Unlock your full potential by mastering the most common Heavy Equipment Handling and Control interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Heavy Equipment Handling and Control Interview

Q 1. Describe your experience operating excavators.

My experience with excavators spans over 10 years, encompassing a wide range of projects from residential construction to large-scale infrastructure developments. I’m proficient in operating various excavator models, from compact machines ideal for tight spaces to larger, more powerful excavators used for heavy digging and lifting. This includes experience with both hydraulic and cable-operated excavators. I’ve consistently demonstrated precision and efficiency in tasks such as trenching, excavation, demolition, and material handling. For example, on a recent road construction project, I successfully excavated over 500 cubic meters of earth within the project timeline, maintaining consistent accuracy in trench depth and width, minimizing material waste, and ensuring the safety of the worksite.

My expertise also extends to understanding the nuances of different excavator types – including long-reach excavators for deep excavations, and those with specialized attachments for specific tasks. I am confident in my ability to adapt my operating techniques to the specific needs of each project and machine.

Q 2. What safety protocols do you follow when operating heavy equipment?

Safety is paramount in heavy equipment operation. My safety protocols are comprehensive and cover every aspect of the job. Before starting any work, I always conduct a thorough pre-operational inspection, checking fluid levels, tire pressure, and the overall condition of the machine. I also ensure that all safety devices, such as seatbelts, emergency stops, and warning lights, are functioning correctly. During operation, I maintain a safe distance from other personnel and equipment, adhering strictly to designated work zones and signaling procedures. I consistently use audible warnings to alert others of my movements.

Furthermore, I am vigilant about maintaining situational awareness, adapting my operating techniques to changing conditions, such as limited visibility or uneven terrain. I regularly review and update my understanding of relevant safety regulations and best practices. In short, my approach to safety is proactive and consistent, reflecting a commitment to both personal safety and the safety of others on the worksite.

Q 3. Explain your experience with preventative maintenance on heavy machinery.

Preventative maintenance is crucial for ensuring the longevity and optimal performance of heavy machinery. My experience includes performing daily checks, such as inspecting fluid levels, checking for leaks, and lubricating moving parts. I’m also skilled in more advanced maintenance tasks, such as changing filters, replacing worn components, and conducting regular inspections of critical systems. I meticulously record all maintenance activities in logs, ensuring that service schedules are adhered to and any issues are promptly addressed. This proactive approach minimizes downtime, extends the lifespan of equipment, and prevents costly repairs. For instance, I detected a minor hydraulic leak during a routine inspection, preventing it from escalating into a major system failure that could have resulted in significant downtime and repair costs.

Moreover, I understand the importance of using only manufacturer-approved parts and fluids, ensuring compatibility and avoiding potential damage to the machine. My maintenance approach is guided by manufacturer’s recommendations and best industry practices.

Q 4. How do you handle challenging terrain or weather conditions during operation?

Operating heavy equipment in challenging terrain or weather conditions requires a combination of skill, experience, and caution. When working on uneven or unstable ground, I adjust my operating speed and technique to maintain stability, avoiding sudden movements or excessive loads. I use appropriate counterweights and adjust the machine’s stance to ensure balance. In adverse weather, such as rain or snow, I reduce my speed to account for reduced traction and visibility. I also use additional lighting or safety measures to compensate for reduced visibility.

For extreme weather conditions, such as heavy storms, I prioritize safety by halting operations and securing the equipment. I am always prepared with appropriate clothing and safety gear to protect myself from the elements and ensure my safety. Risk assessment is key – I evaluate the conditions before starting work and make informed decisions about whether it’s safe to proceed. My experience allows me to adapt to a wide range of challenging conditions safely and efficiently.

Q 5. Describe a time you encountered a malfunctioning piece of equipment. How did you respond?

During a large-scale excavation project, the hydraulic system on my excavator malfunctioned, resulting in a complete loss of digging power. My immediate response was to safely bring the machine to a complete stop, ensuring the safety of myself and any nearby personnel. I then conducted a thorough visual inspection, checking for obvious leaks or damage. Following established protocols, I contacted the site supervisor and the equipment mechanic, detailing the nature of the malfunction.

While waiting for the mechanic, I reviewed the excavator’s operating manual and troubleshooting guide. The mechanic determined that the problem stemmed from a faulty hydraulic pump. The repair was swift and efficient, minimizing downtime and avoiding further disruption to the project schedule. The experience highlighted the importance of quick thinking, effective communication, and a thorough understanding of both the equipment and safety protocols.

Q 6. What are the different types of excavator attachments and their uses?

Excavators utilize a variety of attachments depending on the task at hand. Common attachments include:

- Buckets: These are the most common attachment, used for digging, loading, and moving materials. Different bucket types exist, such as general-purpose buckets, narrow buckets for trenching, and rock buckets for tougher materials.

- Rakes: Used for leveling and grading, these attachments are crucial for land preparation and finishing work.

- Hydraulic Hammers: Powerful tools used for breaking up concrete, rock, and other hard materials.

- Rippers: These are used for breaking up compacted soil and rock.

