Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Hardscaping and Masonry interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Hardscaping and Masonry Interview

Q 1. Describe your experience with different types of masonry materials (brick, stone, concrete).

My experience encompasses a wide range of masonry materials. Brick, for example, offers incredible versatility – from traditional clay bricks offering durability and aesthetic appeal to modern engineered bricks with enhanced strength and weather resistance. I’ve worked extensively with various brick sizes, colors, and textures, understanding their unique properties and best applications. Stone masonry involves a deeper understanding of material sourcing and preparation. I’m proficient in working with various stone types, including granite, limestone, and flagstone, each requiring different techniques for cutting, shaping, and laying. This includes understanding their inherent strengths and weaknesses, and adapting techniques accordingly. Finally, concrete masonry units (CMUs) – often called cinder blocks – provide a cost-effective and efficient building solution. My experience involves using different CMU sizes and finishes, integrating them into projects with both aesthetic and structural considerations.

I’ve worked on projects where we’ve strategically blended these materials for unique architectural effects. For instance, a recent project involved a combination of exposed brick for an interior accent wall and sleek concrete for the exterior structure, creating a visually stunning contrast.

Q 2. Explain the process of laying a brick wall, including considerations for mortar selection and placement.

Laying a brick wall is a precise process that involves several key steps. First, a solid foundation is crucial – typically a concrete footing that ensures stability. Next, we establish the first course of bricks using a line level to ensure perfect alignment. Mortar selection is critical; the type of mortar (type N, S, M, etc.) depends on the load-bearing requirements and weather exposure. We carefully mix the mortar according to manufacturer specifications to ensure proper workability. Brick placement involves applying a consistent bed of mortar, ensuring full coverage and avoiding gaps. Each brick is laid and tapped gently to ensure proper seating and level alignment. The use of a level and plumb bob is essential to maintain vertical and horizontal accuracy. We typically create a running bond pattern, which is both strong and aesthetically pleasing, though other patterns are also possible depending on the design.

Proper mortar placement is crucial for both strength and aesthetics. Too much mortar results in messy joints, while too little compromises the structural integrity. Consistent spacing between bricks (joints) is vital, influencing both the look and the wall’s performance. We often use a jointing tool to create uniform concave, convex, or weathered joints, depending on the desired aesthetic.

Q 3. How do you ensure the proper leveling and alignment of hardscape elements?

Ensuring proper leveling and alignment is fundamental to any successful hardscape project. We employ a variety of tools to achieve this precision. String lines, laser levels, and transit levels are all used to create reference points and check the alignment of features. For example, before laying pavers, we establish a perfectly level base using compacted gravel and a screed. This ensures that the pavers are all at the same height and won’t settle unevenly over time. The use of a spirit level throughout the construction process allows for ongoing checks. For retaining walls, precise leveling of each course is paramount to prevent instability and collapse. We use plumb bobs frequently to ensure verticality of the walls.

In practice, I constantly monitor alignment, making small adjustments as needed. It’s a continuous process throughout the project, not just at the beginning. This commitment to accuracy directly contributes to the long-term performance and visual appeal of the project.

Q 4. What are the different types of retaining wall systems, and what are their advantages and disadvantages?

Retaining walls serve to hold back soil on slopes. Different systems offer varying advantages and disadvantages:

- Gravity Walls: These rely on their own weight for stability. Advantages include simplicity and relative low cost. Disadvantages include limited height and suitability only for low slopes.

- Crib Walls: Constructed from interlocking units (often timber or concrete), they’re versatile and can handle moderate slopes. Advantages include ease of construction and drainage capabilities. Disadvantages include potential for settling if not properly installed and higher cost compared to gravity walls.

- Segmented Retaining Walls: Use precast concrete blocks that interlock. Advantages include speed of construction and good drainage. Disadvantages are limitations on height and curve adaptability.

- Mechanically Stabilized Earth (MSE) Walls: These use reinforced geosynthetics (like geogrids) to stabilize the soil. Advantages include handling of tall walls and challenging soils. Disadvantages include higher initial costs and require specialized knowledge.

The choice of retaining wall system depends on the project’s specific needs, including soil type, height requirements, aesthetic preferences, and budget. I always perform a thorough site assessment before recommending a system, ensuring the chosen design can withstand the site conditions.

Q 5. Describe your experience with different paving materials (pavers, concrete, natural stone).

