Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Industrial Combustion Fundamentals interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Industrial Combustion Fundamentals Interview

Q 1. Explain the stoichiometric combustion process.

Stoichiometric combustion refers to the ideal burning scenario where the fuel and oxidizer (typically air) react completely, leaving no excess of either. It’s the perfect balance, like perfectly mixing the ingredients in a recipe. The reaction produces only the products of complete combustion, primarily carbon dioxide (CO2) and water (H2O) if the fuel is a hydrocarbon. For example, consider the complete combustion of methane (CH4):

CH4 + 2O2 → CO2 + 2H2O

This equation shows that one molecule of methane reacts with two molecules of oxygen to produce one molecule of carbon dioxide and two molecules of water. In practice, achieving perfectly stoichiometric conditions is difficult, as factors like incomplete mixing and variations in fuel composition can lead to deviations.

Q 2. Describe different types of flames and their characteristics.

Flames are characterized by their appearance, temperature, and stability. Different types exist, each with distinct characteristics. Think of flames like different personalities – each unique and requiring a different approach.

- Premixed Flames: Fuel and oxidizer are mixed before ignition, resulting in a relatively stable and uniform flame, like the smooth blue flame of a Bunsen burner. They are often used in industrial applications requiring precise temperature control.

- Diffusion Flames: Fuel and oxidizer mix during combustion, creating a less stable flame with a visible luminous zone due to incomplete combustion and soot formation. A candle flame is a classic example of a diffusion flame. These flames can be less efficient due to incomplete burning.

- Laminar Flames: Characterized by smooth, parallel layers of flow, these flames are relatively stable and predictable. They are often studied in controlled laboratory settings to better understand the combustion process.

- Turbulent Flames: These are highly unsteady flames characterized by chaotic mixing and fluctuating velocity. They are common in industrial furnaces and power plants, providing better mixing and increased heat transfer rate but are harder to control and model accurately.

Q 3. What are the key factors affecting combustion efficiency?

Combustion efficiency is crucial for minimizing fuel waste and emissions. Several factors influence it, much like several factors affect a baker’s success in making a cake. Key factors include:

- Air-Fuel Ratio: The stoichiometric ratio is ideal, but slight excess air is often needed for complete combustion. Too much or too little air reduces efficiency.

- Mixing of Fuel and Air: Proper mixing is crucial for uniform combustion. Inadequate mixing leads to incomplete combustion and lower efficiency.

- Temperature: Sufficient temperature is necessary to initiate and sustain combustion. Lower temperatures can lead to incomplete combustion.

- Residence Time: The time the reactants spend in the combustion zone. Insufficient time hinders complete combustion.

- Fuel Properties: The type and quality of fuel used significantly impacts efficiency. For example, a cleaner fuel will lead to better combustion.

- Burner Design: The burner’s design affects the mixing, distribution, and stability of the flame.

Q 4. How do you calculate the adiabatic flame temperature?

The adiabatic flame temperature (AFT) is the theoretical maximum temperature achievable during combustion, assuming no heat loss to the surroundings. It’s a crucial parameter in designing combustion systems. Calculating AFT involves an energy balance, considering the heat released by combustion and the heat capacity of the products. A simplified approach for a hydrocarbon fuel and air combustion involves using the enthalpy of formation of the reactants and products. More sophisticated calculations incorporate specific heat variations with temperature. Software packages and thermodynamic databases are typically used for accurate AFT calculations, especially for complex fuel compositions.

The calculation involves determining the enthalpy change during combustion (ΔHc) and then relating this to the temperature increase using the heat capacities of the combustion products. It’s an iterative process as heat capacity is temperature-dependent.

Q 5. Explain the concept of excess air and its impact on combustion.

Excess air refers to the amount of air supplied to the combustion process beyond the stoichiometric requirement. While stoichiometric combustion is ideal for complete burning, some excess air is often necessary to ensure complete combustion of the fuel. Think of it like adding a little extra oxygen to help your campfire burn brighter.

Impact of Excess Air:

- Complete Combustion: Excess air helps ensure all fuel is burned, reducing unburned hydrocarbons and carbon monoxide emissions.

