Preparation is the key to success in any interview. In this post, we’ll explore crucial Instrumentation and Sensors interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Instrumentation and Sensors Interview

Q 1. Explain the difference between accuracy and precision in instrumentation.

Accuracy and precision are crucial concepts in instrumentation, often confused but distinctly different. Accuracy refers to how close a measurement is to the true value. Think of it like hitting the bullseye on a dartboard – a highly accurate measurement is very close to the center. Precision, on the other hand, refers to how close repeated measurements are to each other. This is like consistently hitting the same spot on the dartboard, even if that spot isn’t the bullseye. You can have high precision without high accuracy (consistently missing the bullseye by the same amount), and vice-versa (occasionally hitting the bullseye but with inconsistent results).

Example: Imagine measuring the length of a table. An accurate measurement might be 1.5 meters, the true length. High precision would mean that multiple measurements with the same instrument would yield results very close to each other, perhaps 1.49m, 1.51m, 1.50m. Low accuracy and low precision could result in measurements like 1.2m, 1.7m, 1.3m.

Q 2. Describe different types of sensors and their applications.

Sensors are the foundation of any measurement system, converting physical phenomena into measurable signals. There’s a vast array of sensor types, each tailored to specific applications:

- Temperature Sensors: Thermocouples, RTDs (Resistance Temperature Detectors), thermistors, and infrared sensors measure temperature in various applications like industrial process control, weather monitoring, and medical equipment.

- Pressure Sensors: Piezoresistive, capacitive, and strain gauge pressure sensors are used in everything from tire pressure monitoring systems to industrial automation and aerospace applications.

- Flow Sensors: These measure fluid flow rate, using technologies like ultrasonic, vortex shedding, and differential pressure. Applications range from water management to chemical processing.

- Light Sensors: Photodiodes, phototransistors, and photoresistors detect light intensity, finding use in cameras, lighting control systems, and environmental monitoring.

- Position Sensors: Potentiometers, encoders, and LVDTs (Linear Variable Differential Transformers) measure position or displacement, critical in robotics, automation, and machine control.

- Accelerometers and Gyroscopes: These inertial sensors measure acceleration and angular velocity, essential in smartphones, drones, and navigation systems.

The choice of sensor depends heavily on the application’s requirements, including the type of physical quantity to be measured, the required accuracy and precision, the operating environment, and cost constraints.

Q 3. What are the common sources of error in measurement systems?

Measurement systems are susceptible to various errors that can significantly affect the accuracy and reliability of the results. These errors can be broadly classified into:

- Systematic Errors: These errors are consistent and repeatable, often caused by imperfections in the instrument or the measurement process. Examples include calibration errors, zero offset, and environmental effects (temperature, pressure).

- Random Errors: These errors are unpredictable and vary randomly. They’re often due to noise in the signal, fluctuations in the measured quantity, or limitations in the instrument’s resolution.

- Human Errors: These are introduced by the operator, such as incorrect reading of the instrument, improper setup, or recording mistakes.

Understanding and mitigating these error sources is vital for ensuring the quality of measurements. Techniques like proper calibration, using appropriate signal processing techniques, and establishing rigorous measurement procedures are crucial.

Q 4. How do you calibrate a sensor?

Sensor calibration is a critical procedure to ensure accurate and reliable measurements. It involves comparing the sensor’s output to known, accurate standards. The process generally involves these steps:

- Prepare the equipment and environment: Ensure the sensor is in good condition, the calibration standards are traceable and accurate, and the environment is stable.

- Establish the calibration points: Select a range of input values representing the sensor’s operating range.

- Apply the calibration standards: Apply the known input values to the sensor and record the corresponding output values.

- Develop a calibration curve: Plot the input values against the output values. This curve can be linear or non-linear depending on the sensor’s characteristics.

- Implement the calibration: Use the calibration curve to correct the sensor’s readings, either through software adjustments or by creating a lookup table.

- Document the calibration: Record the calibration date, standards used, and the calibration curve or parameters. This ensures traceability and helps identify potential drifts over time.

Different calibration methods exist, such as two-point calibration, multi-point calibration, and using specialized calibration equipment.

Q 5. Explain the concept of signal conditioning.

Signal conditioning is the process of modifying or enhancing a sensor’s output signal to make it suitable for processing, display, or further use. Raw sensor signals are often weak, noisy, or in an unsuitable format. Signal conditioning addresses these issues. Common signal conditioning techniques include:

- Amplification: Increasing the signal’s amplitude to improve its signal-to-noise ratio.

- Filtering: Removing unwanted noise or interference from the signal.

