Preparation is the key to success in any interview. In this post, we’ll explore crucial Garage Door Sectional Repair interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Garage Door Sectional Repair Interview

Q 1. Explain the different types of sectional garage door springs.

Garage door springs are crucial for lifting and lowering the door. They come in two main types: extension springs and torsion springs.

- Extension Springs: These are the most common type, found on lighter garage doors. They’re located above the door on either side of the track, extending and contracting as the door moves. Think of them like a giant, powerful rubber band. They work in pairs, one on each side, to balance the weight of the door.

- Torsion Springs: These are more powerful and usually found on heavier doors. A single, tightly wound spring is located horizontally above the door, typically connected to a shaft. As the door opens, the spring unwinds, storing energy, and as it closes, it winds back up. This is like a coiled clock spring.

Choosing the right spring type is critical for safety and proper operation. An incorrectly sized spring can lead to damage or injury. Always consult with a professional to determine the appropriate spring type and size for your garage door.

Q 2. Describe the process of replacing a broken garage door spring.

Replacing a broken garage door spring is extremely dangerous and should only be attempted by trained professionals. The stored energy in these springs is immense and can cause serious injury if mishandled. However, understanding the basic steps provides context.

The process generally involves:

- Disconnecting the springs: This requires carefully releasing the tension using specialized tools. A mistake here can be catastrophic.

- Removing the broken spring: The broken spring is removed and the appropriate replacement spring is carefully measured and selected.

- Installing the new spring: The new spring is carefully installed, ensuring correct tension and alignment. This is the most critical step.

- Testing the door: After installation, the door is thoroughly tested to ensure it operates smoothly and safely.

Again, I strongly emphasize that this is a highly dangerous task. Contact a professional garage door repair technician for safe and proper spring replacement. Your safety is paramount.

Q 3. How do you troubleshoot a garage door opener that won’t close?

A garage door opener that won’t close can have several causes. Systematic troubleshooting is key.

- Check the power supply: Ensure the opener is plugged in and the circuit breaker hasn’t tripped.

- Inspect the remote: Test the remote’s batteries and ensure it’s properly programmed. Try using the wall button.

- Examine the safety sensors: These are usually located near the bottom of the door tracks. Any obstruction between them (e.g., a toy, debris) will prevent the door from closing. Clean the lenses and ensure proper alignment.

- Check the limit settings: The opener’s limit switches control how far the door opens and closes. If these are misadjusted, the door might not close fully. Consult your opener’s manual for adjustment procedures.

- Inspect the chain or belt: Look for any signs of damage, slippage, or derailment. A broken belt or a disconnected chain will prevent the door from functioning.

- Assess the springs and cables: Broken or damaged springs or cables are major contributors to opener issues. Call a professional if you suspect these are involved.

If the problem persists after these checks, it is advisable to contact a professional for further diagnosis.

Q 4. What are the common causes of garage door track misalignment?

Garage door track misalignment is a common issue, often leading to noisy operation, difficulty opening or closing, and even damage to the door or opener. Several factors contribute:

- Door impact: A car or other object hitting the door can easily bend or damage the tracks.

- Settlement of the garage structure: Over time, the garage foundation can settle, causing the tracks to become misaligned.

- Improper installation: If the tracks weren’t initially installed correctly, misalignment is more likely.

- Obstructions: Debris in the track, or something catching on the door, can force it off track.

- Loose screws or fasteners: Over time, screws holding the track in place can loosen, causing sagging and misalignment.

Addressing these causes usually involves tightening loose fasteners, carefully straightening bent sections of the track, or, in more severe cases, replacing parts of the track system. A professional can assess the extent of the problem and execute the necessary repairs.

Q 5. How do you safely repair a broken garage door cable?

Repairing a broken garage door cable is another extremely dangerous task that should only be undertaken by experienced professionals. The tension in these cables is significant, and a sudden release can cause serious injury. However, here’s a general overview (for informational purposes only):

The process generally involves:

- Releasing tension: This must be done carefully and methodically to prevent a sudden release. Specialized tools are necessary.

- Removing the broken cable: The broken cable is removed from its pulleys and drum.

- Installing a new cable: A new cable of the correct length and specifications is installed, routed through all the pulleys and secured to the drum. Proper tensioning is crucial.

- Testing and adjustment: The door is tested to ensure the new cable is properly seated and functioning correctly. Any adjustments to tension are made.

Remember, incorrect installation can lead to severe damage or injury. Leave this task to the experts.

Q 6. Explain the process of replacing a damaged garage door panel.

Replacing a damaged garage door panel is a moderately challenging DIY project if you possess basic handyperson skills. However, caution and precision are paramount.

The process usually involves:

- Accessing the damaged panel: Remove any screws or fasteners securing the damaged panel.

