Cracking a skill-specific interview, like one for Garage Door Servicing, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Garage Door Servicing Interview

Q 1. Describe your experience troubleshooting common garage door opener malfunctions.

Troubleshooting garage door opener malfunctions requires a systematic approach. I start by visually inspecting the entire system, checking for obvious issues like broken or disconnected wires, damaged sensors, or a malfunctioning motor. Many problems stem from simple things like a dead battery in the remote or a tripped circuit breaker.

For example, if the door opens but doesn’t close, I’d first check the safety sensors. These infrared beams, usually located near the floor on either side of the door, must be unobstructed for the door to close. Even a small object blocking the path can prevent closure.

If the opener makes unusual noises, like grinding or clicking, it points towards a mechanical problem – potentially within the motor gear, chain, or sprocket. I have experience identifying these sounds and knowing which components require attention. Sometimes, a simple lubrication fixes the problem, but in more serious cases, replacement parts may be needed. I use my diagnostic tools and knowledge of the various opener brands (like Chamberlain, LiftMaster, and Genie) to quickly pinpoint the source of the malfunction and implement the appropriate repair.

Q 2. Explain the different types of garage door springs and their maintenance requirements.

Garage doors use two main types of springs: extension springs and torsion springs. Extension springs, located on either side of the door, stretch as the door opens and contract as it closes. Torsion springs, more common on heavier doors, are tightly coiled above the door, winding and unwinding to control the movement.

Extension Springs: These require regular lubrication (every 6-12 months) with a silicone-based lubricant to prevent rust and ensure smooth operation. Visual inspection for broken or frayed wires is crucial. Replacement should be done by a professional due to the high tension involved.

Torsion Springs: These are under extremely high tension and should *never* be handled by a DIYer unless they possess extensive experience with spring mechanics. Even a slight mistake can cause serious injury. Routine maintenance is limited to visual inspection for corrosion or damage. These require professional replacement, and they often need adjustment for optimal tension which I regularly perform.

Ignoring spring maintenance can lead to premature failure, causing the door to become difficult to operate, or even causing the door to unexpectedly fall down creating a potential hazard. Regular maintenance extends the life and safety of your garage door system.

Q 3. How do you diagnose and repair a garage door that is off track?

A garage door off track is a fairly common issue, usually caused by forceful operation (like hitting the door with a car), an obstruction, or general wear and tear. Diagnosing it involves careful observation.

I first identify *where* the door is off track. Is it at the top, bottom, or somewhere in the middle? This helps determine which rollers and tracks are affected. I often use a ladder to carefully examine the entire length of the tracks, looking for any bends, obstructions (like debris or paint buildup), or damaged rollers.

Repair Steps: The repair process generally involves:

- Manually lifting the door to reduce its weight and making it easier to maneuver back onto the tracks.

- Identifying the point where it went off-track.

- Carefully realigning the rollers with the tracks, often starting from the bottom and working my way up. This might require gently pushing or pulling the door to guide it back into the correct position.

- Once on track, I’ll test the opener to ensure smooth operation. If there are any remaining issues, the tracks or rollers might require repair or replacement.

It’s crucial to be methodical during this process to avoid further damage. For very stubborn situations, additional tools, like track straightening tools, might be needed.

Q 4. What safety precautions do you take when working with garage door springs?

Safety is paramount when working with garage door springs. These springs store immense potential energy; even a minor miscalculation can result in serious injury. I always use the appropriate safety equipment, including safety glasses, gloves, and sturdy work boots.

Before working on any spring, I always completely disconnect the opener from the door. This eliminates the risk of the door moving unexpectedly. I utilize tools designed specifically for compressing and decompressing springs, which allow controlled and safe manipulation. I never attempt to work on broken springs myself, leaving this to specialized technicians with specialized tools and training due to the extreme dangers involved. My training emphasizes the importance of understanding spring mechanics and tension and I strictly adhere to all safety protocols.

Q 5. Describe your experience installing and programming garage door openers.

I have extensive experience installing and programming a wide range of garage door openers, from basic models to those with advanced features like Wi-Fi connectivity and keypads. Installation involves mounting the opener to the ceiling or wall, securely attaching the rail and trolley system, connecting the power and safety sensors, and finally programming the remote controls.

Programming typically involves following the manufacturer’s instructions, often using a series of button presses on the opener’s control panel and the remote. I’m proficient in handling various programming methods and troubleshooting any connectivity issues that may arise. For instance, sometimes the opener might not recognize the remote, which often requires resetting the opener or reprogramming the remote. I handle this situation effectively using my expertise and experience to ensure successful integration and functionality of the system.

Q 6. How do you handle a situation where a customer is dissatisfied with your service?

Customer satisfaction is my top priority. If a customer is dissatisfied, I start by actively listening to their concerns without interruption. I ask clarifying questions to fully understand their perspective. Empathy is key; I acknowledge their feelings and validate their concerns.

