Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Gyroscope Signal Conditioning interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Gyroscope Signal Conditioning Interview

Q 1. Explain the different types of noise encountered in gyroscope signals.

Gyroscope signals are susceptible to various noise sources, significantly impacting accuracy. Think of it like trying to hear a quiet whisper in a noisy room – the whisper (the actual rotation) gets masked by the noise.

- White Noise: This is random noise with equal power across all frequencies, much like static on a radio. It’s often caused by thermal effects in the sensor.

- Flicker Noise (1/f noise): Its power is inversely proportional to frequency. It’s more prominent at low frequencies and is difficult to filter out completely. Imagine a persistent low hum interfering with your signal.

- Quantization Noise: This arises from the digitization process, where continuous analog signals are converted into discrete digital values. It’s like trying to represent a smooth curve with a series of stair steps; the smaller the steps, the less noticeable the noise.

- Bias Instability: This is a slow, random fluctuation of the output signal even when the gyroscope is stationary. It’s like a slight drift in the zero point of your measuring device.

- Vibration Noise: External vibrations, even subtle ones, can significantly impact gyroscope readings, causing spurious signals. Think of shaking the gyroscope while trying to measure its output.

Understanding these noise sources is crucial for designing effective signal conditioning techniques.

Q 2. Describe common gyroscope signal conditioning techniques, such as filtering and bias compensation.

Signal conditioning for gyroscopes aims to minimize noise and improve the quality of the measured angular rate. Common techniques include:

- Filtering: This is a crucial step. We often use low-pass filters to remove high-frequency noise (like white noise and some vibration noise), and notch filters to eliminate specific interfering frequencies. A common example is a Kalman filter, which is particularly good at handling noisy data by incorporating predictions and measurements.

// Example Kalman filter implementation (simplified): x = x_pred + K*(z - H*x_pred) - Bias Compensation: Gyroscopes often exhibit a non-zero output when stationary (bias). This is usually compensated by measuring the bias during a stationary period and subtracting it from subsequent measurements. Imagine zeroing out the scale before you start weighing something.

- Gain Calibration: This ensures the output signal accurately reflects the input angular rate. The gyroscope’s sensitivity is calibrated with a known rotation, and the signal is scaled accordingly.

- Temperature Compensation: Gyroscope performance is affected by temperature changes. Temperature sensors and compensation algorithms are often integrated to maintain accuracy across temperature ranges.

The choice of techniques depends on the application, the type of gyroscope, and the characteristics of the noise. For instance, a high-precision navigation system will require more sophisticated filtering and compensation than a simple gaming application.

Q 3. How do you calibrate a gyroscope?

Gyroscope calibration is essential for accurate measurements. It involves determining the gyroscope’s bias, scale factor (gain), and potentially other parameters like non-orthogonality errors. A common method is using a calibration fixture:

- Static Calibration: The gyroscope is kept stationary for a period to estimate the bias. This establishes the sensor’s ‘zero point’.

- Dynamic Calibration: The gyroscope is subjected to known rotations using a turntable or similar device. The outputs are compared to the known rotations to determine the scale factor and other error parameters. This determines how closely the sensor’s readings match reality.

- Mathematical Model: Calibration data is used to create a mathematical model to correct for errors in subsequent measurements. This model can compensate for non-linearities in the sensor’s response.

Calibration procedures vary based on the gyroscope type and application requirements. High precision applications may involve more complex calibration procedures and mathematical models.

Q 4. What are the challenges of integrating gyroscope data with other sensor data (e.g., accelerometers)?

Integrating gyroscope data with other sensors, especially accelerometers, is common in inertial navigation systems. However, challenges exist:

- Sensor Drift and Noise: Each sensor has its own noise and drift characteristics. The combined data needs careful filtering and compensation to avoid error propagation.

- Data Fusion Techniques: Effective data fusion algorithms, like Kalman filters or complementary filters, are needed to optimally combine the data from different sensors, balancing accuracy and responsiveness.

- Coordinate Systems: Gyroscopes and accelerometers typically operate in different coordinate systems. Transformations are required to align the data before fusion.

- Bias Mismatch: Differences in bias between sensors can lead to significant errors if not accounted for. Careful calibration of each sensor is crucial.

For example, integrating accelerometer data (which measures acceleration) with gyroscope data (which measures angular rate) allows for improved estimation of orientation and position through sensor fusion algorithms. A properly calibrated and fused system provides a much better estimate of the object’s movement than relying on either sensor alone.

Q 5. Explain the concept of gyroscope drift and how to mitigate it.

Gyroscope drift refers to the slow, cumulative error in the output of a gyroscope over time, even when it’s not rotating. Think of a clock that gradually runs slow or fast – its readings drift from the true time. This is primarily caused by bias instability and temperature-dependent effects.