- Flame Temperature: Excess air reduces the flame temperature as it dilutes the reactants.

- Efficiency: While some excess air is beneficial, excessive amounts can lower efficiency by increasing heat loss and energy required for heating excess air.

- Emissions: Optimal excess air minimizes pollutants (like NOx), but too much can lead to increased NOx.

The optimal amount of excess air is determined through careful experimentation and modelling and depends significantly on the burner design, fuel type, and desired operating conditions.

Q 6. What are the common methods for controlling combustion?

Controlling combustion is vital for maintaining efficiency, minimizing emissions, and ensuring safe operation. Several methods are employed:

- Air-Fuel Ratio Control: Precisely controlling the ratio of air to fuel supplied to the combustion chamber is fundamental. This often involves using sensors (e.g., oxygen sensors) and feedback control systems.

- Temperature Control: Maintaining the optimal combustion temperature range is crucial. This involves monitoring flame temperature and adjusting fuel or air flow accordingly.

- Burner Management: Controlling the location and geometry of the flame using specialized burner designs helps optimize mixing and combustion.

- Preheating Air: Increasing the temperature of the incoming air can improve combustion efficiency and reduce emissions.

- Exhaust Gas Recirculation (EGR): Recirculating a portion of the exhaust gases into the combustion chamber lowers the peak combustion temperature, which helps to reduce nitrogen oxide (NOx) emissions.

Q 7. Describe different types of industrial burners and their applications.

Industrial burners are designed for specific applications, each optimized for efficiency and safety. Think of them like specialized tools for different tasks.

- Diffusers Burners: These burners use a diffusion flame, ideal for applications where high temperatures are needed but precise control is not paramount. Often seen in furnaces.

- Premix Burners: Designed for precise control over the flame characteristics, including temperature and stability. They utilize premixed fuel and air, common in high-efficiency boilers and kilns.

- High-Velocity Burners: These burners use high-velocity jets to promote rapid mixing of fuel and air, allowing for very rapid and efficient combustion. They find application in power generation where high heat fluxes are needed.

- Register Burners: These have adjustable registers to alter the air-fuel ratio and the shape of the flame, offering versatile control for different operating conditions. Commonly used in larger furnaces.

- Fluidized Bed Burners: These are specifically designed for combustion in fluidized bed reactors, which are used for combustion of low-quality fuels or waste materials.

The choice of burner depends on the application’s specific requirements, including fuel type, desired temperature, heat transfer needs, and emission limits.

Q 8. How do you analyze combustion products (e.g., flue gas analysis)?

Flue gas analysis is crucial for optimizing combustion efficiency and minimizing emissions. It involves measuring the composition of gases exiting a combustion process, typically using a gas analyzer. This analyzer employs various techniques, such as infrared spectroscopy or electrochemical sensors, to determine the concentrations of key components.

Key components analyzed typically include:

- Oxygen (O2): Indicates the excess air supplied during combustion. High O2 suggests inefficiency; low O2 might indicate incomplete combustion.

- Carbon Dioxide (CO2): A primary combustion product. Its concentration helps assess the carbon-to-fuel ratio and overall combustion efficiency.

- Carbon Monoxide (CO): A significant pollutant indicating incomplete combustion. High CO levels signal inefficient combustion and potential safety hazards.

- Nitrogen Oxides (NOx): A group of pollutants formed from nitrogen in the air at high temperatures. Their measurement is critical for environmental compliance.

- Sulfur Dioxide (SO2): Formed from sulfur in the fuel. Its concentration is important for determining compliance with sulfur emission regulations.

- Water Vapor (H2O): While not directly a pollutant, its presence helps determine the overall efficiency of the combustion process.

Practical Application: A power plant uses flue gas analysis to adjust the air-fuel ratio, ensuring maximum power output while minimizing CO and NOx emissions. Based on the analysis, operators can make real-time adjustments to optimize the combustion process.

Q 9. Explain the concept of flame stability.

Flame stability refers to the ability of a flame to remain anchored and burn steadily at a specific location within a combustion chamber. It’s influenced by several factors, creating a delicate balance.

