency and dependency. For example, removing damaged panels always comes before installing new ones. I break down large tasks into smaller, manageable chunks. This keeps me focused and prevents feeling overwhelmed. I use a checklist to ensure nothing is overlooked, and regularly check my progress against the estimated timeline. If unexpected delays arise, I immediately reassess and adjust my plan, communicating any changes to the client. For instance, if I discover significant underlying damage, I’ll inform the client immediately and adjust the schedule accordingly. This proactive approach keeps everything running smoothly.

Q 23. What is your experience with working at heights or using ladders safely?

Safety is my top priority when working at heights. I’ve extensive experience using ladders, and I always follow safety regulations. This includes using the correct ladder type and size for the job, ensuring the ladder is properly positioned on stable ground, and always maintaining three points of contact when climbing. I regularly inspect ladders for damage before each use. I also utilize safety harnesses and fall protection equipment whenever necessary, especially on taller garage doors or when working on uneven terrain. I regularly update my knowledge on ladder safety best practices through industry training and online resources. For example, I recently completed a course on fall protection, significantly enhancing my safety protocols on-site. My record shows zero accidents related to working at heights.

Q 24. Describe your experience in handling different types of garage door springs.

I have considerable experience working with various types of garage door springs, including extension springs, torsion springs, and their different strengths and types (e.g., oil-tempered, galvanized). Understanding the mechanics and tension of these springs is critical for safe and effective operation. I’m proficient in safely disassembling and installing these springs using the proper tools and techniques. This includes using spring winders to carefully compress and decompress springs, minimizing the risk of injury from sudden spring release. I’m also experienced in identifying signs of spring wear and tear, advising clients on timely replacements to prevent accidents or malfunctions. For example, a broken torsion spring can cause serious damage to the garage door and pose a safety risk. My knowledge allows me to correctly assess the spring’s condition and suggest the appropriate replacement based on the door’s weight and size.

Q 25. How do you handle unexpected issues during a garage door panel replacement?

Handling unexpected issues is an integral part of this job. My approach is methodical and client-focused. I always have a contingency plan in place. For example, if I discover rotted wood during panel removal, I immediately photograph and document the damage. I then discuss the repair options with the client, providing a clear explanation of the problem and potential solutions (e.g., wood repair, panel replacement). If I encounter a part incompatibility, I use my expertise to identify a suitable substitute. If I run into a problem outside my expertise, I’m not hesitant to seek advice from experienced colleagues or consult manufacturer instructions. Open communication with the client keeps them informed and maintains trust throughout the process. For instance, a recent job required a custom panel due to an unusual door configuration. I immediately communicated this, obtained the panel, and rescheduled the completion with the client’s consent.

Q 26. What are your skills in using power tools safely and effectively?

Safety is paramount when using power tools. I’m proficient with a wide range of tools, including drills, saws, and pneumatic tools, relevant to garage door panel replacement. I always use appropriate safety gear, such as eye protection, gloves, and hearing protection. Before starting any task, I meticulously inspect the tools for damage or wear. I follow all manufacturer guidelines for each tool’s safe operation and maintenance. I understand how to select the right bit or blade for different materials and applications, ensuring clean cuts and preventing damage to the door components. For example, I always use a fine-toothed blade when cutting wood to avoid splintering. I regularly maintain my tools, keeping them sharp and in proper working order. I am very conscious of proper tool storage and transportation.

Q 27. How do you maintain accurate records and documentation for each job completed?

Maintaining accurate records is essential for both client satisfaction and my business operations. For each job, I maintain a detailed record including: the client’s information, job date, description of work performed (including parts used and their serial numbers), before and after pictures, and the total cost. I use a combination of digital and physical documentation. I use a mobile app for recording job details and uploading photos directly from the field, and a physical notebook for quick notes and sketches. All information is stored securely and backed up regularly. This system ensures efficient record-keeping, facilitates easy access to past job information, assists with warranty claims, and aids in ongoing professional development.

Q 28. Describe your experience in maintaining a clean and organized work environment.

Maintaining a clean and organized work environment is vital for safety and efficiency. Before starting a job, I always protect the client’s property using drop cloths and floor coverings. I organize my tools and materials strategically, ensuring easy access and preventing tripping hazards. As I work, I regularly clear away debris and dispose of waste properly. Upon completion, I thoroughly clean the work area, ensuring the site is left better than how I found it. This demonstrates professionalism and respects the client’s property. A clean workspace is also critical for safety; a clear area minimizes accidents and allows for a more efficient workflow.