Mitigation strategies include:

- High-Quality Sensors: Selecting gyroscopes with low drift characteristics is the first step.

- Bias Compensation: Regularly measuring and subtracting the bias is essential. Advanced techniques like Kalman filtering can dynamically estimate and compensate for bias.

- Temperature Compensation: Controlling temperature variations or incorporating temperature compensation algorithms minimizes drift caused by temperature changes.

- Sensor Fusion: Combining gyroscope data with other sensors (like accelerometers) helps to constrain and correct for drift through data fusion techniques. This approach leverages the strengths of each sensor to reduce errors.

Effective drift mitigation is particularly important in applications requiring long-term stability, such as navigation systems and stabilization platforms.

Q 6. Discuss different types of gyroscopes (e.g., MEMS, fiber optic) and their signal characteristics.

Various types of gyroscopes exist, each with unique characteristics:

- MEMS (Microelectromechanical Systems) Gyroscopes: These are small, low-cost, and widely used in consumer electronics and many other applications. They typically have higher noise and drift compared to higher-end gyroscopes. Their signals are often digital and can be easily interfaced with microcontrollers. Signal characteristics are affected by temperature and vibration.

- Fiber Optic Gyroscopes (FOGs): FOGs are based on the Sagnac effect and offer high accuracy and low drift. They are used in applications requiring high precision, like navigation systems. Their signals are analog and require more sophisticated signal conditioning.

- Ring Laser Gyroscopes (RLGs): These are highly accurate and robust gyroscopes, but they are larger and more expensive than MEMS or FOGs. They use laser interference to measure rotation. Signal processing often involves complex techniques to account for lock-in effects.

The choice of gyroscope depends on the application’s requirements for accuracy, cost, size, and power consumption. MEMS gyroscopes are ideal for many consumer applications, while FOGs and RLGs are preferred for high-precision navigation systems.

Q 7. How do you handle data outliers in gyroscope measurements?

Data outliers in gyroscope measurements can significantly affect the accuracy of any analysis or system. Think of it as a single wildly inaccurate reading in a series of otherwise accurate readings.

Handling outliers requires a combination of techniques:

- Statistical Methods: Methods like the standard deviation or interquartile range (IQR) can identify data points far from the average. Points outside a defined threshold can be labeled outliers.

- Median Filtering: Replacing outliers with the median value of neighboring data points can reduce their impact. This is particularly effective for handling isolated spikes in the data.

- Moving Average Filtering: This filters out short bursts of noise or erratic readings by averaging over a sliding window of data points.

- Robust Regression: This statistical technique is less susceptible to outliers than standard least-squares regression, useful when fitting models to the gyroscope data.

- Outlier Rejection Algorithms: More sophisticated algorithms, like Hampel filters or other robust estimation techniques, can identify and replace or remove outliers more effectively than simple thresholding techniques.

The best approach depends on the nature and frequency of the outliers and the application’s sensitivity to errors. It’s often necessary to combine multiple techniques for optimal outlier handling.

Q 8. Explain the role of signal conditioning in improving gyroscope accuracy.

Gyroscope signal conditioning is crucial for enhancing the accuracy of angular rate measurements. Raw gyroscope outputs are often contaminated with noise, bias, and drift. Signal conditioning techniques mitigate these imperfections, resulting in cleaner, more reliable data. Think of it like polishing a gem – the raw material is there, but careful refinement reveals its true brilliance.

The process typically involves several steps: amplification to boost weak signals, filtering to remove noise, and calibration to compensate for systematic errors like bias and scale factor inaccuracies. Without these steps, the inherent inaccuracies of the gyroscope would render it largely unusable in many precision applications.

Q 9. Describe different filtering techniques used in gyroscope signal processing (e.g., Kalman filter).

Numerous filtering techniques enhance gyroscope data. Simple filters like moving averages smooth the signal but can lag behind rapid changes. More advanced methods offer superior performance:

Complementary Filters: Combine gyroscope data (high-frequency, prone to drift) with accelerometer or other sensor data (low-frequency, prone to noise) to achieve a balance between responsiveness and stability. This is frequently used in attitude estimation.

Kalman Filters: These powerful filters leverage a mathematical model of the system dynamics and noise characteristics to provide optimal estimates of the angular rate. They’re particularly effective in handling uncertainty and dynamically changing conditions, making them ideal for applications like robotics and navigation.

Low-pass Filters: Attenuate high-frequency noise while preserving lower frequency signals representing actual rotational movement. Butterworth and Bessel filters are common choices due to their desirable frequency response characteristics.