Key Factors Affecting Flame Stability:

- Fuel-Air Mixing: Proper mixing of fuel and oxidizer (air) is essential. Insufficient mixing leads to unstable, flickering flames or even flame blow-out.

- Velocity of the Mixture: The speed at which the fuel-air mixture flows through the combustion zone influences stability. Too high a velocity can extinguish the flame.

- Temperature: The temperature of the incoming mixture significantly impacts ignition and flame stability. A minimum temperature is needed to sustain the reaction.

- Turbulence: Moderate turbulence enhances mixing but excessive turbulence can disrupt the flame front.

Example: Imagine a Bunsen burner. If the gas flow is too high or the air intake is insufficient, the flame will lift off the burner’s tip and become unstable, potentially even extinguishing itself. A stable flame ensures consistent and efficient combustion.

Q 10. What are the different types of pollutants produced during combustion?

Combustion processes, especially those involving fossil fuels, generate various pollutants. These pollutants can be broadly categorized:

- Gaseous Pollutants:

- NOx (Nitrogen Oxides): Formed at high temperatures from the reaction of nitrogen and oxygen in the air.

- SOx (Sulfur Oxides): Formed from the combustion of sulfur-containing fuels, primarily sulfur dioxide (SO2).

- CO (Carbon Monoxide): A product of incomplete combustion; a toxic and colorless gas.

- Unburned Hydrocarbons (UHC): Unreacted fuel components that escape combustion.

- Particulate Matter (PM):

- PM10: Particulate matter with a diameter of 10 micrometers or less.

- PM2.5: Particulate matter with a diameter of 2.5 micrometers or less, posing serious health risks.

The specific pollutants and their concentrations depend on factors such as fuel type, combustion conditions, and emission control technologies.

Q 11. Describe methods for controlling NOx emissions.

Controlling NOx emissions is critical for environmental protection. Several methods are employed:

- Low NOx Burners: These burners modify the fuel-air mixing and combustion process to reduce peak flame temperatures, thereby minimizing NOx formation. Examples include staged combustion and lean premixed combustion.

- Selective Catalytic Reduction (SCR): This technology uses a catalyst to reduce NOx to harmless nitrogen (N2) and water (H2O) by injecting a reducing agent, such as ammonia (NH3), into the flue gas.

- Selective Non-Catalytic Reduction (SNCR): Similar to SCR but without a catalyst. It’s less effective but simpler and less expensive.

- Exhaust Gas Recirculation (EGR): A fraction of the exhaust gas is recirculated back into the combustion chamber. This lowers the combustion temperature and reduces NOx formation.

The choice of method depends on factors like the type of combustion system, fuel used, and the desired level of emission reduction.

Q 12. How do you control SOx emissions from combustion processes?

Controlling SOx emissions, primarily SO2, focuses on reducing the sulfur content in the fuel or removing SO2 from the flue gas.

- Fuel Switching: Replacing high-sulfur fuels with low-sulfur alternatives (e.g., natural gas instead of high-sulfur coal) is the simplest approach.

- Fuel Cleaning: Processes like hydrodesulfurization remove sulfur from liquid fuels before combustion.

- Flue Gas Desulfurization (FGD): This technology uses sorbents (e.g., lime or limestone) to react with and remove SO2 from the flue gas. The resulting byproduct is often gypsum, which can have industrial applications.

The choice of method depends on the fuel used, cost considerations, and regulatory requirements.

Q 13. Explain the importance of proper air-fuel mixing in combustion.

Proper air-fuel mixing is paramount for efficient and complete combustion. It determines the rate and completeness of the combustion reaction.

Importance:

- Complete Combustion: Thorough mixing ensures that sufficient oxygen is available to react with all the fuel, maximizing heat release and minimizing the formation of harmful byproducts like CO and UHCs.

- Efficient Combustion: Optimal mixing reduces energy losses by ensuring that the combustion process is completed quickly and efficiently.

- Flame Stability: Good air-fuel mixing promotes stable flame behavior, preventing flame blow-out or flashback.

- Reduced Emissions: By promoting complete combustion, proper mixing reduces emissions of pollutants such as CO, UHCs, and particulate matter.