Key Topics to Learn for Garage Door Panel Replacement Interview

- Understanding Garage Door Panel Types: Learn to identify different panel materials (steel, wood, aluminum, fiberglass), styles (raised panel, recessed panel, carriage house), and their respective strengths and weaknesses. This is crucial for recommending the right replacement.

- Assessing Damage and Determining Replacement Needs: Practice diagnosing various types of panel damage (dents, cracks, rust, rot). Understand when a simple repair is sufficient versus a full panel replacement. Develop a systematic approach to damage assessment.

- Panel Removal and Installation Techniques: Master the safe and efficient removal of damaged panels, including the use of appropriate tools and safety precautions. Become proficient in installing new panels, ensuring proper alignment and secure fastening.

- Safety Procedures and Best Practices: Demonstrate knowledge of safety regulations and best practices related to working with garage doors, including proper use of safety equipment (gloves, eye protection) and awareness of potential hazards.

- Troubleshooting Common Issues: Prepare to discuss common problems encountered during panel replacement (e.g., misaligned tracks, damaged rollers, incorrect panel sizing) and demonstrate your ability to troubleshoot and find solutions.

- Customer Interaction and Communication: Discuss how to effectively communicate with customers, explain technical details in a clear and understandable manner, and manage expectations regarding timelines and costs.

- Tools and Equipment Familiarity: Be prepared to discuss the various tools and equipment used in garage door panel replacement (e.g., pry bars, screwdrivers, measuring tools, power drills) and their proper use.