The choice of filter depends heavily on the application’s specific requirements. For instance, a highly dynamic application might favor a Kalman filter’s adaptive nature, while a simpler application might suffice with a complementary filter or a well-designed low-pass filter.

Q 10. How do you determine the appropriate sampling rate for gyroscope data acquisition?

Determining the appropriate sampling rate is a critical aspect of gyroscope data acquisition. The Nyquist-Shannon sampling theorem dictates that the sampling rate must be at least twice the highest frequency component present in the signal to avoid aliasing (a distortion where high-frequency noise appears as low-frequency noise).

In practice, it’s common to sample at a rate significantly higher than the Nyquist rate to capture subtle changes and provide sufficient data for processing. Consider the anticipated rotational dynamics of the application. A rapidly spinning object will require a much higher sampling rate than a slowly rotating one. A good rule of thumb is to oversample by a factor of 4-10. For example, if the highest expected rotation rate is 100 Hz, you might sample at 400-1000 Hz.

Oversampling provides headroom for more robust filtering and allows for more accurate interpolation between samples, leading to more reliable results.

Q 11. What are the common sources of error in gyroscope measurements?

Gyroscope measurements are susceptible to various error sources, impacting their accuracy and precision. These include:

Bias: A constant offset in the measured angular rate. This can be caused by imperfections in the gyroscope’s internal components or environmental factors.

Drift: A gradual change in bias over time, often caused by temperature variations or aging effects.

Noise: Random fluctuations in the measured angular rate, stemming from electronic noise within the sensor or external sources.

Scale Factor Error: Inaccuracy in the relationship between the output signal and the actual angular rate. This means the sensor might consistently report a slightly wrong value.

Temperature Sensitivity: Bias, drift, and scale factor errors are often influenced by temperature changes. Careful temperature compensation is often crucial.

Cross-axis Sensitivity: A rotation about one axis can cause a small output on another axis (an example would be a slight reading along the y-axis when rotating around the x-axis).

Understanding and compensating for these errors through calibration and signal processing is vital for obtaining accurate and reliable data.

Q 12. How do you test the accuracy and precision of a gyroscope?

Testing gyroscope accuracy and precision involves comparing its measurements to a known reference. Methods include:

Rate Table Testing: Mounting the gyroscope on a precisely controlled rate table, which rotates at known speeds. This allows for direct comparison between the measured and actual angular rates, assessing accuracy and repeatability.

Static Tests: Measuring the bias and drift under static conditions, which helps identify systematic errors. This includes monitoring output over time to evaluate drift.

Statistical measures like standard deviation quantify precision (how consistently the gyroscope produces the same output for the same input), while the difference between measured and actual values indicates accuracy. Testing is often performed under various conditions (temperature, orientation) to evaluate the sensor’s performance robustness.

Q 13. Explain the concept of Allan variance and its application to gyroscope characterization.

Allan variance (also known as two-sample variance) is a powerful tool for characterizing the noise characteristics of gyroscopes and other sensors. Unlike standard deviation, which measures the total noise, Allan variance helps decompose the noise into different types (e.g., white noise, flicker noise, bias instability) with distinct frequency dependence.

A plot of Allan deviation (square root of Allan variance) against averaging time reveals the dominant noise sources and their impact on the gyroscope’s performance at different time scales. For example, a flat region indicates white noise dominance, while a decreasing slope suggests bias instability. This analysis guides the selection of optimal filtering techniques and the determination of the sensor’s performance limits for specific applications. Imagine it as a fingerprint for the gyroscope’s noise, allowing for a detailed understanding of its error sources.

Q 14. Describe your experience with different signal processing software (e.g., MATLAB, Python).

I have extensive experience using MATLAB and Python for gyroscope signal processing. In MATLAB, I’ve used its signal processing toolbox extensively for tasks such as filtering (Kalman, Butterworth, etc.), FFT analysis, and Allan variance calculation. For example, I utilized fft() for frequency analysis to identify noise sources, and the allanvar() function for noise characterization.

% Example MATLAB code snippet for applying a Butterworth filter [b,a] = butter(4, 0.1); % 4th order Butterworth filter, cutoff frequency 0.1 filteredSignal = filter(b,a,rawSignal);

In Python, I’ve leveraged libraries like NumPy, SciPy, and matplotlib for similar tasks. SciPy’s signal processing module offers a range of filtering functions, and NumPy provides efficient array manipulation for data processing. I’ve also incorporated machine learning algorithms for advanced noise reduction and calibration in certain projects. My familiarity with these tools allows me to implement complex signal processing pipelines efficiently and effectively, enabling accurate and insightful analysis of gyroscope data.

Q 15. How do you ensure the stability and reliability of a gyroscope system?