My experience with paving materials is extensive. Pavers, whether concrete, brick, or natural stone, offer design flexibility and individual replacement capabilities. Concrete paving provides a durable and cost-effective solution, particularly for large areas. However, its monolithic nature limits design variation. Natural stone pavers, such as granite, bluestone, or flagstone, bring unique aesthetics and high durability. Their cost, however, can be higher, and careful selection and installation are crucial to avoid inconsistencies in color and texture. I always choose materials that meet the project’s specific needs regarding load bearing, aesthetics, and budget.

I’ve worked on projects using all three materials – creating intricate patterns with pavers, providing sleek surfaces with concrete, and adding a touch of elegance with natural stone. The choice often depends on the context of the project, balancing aesthetics and practicality.

Q 6. How do you handle drainage issues in hardscape projects?

Drainage is a critical consideration in hardscaping. Poor drainage can lead to erosion, settling, and damage to the hardscape elements. My approach involves several strategies:

- Grading: Proper sloping of the ground ensures water flows away from structures and paved areas. This is often the first step and is crucial for preventing water accumulation.

- Drainage Systems: This may include installing perforated pipes, gravel trenches, or dry wells to collect and redirect water. These are typically integrated during construction.

- Permeable Paving: Using permeable pavers or porous concrete allows water to seep into the ground, reducing runoff. This environmentally friendly option minimizes water buildup.

- Catch Basins and Gutters: In situations with significant runoff, these collect water and channel it away from the hardscape.

Each project requires a tailored drainage plan considering the site’s specific conditions, soil type, and rainfall patterns. The selection of materials and the design of the drainage system must work together seamlessly to ensure long-term functionality.

Q 7. Explain your knowledge of different types of mortar and their applications.

Mortar is a critical component in masonry construction, and its type significantly affects the project’s durability and performance. Different types are categorized by their compressive strength and water retention properties:

- Type N (Normal): A general-purpose mortar suitable for most applications, offering a balance of strength and workability.

- Type S (High Strength): Used for load-bearing walls and applications requiring higher strength than Type N.

- Type M (High Strength): Even stronger than Type S, suitable for severe weather conditions and heavy loads.

- Type O (Low Strength): Used primarily for non-load-bearing applications, such as interior veneer.

The choice of mortar type is influenced by factors such as the strength requirements, the exposure to the elements, and the specific masonry material used. For instance, Type M mortar might be selected for a retaining wall that’s subjected to significant lateral pressure, while Type N would suffice for an interior brick wall. Understanding these nuances is essential for creating a durable and long-lasting structure.

Q 8. What are the safety precautions you take when working with masonry materials?

Safety is paramount in masonry. My approach is proactive, not reactive. It begins with a thorough site assessment identifying potential hazards like uneven terrain, overhead obstructions, and the presence of underground utilities. Then, I ensure everyone on the team is equipped with the appropriate Personal Protective Equipment (PPE), including safety glasses, hard hats, gloves, steel-toed boots, and dust masks, especially when working with materials like cement dust. We use proper lifting techniques to avoid injuries from heavy materials, employing lifting aids where necessary. I emphasize regular safety briefings to refresh our knowledge of safe working practices. For example, before starting any cutting operation, we always ensure the area is clear and the cutting tool is properly maintained. Furthermore, we have established emergency procedures and know the location of the nearest first-aid kit and how to contact emergency services. Finally, proper storage of materials prevents accidents caused by toppling or shifting items.

Q 9. How do you read and interpret construction plans for hardscape projects?

Reading construction plans for hardscape projects is like reading a map for a treasure hunt. The detailed drawings represent the ‘treasure’ – our final hardscape design. I start by carefully reviewing the overall site plan, noting the scale, north direction, and existing features. Then, I move to the detailed drawings, examining dimensions, elevations, materials specified (like brick type, paver style, concrete mix design), and locations for drainage, retaining walls, and other structural elements. I pay close attention to the specifications for materials – their size, color, and installation methods. For example, if the plan calls for a specific type of paving stone, I verify its availability and order it in advance. I also cross-reference different drawings to ensure consistency, checking that details like wall heights and paving patterns align seamlessly. Section drawings are invaluable to understand underground construction, drainage systems, and foundation details. Finally, I check for notes and specifications provided by the architect or engineer, as these contain critical information about materials, tolerances, and special considerations.

