Unlock your full potential by mastering the most common Joint Pointing interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Joint Pointing Interview

Q 1. What are the different types of joint pointing mortars?

Joint pointing mortars are categorized primarily by their properties and intended use. The most common types include:

- Lime Mortar: A traditional mix of lime, sand, and water. It’s breathable, allowing moisture to escape, making it ideal for older buildings and heritage structures. It’s also relatively flexible, accommodating movement in the structure. Think of it as the ‘gentle giant’ of mortars, adaptable and forgiving.

- Cement Mortar: A stronger, more durable mortar composed of cement, sand, and water. It’s less permeable than lime mortar but offers greater strength. Often used in modern constructions or where high strength is needed. It’s the ‘workhorse,’ reliable and strong.

- Cement-Lime Mortar: A blend of cement and lime, combining the strength of cement with the breathability of lime. This is a popular choice for many applications as it offers a balance of strength and permeability, offering the best of both worlds.

- Polymer-Modified Mortars: These mortars contain polymers that enhance their properties, such as increased strength, flexibility, and water resistance. They’re often used in demanding environments or for repairs where superior performance is critical; think of them as the ‘high-performance’ athletes.

The choice of mortar depends heavily on the building material, the climate, and the desired longevity of the pointing.

Q 2. Explain the process of preparing a surface for repointing.

Preparing a surface for repointing is crucial for a successful and lasting repair. The process involves several key steps:

- Cleaning: Thoroughly remove all loose debris, dirt, vegetation, and any existing loose or failing mortar from the joints using wire brushes, scrapers, and even high-pressure water jets (carefully). The surface needs to be sound and clean for the new mortar to adhere properly. Think of it as preparing a canvas before painting.

- Assessment: Inspect the brickwork for any signs of damage, such as cracks or crumbling bricks. Address major issues before repointing to prevent future problems. This step is crucial for identifying any underlying problems.

- Moisture Control: Ensure the surface is dry before applying the new mortar. Damp surfaces will hinder the setting and curing of the mortar. This is like ensuring your ingredients are at the right temperature for baking a cake.

- Priming (optional): In some cases, particularly with porous materials or those prone to water absorption, a bonding agent or primer may be applied to improve adhesion. This enhances the bond between the old and new mortar.

Thorough preparation ensures a long-lasting and aesthetically pleasing result. Skipping steps can lead to premature failure of the repointing.

Q 3. Describe the proper technique for raking out old mortar.

Raking out old mortar requires precision and care to avoid damaging the surrounding bricks or stones. The key is to remove only the necessary amount of old mortar, creating a clean, V-shaped groove. Here’s how:

- Tools: Use appropriate tools such as a bolster chisel or a pointing tool. The size of the tool will depend on the joint width.

- Technique: Hold the tool at a slight angle to the joint, tapping it gently with a hammer. Avoid excessive force to prevent damaging the brickwork. Work systematically along the joint, removing the old mortar to a consistent depth. Think of it like carefully carving away unwanted material.

- Depth: The depth should be sufficient to allow for proper bonding of the new mortar (usually around 15-25mm but this depends on the joint size and the type of mortar). A consistently raked joint is key.

- Cleaning: Once the old mortar is removed, clean the joint thoroughly to remove any dust or debris.

Proper raking out ensures a strong bond between the old and new mortar, preventing future issues such as cracking or spalling.

Q 4. What are the common causes of mortar failure?

Mortar failure can stem from various factors, often a combination rather than a single cause:

- Poor Quality Mortar: Using incorrect mortar mixes or using substandard materials weakens the joint.

- Insufficient Raking Out: Improperly raked joints leave insufficient space for the new mortar to adhere properly.

- Moisture ingress: Water penetrating the joints can freeze and thaw, causing expansion and contraction which damages the mortar.

- Movement in the Structure: Settlement or expansion of the building can put stress on the joints, leading to cracking and failure.

- Efflorescence: Salts migrating to the surface of the brickwork can cause mortar degradation.

- Exposure to pollutants: Acid rain or other environmental pollutants can chemically attack the mortar.

Addressing these factors during construction and maintenance helps prevent mortar failure and ensure the longevity of the masonry.

Q 5. How do you choose the appropriate mortar mix for a specific application?

Selecting the right mortar mix is paramount. The choice depends on several factors:

- Building Material: Lime mortars are often preferred for historic brick or stone structures, while cement mortars might be more suitable for modern concrete blocks.

- Environmental Conditions: In areas with high rainfall or freezing temperatures, a more water-resistant mortar is needed. Polymer-modified mortars might be a better option.

- Aesthetic Considerations: The color and texture of the mortar should blend with the existing masonry.

