The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to HVAC Equipment Selection and Installation interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in HVAC Equipment Selection and Installation Interview

Q 1. Explain the difference between a heat pump and a furnace.

The primary difference between a heat pump and a furnace lies in how they heat a space. A furnace burns fuel (natural gas, propane, or oil) to generate heat, which is then distributed through ductwork. Think of it as a big, controlled fire. It’s a simple, reliable system for heating, but inefficient for cooling.

A heat pump, on the other hand, moves heat rather than generating it. In heating mode, it extracts heat from the outside air (even in relatively cold temperatures) and transfers it inside. In cooling mode, it reverses the process, moving heat from inside to outside. This makes them much more energy-efficient than furnaces, especially in regions with moderate climates. They are essentially an air conditioner that can also heat.

Imagine it like this: a furnace is like a campfire – it creates heat directly. A heat pump is like a refrigerator in reverse – it moves existing heat around.

Q 2. What factors influence the selection of an HVAC system for a specific building?

Selecting the right HVAC system involves a multifaceted assessment. Key factors include:

- Building size and layout: Larger buildings require more powerful systems. The layout influences ductwork design and placement of units.

- Climate: Extreme temperatures demand systems with higher capacity and efficient heating/cooling capabilities. A heat pump might be ideal in moderate climates, while a furnace might be necessary in very cold areas.

- Occupancy and usage patterns: A home with many occupants will need a larger system than a single-person apartment. A building primarily occupied during the day will have different demands than one used around the clock.

- Budget: Different systems have varying upfront and operating costs. Energy-efficient systems may have higher initial costs but lower long-term expenses.

- Energy efficiency standards: Compliance with local energy codes is crucial, often influencing the choice of system and equipment.

- Aesthetics: The size and location of units should be carefully considered to maintain the building’s visual appeal.

For example, a high-rise building in a city with hot summers and mild winters might benefit from a central air conditioning system with high-efficiency heat pumps for heating, while a small, rural cabin might be best served by a smaller, less complex furnace and a window air conditioning unit.

Q 3. Describe your experience with different types of refrigerants and their environmental impact.

My experience encompasses various refrigerants, each with unique properties and environmental impacts. Older systems often used chlorofluorocarbons (CFCs) and hydrochlorofluorocarbons (HCFCs), which significantly depleted the ozone layer. These are now largely phased out under international agreements like the Montreal Protocol.

Currently, the industry is transitioning towards hydrofluoroolefins (HFOs) and other low-global-warming-potential (GWP) refrigerants. These refrigerants have a minimal impact on ozone depletion and significantly reduced global warming potential compared to their predecessors. I have extensive experience with R-410A (a common HFC), but more recently I’ve been working extensively with R-32 and R-1234yf, which offer superior environmental profiles. Proper handling and leak detection are crucial with all refrigerants to minimize environmental impact and ensure worker safety.

Selecting the right refrigerant is critical for both efficiency and environmental responsibility. I always prioritize refrigerants with low GWP values and adhere to all relevant safety regulations.

Q 4. How do you determine the appropriate tonnage for an air conditioning system?

Determining the appropriate tonnage (or BTU/hr) for an air conditioning system requires careful calculation. This isn’t a simple matter of square footage; several factors come into play.

- Building’s square footage: This provides a baseline estimate.

- Ceiling height: Higher ceilings require more cooling power.

- Climate: Hotter climates require higher tonnage.

- Window size and insulation: More windows and poor insulation necessitate increased cooling capacity.

- Number of occupants and appliances: Heat-generating appliances like ovens and computers add to the cooling load.

- Desired comfort level: Preference for cooler temperatures necessitates higher tonnage.

Load calculations using specialized software are typically performed to accurately determine the necessary tonnage. These calculations consider all the factors mentioned above, leading to precise sizing to avoid overcooling (wasted energy) or undercooling (inadequate comfort). Underestimating tonnage leads to inefficient cooling and higher energy bills; overestimating leads to unnecessary energy consumption and financial losses.

Q 5. Explain the importance of proper ductwork design and installation.

Proper ductwork design and installation are paramount for efficient HVAC system operation. Poorly designed or installed ductwork can lead to significant energy loss, uneven temperature distribution, and reduced system lifespan.

Key aspects include:

- Proper sizing: Ducts must be appropriately sized to ensure adequate airflow to each room.

- Airtight seals: Leaks in the ductwork reduce efficiency by causing air loss and pressure imbalances.

- Insulation: Insulating ducts, especially in unconditioned spaces like attics or crawlspaces, prevents energy loss and maintains consistent air temperatures.

- Strategic routing: Ducts should be routed efficiently to minimize length and bends, reducing friction and pressure drop.

