Are you ready to stand out in your next interview? Understanding and preparing for Job Site Management and Clean-up interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Job Site Management and Clean-up Interview

Q 1. Describe your experience in managing waste disposal on a job site.

Effective waste disposal management on a job site is crucial for safety, environmental compliance, and project efficiency. My approach involves a multi-pronged strategy focusing on segregation, containment, and proper disposal.

Firstly, I implement a clear waste segregation plan, categorizing materials into recyclable (metal, wood, plastic, cardboard), non-recyclable (general waste), and hazardous waste (chemicals, asbestos, etc.). Clearly labelled bins are strategically placed across the site to encourage proper sorting. This reduces the volume of waste sent to landfills and maximizes recycling opportunities.

Secondly, I ensure all waste is properly contained. This means using appropriate containers – sealed bins for hazardous waste, sturdy dumpsters for general waste – and regularly emptying them to prevent overflowing and potential hazards. I also implement measures to prevent litter, such as regular sweeps and the use of windbreaks.

Finally, I work closely with licensed waste haulers to ensure all waste is disposed of according to local and national regulations. This includes maintaining detailed records of waste generation and disposal, including manifests for hazardous materials. For example, on a recent demolition project, we meticulously documented the disposal of asbestos-containing materials, ensuring complete compliance with all EPA regulations. This ensured minimal risk to workers and the environment.

Q 2. Explain your approach to ensuring site safety during cleanup operations.

Site safety during cleanup is paramount. My approach is proactive, focusing on prevention and control. This begins with a thorough risk assessment identifying potential hazards specific to the site – sharp objects, trip hazards, dust, chemicals, etc. Based on this assessment, we develop a comprehensive safety plan.

This plan includes clear procedures for handling different types of waste, the use of appropriate personal protective equipment (PPE) – gloves, safety glasses, masks, high-visibility clothing – and the implementation of traffic control measures to prevent accidents involving vehicles and personnel. Regular safety briefings are conducted to reinforce best practices and address any concerns.

For example, during the cleanup of a demolition site, we designated specific areas for waste storage and clearly marked walkways to prevent falls and collisions. All workers were equipped with the necessary PPE, and we implemented regular air monitoring to detect and mitigate dust exposure. A designated safety officer continuously monitored compliance with safety protocols.

Q 3. How do you handle unexpected cleanup challenges on a construction site?

Unexpected challenges are inevitable on construction sites. My approach involves a structured problem-solving process. First, I assess the nature of the challenge – is it a material spill, unexpected hazardous waste discovery, equipment malfunction, or something else? Then, I evaluate the potential risks and prioritize addressing immediate safety concerns.

Next, I gather my team and utilize our emergency response plan, if applicable. This may include contacting specialized contractors for hazardous waste removal or arranging for equipment repairs. Detailed documentation of the incident is maintained, including photos and notes. We then analyze the root cause of the issue to prevent similar incidents in the future. For example, when we encountered an unexpected asbestos discovery during a renovation project, I immediately stopped all work in the affected area, called in a licensed asbestos abatement company, and notified the relevant authorities.

Finally, we review our existing procedures to identify gaps and implement improvements. This could involve additional training for workers or revisions to the safety plan. Through a systematic review and improvement process, we aim to prevent similar issues from recurring and to increase the site’s overall safety and efficiency.

Q 4. What methods do you use to track and manage cleanup costs?

Accurate cost tracking is essential for project budgeting and profitability. I utilize a combination of methods to manage cleanup costs effectively. This begins with detailed pre-project planning, where I estimate the type and quantity of waste anticipated, and I then research the costs of disposal for each waste stream. This allows for a detailed budget.

During the project, I maintain meticulous records of all expenses related to cleanup, including waste disposal fees, equipment rental, PPE costs, and labor hours. I use project management software to track these expenses and generate regular reports. This allows for real-time monitoring of costs against the budget and identification of any potential overruns.