- Structural Requirements: If the joints are under significant stress, a higher strength mortar, such as a cement-lime mix or a polymer-modified mortar, is needed.

Consulting relevant standards and specifications is vital, along with considering the advice of a qualified mason or building professional. Each project demands a tailored approach to ensure optimal performance and longevity.

Q 6. What safety precautions are necessary when undertaking joint pointing?

Safety is paramount when undertaking joint pointing. Precautions include:

- Personal Protective Equipment (PPE): Always wear safety glasses or goggles, gloves, and a dust mask to protect against flying debris, chemicals, and dust.

- Safe Working Practices: Use appropriate tools correctly, avoid over-reaching, and work on stable scaffolding or ladders. Never work alone at heights.

- Handling Chemicals: When using chemical cleaners or primers, follow the manufacturer’s safety instructions and ensure adequate ventilation.

- Waste Disposal: Dispose of waste materials responsibly, in accordance with local regulations.

- First Aid: Have a first aid kit readily available and know what to do in case of accidents.

A risk assessment should be conducted before commencing any work to identify potential hazards and implement control measures to ensure a safe working environment.

Q 7. How do you determine the depth of raking out required?

Determining the correct raking-out depth is crucial for a strong and durable repair. The depth shouldn’t be too shallow (resulting in poor adhesion) or too deep (damaging the masonry). Consider these points:

- Joint Size: A larger joint will require a deeper rake-out, typically around 20-25mm, to ensure adequate space for the new mortar. Smaller joints require less, perhaps 15mm.

- Mortar Type: Some mortars require a deeper rake to provide sufficient bonding area.

- Brick Condition: If the bricks are damaged or crumbling, a shallower rake-out might be necessary to avoid further damage.

- Visual Inspection: A good rule of thumb is to rake out to a depth where the old mortar is noticeably loose and crumbly.

In cases of doubt, consult a qualified mason to determine the appropriate raking-out depth. Consistent depth across all joints contributes to a professional and lasting finish.

Q 8. What are the different types of joint profiles?

Joint profiles refer to the shape and size of the mortar joint between masonry units. Choosing the right profile is crucial for both aesthetics and structural integrity. Different profiles offer varying degrees of weather resistance and visual appeal.

- Concave (V-joint): This is a classic, aesthetically pleasing profile that sheds water well. Think of it as a mini gutter for each joint.

- Convex (Weathered): This profile is more rustic and creates a shadow line that adds depth to the wall. It’s also good at shedding water.

- Flush: A simple, flat joint that is often used for modern or minimalist designs. It requires more precise workmanship to ensure proper water resistance.

- Recessed: A slightly indented joint. Offers a slightly less prominent joint line than a flush joint.

- Struck Joint: A simple joint created by simply pressing the mortar into place.

- Beaded Joint: A raised, rounded joint profile. Often used for a decorative effect.

The choice of joint profile depends on factors such as the style of the building, the type of masonry unit, and the climate. For example, a concave joint might be preferred in a rainy climate for its superior water shedding capabilities.

Q 9. Explain the importance of proper curing after joint pointing.

Proper curing is absolutely critical for the long-term durability and weather resistance of pointed joints. Curing allows the mortar to hydrate properly, developing its full strength and minimizing shrinkage cracking. Without adequate curing, the mortar will be weak and vulnerable to damage from freeze-thaw cycles, moisture penetration, and erosion.

Methods of curing include:

- Water Curing: Keeping the joints consistently moist for several days by spraying them with water (this is particularly important in hot, dry conditions).

- Membrane Curing: Covering the work with a waterproof sheet to prevent rapid moisture loss.

- Chemical Curing Compounds: Applying specialized curing compounds that seal in moisture.

The duration of the curing process depends on factors such as temperature and humidity, but generally, several days of consistent moisture are necessary. Neglecting proper curing can lead to premature failure of the jointing work and necessitate costly repairs down the line. Think of it like baking a cake – you need to let it cool down properly or else it’ll crumble.

Q 10. What tools and equipment are essential for effective joint pointing?

Effective joint pointing requires a range of specialized tools and equipment. The specific tools might vary depending on the project’s scale and complexity, but some essentials include:

- Pointing Trowels: These come in various shapes and sizes, designed for creating different joint profiles and for precise application of mortar.

- Jointing Tools: Specialized tools for creating specific joint profiles, like concave or convex joints.

- Mortar Boards: A flat, working surface for mixing and preparing the mortar.

- Buckets and Mixing Tools: For mixing mortar to the correct consistency.

- Brushes and Sponges: For cleaning excess mortar and maintaining a neat finish.

- Brick Hammers and Chisels: For removing loose or damaged mortar before repointing.