- Proper dampers and registers: These components control airflow distribution and must be correctly sized and installed.

Imagine ductwork as the circulatory system of your HVAC system. If the arteries and veins are leaky or too narrow, blood (air) won’t circulate properly. Similarly, faulty ductwork leads to inefficient and inconsistent heating and cooling.

Q 6. What are the common causes of HVAC system malfunctions and how would you troubleshoot them?

Troubleshooting HVAC system malfunctions requires a systematic approach. Common causes and troubleshooting steps include:

- No power: Check breakers, fuses, and power supply to the unit.

- Frozen evaporator coil: This often results from low refrigerant, restricted airflow, or a dirty air filter. Addressing these issues usually resolves the problem.

- Refrigerant leaks: Requires detection and repair by a qualified technician. A leak can dramatically reduce cooling capacity.

- Compressor failure: This is a more significant issue typically requiring compressor replacement. Diagnosing this requires specialized tools and knowledge.

- Dirty air filter: A simple but common problem, a clogged filter restricts airflow and reduces efficiency. Regular filter replacement is crucial.

- Blower motor issues: Could be due to worn bearings, electrical problems, or belt issues. Assessment and possible motor replacement may be needed.

I approach troubleshooting using a combination of diagnostic tools (multimeters, pressure gauges, etc.), visual inspection, and a systematic process of elimination. I begin by gathering information from the user about the symptoms, then proceed through a sequence of tests to identify the root cause and implement the appropriate solution.

Q 7. Describe your experience with various HVAC control systems.

My experience includes a wide range of HVAC control systems, from basic thermostats to sophisticated building management systems (BMS).

Basic thermostats provide simple on/off control, while programmable thermostats offer scheduling options for energy savings. I’ve worked with various brands and models, ensuring compatibility with different HVAC systems. Smart thermostats offer advanced features like remote control, energy monitoring, and learning algorithms to optimize energy use. These are becoming increasingly prevalent in residential and commercial settings.

Building Management Systems (BMS) are used in larger buildings to control multiple HVAC units and other building systems. My experience with BMS includes system integration, programming, troubleshooting, and maintenance. They allow for centralized monitoring and control of the entire HVAC infrastructure, leading to optimized energy efficiency and enhanced comfort.

The selection of the appropriate control system depends on factors such as the building’s size, complexity, and the level of automation desired. I always aim to recommend systems that offer a balance of functionality, ease of use, and energy efficiency.

Q 8. How do you ensure the safety of yourself and your team during HVAC installation?

Safety is paramount in HVAC installation. We adhere to a strict safety protocol, starting with comprehensive risk assessments before any work begins. This involves identifying potential hazards like electrical risks, working at heights, and exposure to refrigerants. We then implement control measures, including the use of appropriate Personal Protective Equipment (PPE) such as hard hats, safety glasses, gloves, and fall protection harnesses. Regular safety meetings emphasize safe working practices, lockout/tagout procedures for electrical work, and proper handling of refrigerants. We also maintain a clean and organized worksite to prevent accidents caused by tripping or falling. For example, if working on a roof, we’d ensure proper scaffolding and fall arrest systems are in place. Furthermore, we rigorously follow all OSHA regulations and maintain thorough documentation of all safety procedures and incident reports.

Q 9. What are your preferred methods for calculating HVAC system efficiency?

Calculating HVAC system efficiency involves several key metrics. The most common is the Seasonal Energy Efficiency Ratio (SEER) for air conditioners and the Annual Fuel Utilization Efficiency (AFUE) for furnaces. SEER represents the cooling output over a season divided by the total energy consumed. AFUE indicates the percentage of heat energy from the fuel that’s converted into usable heat. We use industry-standard software and load calculations to determine the precise energy requirements of a building. This involves factors like climate, building insulation, window efficiency, and occupancy. For example, Manual J is a widely used method for accurately calculating heating and cooling loads, ensuring the selected system is appropriately sized to meet the building’s needs without over or under-performing. This optimization leads to improved efficiency and reduced operating costs. Additionally, we consider the efficiency of individual components like the compressor, blower motor, and heat exchangers when selecting equipment.

Q 10. Explain your understanding of building codes and regulations related to HVAC installation.

Understanding and adhering to building codes and regulations is critical. These vary by location but generally cover aspects like refrigerant handling, electrical safety, ductwork sizing and installation, fire safety, and ventilation requirements. We’re intimately familiar with the International Mechanical Code (IMC), International Energy Conservation Code (IECC), and local ordinances. Before starting any project, we thoroughly review the applicable codes to ensure compliance. This includes checking for permit requirements, inspections, and the necessary documentation. For example, proper insulation of ductwork is vital to prevent energy loss and meet energy efficiency standards. Failure to comply can result in costly fines, delays, and even system rejection. We ensure meticulous documentation of our compliance throughout the entire process.