Ensuring the stability and reliability of a gyroscope system involves a multi-faceted approach focusing on both hardware and software aspects. Think of it like building a sturdy bridge – you need strong foundations and careful construction.

- High-Quality Components: Selecting gyroscopes with low noise, high accuracy, and good temperature stability is paramount. We often use MEMS (Microelectromechanical Systems) gyroscopes for their compact size and cost-effectiveness, but the selection depends heavily on the application’s needs.

- Proper Calibration: Initial calibration is crucial to remove inherent biases and offsets in the sensor readings. This often involves a static calibration procedure where the gyroscope is held still, and its output is measured to determine its bias.

- Robust Signal Conditioning: This involves amplification, filtering (to remove noise), and potentially temperature compensation circuits. We often use operational amplifiers (op-amps) for amplification and various filter designs – like Butterworth or Bessel – to attenuate unwanted frequencies. The specific filter is selected based on noise characteristics and desired bandwidth.

- Software Compensation: Advanced algorithms, such as Kalman filtering, are used to estimate and compensate for drift, noise, and other systematic errors in the gyroscope measurements. This continuously improves the accuracy of the gyroscope readings over time.

- Environmental Shielding: Protecting the gyroscope from external vibrations and electromagnetic interference (EMI) is vital. This can involve using vibration dampening materials or Faraday cages.

For example, in a drone application, reliable gyroscope data is critical for stable flight. A poorly calibrated or unstable gyroscope could lead to erratic movements or even crashes. Therefore, rigorous testing and careful consideration of all these factors are necessary.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the impact of temperature on gyroscope performance.

Temperature significantly affects gyroscope performance, primarily by inducing bias drift and scale factor variations. Imagine a metal ruler expanding in the sun – its measurements become inaccurate. Similarly, temperature changes can alter the physical properties of the gyroscope’s components, impacting its sensitivity and accuracy.

- Bias Drift: Temperature changes can cause a systematic shift in the gyroscope’s output, even when no rotation is occurring. This means the gyroscope might report a rotation when it’s stationary.

- Scale Factor Variations: The gyroscope’s sensitivity (the relationship between angular rate and output) can also change with temperature. A higher temperature might lead to underestimation or overestimation of the actual angular rate.

- Noise Increase: In some gyroscopes, increased temperature can also increase the level of inherent noise in the signal, making it harder to extract meaningful information.

The magnitude of these effects depends on the gyroscope type and its design. High-grade gyroscopes are designed with temperature compensation techniques to minimize these effects, but it’s still a significant factor to account for in the design process.

Q 17. How do you design a system to compensate for temperature variations?

Compensating for temperature variations involves a combination of hardware and software techniques. The goal is to maintain consistent performance over a wide temperature range. Think of it as adding a thermostat to your home – it adjusts the temperature to maintain a comfortable level.

- Hardware Compensation: This involves using temperature sensors to measure the gyroscope’s temperature and employing circuitry (e.g., thermistors, operational amplifiers in a feedback loop) to adjust the gyroscope’s output based on the measured temperature. This often involves creating a calibration curve using data collected over a range of temperatures.

- Software Compensation: This involves using a temperature-dependent model of the gyroscope’s behavior to correct the output. The model is usually based on calibration data collected at different temperatures. The model can be as simple as a linear correction or more complex using polynomial fitting or look-up tables.

- Temperature-Stable Components: Using components with inherent low temperature sensitivity reduces the need for extensive compensation. For example, choosing a gyroscope with a specified low temperature coefficient is a crucial first step.

A practical example is using a look-up table in embedded software that maps measured temperature to corresponding bias and scale factor corrections. The software then applies these corrections to the raw gyroscope data, enhancing accuracy.

Q 18. Describe your experience working with different types of gyroscope interfaces (e.g., SPI, I2C).

I have extensive experience working with various gyroscope interfaces, including SPI and I2C. The choice of interface depends on factors like data rate requirements, power consumption constraints, and the complexity of the system.

- SPI (Serial Peripheral Interface): SPI is a full-duplex, synchronous interface that offers high data rates and is relatively easy to implement. It’s often preferred when speed is crucial. I’ve used it in high-performance applications like robotics and drone control systems.

// Example SPI configuration (pseudocode) SPI_Begin(gyroscope_cs_pin, SPI_MODE0, SPI_CLOCK_SPEED); - I2C (Inter-Integrated Circuit): I2C is a simpler, multi-master interface with lower data rates. It’s typically chosen for systems with multiple sensors sharing a bus and when power consumption is a significant concern. I’ve utilized I2C in wearable applications due to its lower power consumption.

// Example I2C configuration (pseudocode) I2C_Begin(gyroscope_address);

Understanding the specific requirements of each protocol, such as clock speeds, data formats, and communication protocols, is essential for proper integration and operation.

