Unlock your full potential by mastering the most common Garage Door Track Repair interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Garage Door Track Repair Interview

Q 1. Explain the different types of garage door tracks.

Garage door tracks come in various types, primarily distinguished by their material and profile. The most common are steel tracks, known for their durability and affordability. These can be further categorized by their gauge (thickness), with heavier gauge tracks offering greater strength and resistance to bending. Aluminum tracks are lighter and often used in less demanding applications, though they are susceptible to damage. Finally, some high-end systems might utilize composite materials for enhanced corrosion resistance. The track’s profile, meaning its shape and dimensions, varies depending on the garage door’s type and manufacturer, affecting the roller alignment and overall performance. For example, a sectional door will have a different track profile than a rolling door.

- Steel Tracks: The industry standard, offering robust performance and cost-effectiveness.

- Aluminum Tracks: Lighter weight but less durable than steel, often seen in residential applications.

- Composite Tracks: Premium option providing superior corrosion resistance, but at a higher price point.

Q 2. Describe the process of diagnosing a bent garage door track.

Diagnosing a bent garage door track involves a systematic approach. First, visually inspect the entire track for any obvious bends, kinks, or distortions. Pay close attention to areas where the rollers might have experienced increased friction or impact, as these are common locations for bending. Then, check for smooth roller movement along the track. A stuck or jerky roller often indicates a bent or misaligned section. If you find a bent section, carefully measure the amount of deviation from a straight line using a level or a straight edge. Document the location and extent of the bending for repair purposes. Don’t hesitate to use a flashlight to improve visibility in hard-to-reach areas. Remember safety first – always disconnect the power supply to the garage door opener before starting any inspection or repair.

For instance, I once encountered a track severely bent near the bottom because a customer accidentally backed into it with their car. The visual inspection revealed a significant outward curve. Careful measurements indicated an approximately 1-inch deviation from straight.

Q 3. How do you repair a severely damaged garage door track?

Repairing a severely damaged track often requires replacement rather than simple straightening. If the bend is significant or the track is cracked or broken, attempting a repair may compromise the door’s safety and functionality. The process involves carefully removing the old track sections, measuring the replacement pieces accurately, and securely installing the new track segments. Ensuring proper alignment is crucial. For minor dents or kinks, gentle straightening using a specialized track bender (or a combination of a hammer and block of wood for smaller bends) might be feasible, but only if the material isn’t compromised. It is however advisable to err on the side of caution and replace the track if in doubt. Always replace any damaged rollers as well.

In one case, a customer hit their track with their car creating a severe bend. Instead of trying to straighten the track, which would have been structurally weak, we decided the safer and more reliable option was replacing the entire length of the affected track, this restored the proper alignment and safety.

Q 4. What tools are essential for garage door track repair?

The essential tools for garage door track repair vary depending on the complexity of the repair. However, a basic set includes:

- Measuring Tape: For accurate measurements of the track.

- Level: To ensure proper alignment of the track.

- Screwdrivers (Phillips and Flathead): For removing and installing screws.

- Pliers (Needle-nose and Channel Lock): For gripping and manipulating small parts.

- Hammer: For minor track straightening (with caution).

- Track Bender (optional): A specialized tool for precise track straightening.

- Safety Glasses: To protect eyes from debris.

- Work Gloves: To protect hands.

- Drill (sometimes): For drilling pilot holes.

- Metal Cutting Saw or Hacksaw (sometimes): To cut track sections.

Q 5. How do you measure and cut a replacement garage door track?

Measuring and cutting a replacement garage door track requires precision. First, carefully measure the length of the damaged section you are replacing. Remember to account for any overlaps or connections with other track sections. Use a metal-cutting saw or hacksaw to cut the replacement track to the exact length. Always wear safety glasses during cutting. Use a straight edge to ensure a clean, perpendicular cut. Once cut, compare the replacement track section to the existing track to ensure a perfect fit and alignment before installation. Avoid making cuts too short or too long since this will impact the alignment and potentially cause issues with your garage door’s operation. Test fit before permanently securing the new section.

In one case, an inaccurate cut meant the track was too short, leading to an imbalanced door that didn’t close smoothly. It was crucial to measure precisely to ensure the new track was the exact length required.