Q 11. How do you manage a project timeline and budget for an HVAC installation?

Project management is a crucial aspect of successful HVAC installation. We begin by establishing a clear project scope, including detailed specifications, a realistic timeline, and a comprehensive budget. This involves careful planning and coordination with the client, architects, and other contractors. We utilize project management software to track progress, manage resources, and monitor expenses. We break down the project into smaller, manageable tasks with assigned deadlines. Regular progress meetings with the client keep everyone informed and allow for timely adjustments. If unforeseen issues arise, such as material delays or equipment failures, we implement contingency plans and proactively communicate any potential impact on the timeline and budget. We’ve learned to be flexible and adapt to changing circumstances while maintaining transparency with the client. For instance, a detailed Gantt chart helps visualize the project’s timeline and dependencies.

Q 12. Describe your experience with different types of HVAC equipment, such as chillers, boilers, and air handlers.

My experience encompasses a wide range of HVAC equipment. I’m proficient in the selection, installation, and maintenance of chillers (absorption and centrifugal), boilers (gas, electric, steam), and air handlers (variable air volume, constant volume). I understand the different operating principles, efficiency ratings, and control strategies for each type. For example, I’ve worked on projects involving large-scale centrifugal chillers in commercial buildings, requiring expertise in piping, plumbing, and electrical connections. I also have experience with high-efficiency condensing boilers in smaller applications, focusing on optimized heat distribution and energy savings. The selection process always considers factors like capacity, efficiency, operating costs, and environmental impact. We also consider building loads, operating hours, maintenance requirements, and space constraints when making equipment choices.

Q 13. How do you select the appropriate size and type of ductwork for a specific application?

Selecting the appropriate ductwork involves several steps. First, we conduct a thorough load calculation using software like Manual D to determine the required airflow for each zone. Then, we select the duct size and material based on factors like airflow, pressure drop, and space limitations. We prioritize minimizing pressure drop to reduce fan energy consumption. Different materials are considered based on factors like cost, durability, and application. For example, galvanized steel is commonly used for main runs, while flexible ductwork might be used for smaller branches. We use specialized software and tools to design the duct layout and ensure smooth airflow. Proper design is crucial to prevent noise, vibrations, and inefficient air distribution. We always comply with relevant codes and standards regarding ductwork installation and sealing, to ensure air tightness and prevent energy losses.

Q 14. Explain the process of commissioning a new HVAC system.

Commissioning is a systematic process verifying that the installed HVAC system functions according to design specifications. It involves thorough testing, inspection, and documentation to ensure the system meets its performance requirements. This typically involves several stages: pre-commissioning (reviewing designs and equipment), functional testing (verifying individual components work), integrated testing (checking the interaction of components), and performance testing (measuring system efficiency). Documentation of test results is vital. We use specialized tools and software to measure airflow, pressure, temperature, and other parameters. Any deficiencies identified during commissioning are addressed before final acceptance by the client. Commissioning is crucial for long-term system performance, energy efficiency, and occupant comfort. A properly commissioned system will operate more reliably, reduce maintenance costs and increase energy efficiency.

Q 15. How do you ensure proper ventilation and air quality in a building?

Ensuring proper ventilation and air quality involves a multifaceted approach focusing on both the quantity and quality of air exchanged within a building. This starts with a thorough understanding of the building’s occupancy, intended use, and potential sources of indoor air pollutants.

- Sufficient Air Exchange Rate: We calculate the required air changes per hour (ACH) based on building codes and occupancy levels. This dictates the capacity of the HVAC system’s ventilation components, such as supply and exhaust fans. For example, a high-occupancy office building might require a higher ACH than a residential dwelling.

- Air Filtration: High-efficiency particulate air (HEPA) filters are crucial for removing airborne particles, including dust, pollen, and mold spores. We select filter types based on the specific needs; a hospital, for instance, would necessitate a higher-efficiency filter than a typical office. Regular filter replacement is non-negotiable.

- Outdoor Air Intake: Fresh air intake is vital. We strategically locate outdoor air intakes to avoid recirculating polluted air and consider pre-filtration to prevent contaminants from entering the system. The size of the intake is critical to providing adequate fresh air.

- Exhaust Systems: Effective exhaust systems remove stale, humid, or polluted air from areas like bathrooms, kitchens, and laboratories. Properly sized and located exhaust fans prevent the buildup of moisture and contaminants, contributing to better air quality and reducing the risk of mold growth.

- Monitoring and Control: Modern HVAC systems often incorporate sensors to monitor air quality parameters such as carbon dioxide (CO2) levels, temperature, and humidity. This allows for real-time adjustments to maintain optimal conditions. For instance, a CO2 sensor can trigger increased ventilation when levels exceed a predetermined threshold.