- Grapples: Designed for handling logs, scrap metal, or other bulky materials.

- Augers: Used for drilling holes for posts or foundations.

- Thumbs: Added to buckets, they improve material handling and allow for more precise control.

The selection of the appropriate attachment is crucial for maximizing efficiency and safety. The wrong attachment could damage the excavator or be ineffective for the task. I have experience utilizing all of these attachments and can readily choose the right one for a given job.

Q 7. Explain your understanding of load capacity and stability in heavy equipment operation.

Understanding load capacity and stability is critical for safe and efficient operation of heavy equipment. Load capacity refers to the maximum weight an excavator can lift or carry without compromising its structural integrity. Exceeding this limit can lead to equipment failure, damage, and potential injury. Stability, on the other hand, refers to the excavator’s ability to remain upright and balanced during operation. Factors affecting stability include ground conditions, load distribution, and the excavator’s position.

I always consult the excavator’s specifications to determine its load capacity before undertaking any lifting or carrying task. I carefully consider the weight of the material and ensure it is well within the safe working load limit (SWL). I also pay close attention to the stability of the machine, avoiding working on slopes or unstable ground, unless appropriate safety measures are in place. When lifting heavy loads, I perform smooth and controlled movements, minimizing sudden changes in direction or speed. Maintaining a proper stance and distributing the load evenly are crucial for maintaining stability. Ignoring these factors could lead to rollovers or other serious incidents. My approach is always cautious and methodical, prioritizing safety and efficiency.

Q 8. How do you ensure the safe transportation and loading/unloading of heavy equipment?

Safe transportation and loading/unloading of heavy equipment hinges on meticulous planning and execution. It’s not just about moving the machine; it’s about ensuring the safety of personnel, the equipment itself, and the surrounding environment.

- Pre-transport Inspection: Before any movement, a thorough inspection is crucial. This includes checking tire pressure, fluid levels, securing any loose parts, and verifying the functionality of all safety mechanisms (lights, brakes, etc.). Think of it like pre-flight checks for an airplane – no detail is too small.

- Route Planning: The route must be carefully assessed for obstacles, weight limits, overhead clearances, and potential hazards. This often involves consulting maps, considering bridge capacities, and potentially contacting local authorities for permits. Imagine trying to navigate a giant Lego brick through a city – careful planning is essential.

- Securement Methods: Proper securing is paramount. This involves using appropriate tie-down straps, chains, and blocks to prevent shifting during transport. The number and placement of these restraints depend on the equipment’s weight, size, and the type of transport (trailer, lowboy, etc.). Think of it like packing fragile items for a move – you wouldn’t just throw them in a box!

- Loading/Unloading Procedures: Loading and unloading should be conducted using appropriate lifting equipment (cranes, forklifts) and trained personnel. Using checklists and following established safety protocols is essential. Clear communication between the crane operator and ground crew is non-negotiable to prevent accidents. This is akin to a well-choreographed ballet – everyone needs to know their part and execute it flawlessly.

Ignoring any of these steps can lead to accidents, equipment damage, and potentially serious injuries.

Q 9. Describe your experience with GPS-guided heavy equipment.

My experience with GPS-guided heavy equipment is extensive. I’ve worked with systems that provide real-time location data, allowing for precise machine control and increased efficiency. These systems are particularly beneficial in large-scale projects, such as road construction or mining operations.

- Enhanced Accuracy: GPS guidance dramatically improves the accuracy of tasks like grading, excavating, and land leveling. Instead of relying solely on operator skill and visual estimation, the system guides the equipment, minimizing errors and material waste.

- Increased Productivity: By automating certain aspects of the operation, GPS systems increase overall productivity. Operators can focus more on managing the overall process rather than constantly making small adjustments.

- Improved Safety: Reduced operator workload and increased accuracy contribute to improved safety on the job site. Fewer errors mean fewer potential accidents.

- Data Collection and Analysis: Modern GPS systems collect extensive data on equipment usage and performance, which can be used for analysis, optimizing future operations, and improving overall efficiency. This data-driven approach allows us to fine-tune processes and improve overall outcomes.

For example, in a recent road construction project, GPS-guided graders allowed us to achieve precise grade elevations within a fraction of an inch, resulting in significant time and cost savings.

Q 10. What are your skills in troubleshooting mechanical issues on heavy equipment?

Troubleshooting mechanical issues on heavy equipment demands a systematic approach combining practical experience, diagnostic skills, and a good understanding of hydraulics, engines, and electrical systems. My approach involves:

- Systematic Diagnosis: I start by gathering information: what symptoms are present? When did they start? What were the operating conditions at the time? This is like being a detective, following clues to identify the root cause.

- Visual Inspection: A thorough visual inspection often reveals obvious issues like leaks, loose connections, or damaged components.

- Testing and Measurement: I use diagnostic tools like pressure gauges, multimeters, and diagnostic software to check various system parameters and identify malfunctions. This provides objective data to confirm suspicions.

- Component Replacement/Repair: Once the problem is identified, the necessary repairs or component replacements are carried out, adhering to all safety procedures and using OEM-approved parts whenever possible.

