Warning: search_filter(): Argument #2 ($wp_query) must be passed by reference, value given in /home/u951807797/domains/techskills.interviewgemini.com/public_html/wp-includes/class-wp-hook.php on line 324

Preparation is the key to success in any interview. In this post, we’ll explore crucial Knowledge of engineering principles and practices interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Knowledge of engineering principles and practices Interview

Q 1. Explain the difference between precision and accuracy in engineering measurements.

Precision and accuracy are crucial concepts in engineering measurements, often confused but distinctly different. Accuracy refers to how close a measurement is to the true value. Precision, on the other hand, describes how close repeated measurements are to each other. Think of it like archery: high accuracy means your arrows consistently hit the bullseye, while high precision means your arrows consistently hit the same spot, regardless of whether that spot is the bullseye.

- High Accuracy, High Precision: The measurements are clustered tightly around the true value.

- High Accuracy, Low Precision: The measurements are scattered but their average is close to the true value.

- Low Accuracy, High Precision: The measurements are tightly clustered, but far from the true value. This indicates a systematic error in the measurement process.

- Low Accuracy, Low Precision: The measurements are scattered and far from the true value, indicating both random and systematic errors.

For example, if we’re measuring the length of a component, high accuracy would mean our measurements are very close to the actual length, while high precision would mean that multiple measurements yield nearly identical results. In manufacturing, both accuracy and precision are essential to ensure consistent product quality and functionality.

Q 2. Describe your experience with different types of engineering design processes (e.g., Agile, Waterfall).

I have extensive experience with both Waterfall and Agile methodologies in engineering design. Waterfall, a linear approach, is ideal for projects with clearly defined requirements and minimal anticipated changes. Each phase (requirements, design, implementation, testing, deployment, maintenance) must be completed before moving to the next, making it suitable for projects where stability and predictability are paramount. I’ve used Waterfall successfully in projects involving the design of large-scale infrastructure systems where deviations from initial plans would be costly and time-consuming.

Conversely, Agile emphasizes iterative development and flexibility. This approach, using sprints and frequent feedback loops, is beneficial for projects with evolving requirements or a need for rapid prototyping. I’ve applied Agile principles in software development and embedded systems design, where rapid adaptation to changing market demands or technological advancements is crucial. The iterative nature of Agile allows for continuous improvement and faster delivery of functional products.

My experience has shown that the best choice of methodology depends heavily on the specific project. Sometimes a hybrid approach, combining elements of both Waterfall and Agile, is the most effective strategy.

Q 3. How do you approach troubleshooting complex engineering problems?

Troubleshooting complex engineering problems requires a systematic and methodical approach. I typically follow these steps:

- Clearly Define the Problem: Thoroughly understand the symptoms, gather data, and articulate the problem precisely. Avoid jumping to conclusions.

- Gather Information: Collect relevant data through observation, testing, and consultation with colleagues. Examine existing documentation, schematics, and logs.

- Formulate Hypotheses: Develop potential explanations for the problem based on the gathered information. Consider multiple possibilities.

- Test Hypotheses: Design experiments or tests to evaluate each hypothesis. Isolate variables and carefully document the results.

- Implement Solutions: Once the root cause is identified, implement corrective actions. Verify that the solution resolves the problem without introducing new issues.

- Document Findings: Thoroughly document the troubleshooting process, including the problem description, hypotheses, tests performed, results, and solutions implemented. This is crucial for future reference and continuous improvement.

For instance, when troubleshooting a malfunctioning robotic arm, I would start by examining the error logs, inspecting the mechanical components, and testing the electrical circuits. I’d systematically eliminate possibilities, documenting each test and result until I pinpoint the root cause — whether it’s a faulty sensor, a software bug, or a mechanical failure.

Q 4. Explain the concept of failure analysis and its importance in engineering.

Failure analysis is the process of investigating the cause of a failure or malfunction in a system or component. It’s critical in engineering because it helps prevent future failures, improves product design, and enhances safety. By understanding why something failed, we can implement changes to make it more reliable and robust.

The process typically involves:

- Data Collection: Gathering information about the failure event, such as photographs, witness accounts, and operational data.

- Visual Inspection: Carefully examining the failed component to identify any visible signs of damage or wear.