- Safety Equipment: Safety glasses, gloves, and dust masks are essential to protect against eye injuries, skin irritation, and dust inhalation.

Investing in high-quality tools ensures precision and efficiency, ultimately leading to a superior finish and extended lifespan of the pointing work.

Q 11. How do you handle different types of masonry units (brick, stone, etc.)?

Different masonry units require different approaches to joint pointing. The key is to understand the specific properties of each material and adapt the techniques accordingly.

- Brick: Brickwork generally requires careful cleaning of the existing mortar before repointing. The brick’s porosity needs to be considered when choosing mortar.

- Stone: Stone masonry often involves larger joints and may require specialized tools and techniques to achieve a proper fit and finish. The type of stone influences the choice of mortar. Some stones are more absorbent than others.

- Concrete Block: Concrete blocks often have larger joints and may require a more robust mortar mix. The surface texture of the block needs to be considered.

Regardless of the masonry unit, it’s crucial to match the mortar color and texture to the existing work, ensuring a seamless and aesthetically pleasing result. For example, using a lime-based mortar with old brickwork would be more historically accurate and would often be preferred over a modern cement mortar.

Q 12. Describe the process of tuckpointing.

Tuckpointing is a specialized technique used to restore deteriorated mortar joints. It involves carefully raking out the old, damaged mortar to a consistent depth and replacing it with a contrasting mortar, typically a lighter-colored mortar (often a mix of lime and sand), that creates a visually striking and historically accurate effect. It’s not merely replacing mortar; it’s a meticulous process to restore both the structural integrity and the aesthetic appeal.

The process typically involves:

- Preparation: Carefully removing the deteriorated mortar using a specialized tool called a tuckpointing tool or a chisel.

- Cleaning: Thoroughly cleaning the joints to remove debris and loose particles.

- Mortar Mixing: Mixing a suitable mortar mix that matches the color and texture of the existing mortar but with a contrasting color for the tuckpointing.

- Tuckpointing: Carefully applying the contrasting mortar into the cleaned-out joints, ensuring a clean and even finish.

- Tooling: Using a tuckpointing tool to create a neat, consistent joint profile (usually concave).

- Curing: Properly curing the newly applied mortar to ensure its strength and durability.

Tuckpointing requires a high degree of skill and precision to achieve a historically accurate and aesthetically pleasing result. It’s more of an art form than just a simple repair.

Q 13. How do you match existing mortar color and texture?

Matching existing mortar color and texture is crucial for a seamless and aesthetically pleasing restoration. This requires a keen eye for detail and often involves some experimentation. The best method involves:

- Sampling Existing Mortar: Carefully removing a small sample of the existing mortar to analyze its color and texture.

- Color Matching: Using this sample, working with a mortar supplier to match the color accurately. They can often use color charts and computer aided color matching to closely achieve the original color.

- Texture Matching: Experimenting with different mortar mixes to achieve the desired texture. This can involve adjusting the sand-to-cement ratio and using additives to achieve the correct consistency and finish.

- Test Application: Applying a small test area to verify that the color and texture match before proceeding with the entire project.

This process often involves multiple iterations to achieve the best match, especially if dealing with aged mortar where the color and texture have changed over time due to weathering. Accurate matching is vital for preserving the building’s character and ensuring a historically accurate restoration.

Q 14. What are the signs of damp penetration and how does it relate to joint pointing?

Damp penetration is a serious issue that can lead to structural damage, mold growth, and deterioration of the masonry. Signs of damp penetration include:

- Discoloration: Dark stains or streaks on the walls, often indicative of moisture penetration.

- Efflorescence: White, powdery deposits on the surface of the masonry, resulting from soluble salts leaching out due to moisture.

- Mould Growth: The presence of mold or mildew, especially in damp areas.

- Deterioration of Mortar Joints: Cracking, crumbling, or spalling of the mortar, indicating water damage.

Poor joint pointing can significantly contribute to damp penetration. Gaps and cracks in the mortar joints provide pathways for water to penetrate the masonry. By ensuring that joints are properly pointed, well-sealed, and properly cured, we can significantly reduce the risk of water damage. Effective joint pointing is essential for protecting the building from the damaging effects of moisture. Think of mortar joints as the building’s skin – if the skin has holes, moisture can get through easily.

Q 15. How do you address pointing issues on listed buildings or historical structures?

Repointing listed buildings and historical structures demands a meticulous approach, prioritizing preservation over mere repair. We must first understand the building’s history and the materials used in its original construction. This often involves researching historical records, analyzing existing mortar samples, and sometimes even consulting with architectural historians. The goal is to match the original pointing as closely as possible in terms of material composition, colour, and texture. This includes careful consideration of the type of mortar used (lime mortar is often preferred for its breathability and compatibility with historic masonry), the joint profile (e.g., concave, V-shaped, weatherstruck), and the tooling techniques employed. For instance, if the original pointing was done using a specific type of tooling, we’d replicate that to maintain the building’s aesthetic integrity. Any deviations from the original must be carefully documented and justified.