Example: In a gas turbine engine, intricate designs of the combustor aim for precise fuel-air mixing to maximize efficiency and minimize emissions. Poor mixing can lead to hot spots, incomplete combustion, and higher emissions.

Q 14. What are the safety considerations for industrial combustion systems?

Safety is paramount in industrial combustion systems. Key considerations include:

- Explosion Prevention: Proper ventilation and monitoring of combustible gas levels are crucial to prevent the buildup of flammable mixtures that could lead to explosions. This requires implementing safety systems such as gas detectors and emergency shut-off valves.

- Fire Prevention: Regular inspections and maintenance are critical to prevent fires due to leaks, overheating, or malfunctions. Fire suppression systems, such as sprinklers or fire extinguishers, are vital safety measures.

- Thermal Hazards: High temperatures associated with combustion can pose risks to personnel and equipment. Protective measures include insulation, barriers, and safety signage. Regular temperature monitoring is crucial.

- Toxic Gas Emissions: Combustion processes can generate toxic gases like CO and NOx. Monitoring systems are needed to detect leaks and ensure adequate ventilation to prevent hazardous concentrations.

- Personnel Safety: Training and proper safety procedures are critical for personnel working near combustion systems. This includes the use of personal protective equipment (PPE) and emergency response plans.

Regular inspections, maintenance, and adherence to safety regulations are essential for ensuring safe operation of industrial combustion systems.

Q 15. Describe different types of combustion instrumentation.

Combustion instrumentation is crucial for monitoring and controlling the efficiency and safety of industrial combustion processes. These instruments measure various parameters to ensure optimal operation and prevent malfunctions. Different types include:

Temperature Sensors: Thermocouples, RTDs (Resistance Temperature Detectors), and pyrometers measure temperatures at various points in the combustion chamber, flue gas, and other critical areas. For example, a thermocouple might be used to monitor the flame temperature to ensure complete combustion.

Pressure Sensors: These measure pressure within the combustion chamber and in the flue gas stream. Maintaining the correct pressure is vital for efficient fuel-air mixing and to prevent back pressure issues. Pressure transducers are commonly employed for this purpose.

Gas Analyzers: These are used to determine the composition of the flue gases, specifically measuring O2 (oxygen), CO (carbon monoxide), CO2 (carbon dioxide), and NOx (nitrogen oxides). Low O2 indicates inefficient combustion, while high CO signifies incomplete combustion, and high NOx levels raise environmental concerns. Examples include electrochemical sensors and infrared analyzers.

Flow Meters: These measure the flow rates of fuel and air entering the combustion system. Accurate flow measurement is essential for maintaining the correct fuel-air ratio, which is critical for efficient and clean combustion. Examples include orifice plates, venturi meters, and ultrasonic flow meters.

Flame Detectors: These detect the presence and stability of the flame. This is crucial for safety, as a flame failure can lead to fuel accumulation and potential explosions. Photoelectric sensors and UV detectors are often used.

The selection of instrumentation depends on the specific application and requirements of the combustion system.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you troubleshoot a malfunctioning combustion system?

Troubleshooting a malfunctioning combustion system requires a systematic approach. It begins with understanding the symptoms, such as incomplete combustion (indicated by high CO levels), low efficiency (low steam production in a boiler), or flame instability. Here’s a step-by-step approach:

Gather Data: Collect data from all available instrumentation (temperature, pressure, gas analyzer readings, flow rates). Compare these readings to historical data and established operating parameters.

Visual Inspection: Carefully inspect the combustion chamber, burners, and fuel supply lines for any visible damage, blockages, or signs of corrosion. Look for soot buildup, which often indicates incomplete combustion.

Check Fuel Supply: Verify the fuel supply pressure, flow rate, and quality. A low fuel supply or contaminated fuel can significantly impact combustion efficiency.

Examine Air Supply: Ensure the air supply is adequate and properly mixed with the fuel. Insufficient air will lead to incomplete combustion, while uneven mixing can cause unstable flames.

Analyze Flue Gas: Carefully analyze the flue gas composition. High CO indicates incomplete combustion (requiring adjustments to fuel/air ratio or burner settings), while high O2 indicates excessive air (suggesting a need for fuel adjustment). High NOx levels require scrutiny of combustion temperature and strategies for NOx reduction.