- Material Testing: Conducting tests such as tensile testing or chemical analysis to determine the material properties and identify any defects.

- Root Cause Analysis: Identifying the underlying cause of the failure, rather than just the immediate symptoms.

- Corrective Actions: Implementing changes to the design, manufacturing process, or operational procedures to prevent similar failures.

For example, a failure analysis of a fractured bridge beam might involve metallurgical analysis to determine if material fatigue played a role, or a structural analysis to evaluate if the design was inadequate for the expected loads. The insights gleaned inform future bridge designs and maintenance practices, enhancing safety and longevity.

Q 5. Describe your experience with various CAD software and tools.

I’m proficient in a variety of CAD software and tools, including AutoCAD, SolidWorks, and Pro/ENGINEER. My experience extends to using these tools for a range of tasks, from 2D drafting and detailed 3D modeling to finite element analysis (FEA) and simulations. I have experience creating detailed drawings, generating bills of materials (BOMs), and performing design reviews using these software packages. In particular, my proficiency with SolidWorks has allowed me to effectively create and manage complex assemblies, while my use of AutoCAD has been instrumental in developing precise 2D blueprints for various projects.

Furthermore, I am comfortable working with various file formats and integrating CAD data with other engineering software for analysis and simulation. I find that familiarity with multiple CAD packages allows for flexibility and adaptability across diverse projects and teams.

Q 6. How do you ensure the quality and reliability of your engineering work?

Ensuring the quality and reliability of my engineering work is paramount. I employ a multi-faceted approach that incorporates several key strategies:

- Rigorous Design Process: Following established engineering principles and best practices throughout the design phase, including detailed calculations, simulations, and design reviews.

- Quality Control Checks: Implementing regular quality checks at each stage of the process, ensuring that intermediate results meet specified requirements.

- Testing and Validation: Conducting thorough testing and validation to ensure that the final product meets all performance and safety requirements. This includes unit testing, integration testing, and system testing.

- Documentation: Maintaining detailed and accurate documentation of all design decisions, calculations, test results, and changes made throughout the development process. This provides a clear audit trail.

- Continuous Improvement: Regularly reviewing past projects to identify areas for improvement and implement changes to enhance the quality and reliability of future work. This includes using lessons learned from failure analysis.

For example, in a recent project, we implemented a robust testing regimen that included environmental testing to ensure our product could withstand extreme temperatures and vibrations. This meticulous approach minimized the risk of failure and significantly enhanced the reliability of our final product.

Q 7. Explain your understanding of different engineering standards and codes (e.g., ASME, IEEE).

My understanding of engineering standards and codes is comprehensive. I am familiar with a variety of standards, including those published by ASME (American Society of Mechanical Engineers), IEEE (Institute of Electrical and Electronics Engineers), and others relevant to specific disciplines. These codes and standards provide a framework for safe and reliable design, manufacturing, and operation of engineering systems. They help ensure consistency and minimize risk.

For example, ASME codes are crucial in the design of pressure vessels and piping systems, specifying design criteria to prevent catastrophic failures. IEEE standards are essential in electrical engineering, providing guidelines for safe and reliable electrical installations and equipment. Adherence to these standards is vital for ensuring product safety, regulatory compliance, and minimizing potential liability. I always make sure to consult the relevant standards early in the design process to ensure compliance and incorporate best practices.

Q 8. How do you manage risk and uncertainty in engineering projects?

Managing risk and uncertainty in engineering projects is crucial for success. It involves a proactive approach, starting with thorough risk identification. This means systematically identifying potential problems, from material failures to schedule delays or unexpected environmental factors. We use techniques like brainstorming, checklists (based on past project experiences and industry best practices), and Failure Mode and Effects Analysis (FMEA) to achieve this.

Once risks are identified, we perform a risk assessment. This involves evaluating the likelihood and potential impact of each risk. We might use qualitative methods (e.g., assigning high, medium, or low ratings) or quantitative methods (e.g., probability and consequence matrices). This allows prioritization – focusing on the most critical risks first.