- Linearization: Converting a non-linear sensor response into a linear one for easier processing.

- Offset Compensation: Removing any bias or offset in the sensor’s output.

- Analog-to-Digital Conversion (ADC): Converting an analog signal from the sensor into a digital format for computer processing.

Example: A thermocouple might produce a very weak millivolt signal. Signal conditioning would involve amplifying this signal and removing any noise before converting it into a digital representation of temperature for display on a digital thermometer.

Q 6. What are different types of transducers?

Transducers are devices that convert one form of energy into another. They are often used interchangeably with the term ‘sensor,’ but a transducer is a broader term. Here are some types:

- Electromagnetic Transducers: These convert mechanical energy into electrical energy, or vice versa. Examples include LVDTs (Linear Variable Differential Transformers), which convert displacement into voltage, and loudspeakers, which convert electrical signals into sound.

- Photoelectric Transducers: These convert light energy into electrical energy. Examples include photodiodes and phototransistors used in light sensors.

- Piezoelectric Transducers: These convert mechanical pressure or stress into electrical energy, and vice versa. Applications include pressure sensors and ultrasonic transducers.

- Thermoelectric Transducers: These convert temperature differences into electrical voltage (thermocouples) or vice versa (Peltier elements).

- Capacitive Transducers: These measure changes in capacitance due to changes in distance, pressure, or other physical parameters.

The type of transducer selected depends on the specific energy conversion required for the application.

Q 7. Describe different types of signal transmission methods.

Signal transmission methods depend on several factors including distance, bandwidth requirements, noise immunity, and cost. Common methods include:

- Wired Transmission: Signals are transmitted via physical wires. This offers good reliability and high bandwidth but can be expensive and inflexible for long distances. Examples include twisted-pair cables, coaxial cables, and fiber optic cables.

- Wireless Transmission: Signals are transmitted through the air using radio waves, microwaves, or infrared signals. This offers flexibility and mobility but is susceptible to interference and has limited bandwidth in some cases. Examples include Bluetooth, Wi-Fi, and Zigbee.

Choosing the right method involves careful consideration of factors like distance, data rate, environmental conditions (interference), power consumption, and cost.

Q 8. How do you handle noisy signals in instrumentation?

Noisy signals are a common problem in instrumentation, stemming from various sources like electromagnetic interference (EMI), sensor drift, or environmental factors. Handling them effectively is crucial for accurate measurements. The approach involves a combination of techniques:

Filtering: This is a fundamental step. Low-pass, high-pass, band-pass, and notch filters can be implemented digitally or using analog circuits to remove unwanted frequencies. For example, a low-pass filter can eliminate high-frequency noise while preserving the desired signal. The choice of filter depends on the nature of the noise and the signal characteristics.

Averaging: Taking multiple readings and calculating the average can significantly reduce random noise. This is particularly effective for high-frequency noise. The more readings averaged, the better the noise reduction, but at the cost of response time.

Signal Conditioning: Techniques like amplification, attenuation, and impedance matching can improve the signal-to-noise ratio (SNR) before further processing. For example, amplifying a weak signal makes it less susceptible to noise.

Calibration and Compensation: Regular calibration of sensors helps to correct for systematic errors and drift. Compensation techniques, often involving software algorithms, can further improve accuracy by adjusting for known error sources.

Shielding and Grounding: Proper shielding of cables and equipment minimizes the impact of EMI. Good grounding practices further reduce noise by providing a low-impedance path for stray currents.

Imagine trying to hear a quiet conversation in a noisy room. Filtering is like using noise-canceling headphones, averaging is like focusing on the overall tone of the voices, and signal conditioning is like moving closer to the speakers. A combination of these approaches is often necessary for optimal results.

Q 9. Explain the concept of a control loop.

A control loop is a closed-loop system that uses feedback to maintain a process variable at a desired setpoint. Think of it as a self-regulating system. It consists of four key elements:

Sensor: Measures the process variable (e.g., temperature, pressure, level).

Controller: Compares the measured value with the setpoint and generates a control signal.

Actuator: Acts on the process based on the control signal (e.g., opening or closing a valve, adjusting a heater).

Process: The system being controlled.

The sensor feeds back information to the controller. The controller compares the actual value to the desired value and adjusts the actuator accordingly. For example, in a home thermostat, the sensor measures the room temperature, the controller compares it to the setpoint, and the actuator (furnace or AC) turns on or off to maintain the desired temperature. This feedback loop ensures continuous adjustment and stability.

Q 10. What are PID controllers and how do they work?