Q 10. Describe your experience with estimating materials and labor costs for hardscape projects.

Accurate cost estimation is crucial for successful project bidding and management. My approach is systematic. First, I meticulously measure the site and quantify the required materials using the construction plans as a guide. I then consult current pricing from reliable suppliers for various materials like concrete, bricks, pavers, aggregates, and retaining wall components. I include a contingency buffer for potential material wastage and price fluctuations. For labor costs, I consider the complexity of the project, the number of workers needed, and their hourly rates. For example, installing complex curved paving patterns will naturally require more labor than a simple rectangular design. I also account for potential delays due to weather conditions or material delivery issues. I use specialized software to manage estimates and automatically generates a detailed breakdown. Finally, I review the estimate thoroughly before presenting it to the client, ensuring all aspects are transparent and justifiable.

Q 11. How do you manage a team of workers on a hardscape project?

Managing a team effectively involves clear communication, delegation, and fostering a safe and productive work environment. Before starting a project, I hold a pre-construction meeting where I clearly outline individual roles and responsibilities, ensuring everyone understands their tasks and deadlines. I regularly monitor progress, offering guidance and addressing challenges proactively. Open communication is key, enabling team members to voice concerns and contribute ideas. I encourage teamwork and collaboration, often assigning tasks requiring combined skills and expertise. For example, a complex retaining wall project may involve a mason, a skilled laborer, and a helper working collaboratively. I implement regular safety checks to ensure adherence to established protocols. I actively address conflicts in a constructive manner, focusing on solutions rather than blame. By creating a positive and supportive atmosphere, I motivate my team and achieve efficient project completion.

Q 12. What are your preferred methods for cutting and shaping masonry materials?

Cutting and shaping masonry materials requires precision and the right tools. My preferred methods depend on the material and the desired shape. For bricks, I typically use a brick chisel and mallet for clean breaks along the mortar lines. For precise cuts, I might use a masonry saw, which is particularly useful for creating intricate patterns. For pavers, a wet saw is crucial to ensure clean cuts and prevent chipping. Cutting concrete can be done using a variety of tools, from diamond blades in hand-held saws for smaller jobs to large walk-behind saws for extensive cuts. For more intricate shapes or curved cuts, I utilize angle grinders with diamond cutting discs, always employing appropriate safety measures. The selection of the right tool is driven by the specific material hardness and the complexity of the cut required. Regular maintenance of the tools, such as blade sharpening, is crucial to achieve clean, accurate cuts and maintain the tool’s longevity. This ensures high-quality finishes and efficient project execution.

Q 13. How do you ensure the longevity and durability of your hardscape installations?

Ensuring longevity and durability in hardscape installations involves meticulous planning and execution. Proper site preparation is fundamental; this includes compacting the base material to prevent settling and using a suitable drainage system to manage water runoff. Selecting high-quality, weather-resistant materials is key. For example, I specify frost-resistant paving stones in areas prone to freezing temperatures. Proper installation techniques are paramount. Correctly mixing concrete to the specified strength and curing it adequately avoids cracks and premature degradation. For retaining walls, I ensure proper geotechnical engineering considerations are incorporated to prevent structural failure. Regular maintenance plays a crucial role, including cleaning debris, repairing minor cracks promptly, and re-sealing joints if needed. By considering these factors, I ensure my hardscape installations stand the test of time, providing both aesthetic appeal and functional reliability for years to come.

Q 14. Describe your experience with different types of concrete finishes.

My experience encompasses various concrete finishes, each offering a unique aesthetic and functional quality.

- Smooth Finish: This is achieved through troweling and produces a sleek, modern look, commonly found in patios and driveways.

- Broomed Finish: This textured finish, created by brushing the concrete surface with a broom, provides good slip resistance, ideal for walkways and pool decks.

- Stamped Concrete: Using specialized stamps, diverse patterns like brick, stone, or wood can be imprinted onto the fresh concrete, adding a customized and visually appealing finish. This can create the look of expensive materials at a more affordable cost.

- Exposed Aggregate Finish: This technique involves washing away the cement paste from the surface, revealing the decorative aggregate within, creating a unique textured and durable finish. This finish is very durable and requires little maintenance.

- Stained Concrete: Acid stains penetrate the concrete surface, producing vibrant, translucent colors and enhancing the natural texture of the concrete. This creates a rich and natural look.

