The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to GLP and Pharmacopoeia Compliance interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in GLP and Pharmacopoeia Compliance Interview

Q 1. Explain the principles of Good Laboratory Practice (GLP).

Good Laboratory Practice (GLP) is a quality system that ensures the uniformity, consistency, reliability, reproducibility, quality, and integrity of non-clinical laboratory studies that support the safety assessment of chemicals or products. Think of it as a detailed recipe book for conducting experiments, guaranteeing that anyone following the instructions will get the same results. Its core principles revolve around ensuring the data generated is credible and trustworthy.

- Standard Operating Procedures (SOPs): All procedures must be documented and followed consistently. Imagine a bakery following a precise recipe for a cake – every step is documented to ensure consistency.

- Personnel Qualification: Scientists performing the studies must be adequately trained and qualified. A skilled baker is crucial for making a perfect cake.

- Facility and Equipment: The laboratory must be properly equipped and maintained. This is like ensuring the bakery has the right ovens and tools.

- Test Article Management: The materials being tested must be properly identified, stored, and handled. This relates to using high-quality ingredients in the cake.

- Quality Assurance Unit (QAU): An independent unit oversees the study to ensure GLP compliance. They’re like the food inspectors ensuring the bakery maintains hygiene and quality.

- Data Management and Archiving: All data generated must be meticulously recorded, reviewed, and archived. This is like keeping meticulous records of every step in cake-making, from measuring ingredients to baking time.

Q 2. What are the key differences between GLP and GMP?

While both GLP and GMP (Good Manufacturing Practice) are quality systems aimed at ensuring product safety and quality, they apply to different stages and aspects of product development. GLP focuses on the testing phase, specifically non-clinical laboratory studies, whereas GMP focuses on the manufacturing phase of pharmaceuticals, medical devices, food, and other products.

- GLP: Concerned with the reliability and integrity of test data generated in a laboratory setting. It’s about the process of generating data that supports safety assessments of products.

- GMP: Focuses on the production process itself, ensuring consistency and quality of the final product. It’s about making sure the product meets safety and efficacy requirements.

Analogy: Imagine developing a new drug. GLP governs the laboratory tests to ensure the drug’s safety, while GMP governs the manufacturing process to ensure a consistent, safe, and effective product reaches the market.

Q 3. Describe the importance of documentation in GLP compliance.

Documentation is the cornerstone of GLP compliance. It provides a complete and auditable trail of all activities performed during a study. Without meticulous documentation, the integrity and validity of the generated data are severely compromised. This is crucial for regulatory submissions and potential legal challenges.

- Raw Data: Original recordings, including lab notebooks, instrument printouts, and spreadsheets.

- SOPs: Detailed procedures for every step of the study.

- Study Plans: Detailed outlines of the study objectives, methodology, and statistical analysis plan.

- Reports: Summarizing the study findings and conclusions.

- Corrective and Preventive Actions (CAPAs): Documented responses to any deviations from SOPs or other unexpected events.

Think of it as a detective’s case file – every piece of evidence is meticulously documented to reconstruct the events and support conclusions.

Q 4. How do you ensure data integrity within a GLP environment?

Ensuring data integrity in a GLP environment requires a multi-faceted approach, focusing on prevention and detection. Key aspects include:

- Electronic Data Management Systems (EDMS): Using secure, validated EDMS reduces risks associated with manual data handling.

- Audit Trails: Tracking every change made to data, including who, when, and why. This is crucial for detecting errors and intentional manipulations.

- Data Backup and Recovery: Implementing robust systems to protect against data loss. This safeguards years of research in case of an incident.

- Regular Data Audits: Systematic reviews of the data for accuracy, completeness, and consistency.

- SOPs for Data Handling: Clear and well-defined procedures for data entry, validation, and archiving.

- Training and Awareness: Educating personnel on the importance of data integrity and best practices.

Data integrity is not just about accuracy; it’s about the entire lifecycle of the data, from its creation to its archiving.

Q 5. What are the common deviations from GLP and their consequences?

Deviations from GLP can range from minor procedural errors to significant breaches of protocol. Common deviations include:

- Incomplete or Missing Documentation: Failing to properly record all aspects of a study. This can render the study results unreliable and casts doubts on the whole process.