Q 6. Explain the importance of proper track alignment.

Proper track alignment is paramount for safe and efficient garage door operation. Misalignment can cause binding, jerky movement, strain on the door opener, and even potential derailment of the rollers. A misaligned track puts excessive stress on the entire system, potentially leading to premature wear and tear. In extreme cases, it can create a safety hazard. Think of the track as a railway; if the tracks are crooked, the train (the door) will have a hard time running smoothly, possibly derailing.

Q 7. How do you address track issues caused by misaligned rollers?

Misaligned rollers contribute significantly to track problems. Worn, damaged, or improperly installed rollers can cause the door to bind, making it difficult or impossible to open or close. To address this, first, inspect the rollers. Replace any worn, damaged, or misaligned rollers. Then, ensure all rollers are correctly seated and running smoothly within their respective track grooves. If the rollers are still causing issues, re-evaluate the track alignment, as misaligned rollers are frequently a symptom of underlying track problems that need to be addressed. Addressing track alignment before simply changing rollers will prevent replacing them only to discover they are still misaligned because of the track issue.

Q 8. What are the safety precautions when working on garage door tracks?

Safety is paramount when working on garage door tracks. Think of it like working on any heavy machinery – one wrong move could lead to injury or damage. Always disconnect the power to the garage door opener before starting any work. This prevents accidental movement of the door. Next, you’ll want to support the door securely. This might involve using a sturdy ladder and manually propping the door open, or using safety straps to ensure it can’t fall. Wear work gloves to protect your hands from sharp edges or debris on the tracks. Safety glasses are crucial to protect your eyes from flying particles during cleaning or repair. Finally, if you’re uncomfortable performing any task, don’t hesitate to call a professional. It’s better to be safe than sorry.

Q 9. How do you identify and address a derailed garage door?

A derailed garage door is usually pretty obvious – the door is off track! You’ll see it either dragging on the floor or stuck at an angle. The first step is to disconnect the power to the opener to prevent the motor from struggling and causing more damage. Then, carefully inspect the track to find where the door came off. Common causes include bent tracks, loose rollers, or obstacles on the track itself. To get it back on track, you may need to manually lift the door (using appropriate safety measures, of course), realign the rollers, and gently guide the door back onto the track. If the track is significantly bent or damaged, you’ll likely need to repair or replace the section before reinstalling the door.

Remember: If you’re unsure about any part of this process, it’s best to consult a professional.

Q 10. Describe the process of reinstalling a garage door track.

Reinstalling a garage door track requires precision and patience. Start by making sure the track is free from any damage or obstructions. Then, secure the track to the header using appropriate fasteners. The header is usually the strong horizontal beam above your garage door. Ensure the track is perfectly aligned, using a level to verify both the horizontal and vertical positioning. This is critical to ensure smooth operation. Once the track is securely attached to the header, begin carefully guiding the rollers back onto the track, starting at the bottom and working your way up. It’s crucial to do this smoothly and evenly; otherwise, you risk further damage. Then, test the door’s operation thoroughly. Listen for any grinding or unusual noises, and check for smooth movement.

Q 11. How do you handle a track repair involving a broken section?

A broken section of track requires a more significant repair. Simply patching it usually won’t suffice for long-term reliability. The best approach often involves replacing the damaged section. This requires carefully measuring the affected area to ensure you get the correct replacement piece. You’ll then need to remove the old damaged section and secure the new section in place, ensuring proper alignment. This often involves using appropriate tools like a saw to cut the track and fasteners to secure the new piece. After the repair, it’s essential to test the entire track thoroughly for any loose connections or obstructions.

For complex repairs, professional help is advisable.

Q 12. What types of materials are commonly used in garage door tracks?

Garage door tracks are typically made of steel or aluminum. Steel tracks are more robust and durable, capable of withstanding significant stress. However, they are also heavier and more prone to rust. Aluminum tracks are lighter, less prone to rust, and often require less maintenance. However, they are not as strong as steel and may bend more easily under heavy loads. The choice of material often depends on factors such as the door’s weight, the frequency of use, and the overall budget.

Q 13. How do you identify and resolve track binding issues?