Q 15. How do you deal with unexpected challenges or problems during a project?

Unexpected challenges are inevitable in hardscaping. My approach is methodical and proactive. First, I carefully assess the situation, identifying the root cause of the problem. This often involves consulting blueprints, site surveys, and even engaging with the client to understand their initial vision and any changes in requirements. Then, I brainstorm potential solutions, considering factors like cost, time constraints, and the overall project aesthetic. For example, I once encountered unexpected bedrock during a patio excavation. Instead of forcing the issue, I adjusted the design slightly, minimizing the amount of bedrock removal needed and opted for a slightly elevated design which highlighted the rock face instead of trying to hide it. This approach maintained the project timeline and enhanced the final product’s unique character. Finally, I communicate the changes clearly to the client, obtaining their approval before proceeding. Thorough documentation throughout this process ensures accountability and transparency.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What software or tools do you use for design or project management?

For design, I primarily use AutoCAD and SketchUp. AutoCAD provides precision for detailed drawings, essential for complex hardscapes, while SketchUp offers a user-friendly 3D modeling environment, allowing clients to visualize the final product effectively. I also utilize Lumion for creating realistic renderings to showcase the project’s aesthetic appeal. For project management, I rely heavily on software like Asana or Monday.com to track tasks, deadlines, and materials. These tools streamline communication with subcontractors and ensure timely project completion. We use these tools to document all aspects of the project, from initial concept design to final completion.

Q 17. Explain your understanding of building codes and regulations related to hardscaping.

Understanding and adhering to building codes and regulations is paramount. This includes local codes pertaining to drainage, foundation depth, material specifications, and ADA (Americans with Disabilities Act) compliance for accessibility. For example, the International Building Code (IBC) often dictates minimum slope requirements for patios and walkways to prevent water accumulation. I meticulously review all relevant codes before commencing any project, ensuring all aspects of the design and construction comply with regulations. This involves obtaining necessary permits and regularly updating my knowledge of the latest code revisions. Non-compliance can lead to costly delays, project shutdowns, and even legal repercussions. Therefore, I take this aspect of my work very seriously.

Q 18. Describe your experience with different types of foundation preparation for hardscape installations.

Foundation preparation varies significantly depending on the hardscape element and soil conditions. For patios and walkways, I often employ a compacted gravel base, typically 4-6 inches deep, ensuring proper drainage and load support. For retaining walls, a more substantial foundation might be necessary, often involving excavation and the installation of reinforced concrete footings. In cases of expansive clay soils, which can cause upheaval and cracking, specialized techniques like geogrid reinforcement are utilized to stabilize the base. Each project’s foundation is tailored to its specific needs, considering factors like anticipated loads, soil type, and local climate. This thorough preparation is critical to preventing long-term issues like settling, cracking, or shifting.

Q 19. How do you ensure the proper compaction of the base material for paving projects?

Proper compaction of base materials is crucial for long-lasting hardscapes. I use a combination of methods to achieve optimal compaction. This typically involves layering the base material (gravel, crushed stone, etc.), then using a plate compactor to mechanically compact each layer. The compaction level is checked regularly using a density gauge or Proctor test to guarantee that each layer meets the required specifications. For larger projects, I may use a vibratory roller to enhance compaction efficiency. Insufficient compaction leads to settling and instability over time, causing uneven surfaces, cracking, and potentially structural failure. My meticulous approach to compaction ensures a durable and stable foundation for any hardscape installation.

Q 20. What are some common issues you encounter in hardscape projects, and how do you solve them?

Common issues include poor drainage leading to erosion or water damage, improper base preparation resulting in settling or cracking, and the use of substandard materials leading to premature deterioration. Solutions involve addressing drainage challenges through the implementation of proper grading, drainage systems, and the use of permeable paving materials. I troubleshoot settling by excavating and recompacting the base material as needed. Substandard materials are avoided through rigorous quality control and the selection of high-quality products. Proactive measures, such as thorough site assessment, diligent planning, and the use of appropriate materials, greatly minimize the occurrence of these problems. Open communication with clients and careful documentation allows for effective problem-solving throughout the project lifecycle.

Q 21. What is your experience with different types of jointing techniques for masonry work?