- Unqualified Personnel: Allowing untrained or inadequately qualified personnel to conduct or oversee studies. This risks errors and compromised results.

- Inadequate Equipment Calibration: Using equipment that is not properly calibrated, leading to inaccurate measurements. Think of a baker using a faulty scale – the cake would be wrong!

- Improper Sample Handling: Incorrectly storing or handling test articles, leading to degradation or contamination. This compromises the quality and integrity of the samples.

- Data Falsification or Manipulation: Intentionally altering or fabricating data, which is a serious ethical and regulatory violation. This is unacceptable and carries severe consequences.

Consequences of GLP deviations can include study invalidation, regulatory sanctions (including warning letters or fines), reputational damage, and legal repercussions.

Q 6. Explain the role of a GLP compliance officer.

A GLP compliance officer plays a vital role in ensuring adherence to GLP principles within an organization. They act as the independent oversight body, ensuring that all studies comply with regulations and internal SOPs. They are responsible for:

- Developing and Maintaining SOPs: Creating and updating standard operating procedures to ensure consistency in study conduct.

- Conducting Internal Audits: Regularly assessing the GLP compliance status of different studies and laboratory operations.

- Investigating Deviations: Examining any deviations from SOPs and implementing corrective and preventive actions (CAPAs).

- Training Personnel: Educating scientists and laboratory staff on GLP principles and best practices.

- Supporting Regulatory Inspections: Assisting during regulatory inspections and responding to any queries or findings.

- Overseeing Data Management: Ensuring the integrity and security of data generated during studies.

The GLP compliance officer is the guardian of data integrity and regulatory compliance within the organization, ensuring the quality and credibility of research.

Q 7. Describe your experience with GLP audits and inspections.

I have extensive experience with GLP audits and inspections, having participated in numerous audits both as an auditor and an auditee. My experience encompasses a wide range of studies including toxicology, pharmacology, and environmental safety studies. I’m familiar with various regulatory requirements and have successfully navigated the inspection process, ensuring successful audits and minimal findings. For example, during a recent audit of a toxicology study, I identified a minor deviation related to record-keeping, but through proactive measures and swift CAPA implementation, we prevented the findings from affecting the overall study’s validity. My approach emphasizes proactive preparation, comprehensive documentation review, and effective communication with inspectors. This collaborative approach ensures the audit process runs smoothly and any identified issues are promptly addressed, demonstrating a commitment to GLP principles.

Q 8. How do you handle non-conformances related to GLP?

Handling GLP non-conformances requires a systematic approach. It starts with immediate investigation to understand the root cause. This involves documenting the deviation from the GLP standard, interviewing personnel involved, and reviewing relevant laboratory records. A thorough investigation helps identify whether the non-conformance impacts data integrity. Based on the severity and impact, corrective actions (CAPA) are implemented. This could range from retraining staff on proper procedures to replacing faulty equipment. Crucially, preventative actions are also defined to avoid recurrence. The entire process is documented, reviewed, and approved. Think of it like a detective solving a case – we need to find the ‘who’, ‘what’, ‘when’, ‘where’, and ‘why’ of the non-conformance, and then implement strategies to prevent it from happening again.

For example, if a technician accidentally uses the wrong reagent, we’d investigate: Was there inadequate training? Was the labeling unclear? Was there insufficient oversight? Corrective actions might include updated training materials, improved labeling protocols, and increased supervision. Preventative measures could involve implementing a double-checking system for reagent use. All steps of this process are meticulously recorded.

Q 9. What is a Standard Operating Procedure (SOP) and its importance in GLP?

A Standard Operating Procedure (SOP) is a detailed, step-by-step instruction for performing a specific task in a laboratory setting. It ensures consistency, accuracy, and reproducibility of results. In GLP, SOPs are crucial because they provide a standardized framework for all laboratory activities, ensuring everyone follows the same documented procedures. This minimizes variability and strengthens data integrity. They serve as a critical piece of evidence during audits or inspections.

Imagine baking a cake – without a recipe (SOP), everyone would bake a different cake. Some might be burnt, others undercooked. SOPs for laboratory procedures are like the recipe, providing the same quality and consistent outcome every time. A well-written SOP includes the objective, materials and equipment, procedure steps, quality control checks, data recording methods, and safety precautions.

Q 10. How do you ensure the accuracy and reliability of laboratory data?