- Record Keeping: Detailed records of all troubleshooting steps, repairs made, and parts used are meticulously documented for future reference and maintenance scheduling.

For instance, recently I diagnosed a problem with a bulldozer’s hydraulic system that was causing a loss of power. By using a pressure gauge, I identified a leak in a hydraulic hose, which was quickly replaced, restoring the machine to full functionality.

Q 11. How do you maintain accurate records of equipment operation and maintenance?

Maintaining accurate records is crucial for efficient equipment management, preventative maintenance, and regulatory compliance. I utilize a combination of digital and physical methods to ensure accuracy and accessibility.

- Digital Logbooks: Software applications designed for heavy equipment management are used to track operational hours, fuel consumption, maintenance schedules, and repair history. This eliminates the need for manual record-keeping and provides easily accessible data for analysis.

- Pre- and Post-Operational Checklists: Before and after each use, I complete a detailed checklist to document the machine’s condition, identify any issues, and record the operational hours. This proactive approach helps catch small problems before they become major ones.

- Maintenance Schedules: A computerized maintenance management system (CMMS) helps track scheduled maintenance tasks, ensuring that all preventative maintenance activities are carried out on time. This helps prolong equipment life and minimizes downtime.

- Repair Records: Detailed records of all repairs, including parts used, labor costs, and dates, are maintained. This helps track repair costs, identify recurring issues, and inform future maintenance decisions.

This comprehensive approach allows for efficient tracking of equipment performance, identification of potential problems, and cost-effective management of resources.

Q 12. Describe your experience with different types of heavy equipment (e.g., bulldozers, loaders, graders).

My experience encompasses a wide range of heavy equipment, including bulldozers, loaders, excavators, graders, and backhoes. Each machine has unique operating characteristics and applications, requiring specialized skills and knowledge.

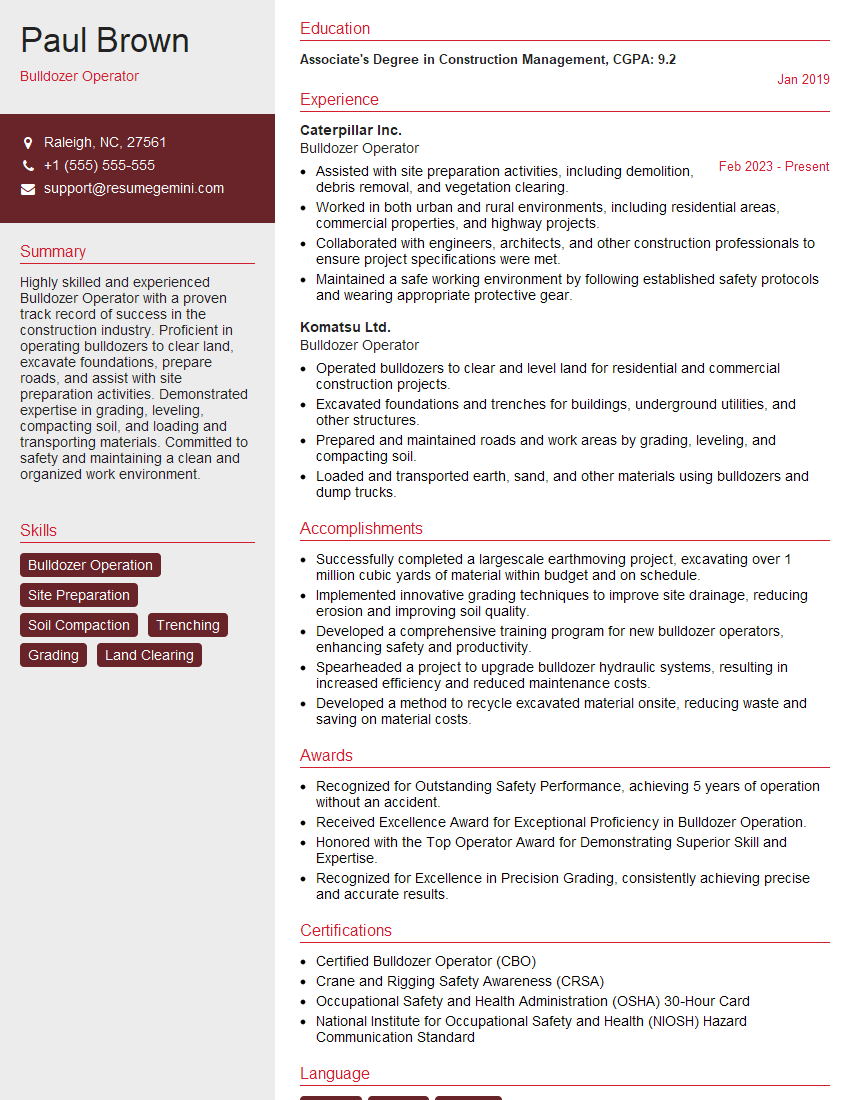

- Bulldozers: Proficient in using bulldozers for earthmoving, land clearing, and site preparation. Understanding blade types and their applications is essential for efficient and safe operation.