My experience encompasses various jointing techniques for masonry, including traditional mortar joints, which require precise mixing and application, and more contemporary methods such as dry-stacking, which creates a more rustic appearance. I’m also proficient in using different types of mortar, selecting the appropriate type based on the masonry material and project requirements. For example, a lime-based mortar offers flexibility and superior weathering resistance for historic structures. Proper jointing ensures structural integrity, water resistance, and enhances the aesthetic appeal of the finished work. I meticulously consider factors such as joint size, shape, and tooling to achieve the desired visual effect while maintaining structural soundness.

Q 22. Describe your knowledge of different types of sealants and their applications in hardscaping.

Choosing the right sealant is crucial for the longevity and aesthetic appeal of any hardscape project. Different sealants offer varying levels of protection against water damage, staining, and weathering. The selection depends heavily on the material being sealed and the climate.

- Acrylic Sealers: These are common, water-based sealers that offer good protection against water damage and UV degradation. They are relatively easy to apply and are suitable for most hardscape materials like concrete, brick, and natural stone. Think of them as a breathable raincoat for your paving stones.

- Silicone Sealers: Offering superior water resistance, silicone sealers are excellent for areas with high moisture or freeze-thaw cycles. They are durable but can be more challenging to apply and require careful surface preparation. They’re like a waterproof barrier against the elements.

- Epoxy Sealers: These are two-part sealants that cure to a very hard, durable finish. They’re ideal for high-traffic areas or applications requiring extreme durability, but they can be more expensive and require specialized application techniques. They’re the heavy-duty, industrial-strength option.

- Penetrating Sealers: Unlike surface sealers, these sealants seep into the material, protecting it from within. They’re ideal for porous materials like pavers and natural stone, offering long-term protection without altering the appearance significantly. Imagine it like giving the stone a deep conditioning treatment.

For example, I recently used a penetrating sealer on a flagstone patio in a high-rain area. The sealer allowed the stone to breathe, preventing moisture buildup and potential frost damage, while enhancing its natural beauty. On another project involving a high-traffic concrete driveway, I opted for a durable epoxy sealer to ensure long-lasting protection against cracking and staining.

Q 23. How do you maintain quality control throughout a hardscape project?

Maintaining quality control is paramount in hardscaping. It starts with meticulous planning and extends throughout every phase of the project. I employ a multi-pronged approach:

- Detailed Plans and Specifications: I ensure that the project plans are clear, comprehensive, and accurately reflect the client’s vision and site conditions. This includes material specifications, installation techniques, and quality standards.

- Material Selection and Inspection: Careful selection of high-quality materials is critical. Before installation, I inspect all materials for defects, ensuring they meet the specified requirements. I might, for example, reject a batch of pavers with inconsistent color or size.

- Regular Site Inspections: Frequent on-site inspections are crucial to identify and address any issues immediately. I document each step of the process, including photos and notes, allowing me to track progress and identify potential problems early on.

- Experienced Crew and Training: I work with a skilled and experienced team who understand the importance of precision and quality. Regular training ensures everyone is up-to-date on best practices and safety procedures.

- Client Communication and Feedback: Open communication with the client is vital. I provide regular updates, address concerns promptly, and actively solicit feedback throughout the project. This allows for course correction and ensures the final product meets client expectations.

For instance, on a recent retaining wall project, regular inspections allowed me to detect a slight misalignment early on. Addressing it promptly prevented further complications and ensured the structural integrity of the wall.

Q 24. Explain your understanding of frost heave and how it impacts hardscape design.

Frost heave is the upward movement of soil caused by the freezing and thawing of water. It’s a significant concern in hardscaping, as it can cause damage to pavements, walls, and other structures. Water seeps into the soil, freezes and expands, creating pressure that lifts the soil and anything resting on it. This can lead to cracking, heaving, and ultimately, structural failure.

To mitigate frost heave, proper site preparation is essential. This includes:

- Proper Drainage: Implementing effective drainage systems is crucial to prevent water from accumulating in the soil. This can include grading, the use of gravel base layers, and installing drainage pipes.

- Compaction: Thoroughly compacting the base layer reduces soil permeability, preventing water from penetrating and causing frost heave.

- Frost-Proofing Materials: Choosing frost-resistant materials is also important. Some stones and concrete mixes are specifically designed to withstand freeze-thaw cycles.