PID controllers are ubiquitous in control systems. PID stands for Proportional, Integral, and Derivative. They use three terms to calculate the control signal:

Proportional (P): The output is proportional to the error (difference between setpoint and measured value). A large error results in a large output. This term addresses the current error.

Integral (I): The output is proportional to the accumulated error over time. This term addresses past errors and eliminates steady-state error. It helps the system reach the setpoint.

Derivative (D): The output is proportional to the rate of change of the error. This term anticipates future errors and reduces oscillations. It helps to prevent overshoot.

The overall control signal is the sum of these three terms: Output = Kp * Error + Ki * ∫Error dt + Kd * d(Error)/dt where Kp, Ki, and Kd are tuning parameters (gain constants) that determine the relative contribution of each term. Tuning these parameters is crucial to achieve optimal performance, balancing responsiveness and stability. Improper tuning can lead to oscillations or slow response.

Q 11. Describe different types of industrial communication protocols (e.g., Profibus, Modbus).

Industrial communication protocols are crucial for transferring data between instruments, controllers, and other devices in an industrial setting. Some common protocols include:

Profibus (PROFIsafe): A fieldbus system widely used in industrial automation for process control and factory automation. It supports both digital and analog signals and offers high speed and reliability. Profisafe is its safety-related extension.

Modbus: A simple, widely used serial communication protocol, often found in SCADA (Supervisory Control and Data Acquisition) systems. It’s known for its open standard and ease of implementation. It’s commonly used in simpler applications.

Ethernet/IP: An industrial Ethernet protocol, offering high bandwidth and flexibility. This protocol is used extensively in modern industrial environments where high data transmission rates are crucial.

Profinet: Another industrial Ethernet protocol based on standard Ethernet but optimized for industrial environments. It’s frequently found in demanding applications needing high speed and deterministic communication.

CANopen: A communication protocol based on the Controller Area Network (CAN) bus system, often used in motion control and robotics. It is robust and well-suited for applications requiring real-time control.

Each protocol has its own strengths and weaknesses, making the choice dependent on the specific application requirements, such as speed, distance, reliability, and cost.

Q 12. Explain the importance of sensor selection in a specific application.

Sensor selection is paramount. The wrong sensor can lead to inaccurate measurements, system malfunctions, and even safety hazards. Consider these factors:

Measurand: What physical quantity needs to be measured (temperature, pressure, flow, etc.)?

Range and Accuracy: What is the expected range of values and the required accuracy? A sensor with too narrow a range or low accuracy will be useless.

Environmental Conditions: Will the sensor be exposed to extreme temperatures, humidity, vibration, or corrosive substances? The sensor must withstand these conditions.

Output Signal: What type of output signal does the sensor provide (analog, digital, etc.)? The output should be compatible with the data acquisition system.

Cost and Availability: Balance cost with performance and reliability. Consider maintenance and replacement costs over the sensor’s lifespan.

Response Time: How fast does the sensor need to respond to changes in the measurand? High-speed applications require sensors with short response times.

For example, measuring the temperature of a high-pressure steam line requires a robust, high-temperature sensor with appropriate pressure ratings. Using a standard thermocouple designed for room temperature would be disastrous.

Q 13. How do you troubleshoot a malfunctioning sensor?

Troubleshooting a malfunctioning sensor involves a systematic approach:

Check the Obvious: Start with the simple things. Is the sensor properly connected? Is there power to the sensor? Are there any visible signs of damage?

Inspect the Wiring: Examine the wiring for breaks, shorts, or loose connections. Use a multimeter to check continuity and voltage levels.

Calibrate the Sensor: Compare the sensor’s reading to a known standard. Calibration can reveal drift or other systematic errors.

Review Sensor Specifications: Check the sensor’s operating range, accuracy, and response time. Is the sensor being used within its specifications? Are there any environmental conditions exceeding the specifications?

Test with a Known Signal: If possible, apply a known input to the sensor and verify the output. This helps isolate whether the problem lies with the sensor itself or the signal conditioning circuitry.

Check for Interference: Assess for electromagnetic interference (EMI) or other environmental factors that may affect the sensor’s reading.

Replace the Sensor: If all else fails, replacing the sensor is often the most straightforward solution. This is especially true if the sensor is old, or there is a suspicion that there is something fundamentally wrong with the sensor.

Remember to always follow safety procedures when working with sensors and instrumentation.

Q 14. What are the safety considerations when working with instrumentation?

Safety is paramount in instrumentation. Risks include electrical hazards, high temperatures, high pressures, hazardous materials, and moving machinery. Safety considerations include:

Lockout/Tagout (LOTO): Proper lockout/tagout procedures must be followed before working on any equipment to prevent accidental energization.