Ensuring the accuracy and reliability of laboratory data is paramount in GLP and involves multiple layers. Firstly, properly calibrated and maintained equipment is essential. Regular calibration with traceable standards is a must. Secondly, using validated analytical methods minimizes errors. This includes method validation parameters like accuracy, precision, specificity, linearity, and limit of detection/quantification. Thirdly, proper training of personnel, including proficiency testing, is critical. Finally, a robust quality control system, incorporating checks at every stage of the process, ensures data integrity. This involves regular audits of the laboratory’s processes, data review by supervisors, and the use of control samples to monitor performance.

For example, regular checks of pipettes and balances ensure their accuracy. Including blanks and controls in assays allows for the detection and correction of systematic errors. Regular proficiency testing for analysts makes sure that individuals are capable of performing their tasks accurately and reliably.

Q 11. Explain your understanding of Pharmacopoeia standards.

Pharmacopoeias are official compendia of standards for drugs and pharmaceutical products. They provide detailed specifications for the identity, purity, quality, and strength of medicinal substances. These standards are legally binding in many countries and are used to ensure the safety and efficacy of medications. They contain monographs that describe specific tests and requirements for individual drugs and excipients. These monographs are regularly updated to reflect advances in scientific knowledge and analytical techniques.

Think of pharmacopoeias as the ‘rule book’ for pharmaceutical quality. They provide the framework that pharmaceutical companies use to demonstrate the quality of their products, ensuring they are safe and meet the required specifications for patient use.

Q 12. What are the key differences between USP, EP, and JP Pharmacopoeias?

While USP (United States Pharmacopeia), EP (European Pharmacopoeia), and JP (Japanese Pharmacopoeia) all aim to ensure drug quality, they differ in their scope, specific tests, and acceptance criteria. They might use slightly different methods for the same analysis, or set different limits for impurities. Although there’s often significant overlap, differences arise from national regulatory preferences, local variations in manufacturing practices, and the specific focus areas of each pharmacopoeia. These differences mean that a drug formulation meeting USP standards might not automatically meet EP or JP standards, and vice versa. This highlights the importance of understanding the specific requirements of the target market when developing and manufacturing pharmaceuticals.

For example, the acceptance criteria for a specific impurity might vary across the three pharmacopoeias, resulting in a product passing one standard but failing another.

Q 13. How do you ensure compliance with Pharmacopoeia monograph requirements?

Ensuring compliance with Pharmacopoeia monograph requirements involves meticulously following the prescribed tests and acceptance criteria detailed in the relevant monograph. This includes using the specified analytical methods, employing appropriate instrumentation, and meticulously documenting all results. Reference standards of high purity and traceability are also crucial. Deviations from the monograph must be justified and fully documented, with impact assessments performed to determine if the deviation affects product quality and safety. Regular audits and quality control checks verify continuous compliance.

For instance, if a monograph specifies a particular HPLC method for assaying a drug substance, that precise method must be used, including the specified column, mobile phase, and detection wavelength. Any deviations necessitate thorough justification and impact analysis.

Q 14. Describe your experience with method validation in accordance with GLP and Pharmacopoeia guidelines.

Method validation is a critical process within GLP and Pharmacopoeia compliance, ensuring the reliability and suitability of analytical methods. My experience encompasses validating a wide range of analytical techniques, including HPLC, GC, UV-Vis spectrophotometry, and dissolution testing, all aligned with ICH guidelines and relevant pharmacopoeial chapters. This involves designing and executing validation studies to demonstrate parameters like accuracy, precision, linearity, range, specificity, limit of detection, and limit of quantitation. Thorough documentation is essential, including protocols, raw data, calculations, and conclusions. Any deviations from expected performance need to be investigated and documented. The validated methods are then incorporated into SOPs for routine use, and their performance is routinely monitored using quality control samples.

For example, when validating an HPLC method for a new drug substance, I would design experiments to determine the accuracy and precision of the method across multiple concentrations, showing linearity of response, and demonstrating its specificity by analyzing potential interfering substances. The results would be documented in a comprehensive validation report. If the method doesn’t meet pre-defined acceptance criteria, investigations and corrective actions would be implemented before approval.

Q 15. How do you manage changes to analytical methods while maintaining GLP and Pharmacopoeia compliance?