- Joint Spacing: Allowing sufficient space between pavers or other hardscape elements allows for some movement without causing damage.

In colder climates, neglecting these steps can lead to costly repairs, so I always incorporate frost-proofing measures into my designs. I once saw a beautiful patio completely destroyed by frost heave because the installer hadn’t considered proper drainage. That’s a costly lesson learned.

Q 25. What is your experience with working with different types of stone and their unique properties?

Working with various stones is a core part of my expertise. Each stone possesses unique properties influencing its suitability for different applications:

- Granite: Known for its exceptional durability, hardness, and resistance to weathering, granite is ideal for high-traffic areas like driveways and patios. However, it can be expensive and difficult to work with.

- Limestone: A more porous stone, limestone is softer than granite but offers a beautiful aesthetic. It requires sealing to protect it from staining and water damage. It’s a good choice for walkways or features where its softer nature is less of a concern.

- Bluestone: With its distinct bluish-gray hue and natural cleft texture, bluestone is a popular choice for patios and walkways. Its durability and slip resistance make it suitable for various climates and applications.

- Flagstone: This natural stone comes in various colors and sizes, offering a rustic and organic look. Its irregular shape and thickness require careful planning and installation.

Understanding each stone’s properties – its hardness, porosity, and resistance to weathering – is crucial for selecting the right material for the project and implementing the appropriate installation techniques. For example, I recently used granite for a driveway because of its superior durability, and I used limestone for a garden wall, mindful of the need for proper sealing to maintain its beauty.

Q 26. How do you handle repairs or maintenance requests for completed hardscape projects?

Handling repairs and maintenance requests efficiently is essential for client satisfaction and maintaining a strong reputation. My process involves:

- Prompt Response: I respond to all requests promptly, usually within 24-48 hours.

- On-Site Assessment: I conduct a thorough on-site assessment to determine the cause of the problem and the extent of the repairs needed.

- Detailed Quotation: I provide a detailed quotation outlining the materials, labor, and timeline for the repair work. This avoids any surprises for the client.

- Efficient Repair: I schedule and complete the repairs efficiently and effectively, using high-quality materials and techniques to ensure a long-lasting solution.

- Follow-up: I always follow up with the client after the repairs are completed to ensure they are satisfied with the work. This feedback loop helps identify any potential systemic issues.

For example, a recent repair involved replacing a few damaged pavers on a patio. By quickly assessing the damage, providing a clear quote, and performing the repair efficiently, I kept disruption to a minimum and ensured the client was happy with the outcome.

Q 27. Explain your knowledge of sustainable and eco-friendly hardscaping practices.

Sustainable and eco-friendly hardscaping practices are increasingly important. My approach integrates several key elements:

- Permeable Paving: Using permeable pavers or gravel allows rainwater to seep into the ground, reducing runoff and replenishing groundwater supplies. This helps to mitigate the impact of urban development on natural water cycles.

- Locally Sourced Materials: Whenever possible, I source materials locally to reduce transportation costs and emissions. This minimizes the environmental impact of material transport.

- Reclaimed Materials: Incorporating reclaimed materials, like recycled bricks or stones, reduces the demand for newly manufactured materials and conserves natural resources. This adds character and reduces the environmental footprint.

- Reduced Waste: I meticulously plan and execute projects to minimize waste generation. Leftover materials are either reused or responsibly disposed of.

- Water Conservation: Designing hardscapes that minimize water usage through efficient irrigation systems and drought-tolerant plants is key to reducing water consumption.

Recently, I worked on a project where we used permeable pavers and reclaimed bricks, resulting in a beautiful and environmentally conscious hardscape that effectively manages rainwater and reduces the overall environmental impact.

Q 28. What are your career goals related to hardscaping and masonry?

My career goals center around continued growth in the hardscaping and masonry field. I aim to deepen my expertise in sustainable design and construction techniques, integrating green building principles into every project. I also aspire to mentor and train the next generation of hardscape professionals, sharing my knowledge and experience to promote high standards of workmanship and environmental responsibility. Ultimately, I envision establishing a respected firm known for its commitment to creating beautiful, functional, and sustainable outdoor spaces.

Key Topics to Learn for Your Hardscaping and Masonry Interview

- Design & Planning: Understanding client briefs, site surveys, material selection, and creating detailed project plans. Consider the practical application of CAD software or sketching to visualize projects.