A well-designed ventilation system isn’t just about comfort; it directly impacts occupant health and productivity. For instance, in a school setting, maintaining good air quality is paramount for student and teacher well-being and can directly affect learning outcomes.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are some common energy-efficient HVAC practices?

Energy-efficient HVAC practices are crucial for reducing operational costs and minimizing environmental impact. They encompass various strategies that optimize system performance and reduce energy consumption.

- High-Efficiency Equipment: Selecting equipment with high SEER (Seasonal Energy Efficiency Ratio) and EER (Energy Efficiency Ratio) ratings for air conditioners and high AFUE (Annual Fuel Utilization Efficiency) ratings for furnaces is a fundamental step. These ratings directly reflect how efficiently the equipment converts energy into cooling or heating.

- Variable-Speed Equipment: Employing variable-speed fans and compressors allows the system to modulate its output based on the actual heating or cooling demand. This eliminates the energy waste associated with constantly cycling on and off. Think of it as having a car with a smoothly accelerating engine versus one that constantly jerks.

- Proper Ductwork Design and Installation: Well-designed and properly insulated ductwork minimizes air leakage and pressure losses, improving system efficiency and comfort. Leaky ducts can account for significant energy loss.

- Smart Thermostats and Controls: Programmable or smart thermostats allow for customized scheduling and remote control, optimizing energy use according to occupancy patterns. Some even learn your preferences over time.

- Regular Maintenance: Preventative maintenance, including filter changes, coil cleaning, and system inspections, ensures optimal performance and prevents premature equipment failure. This keeps the system running efficiently and prevents costly repairs.

- Zone Control: Dividing the building into zones allows for independent climate control in different areas, reducing energy waste in unoccupied or less-used spaces. This is particularly effective in larger buildings.

Implementing these practices can drastically reduce energy bills and reduce a building’s carbon footprint. For example, I once worked on a project where the implementation of variable-speed equipment and improved ductwork resulted in a 25% reduction in energy consumption.

Q 17. Describe your experience with using HVAC design software.

I have extensive experience using various HVAC design software packages, including Carrier HAP, Trane Trace, and Revit MEP. These tools are indispensable for creating accurate and efficient HVAC system designs.

- Load Calculations: The software facilitates precise load calculations, determining the heating and cooling requirements for the building based on factors like climate, building envelope, and occupancy. This ensures that the selected equipment is properly sized.

- Ductwork Design: These programs allow for the design and optimization of ductwork systems, minimizing pressure losses and ensuring uniform airflow throughout the building. We can model different duct configurations and materials to find the most efficient solution.

- Equipment Selection: The software helps in selecting appropriate HVAC equipment based on the calculated loads and project requirements. It provides access to comprehensive equipment databases and allows for comparisons of different options.

- System Simulation: Advanced features simulate the performance of the designed system under various operating conditions, allowing for identification and correction of potential issues before construction.

- Documentation and Collaboration: The software generates detailed design drawings, specifications, and reports. It also facilitates collaboration among the design team through shared models and data.

In a recent project, using Revit MEP, I was able to quickly generate multiple design options and compare their energy performance, ultimately leading to a more sustainable and cost-effective solution. The software’s ability to create detailed 3D models allowed for better visualization and coordination with other building systems.

Q 18. How do you handle conflicts with subcontractors or clients during an HVAC project?

Conflict resolution is a crucial skill in project management. My approach emphasizes proactive communication and collaborative problem-solving.

- Clear Communication: Establishing clear communication channels and expectations from the outset helps prevent misunderstandings. Regular meetings and documented agreements are essential.

- Collaborative Problem-Solving: When conflicts arise, I facilitate open discussions involving all parties to identify the root cause of the issue. This includes subcontractors, clients, and other stakeholders. The focus is on finding mutually acceptable solutions rather than assigning blame.

- Mediation and Negotiation: If a direct approach fails to resolve the conflict, I employ mediation techniques to guide discussions and help parties reach a consensus. Negotiation is crucial to finding compromise and maintaining positive working relationships.

- Escalation Protocol: For intractable conflicts, I have a defined escalation protocol to involve higher management or legal counsel when necessary. This ensures that the project remains on track.

- Documentation: Meticulous documentation of all communications, agreements, and resolutions is crucial to minimize future misunderstandings and provide a record of the process.

For example, I once encountered a scheduling conflict between the electrical and plumbing subcontractors. By facilitating a joint meeting and helping them re-sequence their work, we avoided significant delays and maintained the project timeline. Open communication and a collaborative approach are key to successful conflict resolution.

Q 19. How do you stay up-to-date on the latest advancements in HVAC technology?