Track binding happens when the door struggles to move smoothly along the track. This could be caused by several factors. First, check for any obstructions – debris, paint, or even insects can cause the door to bind. Carefully clean the track and rollers to eliminate any potential obstacles. Next, check for misalignment – a bent or damaged section of track can prevent smooth movement. Inspect the track thoroughly for any bends, dents, or distortions. Repair or replace any damaged sections. Lastly, lubricate the track. Proper lubrication significantly reduces friction, allowing for smoother operation. If the problem persists after this, you may need to call a professional for more specialized diagnostics.

Q 14. Explain how to lubricate a garage door track properly.

Lubricating a garage door track is a crucial maintenance task, ensuring smooth and quiet operation. It’s best to use a garage door lubricant, or a light-weight silicone spray. Avoid using general purpose grease or oil, as these can attract dust and dirt, making the problem worse in the long run. Apply the lubricant along the entire length of the track, focusing on areas where the rollers make contact. Apply small amounts; too much lubricant can attract excess debris. Once the lubricant is applied, gently move the door up and down several times to distribute the lubricant evenly. Regular lubrication (at least once or twice a year, or more frequently depending on usage) will extend the lifespan of your garage door and track significantly.

Q 15. What are the common causes of garage door track damage?

Garage door track damage is a common problem stemming from several factors. Think of the track as the railway for your garage door; any disruption affects its smooth operation. The most frequent culprits are:

- Impact damage: This is often caused by accidentally hitting the track with a car, lawnmower, or other objects. A sharp blow can bend or dent the track, causing the door to bind or derail.

- Rust and corrosion: Exposure to the elements, especially moisture, leads to rust formation, weakening the track material and creating friction points. This is particularly prevalent in older garage doors or those lacking proper weatherproofing.

- Wear and tear: Over time, constant use causes the rollers to wear down and put extra stress on the track. This is a gradual process, but eventually leads to bending or deformation.

- Improper installation: A poorly installed track can be prone to misalignment, which will put undue strain on the system, causing premature wear and tear.

- Debris buildup: Leaves, dirt, and other debris can accumulate in the track, hindering the smooth movement of the rollers and potentially causing damage.

Addressing these root causes is crucial for preventing further damage and ensuring the longevity of your garage door system.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you determine if a track needs to be replaced versus repaired?

The decision to repair or replace a garage door track depends on the extent of the damage. Think of it like fixing a crack in a wall versus demolishing the wall entirely.

- Repair: Minor bends or dents, especially in the sections of the track where the rollers run are usually repairable. This often involves carefully straightening the bent metal using specialized tools. Rust spots might be cleaned and treated with anti-rust paint. This option is cost-effective and preserves the existing track.

- Replacement: Severe damage like cracks, significant bends, or extensive corrosion necessitates track replacement. If a section of the track is completely compromised or multiple repair attempts have failed, replacement ensures the safety and smooth operation of your garage door. It’s a more involved process but guarantees long-term reliability.

I always assess the track thoroughly, considering the cost of repair versus replacement and the overall structural integrity of the track to determine the best approach. A severely damaged track poses safety risks; replacement is preferable in such cases.

Q 17. Describe your experience working with different types of garage door openers.

My experience spans a wide range of garage door opener types, including chain drive, belt drive, screw drive, and direct drive systems. Each type has its own nuances.

- Chain drive openers are the most common and generally more affordable. However, they can be noisy.

- Belt drive openers are quieter and often preferred for their smoother operation. They are generally more expensive than chain drive systems.

- Screw drive openers offer robust performance but can sometimes be slower.

- Direct drive openers are the quietest and most powerful, but also the most expensive option.

Understanding the specific mechanics of each opener type is crucial for identifying how opener issues might contribute to track damage or how track damage might affect the opener’s performance. For example, a misaligned track can put extra stress on the motor of any type of opener, potentially leading to premature wear and tear or even failure.

Q 18. How do you ensure the safety of the garage door after track repair?

Safety is paramount after any garage door track repair. My process includes:

- Thorough inspection: A comprehensive check of all components, including the track, rollers, springs, cables, and opener, to ensure everything is properly aligned and functioning correctly.

- Testing: Carefully opening and closing the garage door multiple times to verify smooth and safe operation. I’ll listen for any unusual sounds or resistance.