Next comes risk mitigation. This is about developing strategies to reduce the likelihood or impact of identified risks. This might involve: using higher-quality materials, adding buffer time to the schedule, implementing contingency plans (like alternative suppliers), or simply improving communication and collaboration among team members. For example, on a recent bridge project, we identified the risk of flooding during construction. Our mitigation strategy included detailed hydrological assessments, adjusted construction timelines, and provisions for temporary flood defenses.

Finally, monitoring and control are essential throughout the project lifecycle. We continuously track progress, identify emerging risks, and adapt our mitigation strategies as needed. Regular risk reviews and updates keep the team focused and allow for timely corrective actions. Think of it as constantly navigating a ship – adjusting the course based on the latest weather information (risks).

Q 9. Discuss your experience with project management methodologies in an engineering context.

My experience encompasses several project management methodologies, primarily Agile and Waterfall. Waterfall, a more linear approach, suited projects with well-defined requirements and minimal anticipated changes. For example, in a manufacturing facility upgrade project, where the scope was clearly outlined upfront, a Waterfall approach worked well due to its structured phase-based execution.

However, many engineering projects benefit from Agile’s iterative and flexible nature. Agile allows for adaptation to evolving requirements and client feedback. On a recent software development project integrated with a robotic system, we used Scrum, an Agile framework. This allowed us to quickly iterate, test, and refine the system, resulting in a more robust and user-friendly final product. Sprints provided regular feedback loops and allowed us to adjust our approach based on real-time data and client interaction.

Regardless of the chosen methodology, effective project management in engineering requires a strong emphasis on clear communication, meticulous documentation, risk management (as discussed previously), and consistent monitoring of progress against the project plan. I’m proficient in using project management tools like Jira and MS Project to track tasks, manage resources, and monitor deadlines.

Q 10. Explain the importance of ethical considerations in engineering practice.

Ethical considerations are paramount in engineering. Our work directly impacts public safety, the environment, and societal well-being. This demands a commitment to honesty, integrity, and responsibility. Ethical considerations manifest in many ways:

- Safety: Designing and building structures, systems, and products that are safe for users and the public. This involves adhering to safety standards and regulations, performing thorough testing, and considering potential failure modes.

- Environmental Responsibility: Minimizing the environmental impact of our projects. This requires considering the lifecycle of products and infrastructure, choosing sustainable materials, and employing energy-efficient designs. For instance, designing a building to meet LEED certification standards demonstrates this commitment.

- Social Responsibility: Ensuring that our work benefits society and does not negatively impact communities. This involves considerations of social equity and accessibility in our design choices. It can also include considerations of fair labor practices throughout the project’s lifecycle.

- Confidentiality: Protecting sensitive information related to projects and clients. This is crucial for maintaining trust and protecting intellectual property.

Ethical lapses can have severe consequences, from project failures and financial losses to legal repercussions and damage to reputation. A strong ethical framework guides our decisions and ensures responsible engineering practice.

Q 11. Describe your experience with finite element analysis (FEA) or similar simulation techniques.

I have extensive experience using Finite Element Analysis (FEA) software, primarily ANSYS and Abaqus. FEA is a powerful computational technique for simulating the behavior of structures and systems under various loads and conditions. It allows for predicting stress, strain, displacement, and other relevant parameters without the need for expensive and time-consuming physical testing. For example, in designing a complex aerospace component, I used ANSYS to model the stress distribution under various flight loads. This helped to optimize the design for weight and strength, ensuring its structural integrity.

My experience encompasses a wide range of applications, including static and dynamic analysis, thermal analysis, and fluid-structure interaction. I’m proficient in mesh generation, boundary condition definition, and result interpretation. I also understand the limitations of FEA and the importance of validating simulation results with experimental data where possible. A crucial aspect is selecting the appropriate element type and mesh density to achieve the desired accuracy while maintaining computational efficiency.

In addition to FEA, I have experience with other simulation techniques like Computational Fluid Dynamics (CFD) for analyzing fluid flow and heat transfer. These tools are invaluable for validating design choices, optimizing performance, and minimizing the risk of failures.

Q 12. How do you handle conflicting priorities or deadlines in engineering projects?

Handling conflicting priorities and deadlines requires effective communication, prioritization, and sometimes, negotiation. I typically start by clearly defining all competing demands and their relative importance. This often involves discussions with stakeholders to understand their priorities and constraints. A useful tool is a prioritization matrix, where tasks are ranked based on urgency and importance.