Check Ignition System: If the flame is unstable or absent, check the ignition system components, including electrodes, igniters, and control circuits.

Consult System Diagrams and Manuals: Refer to the system’s operational diagrams, maintenance manuals, and historical data for valuable insights.

Remember, safety is paramount. Always follow safety protocols and lockout/tagout procedures when working on a combustion system.

Q 17. Explain different types of heat exchangers used in combustion systems.

Heat exchangers in combustion systems transfer heat from the hot combustion products to a working fluid, such as water or air. Different types exist, each suited to specific applications:

Shell and Tube Heat Exchangers: These consist of a shell containing a bundle of tubes. The hot combustion gases flow through the shell, while the working fluid flows through the tubes. They’re commonly used in boilers and industrial furnaces. Think of it like a radiator in a car, but on a much larger scale.

Plate Heat Exchangers: These use a series of corrugated plates to create a large heat transfer surface area. They are compact and efficient, often used where space is limited. Imagine a stack of thin, wavy metal sheets with the fluids flowing between them.

Air Preheaters: These heat the combustion air before it enters the combustion chamber. Preheating the air increases combustion efficiency and reduces fuel consumption. Economizers are a common type of air preheater integrated into boiler systems.

Recuperative Heat Exchangers: These transfer heat between two fluid streams without direct mixing. They’re often used to recover waste heat from the flue gases, further increasing efficiency.

Regenerative Heat Exchangers: These utilize a heat-storage medium (like ceramic bricks) to transfer heat between the hot and cold streams. The medium is cycled periodically between the hot and cold sides to absorb and release heat.

The choice of heat exchanger depends on factors such as temperature, pressure, flow rate, and the required heat transfer rate. The design must also consider material compatibility with the combustion products and the working fluid.

Q 18. What are the different types of fuels used in industrial combustion?

Industrial combustion utilizes a variety of fuels, each with its own properties and advantages/disadvantages:

Natural Gas: A widely used fuel due to its clean burning properties and relatively low cost. It primarily consists of methane (CH4).

Fuel Oil: Includes various grades, from light distillates to heavy residual oils. The viscosity and sulfur content vary significantly, impacting combustion characteristics and environmental impact.

Coal: A solid fuel with high energy density but relatively high emissions of pollutants like SOx and particulate matter. Different types exist (anthracite, bituminous, lignite), each with unique properties.

Biofuels: Derived from biomass sources such as wood, agricultural residues, and algae. They are renewable but often require pretreatment for efficient combustion.

Liquefied Petroleum Gas (LPG): A mixture of propane and butane, commonly used in smaller-scale combustion applications. It is easily stored and transported in pressurized cylinders.

Syngas: A mixture of carbon monoxide and hydrogen produced from gasification of coal or biomass. It is used in certain power generation and industrial processes.

The selection of a fuel is influenced by factors such as availability, cost, environmental regulations, and the specific requirements of the combustion system.

Q 19. How do you determine the heating value of a fuel?

The heating value of a fuel represents the amount of heat released when a unit mass or volume of the fuel is completely burned. There are two main types:

Higher Heating Value (HHV): Also known as gross heating value, this accounts for the heat released when the water produced during combustion remains in the vapor phase. It represents the maximum theoretical heat available from the fuel.

Lower Heating Value (LHV): Also known as net heating value, this accounts for the heat released when the water produced during combustion is in the liquid phase. It is a more practical measure of the available heat as it considers the latent heat of vaporization of the water.

The heating value is typically determined experimentally using a bomb calorimeter. In this device, a sample of the fuel is burned in a sealed container under controlled conditions, and the heat released is measured precisely. Standard procedures and calculations, often found in ASTM standards, are used to convert the raw calorimeter data into the HHV and LHV values. Theoretical calculations using the fuel’s chemical composition can also provide estimations, but experimental measurement is more accurate.

Q 20. Explain the concept of radiative heat transfer in combustion.