Staying abreast of advancements in HVAC technology is critical for maintaining competitiveness and providing clients with the most efficient and effective solutions. My approach is multifaceted:

- Industry Publications and Journals: I regularly read industry publications such as ASHRAE Journal and HPAC Engineering to keep informed about new technologies, research findings, and best practices.

- Professional Associations: Active participation in professional organizations like ASHRAE provides access to continuing education courses, conferences, and networking opportunities with leading experts in the field.

- Manufacturer Training Programs: I participate in training programs offered by HVAC equipment manufacturers to stay updated on their latest product offerings and technologies.

- Online Resources and Webinars: I utilize online resources such as manufacturer websites, industry blogs, and webinars to learn about new developments and emerging trends.

- Networking with Peers: Regular interaction with colleagues and industry professionals through conferences and online forums allows for sharing of best practices and insights on the latest technologies.

Recently, I attended a webinar on the application of AI in HVAC system optimization. This provided valuable insights into how machine learning can enhance energy efficiency and predictive maintenance. Continuous learning is essential in this rapidly evolving field.

Q 20. Explain the importance of preventative maintenance for HVAC systems.

Preventative maintenance is paramount for ensuring the long-term efficiency, reliability, and lifespan of HVAC systems. Neglecting preventative maintenance leads to increased energy consumption, premature equipment failure, and costly repairs.

- Extended Equipment Lifespan: Regular maintenance prevents minor issues from escalating into major problems, extending the lifespan of the equipment and reducing the frequency of costly replacements.

- Improved Energy Efficiency: A well-maintained system operates at peak efficiency, reducing energy consumption and lowering operating costs. Dirty filters and clogged coils significantly reduce efficiency.

- Enhanced Indoor Air Quality: Cleaning filters, coils, and other components removes dust, allergens, and other contaminants that can impact indoor air quality. Regular maintenance is vital for maintaining a healthy indoor environment.

- Reduced Repair Costs: Addressing minor issues proactively during preventative maintenance prevents them from becoming costly repairs later. Early detection is key to cost-effective maintenance.

- Increased System Reliability: Regular inspections and maintenance help identify potential problems before they lead to system breakdowns or unexpected downtime.

I always recommend a preventative maintenance schedule that includes regular filter changes, coil cleaning, blower motor inspection, and system performance checks. A well-structured maintenance plan is not only cost-effective but also contributes to the overall well-being of the building’s occupants.

Q 21. Describe your experience with different types of HVAC controls, such as thermostats and programmable logic controllers (PLCs).

My experience encompasses a wide range of HVAC controls, from basic thermostats to sophisticated programmable logic controllers (PLCs).

- Thermostats: I’m proficient in working with various types of thermostats, including basic mechanical, programmable, and smart thermostats. Understanding their functionalities and limitations is crucial for providing clients with the best control solutions. Smart thermostats, for instance, offer enhanced energy savings through automated scheduling and learning algorithms.

- Programmable Logic Controllers (PLCs): PLCs offer advanced control capabilities for larger and more complex HVAC systems. I have experience programming and troubleshooting PLCs to optimize system performance, integrate with building management systems (BMS), and implement sophisticated control strategies. This includes implementing strategies like variable-frequency drives for fan speed control and optimizing chilled water systems.

- Building Management Systems (BMS): I’m familiar with various BMS platforms and their integration with HVAC equipment. BMS provide centralized control and monitoring of building systems, including HVAC, lighting, and security. This allows for improved efficiency, enhanced occupant comfort, and simplified system management.

- Direct Digital Controls (DDC): DDC systems use digital technology for accurate and efficient control of HVAC equipment. I have hands-on experience in configuring and maintaining DDC systems to optimize system performance and energy efficiency. DDC systems allow for precise control and monitoring of numerous parameters, leading to superior system performance.

In a recent project, I used a PLC to integrate a VAV (Variable Air Volume) system with the building’s BMS. This allowed for real-time monitoring and control of air flow in different zones, resulting in significant energy savings and enhanced occupant comfort. Choosing the right control system depends on the complexity and size of the HVAC system and the level of control desired.

Q 22. How do you address indoor air quality concerns during HVAC design and installation?

Addressing indoor air quality (IAQ) is paramount in HVAC design and installation. It’s not just about heating and cooling; it’s about creating a healthy environment. We achieve this through a multi-pronged approach.

- Proper Ventilation: We ensure sufficient fresh air intake and exhaust, often using Energy Recovery Ventilators (ERVs) or Heat Recovery Ventilators (HRVs) to minimize energy loss while maximizing fresh air delivery. This is crucial for diluting indoor pollutants and preventing the buildup of stale air.