Once priorities are established, I create a revised project plan that incorporates the necessary adjustments. This might involve re-allocating resources, adjusting timelines (where possible), or identifying tasks that can be deferred or eliminated altogether. Open and honest communication with the project team and stakeholders is crucial throughout this process to ensure everyone is aware of the changes and their implications.

In situations where compromises are unavoidable, I focus on finding solutions that minimize negative impact while preserving the project’s overall goals. This may involve negotiating with stakeholders to adjust expectations or explore alternative approaches. For example, on a recent project, we faced a delay in receiving a key component. By communicating proactively with the client and adjusting the work schedule, we managed to meet the critical deadlines without compromising the overall project quality.

Q 13. Describe your experience with different types of manufacturing processes.

My experience with manufacturing processes spans a range of techniques, including:

- Subtractive Manufacturing: This involves removing material to create a final product, such as machining (e.g., milling, turning, drilling) and 3D printing (using techniques like material jetting or laser sintering). I have firsthand experience with CNC machining centers, where I’ve worked on projects involving complex part geometries.

- Additive Manufacturing (3D Printing): This is a rapidly growing area, and I have hands-on experience with several 3D printing technologies, including Fused Deposition Modeling (FDM) and Stereolithography (SLA). These techniques are useful for prototyping and creating complex shapes not easily achievable through traditional methods.

- Casting: I’ve worked with projects involving sand casting and investment casting, which are suitable for mass production of components with intricate designs. Understanding the properties of different casting materials and the potential for defects is key.

- Forming: This includes processes such as forging and stamping, used for shaping metal components. I understand the design considerations for these processes and their impact on part strength and integrity.

My knowledge extends to understanding the limitations and capabilities of each process, allowing me to select the most appropriate technique for a specific application considering factors like material properties, production volume, cost, and desired accuracy.

Q 14. Explain the importance of sustainability in engineering design and implementation.

Sustainability is no longer optional in engineering; it’s a necessity. It’s about designing and building systems and products that meet the needs of the present without compromising the ability of future generations to meet their own needs. This principle guides design choices across many aspects:

- Material Selection: Choosing materials with low environmental impact, considering their lifecycle from extraction to disposal. This might involve using recycled materials, bio-based materials, or materials with high recyclability.

- Energy Efficiency: Designing systems that minimize energy consumption throughout their operation. Examples include optimizing building insulation, implementing energy-efficient lighting and HVAC systems, and designing energy-harvesting technologies.

- Waste Reduction: Minimizing waste generated during manufacturing and operation. This requires efficient material utilization, recycling programs, and proper waste management procedures. Lean manufacturing principles are incredibly helpful here.

- Lifecycle Assessment: Considering the entire environmental impact of a product or system throughout its lifecycle, from material sourcing to end-of-life disposal. This provides a holistic view of its sustainability.

Embracing sustainability isn’t just environmentally responsible; it often leads to cost savings through reduced energy consumption and material usage. Moreover, it enhances a project’s reputation and aligns with growing consumer demand for eco-friendly products and services.

Q 15. How do you stay current with the latest advancements and trends in your engineering field?

Staying current in a rapidly evolving field like engineering requires a multi-pronged approach. I actively participate in several strategies to ensure I remain at the forefront of advancements.

- Professional Organizations and Conferences: I’m a member of [Name of relevant professional organization(s)], attending their annual conferences and webinars. These events offer invaluable opportunities to network with peers and learn about the latest research and breakthroughs from leading experts. For example, at last year’s conference, I learned about a new material with superior heat resistance, directly applicable to my current project.

- Peer-Reviewed Publications and Journals: I regularly read journals such as [Name of relevant journals], focusing on articles relevant to my specialization. Critically reviewing these publications helps me understand the latest research methodologies and their implications.

- Online Courses and Webinars: Platforms like Coursera, edX, and LinkedIn Learning offer excellent resources for professional development. I’ve recently completed a course on [Name of relevant course], enhancing my skills in [Specific skill gained].

- Industry News and Blogs: Staying informed through reputable industry news sources and blogs allows me to track emerging trends and technological shifts in real-time. This proactive approach helps me anticipate future challenges and opportunities.