Radiative heat transfer is a significant mode of heat transfer in combustion systems, particularly in high-temperature environments. It involves the emission of electromagnetic radiation from hot combustion products (gases, soot particles) and their subsequent absorption by other surfaces within the combustion chamber or heat exchanger. Think of it like the heat you feel from a campfire – the heat isn’t transferred through the air (conduction/convection), but directly as radiation.

The intensity of radiative heat transfer depends on factors such as the temperature of the emitting surface, the emissivity (ability to emit radiation) of the surface, and the distance between the emitting and absorbing surfaces. Soot particles play a crucial role, significantly increasing the radiative heat transfer in many combustion systems. Their presence enhances the absorption and emission of radiation across a wide range of wavelengths.

In practical applications, understanding radiative heat transfer is essential for designing efficient combustion systems. For example, the design of furnace walls, baffles, and heat exchangers should consider the radiative heat transfer to optimize heat absorption and minimize heat loss.

Q 21. Describe the role of catalysts in combustion processes.

Catalysts play a role in combustion, mainly in accelerating certain reactions at lower temperatures, often achieving more complete combustion and reducing pollutant emissions. However, their direct use in the primary combustion zone of a typical industrial furnace or boiler is less common than other applications.

Catalysts are more prevalent in applications like catalytic converters in vehicles or in processes related to after-treatment of combustion exhaust gases. In those contexts, catalysts facilitate the oxidation of unburned hydrocarbons (HC) and carbon monoxide (CO) to carbon dioxide (CO2) and water (H2O) at lower temperatures. This reduces harmful emissions. Specific catalysts are designed for specific reactions and operating conditions.

For instance, platinum, palladium, and rhodium are commonly used in automotive catalytic converters. The selection of a catalyst depends on factors such as the target reaction, desired operating temperature, and the need for durability and resistance to poisoning by impurities in the exhaust stream.

Q 22. Explain the difference between complete and incomplete combustion.

Complete combustion occurs when a fuel reacts completely with oxygen, producing only carbon dioxide (CO2) and water (H2O) as byproducts. Think of it like perfectly burning a piece of wood – leaving only ash (minerals) behind. Incomplete combustion, on the other hand, happens when there isn’t enough oxygen or the conditions aren’t optimal, resulting in the formation of carbon monoxide (CO), unburned hydrocarbons (UHC), and soot. Imagine a car engine running poorly – producing black smoke indicates incomplete combustion, releasing harmful pollutants into the air.

- Complete Combustion:

Fuel + O2 → CO2 + H2O + Heat - Incomplete Combustion:

Fuel + O2 → CO + UHC + Soot + Heat

The difference is crucial for efficiency and environmental impact. Complete combustion maximizes energy release, while incomplete combustion wastes fuel and generates harmful emissions.

Q 23. How does pressure affect the combustion process?

Pressure significantly impacts combustion. Higher pressure generally leads to faster reaction rates and increased combustion intensity. This is because it increases the collision frequency of fuel and oxidizer molecules, leading to more frequent successful reactions. Imagine squeezing a sponge – the closer the molecules are, the easier it is for them to react.

In practical terms, higher pressure can improve combustion efficiency in many industrial applications, like gas turbines, where the increased pressure helps to achieve higher temperatures and better mixing of fuel and air. However, excessively high pressures can lead to issues like pre-ignition or detonation, especially in internal combustion engines. Therefore, the optimal pressure must be carefully balanced for a specific application to maximize efficiency and safety.

Q 24. What is the impact of temperature on combustion efficiency?

Temperature plays a vital role in combustion efficiency. Combustion is an exothermic reaction, meaning it releases heat. A higher temperature accelerates the reaction rate, leading to more complete combustion and higher efficiency. Think of lighting a fire – you need a sufficiently high temperature to ignite the fuel. Below a certain temperature (ignition temperature), combustion won’t initiate at all.

However, excessively high temperatures can lead to the formation of nitrogen oxides (NOx), a significant pollutant. So, finding the optimal temperature range is crucial for balancing efficiency and emissions control. This is often managed through sophisticated burner designs and control systems.

Q 25. Describe the challenges of combustion in different fuel types.