For example, I often use spreadsheets to categorize expenses. This allows me to quickly identify areas where costs might be excessive. By comparing actual costs to the initial estimates, we can identify areas for improvement and optimize future projects.

Q 5. Describe your experience with hazardous waste disposal procedures.

Handling hazardous waste requires meticulous attention to detail and strict adherence to regulations. My experience encompasses all aspects, from identification and segregation to safe transportation and disposal. I am proficient in identifying various hazardous materials – asbestos, lead paint, chemicals, etc. – using appropriate testing methods when necessary.

I ensure all hazardous waste is segregated from other waste streams, stored in designated containers that meet safety standards, and labelled according to regulations. Disposal is handled exclusively by licensed and insured hazardous waste haulers. I meticulously maintain all necessary documentation, including manifests and disposal records, to ensure complete compliance.

For instance, on a project involving lead paint removal, I oversaw the entire process – from proper containment and removal to the safe transportation and disposal of the hazardous waste by a certified contractor. All documentation, including waste manifests and worker exposure records, were maintained meticulously, demonstrating full compliance with environmental regulations.

Q 6. How do you ensure compliance with environmental regulations on job sites?

Environmental compliance is non-negotiable. My approach involves proactive engagement with all relevant regulations at the local, state, and federal levels. Before commencing any project, I conduct a thorough review of all applicable environmental laws and regulations pertaining to waste disposal, air quality, water quality, and land use.

I ensure that all waste disposal practices adhere to these regulations, and I work closely with environmental consultants when necessary to ensure compliance. This includes obtaining all necessary permits, maintaining accurate records, and conducting regular site inspections. Employee training programs also emphasize environmental responsibility.

For example, on a recent project, we obtained all necessary permits from the EPA before commencing any earthworks to ensure compliance with water quality regulations. Throughout the project, regular monitoring of water runoff was performed and recorded to ensure no environmental contamination occurred.

Q 7. Explain your proficiency in using various cleanup equipment.

Proficiency in using various cleanup equipment is essential for efficient and safe site management. My experience encompasses a range of equipment, including:

- Roll-off dumpsters: For efficient handling and transportation of large volumes of waste.

- Small containerized dumpsters: For specific waste types and smaller-scale projects.

- Vacuum trucks: For cleaning up spills and removing loose debris.

- Power washers: For cleaning equipment and removing stubborn dirt.

- Hand tools: Shovels, rakes, brooms, etc., for smaller cleanup tasks.

I am also experienced in operating and maintaining this equipment, ensuring it’s in good working order and used safely. Regular equipment inspections and maintenance are critical for preventing breakdowns and accidents. Proper training on the safe use of all equipment is provided to all team members. This ensures not only efficient cleaning but a safe working environment for everyone involved.

Q 8. Describe a time you had to resolve a conflict related to site cleanup.

Conflict resolution on a job site often involves differing opinions on cleanup priorities or methods. For example, I once faced a disagreement between the demolition crew and the site cleanup team regarding the disposal of construction debris. The demolition crew prioritized speed, leaving debris scattered, while the cleanup team needed organized piles for efficient removal. I resolved this by holding a brief meeting, clearly outlining the safety and logistical implications of both approaches. We established a system where the demolition crew organized debris into designated areas, streamlining cleanup and minimizing safety risks. This collaborative approach improved efficiency and fostered better teamwork. The key was open communication and a focus on a shared goal: a safe and efficient site cleanup.

Q 9. How do you maintain a clean and organized job site?

Maintaining a clean and organized job site is crucial for safety, efficiency, and professional image. My approach is multi-faceted and involves daily and weekly routines. Daily, we implement a ‘5S’ methodology: Seiri (Sort) – removing unnecessary items; Seiton (Set in Order) – organizing tools and materials; Seiso (Shine) – cleaning the work area; Seiketsu (Standardize) – maintaining consistent organization; and Shitsuke (Sustain) – sticking to the process. Weekly, we conduct more thorough cleaning, including power washing, and review the effectiveness of our 5S implementation. Designated areas for waste disposal are crucial, clearly labeled for different materials (e.g., wood, metal, hazardous waste). We use color-coded bins to further improve sorting. Regularly scheduled tool checks prevent clutter and ensure all equipment is accounted for. This systematic approach keeps the site functional, safe, and presentable.