- Removing the old panel: Carefully remove the damaged panel, taking note of how it was attached.

- Preparing the replacement panel: Ensure the replacement panel is the correct size and type for your door. Some minor adjustments might be necessary.

- Installing the new panel: Carefully install the new panel, mimicking how the old one was fitted. Secure it using appropriate screws or fasteners.

- Testing the door: Test the door for smooth operation. Ensure all panels are aligned.

If the damage is extensive, or if you are uncomfortable performing this repair, it’s always wise to consult a professional. They have the tools, experience, and expertise to ensure the job is done correctly and safely.

Q 7. Describe different types of garage door openers and their functionalities.

Garage door openers come in various types, each with its own features and functionalities:

- Chain-drive openers: These are the most common and affordable type. They use a metal chain to lift and lower the door, producing a noticeable, somewhat noisy operation. Simple and reliable.

- Belt-drive openers: These use a reinforced rubber belt instead of a chain, resulting in quieter operation. They tend to be slightly more expensive but offer a smoother, quieter experience.

- Screw-drive openers: These utilize a threaded steel rod that turns to lift the door. They are known for their smooth and quiet operation, but can sometimes be slower than other types.

- Direct-drive openers: These are the quietest openers available. The motor is directly connected to the door, eliminating the need for a chain, belt, or screw. They are very quiet but usually the most expensive option.

Many openers offer additional features such as:

- Keypads: For keyless entry.

- Remote controls: For convenient operation from a distance.

- Smartphone integration: Allowing you to control your garage door from your phone.

- Safety sensors: To prevent accidental injury or damage.

Choosing the right opener depends on your budget, noise tolerance, and desired features.

Q 8. How do you diagnose and fix a noisy garage door?

A noisy garage door is often a symptom of a problem needing attention. The noise can range from a squeaking sound to a loud banging. Diagnosing the source requires a systematic approach. I start by visually inspecting the entire system, looking for any obvious issues like loose hardware, damaged rollers, or misaligned tracks. I then listen carefully as the door opens and closes, trying to pinpoint the location of the noise.

- Squeaking: This usually points to dry rollers or hinges. Applying a high-quality lubricant, like silicone spray, directly to the moving parts is often the solution.

- Banging or Clunking: This could indicate loose or broken parts, often the springs, cables, or rollers. A loose track could also be the culprit. Addressing this requires careful inspection and often replacement of the damaged components.

- Grinding: This often suggests metal-on-metal contact. It is usually indicative of severely worn rollers, or a problem with the track requiring realignment or replacement.

For example, I recently worked on a garage door that was making a loud banging noise. Upon inspection, I found that one of the springs had broken. Replacing the spring resolved the problem immediately. Sometimes, a simple adjustment can suffice – for example, tightening loose bolts on the hinges or track often eliminates squeaks.

Q 9. What safety precautions do you take when working on garage doors?

Safety is paramount when working on garage doors. These are heavy, moving mechanical systems, and mistakes can lead to serious injuries. My safety precautions include:

- Disconnecting the power: Always disconnect the garage door opener from the power supply before beginning any work. This prevents accidental operation of the door while you’re working on it.

- Using proper tools: I utilize appropriate tools for the job and ensure they are in good working order. Improper tools can lead to slips and accidents.

- Wearing safety gear: This includes gloves, safety glasses, and sturdy work boots to protect against cuts, impacts, and falling debris.

- Working with an assistant: For complex repairs or heavy components, an assistant helps manage parts and provides additional safety.

- Securing the door: Once the power is disconnected, I’ll often manually support the door using a ladder or other secure method, especially when working on springs or cables, preventing the door from suddenly moving.

Imagine attempting to adjust the springs without disconnecting the power – a serious risk of injury. My consistent adherence to these safety protocols ensures both my safety and that of my clients.

Q 10. How do you inspect and maintain garage door safety sensors?

Garage door safety sensors are crucial for preventing accidents. They detect obstructions in the door’s path and prevent it from closing on people or objects. Inspection involves checking both the sensors themselves and their alignment:

- Sensor Alignment: The sensors must be perfectly aligned. A tiny misalignment can render them ineffective. I use a laser pointer or small light source to verify alignment. The red LED light of one sensor should be clearly visible through the receiver lens of the other sensor.

- Sensor Lens Condition: Dust or debris can obscure the sensors. I clean the lenses with a soft cloth to ensure clear visibility.

- Sensor Wiring: I check the wiring to ensure that it is securely connected and undamaged. Loose or damaged wires can interrupt the sensor’s function.

- Sensor Functionality Test: After cleaning and checking alignment, I test the sensor by placing an object in their path. The door should reverse upon encountering the object.

A simple example: I once found a spiderweb had obscured one of the sensors. Simply removing the web restored the sensor’s function and greatly improved safety.

Q 11. Explain the process of adjusting the garage door’s travel limit.