Managing changes to analytical methods while maintaining GLP and Pharmacopoeia compliance requires a meticulous, documented approach. Think of it like renovating a house – you need a detailed plan and approvals before starting any work. Any change, no matter how small, must be formally documented and justified.

- Change Control Process: This is the cornerstone. A formal change control system is implemented to evaluate the impact of the change on the validity of existing data, the quality of the results, and overall compliance. This often involves a documented proposal, review by relevant personnel (including management and potentially QA/QC), and final approval before implementation.

- Validation/Verification: After the change is implemented, the method must be re-validated or verified to ensure it still meets the required performance characteristics. This may involve re-performing method validation studies (accuracy, precision, linearity, etc.) or a simpler verification process if the change is deemed minor. The scope of validation/verification depends on the nature of the change.

- Documentation is Key: Every step, from the initial change request to the final validation report, must be meticulously documented. This includes the rationale for the change, the impact assessment, the validation/verification data, and any deviations and their resolutions.

- Deviation Management: If deviations occur during the change process or during method application, a robust deviation management system should be in place to investigate, document, and implement corrective and preventative actions.

Example: Imagine a change to a HPLC method involving a new column. The change control process would outline the rationale (e.g., improved separation, increased sensitivity), the proposed modifications, and a plan to re-validate the method using established parameters. This revalidation would generate data demonstrating the method’s continued suitability for its intended purpose.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the concept of calibration and its importance in GLP.

Calibration in GLP is the process of verifying the accuracy of measuring instruments by comparing their readings to a known standard. It’s like checking the accuracy of your kitchen scale by weighing a known weight. Without calibration, your results are unreliable, and your data, therefore, meaningless.

- Importance: GLP demands accurate and reliable data. Calibration ensures that instruments are functioning within acceptable limits, reducing errors and generating trustworthy results. It helps to identify and correct instrument drift over time. This is critical in producing reliable data for regulatory submissions.

- Frequency: The frequency of calibration depends on the instrument and its use, often outlined in Standard Operating Procedures (SOPs) or instrument manufacturer instructions. Some equipment requires daily calibration, while others might only need it annually.

- Documentation: Every calibration event must be thoroughly documented, including the date, time, instrument details, standards used, results, and any corrective actions taken if the instrument is outside the acceptable limits.

Example: A balance used for weighing samples in a pharmaceutical laboratory requires regular calibration using certified weights. The calibration record shows the balance’s readings for each weight, confirming its accuracy. If the balance fails calibration, it’s taken out of service until it’s repaired and recalibrated.

Q 17. How do you handle equipment malfunctions that affect GLP compliance?

Equipment malfunctions that affect GLP compliance are handled with a structured approach focusing on investigation, documentation, and corrective actions. It’s like diagnosing a car problem – you need to identify the root cause before fixing it.

- Immediate Action: The malfunctioning equipment should be immediately removed from service to prevent further issues. A clear indication should be placed on the equipment to prevent its accidental use.

- Investigation: A thorough investigation is conducted to determine the root cause of the malfunction. This often involves reviewing operational logs, maintenance records, and interviewing personnel who were using the equipment.

- Documentation: All aspects of the malfunction, the investigation, and the corrective actions must be meticulously documented. This documentation becomes part of the deviation report.

- Corrective Actions: Corrective actions are implemented to fix the equipment. This may involve repairs, calibration, or replacement. The corrective actions should prevent recurrence of the malfunction.

- Impact Assessment: Evaluate the impact of the equipment malfunction on the validity of any data generated prior to the malfunction. It may require re-testing of affected samples.

- CAPA (Corrective and Preventive Action): The entire process should follow the established CAPA procedures to ensure that appropriate corrective actions are implemented and preventative measures are in place to reduce the likelihood of future malfunctions.

Example: If a HPLC system malfunctions mid-run, the run is immediately stopped. A detailed log documenting the error message and observed issues is generated. The instrument is then sent to maintenance for repair. Upon its return, calibration and system suitability testing is performed, and documentation is kept for all actions.

Q 18. Describe your experience with instrument qualification and validation.

Instrument qualification and validation are crucial aspects of GLP compliance. Qualification ensures the instrument is fit for its intended purpose, while validation verifies the method used with the instrument produces reliable results.