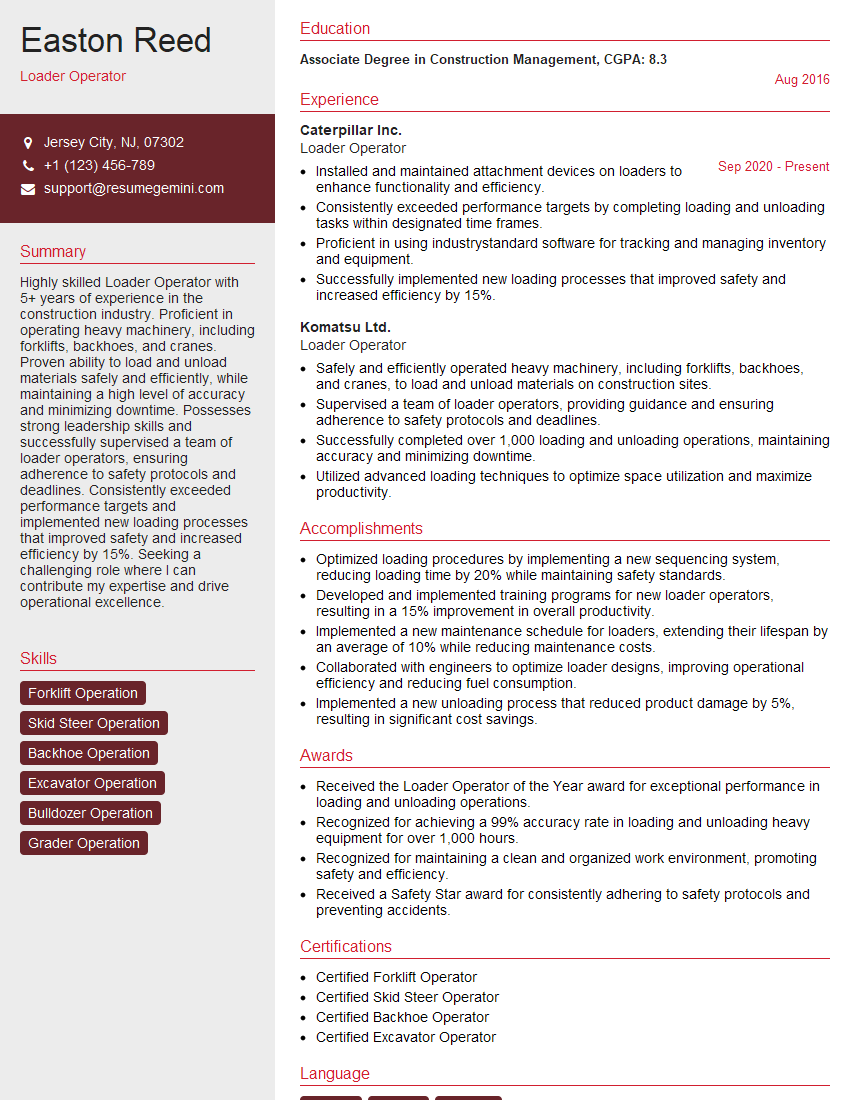

- Loaders: Experienced in operating loaders for material handling, loading trucks, and stockpiling. Knowledge of different bucket types and their uses is crucial for maximizing efficiency.