- Filtration: High-efficiency particulate air (HEPA) filters or other specialized filters are selected based on the specific needs of the building and its occupants. For example, a hospital would require much stricter filtration standards than a residential home. Regular filter changes are also critical and we often work with clients to establish a preventative maintenance schedule.

- Mitigating Moisture: Properly sized and installed systems prevent excessive humidity, which can lead to mold and mildew growth. This includes careful ductwork design to avoid condensation and the use of dehumidifiers where necessary. I’ve seen firsthand the devastating effects of poor moisture control, causing significant damage and health problems.

- Source Control: This involves identifying and addressing the sources of indoor pollutants, such as volatile organic compounds (VOCs) from building materials or cleaning products. Working closely with architects and builders is key here for long-term IAQ management.

- Air Sealing: We meticulously seal all ductwork to prevent air leaks, which can reduce efficiency and compromise IAQ. Air leaks can introduce dust, pollen, and other contaminants from unconditioned spaces. Proper sealing and insulation also improves energy efficiency.

For instance, in a recent project for a school, we incorporated UV-C lights in the HVAC system to further disinfect the air and reduce airborne pathogens, addressing specific health concerns of the occupants.

Q 23. What is your experience with different types of duct sealing and insulation materials?

My experience encompasses a wide range of duct sealing and insulation materials. The choice depends heavily on the application, budget, and environmental considerations.

- Sealants: I’ve worked extensively with mastic sealants, foil tapes, and specialized sealants designed for high-temperature or high-humidity environments. Mastic sealants provide a good all-around solution but require skilled application to ensure proper adhesion. Foil tapes are excellent for sealing seams and joints in flexible ductwork. Specific sealants are necessary for applications where fire resistance or chemical resistance are needed.

- Insulation: Common insulation materials include fiberglass, rigid foam boards (like polyisocyanurate or polyurethane), and mineral wool. Fiberglass is cost-effective but can be irritating to handle; rigid foam offers excellent R-value (insulation rating) per inch and is easier to work with; mineral wool provides superior fire resistance. I always consider the R-value requirements based on local climate codes and aim for optimal energy efficiency.

For example, in a recent commercial project, we utilized a high-performance, closed-cell spray foam insulation for the ductwork to maximize energy savings and minimize air leakage. The selection process considers factors such as moisture resistance, thermal performance, and environmental impact.

Q 24. How do you calculate the pressure drop in a duct system?

Calculating pressure drop in a duct system is critical for proper system design and performance. It’s essentially the loss of pressure as air moves through the ductwork. Accurate calculation ensures sufficient airflow to all zones. We use several methods:

- The Equal Friction Method: This method assumes a constant friction rate throughout the duct system. It simplifies the calculations but might not be perfectly accurate for complex systems.

- The Static Regain Method: This method accounts for the pressure regain between fittings, providing a more accurate estimate of the total pressure drop. It’s more complex but offers improved precision.

- Software Programs: We leverage specialized HVAC design software which uses algorithms to perform these calculations, considering factors like duct size, shape, length, fittings, and airflow rates. These programs save time and provide highly accurate results.

The formula for pressure drop (ΔP) using the Darcy-Weisbach equation is:

ΔP = f * (L/D) * (ρ * V²/2)where:

- f = friction factor (dimensionless)

- L = duct length

- D = duct diameter

- ρ = air density

- V = air velocity

This formula, though fundamental, is often applied within the context of more sophisticated software to account for all the variables and complexities of a real-world duct system.

Q 25. Explain the process of balancing an HVAC system.

Balancing an HVAC system ensures that the correct amount of airflow reaches each zone or room. An unbalanced system leads to uneven heating or cooling, discomfort, and reduced efficiency. The process involves several steps:

- System Design Review: We review the design specifications and ensure that the ductwork is appropriately sized and routed. Often, initial imbalances stem from design oversights.

- Airflow Measurement: We use calibrated flow hoods or pressure gauges to measure the actual airflow at each supply and return register. This provides a baseline to identify imbalances.

- Balancing Dampers Adjustment: We adjust balancing dampers (located in the ductwork) to regulate the airflow to each zone. These dampers restrict or increase airflow as needed until we achieve the design airflow rates.

- Verification and Fine-tuning: After adjusting dampers, we re-measure airflow to confirm the system is balanced. Minor adjustments might be needed for optimal performance. This iterative process ensures precision.

- Documentation: We document the final damper positions for future reference and maintenance purposes. This is crucial for future troubleshooting.

Think of it like balancing a seesaw – we carefully adjust the airflow to each area until the system operates smoothly and efficiently. Improper balancing leads to wasted energy and occupant dissatisfaction.

Q 26. What safety precautions do you take when working with high-voltage equipment?