- Safety sensors: I always make sure the safety sensors are properly aligned and functioning. These sensors prevent the door from closing on obstacles, crucial for preventing accidents.

- Manual operation check: Even if the automatic opener is working correctly, I always check the manual release mechanism, ensuring the door can be opened and closed manually in case of power failure.

- Client education: I educate the client on proper maintenance practices to prevent future issues. I share tips to keep the track clear of debris and how to properly lubricate the moving parts.

This multi-step approach ensures the garage door is both functional and safe for daily use.

Q 19. What are the warning signs indicating potential track problems?

Several warning signs can indicate potential track problems. Don’t ignore them!

- Noisy operation: Grinding, squeaking, or rattling sounds during door operation often signal misalignment, wear, or debris buildup in the track.

- Binding or sticking: The door struggles to move smoothly, indicating a problem with the track, rollers, or other components.

- Door off track: The door derails, completely coming off the track, indicating significant track damage or misalignment.

- Uneven movement: One side of the door moves faster or slower than the other, suggesting track misalignment.

- Visible damage: Bent, damaged, or rusty sections of the track are clear indicators of a problem needing attention.

If you notice any of these signs, it’s best to contact a professional for inspection and repair to avoid further damage and potential safety hazards.

Q 20. Explain the process of replacing a garage door roller.

Replacing a garage door roller is a relatively straightforward process, but requires care and attention to detail. Here’s a step-by-step procedure:

- Safety first: Disconnect the garage door opener to prevent accidental closure.

- Locate the roller: Identify the damaged roller.

- Remove the roller: Use the appropriate tools (usually pliers or a screwdriver) to remove the retaining pins or clips securing the roller to the track. Gently pull the roller out.

- Install the new roller: Insert the new roller into the track, making sure it aligns correctly.

- Secure the roller: Re-insert the retaining pins or clips to secure the new roller in place.

- Test operation: Reconnect the garage door opener and test the door operation to confirm smooth movement.

If you’re not comfortable performing this repair yourself, it’s always best to contact a qualified garage door technician. Improper installation can lead to further damage and safety issues.

Q 21. Describe your experience with different types of garage door materials.

My experience includes working with a variety of garage door materials, each possessing unique characteristics that affect track design and repair considerations:

- Steel: The most common material; it’s durable but susceptible to rust and corrosion. Steel tracks are usually repairable, but severe damage might necessitate replacement.

- Aluminum: Lightweight and resistant to corrosion, but less durable than steel. Repairs are possible, but replacement might be necessary for significant damage.

- Wood: Less common for tracks themselves, but sometimes used in conjunction with other materials. Wood tracks require specialized repair techniques.

The material influences the repair strategies. For instance, a dented steel track might be repairable by straightening, but a severely cracked aluminum track might need complete replacement due to potential weakening of the metal.

Q 22. How do you handle customer concerns related to track repairs?

Addressing customer concerns about track repairs begins with active listening. I make sure I understand their specific problem – is the door off track, is it noisy, or is it simply not moving smoothly? Then, I explain the issue clearly, using non-technical language where possible, and outline the repair process in detail. Transparency is key; I’ll always discuss potential costs upfront and obtain approval before proceeding. If unexpected issues arise during the repair, I immediately communicate them to the customer, offering various solutions and obtaining their consent before making any changes to the original plan. For example, if I find significant rust damage beyond the initial assessment, I’ll explain the implications and the added cost of addressing that damage.

I always aim to build trust by emphasizing my expertise and ensuring they feel heard and valued. Following up after the repair is crucial to ensure complete customer satisfaction. Addressing any post-repair concerns promptly shows my commitment to quality service.

Q 23. What are the typical warranty terms for garage door track repair?

Warranty terms for garage door track repairs typically vary depending on the repair itself and the company. Generally, parts may have a manufacturer’s warranty (often 1-2 years), while the labor may be covered for a shorter period, perhaps 30-90 days. However, this is not universal. Some companies may offer extended warranties at an additional cost. The warranty usually covers defects in materials and workmanship, but generally doesn’t cover damage caused by misuse, neglect, or accidents (like a car hitting the door). I always provide customers with a detailed written warranty outlining the specifics of what is covered and for how long. This prevents any misunderstandings down the line. For example, a warranty might cover the replacement of a bent track section if it’s due to a manufacturing defect, but it wouldn’t cover damage caused by a tree branch falling on the track.