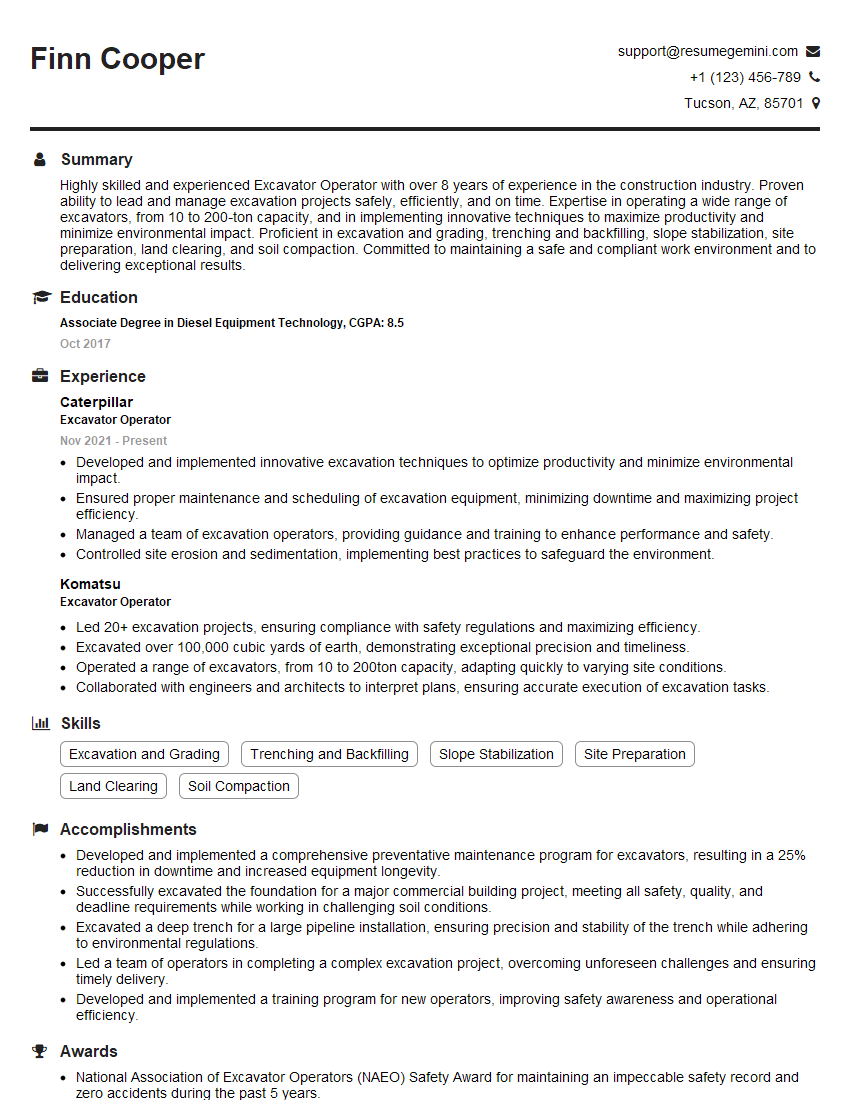

- Excavators: Skillful in operating excavators for excavation, trenching, and demolition. Understanding different attachment types and their application is essential for efficient and safe operation.

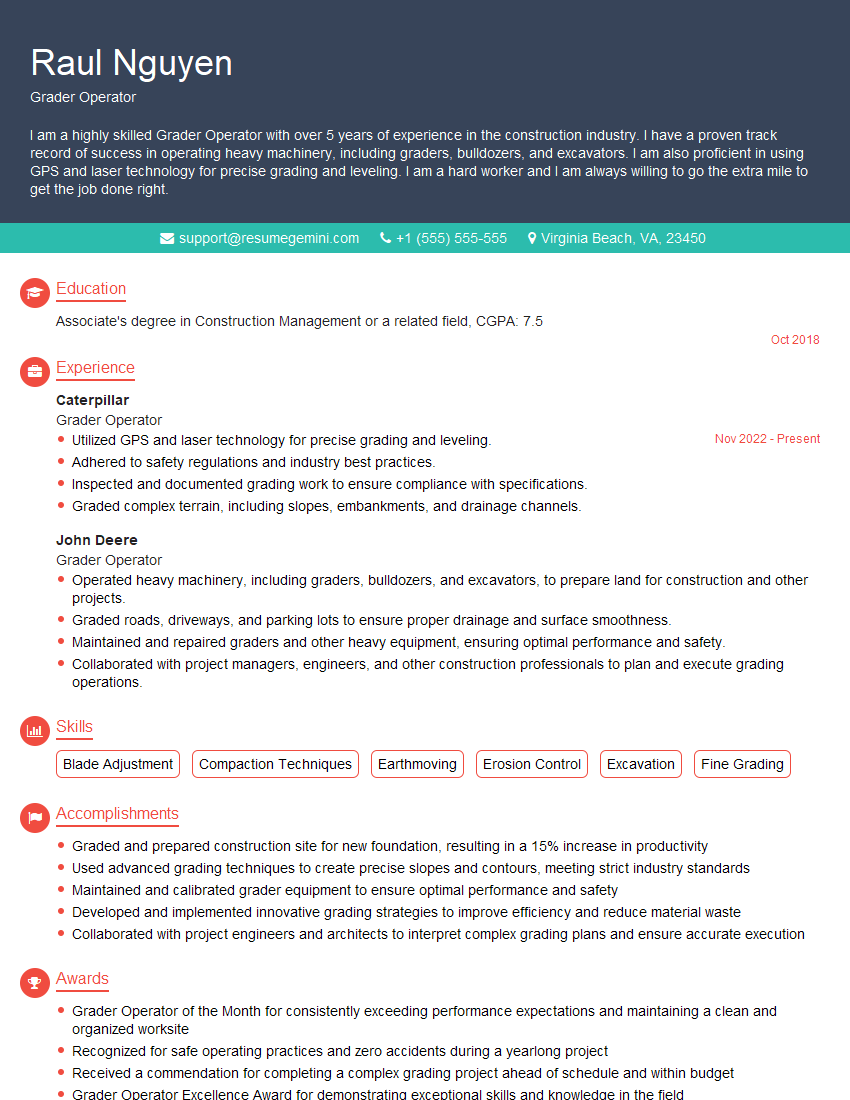

- Graders: Experienced in using graders for fine grading, road construction, and land leveling. Precision and understanding of blade angles are paramount for achieving accurate results.

- Backhoes: Proficient in operating backhoes for excavation, trenching, and material handling. Understanding the versatility of backhoes in various applications is crucial for effective utilization.

This broad experience allows me to adapt quickly to different projects and equipment requirements, making me a versatile and valuable asset.

Q 13. What are your experience and skills with different types of terrain?