Q 19. How do you troubleshoot a malfunctioning gyroscope system?

Troubleshooting a malfunctioning gyroscope system is a systematic process that requires careful observation and testing. It’s like diagnosing a car problem – you need to systematically eliminate possibilities.

- Check Connections: Begin by verifying all physical connections, ensuring the power supply is stable and the interface is correctly configured.

- Examine Sensor Output: Observe the raw data from the gyroscope to identify unusual patterns or values (unexpected spikes, constant drift). This might indicate hardware or software issues.

- Test Calibration: Perform calibration procedures to determine if the bias or scale factor is significantly off.

- Investigate Environmental Factors: Check for external interferences like electromagnetic fields or excessive vibrations that may be affecting the gyroscope’s readings.

- Review Software Code: Examine the code for any errors or bugs in the data processing and compensation algorithms.

- Compare with Known Good Data: Compare the gyroscope readings with data from a similar, known-good system under similar conditions.

- Analyze Temperature Effects: Account for temperature variation, especially if the gyroscope is sensitive to temperature changes.

Using diagnostic tools and logging data can significantly aid the troubleshooting process. The specific steps depend heavily on the nature of the malfunction and the system’s architecture. But a systematic approach, as described above, is vital for efficient problem solving.

Q 20. What are the advantages and disadvantages of using digital vs. analog gyroscopes?

The choice between digital and analog gyroscopes depends on the application’s requirements and priorities. Think of it like choosing between a digital and analog watch – each has its pros and cons.

- Digital Gyroscopes:

- Advantages: Higher accuracy, better stability, easier integration with digital systems, built-in temperature compensation, often include digital filtering and data processing capabilities.

- Disadvantages: Higher cost, potentially higher power consumption (depending on design).

- Analog Gyroscopes:

- Advantages: Lower cost, potentially lower power consumption, simpler design.

- Disadvantages: Lower accuracy, more susceptible to noise, requires external signal conditioning and filtering, typically requires more sophisticated signal processing.

For high-precision applications requiring high stability and ease of integration, digital gyroscopes are generally preferred. For low-cost, low-power applications where accuracy requirements are less stringent, analog gyroscopes might be a suitable choice. For example, in a high-end navigation system, digital gyroscopes are essential. In a simple tilt sensor application, an analog gyroscope might suffice.

Q 21. Explain the concept of gyroscope bias instability.

Gyroscope bias instability refers to the random fluctuations in the gyroscope’s output bias over time. Even when the gyroscope is stationary, its output will exhibit small, unpredictable variations. Imagine a slightly inaccurate clock – it’s not always consistently off by the same amount.

This instability is a significant source of error, particularly in applications requiring long-term accuracy. Factors influencing bias instability include temperature variations, aging of the sensor, and inherent noise within the gyroscope’s mechanics. The level of bias instability is usually specified as a rate (e.g., degrees per hour) and is a critical parameter when selecting a gyroscope for a specific application.

Techniques such as Kalman filtering can be used to estimate and compensate for this instability, significantly improving the overall accuracy of the system. However, completely eliminating bias instability is usually not feasible; it’s always a design challenge to minimize its impact on the system’s performance.

Q 22. How do you compensate for gyroscope bias instability?

Gyroscope bias instability refers to the slow drift in the gyroscope’s output even when it’s stationary. This drift can significantly affect the accuracy of motion tracking. Compensation involves techniques to estimate and remove this bias. A common approach is to perform a calibration procedure where the gyroscope is held stationary for a period. The average output during this time represents the bias. This bias value is then subtracted from subsequent readings to correct for the drift.

More sophisticated methods leverage filtering techniques like Kalman filtering. Kalman filters combine gyroscope data with other sensor data (like accelerometer data) to estimate the bias dynamically. This approach is crucial in applications where the bias is not constant. For instance, temperature changes can influence bias, and a Kalman filter can dynamically adapt to those changes.

Imagine trying to navigate using only a compass that slowly drifts. Calibration ensures the compass initially points North, while a Kalman filter continuously corrects minor drifts, resulting in a more accurate navigation experience.

Q 23. Describe your experience with integrating gyroscopes into embedded systems.

My experience with integrating gyroscopes into embedded systems spans several projects, focusing primarily on low-power, resource-constrained environments. I’ve worked extensively with microcontrollers like the STM32 and ESP32, leveraging their built-in peripherals to interface with various gyroscope models – from low-cost MEMS sensors to more precise units.

A key challenge is optimizing power consumption. This often involves careful selection of communication protocols (I2C, SPI) and employing low-power modes for the gyroscope and microcontroller. I’ve implemented custom power management strategies to extend battery life, a critical aspect in battery-powered applications like wearable sensors and drones.