Adjusting the garage door’s travel limit ensures the door opens and closes completely without hitting the ceiling or floor. This adjustment is done via the garage door opener’s control panel or through its DIP switches.

- Locate the Limit Adjustments: Most openers have controls specifically labeled “Limit” or “Travel.” These controls allow for the fine-tuning of the upward and downward travel limits.

- Open the Door: Initiate the door’s opening process.

- Adjust the Upward Limit: Once the door is fully open, use the adjustment to stop the door precisely at its uppermost position, preventing it from striking the ceiling.

- Close the Door: Initiate the closing process.

- Adjust the Downward Limit: Once the door is fully closed, use the adjustment to stop the door accurately in its closed position.

- Test the Limits: Cycle the door several times to confirm it opens and closes correctly within the adjusted limits.

Incorrectly set limits can lead to the door not closing completely, posing security risks, or hitting the ceiling, leading to damage. Careful adjustment is crucial.

Q 12. How do you address issues related to garage door rollers and tracks?

Garage door rollers and tracks are critical components. Problems here can lead to noisy operation and even derailment. Diagnosis involves careful inspection:

- Roller Inspection: Check rollers for wear and tear. Flattened or cracked rollers need replacement. Check the bearings within the rollers; noisy rollers often indicate bearing failure.

- Track Inspection: Inspect the tracks for dents, bends, or misalignments. Bent tracks can cause the door to bind and can damage rollers. Loose screws that secure the track to the wall also need to be addressed.

- Track Cleaning: Clean the tracks of any dirt, debris, or paint that could interfere with roller movement. This can make a significant difference in door operation.

- Realignment/Replacement: For bent tracks, straightening them might be possible. Sometimes, replacement is necessary. Damaged or worn rollers always need replacing.

I had a client whose garage door was dragging. After inspection, I found several bent sections of the track. Straightening them out improved the door’s movement and eliminated the noise.

Q 13. Describe the steps involved in lubricating a garage door system.

Lubricating a garage door system enhances its smooth operation, reduces noise, and extends its lifespan. The best lubricant for this purpose is a silicone-based spray lubricant. It won’t attract dirt and is less likely to damage certain components.

- Identify Lubrication Points: The main lubrication points are the rollers, hinges, and tracks.

- Apply Lubricant Sparingly: Apply a small amount of lubricant to each moving part. Avoid over-lubrication. Too much can attract dirt and dust which will hinder the system, or cause damage to the motor.

- Open and Close the Door: After lubricating, operate the door several times to distribute the lubricant evenly.

- Wipe Excess Lubricant: Wipe off any excess lubricant to prevent attracting dirt and dust.

Regular lubrication (at least annually or more often if needed) keeps the garage door operating smoothly and quietly, preventing damage from friction and extending its service life.

Q 14. How do you test the functionality of a garage door’s emergency release mechanism?

The emergency release mechanism allows manual operation of the garage door in case of power failure or opener malfunction. Testing it is straightforward:

- Locate the Release Cord: The release cord is usually located on the track inside the garage, often near the ceiling or where the tracks meet.

- Pull the Release Cord: Gently pull the release cord. This disengages the door from the opener’s drive mechanism. The door will then become manually operable.

- Manually Operate the Door: Try opening and closing the door manually.

- Reengage the Mechanism: Once finished, carefully reengage the opener by gently lifting the door until the mechanism automatically reconnects.

Knowing how to use this is crucial in case of a power outage. Regularly testing ensures it remains functional when needed.

Q 15. What are the common causes of a garage door not closing completely?

A garage door failing to close completely usually stems from a few key issues. Think of it like a chain – if one link is weak, the whole system falters. The most common culprits are:

Track Problems: Bent, damaged, or misaligned tracks prevent the door from smoothly sliding along its path. Imagine a train derailing – the track needs to be straight and level for the door to close correctly. This often requires track straightening or replacement.

Spring Issues: Broken or weakened springs are major offenders. These springs are responsible for counterbalancing the door’s weight, making it easy to open and close. If they’re compromised, the door might sag or become too heavy to close completely. This is a safety hazard and requires professional spring replacement.

Safety Sensors: These infrared beams at the bottom of the door detect obstacles. If they’re misaligned, dirty, or obstructed, the door will reverse before fully closing. Cleaning the sensors or adjusting their alignment usually solves this issue.

Opener Issues: Problems with the garage door opener’s motor, limit switches (which tell the opener when the door is fully open or closed), or its chain can prevent complete closure. This often requires troubleshooting the opener or replacing components.

Roller Problems: Worn-out or damaged rollers create friction and hinder the smooth operation of the door. They are like the wheels of a car – if they are damaged, the car cannot run smoothly. Replacing the rollers is often the solution.