Personal Protective Equipment (PPE): Appropriate PPE, such as safety glasses, gloves, and hearing protection, should be worn at all times.

Proper Grounding and Shielding: Ensure proper grounding and shielding to prevent electrical shocks and interference.

Risk Assessment: Conduct a thorough risk assessment before commencing any work to identify and mitigate potential hazards.

Emergency Procedures: Establish clear emergency procedures and ensure all personnel are familiar with them.

Calibration and Maintenance: Regular calibration and maintenance of instrumentation help prevent malfunctions and accidents.

Hazardous Area Classifications: Follow guidelines for working in hazardous areas (e.g., areas with flammable gases or dust). Choose intrinsically safe equipment where necessary.

Never compromise on safety. It’s better to be overly cautious than to suffer an accident.

Q 15. Explain the concept of data acquisition systems.

A Data Acquisition System (DAS) is a collection of hardware and software components designed to measure, record, and analyze physical phenomena. Think of it as a sophisticated, automated measuring system. It typically involves sensors to capture data from the real world, signal conditioning circuits to prepare the signals for processing, an analog-to-digital converter (ADC) to translate analog signals into digital form for computer processing, and software to store and analyze the resulting data.

For instance, a DAS might be used in a manufacturing plant to monitor the temperature and pressure within a reactor. Sensors would measure these parameters, the DAS would collect, store, and display the data, possibly triggering an alarm if the values exceed pre-set limits. Another example is in environmental monitoring, where a DAS could record air quality parameters like pollutants over time.

A basic DAS architecture usually includes: Sensors -> Signal Conditioning -> Analog-to-Digital Converter (ADC) -> Data Acquisition Card (DAQ) -> Computer with Software.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe different methods for data logging and analysis.

Data logging and analysis methods vary depending on the application and the scale of data. Common approaches include:

- Spreadsheet Software (e.g., Excel): Suitable for smaller datasets, enabling basic data visualization and analysis. Simple calculations and charting can be performed. However, it struggles with large volumes of data and advanced analysis.

- Specialized Data Acquisition Software (e.g., LabVIEW, DASYLab): These offer extensive features for data acquisition, logging, and sophisticated analysis including signal processing, filtering, and statistical analysis. They handle large datasets efficiently.

- Databases (e.g., SQL): For large, complex datasets, databases provide robust storage, retrieval, and advanced querying capabilities. This approach is crucial when dealing with extensive long-term monitoring projects.

- Python with Libraries like Pandas and NumPy: Highly flexible for data manipulation, analysis, and visualization. Offers significant programming flexibility. Can be integrated with databases or other software tools.

The choice of method hinges on the volume, complexity, and type of data, as well as the analytical capabilities required. For instance, while a spreadsheet might suffice for simple sensor readings, a database coupled with Python might be necessary for real-time analysis of high-speed data streams from multiple sensors in a complex engineering system.

Q 17. How do you ensure the reliability of instrumentation systems?

Reliability in instrumentation systems is paramount. It’s ensured through a multi-faceted approach:

- Calibration and Verification: Regular calibration against traceable standards ensures accuracy. Verification checks the system’s overall performance.

- Redundancy: Incorporating backup sensors or systems provides continued operation even if one component fails. This is crucial in safety-critical applications.

- Robust Design: Choosing sensors and components rated for the operating environment (temperature, humidity, vibration) minimizes failures. Proper shielding and grounding reduce noise.

- Data Validation: Implementing checks and algorithms to detect faulty or inconsistent data is crucial. This might involve range checks, plausibility checks, or statistical analysis.

- Regular Maintenance: Scheduled maintenance, including cleaning, inspecting, and replacing worn parts, extends the lifespan and reliability of the system. This includes preventative maintenance, which aims to stop potential problems from arising.

For example, in a critical aerospace application, redundant sensors and systems are essential to guarantee safety and reliable data in case one sensor fails. Robust data validation is also crucial to filter out erroneous readings that could lead to dangerous situations.

Q 18. What are the advantages and disadvantages of different sensor technologies?

Different sensor technologies present unique trade-offs:

- Resistive Sensors (e.g., Thermistors): Simple, inexpensive, but often less accurate and sensitive than other types. Sensitive to external factors.

- Capacitive Sensors: Suitable for measuring distance, level, and other parameters. Generally, more precise and less susceptible to external interference than resistive sensors.

- Inductive Sensors: Detect the presence of metallic objects, often used in proximity sensing. Robust and simple.