Q 10. What is your experience with different types of cleanup (e.g., demolition, renovation)?

My experience encompasses diverse cleanup scenarios, from demolition projects involving significant debris removal to smaller-scale renovations requiring meticulous detail. Demolition cleanup involves managing large volumes of materials, often requiring specialized equipment like dumpsters and heavy machinery. Safety protocols are paramount here, ensuring proper PPE (Personal Protective Equipment) and adherence to all relevant regulations. Renovation cleanup, on the other hand, necessitates a different approach. It involves meticulous removal of construction waste, cleaning surfaces, and restoring the site to its pre-construction state, often with specific attention to detail regarding finishing work. For example, in a kitchen renovation, thorough cleaning of appliances and careful removal of dust are essential. I adapt my approach to match the specific requirements of each project, ensuring that all waste disposal is environmentally compliant.

Q 11. How do you prioritize cleanup tasks in a fast-paced environment?

Prioritizing cleanup tasks in a fast-paced environment requires a strategic approach. I use a risk-based prioritization system, focusing on immediate safety hazards first. For example, removing spilled hazardous materials takes precedence over general tidying. I then prioritize tasks based on their impact on project workflow. Clearing access routes for equipment or workers is prioritized over less crucial areas. I utilize a daily task list, updating it regularly to reflect changes and unforeseen events. This list helps the team understand what needs immediate attention and promotes efficient workflow. Visual management tools like Kanban boards can also be beneficial, allowing the team to track progress and adjust priorities as needed. Effective communication is crucial here; regular team briefings ensure everyone understands the priorities and their roles.

Q 12. How do you communicate cleanup plans and progress to stakeholders?

Effective communication regarding cleanup plans and progress is vital. I use a combination of methods. Daily briefings with the team ensures everyone’s on the same page regarding tasks and priorities. Regular progress reports, including photos and videos, are submitted to the project manager and client, showing the completed tasks and highlighting any challenges. These reports may include daily logs detailing completed tasks, quantities of waste removed, and any unexpected issues. For larger projects, weekly meetings with stakeholders are scheduled to review progress, discuss potential concerns, and adjust plans as necessary. Clear communication avoids misunderstandings and maintains transparency throughout the process.

Q 13. What safety measures do you implement to protect workers during cleanup?

Worker safety is my top priority. We strictly adhere to OSHA (Occupational Safety and Health Administration) guidelines and other relevant regulations. This includes mandatory PPE use, such as safety glasses, gloves, hard hats, and high-visibility vests. Before any cleanup begins, a site-specific safety plan is developed and communicated to the entire team. This plan outlines potential hazards and the precautions needed to mitigate risks. Regular safety training and toolbox talks are conducted to address potential hazards and refresh safety procedures. Proper disposal of hazardous materials is carefully managed, following all applicable regulations and using designated containers and licensed haulers. We maintain a clean and organized work environment to minimize trip hazards and other accidents. Regular inspections of equipment and the workspace ensure everything is functioning safely.

Q 14. How do you manage cleanup schedules and deadlines?

Managing cleanup schedules and deadlines requires careful planning and execution. I start by creating a detailed cleanup schedule, factoring in the different stages of the project, the type and quantity of waste, and available resources. This schedule is broken down into smaller, manageable tasks with assigned deadlines. I utilize project management software to track progress, identify potential delays, and reallocate resources as needed. Regular monitoring and adjustments ensure the cleanup stays on track. Communication with the project team and stakeholders is vital, especially when unforeseen delays occur. Proactive communication helps manage expectations and prevents conflicts. Contingency plans are developed to address potential challenges, such as unexpected weather delays or equipment malfunctions. By adhering to a structured schedule, monitoring progress consistently, and actively communicating, we ensure that cleanup deadlines are met effectively.