Diagnosing the exact cause involves a careful visual inspection of the entire system, checking for any of these problems systematically.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you identify and address problems with the garage door opener’s logic board?

The logic board is the brain of your garage door opener, controlling all its functions. Troubleshooting it requires a systematic approach, as a faulty board can manifest in various ways – from the door not responding at all to erratic behavior.

First, I visually inspect the board for any obvious signs of damage, such as burned components or loose connections. This is like checking for visible cracks or burns on a circuit board of a computer. Then I check the power supply to the board, making sure it’s receiving the correct voltage. A multimeter is invaluable here.

If the visual inspection is clear and the power supply is good, I might proceed to check for faulty input signals from the safety sensors or wall controls. This is where a wiring diagram for the specific opener model is incredibly helpful. I would check each wire and connection carefully. A continuity test with a multimeter helps identify broken wires or poor connections.

If all else fails, the logic board itself might need replacement. It’s crucial to find the exact model number of the opener so you can order the correct replacement board, as they’re not universally interchangeable. Installing a new logic board usually involves disconnecting the old one, carefully transferring the necessary components, and reconnecting the wires according to the manufacturer’s instructions.

Q 17. What are the different types of garage door materials and their pros and cons?

Garage doors are available in a variety of materials, each with its own set of advantages and disadvantages. The most common are:

Steel: Steel doors are the most common due to their durability, affordability, and resistance to dents and dings. However, they can be susceptible to rust and may dent under impact. They are sturdy and long lasting, just like steel buildings.

Wood: Wooden doors offer a classic, elegant look and excellent insulation. They’re more expensive than steel and require regular maintenance, including painting or staining, to prevent rot and damage. They are similar to wooden furniture requiring maintenance.

Aluminum: Aluminum doors are lightweight, rust-proof, and relatively low-maintenance. They’re not as strong as steel or wood, and they can dent more easily. They are lightweight just like an aluminum can.

Fiberglass: Fiberglass doors offer a good balance of strength, insulation, and low maintenance. They mimic the look of wood but are more resistant to damage and require less upkeep. They are sturdy and maintainable just like fiberglass insulation.

Vinyl: Vinyl doors are increasingly popular due to their low maintenance, durability and variety of styles. They are relatively inexpensive and easy to install. They are similar to vinyl siding in durability.

The best material for a garage door depends on the budget, aesthetic preferences, and climate.

Q 18. How do you handle a situation where a garage door is jammed?

A jammed garage door is a serious situation, and safety is paramount. Never attempt to force the door open. This could lead to injury or further damage. First, I would ensure the power to the opener is disconnected to prevent any accidental movement. Then:

Assess the situation: Carefully inspect the door and its tracks to identify the point of jam. Is it a problem with the rollers, tracks, springs, or something else? This is like examining a jammed car door to find where the block is.

Manual Release: Most openers have a manual release cord or lever that disengages the opener from the door. This allows you to manually lift or lower the door, at least partially.

Lubrication: If the jam is due to friction, a well-placed lubricant (specifically designed for garage doors) in the tracks and rollers can often free up the door.

Clear Obstructions: Remove any debris or obstacles that might be interfering with the door’s movement. This is like clearing the obstacle blocking a jammed drawer.

Seek Professional Help: If you cannot free the door, or if the problem seems serious (such as a broken spring), immediately contact a garage door professional. Attempting repairs without proper training can be dangerous.

Remember, safety is the top priority when dealing with a jammed garage door. If you’re unsure, always call a professional.

Q 19. Describe your experience with different types of garage door hardware.

My experience encompasses a wide range of garage door hardware, including various types of rollers, hinges, tracks, and springs. I’ve worked with steel rollers (the most common and durable), nylon rollers (quieter but less durable), and even high-performance rollers for smoother operation. Hinges vary in material and design, affecting both durability and the door’s aesthetic appeal.

I’m familiar with different track materials, including steel and aluminum, with variations in design to accommodate different door styles and sizes. My experience with springs includes both extension springs (common in residential doors) and torsion springs (more powerful, often used in commercial settings). I’ve worked extensively with different spring winding methods and safety mechanisms.

Understanding the strengths and weaknesses of different hardware components helps me choose the appropriate materials and designs for each job. Choosing the right hardware is crucial for ensuring safe and efficient garage door operation, and longevity. It is also vital to choose quality hardware to ensure the safety and longevity of the door.

Q 20. How do you determine the appropriate size of replacement springs?

Determining the correct size of replacement springs is critical for safety and proper operation. It’s not a task for the novice. Incorrectly sized springs can be extremely dangerous. The size is determined by several factors:

Door Weight: The weight of the door is the most important factor. This usually requires a spring scale to accurately measure the weight of the door. It’s similar to calculating the weight of a ship before sailing.