- Optical Sensors (e.g., Photodiodes): Excellent for light detection, but can be sensitive to environmental conditions such as temperature and humidity.

- Piezoelectric Sensors: Sensitive to pressure and vibration; useful in applications like accelerometers and microphones. High sensitivity and fast response times.

The choice of sensor technology depends on the application’s requirements for accuracy, sensitivity, cost, and environmental factors. For instance, in a high-precision application like medical imaging, high-accuracy sensors are essential, even if they are more expensive. In contrast, a simple proximity sensor may be sufficient for basic machine control applications where cost is a significant constraint.

Q 19. Explain the concept of sensor integration.

Sensor integration refers to the process of connecting and coordinating multiple sensors within a system to achieve a unified measurement or control objective. This involves both the hardware (physical connections, wiring, power supplies) and software (data synchronization, fusion algorithms) aspects. It often leads to more comprehensive and accurate system measurements than using individual sensors alone.

Imagine a robotic arm needing to accurately position itself. A well-integrated system might incorporate multiple sensors: Position sensors in each joint, force sensors in the end effector, and possibly vision sensors. These sensors feed data to a central processing unit that coordinates the arm’s movements using data fusion techniques, creating a more robust and accurate system than relying on any single sensor’s data in isolation. Sensor integration improves overall measurement accuracy, reduces errors, and enhances functionality.

Q 20. Describe your experience with specific instrumentation software (e.g., LabVIEW, DASYLab).

I have extensive experience with LabVIEW, having used it extensively for data acquisition, control, and analysis in various projects. For instance, in one project, I developed a LabVIEW application to monitor and control a complex chemical reactor. The system acquired temperature, pressure, and flow rate data from multiple sensors, processed it in real-time, and displayed the data on a graphical user interface (GUI). This involved using LabVIEW’s data acquisition functions, signal processing tools, and its powerful graphical programming capabilities. Another project involved designing a user interface in LabVIEW to allow non-technical users to control and monitor an automated testing process. This highlighted LabVIEW’s user-friendly GUI capabilities for designing intuitive user interfaces.

While I haven’t worked directly with DASYLab, my familiarity with other data acquisition software, coupled with its similar functionality, means I can quickly become proficient.

Q 21. How do you deal with sensor drift and aging?

Sensor drift and aging are common challenges in instrumentation. Sensor drift refers to the gradual change in output over time, while aging encompasses various degradation processes that affect sensor performance. These are often addressed using several techniques:

- Calibration: Regular calibration against known standards corrects for drift. Frequent calibration is crucial for highly sensitive applications.

- Compensation Techniques: Software algorithms can compensate for known drift patterns based on sensor characteristics. Temperature compensation is a common example.

- Redundancy: Using multiple sensors and averaging their readings can reduce the impact of individual sensor drift.

- Predictive Maintenance: Monitoring sensor behavior over time allows for predicting when sensor replacement might be necessary.

- Sensor Selection: Choosing sensors with lower drift rates or longer lifespans mitigates the problem from the outset.

For example, in a long-term environmental monitoring project, regular calibration and data validation are essential to account for the impact of sensor drift and aging on the data’s accuracy. Algorithms to detect unusual trends and changes in sensor behaviour also form a significant part of a robust system.

Q 22. Explain your understanding of different types of filters used in signal processing.

Filters are crucial in signal processing for removing unwanted noise and isolating the signal of interest. Think of it like sifting sand to get only the gold – the signal is the gold, and the noise is the sand. Different filters achieve this using various techniques. They are broadly categorized by their characteristics in the frequency domain.

- Low-pass filters: These allow low-frequency signals to pass through while attenuating high-frequency components. Imagine a bass-boost in your audio system – that emphasizes the low frequencies, filtering out the highs. A simple example is an RC circuit.

- High-pass filters: These do the opposite, allowing high-frequency signals to pass while attenuating low-frequency ones. Think of a treble boost, highlighting the high-pitched sounds. Again, a simple RC circuit can be configured as a high-pass filter.

- Band-pass filters: These allow only a specific range of frequencies to pass, rejecting both lower and higher frequencies. Think of a radio tuner; it selects a specific frequency band to receive a station, filtering out other frequencies.

- Band-stop (notch) filters: These are the inverse of band-pass; they reject a specific range of frequencies while allowing others to pass. This is useful for eliminating specific interference signals, like removing a 60Hz hum from a power supply.

- Finite Impulse Response (FIR) filters: These are digital filters with a finite duration impulse response. They are typically more stable and easier to design than IIR filters but can require more computation.