- Construction Techniques: Mastering various masonry techniques (bricklaying, blocklaying, stonework), hardscaping installations (patios, walkways, retaining walls), and knowledge of different materials and their properties (e.g., concrete, pavers, natural stone).

- Material Handling & Equipment: Safe and efficient use of tools and equipment, including power tools, hand tools, and machinery specific to hardscaping and masonry. Be prepared to discuss safety protocols and best practices.

- Estimating & Budgeting: Accurately calculating material quantities, labor costs, and overall project budgets. Demonstrate an understanding of profit margins and cost control.

- Problem-Solving & Troubleshooting: Addressing common challenges during construction, such as uneven surfaces, material defects, and weather-related issues. Highlight your ability to adapt and find solutions.

- Code Compliance & Regulations: Familiarity with building codes, safety standards, and permitting processes related to hardscaping and masonry projects. This demonstrates professionalism and responsibility.

- Project Management & Teamwork: Experience managing timelines, coordinating with subcontractors, and working effectively within a team. Discuss your approach to collaboration and leadership.

Next Steps

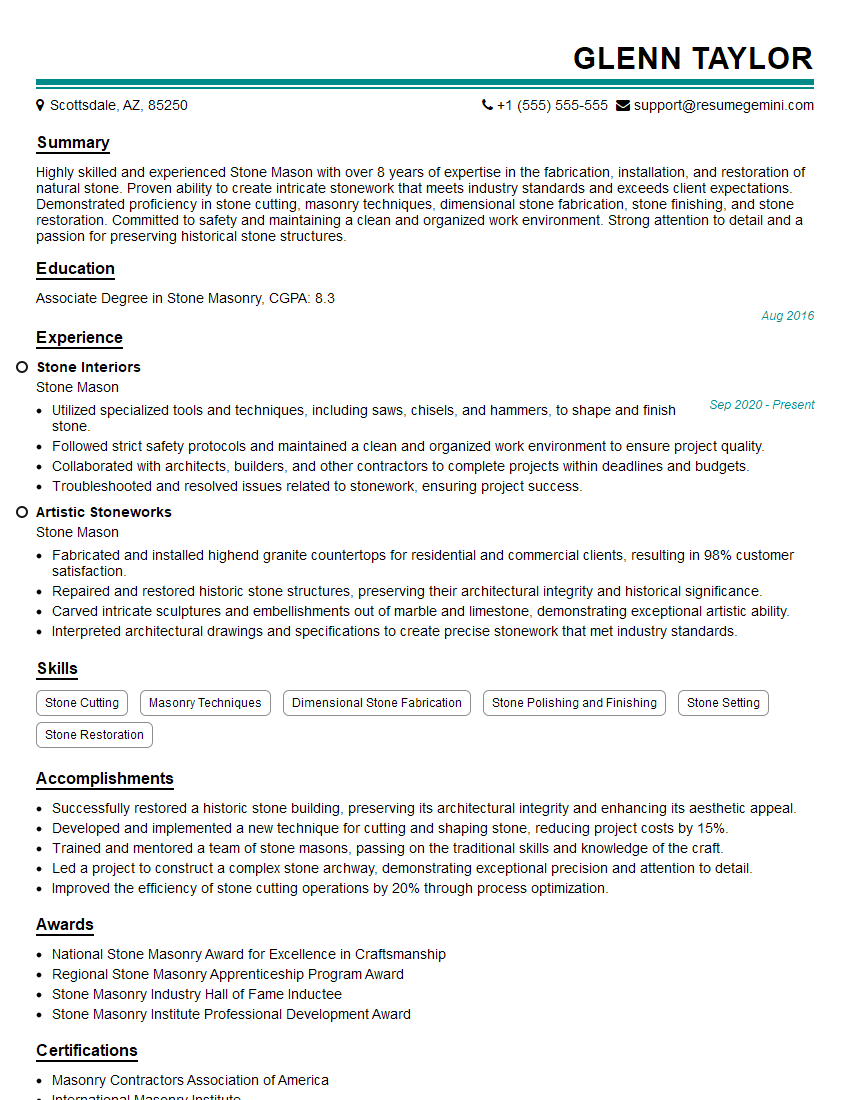

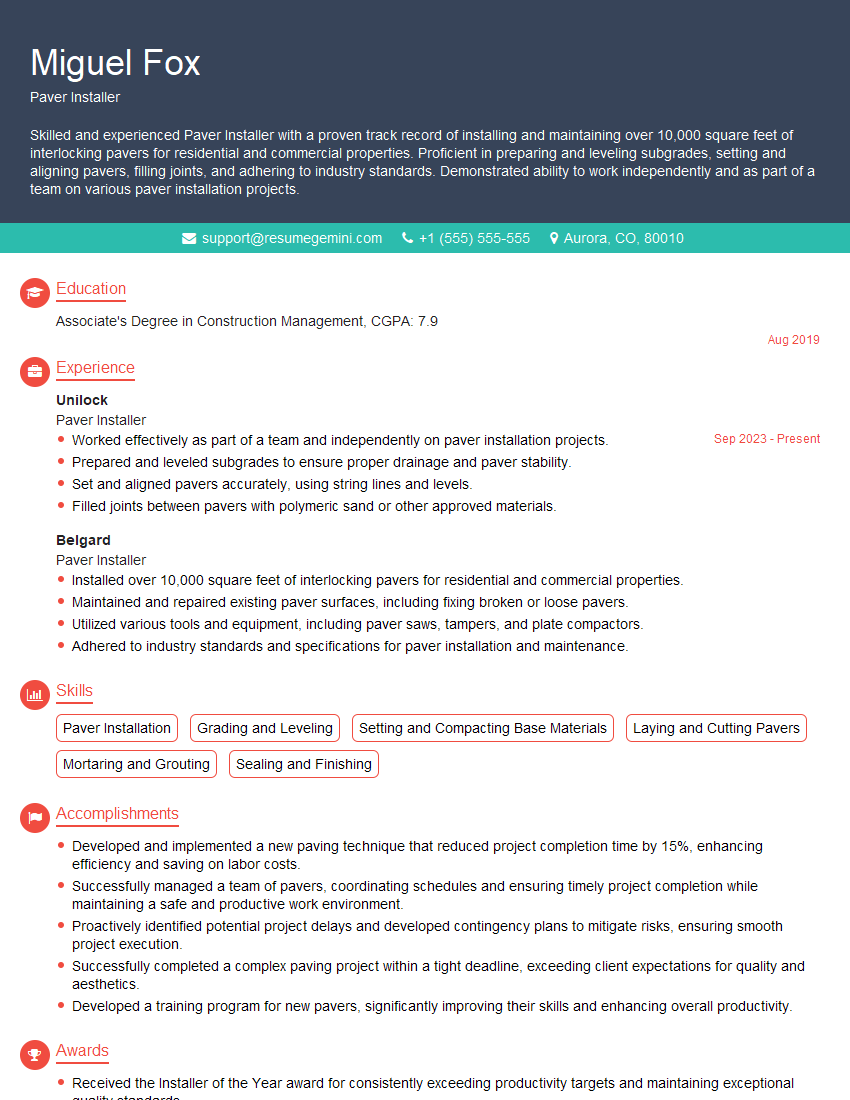