Different fuel types present unique challenges in combustion. For example, gaseous fuels like natural gas are relatively easy to mix with air and burn efficiently, while liquid fuels like oil require atomization (breaking them into fine droplets) for proper combustion. Solid fuels, like coal, pose the greatest challenges due to their heterogeneous nature and the need for efficient heat transfer.

- Gaseous Fuels: Easier to mix and control, but potential for leaks and explosions.

- Liquid Fuels: Require atomization, leading to potential clogging and incomplete combustion if not properly managed.

- Solid Fuels: Heterogeneous nature leading to uneven burning and ash handling issues. Requires careful control of air supply and temperature.

The challenges extend to fuel properties like viscosity, volatility, and ash content, all of which need to be considered for optimal combustion.

Q 26. Explain the importance of burner design in efficient combustion.

Burner design is paramount for achieving efficient combustion. A well-designed burner ensures proper mixing of fuel and air, achieving the stoichiometric ratio (the ideal fuel-to-air ratio for complete combustion). It also controls the flame shape and stability, preventing flashback or blow-off, which are safety hazards.

For example, premix burners achieve thorough mixing before ignition, while diffusion burners mix fuel and air within the flame itself. The choice of burner type depends on the fuel type, the desired flame characteristics, and the specific application. Advanced burner designs often incorporate features like swirlers, to enhance mixing, and air staging, to manage NOx emissions.

Q 27. How do you ensure safe operation and maintenance of industrial combustion systems?

Safe operation and maintenance of industrial combustion systems are critical to prevent accidents and ensure longevity. This involves:

- Regular inspections: Checking for leaks, corrosion, and proper functioning of safety devices.

- Proper training: Ensuring operators are well-trained in safe operating procedures and emergency response.

- Routine maintenance: Cleaning and replacing components as needed to prevent malfunctions.

- Safety systems: Implementing flame monitoring, pressure relief valves, and other safety systems to prevent accidents.

- Emission monitoring: Regular monitoring of emissions to ensure compliance with environmental regulations.

A robust safety protocol, including detailed operating procedures and emergency response plans, is essential. Regular training and competence assessments of operating personnel are key to maintaining a safe working environment.

Q 28. Discuss the environmental regulations related to industrial combustion.

Environmental regulations concerning industrial combustion are stringent and continuously evolving, focusing on minimizing emissions of pollutants like NOx, SOx (sulfur oxides), CO, particulate matter (PM), and unburned hydrocarbons (UHC). Regulations vary by location but generally involve setting emission limits, requiring the use of pollution control technologies, and imposing penalties for non-compliance.

Common pollution control technologies include selective catalytic reduction (SCR) for NOx reduction, flue gas desulfurization (FGD) for SOx removal, and particulate filters for PM control. Compliance with these regulations requires careful design, operation, and maintenance of combustion systems and often involves substantial investments in pollution control equipment.

Key Topics to Learn for Industrial Combustion Fundamentals Interview

- Thermodynamics of Combustion: Understanding enthalpy, entropy, and Gibbs free energy changes during combustion processes; applying these principles to optimize combustion efficiency and minimize pollutant formation.

- Stoichiometry and Combustion Calculations: Mastering the calculation of air-fuel ratios, adiabatic flame temperatures, and combustion product compositions; applying these calculations to real-world industrial combustion systems.

- Types of Combustion Systems: Familiarizing yourself with various industrial combustion systems such as furnaces, boilers, gas turbines, and internal combustion engines; understanding their operating principles and applications.

- Combustion Kinetics and Reaction Mechanisms: Grasping the fundamental chemical reactions involved in combustion; understanding the factors influencing reaction rates and flame propagation.

- Pollutant Formation and Control: Knowing the sources and mechanisms of formation of major pollutants (NOx, SOx, particulate matter); understanding various emission control technologies such as selective catalytic reduction (SCR) and low NOx burners.

- Heat Transfer in Combustion Systems: Understanding the mechanisms of heat transfer (conduction, convection, radiation) in combustion chambers; analyzing heat transfer rates and optimizing heat recovery.

- Combustion Diagnostics and Instrumentation: Familiarizing yourself with techniques used to monitor and control combustion processes; understanding the applications of various sensors and analytical methods.