Then, I thoroughly review my work to identify any potential issues that contributed to their dissatisfaction. This may involve revisiting the job site to re-evaluate my work. Depending on the nature of the problem, I may offer a partial or full refund, schedule a return visit to rectify the problem, or offer alternative solutions to address their concerns. Transparency and open communication are critical in resolving these situations and I aim to find a mutually acceptable solution in a timely and professional manner. Building trust and maintaining a positive reputation is very important to me.

Q 7. What are the common causes of a garage door that doesn’t close completely?

Several factors can prevent a garage door from closing completely. These can be broadly categorized into mechanical and electrical issues.

Mechanical Issues:

- Track misalignment: Bent or damaged tracks prevent smooth movement, hindering complete closure.

- Roller problems: Worn or damaged rollers create friction and resistance.

- Spring issues: Weak or broken springs may not have enough force to close the door fully.

- Obstructions: Objects blocking the door’s path (like toys or debris) prevent it from closing properly.

Electrical Issues:

- Safety sensor problems: Obstructions or misalignment of infrared safety sensors can prevent closure.

- Limit switch issues: The limit switches, which tell the opener when the door is fully open or closed, might be misadjusted.

- Opener motor malfunction: A faulty opener motor may lack sufficient power to close the door completely.

Diagnosing the root cause requires a systematic approach, inspecting each component mentioned above. Often a visual inspection is sufficient, but sometimes additional diagnostic tools may be necessary to identify more subtle electrical issues. I utilize a process of elimination to determine the cause and then employ appropriate repair or replacement strategies.

Q 8. Explain the process of replacing a broken garage door section.

Replacing a broken garage door section is a fairly straightforward process, but safety is paramount. First, you need to identify the damaged section and obtain a replacement section that matches the style and size of your existing door. You’ll need a few basic tools: a sturdy ladder, a screwdriver (likely both Phillips and flathead), possibly a drill with appropriate bits, and safety glasses.

Step-by-step process:

- Safety First: Disconnect the garage door opener to prevent accidental operation. Support the garage door to prevent it from falling while you work. This can be done with sturdy supports placed strategically under each section of the door.

- Remove the Damaged Section: Carefully remove the broken section’s hinges. This usually involves removing pins from the hinges. If the section is severely damaged, it might require more force and careful prying. Be cautious not to damage surrounding sections.

- Install the New Section: Align the new section with the adjacent sections, ensuring they are perfectly level. Insert the hinge pins and secure them tightly, but not overly tight, to avoid damaging the hinges.

- Reconnect and Test: Carefully reconnect the garage door opener and test the operation, ensuring smooth and even movement.

Example: I once had a client with a broken section due to a car accident. Replacing the damaged section involved careful removal of bent hinges, installation of the new section, and ensuring the tracks were aligned. The garage door operated perfectly after the replacement.

Q 9. How do you identify and resolve issues with garage door rollers and tracks?

Problems with garage door rollers and tracks are common culprits of noisy or malfunctioning doors. Rollers wear out, tracks become bent or misaligned, and this can severely affect the door’s functionality and longevity.

Identification and Resolution:

- Visual Inspection: Start with a thorough visual inspection of all rollers and tracks. Look for bent or damaged rollers, signs of rust or wear, and any obstructions in the tracks. Bent tracks are often the result of forceful impacts or misaligned doors.

- Roller Issues: Worn-out rollers will exhibit squeaking, grinding, or difficulty in moving. Replace these rollers with new ones of the correct size and type. The replacement process involves carefully removing the old roller and attaching the new one to the brackets.

- Track Issues: Bent tracks need straightening. Minor bends may be correctable with gentle manipulation and careful use of a hammer and a block of wood for leverage. If the damage is significant, the tracks may require replacement.

- Lubrication: Regular lubrication of rollers and tracks with a silicone-based lubricant significantly reduces friction and noise.

Example: A client reported a loud grinding noise. Inspection revealed several worn and rusty rollers. Replacing those rollers and lubricating the tracks resolved the issue immediately.

Q 10. What are the different types of garage door materials and their pros and cons?

Garage doors are available in a variety of materials, each with its own set of advantages and disadvantages.

- Steel: Steel doors are the most common, offering durability, strength, and affordability. However, they can be prone to dents and rust if not properly maintained.

- Wood: Wooden doors offer a classic, elegant aesthetic. They can be customized with various finishes. However, wood requires regular maintenance to prevent rotting, warping, and insect damage. They are also generally more expensive than steel.

- Aluminum: Aluminum doors are lightweight, resistant to rust and corrosion, and require relatively low maintenance. However, they can be less durable than steel and are more susceptible to dents.

- Fiberglass: Fiberglass doors offer a good balance of durability, aesthetics, and insulation. They are resistant to dents and corrosion. However, they can be more expensive than steel or aluminum.

- Vinyl: Vinyl doors are low maintenance and weather-resistant, mimicking the look of wood. They are also lightweight.

Example: A client looking for a low-maintenance, aesthetically pleasing door opted for a fiberglass door, balancing durability with visual appeal.

Q 11. Describe your experience working with various types of garage door openers (e.g., chain drive, belt drive, direct drive).

I have extensive experience working with various garage door opener types:

- Chain Drive: These are the most common and affordable type. They are robust but can be noisy.