Door Height: The height of the door influences the tension required in the springs. Taller doors require stronger springs. This is similar to selecting the appropriate thickness of a rope to lift a certain weight.

Spring Type: The type of spring (extension or torsion) and the number of springs used will also affect the size requirements. This is the difference between selecting a single or double engine car.

Manufacturer’s Specifications: Referencing the manufacturer’s specifications for the garage door is essential. The markings on the existing springs (if still legible) can also provide valuable information.

If you are unsure, it is highly recommended to consult with a garage door professional, who has the tools and expertise to accurately measure the door weight and select the appropriate springs.

Q 21. Explain the process of installing a new garage door opener.

Installing a new garage door opener is a relatively straightforward process, but proper execution is crucial for safety and functionality. Here’s a step-by-step guide:

Disconnect the old opener: First, disconnect the power to the old opener and detach it from the door and its mounting bracket.

Mount the new opener: Securely mount the new opener’s motor unit to the ceiling or wall, following the manufacturer’s instructions. Ensure it’s properly aligned with the door track.

Attach the trolley: Connect the trolley (the moving part that engages with the door) to the opener’s chain or belt.

Connect the door: Attach the door to the trolley using the provided hardware.

Program the remote control: Follow the manufacturer’s instructions to program your remote controls and any keypads.

Program the travel limits: Adjust the opener’s travel limits so that the door opens and closes fully without hitting the tracks or the floor.

Test operation: Before reconnecting power, carefully test the door’s opening and closing by using the manual release. Once confident, reconnect the power and run a full test cycle.

Test safety sensors: Ensure the safety sensors are correctly aligned and working as expected.

If at any point you are uncertain, consult the manufacturer’s instructions or seek the help of a professional. Improper installation can lead to safety issues and malfunctions.

Q 22. How do you troubleshoot issues with a remote control system?

Troubleshooting a garage door remote control system involves a systematic approach. First, I’d check the simplest things: are the batteries fresh? A surprisingly common issue! Next, I’d test the remote’s range. Is the opener receiving the signal? Try standing closer to the opener’s receiver. If still unresponsive, I’d examine the receiver itself. Is it plugged in properly? Is the antenna damaged or misaligned? Sometimes, external interference from other electronic devices can cause problems. I might try unplugging non-essential electronics temporarily to see if that makes a difference.

Sometimes, the issue lies within the garage door opener itself. I’d check the opener’s programming and try reprogramming the remote. This usually involves following the instructions in the owner’s manual; the process varies slightly by brand and model. If the problem persists, I suspect a fault in the opener’s control board or the remote’s internal circuitry, which often requires professional repair or replacement. I’ve had cases where a simple reset of the opener solved the issue, while others required replacing a faulty component. The key is to approach this systematically – from the simplest to the most complex possible solutions.

Q 23. What are the common causes of a garage door opening unexpectedly?

A garage door opening unexpectedly is a serious safety concern. Several things could be causing this. A malfunctioning safety sensor is very common. These sensors, located near the ground on both sides of the door, use infrared beams to detect obstructions. If misaligned, obstructed by debris, or damaged, they might not stop the door, leading to unexpected opening. I always check the sensors first and ensure the beam path is clear. Another possibility is a problem with the door’s reversing mechanism. If this fails, the door might not stop when encountering resistance. This often means a more serious mechanical issue requiring expert attention.

Less common, but still possible, are issues with the opener’s control board. A short circuit or software glitch could send the wrong signals, causing the door to open unexpectedly. In extreme cases, a faulty keypad or even a compromised wireless signal could cause unintended actions. To determine the culprit, I carefully inspect the entire system, checking for damaged wiring, loose connections, and potential interference. Thoroughly testing each component is vital, ensuring I address the underlying cause, not just a symptom.

Q 24. Describe your experience working with different brands of garage door systems.

I have extensive experience with a wide range of garage door systems, including Chamberlain, LiftMaster, Genie, Craftsman, and many other brands. Each brand has its own design nuances and troubleshooting techniques. For example, Chamberlain and LiftMaster openers often share similar designs and components, making repairs relatively straightforward. Genie openers, on the other hand, can sometimes use proprietary parts that might require specialized knowledge and sourcing. I always ensure I understand the specific model I’m working on, by referring to the manufacturer’s documentation and utilizing my experience to quickly diagnose and repair any issues.

This experience has enabled me to develop efficient and effective strategies for diagnosing and resolving problems across different brands. I’ve learned to identify common problems that transcend specific brands. Whether it’s a broken spring, worn rollers, or a faulty control board, the underlying principles of repair are often similar, albeit with brand-specific variations in component design and assembly. My goal is always to provide clients with the best possible repair, regardless of the brand.

Q 25. How do you address customer concerns regarding garage door repair?