Operating heavy equipment in diverse terrains requires adaptability and a thorough understanding of the limitations of both the machine and the environment. My experience spans various conditions, including:

- Level Ground: While seemingly simple, even level ground can present challenges like soft soil or uneven surfaces requiring careful maneuvering.

- Slopes and Hills: Operating on slopes necessitates additional safety precautions and awareness of potential instability. Proper techniques for maneuvering and maintaining stability are crucial to avoid rollovers or slides.

- Rough Terrain: Navigating rocky, uneven, or muddy surfaces requires skillful machine control and an understanding of the limitations of the equipment’s suspension and undercarriage.

- Confined Spaces: Operating in tight spaces requires precision and spatial awareness. Understanding the machine’s dimensions and limitations is crucial to avoid damage to the equipment or the surrounding environment.

- Adverse Weather Conditions: Operating in rain, snow, or extreme temperatures requires adjustments to operation techniques and increased vigilance for safety.

For example, during a project in a mountainous region, I utilized my experience with steep terrain to safely operate a bulldozer, ensuring the stability of the machine and the safety of the crew. Adaptability and preparedness are key to success in varied conditions.

Q 14. How do you manage your time effectively when operating multiple pieces of equipment?

Managing time effectively when operating multiple pieces of equipment requires careful planning, prioritization, and efficient execution. My approach involves:

- Prioritization: Identifying and prioritizing tasks based on urgency and importance. This may involve determining which tasks have the strictest deadlines or will cause the most significant delays if not completed promptly.

- Task Sequencing: Strategically sequencing tasks to minimize downtime and maximize efficiency. For example, I might schedule tasks that utilize the same equipment consecutively to avoid unnecessary transitions.

- Delegation (where applicable): If feasible, delegating tasks to other qualified operators can help improve overall efficiency and shorten project timelines. However, proper supervision and communication are paramount when delegating tasks.

- Regular Communication: Maintaining clear and constant communication with other crew members, supervisors, and support staff is crucial to coordinate efforts and identify any potential bottlenecks or unexpected delays.

- Utilization of Technology: Leveraging technology like GPS-guided systems and equipment monitoring software to track progress and identify areas for improvement in efficiency. This data-driven approach helps in identifying inefficiencies and optimizing future operations.

By implementing these strategies, I can ensure that all tasks are completed on time and within budget, minimizing delays and maximizing productivity, even when operating multiple pieces of heavy equipment simultaneously.

Q 15. Explain your knowledge of relevant safety regulations and standards.

My understanding of safety regulations and standards in heavy equipment handling is comprehensive and constantly updated. I am familiar with OSHA (Occupational Safety and Health Administration) regulations, specifically those pertaining to construction and heavy equipment operation. This includes, but is not limited to, regulations on personal protective equipment (PPE), machine guarding, lockout/tagout procedures, fall protection, and confined space entry. I also understand the importance of pre-operational inspections, ensuring all equipment is in safe working order before commencing any tasks. For example, I meticulously check tire pressure, hydraulic fluid levels, and the functionality of all safety features like emergency brakes and backup alarms before operating any machine. I’m also well-versed in site-specific safety rules and regulations, adapting my practices to meet the unique challenges of each job. Furthermore, I actively participate in safety training and toolbox talks to remain informed about best practices and emerging safety concerns. Compliance is paramount; a thorough understanding of safety regulations is not merely a requirement, but a cornerstone of my professional ethics.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you communicate effectively with your team and supervisors?

Effective communication is key in my role. I believe in clear, concise, and respectful communication with my team and supervisors. With my team, I use a combination of verbal and non-verbal cues. For instance, before commencing a complex lift, I will verbally confirm the lift plan with my spotter, ensuring everyone understands the procedure and potential hazards. Non-verbally, I use hand signals to guide the movement of the equipment. With supervisors, I proactively update them on project progress, highlight potential challenges, and clearly communicate any safety concerns. I always maintain open lines of communication and readily seek clarification if needed. For example, during a recent project involving a tight deadline, I communicated potential scheduling conflicts early on to my supervisor, allowing us to proactively adjust the timeline and avoid any delays. This proactive approach ensures a smoother workflow and strengthens teamwork.

Q 17. Describe your experience working in a team environment.

I thrive in team environments. My experience working on large-scale construction projects has instilled in me the importance of collaboration and mutual respect. I’ve worked as part of diverse teams, including crane operators, riggers, signalpersons, and engineers. On one particular project involving the erection of a large steel structure, our team’s success hinged on precise coordination. Effective communication, careful planning, and mutual respect ensured the smooth execution of each lift, resulting in the project’s completion ahead of schedule and without incidents. My role often involved mentoring junior operators, guiding them on safety procedures and best practices. This collaborative approach not only ensures project success but also fosters a positive and supportive work environment.

Q 18. How do you prioritize tasks and handle multiple responsibilities?