- Qualification: This is a multi-step process often involving:

- Design Qualification (DQ): Verifying that the instrument’s design meets the requirements of the intended application.

- Installation Qualification (IQ): Confirming that the instrument is correctly installed and configured according to the manufacturer’s specifications.

- Operational Qualification (OQ): Verifying that the instrument operates within its specified parameters.

- Performance Qualification (PQ): Demonstrating that the instrument performs as expected under real-world operating conditions.

- Validation: This refers to the process of demonstrating that the analytical method used with the instrument is suitable for its intended purpose. This may include aspects like accuracy, precision, linearity, range, specificity, and robustness.

Experience: I have extensive experience in both instrument qualification and method validation, across a wide range of analytical techniques (HPLC, GC, spectrophotometry, etc.). My work involves developing qualification protocols, executing qualification studies, documenting results, and reviewing validation reports. I am also proficient in using different software tools to manage data and generate compliance reports.

Example: In one project, I was responsible for the qualification of a new HPLC system. This involved creating IQ, OQ, and PQ protocols, executing the studies, analyzing the data, and compiling a comprehensive qualification report. Subsequently, I led the method validation studies for a new assay method developed for the HPLC.

Q 19. What are the key elements of a GLP compliant laboratory environment?

A GLP-compliant laboratory environment is designed to minimize risks that could compromise data integrity and reliability. Imagine a clean, organized workshop where each tool has its place and is well-maintained.

- Controlled Environment: The lab must have appropriate environmental controls, such as temperature, humidity, and lighting, to ensure the stability of samples and reagents. This frequently involves climate-controlled rooms and dedicated storage facilities.

- Cleanliness and Hygiene: Stringent cleanliness and hygiene protocols are crucial to prevent contamination. This includes regular cleaning and sanitization procedures.

- Proper Storage: Samples, reagents, and materials must be stored appropriately to maintain their integrity and prevent degradation.

- Equipment Maintenance: A regular preventative maintenance program ensures that equipment is functioning correctly and calibration is up to date.

- Secure Data Handling: Secure systems for data management and archiving are essential to prevent data loss or unauthorized access. This is crucial for data integrity and audit trails.

- Physical Security: The laboratory must be secured to prevent unauthorized access to samples, equipment, or data.

- Standard Operating Procedures (SOPs): Detailed SOPs for all laboratory procedures must be in place and followed consistently.

Example: A GLP compliant lab would have a designated area for sample preparation, separate from the analytical testing area, to prevent cross-contamination. They would also have SOPs outlining the protocols for cleaning equipment, storing samples, handling reagents, and conducting analysis.

Q 20. How do you ensure the proper training of laboratory personnel in GLP and Pharmacopoeia procedures?

Ensuring proper training of laboratory personnel is a continuous process. It’s like teaching someone to drive—regular practice and refresher courses keep skills sharp.

- Initial Training: New employees undergo comprehensive training covering all relevant GLP and Pharmacopoeia procedures, safety protocols, and equipment operation. This often includes practical hands-on training and written assessments.

- Continuing Education: Regular refresher training sessions keep employees updated on best practices, new technologies, and changes in regulations.

- Documentation: All training activities, including attendance records, assessment results, and any remedial training, must be meticulously documented.

- Competency Assessment: Regular competency assessments ensure personnel remain proficient and updated. This includes performing routine tasks and undergoing periodic assessments.

- SOPs and Training Manuals: Detailed SOPs and training manuals must be provided to guide laboratory personnel.

Example: We conduct annual GLP refresher training for all laboratory staff, covering topics like data integrity, deviation handling, and new regulatory updates. Training records are meticulously kept to confirm ongoing competency. Each staff member’s competency is regularly assessed based on their performance and work outputs.

Q 21. Describe your experience with CAPA (Corrective and Preventive Actions).

My experience with CAPA (Corrective and Preventive Actions) involves a structured approach to addressing deviations and preventing recurrence. It’s like troubleshooting a computer issue: you not only fix the immediate problem but also identify ways to prevent it in the future.

- Deviation Investigation: A thorough investigation is conducted to understand the root cause of the deviation. This may involve interviewing personnel, reviewing records, and analyzing data.

- Corrective Actions: Corrective actions are implemented to address the immediate problem and restore compliance.