- Infinite Impulse Response (IIR) filters: These digital filters have an impulse response that theoretically lasts forever (though it decays). They’re often more efficient computationally than FIR filters for achieving the same filtering characteristics, but they can be more prone to instability.

The choice of filter depends heavily on the specific application and the nature of the noise. For instance, in biomedical signal processing, a band-pass filter might isolate the heart rate from an ECG signal, while a notch filter might remove power line interference. In industrial control, low-pass filters can smooth out noisy sensor readings.

Q 23. Describe your experience with different types of actuators.

Actuators are the muscles of a control system; they convert energy into mechanical motion or some other form of output. My experience encompasses a variety of actuator types, each suitable for different applications and environments.

- Electric actuators: These use electrical energy, and I’ve worked extensively with stepper motors (precise, step-by-step motion), servo motors (precise motion control with feedback), and solenoid valves (binary on/off operation).

- Pneumatic actuators: Using compressed air, these offer high power-to-weight ratios but require an air compressor. I’ve used pneumatic cylinders in applications requiring significant force, and pneumatic valves for controlling air flow in automated processes.

- Hydraulic actuators: These leverage pressurized liquids, providing immense force but are less precise than electric actuators and require a hydraulic power unit. I have experience integrating hydraulic cylinders in heavy machinery applications.

- Piezoelectric actuators: These use the piezoelectric effect to generate precise, small movements. They are commonly used in precision positioning systems and micro-robotics, where I utilized them in a high-resolution microscopy project.

Selecting the right actuator involves considering factors like precision, speed, power requirements, environmental conditions, cost, and maintenance. For instance, a high-precision positioning system might use a piezoelectric actuator, while a heavy-duty industrial robot arm might need a hydraulic actuator. Each project requires careful actuator selection based on its specific demands.

Q 24. How do you ensure the compatibility of different instruments in a system?

Ensuring compatibility among instruments in a system is crucial for proper function and data integrity. This involves considering several key aspects:

- Signal levels and types: Instruments must be compatible in terms of voltage levels (e.g., 0-5V, 4-20mA), signal types (analog, digital), and data formats (e.g., ASCII, binary). Incompatible signal levels can lead to incorrect readings, or damage instruments.

- Communication protocols: Different instruments may communicate using various protocols like Modbus, Profibus, Ethernet/IP, or CAN bus. Proper selection and configuration of these protocols are vital for seamless data exchange.

- Physical interfaces: The physical connections must be compatible. Consider connector types, cable lengths, grounding, and shielding to prevent signal interference and maintain data integrity. Improper grounding can lead to noise and inaccurate measurements.

- Timing and synchronization: If multiple instruments are used for simultaneous measurements, careful synchronization is vital to ensure accurate temporal relationships between data points. This could involve using a common clock source or implementing a precise synchronization protocol.

- Environmental considerations: Instruments should be selected to withstand the environmental conditions of the application, including temperature, pressure, humidity, and electromagnetic interference. Failure to consider environmental factors can compromise instrument reliability and data accuracy.

A systematic approach, including careful review of instrument specifications and utilizing compatibility matrices, is essential to ensure a smooth integration. In my experience, thorough pre-project planning and careful selection based on well-defined system requirements are key to avoiding compatibility issues.

Q 25. Explain your experience with fault detection and diagnosis in instrumentation systems.

Fault detection and diagnosis (FDD) in instrumentation systems are critical for safety, reliability, and efficient maintenance. My experience involves a multifaceted approach:

- Redundancy and self-checking: Implementing redundant sensors and incorporating self-checking routines allows for early detection of sensor failures. For example, comparing readings from two independent sensors can highlight discrepancies.

- Signal analysis techniques: Analyzing sensor signals for anomalies, such as unexpected drifts, spikes, or oscillations, is crucial. Techniques like statistical process control (SPC), wavelet analysis, and spectral analysis can detect subtle deviations indicating potential faults.

- Expert systems and knowledge-based systems: These employ rules and knowledge bases derived from expert experience to diagnose faults based on symptoms. They can streamline troubleshooting by guiding technicians to likely causes.

- Model-based diagnosis: Comparing measured data with a model of the system’s expected behavior can help identify inconsistencies indicating faults. This can pinpoint the location of the fault more accurately.

- Data logging and trend analysis: Continuous monitoring and recording of instrument data enable the identification of gradual degradation or impending failures through trend analysis. This provides valuable insights into the health and longevity of the instruments.

In a past project, a sudden increase in pressure sensor noise indicated a developing leak. Early detection, thanks to continuous monitoring and noise analysis, prevented a catastrophic failure. A combination of these techniques is usually most effective in achieving robust and timely fault detection and diagnosis.