Q 15. What is your experience with different types of waste materials?

My experience encompasses a wide range of waste materials encountered on various job sites. This includes construction debris (wood, concrete, metal, drywall), demolition waste, hazardous materials (asbestos, lead paint, chemicals), municipal solid waste (paper, plastics, food waste), and recyclable materials (cardboard, metal, plastics). I’m proficient in identifying and segregating these materials according to their type and disposal requirements. For instance, on a recent demolition project, we had to carefully separate asbestos-containing materials from other debris, following strict safety protocols and ensuring proper disposal through licensed hazardous waste handlers. Another project involved managing large quantities of concrete and wood waste, which we recycled and repurposed whenever possible to minimize landfill impact.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure the proper disposal of hazardous materials?

Ensuring proper disposal of hazardous materials is paramount. It involves a multi-step process beginning with proper identification and segregation. We utilize Material Safety Data Sheets (MSDS) to understand the risks associated with each material. Next, we utilize specialized containers and labeling to prevent cross-contamination and accidental exposure. Disposal is then handled through licensed hazardous waste contractors, strictly adhering to all local, state, and federal regulations. We maintain comprehensive documentation, including manifests, to track the entire process from collection to final disposal. This documentation ensures compliance and provides a detailed audit trail. For example, when handling lead paint during a renovation, we followed strict containment protocols, used specialized HEPA-filtered vacuums for cleanup, and engaged a licensed contractor to dispose of the waste according to EPA guidelines. Failure to properly handle hazardous materials can result in severe health risks and environmental damage, as well as hefty fines.

Q 17. Describe your experience with budgeting and resource allocation for cleanup projects.

Budgeting and resource allocation are critical for successful cleanup projects. I begin by conducting a thorough site assessment to estimate the volume of waste, the types of materials involved, and the necessary equipment and personnel. This assessment forms the basis of a detailed budget, factoring in labor costs, disposal fees, equipment rental (if applicable), and potential unforeseen expenses. Resource allocation involves optimizing the use of personnel, equipment, and time to achieve the best cost-efficiency. I always strive to find cost-effective solutions, such as recycling or repurposing materials whenever feasible. For example, on a recent project with a tight budget, we optimized routes to reduce transportation costs and negotiated discounted rates with waste haulers by consolidating waste streams. This approach allowed us to complete the cleanup within the budget and deadline.

Q 18. How do you ensure the efficiency and productivity of your cleanup team?

Efficiency and productivity are enhanced through clear communication, proper training, and effective task management. Before starting any cleanup project, I provide clear instructions and assign roles and responsibilities to each team member. Regular check-ins and open communication channels ensure everyone is on the same page and potential issues are addressed promptly. We utilize checklists and standardized procedures to ensure consistency and prevent errors. Providing the team with the right tools and equipment is also crucial for maximizing efficiency. For example, using power tools for demolition waste removal, as opposed to manual methods, significantly improves productivity. Furthermore, team motivation is fostered by celebrating successes and acknowledging individual contributions.

Q 19. How do you assess the environmental impact of cleanup operations?

Assessing the environmental impact is a key responsibility. This involves identifying potential environmental risks associated with the cleanup operation, such as soil or water contamination, air pollution from dust, and improper waste disposal. We implement strategies to mitigate these risks. This includes using dust suppression techniques, employing proper waste segregation and disposal methods, and implementing erosion and sediment control measures, if necessary. Post-cleanup, we may conduct soil or water testing to confirm the environmental integrity of the site. Comprehensive documentation of all environmental considerations and mitigation strategies is maintained for future reference and regulatory compliance. For instance, on a project involving soil contaminated with hydrocarbons, we followed specific procedures for soil remediation and engaged specialized contractors for testing and disposal. Our aim is to minimize any negative environmental footprint.