Prioritizing tasks and handling multiple responsibilities require a structured approach. I utilize a combination of techniques, including task prioritization matrices (like Eisenhower Matrix), daily planning, and regular progress reviews. I focus on identifying high-impact, urgent tasks first and schedule them accordingly. I break down larger tasks into smaller, manageable sub-tasks, which makes them less daunting and allows for better progress tracking. For example, if I have multiple projects involving different types of heavy equipment, I will prioritize those with the closest deadlines and the highest potential risks, ensuring efficient resource allocation and minimizing delays. This method allows me to stay organized, meet deadlines consistently, and ensure that the most critical tasks are always addressed first. Regular reviews help me stay ahead of potential issues and adapt to changing priorities.

Q 19. How do you adapt to changing work conditions and priorities?

Adaptability is crucial in the dynamic environment of heavy equipment operation. I’m comfortable adjusting to changing work conditions and priorities, often encountered during unexpected site changes or equipment malfunctions. My approach involves remaining flexible, proactively seeking solutions, and collaborating with my team to find the most efficient path forward. For example, during a recent project, unexpected ground conditions required us to adapt our lifting techniques. We quickly assessed the situation, discussed potential solutions, and implemented a revised plan that mitigated the risks while maintaining project progress. By staying informed, communicating effectively, and embracing a problem-solving mindset, I can navigate unpredictable situations and ensure consistent productivity.

Q 20. What are your strengths and weaknesses as a heavy equipment operator?

My strengths as a heavy equipment operator include my precision, safety consciousness, and problem-solving skills. I possess a high level of dexterity and precision in maneuvering heavy equipment, ensuring that loads are handled safely and efficiently. My commitment to safety is unwavering, and I always prioritize safety procedures above all else. When it comes to problem-solving, I am able to think on my feet and devise creative solutions to unforeseen challenges. For example, during a recent project, an unforeseen obstruction required me to quickly adjust my lifting trajectory to prevent damage to both the load and surrounding structures. A potential weakness is my perfectionism; occasionally, this can lead to spending more time than necessary on a particular task to ensure it is executed flawlessly. I’m actively working on improving my time management skills to better balance quality with efficiency.

Q 21. What are your salary expectations?

My salary expectations are in line with my experience, skills, and the industry standard for heavy equipment operators with my qualifications. I am open to discussing a competitive compensation package that reflects my contributions and aligns with the company’s compensation structure. My primary focus is securing a challenging role where I can leverage my expertise and continue to grow professionally.

Q 22. Why are you interested in this position?

My interest in this position stems from a lifelong fascination with heavy equipment and a deep-seated desire to contribute to large-scale projects. I’ve always been captivated by the precision and power involved in operating these machines, and I see this role as a fantastic opportunity to leverage my extensive knowledge and experience in a challenging and rewarding environment. The chance to work with a team of skilled professionals on complex projects, while continuously learning and developing my skills, is particularly appealing.

Furthermore, I am drawn to this company’s reputation for safety and its commitment to innovative technologies within the heavy equipment industry. This aligns perfectly with my own professional values and aspirations.

Q 23. Where do you see yourself in five years?

In five years, I envision myself as a highly skilled and respected member of this team, possibly leading projects or mentoring junior operators. I aim to master advanced operating techniques for a wider range of heavy equipment, and I want to broaden my expertise in areas like preventative maintenance and equipment diagnostics. My goal is to become a go-to resource for problem-solving and contribute significantly to the company’s overall success. I’m particularly interested in exploring opportunities related to the integration of advanced technologies, such as automated guidance systems, into heavy equipment operation.

Q 24. Describe a time you had to work under pressure.

During a large-scale highway construction project, we experienced a significant weather delay. A torrential downpour caused a landslide that blocked access to a critical section of the work site. This meant we were severely behind schedule and faced the risk of hefty penalties. Under immense pressure to meet deadlines, I worked collaboratively with the project manager and other operators to develop a revised plan. This involved re-routing materials, adjusting the work sequence, and implementing additional safety measures for the modified route. Through effective communication and efficient resource allocation, we managed to mitigate the impact of the delay and complete the project successfully, albeit with longer hours and intense focus.

Q 25. How do you handle conflict on the job site?

Conflict resolution on a job site requires a calm, professional, and collaborative approach. My strategy is always to focus on finding solutions rather than assigning blame. I start by actively listening to all parties involved to understand their perspectives and concerns. Then, I facilitate open communication, encouraging everyone to express their views respectfully. I work to identify the root cause of the conflict, focusing on objective facts and avoiding emotional reactions. Once the underlying issue is understood, we collaboratively brainstorm solutions that address everyone’s concerns, ensuring safety and efficiency remain top priorities. If necessary, I’ll escalate the issue to the supervisor only after all attempts at resolution have been exhausted.

For example, I once had a disagreement with another operator about the most efficient way to load a certain material. By calmly discussing our different approaches, we discovered a combined method that maximized both speed and safety.

Q 26. What is your experience with pre-operational checks?

Pre-operational checks are crucial for the safe and efficient operation of heavy equipment. My experience encompasses a thorough understanding and consistent execution of these checks. Before operating any piece of equipment, I meticulously inspect all critical components, including:

- Fluid Levels: Checking engine oil, hydraulic fluid, coolant, and transmission fluid levels and looking for leaks or contamination.