Q 26. What are the latest trends and advancements in instrumentation and sensor technology?

Instrumentation and sensor technology are rapidly evolving. Some key trends include:

- Miniaturization and microelectromechanical systems (MEMS): Sensors are becoming smaller, cheaper, and more energy-efficient, opening doors to new applications like wearable sensors and implantable medical devices. This miniaturization often leads to improvements in sensitivity and response time.

- Wireless sensor networks (WSNs): Wireless communication enhances flexibility and scalability in monitoring large-scale systems. This eliminates the need for extensive cabling, simplifying installation and maintenance.

- Internet of Things (IoT) integration: Sensors are becoming increasingly integrated into IoT platforms, enabling remote monitoring, data analysis, and automation. This allows for better real-time monitoring and control.

- Artificial intelligence (AI) and machine learning (ML) integration: AI and ML algorithms are being used for advanced signal processing, fault detection, and predictive maintenance, leading to increased system reliability and efficiency. AI enables pattern recognition in sensor data that might be missed by traditional methods.

- Advanced materials and fabrication techniques: New materials and manufacturing techniques are constantly improving sensor performance, extending their lifespan, and improving their ability to operate in harsh environments. Graphene and other advanced materials show great promise.

These advancements are transforming various fields, including healthcare, manufacturing, environmental monitoring, and infrastructure management, creating more efficient, reliable, and intelligent systems.

Q 27. Describe a challenging instrumentation project you have worked on and how you overcame the challenges.

A particularly challenging project involved designing and implementing an instrumentation system for monitoring the structural integrity of a large bridge. The challenge stemmed from the harsh environment (extreme temperature fluctuations, vibrations, and exposure to elements), the need for high accuracy and reliability, and the difficult access for maintenance.

To overcome these challenges, we employed a multi-pronged approach:

- Robust sensor selection: We selected sensors specifically designed for harsh environments, ensuring resistance to corrosion, temperature extremes, and vibration. We also incorporated redundancy for critical measurements.

- Wireless communication: To avoid the complexities and costs associated with extensive cabling, we used a wireless sensor network for data transmission. This simplified installation and reduced maintenance needs.

- Data encryption and security measures: Robust security measures were implemented to protect data integrity and prevent unauthorized access to the system.

- Remote monitoring and diagnostics: We implemented a remote monitoring system with diagnostic capabilities, allowing us to detect and address potential issues proactively, even without direct physical access.

- Predictive maintenance: Using machine learning algorithms, we developed a predictive maintenance model to anticipate potential failures and schedule maintenance before critical issues occur.

This project required careful planning, rigorous testing, and close collaboration among engineers from diverse backgrounds. The successful implementation resulted in a reliable, efficient, and cost-effective monitoring system, enhancing the safety and longevity of the bridge.

Q 28. How do you stay up-to-date with the latest advancements in instrumentation and sensor technologies?

Staying current in this rapidly evolving field necessitates a multi-faceted approach:

- Professional organizations and conferences: Actively participating in organizations like IEEE Instrumentation and Measurement Society and attending relevant conferences allows me to network with experts and learn about the latest advancements.

- Technical journals and publications: Regularly reading journals like IEEE Transactions on Instrumentation and Measurement and other specialized publications keeps me abreast of research and development in the field.

- Online resources and webinars: Utilizing online platforms, professional websites, and participating in webinars provide access to a wealth of information and educational resources.

- Industry events and trade shows: Attending trade shows and industry events provides opportunities to see new products and technologies firsthand and engage with manufacturers and other professionals.

- Continuous learning and training: Pursuing continuing education opportunities, such as online courses and workshops, enables me to enhance my skills and knowledge in specific areas of instrumentation and sensor technology.

This combination ensures that I’m constantly learning and adapting my expertise to meet the evolving needs and challenges of the field.

Key Topics to Learn for Your Instrumentation and Sensors Interview

Ace your next interview by mastering these crucial areas within Instrumentation and Sensors. We’ve broken down the key concepts to help you feel confident and prepared.

- Sensor Fundamentals: Understand different sensor types (e.g., resistive, capacitive, inductive, optical), their operating principles, and limitations. Explore signal conditioning techniques crucial for accurate data acquisition.

- Signal Processing: Grasp the basics of signal amplification, filtering, and noise reduction. Practice analyzing and interpreting sensor signals to extract meaningful data. Consider the impact of different filtering techniques on signal accuracy.