Q 24. How do you troubleshoot a noisy garage door track?

Troubleshooting a noisy garage door track involves a systematic approach. First, I visually inspect the entire track for any obvious problems like bent sections, loose rollers, or debris. A squeaking sound often indicates dry rollers; lubricating them with silicone spray usually resolves this. A grinding or scraping noise might point to a bent or damaged track section, requiring straightening or replacement. Loose screws securing the track to the wall or header can also cause noise; tightening them often resolves the problem. Sometimes the noise comes from the door itself – worn hinges or a damaged spring can cause vibrations that make the track seem like the source. I carefully examine the entire system to pinpoint the exact cause of the noise before attempting repairs. For instance, I would first check for loose rollers, then check the track for bends, before inspecting the door hinges and spring mechanism as the cause.

Q 25. Describe a challenging track repair you have completed and how you resolved it.

One challenging repair involved a garage door with a severely rusted and corroded track system. The rust was so extensive that several sections of the track were completely compromised, making it unsafe to operate the door. Simply replacing the damaged sections wasn’t enough; the rust had weakened the surrounding metal. My solution involved carefully removing the rusted sections, cleaning the surrounding area thoroughly to remove all loose rust particles, and then applying a rust-inhibiting primer. After that, I welded in replacement pieces of high-quality steel. This required precision to ensure the new sections were perfectly aligned with the existing structure, maintaining the smooth operation of the door. Finally, I repainted the track to protect it from further rust. The entire process was time-consuming and required specialized tools and techniques, but the result was a completely restored, safe, and functional garage door system. The customer was incredibly relieved and impressed with the quality of the work.

Q 26. What are the most common mistakes made during garage door track repair?

Common mistakes during garage door track repair include using incorrect tools (leading to damage), improper alignment of the track (causing binding), failing to lubricate moving parts (leading to wear and tear), not properly securing the track to the frame (compromising stability), and neglecting safety precautions (resulting in injury). Using the wrong type of lubricant is also a mistake – silicone spray is suitable for most parts, while oil-based lubricants can attract dust and dirt. Another common mistake is failing to identify the root cause of the problem. For example, simply lubricating a noisy track without addressing a bent section will only provide a temporary solution and might ultimately damage the rollers.

Q 27. How do you maintain your tools and equipment for track repairs?

Maintaining my tools and equipment is crucial for safety and efficiency. After each job, I thoroughly clean all tools, removing debris and lubricant residue. I inspect each tool for damage or wear. Worn parts are replaced immediately. My welding equipment is regularly serviced and calibrated to ensure optimal performance and safety. I store my tools in a well-organized manner to prevent damage and make them readily accessible. Power tools are kept charged and stored safely to prevent accidents. Regular maintenance prevents costly repairs or replacements and ensures the tools remain effective and safe to use.

Q 28. Explain your understanding of OSHA safety regulations related to garage door repair.

My understanding of OSHA safety regulations regarding garage door repair is paramount. This includes, but isn’t limited to, proper use of personal protective equipment (PPE) such as safety glasses, gloves, and hearing protection. I am meticulous about following lockout/tagout procedures when working with electrical components. I ensure the work area is properly secured and free of hazards. I am aware of the risks involved with working at heights and utilize appropriate safety equipment such as harnesses and fall protection when needed. I am also aware of the correct lifting techniques to prevent injuries, and I know how to safely handle heavy garage door components and tools. Keeping myself and the work environment safe is a top priority. Regular safety training updates keep my knowledge of OSHA standards current and applicable.

Key Topics to Learn for Your Garage Door Track Repair Interview

- Understanding Garage Door Track Systems: Familiarize yourself with different track types (roller, top-hung, etc.), their components, and how they function. Consider the differences in residential vs. commercial applications.

- Troubleshooting Common Track Problems: Learn to diagnose issues like bent tracks, misaligned rollers, broken brackets, and binding. Practice explaining your diagnostic process and the logic behind your conclusions.

- Repair Techniques and Procedures: Master the safe and efficient methods for straightening bent tracks, replacing damaged rollers and brackets, and ensuring proper alignment. Understand the tools and equipment involved.