- Preventive Actions: Preventive actions are implemented to prevent the recurrence of the deviation. This may involve changes to procedures, training programs, or equipment.

- Effectiveness Verification: The effectiveness of both corrective and preventive actions is verified to ensure that the problem is resolved and does not reoccur.

- Documentation: The entire CAPA process, from deviation identification to verification of effectiveness, is thoroughly documented and reviewed.

Example: In one instance, a deviation occurred in a high-performance liquid chromatography (HPLC) analysis due to a faulty pump. The CAPA involved repairing the pump (corrective action), implementing a preventative maintenance schedule for all HPLC equipment (preventative action), and retraining technicians on routine equipment checks (preventative action). The effectiveness of these actions was verified by ongoing monitoring and subsequent analysis of HPLC data.

Q 22. Explain your understanding of risk assessment in relation to GLP and Pharmacopoeia compliance.

Risk assessment in GLP (Good Laboratory Practice) and Pharmacopoeia compliance is a systematic process to identify, analyze, and control potential hazards that could compromise the reliability, integrity, and quality of data generated. It’s essentially about proactively preventing issues before they impact the study or product.

In GLP, risk assessment focuses on ensuring the study is conducted according to pre-defined protocols, minimizing bias and maximizing data quality. This includes assessing risks associated with personnel, equipment, reagents, and the environment. For example, we might assess the risk of cross-contamination in a chemical analysis by identifying potential sources and implementing preventative measures like dedicated equipment and cleaning protocols.

Pharmacopoeia compliance, on the other hand, extends risk assessment to the entire lifecycle of a pharmaceutical product. This involves assessing the risks to patient safety, product quality, and regulatory compliance. For instance, we might assess the risk of microbial contamination during the manufacturing process by implementing stringent hygiene standards, environmental monitoring, and sterility testing.

Both GLP and Pharmacopoeia compliance leverage similar risk assessment frameworks, often employing a hazard identification, risk analysis, risk evaluation, and risk control strategy. This iterative process ensures that appropriate mitigation strategies are implemented and continuously monitored and improved upon.

Q 23. How do you ensure the security and confidentiality of laboratory data?

Data security and confidentiality are paramount in GLP and Pharmacopoeia environments. We employ a multi-layered approach to ensure data integrity and protection. This starts with controlled access to laboratory spaces and systems, using access badges and robust login credentials with role-based permissions. Only authorized personnel are granted access to specific data or systems based on their job responsibilities, ensuring the ‘principle of least privilege’ is applied.

We utilize secure electronic data management systems (EDMS) with features like audit trails, electronic signatures, and encryption to maintain data integrity and track all modifications and accesses. Data backups are performed regularly and stored securely, often in geographically separate locations.

Furthermore, we adhere to strict data handling procedures, including standardized naming conventions, version control, and documented workflows. Regular security audits and training sessions for all laboratory personnel reinforce best practices and address potential vulnerabilities. All personnel sign confidentiality agreements, outlining their obligations to protect sensitive data. In the case of paper records, secure storage and disposal procedures are in place.

Q 24. Describe a situation where you had to investigate a deviation from GLP procedures. What was the outcome?

During a stability study of a pharmaceutical product, a deviation occurred when the temperature logger malfunctioned for a short period, resulting in a temperature excursion outside the acceptable range. This deviation was immediately identified through our routine monitoring procedures.

Our investigation involved gathering data from the temperature logger, reviewing the equipment maintenance logs, and interviewing the personnel involved. We traced the cause of the malfunction to a power surge, ultimately resulting from a recent electrical storm. The impacted samples were carefully evaluated to assess the impact on the data. Statistical analysis showed that the excursion was short enough to not significantly affect the overall stability data. However, we implemented corrective actions, including installing a backup power supply for the temperature logger and reviewing our emergency response procedures.

A comprehensive deviation report documenting the event, investigation, impact assessment, corrective, and preventive actions (CAPA) was created and submitted to regulatory agencies. The entire process reinforced the importance of proactive monitoring, effective SOPs, and robust documentation.

Q 25. How familiar are you with 21 CFR Part 11?

I am very familiar with 21 CFR Part 11, the FDA regulation on electronic records and electronic signatures. It’s a critical component of compliance in the pharmaceutical industry and deeply impacts how we manage data and ensure its integrity. My understanding encompasses the specific requirements for electronic systems used to create, modify, maintain, archive, retrieve, and delete electronic records.