Q 20. What are some common mistakes to avoid during job site cleanup?

Common mistakes during job site cleanup include inadequate planning, improper waste segregation, insufficient safety precautions, and lack of proper documentation. Failing to identify and segregate hazardous materials can lead to health risks and environmental damage. Not having adequate safety equipment (like gloves, respirators, and safety boots) exposes workers to unnecessary dangers. Insufficient planning can lead to delays and cost overruns. Finally, poor record-keeping creates compliance issues. To avoid these mistakes, thorough planning, risk assessment, and adherence to established safety protocols and regulations are essential. Regular training and supervision of the cleanup crew are equally important.

Q 21. How do you maintain detailed records of cleanup activities?

Maintaining detailed records is crucial for accountability and compliance. We use a combination of digital and physical records. This includes digital photographs and videos documenting the site before, during, and after cleanup; detailed waste manifests tracking the type and quantity of materials disposed of; daily activity logs recording personnel, tasks performed, and equipment used; and signed-off completion certificates to verify the scope of work. All records are stored securely and organized for easy retrieval. This approach ensures transparency, traceability, and compliance with relevant environmental regulations. Having a robust record-keeping system is vital for auditing purposes and can be invaluable if any disputes or discrepancies arise.

Q 22. Describe your experience with using different types of cleaning agents and chemicals.

My experience encompasses a wide range of cleaning agents and chemicals, from everyday products like disinfectants and degreasers to specialized solutions for removing specific substances like paint, adhesives, or hazardous materials. I’m proficient in understanding Safety Data Sheets (SDS) for each product, knowing their proper application, dilution ratios, and potential hazards. For instance, I’ve used biodegradable enzymatic cleaners for organic waste removal on construction sites, preventing environmental damage, while employing stronger alkaline cleaners for grease and grime in industrial settings. I always prioritize selecting the most environmentally friendly and effective option based on the specific job requirements, always adhering to all relevant safety regulations and best practices.

For example, on one project involving a significant oil spill, we used specialized absorbent pads and a solvent designed to break down the oil without harming the surrounding environment. This careful selection, coupled with proper disposal methods, ensured both efficient cleanup and environmental responsibility.

Q 23. How do you deal with complaints regarding noise or dust during cleanup?

Addressing noise and dust complaints requires proactive communication and a methodical approach. Before commencing cleanup, I inform nearby residents and businesses about the anticipated schedule and potential disruptions. This includes specifying the types of equipment we’ll use, and the approximate timeframe of loud or dusty operations. We minimize noise by utilizing quieter equipment where feasible and strategically scheduling louder tasks for less sensitive times of day.

Dust control is crucial. We employ methods like misting water before demolition or using HEPA-filtered vacuum cleaners. Additionally, we frequently inspect and maintain equipment to minimize dust emissions. If complaints arise, I address them promptly and professionally, exploring solutions like adjusting schedules, modifying techniques, or providing temporary soundproofing/dust barriers. Open communication and a willingness to find mutually agreeable solutions are vital to maintaining positive relationships.

Q 24. Explain your approach to maintaining a clean and safe work environment.

Maintaining a clean and safe work environment is paramount. My approach involves a multi-faceted strategy beginning with a thorough pre-cleanup site assessment identifying potential hazards (e.g., exposed wiring, sharp objects, slippery surfaces). We then establish a clearly marked perimeter with appropriate signage and barricades. During cleanup, we implement color-coded systems for waste disposal, ensuring proper segregation of hazardous and non-hazardous materials. Regular waste removal prevents accumulation, minimizing the risk of trips and falls. Regular safety briefings and toolbox talks reinforce safe practices, emphasizing proper use of PPE (personal protective equipment) like gloves, safety glasses, and hard hats. A clean and organized workspace not only prevents accidents, but also improves efficiency and morale.