Furthermore, real-time constraints demand efficient data processing. I’ve successfully implemented algorithms for sensor fusion, gyroscope calibration, and noise reduction, ensuring low latency and high accuracy in applications such as motion tracking and stabilization control. For example, in a drone project, I integrated a gyroscope to stabilize the camera, requiring real-time processing to smooth out camera movements.

// Example code snippet (Simplified):// Read gyroscope datagyroData = readGyroscope();// Apply calibration and filteringfilteredData = applyCalibrationAndFilter(gyroData);// Use data for control systemcontrolSystem(filteredData);Q 24. Explain your understanding of different coordinate systems used in gyroscope applications.

Understanding coordinate systems is fundamental to gyroscope applications. Gyroscopes typically output angular rates around their sensitive axes, which need to be mapped to a global reference frame. This involves several coordinate systems.

- Body Frame (Local Frame): This frame is fixed to the gyroscope itself, with axes aligned with the sensor’s sensitive axes (usually X, Y, and Z).

- World Frame (Global Frame): This is a fixed, inertial reference frame, often representing the Earth’s coordinate system (North, East, Down – NED).

- Sensor Frame: This refers to the specific orientation of the sensor in the body frame. Sometimes, there’s a misalignment between the sensor’s physical axes and its assumed orientation.

Transformations between these frames are crucial. Rotation matrices and quaternions are used to convert angular rates measured in the body frame to the world frame, which provides meaningful data about the orientation and movement of the object the gyroscope is attached to.

Incorrect coordinate system handling leads to errors in orientation estimation, underscoring the need for careful definition and conversion. Imagine a drone – its flight control depends on converting the gyroscope’s measurements in its local frame to the Earth’s frame to maintain stability and accurate direction.

Q 25. How do you deal with data synchronization issues when using multiple sensors?

Data synchronization is crucial when using multiple sensors, including gyroscopes, accelerometers, and magnetometers, to improve accuracy and obtain a comprehensive understanding of motion. Asynchronous readings lead to errors in sensor fusion and pose challenges for accurate estimations.

Several strategies address this issue. A common approach is to use a high-precision time source (e.g., a real-time clock) to timestamp each sensor’s readings. This allows for precise time correlation between the data from different sensors. Software algorithms then use these timestamps to interpolate or align data from various sensors, ensuring that values are correctly matched in time.

Another approach involves employing a master sensor that synchronizes data acquisition from other sensors. This master sensor triggers readings from the other sensors, guaranteeing near-simultaneous acquisition. Careful consideration of sensor latency and data transfer speeds is essential for effective synchronization.

Consider a self-balancing robot: simultaneous readings from the gyroscope and accelerometer are vital for accurate posture control. Poor synchronization can cause instability, leading to falls. Proper synchronization ensures the robot reacts appropriately to real-time changes.

Q 26. Describe your experience with real-time data processing of gyroscope data.

Real-time data processing of gyroscope data is a critical aspect of many applications. My experience includes developing real-time algorithms for sensor fusion, noise filtering, and orientation estimation. I’ve used various techniques, including complementary filters, Kalman filters, and Madgwick filters, to process data efficiently while meeting stringent timing requirements.

Optimization is paramount. Code needs to be highly efficient to ensure minimal latency. This involves careful consideration of data structures, algorithm complexity, and hardware utilization. I frequently use low-level programming techniques and hardware acceleration (where available) to achieve the necessary processing speed. For instance, in a motion capture system, every millisecond delay significantly affects the accuracy of 3D motion tracking.

In several projects, I’ve integrated real-time data processing within embedded systems using operating systems like FreeRTOS, enabling concurrent processing of data and control functions. This multithreaded approach enhances responsiveness while handling sensor data acquisition and other critical tasks.

Q 27. What are the ethical considerations related to gyroscope data acquisition and use?

Ethical considerations surrounding gyroscope data are significant. Gyroscope data often reveals sensitive information about user movement and location. Privacy is a primary concern. Data should be anonymized or securely stored to prevent unauthorized access and misuse.

Informed consent is essential. Users should be fully aware of how their data is being collected and used. Transparency in data collection practices builds trust and ensures ethical compliance. Data security measures, such as encryption, should protect against breaches and ensure the confidentiality of user data.

Furthermore, the application of gyroscope data should be carefully considered. It’s crucial to avoid applications that could infringe on an individual’s privacy or lead to discriminatory practices. A responsible approach necessitates meticulous consideration of potential societal impact.

For example, using gyroscope data to track employee movements without informed consent is a significant breach of ethics. Likewise, using such data for discriminatory purposes is unethical and potentially illegal.