- Combustion Modeling and Simulation: Understanding the use of computational fluid dynamics (CFD) and other modeling techniques to simulate and optimize combustion processes.

- Safety and Environmental Regulations: Understanding relevant safety procedures and environmental regulations concerning industrial combustion systems.

- Practical Problem-Solving: Developing the ability to analyze combustion-related problems, identify root causes, and propose effective solutions. This includes troubleshooting combustion inefficiencies and emission issues.

Next Steps

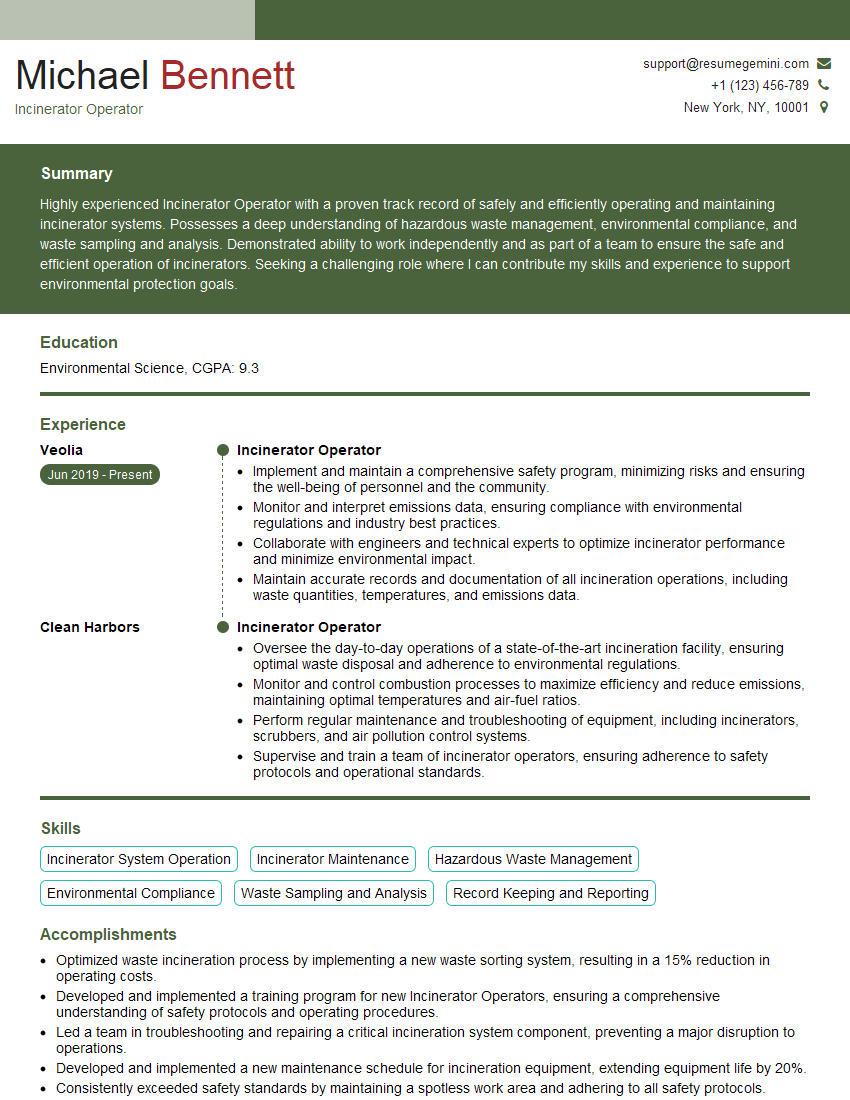

Mastering Industrial Combustion Fundamentals is crucial for advancing your career in power generation, process industries, or environmental engineering. A strong understanding of these principles will make you a highly sought-after candidate. To maximize your job prospects, it’s essential to present your skills effectively. Creating an ATS-friendly resume is key to getting your application noticed by recruiters and hiring managers. ResumeGemini is a trusted resource that can help you build a professional and impactful resume. We offer examples of resumes tailored specifically to Industrial Combustion Fundamentals to guide you through the process. Invest in your future; invest in a strong resume.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?