Q 25. What steps do you take to ensure the security of the job site during cleanup?

Securing the job site during and after cleanup involves multiple layers of protection. This begins with restricting access to unauthorized personnel through physical barriers like fencing and locked gates. Valuable equipment and materials are secured in designated storage areas with locks. Regular patrols are conducted, especially during night hours or periods of inactivity. We utilize security cameras and/or motion detectors for added surveillance in high-risk areas. Detailed inventory records of all equipment and materials are maintained, ensuring easy identification of any losses or discrepancies. All security measures are documented, with daily log entries detailing any incidents or unusual activities. This comprehensive approach ensures both the safety of the site and the protection of assets.

Q 26. How do you prevent accidents and injuries during cleanup operations?

Preventing accidents and injuries is achieved through a combination of proactive measures and responsive actions. Pre-cleanup risk assessments pinpoint potential hazards. We then implement controls such as providing appropriate PPE, enforcing safe work procedures, and regularly inspecting equipment. Our team receives comprehensive safety training covering topics such as hazard recognition, fall protection, and proper lifting techniques. We utilize ‘buddy systems’ for potentially hazardous tasks, ensuring constant supervision and assistance. A thorough post-incident investigation is always conducted to analyze accidents, identify root causes, and prevent recurrences. This commitment to a culture of safety is reinforced through regular safety meetings and a zero-tolerance policy for unsafe behaviors.

Q 27. How do you use technology to improve job site cleanup efficiency?

Technology plays a significant role in improving job site cleanup efficiency. We use mobile devices and specialized software to track waste disposal, monitor equipment usage, and manage personnel assignments. Inventory management software streamlines the process of ordering supplies and tracking equipment. GPS-enabled devices help optimize routes for waste removal. Drones are utilized in some larger sites to inspect areas from a safe distance for potential hazards and to conduct post-cleanup assessments. Data analysis from these technologies allows us to identify bottlenecks and optimize workflows, resulting in reduced costs and improved productivity. For example, using a waste management app, we can track the weight and type of waste generated, which informs better waste disposal strategies and reduces costs.

Q 28. Describe your experience with training and supervising cleanup personnel.

Training and supervising cleanup personnel is a key responsibility. New employees receive comprehensive onboarding, covering safety protocols, equipment operation, waste management procedures, and relevant regulations. I conduct regular training sessions addressing specific hazards or new techniques. Ongoing performance evaluations and feedback sessions ensure consistent performance and adherence to standards. I foster a collaborative and supportive work environment where team members feel comfortable raising concerns or suggesting improvements. Effective communication and clear delegation of responsibilities are central to maintaining a high-performing and safe cleanup team. For example, we’ve implemented a peer-to-peer training program, where experienced team members mentor newcomers, which not only accelerates learning but also strengthens team cohesion.

Key Topics to Learn for Job Site Management and Clean-up Interview

- Safety Regulations and Procedures: Understanding and implementing OSHA regulations, site-specific safety plans, and emergency procedures. Practical application includes demonstrating knowledge of PPE, hazard identification, and incident reporting.

- Waste Management and Disposal: Knowing proper procedures for handling different types of waste (hazardous and non-hazardous), recycling programs, and waste minimization strategies. Practical application includes describing experience with waste segregation, disposal permits, and environmental regulations.

- Logistics and Inventory Management: Efficiently managing materials, tools, and equipment on-site. This includes tracking inventory, ordering supplies, and coordinating deliveries. Practical application: Explain your experience with optimizing material flow and minimizing waste through inventory control.

- Site Organization and Cleanliness: Maintaining a clean, organized, and safe work environment. This includes implementing daily cleaning schedules, organizing tools and materials, and ensuring proper storage. Practical application: Detail your strategies for effective site organization and how you ensure compliance with cleanliness standards.

- Teamwork and Communication: Effective communication with supervisors, subcontractors, and other team members. This includes reporting progress, addressing issues, and coordinating work activities. Practical application: Describe instances where you successfully collaborated with a team to overcome challenges related to site management and cleanup.