Next Steps

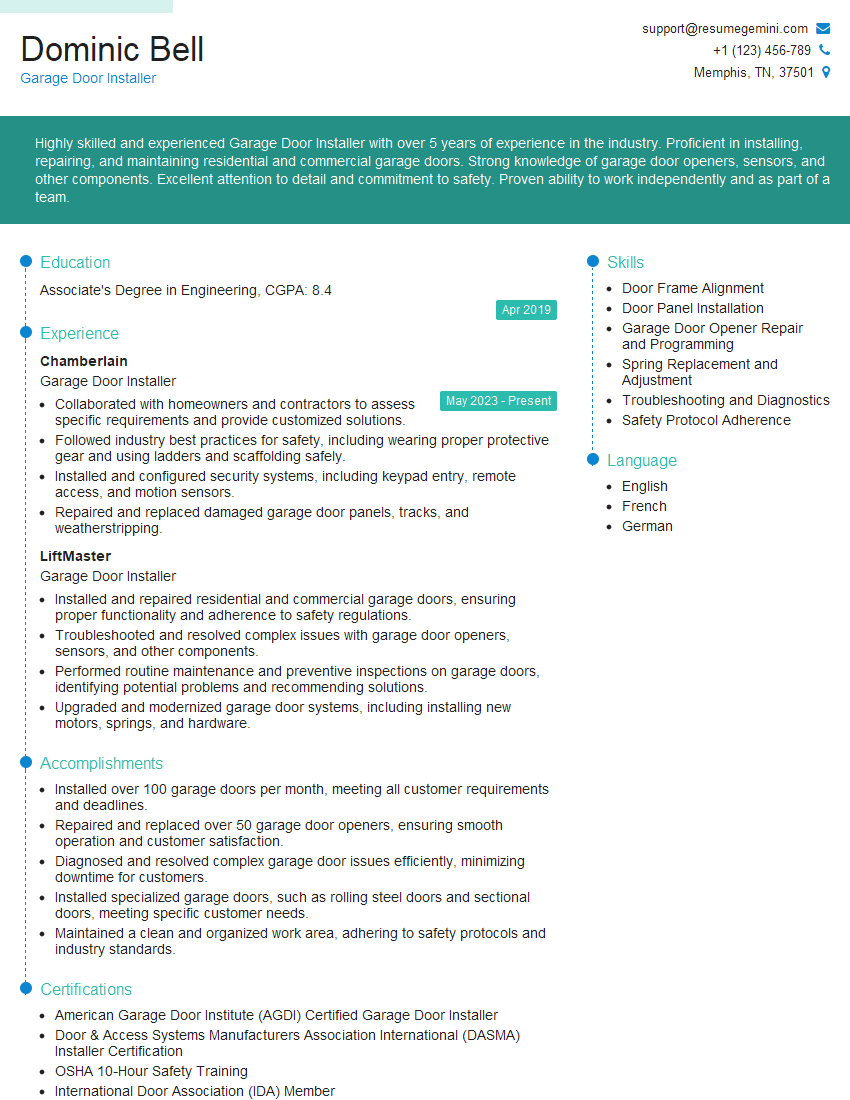

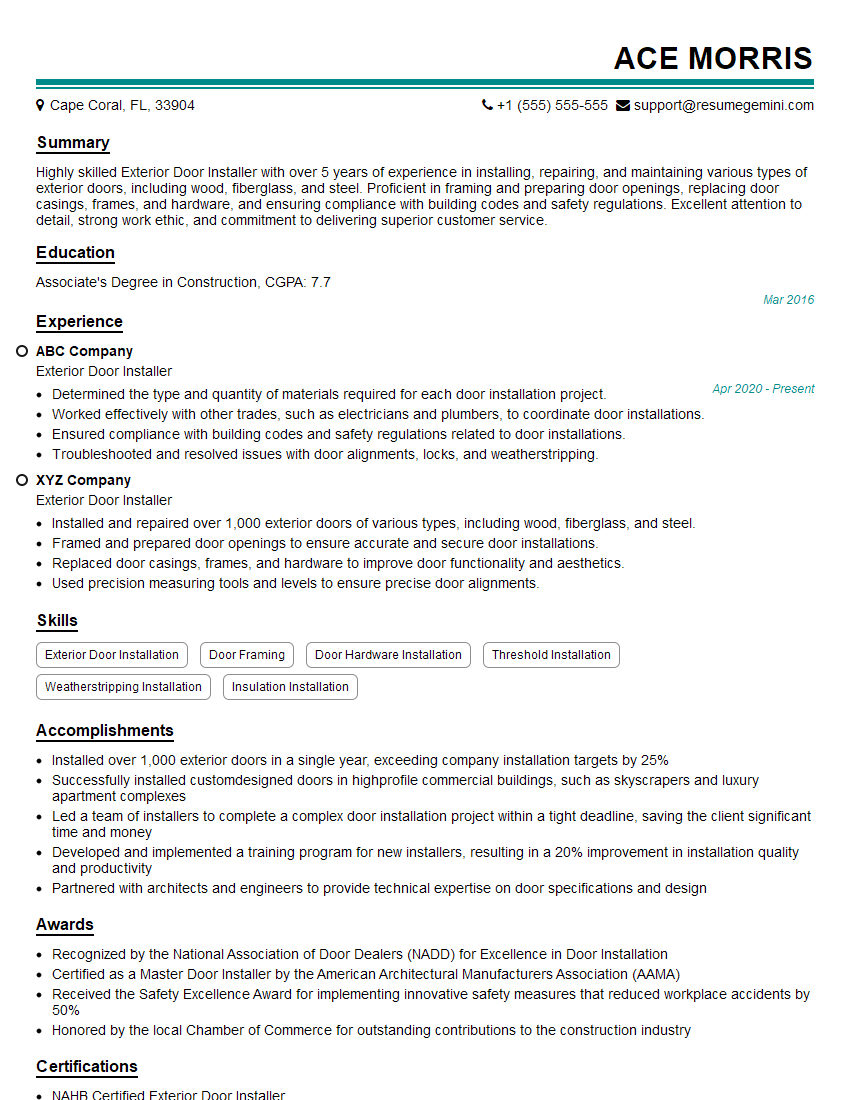

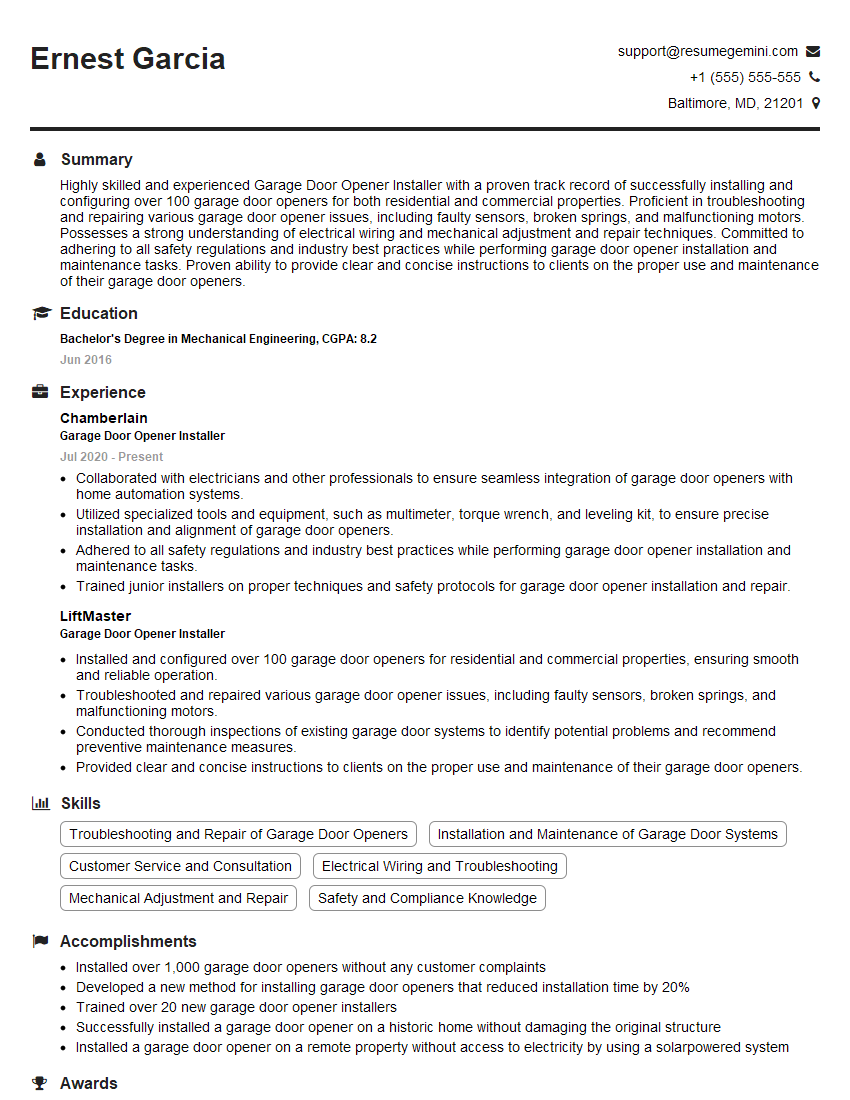

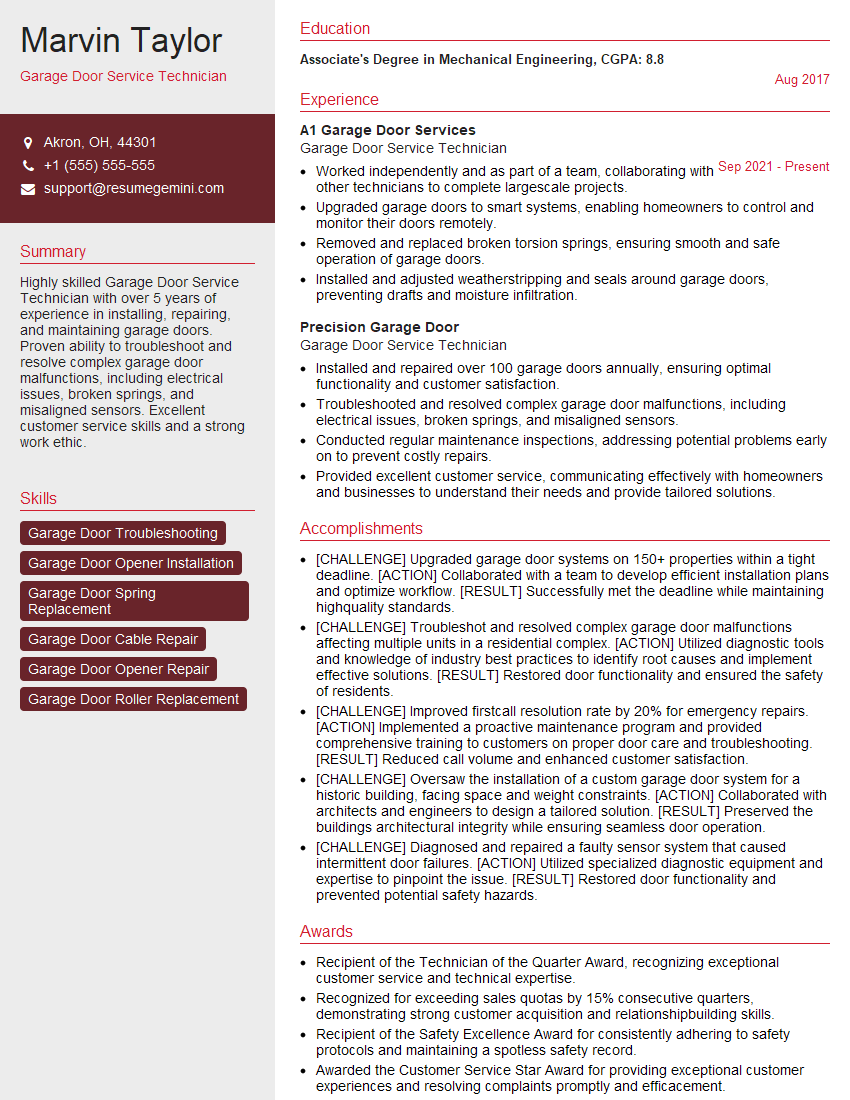

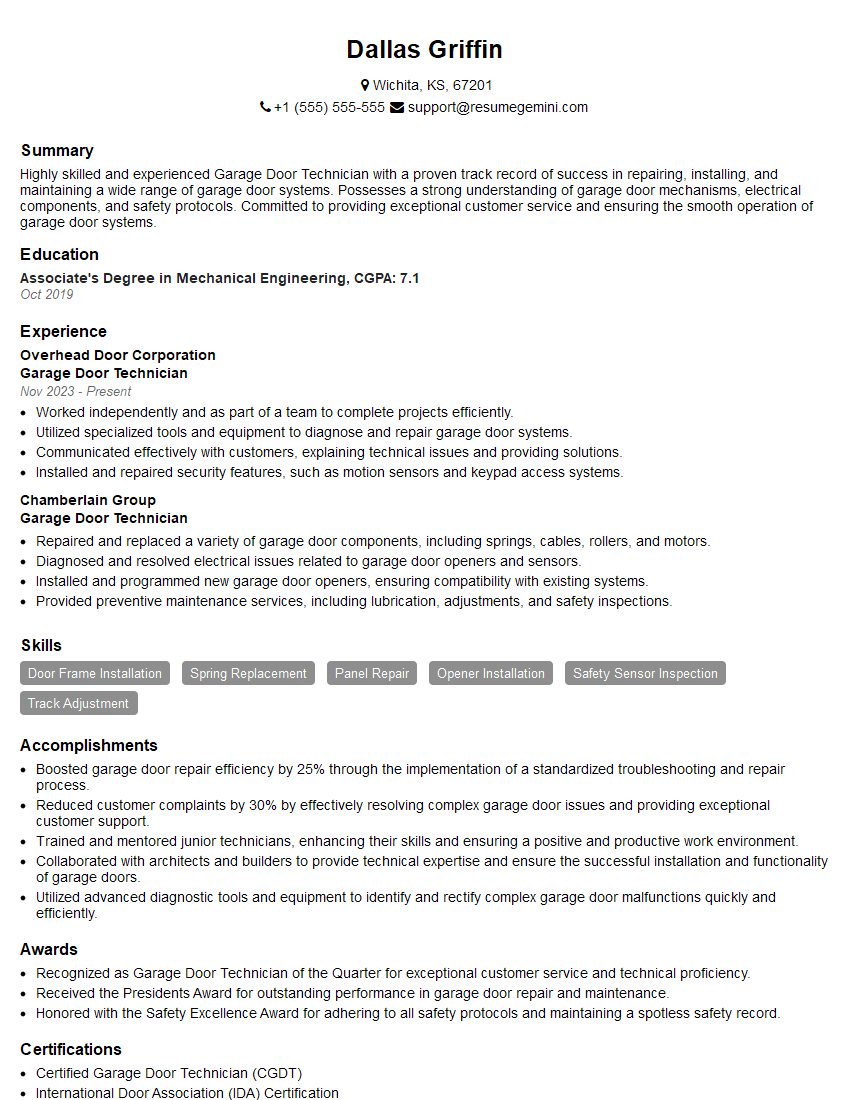

Mastering garage door panel replacement opens doors to a rewarding career with excellent growth potential. It demonstrates practical skills highly valued by employers, showcasing your technical abilities and problem-solving skills. To significantly boost your job prospects, create a compelling and ATS-friendly resume that highlights your expertise. ResumeGemini is a trusted resource that can help you craft a professional resume tailored to showcase your skills and experience in this field. Examples of resumes specifically tailored to Garage Door Panel Replacement are available to help guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I represent a social media marketing agency that creates 15 engaging posts per month for businesses like yours. Our clients typically see a 40-60% increase in followers and engagement for just $199/month. Would you be interested?”

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?