- Data Acquisition Systems (DAQ): Familiarize yourself with the architecture and components of DAQ systems, including analog-to-digital converters (ADCs), microcontrollers, and data logging software. Understand the importance of data synchronization and calibration.

- Instrumentation Systems: Learn about different types of instrumentation systems used in various applications (e.g., industrial process control, environmental monitoring, biomedical engineering). Focus on system design considerations, such as accuracy, precision, and reliability.

- Calibration and Error Analysis: Master techniques for calibrating sensors and instruments to ensure accuracy. Understand different types of errors (systematic, random) and methods for minimizing their impact on measurements. Practice error propagation calculations.

- Specific Sensor Technologies: Depending on your target role, delve deeper into specific sensor technologies, such as pressure sensors, temperature sensors, flow sensors, or accelerometers. Understanding their unique characteristics and applications is key.

- Practical Applications and Case Studies: Prepare examples from your experience (projects, coursework, internships) demonstrating your understanding of instrumentation and sensors in real-world applications. Be ready to discuss challenges faced and solutions implemented.

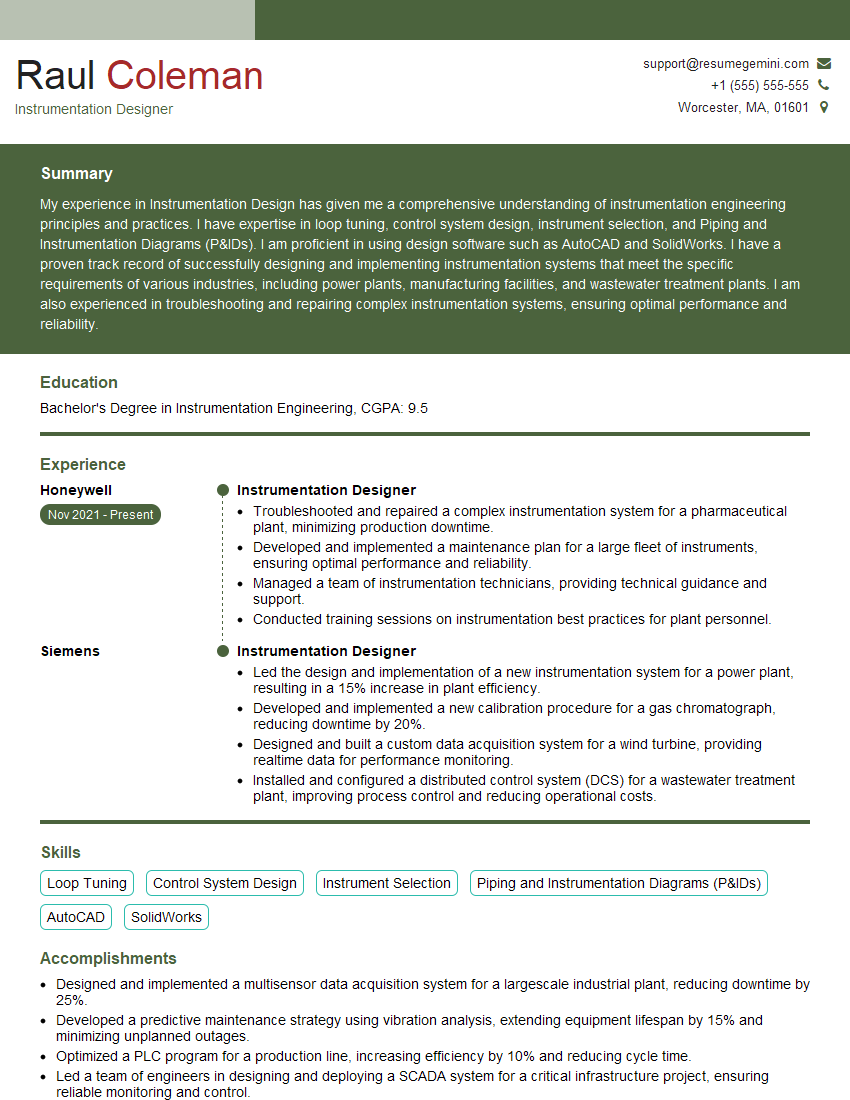

Next Steps: Unlock Your Career Potential

Mastering Instrumentation and Sensors opens doors to exciting career opportunities in diverse fields. To maximize your job prospects, invest time in creating a strong, ATS-friendly resume that highlights your skills and accomplishments effectively. ResumeGemini can significantly help you build a professional resume tailored to the Instrumentation and Sensors field, increasing your chances of landing your dream job. We provide examples of resumes specifically designed for this industry to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?