- Safety Procedures and Best Practices: Demonstrate knowledge of safety protocols when working with garage doors, including proper lifting techniques, use of personal protective equipment (PPE), and awareness of potential hazards.

- Material Knowledge: Familiarize yourself with the types of materials used in garage door tracks (steel, aluminum, etc.) and their properties. Understand how these material choices impact durability and repair strategies.

- Preventive Maintenance: Discuss the importance of regular inspections and lubrication to prevent future track problems and extend the lifespan of garage door systems.

- Customer Service Skills: Highlight your ability to communicate effectively with customers, explain technical issues in a clear and understandable manner, and build rapport to ensure customer satisfaction.

Next Steps

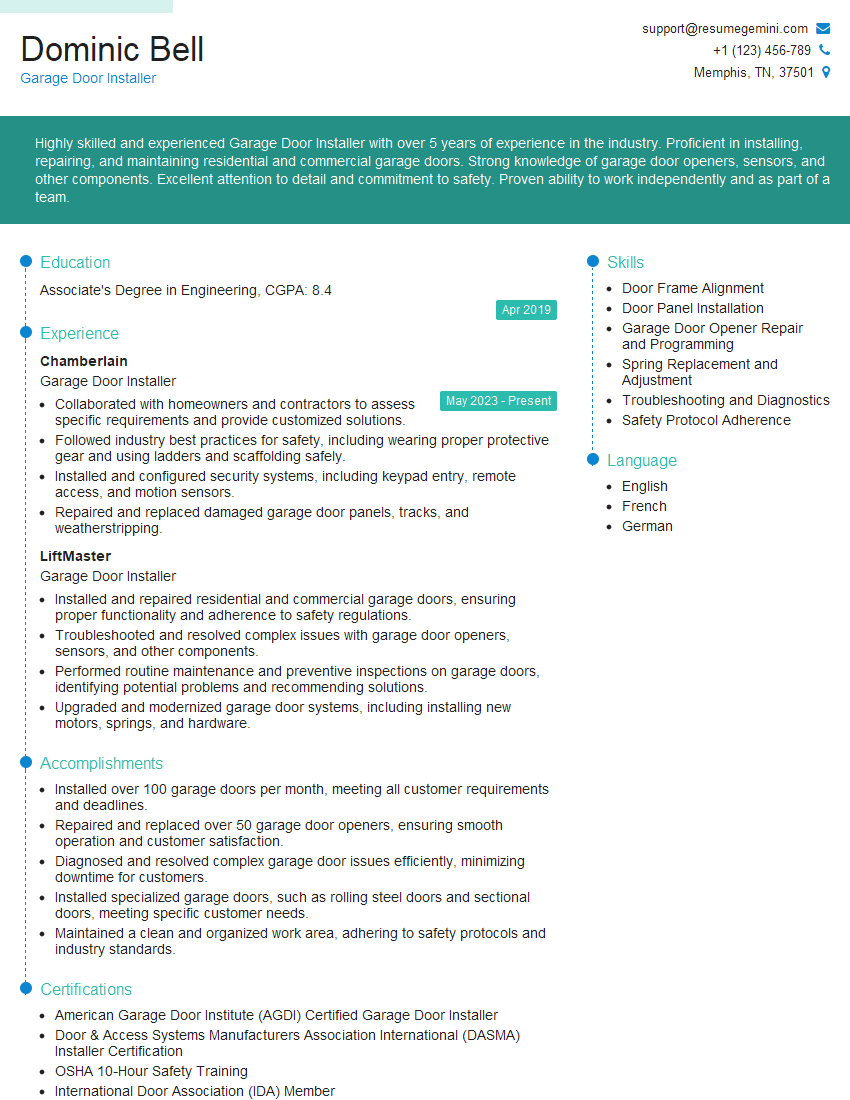

Mastering garage door track repair opens doors to a rewarding career with excellent growth potential. Proficiency in this skillset is highly sought after, leading to greater job security and earning potential. To maximize your job prospects, crafting a strong, ATS-friendly resume is crucial. ResumeGemini can help you build a professional and effective resume that highlights your skills and experience. We provide examples of resumes tailored to the Garage Door Track Repair field to help guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?