- Belt Drive: Belt drive openers are quieter than chain drive openers because the belt offers a smoother operation. They are also generally a bit more expensive.

- Direct Drive: These openers are the quietest and most powerful. The motor is directly connected to the door, eliminating the need for chains or belts. They are generally the most expensive option.

Troubleshooting: Issues I’ve encountered across all types include issues with the motor, limit switches, sensors (safety reversing sensors), and the drive mechanism itself. Diagnosing these issues involves careful inspection, testing the various components, and potentially replacing faulty parts.

Example: A client’s chain drive opener was making a loud, clicking noise. The issue turned out to be a worn chain. Replacing the chain resolved the problem, providing smooth and quiet operation.

Q 12. How do you ensure the safety and security of a garage door system?

Ensuring safety and security is paramount in garage door servicing. This involves several key aspects:

- Safety Sensors: Regularly check the operation of the safety reversing sensors. These sensors prevent the door from closing on obstructions, such as pets or children. If the sensors are misaligned or damaged, the door will not close. Adjusting the alignment or replacing faulty sensors are crucial.

- Emergency Release Cord: The emergency release cord allows manual operation of the door in case of power failure or opener malfunction. I always check its accessibility and functionality.

- Proper Lubrication: Regular lubrication of moving parts minimizes friction, reducing noise and enhancing safety by preventing unexpected binding or stalling.

- Regular Inspections: Regular inspections identify potential issues before they become major safety hazards. Checking the tracks for misalignment, the springs for wear, cables for fraying, and rollers for damage are critical safety checks.

- Security Features: For added security, I often recommend clients upgrade to openers with rolling code technology, which prevents unauthorized access by cloning radio frequencies.

Example: I advised a client to replace their older opener with a more modern model featuring rolling code technology and enhanced safety sensors. This significantly improved both the safety and security of their garage.

Q 13. Explain your experience with diagnosing and repairing broken cables.

Broken garage door cables are a serious safety hazard, requiring immediate attention. A broken cable can cause the door to fall unexpectedly, potentially causing damage or injury.

Diagnosis and Repair:

- Visual Inspection: A thorough visual inspection identifies broken, frayed, or loose cables. Look for signs of wear and tear, rust, or any damage to the cable drum.

- Safety Precautions: Before attempting repairs, disconnect the garage door opener and ensure the door is properly supported to prevent it from falling.

- Cable Replacement: Replacing a broken cable requires carefully removing the old cable, attaching the new one to the drum and the door, and ensuring proper tension.

- Professional Assistance: Replacing garage door cables is complex and can be dangerous, often requiring specialized tools and knowledge. I always advise clients to consider professional help, especially if they lack experience in handling such repairs.

Example: I responded to a call about a broken cable. After safely securing the door, I replaced the damaged cable, ensuring proper tension and functionality. It’s crucial to be meticulous in these repairs because a wrongly tensioned cable can lead to further damage.

Q 14. What is your process for diagnosing a noisy garage door?

A noisy garage door is an indication of a problem that needs attention. Identifying the source of the noise is key to effective repair.

Diagnostic Process:

- Listen Carefully: The type of noise (squeaking, grinding, banging, etc.) provides clues. Squeaking often points to dry rollers, while grinding suggests worn rollers or tracks. Banging usually means loose hardware.

- Visual Inspection: Inspect the rollers, tracks, hinges, springs, and opener mechanism for signs of damage or wear.

- Operate the Door: Operate the door manually (after disconnecting the opener) to isolate the source of the noise. Does the noise change when the door is opening or closing? Try moving it section by section to pinpoint the problem area.

- Check Lubrication: Apply a silicone-based lubricant to the rollers and tracks. If squeaking is the problem, this will resolve it. But if not, then further checks are necessary.

- Tighten Loose Hardware: Check all bolts and screws for looseness. Tighten those that are loose.

Example: A client complained of a loud banging noise. Upon inspection, I found loose bolts on the hinges. Tightening the bolts eliminated the noise entirely. Sometimes, simple fixes lead to big improvements.

Q 15. How do you troubleshoot issues with garage door remotes?

Troubleshooting garage door remotes often involves a systematic approach. First, I check the batteries – this is the most common culprit! A simple battery change often solves the problem. If that doesn’t work, I examine the remote itself for any physical damage. Cracks or broken buttons can disrupt the signal.

Next, I’ll test the signal strength. I might try moving closer to the garage door opener to see if the range is the issue. Sometimes interference from other electronic devices can affect the signal. I’ll try to identify and temporarily disable any potential sources of interference.

If the problem persists, I’ll then check the receiver on the garage door opener. I’ll verify it’s properly connected and receiving power. In some cases, the receiver may need to be reprogrammed, which involves a specific process that varies depending on the brand and model of the opener.

Finally, if none of these steps work, the problem could lie within the opener’s control board itself, and a professional repair or replacement might be necessary.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is your experience with different types of garage door sensors and safety mechanisms?

I have extensive experience with various garage door sensors and safety mechanisms. The most common are infrared sensors, which use beams of light to detect obstructions. If something breaks that beam – like a person or a pet – the door stops and reverses to prevent accidents. I’m experienced in troubleshooting these sensors, which might involve cleaning lenses, adjusting alignment, or replacing faulty units.