This includes my knowledge of the requirements for validation, audit trails, security, and electronic signatures. I understand the importance of system design and implementation to meet the requirements for data security, authenticity, and non-repudiation. I am familiar with the requirements related to access control, data integrity, and system maintenance. I also understand the documentation requirements, including validation plans, test scripts, and audit trails, to support compliance.

Q 26. What is your experience with electronic data management systems (EDMS) in a GLP/Pharmacopoeia context?

I have extensive experience with various EDMS (Electronic Data Management Systems) in GLP and Pharmacopoeia compliant settings. These systems have been instrumental in improving efficiency, enhancing data security, and streamlining compliance efforts.

My experience includes using EDMS to manage various types of data, including raw data from analytical instruments, study protocols, reports, and audit trails. I am proficient in using EDMS to meet the requirements of 21 CFR Part 11, ensuring data integrity and electronic signature compliance. This includes experience with system validation, user training, and ongoing maintenance. Moreover, I have practical experience in migrating legacy data to new EDMS, ensuring data integrity throughout the transfer process. I can effectively evaluate the functionalities of different EDMS to select the most suitable system for specific needs.

Q 27. Describe your understanding of quality by design (QbD) principles.

Quality by Design (QbD) is a systematic approach to pharmaceutical development that focuses on understanding and controlling the factors that influence product quality. It’s a proactive strategy that moves away from traditional trial-and-error methods towards a more scientific and risk-based approach.

In essence, QbD uses scientific knowledge and data to design and control manufacturing processes, ensuring consistent product quality. It involves understanding the critical quality attributes (CQAs) of a product, the critical process parameters (CPPs) that affect those CQAs, and the critical material attributes (CMAs) that affect both the CPPs and the CQAs. The goal is to define a design space, representing the ranges of CPPs and CMAs that reliably deliver a product with the desired CQAs. This requires a thorough understanding of materials science, analytical techniques, process engineering, and statistical methods. It is a continuous improvement cycle involving risk assessment and mitigation at every stage, significantly enhancing product quality and consistency, while minimizing the need for extensive post-market changes.

Q 28. How do you stay updated on the latest changes to GLP and Pharmacopoeia guidelines?

Staying updated on GLP and Pharmacopoeia guidelines is crucial for maintaining compliance. I utilize several strategies to achieve this.

- Subscription to professional journals and regulatory agency updates: I actively subscribe to publications like the USP (United States Pharmacopeia) journal and relevant regulatory agency websites (e.g., FDA, EMA) to receive alerts on updates and new guidelines.

- Participation in conferences and webinars: Attending industry conferences and webinars helps stay abreast of the latest research, technological advancements, and regulatory changes affecting GLP and Pharmacopoeia compliance.

- Networking with industry professionals: I regularly engage in discussions with colleagues and experts through professional organizations and networking events, benefiting from shared knowledge and diverse perspectives.

- Internal training programs: My company invests in regular internal training programs to keep staff informed about the latest regulations and best practices.

By combining these methods, I ensure that my knowledge base remains up-to-date, enabling me to contribute effectively to maintaining compliance and applying the most current methodologies in our work.

Key Topics to Learn for GLP and Pharmacopoeia Compliance Interview

- Good Laboratory Practice (GLP) Principles: Understanding the core principles of GLP, including study design, documentation, quality assurance, and data integrity. This includes understanding the regulatory requirements and their practical implementation in a laboratory setting.

- Pharmacopoeia Standards: Familiarity with major pharmacopoeias (e.g., USP, EP, JP) and their impact on testing methods, quality control, and product specifications. This involves understanding the specific monograph requirements and their application to different drug products and excipients.

- Data Integrity and Audit Trails: Mastering the concepts of data integrity within the context of GLP and pharmacopoeia compliance. This includes understanding the importance of ALCOA+ principles (Attributable, Legible, Contemporaneous, Original, Accurate + Complete, Consistent, Enduring) and the implications of non-compliance.

- Deviation Management and CAPA: Practical application of deviation management processes and Corrective and Preventive Action (CAPA) systems. This includes understanding root cause analysis and the implementation of effective corrective actions.