This combination of active learning and engagement ensures I’m not just keeping up, but actively contributing to the evolution of my field.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with data analysis and interpretation in an engineering context.

Data analysis and interpretation are crucial to my engineering work. I’ve extensively used data analysis in several projects to optimize designs, troubleshoot issues, and predict future performance.

- Example 1: In a recent project involving the design of a new bridge, I analyzed extensive data on traffic flow, material strengths, and environmental factors using statistical software like R and Python. This analysis allowed us to optimize the bridge’s design for maximum efficiency and durability while minimizing costs.

- Example 2: During the manufacturing process of a specific component, we were experiencing higher-than-expected failure rates. By analyzing production data using control charts and regression analysis, I pinpointed the root cause to a specific machine setting. Adjusting this setting significantly improved yield and reduced waste.

My experience encompasses various techniques, including descriptive statistics, regression analysis, hypothesis testing, and data visualization. I’m proficient in using statistical software packages to perform these analyses and interpret the results effectively, translating complex data into actionable insights that drive informed decision-making.

Q 17. Explain your understanding of different types of engineering materials and their properties.

Understanding engineering materials and their properties is fundamental to my profession. My knowledge covers a wide range of materials, encompassing their strengths, weaknesses, and suitability for specific applications.

- Metals: I’m familiar with various metals, including steel (various grades and alloys), aluminum, titanium, and their respective properties, like tensile strength, yield strength, ductility, and fatigue resistance. For example, I’ve used high-strength low-alloy steel in structural applications where high tensile strength and weldability were critical.

- Polymers: My expertise extends to polymers, including thermoplastics (like ABS, polyethylene, and polypropylene) and thermosets (like epoxy and polyester resins). I understand their behavior under different temperature and stress conditions and their suitability for applications ranging from insulation to protective coatings. For example, I selected a specific type of high-temperature epoxy resin for use in an electronic device to withstand high operating temperatures.

- Ceramics and Composites: I’m also knowledgeable about ceramics (like alumina and silicon carbide) and composites (like fiber-reinforced polymers). These materials offer unique properties, like high strength-to-weight ratios and resistance to extreme temperatures and corrosion. For instance, I’ve utilized carbon fiber reinforced polymers in aerospace applications to reduce weight and improve structural performance.

This knowledge allows me to select the appropriate materials for a given design, considering factors like cost, performance requirements, and environmental impact. I often use material property databases and finite element analysis (FEA) software to refine material selection and predict the performance of a component under various loading conditions.

Q 18. How do you collaborate effectively with cross-functional teams in an engineering environment?

Effective collaboration is paramount in engineering. My approach emphasizes clear communication, active listening, and a collaborative mindset.

- Clear Communication: I ensure clear and concise communication of technical information to colleagues from different disciplines. This includes using visual aids, such as diagrams and charts, to effectively convey complex ideas. I also actively solicit feedback to ensure everyone is on the same page.

- Active Listening: I actively listen to diverse perspectives and viewpoints, valuing the contributions of team members with different areas of expertise. This inclusivity allows us to leverage the collective knowledge of the team, leading to innovative solutions.

- Conflict Resolution: I approach conflicts constructively, facilitating open discussions to identify the root causes of disagreements and find mutually acceptable solutions. This prevents conflicts from derailing the project and strengthens team cohesion.

- Project Management Tools: I leverage project management tools like Jira or Asana to track progress, assign tasks, and ensure seamless communication among team members. This fosters transparency and accountability across the team.

Through these practices, I’ve successfully collaborated with teams involving designers, manufacturing engineers, and quality control specialists on complex projects, consistently delivering high-quality results on time and within budget.

Q 19. Explain your experience with testing and validation methodologies in engineering.

Testing and validation are crucial for ensuring the quality, reliability, and safety of engineered systems. My experience includes a wide range of methodologies, from unit testing to system-level validation.

- Unit Testing: I employ unit testing to verify the functionality of individual components or modules. This involves creating test cases that simulate various inputs and compare the outputs to expected results.

- Integration Testing: Integration testing focuses on verifying the interaction between different components and modules to ensure they work together seamlessly. This often involves using mock objects or stubs to simulate the behavior of external systems.