Beyond infrared sensors, I also work with pressure-sensitive safety edges. These are usually found along the bottom of the door, and they’ll stop and reverse the door if they come into contact with an obstacle. I’m familiar with diagnosing problems like broken or damaged safety edges, and I know how to correctly test and replace them.

Furthermore, my experience encompasses different types of safety mechanisms, like those that limit the door’s closing force. These prevent the door from slamming shut with excessive force. I understand the importance of regular inspections to ensure all safety features are functioning correctly, preventing potential injuries and property damage.

Q 17. Describe your experience with maintaining and lubricating garage door components.

Maintaining and lubricating garage door components is crucial for longevity and smooth operation. I regularly inspect the tracks, rollers, hinges, and springs. I remove any debris that may be causing friction or hindering movement. Then, I apply a high-quality garage door lubricant, specifically designed to withstand temperature fluctuations and not attract dirt.

I use a spray lubricant applicator to apply a small amount to each moving part, ensuring even distribution. This prevents squeaking, groaning, and ensures smooth operation. Lubricating the rollers and hinges reduces wear and tear, prolonging their lifespan and preventing potential damage to the door itself.

For the springs, which are under considerable tension, safety is paramount. I only work on these if I’m absolutely certain I can handle the job safely, as improperly handling them could be very dangerous. If I have any doubts, I always advise professional spring replacement. Regular maintenance, including lubrication, dramatically extends the life of the entire door system and prevents costly repairs down the line.

Q 18. How familiar are you with different brands of garage door openers and components?

My familiarity with different brands extends to industry leaders such as Chamberlain, LiftMaster, Genie, and Craftsman. I understand the nuances of each brand’s opener models, from the older, more mechanical systems to the newer, more technologically advanced ones with features like Wi-Fi connectivity and smartphone integration. I also have expertise in identifying and sourcing replacement parts from various manufacturers.

This knowledge extends to their specific components, too – such as different types of springs, belt systems versus chain systems, and control boards. Being familiar with multiple brands allows me to offer customers the best solution based on their needs and budget, whether that involves repairs, maintenance or a full replacement. I can even explain the pros and cons of each to help them make the best decision.

Q 19. Describe your problem-solving approach when confronted with an unusual garage door issue.

When confronted with an unusual garage door issue, my approach is methodical and systematic. First, I carefully listen to the customer’s description of the problem, asking clarifying questions to gain a complete understanding. I’ll then perform a visual inspection of the entire system, checking all components for any obvious damage or malfunctions. This often gives me initial clues to narrow down the potential causes.

Next, I’ll engage in a series of targeted tests. For example, if the door is not opening or closing, I’ll check the power supply, examine the safety sensors, and inspect the tracks for obstructions. If there is an unusual noise, I’ll identify which component the sound is originating from, isolating the problem area. I utilize diagnostic tools when necessary, like multimeters to check voltage and continuity, guiding me toward the root cause of the malfunction.

My experience allows me to often diagnose the issue quickly and efficiently, however, if the problem is particularly complex or involves potentially dangerous components like springs or the drive mechanism, I won’t hesitate to seek further consultation or advise the customer on getting a second opinion. I prioritize safety in every aspect of my work.

Q 20. What are the common signs of a garage door needing replacement?

Several signs indicate a garage door needs replacement. Frequent repairs, especially if they involve the same components repeatedly, are a strong indicator that the door is nearing the end of its lifespan. Visible damage such as dents, rust, or significant warping of the door panels can compromise its structural integrity and functionality.

Furthermore, if the door operates poorly, with excessive noise, slow opening/closing times, or difficulty moving smoothly, these are all potential signs of age or damage. Also, if the door no longer provides adequate insulation or if it’s becoming difficult to maintain the safety sensors, a replacement may be a worthwhile investment. Security concerns, such as noticeable weaknesses in the door structure, also necessitate a closer look at a potential replacement.

Ultimately, a comprehensive assessment, taking into account the door’s age, condition, and the frequency of repairs, is necessary to determine whether replacement is the most cost-effective solution.

Q 21. How do you determine the appropriate size and type of garage door for a customer?

Determining the appropriate size and type of garage door for a customer involves several considerations. First, I precisely measure the garage opening’s dimensions – height and width – ensuring an accurate fit. I consider factors such as headroom, side room, and the track type (standard or high-lift). These measurements determine the suitable door size.

Next, I discuss the customer’s preferences and needs. This includes the style of the door (carriage house, raised panel, flush panel, etc.), material (steel, wood, aluminum, composite), insulation requirements, and budget constraints. The choice of material impacts insulation, durability, and maintenance requirements. For instance, insulated steel doors offer good value and energy efficiency.

I also factor in local climate conditions. In colder climates, well-insulated doors are essential for energy conservation. Finally, I discuss the functionality needed, such as automatic openers, windows or decorative hardware. Once all factors are considered, I help the customer select the best garage door suited to their specific needs and preferences, creating a tailored and optimal solution.

Q 22. What are your skills in using diagnostic tools and equipment for garage door repair?