Q 28. Discuss your experience with different gyroscope signal conditioning hardware (e.g., ADCs, amplifiers)

My experience with gyroscope signal conditioning hardware encompasses a broad range of components. Analog-to-digital converters (ADCs) are critical for converting the analog output of gyroscopes into digital signals that can be processed by microcontrollers or computers. I’ve worked with various ADC resolutions and sampling rates, selecting the optimal configuration based on the application’s requirements.

Amplifiers are often necessary to boost the weak signals from gyroscopes, improving signal-to-noise ratio and accuracy. I’ve used operational amplifiers (op-amps) in various configurations (e.g., instrumentation amplifiers) to achieve desired signal amplification and noise reduction. Careful consideration of amplifier bandwidth and noise characteristics is crucial for optimal performance.

In addition to ADCs and amplifiers, I’ve worked with anti-aliasing filters to prevent signal distortion during ADC conversion, and signal conditioning circuits to remove unwanted noise and interference. The choice of components significantly impacts the overall system performance, and selecting appropriate components is essential for achieving high accuracy and reliability.

For example, in a high-precision navigation system, the selection of high-resolution ADCs and low-noise amplifiers is crucial for achieving accurate orientation estimation.

Key Topics to Learn for Gyroscope Signal Conditioning Interview

- Gyroscope Fundamentals: Understanding different types of gyroscopes (e.g., MEMS, fiber optic), their operating principles, and inherent limitations.

- Signal Acquisition and Noise Reduction: Techniques for acquiring gyroscope signals, identifying sources of noise (e.g., thermal noise, vibration), and implementing effective filtering and noise reduction strategies.

- Calibration and Compensation: Methods for calibrating gyroscopes to ensure accuracy, understanding and mitigating biases, drift, and scale factor errors.

- Signal Conditioning Circuits: Familiarity with common signal conditioning circuits used with gyroscopes, including amplification, filtering, and analog-to-digital conversion (ADC).

- Data Interpretation and Analysis: Techniques for interpreting gyroscope data, including understanding angular rate, angle, and orientation calculations. Experience with relevant data analysis tools is beneficial.

- Practical Applications: Understanding the applications of gyroscope signal conditioning in various fields such as inertial navigation systems (INS), robotics, aerospace, and automotive systems.

- Error Modeling and Mitigation: Developing an understanding of common error sources and strategies for mitigating their impact on system performance.

- Integration with other Sensors: Understanding how gyroscope data is integrated with other sensor data (e.g., accelerometers, magnetometers) for improved accuracy and robustness (e.g., Kalman filtering).