Mastering hardscaping and masonry opens doors to a rewarding career with diverse opportunities for growth, from independent contracting to working with established landscaping firms. To maximize your job prospects, a strong and ATS-friendly resume is crucial. ResumeGemini can help you craft a professional resume that highlights your skills and experience effectively. We provide examples of resumes tailored specifically to the hardscaping and masonry industry to guide you. Take the next step toward your dream career – build a powerful resume with ResumeGemini today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

hello,

Our consultant firm based in the USA and our client are interested in your products.

Could you provide your company brochure and respond from your official email id (if different from the current in use), so i can send you the client’s requirement.

Payment before production.

I await your answer.

Regards,

MrSmith

hello,

Our consultant firm based in the USA and our client are interested in your products.

Could you provide your company brochure and respond from your official email id (if different from the current in use), so i can send you the client’s requirement.

Payment before production.

I await your answer.

Regards,

MrSmith

These apartments are so amazing, posting them online would break the algorithm.

https://bit.ly/Lovely2BedsApartmentHudsonYards

Reach out at [email protected] and let’s get started!

Take a look at this stunning 2-bedroom apartment perfectly situated NYC’s coveted Hudson Yards!

https://bit.ly/Lovely2BedsApartmentHudsonYards

Live Rent Free!

https://bit.ly/LiveRentFREE

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?