Safety is paramount when working with high-voltage equipment. We adhere to strict safety protocols to mitigate risks:

- Lockout/Tagout Procedures: Before working on any electrical component, we employ lockout/tagout procedures to ensure the power is completely disconnected and cannot be accidentally re-energized. This is a non-negotiable safety measure.

- Personal Protective Equipment (PPE): We always wear appropriate PPE, including insulated gloves, safety glasses, and arc flash suits (depending on voltage level). This protects us from electrical shock and arc flash hazards.

- Voltage Testing: Before touching any electrical component, even after lockout/tagout, we use a non-contact voltage tester to verify that the power is indeed off. This is an additional verification step.

- Trained Personnel: Only qualified and trained personnel with appropriate certifications are allowed to work on high-voltage equipment. Ongoing training keeps our team updated on the latest safety practices.

- Emergency Procedures: We have clearly defined emergency procedures in place, including knowing the location of the nearest emergency shut-off switches and having a plan for responding to electrical shock or arc flash incidents. This includes practicing our emergency procedures regularly.

Ignoring these precautions can result in serious injury or fatality. Safety is not just a policy; it’s a fundamental value that guides every aspect of our work.

Q 27. How do you handle unexpected challenges or problems during an HVAC installation?

Unexpected challenges are inevitable in HVAC installation. Our approach is systematic and proactive:

- Thorough Site Assessment: Before installation begins, we conduct a thorough site assessment to anticipate potential problems, such as hidden obstructions or unexpected building configurations.

- Contingency Planning: We develop contingency plans to address common issues, such as material shortages or equipment malfunctions. This includes having backup materials and equipment ready.

- Problem-Solving Skills: Our team possesses strong problem-solving skills and is equipped to handle unexpected problems creatively and efficiently. We utilize our experience to find resourceful solutions.

- Communication: Open communication with the client and other stakeholders is crucial during unexpected challenges. We keep them informed, discuss options, and work collaboratively to find the best solution.

- Documentation: We meticulously document all changes and modifications made during the installation process. This detailed documentation ensures smooth operation and maintenance in the future. It is also valuable for future projects.

For example, I once encountered unforeseen ductwork obstructions during a retrofit project. We quickly assessed the situation, devised an alternate routing plan, and communicated the changes to the client, minimizing project delays.

Q 28. Describe your experience with different types of HVAC system controls, including direct digital control (DDC) systems.

My experience with HVAC system controls is extensive, encompassing various types, from simple pneumatic controls to sophisticated DDC systems.

- Pneumatic Controls: These older systems utilize compressed air to control various components. While simpler, they lack the precision and flexibility of modern systems.

- Electronic Controls: These systems offer more precise control than pneumatic controls, typically using various sensors and actuators. They are more energy-efficient and can be easily integrated with building management systems (BMS).

- Direct Digital Control (DDC) Systems: DDC systems are the most advanced, utilizing microprocessors and digital communication to provide precise control, monitoring, and data logging. They allow for remote access, advanced algorithms for energy optimization, and sophisticated fault detection capabilities. They are increasingly common in modern buildings and offer the most extensive data analysis features.

I’ve worked extensively with DDC systems, programming them to optimize energy consumption, provide remote diagnostics, and integrate with other building systems. For instance, in a recent commercial building project, we implemented a DDC system with predictive maintenance capabilities, which reduced energy consumption by 15% and minimized downtime. The capabilities of these systems are constantly evolving, offering better insights and control.

Key Topics to Learn for HVAC Equipment Selection and Installation Interview

- Load Calculation and System Sizing: Understanding heat load and cooling load calculations, and applying this knowledge to select appropriately sized HVAC equipment for various building types and climates. Practical application includes using software and manual J calculations.

- Equipment Selection Criteria: Evaluating different types of HVAC systems (split systems, heat pumps, packaged units, etc.), considering factors like efficiency (SEER, EER, HSPF), capacity, operating costs, and environmental impact. Consider scenarios involving budget limitations and specific client needs.

- Installation Procedures and Best Practices: Familiarity with proper installation techniques, including refrigerant handling, electrical connections, ductwork design and installation, and adherence to safety regulations (e.g., OSHA, local codes). Practical application involves troubleshooting common installation problems.

- Refrigerant Types and Handling: Knowledge of different refrigerants (R-410A, R-32, etc.), their properties, and safe handling procedures. This includes understanding environmental regulations and best practices for minimizing refrigerant leakage.

- Troubleshooting and Diagnostics: Ability to identify and diagnose common HVAC system malfunctions, using diagnostic tools and your understanding of system operation. Practical application includes explaining your approach to identifying issues and proposing solutions.

- Building Codes and Regulations: Understanding relevant building codes and regulations pertaining to HVAC installation and safety. This includes local and national codes.