Addressing customer concerns is paramount in my line of work. I start by actively listening to their concerns, ensuring I fully understand the problem from their perspective. Then, I clearly explain the potential causes of the problem using simple language, avoiding technical jargon as much as possible. I strive to offer several solutions, outlining the pros and cons of each, including cost estimates, so they are empowered to make informed decisions.

Transparency is key. If a repair is going to take longer than expected, or if additional costs are involved, I communicate that proactively. I believe in building trust by being honest and upfront with customers. I’ve found that providing clear, concise information helps alleviate customer anxieties and fosters a positive working relationship. I’ve had cases where simply explaining the root cause of a problem and demonstrating the repair process has calmed anxious homeowners. Customer satisfaction is my top priority.

Q 26. How do you prioritize repair tasks during a busy workday?

Prioritizing repair tasks during a busy workday requires a structured approach. I typically begin by categorizing jobs based on urgency. Emergency calls, like a completely inoperable door or a safety hazard, take precedence. Next, I consider factors such as location (to minimize travel time) and the complexity of the repairs. Jobs requiring specialized tools or parts might be scheduled later, to avoid delays on simpler tasks.

I use a digital scheduling system to manage appointments and track progress. This system allows me to view all upcoming jobs at a glance, keeping track of customer contact information, specific details about each repair, and the status of each task. By employing such a system, I can easily assess and adapt to changing priorities throughout the day, maximizing efficiency and providing timely service. My experience allows me to estimate job duration accurately, preventing scheduling conflicts and keeping customers informed about potential delays.

Q 27. Describe your experience with diagnosing and repairing garage door weather stripping issues.

Diagnosing and repairing garage door weather stripping issues involves a thorough inspection. First, I check for signs of damage, such as tears, gaps, or deterioration of the rubber seals. I assess the extent of the damage to determine the best repair strategy. Often, simple repairs involve cleaning the stripping with a mild detergent and applying a silicone-based lubricant to restore its flexibility and seal. For more extensive damage, I may need to replace sections or the entire weather stripping. This requires accurate measurements and careful selection of the correct replacement material to ensure a proper fit.

When dealing with weather stripping, it’s crucial to understand its function, which is preventing drafts, water intrusion, and the infiltration of pests. Replacing worn or damaged weather stripping enhances energy efficiency and keeps the garage environment more comfortable and pest-free. I’ve seen cases where neglecting damaged weather stripping led to significant water damage to the garage and nearby areas of the home. Therefore, addressing weather stripping issues promptly is essential for both functionality and long-term protection.

Q 28. What are your methods for ensuring the safe disposal of old garage door components?

Safe disposal of old garage door components is crucial for environmental responsibility. I adhere to all local regulations and recycling guidelines. Metal components, such as springs, tracks, and rollers, are taken to designated scrap metal recycling centers. Wooden parts, if suitable, are often recycled, or disposed of through the appropriate local waste management channels. Plastic parts are separated and disposed of according to local guidelines.

I’m committed to eco-friendly practices and ensure that all hazardous materials, such as certain types of lubricants or paints, are disposed of responsibly, in accordance with all relevant environmental protection regulations. Proper disposal ensures that these materials don’t contaminate landfills or the environment, minimizing environmental impact and promoting sustainability in my work. Understanding and adhering to these guidelines is part of my professional responsibility.

Key Topics to Learn for Your Garage Door Sectional Repair Interview

- Understanding Sectional Door Components: Familiarize yourself with the different parts of a sectional garage door (panels, rollers, tracks, springs, cables, opener mechanisms) and their functions.

- Troubleshooting Common Issues: Learn to identify and diagnose problems like broken springs, off-track doors, malfunctioning openers, and binding rollers. Practice explaining your diagnostic process.

- Safety Procedures: Demonstrate a thorough understanding of safety protocols when working with garage doors, including proper use of safety equipment and awareness of potential hazards.

- Repair Techniques: Understand the practical application of repair techniques, such as replacing springs, rollers, cables, and tracks. Be prepared to discuss your experience with different repair methods.

- Maintenance and Preventative Care: Discuss the importance of regular maintenance and lubrication to extend the lifespan of garage doors. Know how to advise clients on preventative measures.

- Working with Different Door Types: Be familiar with various sectional door materials (wood, steel, aluminum, composite) and their specific maintenance requirements.

- Problem-Solving and Diagnostics: Prepare examples showcasing your ability to troubleshoot complex problems, using logical steps to identify the root cause and implement effective solutions.

- Customer Service and Communication: Discuss your approach to interacting with clients, explaining repairs clearly, and addressing concerns professionally.