- Problem-Solving and Decision-Making: Identifying and resolving issues related to site management and cleanup effectively and efficiently. Practical application: Give examples of how you proactively identified and addressed potential safety hazards or logistical problems on a job site.

Next Steps

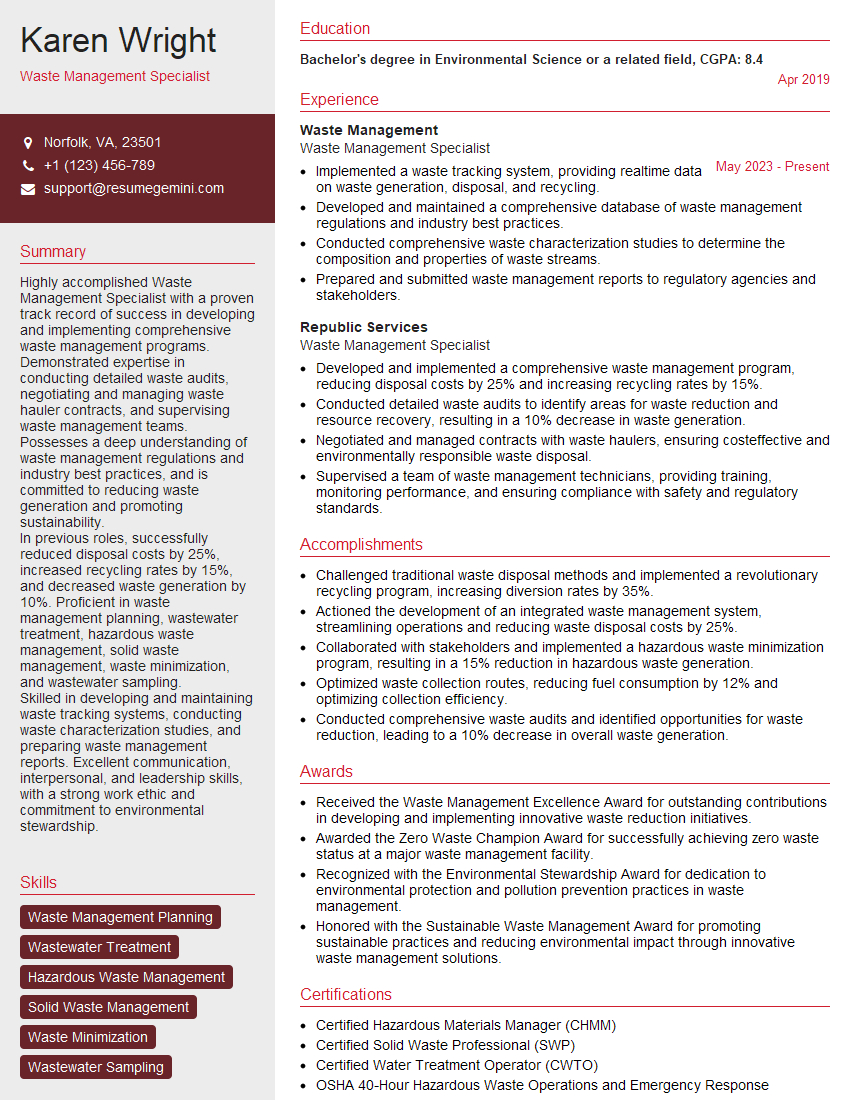

Mastering Job Site Management and Clean-up is crucial for career advancement in the construction and related industries. It demonstrates your commitment to safety, efficiency, and professionalism, opening doors to higher-paying positions and leadership roles. To maximize your job prospects, it’s essential to create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource to help you build a professional and impactful resume that stands out. We provide examples of resumes tailored to Job Site Management and Clean-up to guide you through the process. Invest the time to craft a compelling resume – it’s your first impression and a key to unlocking your career potential.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?