Next Steps

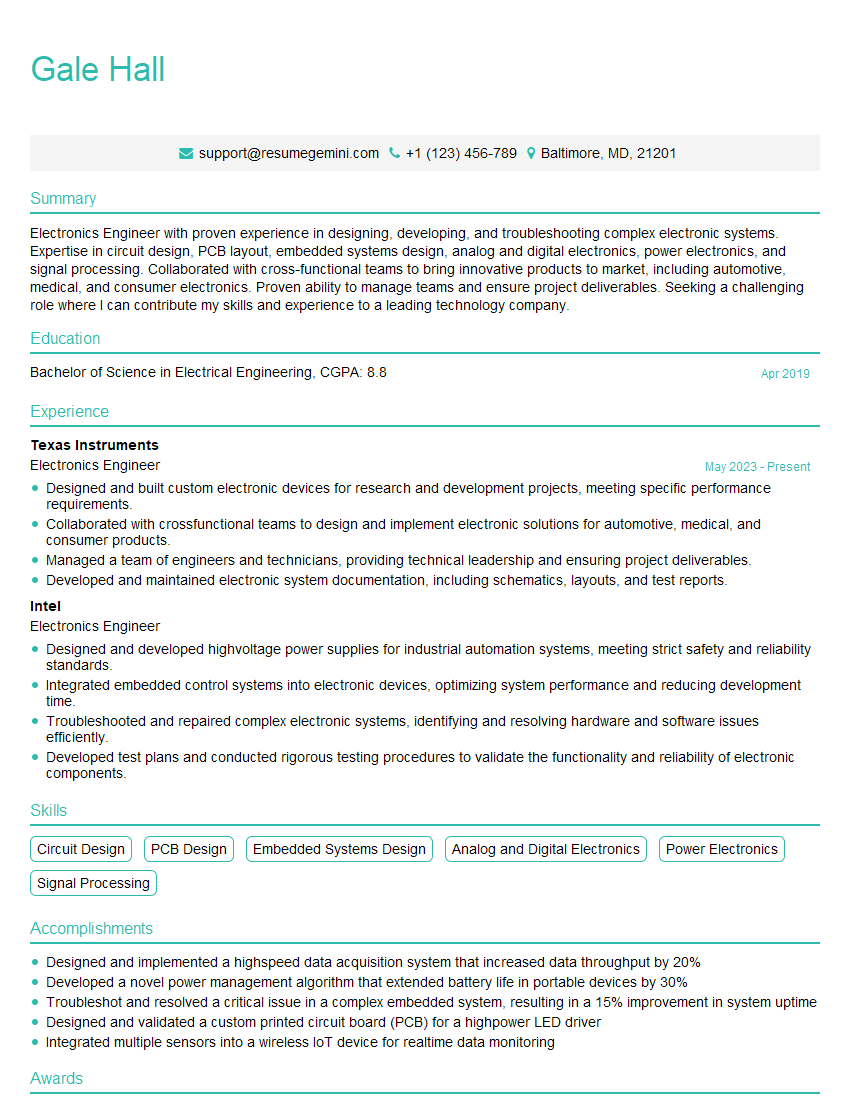

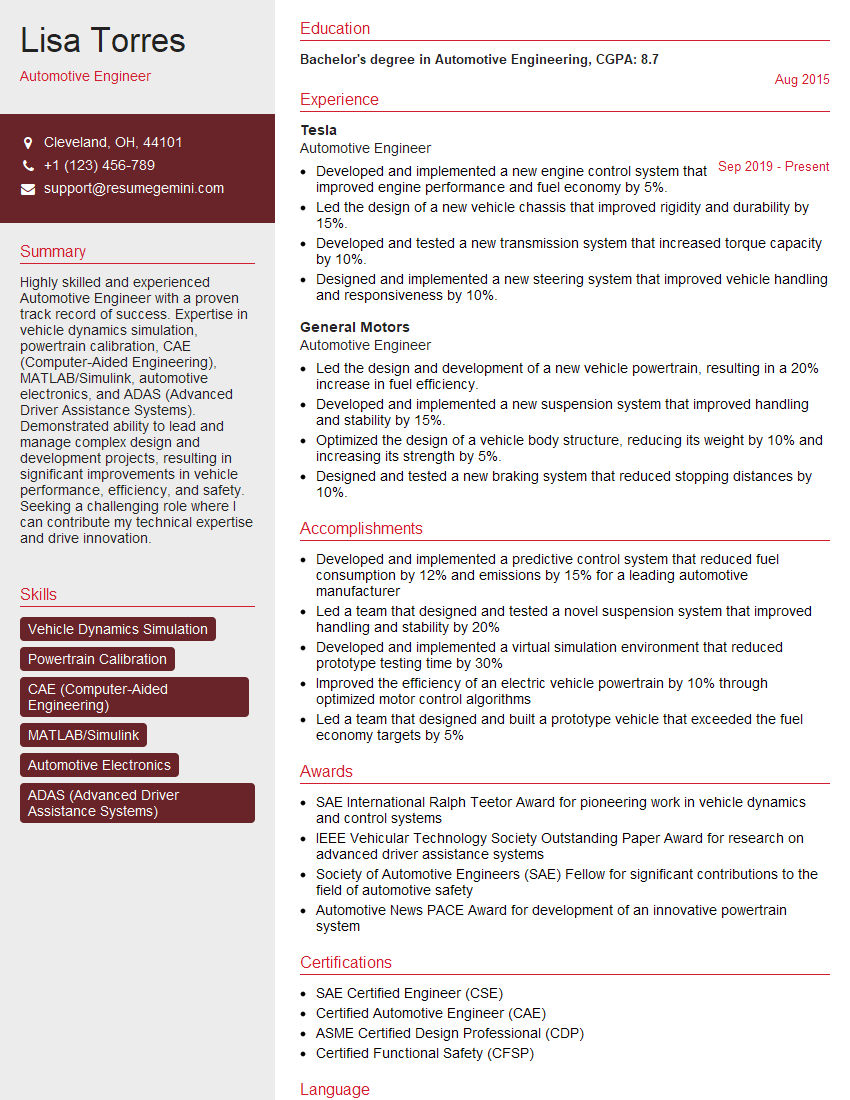

Mastering gyroscope signal conditioning opens doors to exciting and rewarding career opportunities in cutting-edge technologies. A strong understanding of these principles is highly sought after in many industries. To maximize your chances of landing your dream role, crafting a compelling and ATS-friendly resume is crucial. ResumeGemini is a trusted resource to help you build a professional resume that showcases your skills and experience effectively. Examples of resumes tailored to highlight expertise in Gyroscope Signal Conditioning are available through ResumeGemini, allowing you to present your qualifications in the best possible light.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?