A crucial aspect is the use of sympathetic techniques. We wouldn’t use power tools that could damage the existing masonry. Instead, we’d employ hand tools to carefully remove the old mortar, ensuring we don’t dislodge any bricks or stones. We then meticulously prepare the joints before applying the new mortar, paying close attention to achieving the correct depth and profile. Finally, we would carefully weather the newly pointed joints to blend them seamlessly with the aged masonry. This entire process requires patience, skill, and a deep respect for the building’s historical significance.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the different types of pointing tools and their uses?

A variety of tools are essential for effective joint pointing. The choice of tool depends on the type of pointing being carried out, the material of the masonry, and the desired joint profile. Here are some key examples:

- Pointing Trowels: These come in various sizes and shapes (e.g., London trowel, hawk-billed trowel). They’re used for applying and shaping the mortar in the joints.

- Jointing Tools: These tools, including the pointing tool and the tuck pointer, are used to create specific joint profiles, such as concave, V-shaped, or weathered joints. They can be made from steel, wood, or plastic, each having a slightly different effect on the mortar’s finish.

- Chisels and Hammers: Essential for carefully removing old, damaged mortar. Different chisels are used depending on the width of the joint and the type of masonry.

- Brushes and Scrapers: Used for cleaning the joints before applying new mortar and for removing excess mortar after pointing.

- Joint Rakes: These help to create a key for the mortar to bond to.

- Brick Seamers: These special tools create neatly raked joints and a consistent look across a larger area.

The correct selection and use of these tools are crucial for achieving a high-quality and durable pointing job.

Q 17. Describe your experience working at heights or in confined spaces (if applicable).

I possess extensive experience working at heights and in confined spaces, both of which are frequently encountered in joint pointing, especially on larger buildings or structures with intricate detailing. I’m fully qualified in the use of appropriate safety equipment, including harnesses, lanyards, and fall arrest systems. I understand the importance of risk assessments and method statements before undertaking such work. For example, on a recent project involving a high-rise building, we implemented a comprehensive scaffolding system that met all safety regulations. Each member of the team received thorough training on safe working practices at height, including emergency procedures. In confined spaces, such as narrow crevices between stonework, the use of appropriate lighting, ventilation, and communication systems were crucial aspects of our approach. I am comfortable operating within these environments while maintaining a high level of safety and productivity. My experience includes work on several heritage buildings requiring meticulous work in confined and elevated spaces, demanding a high level of precision and attention to detail.

Q 18. What are the limitations of different pointing mortars?

Different pointing mortars have specific limitations depending on their composition and intended use. For example, cement-based mortars are strong and durable but can be less breathable than lime mortars, potentially leading to trapped moisture and damage to the masonry over time, especially in older buildings. Lime mortars, while more breathable and suitable for historic structures, are generally weaker and less resistant to frost damage than cement mortars. Modern proprietary mortars often offer improved strength and durability compared to traditional lime mortars, but may not be aesthetically compatible with historical buildings. The choice of mortar should always consider:

- Strength: The ability of the mortar to withstand compressive and tensile stresses.

- Durability: Its resistance to weathering, frost, and other environmental factors.

- Breathability: Its ability to allow moisture to pass through, preventing damage from trapped water.

- Workability: How easily it can be mixed, applied, and tooled.

- Compatibility: How well it bonds with the existing masonry and pointing.

Ignoring these limitations can lead to premature failure of the pointing and potentially damage to the underlying masonry. Therefore, careful material selection is essential for long-term success.

Q 19. How do you deal with challenging weather conditions during joint pointing?

Adverse weather conditions can significantly impact the quality and longevity of pointing work. Extreme heat can cause the mortar to dry too quickly, leading to cracking and reduced strength. Rain can wash away the mortar before it has set, while frost can cause damage to the newly applied mortar. To mitigate these risks, we implement several strategies. These include:

- Careful scheduling: Avoiding work during periods of extreme heat, rain, or frost.

- Protection from the elements: Using tarpaulins or other coverings to shelter the work area from rain or direct sunlight.

- Modified mortars: Employing mortars specifically formulated to withstand harsh weather conditions.

- Adaptive techniques: Adjusting the working methods and materials to suit the prevailing weather. For example, on a particularly windy day, we might focus on smaller sections of wall to limit the impact of windblown debris.

Thorough weather monitoring and careful planning are crucial for ensuring the success of any pointing project.