My expertise in garage door repair extends to proficient use of a wide range of diagnostic tools and equipment. This includes, but isn’t limited to, multimeters for checking electrical components, tension gauges for springs, pressure gauges for hydraulic systems, and sophisticated diagnostic tools that can detect problems within the opener’s control board. For instance, a multimeter helps pinpoint whether a faulty opener motor is drawing too much current, indicating a short circuit or other internal failure. Similarly, a pressure gauge is crucial for ensuring the correct inflation pressure of hydraulic dampeners, which are essential for smooth and safe door operation. I also regularly use infrared thermometers to check for overheating components, which is a vital preventative maintenance step.

I’m adept at interpreting the data these tools provide. A reading outside the normal range immediately flags a potential problem, which I then investigate systematically. For example, if a spring tension gauge reveals that the spring tension is significantly lower than the manufacturer’s specifications, this points towards the need for spring replacement or adjustment before it breaks causing potential damage or injury.

Q 23. Describe your knowledge of relevant safety regulations and codes.

Safety is paramount in my work. I’m intimately familiar with OSHA regulations and all relevant local building codes pertaining to garage door installation, repair, and maintenance. This includes understanding the importance of proper safety gear, like gloves and safety glasses, and employing safe working practices. I always ensure the area is properly secured before working on a garage door, especially during spring replacements, which involve high-tension components. I follow strict protocols to prevent accidental disengagement of the safety mechanisms, which can lead to serious injury. A critical aspect of my work involves regular inspections for any potential hazards, such as damaged cables, rollers, or tracks, ensuring immediate remediation or replacement of any unsafe components.

I also educate customers about safe usage of their garage doors, emphasizing the importance of regular inspections and maintenance to prevent accidents. For example, I explain how to regularly lubricate moving parts to minimize wear and tear and ensure quiet operation. This proactive approach is essential for avoiding many common garage door issues.

Q 24. How do you prioritize your tasks effectively when dealing with multiple service calls?

When dealing with multiple service calls, I prioritize them based on urgency and the nature of the problem. Emergency calls, such as a completely inoperable door leaving a customer stranded or posing a security risk, take precedence. I use a scheduling system that factors in travel time, estimated repair time, and the severity of each issue. I communicate proactively with clients, providing estimated arrival times and keeping them updated on my progress. This prevents delays and ensures customer satisfaction.

For example, if I receive multiple calls – one for a broken spring (emergency), one for a noisy opener (non-emergency), and one for a routine maintenance check – I’d immediately focus on the broken spring, then schedule the noisy opener repair, and lastly, the maintenance check. This approach ensures efficient time management while prioritizing the most urgent needs first.

Q 25. Describe your experience with working on both residential and commercial garage doors.

My experience encompasses a wide range of garage door systems in both residential and commercial settings. Residential work often involves repairing or maintaining standard residential garage doors, dealing with issues like broken springs, malfunctioning openers, and track misalignments. These situations require attention to detail and efficient problem-solving to restore functionality quickly. Commercial settings often involve larger, heavier doors and more complex operating systems that demand a higher level of expertise and specialized tools. I’ve worked on high-speed doors, fire-rated doors, and loading dock systems. These doors often integrate with more intricate safety features and require a deeper understanding of their operational intricacies.

I remember one challenging job involving a commercial high-speed roll-up door that had been repeatedly malfunctioning, disrupting the warehouse’s operations. By systematically diagnosing the problem using specialized equipment, I was able to identify a faulty sensor causing the repeated stoppages, ultimately restoring smooth, efficient door operation and preventing further disruptions.

Q 26. Explain how you maintain your tools and equipment.

Maintaining my tools and equipment is crucial for efficient and safe operation. After each job, I meticulously clean and inspect all tools, paying particular attention to moving parts. I lubricate components as needed to prevent wear and tear and ensure smooth operation. I store my tools in an organized manner, preventing damage from improper storage and making them easily accessible. Regularly scheduled maintenance, such as sharpening blades, inspecting electrical connections, and checking for loose parts, is essential for prolonging tool life and ensuring safety. For larger equipment, such as my service truck and specialized diagnostic tools, I adhere to the manufacturer’s recommended maintenance schedules.

For example, I regularly inspect my spring compressors for wear and tear, as these are vital tools requiring meticulous care to ensure safety during spring replacement jobs. Similarly, I always check the calibration of my tension gauges to make sure they are accurate during spring adjustments.

Q 27. What is your experience with emergency garage door repair calls?

I have extensive experience handling emergency garage door repair calls. These often involve situations where a door is completely inoperable, posing a security risk or leaving a client stranded. I understand the urgency of these situations and prioritize these calls above all others. I am available 24/7 for emergencies and can typically arrive on-site within a short timeframe. I’m well-equipped to handle diverse emergency situations, including broken springs, jammed doors, and malfunctioning openers. My quick diagnostic skills and efficient repair techniques allow me to resolve most emergencies quickly and safely.