- Tire Pressure: Ensuring proper inflation for optimal performance and safety.

- Brakes and Steering: Testing the responsiveness and functionality of both systems.

- Lights and Signals: Verifying that all lights, indicators, and warning systems are operating correctly.

- Safety Devices: Inspecting seatbelts, emergency stops, and other safety features to ensure they’re in good working order.

- Visual Inspection: A thorough check for any visible damage, loose parts, or potential hazards.

I document all checks, highlighting any issues identified, ensuring that any problems are rectified before commencing operations. This rigorous approach minimizes the risk of accidents and breakdowns, promoting both safety and productivity.

Q 27. Explain your understanding of different fuel types and their impact on equipment performance.

Different fuel types significantly impact heavy equipment performance. The most common are diesel, gasoline, and biofuels. Diesel fuel offers high torque and is suitable for heavy-duty applications, although it tends to produce more emissions than other alternatives. Gasoline offers a lower operating cost but is less efficient for heavy-duty equipment. Biofuels, such as biodiesel, can be a sustainable alternative but require careful consideration of their compatibility with existing engines and their potential impact on performance.

Using the wrong fuel type can have severe consequences, ranging from reduced engine efficiency and power output to complete engine failure. For example, using gasoline in a diesel engine can cause significant internal damage.

Understanding the fuel specifications of each piece of equipment is critical for optimal performance and longevity. Regular fuel analysis can help detect contamination or issues with fuel quality that might impact the equipment’s operation.

Q 28. Describe your experience with hydraulic systems in heavy equipment.

Hydraulic systems are fundamental to the operation of most heavy equipment, powering functions such as lifting, digging, and articulation. My experience includes troubleshooting, maintenance, and operation of these systems. I understand the principles of hydraulic pressure, flow, and control, and I’m familiar with various hydraulic components, including pumps, valves, cylinders, and actuators. I can identify and resolve common hydraulic issues, such as leaks, low pressure, and component failure. I am also proficient in using diagnostic tools to identify and rectify more complex problems.

For example, I once diagnosed a hydraulic leak in an excavator by systematically checking each component, ultimately identifying a faulty seal in the hydraulic cylinder. I replaced the seal, restoring the excavator to full functionality, minimizing downtime, and preventing further damage.

Key Topics to Learn for Heavy Equipment Handling and Control Interview

- Equipment Operation & Maintenance: Understanding the mechanics, safety procedures, and routine maintenance of various heavy equipment types (e.g., excavators, loaders, bulldozers, cranes). This includes pre-operational checks, troubleshooting common issues, and knowing limitations.

- Safety Regulations & Procedures: Deep knowledge of OSHA (or relevant regional) safety regulations pertaining to heavy equipment operation, including site safety, personal protective equipment (PPE), and hazard identification/mitigation. Practical application includes explaining how you’ve ensured a safe work environment.

- Site Assessment & Planning: Demonstrate your ability to analyze a worksite, assess potential risks, and plan efficient and safe operation strategies. This involves understanding ground conditions, load capacity calculations, and effective maneuvering techniques.

- Advanced Operating Techniques: Mastering precise control techniques for various tasks, such as grading, digging, lifting, and material handling. Be prepared to discuss your experience and proficiency with different attachments and their applications.

- Troubleshooting & Problem Solving: Showcase your ability to identify and resolve mechanical issues, operational challenges, or unexpected site conditions. Emphasize your methodical approach to diagnosing problems and finding solutions.

- Communication & Teamwork: Explain your experience collaborating effectively with other crew members, supervisors, and clients. Highlight instances where clear communication was crucial for project success and safety.

Next Steps

Mastering Heavy Equipment Handling and Control opens doors to rewarding and well-compensated careers in construction, mining, and various other industries. Your expertise is highly valued, and showcasing this effectively is key to securing your dream job. A strong, ATS-friendly resume is your first impression, and crafting one that highlights your skills and experience is crucial. To help you present yourself in the best possible light, consider using ResumeGemini. ResumeGemini provides a powerful tool for building professional resumes, and they offer examples tailored to the Heavy Equipment Handling and Control field to help guide you. Take the next step in advancing your career – invest time in creating a compelling resume that accurately represents your skills and experience.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

hello,

Our consultant firm based in the USA and our client are interested in your products.

Could you provide your company brochure and respond from your official email id (if different from the current in use), so i can send you the client’s requirement.

Payment before production.

I await your answer.

Regards,

MrSmith

hello,

Our consultant firm based in the USA and our client are interested in your products.

Could you provide your company brochure and respond from your official email id (if different from the current in use), so i can send you the client’s requirement.

Payment before production.

I await your answer.

Regards,

MrSmith

These apartments are so amazing, posting them online would break the algorithm.

https://bit.ly/Lovely2BedsApartmentHudsonYards

Reach out at [email protected] and let’s get started!

Take a look at this stunning 2-bedroom apartment perfectly situated NYC’s coveted Hudson Yards!

https://bit.ly/Lovely2BedsApartmentHudsonYards

Live Rent Free!

https://bit.ly/LiveRentFREE

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?