Q 20. How do you ensure the structural integrity of the wall during repointing?

Maintaining the wall’s structural integrity during repointing is paramount. This requires a careful and considered approach, starting with a thorough assessment of the wall’s condition. We look for any signs of structural weakness, such as cracks, loose stones, or unstable sections. Before commencing any repointing, we may need to carry out remedial works to address any underlying structural issues, which may involve stabilizing loose stones, repairing cracks, or underpinning the foundation. When removing old mortar, we use controlled techniques to avoid damaging the existing masonry. We would only remove as much old mortar as is necessary to create a sound key for the new mortar to bond to. Finally, the new mortar must be carefully chosen and applied to ensure it doesn’t put undue stress on the wall. The use of breathable mortars is essential to avoid trapping moisture and causing further damage to the structure. Regular inspections during and after the pointing work are vital to ensure that the wall remains structurally sound and that any unforeseen issues are promptly addressed.

Q 21. What are the environmental considerations for selecting pointing materials?

Environmental considerations are increasingly important in the selection of pointing materials. We prioritize the use of sustainable and environmentally friendly materials whenever possible. This often involves choosing lime-based mortars, which have a lower carbon footprint than cement-based mortars. We also consider the sourcing of materials, aiming to use locally produced materials to reduce transportation emissions. The disposal of waste materials is also a key consideration. We strive to minimize waste generation through careful planning and execution of the project. Any waste materials are disposed of responsibly, in accordance with relevant environmental regulations. We also aim to select materials that have low embodied energy and are readily recyclable. Selecting materials with low toxicity and minimal environmental impact during manufacturing and transportation is another aspect of our commitment to responsible environmental practices. The overall aim is to minimise the project’s impact on the environment throughout its lifecycle.

Q 22. Describe your experience with different pointing techniques (e.g., pointing with lime mortar, cement mortar).

My experience encompasses a wide range of pointing techniques, primarily focusing on lime and cement mortars. Lime mortar, a traditional method, offers breathability and allows the wall to ‘breathe’, preventing moisture damage. It’s ideal for historic buildings and where preserving authenticity is crucial. I’ve worked extensively with various lime mortars, including those using different types of lime (e.g., NHL 3.5, NHL 5) and aggregates (e.g., sand, crushed brick). The mix design is crucial and depends on the specific application and the properties of the existing masonry. Cement mortar, on the other hand, is stronger and sets faster, making it suitable for modern constructions or where rapid completion is needed. However, its impermeability can trap moisture, leading to potential problems in the long term. I’ve used various cement-based mortars, adjusting the mix to achieve the desired strength and workability, always considering the substrate.

For instance, I recently worked on a Victorian terrace where we used a traditional lime mortar to repoint the brickwork, carefully matching the existing mortar colour and texture. This ensured the aesthetic integrity of the building was maintained. In contrast, for a modern extension, a high-strength cement mortar was used to ensure structural stability and rapid curing.

Q 23. How do you assess the condition of existing pointing before starting work?

Assessing existing pointing involves a thorough visual inspection and sometimes more invasive tests. I begin by carefully examining the joints for signs of deterioration such as cracking, spalling, crumbling, or significant discoloration. This gives me an idea of the mortar’s condition and the extent of the damage. I check for bulging or movement of the masonry units, indicative of underlying structural problems that may need addressing before pointing. Using a small, sharp tool, I’ll gently probe the joints to determine their depth and the adhesion between the mortar and masonry. Loose or friable mortar is a clear sign that repointing is needed. In some cases, I may use a moisture meter to check for dampness within the wall, which could affect the choice of mortar and the pointing technique.

For example, on a recent project, I identified significant deterioration in the pointing of a sandstone wall. The mortar was completely crumbling, and some stones were loose. This indicated a need for complete repointing using a suitable lime mortar that would be compatible with the sandstone. In another case, only minor cracking was found, requiring only careful cleaning and re-pointing of affected areas using a patching mortar that matches existing material.

Q 24. Explain the importance of maintaining consistent joint depth and profile.

Maintaining consistent joint depth and profile is crucial for both aesthetics and structural integrity. Inconsistent joints look unprofessional and can weaken the wall. The depth of the joint should be consistent to ensure proper bonding between the masonry and the pointing mortar. Furthermore, the profile (shape) of the joint—whether it’s concave, raked, or struck—should be consistent to enhance the overall appearance and ensure water runoff. An uneven joint depth can create stress points, leading to cracking and further deterioration. An inconsistent profile can create areas where water can pool, leading to frost damage and erosion.

Imagine trying to build a brick wall with some bricks extending further than others. The wall would be weak and unstable. Similarly, inconsistent joints create weak points in a wall, compromising its structural strength and longevity.