- Laboratory Equipment Calibration and Maintenance: Knowledge of proper calibration and maintenance procedures for laboratory equipment used in GLP and pharmacopoeia-compliant testing, ensuring accurate and reliable results.

- Standard Operating Procedures (SOPs): Understanding the importance of well-written and followed SOPs in maintaining compliance and ensuring consistent results. This also includes the role of SOP authoring and review.

- Regulatory Inspections and Audits: Preparing for and responding to regulatory inspections and audits, understanding the potential challenges and how to effectively address them.

- Risk Assessment and Mitigation: Identifying potential risks related to GLP and pharmacopoeia compliance and implementing effective mitigation strategies.

Next Steps

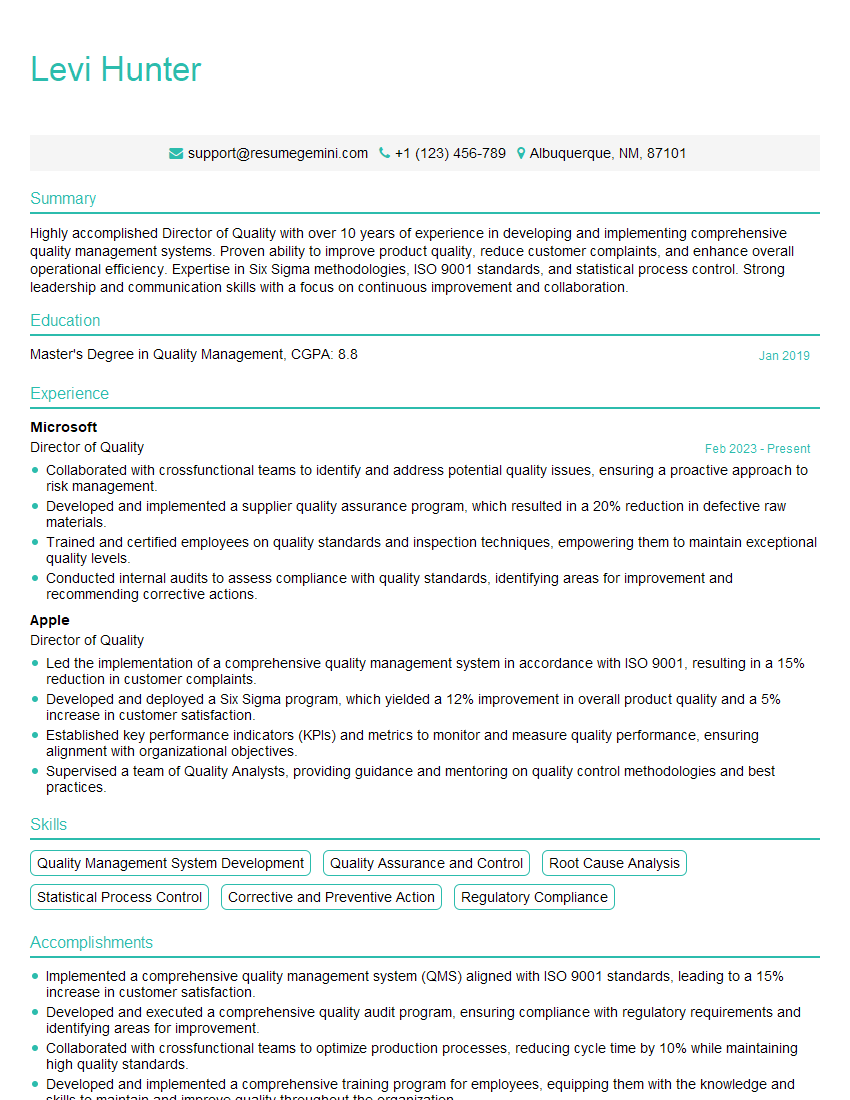

Mastering GLP and Pharmacopoeia Compliance significantly enhances your career prospects in the pharmaceutical and related industries, opening doors to more senior roles and greater responsibilities. A strong understanding of these principles demonstrates your commitment to quality and regulatory compliance, highly valued attributes in this field. To maximize your job search success, create an ATS-friendly resume that highlights your relevant skills and experience. ResumeGemini is a trusted resource that can help you build a professional and effective resume. Examples of resumes tailored to GLP and Pharmacopoeia Compliance are available to help guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?