I recall an instance where a customer called late at night with a completely jammed garage door. Their car was trapped inside. I responded immediately, diagnosed the issue as a misaligned track, and quickly made the necessary repairs, enabling them to access their vehicle and restoring their sense of security. Such situations highlight the crucial role of rapid response and efficient problem-solving in emergency garage door repair.

Q 28. How do you communicate technical information clearly to non-technical customers?

Communicating technical information clearly to non-technical customers is a key aspect of my work. I avoid using jargon and technical terms whenever possible, instead opting for simple, straightforward explanations. I use analogies and visual aids to help customers understand complex concepts. For example, explaining the function of a garage door spring by comparing it to a car’s suspension system helps clients grasp its crucial role in door operation. I show customers the parts involved during repair, explaining what’s broken and how it’s being fixed. I also demonstrate how to properly use and maintain their garage door to prevent future problems.

I always ensure the customer understands the problem, the proposed solution, and the associated costs before proceeding with any repairs. I answer all questions patiently and thoroughly, empowering them to make informed decisions. Building trust and transparency is essential in creating a positive customer experience.

Key Topics to Learn for Your Garage Door Servicing Interview

- Safety Procedures: Understanding and adhering to all safety protocols when handling garage doors, springs, and related equipment. This includes proper use of PPE and lockout/tagout procedures.

- Door Components and Mechanisms: Detailed knowledge of the various parts of a garage door system (springs, rollers, tracks, cables, openers, etc.) and how they interact. Practical application: Troubleshooting common malfunctions by identifying the faulty component.

- Types of Garage Doors: Familiarity with different garage door materials (wood, steel, aluminum, fiberglass), styles (carriage house, sectional, roll-up), and operating mechanisms (manual, automatic).

- Troubleshooting and Repair: Diagnosing and resolving common issues like broken springs, off-track doors, malfunctioning openers, and noisy operation. This includes understanding the root cause of the problem and selecting the appropriate repair strategy.

- Maintenance and Lubrication: Performing routine maintenance tasks, such as lubricating moving parts, inspecting for wear and tear, and recommending preventative measures to extend the lifespan of the garage door system.

- Garage Door Openers: Understanding the mechanics and functionality of different opener types (belt drive, chain drive, direct drive), troubleshooting malfunctions, and performing basic repairs or replacements.

- Customer Service and Communication: Effectively communicating with customers, explaining technical issues in clear and understandable terms, and providing excellent customer service throughout the repair process.

- Estimating and Billing: Accurately estimating repair costs and providing clear and professional invoices to clients.