Q 25. What are the common problems encountered during joint pointing and how do you solve them?

Common problems include shrinkage cracking (mortar shrinking as it dries), poor adhesion between mortar and masonry (leading to raking and falling out), incorrect mortar selection (resulting in incompatibility with the existing material), and inconsistent joint depth and profile. Solutions depend on the specific issue. Shrinkage cracking may require re-pointing with a low-shrinkage mortar. Poor adhesion may necessitate the removal of loose mortar and better preparation of the joints before repointing. Incorrect mortar selection necessitates using a more suitable material in the repair. Inconsistent joints often require careful removal of the affected sections and repointing to achieve a uniform look and structural integrity.

For instance, if I encounter significant shrinkage cracks, I would use a lime mortar with a lower water-cement ratio or incorporate pozzolanic materials, which help to reduce shrinkage. If there’s poor adhesion, I’ll make sure the surfaces are thoroughly cleaned and brushed to improve the bond. I address these problems systematically by pinpointing the cause and employing appropriate solutions based on my experience and knowledge.

Q 26. How do you manage waste materials during joint pointing?

Waste management is a vital aspect of responsible joint pointing. I always segregate waste materials carefully. Removed mortar is generally considered construction waste and should be disposed of appropriately in accordance with local regulations. Often, I utilize skips or other suitable waste receptacles on-site. Clean water is collected separately for disposal, as it may contain dust or other particulates. Reusable materials are separated and reused where possible. All waste is documented, and appropriate disposal certificates are obtained where required. Minimizing waste is also important; I carefully gauge the required amount of mortar to reduce excess material.

For example, I might carefully rake out only the damaged mortar to minimise material waste, rather than using a harsh method that removes more than necessary. This is a more sustainable approach to the project.

Q 27. What are your methods for quality control during and after the joint pointing process?

Quality control is continuous throughout the process. Before starting, I verify that the chosen mortar mix is correct and meets the project specifications. During pointing, I regularly check the joint depth, profile, and mortar consistency, making adjustments as needed to maintain uniformity. I visually inspect the work regularly for any defects like voids, cracks, or inconsistencies. After completion, a final inspection verifies that the joints are sound, neat, and consistent. Photography and documentation throughout the process ensures the work meets specifications. This detailed approach guarantees a high-quality finish and a durable, long-lasting repair. Feedback from clients also plays a vital role in ensuring customer satisfaction.

I might even take close-up photos of the joints at different stages of the process. This helps document the quality of the work and allows for any minor adjustments to be made before the project is finished.

Key Topics to Learn for Joint Pointing Interview

- Fundamentals of Joint Pointing: Understanding the core principles and methodologies behind joint pointing techniques. This includes different types of joints, materials, and their properties.

- Practical Application in Construction: Explore real-world examples of joint pointing in various construction projects, such as brickwork, stonework, and concrete structures. Consider the implications of different pointing styles and their suitability for specific environments.

- Mortar Selection and Preparation: Mastering the art of selecting appropriate mortar mixes based on project requirements and environmental factors. Understand the process of preparing and applying mortar for optimal joint performance.

- Tools and Techniques: Familiarize yourself with the various tools used in joint pointing and the correct techniques for achieving a professional finish. This includes understanding the importance of proper tooling and cleaning.

- Joint Design and Aesthetics: Learn about different joint designs and their impact on the overall aesthetics of a structure. Understand how to create visually appealing and structurally sound joints.

- Troubleshooting and Problem Solving: Be prepared to discuss common problems encountered during joint pointing, such as cracking, efflorescence, and staining, and how to effectively address these issues.

- Health and Safety: Understand and be able to discuss relevant health and safety regulations and best practices associated with joint pointing, including personal protective equipment (PPE) and safe handling of materials.

- Sustainability and Environmental Considerations: Explore the use of sustainable materials and practices in joint pointing, including the selection of environmentally friendly mortars and waste reduction strategies.