Next Steps

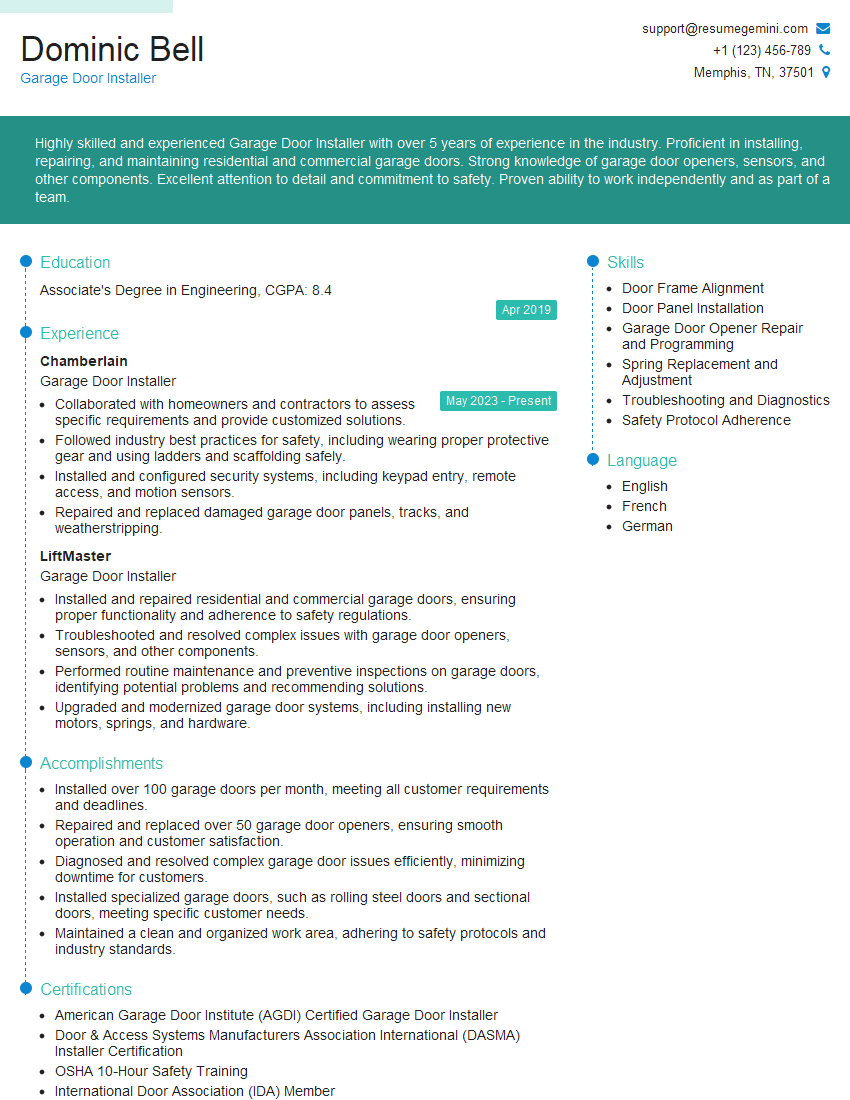

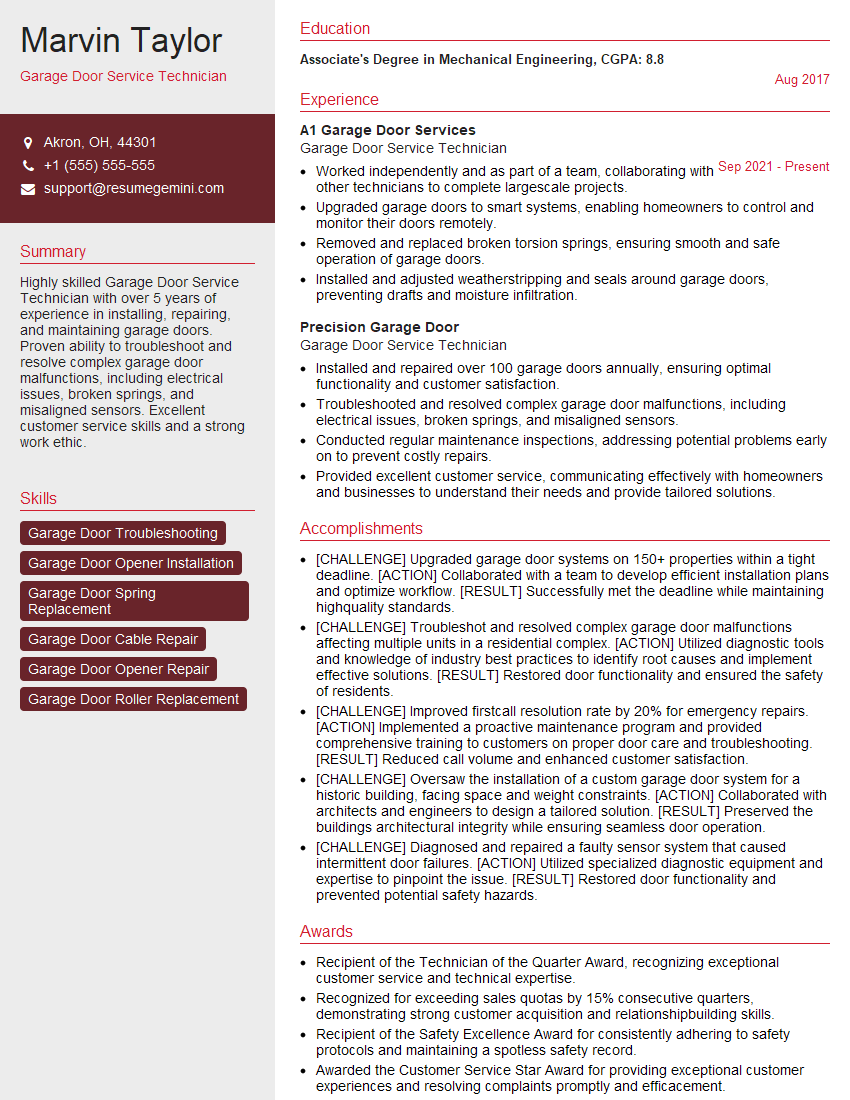

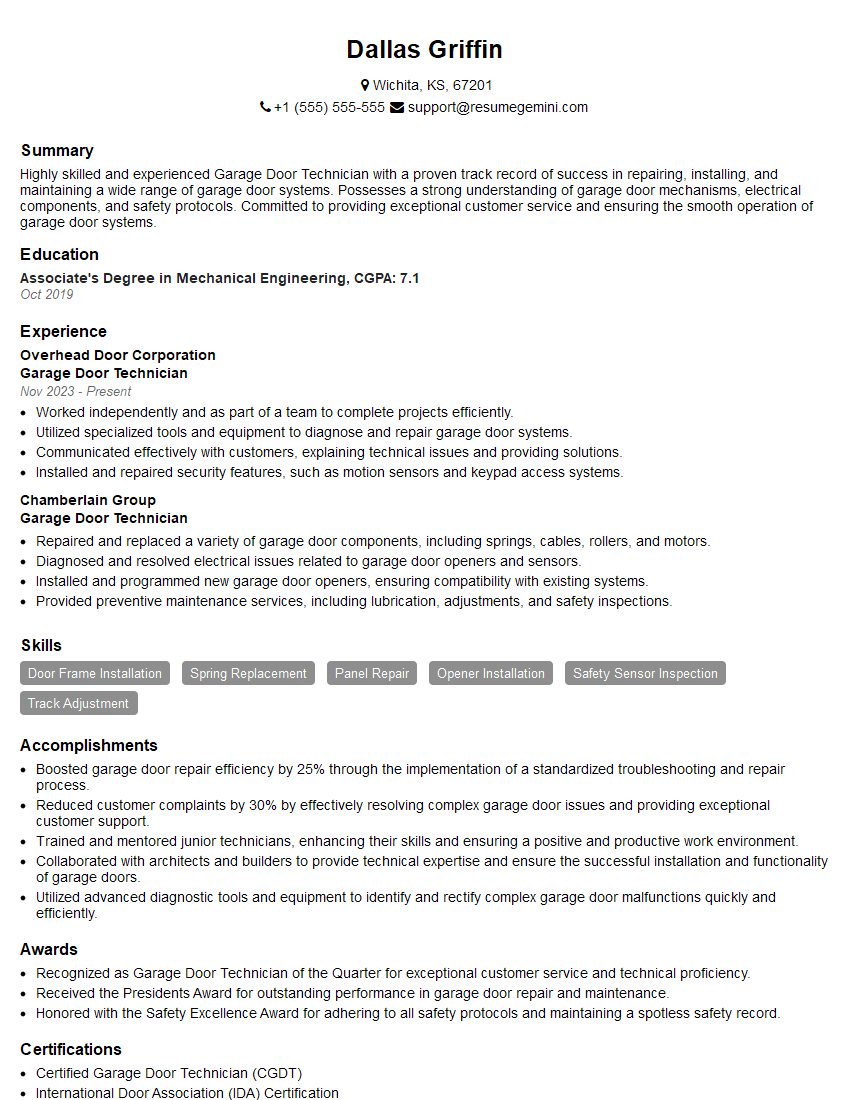

Mastering garage door sectional repair opens doors to a rewarding career with excellent growth potential. The demand for skilled technicians is high, and your expertise will be highly valued. To increase your chances of landing your dream job, create a compelling and ATS-friendly resume that highlights your skills and experience. ResumeGemini is a trusted resource that can help you craft a professional resume that makes a lasting impression. They even provide examples of resumes tailored to the Garage Door Sectional Repair field to help you get started. Take the next step and build a resume that showcases your expertise – your future self will thank you!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?