Next Steps

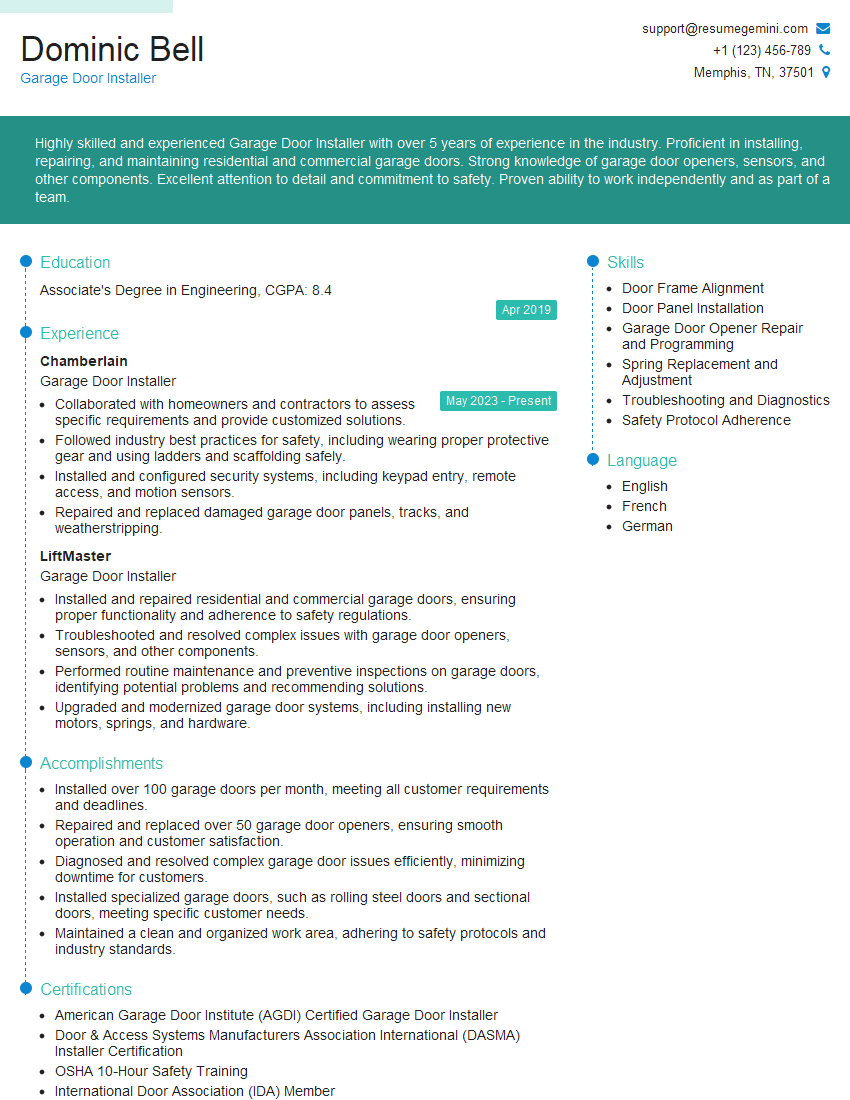

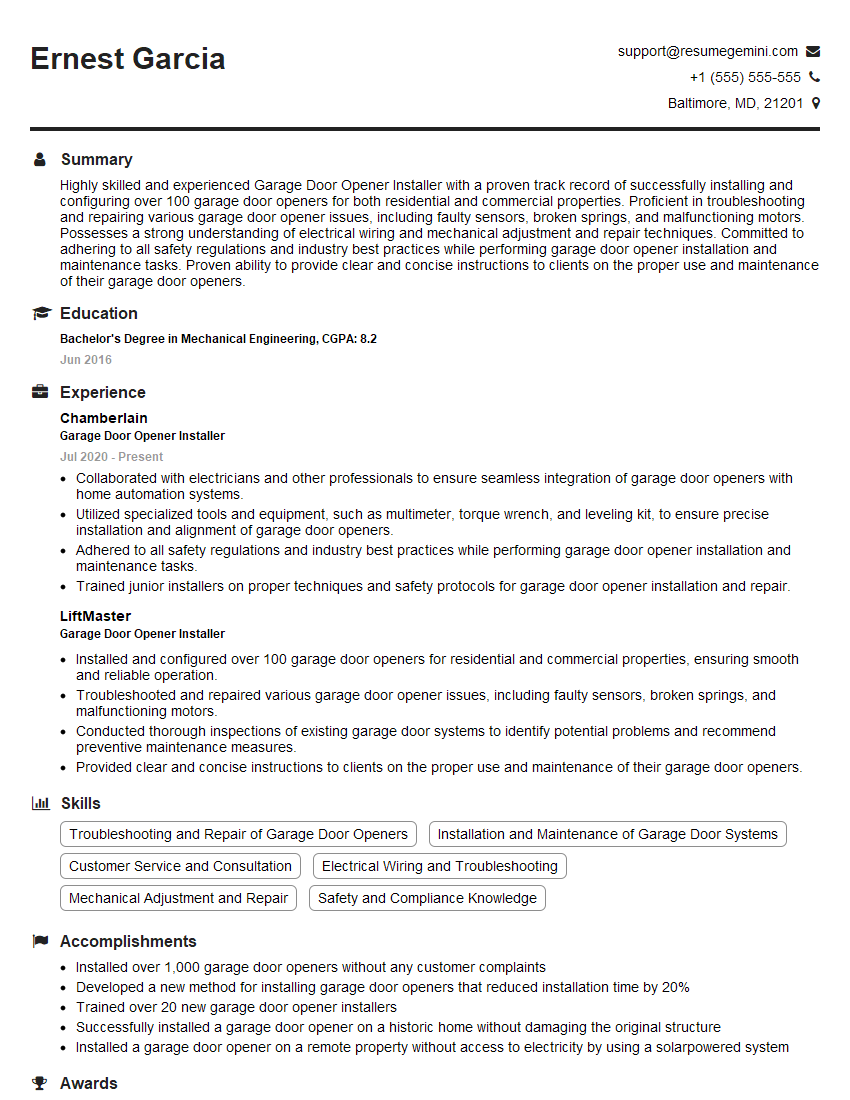

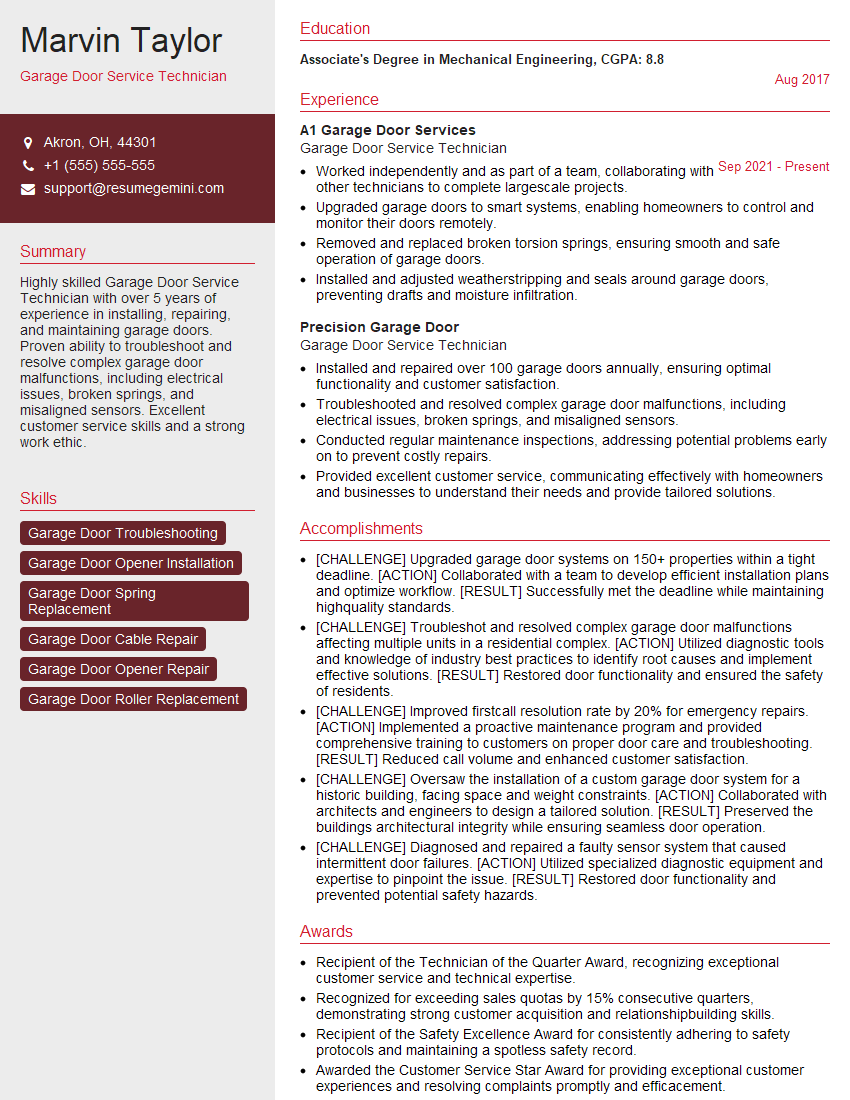

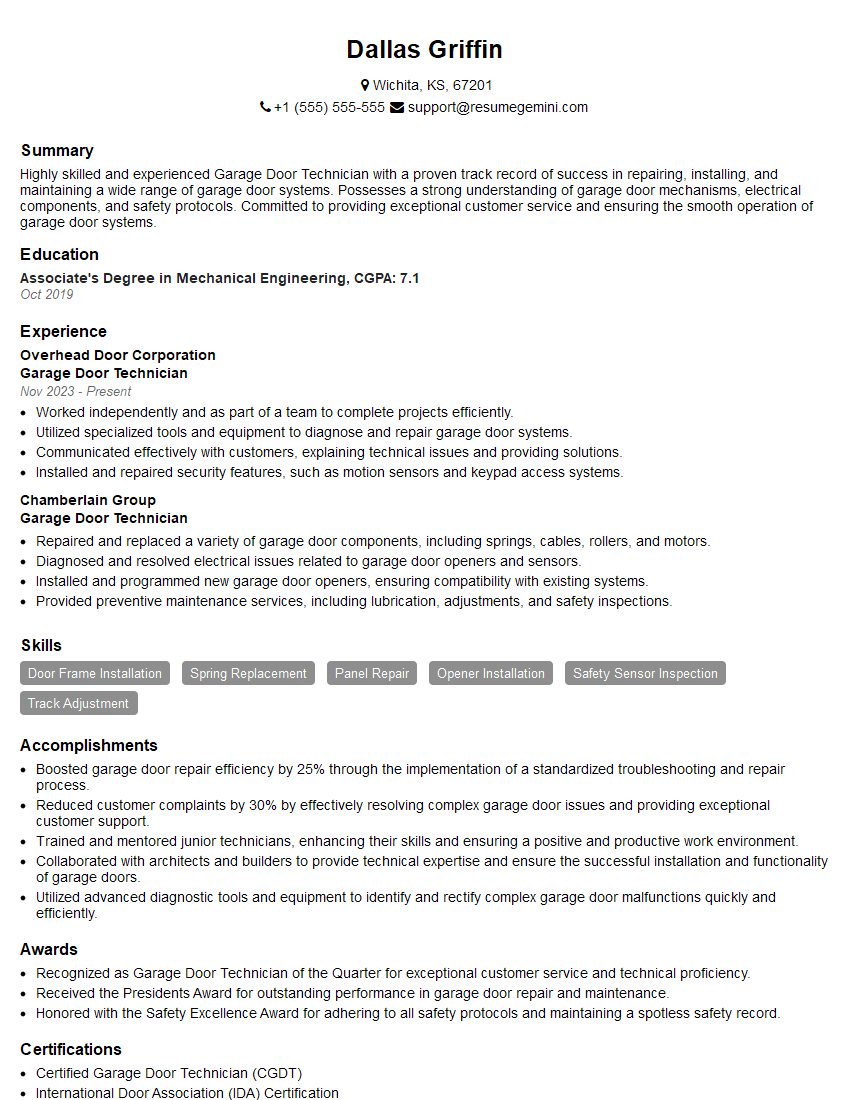

Mastering garage door servicing opens doors to a rewarding career with excellent earning potential and opportunities for advancement. To increase your chances of landing your dream job, a strong, ATS-friendly resume is crucial. ResumeGemini can help you create a professional and impactful resume that highlights your skills and experience effectively. ResumeGemini provides examples of resumes tailored to the Garage Door Servicing industry to guide you through the process. Invest time in crafting a compelling resume – it’s your first impression and a key to unlocking your career potential.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?