- Energy Efficiency and Sustainability: Knowledge of energy-efficient HVAC technologies and practices, and the importance of sustainability in HVAC design and installation.

Next Steps

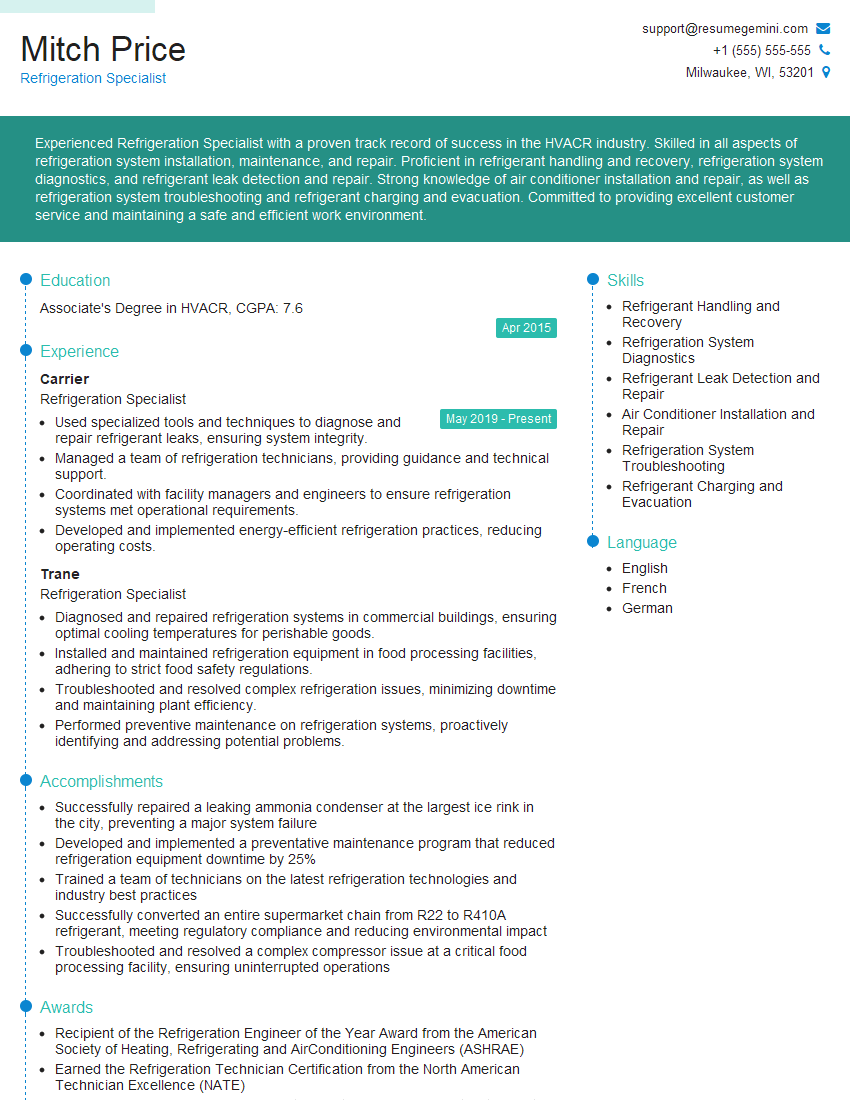

Mastering HVAC Equipment Selection and Installation is crucial for career advancement in this in-demand field. Demonstrating expertise in these areas significantly boosts your job prospects and opens doors to higher-paying roles and leadership opportunities. To maximize your chances of landing your dream job, crafting a compelling and ATS-friendly resume is essential. ResumeGemini is a trusted resource that can help you build a professional resume tailored to highlight your skills and experience effectively. We provide examples of resumes specifically designed for HVAC Equipment Selection and Installation professionals, to give you a head start. Invest in your future—create a resume that showcases your capabilities!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

hello,

Our consultant firm based in the USA and our client are interested in your products.

Could you provide your company brochure and respond from your official email id (if different from the current in use), so i can send you the client’s requirement.

Payment before production.

I await your answer.

Regards,

MrSmith

hello,

Our consultant firm based in the USA and our client are interested in your products.

Could you provide your company brochure and respond from your official email id (if different from the current in use), so i can send you the client’s requirement.

Payment before production.

I await your answer.

Regards,

MrSmith

These apartments are so amazing, posting them online would break the algorithm.

https://bit.ly/Lovely2BedsApartmentHudsonYards

Reach out at [email protected] and let’s get started!

Take a look at this stunning 2-bedroom apartment perfectly situated NYC’s coveted Hudson Yards!

https://bit.ly/Lovely2BedsApartmentHudsonYards

Live Rent Free!

https://bit.ly/LiveRentFREE

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?