Next Steps

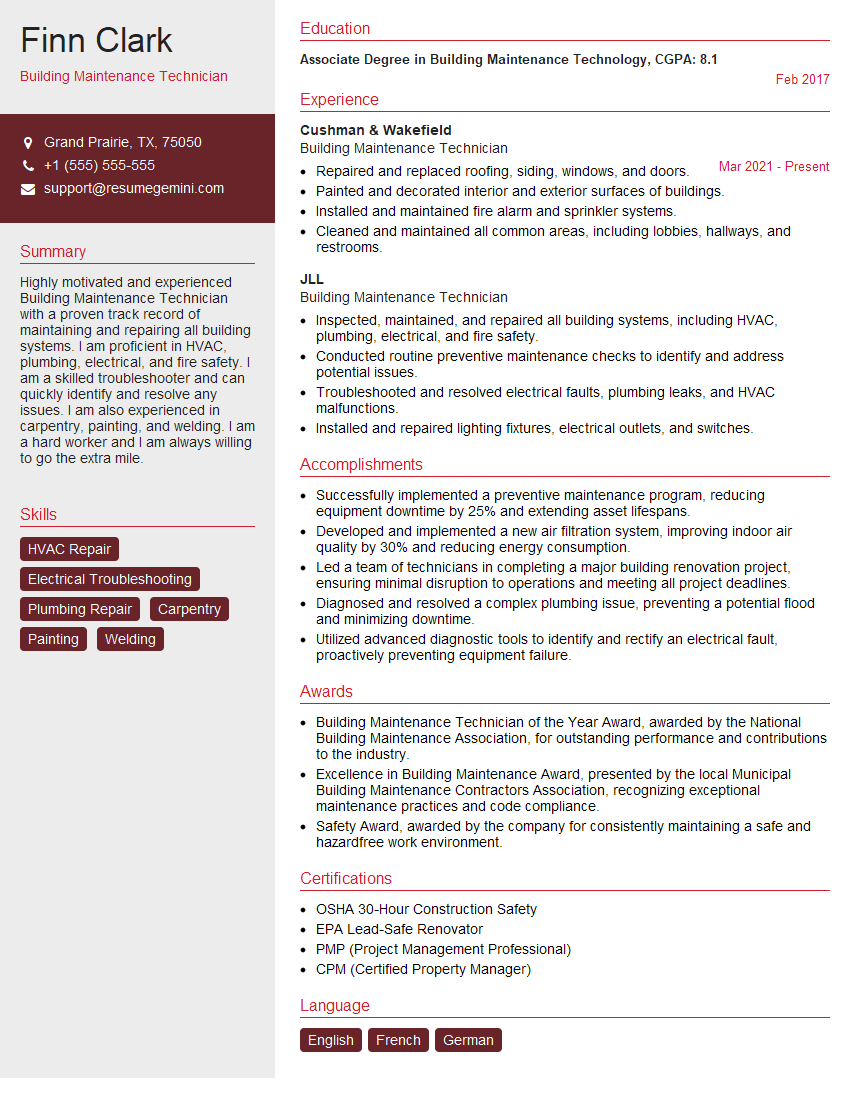

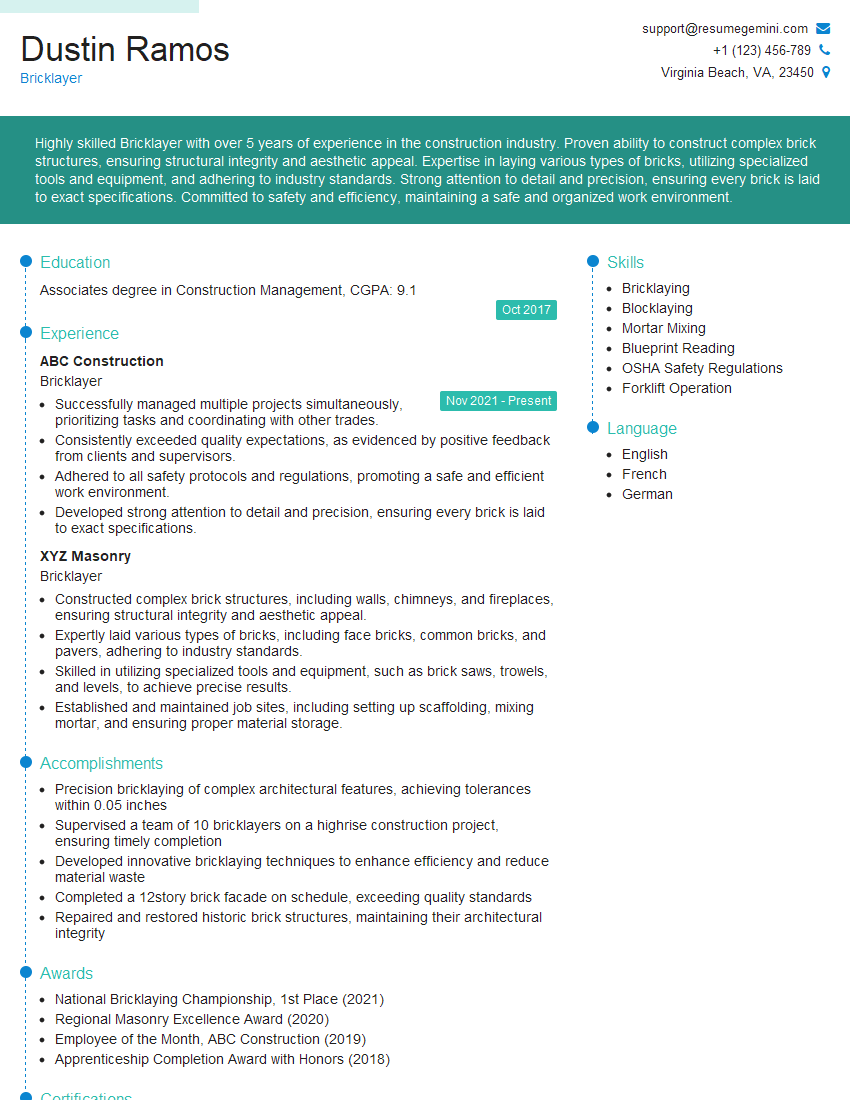

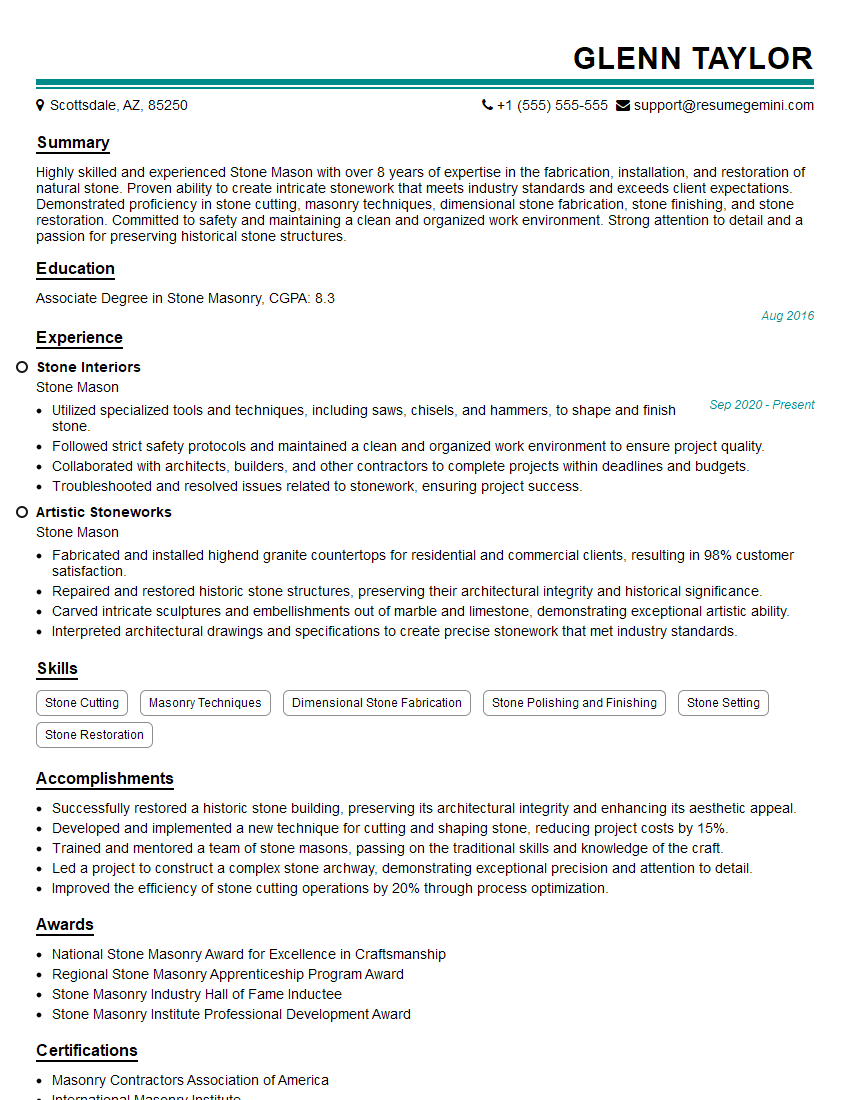

Mastering joint pointing opens doors to exciting career opportunities in the construction and restoration industries. Demonstrating a strong understanding of these techniques significantly enhances your employability and allows you to contribute effectively to high-quality projects. To maximize your job prospects, creating an ATS-friendly resume is crucial. ResumeGemini is a trusted resource to help you build a professional and impactful resume that highlights your skills and experience. Examples of resumes tailored to Joint Pointing are available within ResumeGemini to guide you. Invest time in crafting a compelling resume – it’s your first impression with potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Take a look at this stunning 2-bedroom apartment perfectly situated NYC’s coveted Hudson Yards!

https://bit.ly/Lovely2BedsApartmentHudsonYards

Live Rent Free!

https://bit.ly/LiveRentFREE

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?