- System Testing: System testing involves testing the entire system as a whole to ensure it meets its specified requirements. This often includes functional testing, performance testing, and security testing.

- Validation: Validation ensures that the final product meets the customer’s requirements and expectations. This often involves conducting user acceptance testing (UAT) and gathering feedback from users.

I’m proficient in developing test plans, executing tests, and documenting results. I utilize various testing tools and frameworks, adapting my approach to the specific requirements of each project. A key aspect of my methodology is documenting thorough test reports that clearly communicate the results and any identified issues.

Q 20. Describe your experience with root cause analysis techniques.

Root cause analysis (RCA) is a systematic approach to identifying the underlying causes of problems, rather than just addressing the symptoms. I’m experienced in several RCA techniques, including the ‘5 Whys’ and Fishbone diagrams.

- 5 Whys: This iterative technique involves repeatedly asking ‘why’ to uncover the root cause of a problem. For example, if a machine keeps malfunctioning, the 5 Whys might reveal the root cause to be inadequate preventative maintenance.

- Fishbone Diagram (Ishikawa Diagram): This visual tool helps identify potential causes by categorizing them into different contributing factors, such as materials, methods, manpower, machinery, measurement, and environment. This structured approach helps to brainstorm a wider range of potential causes.

- Fault Tree Analysis (FTA): For complex systems, I use FTA, a deductive technique that starts with an undesired event (top event) and works backward to identify the root causes through a series of logic gates.

By employing these techniques, I can effectively identify the underlying causes of problems, leading to more effective solutions that prevent recurrence. This proactive approach improves efficiency, reduces costs, and enhances overall system reliability.

Q 21. Explain your understanding of engineering economics and cost analysis.

Engineering economics and cost analysis are essential for making sound engineering decisions. I understand the importance of considering both initial costs and lifecycle costs when designing and implementing projects.

- Cost Estimation: I use various techniques to estimate the cost of projects, including bottom-up estimation, top-down estimation, and parametric estimation. These techniques involve detailed cost breakdowns and the use of historical data and industry standards.

- Lifecycle Cost Analysis (LCCA): LCCA considers all costs associated with a project over its entire lifespan, including initial investment, operation and maintenance costs, and disposal costs. This holistic approach ensures that cost-effective solutions are chosen, considering long-term implications.

- Return on Investment (ROI) Analysis: I evaluate project proposals based on their potential ROI, considering the benefits and costs to determine the financial viability of the project.

- Discounted Cash Flow (DCF): For long-term projects, I utilize DCF to account for the time value of money, ensuring accurate financial analysis and informed decision-making.

My experience in this area allows me to make informed decisions regarding resource allocation, project selection, and cost optimization, ensuring the projects are both technically sound and financially viable.

Q 22. How do you ensure the safety and security of your engineering designs and systems?

Ensuring safety and security in engineering design is paramount. It’s not just about meeting regulations; it’s about preventing harm to people and the environment, and protecting intellectual property. My approach is multifaceted and begins at the conceptual stage.

- Hazard Analysis and Risk Assessment (HARA): I consistently employ HARA techniques like Failure Mode and Effects Analysis (FMEA) and Fault Tree Analysis (FTA) to identify potential hazards and their probabilities. This allows for proactive design choices that mitigate risks. For example, in designing a pressure vessel, I’d consider potential failures like material fatigue or weld defects and incorporate safety factors and pressure relief valves.

- Redundancy and Fail-Safes: I design systems with redundancy wherever critical. If one component fails, backups ensure continued safe operation. Think of aircraft flight control systems, which have multiple independent systems.

- Safety Standards and Regulations Compliance: Adherence to relevant safety standards (like ISO, IEC, or industry-specific codes) is crucial. I meticulously document compliance throughout the design process.

- Testing and Validation: Rigorous testing, including simulations, prototypes, and field trials, is essential to validate the design’s safety and performance. This allows for the identification and correction of flaws before deployment.

- Cybersecurity (where applicable): For systems with embedded software or network connectivity, I incorporate cybersecurity measures to protect against unauthorized access and malicious attacks. This includes secure coding practices, intrusion detection systems, and regular security audits.

Ultimately, a culture of safety is fostered through continuous improvement, thorough documentation, and a commitment to learning from past experiences, whether successes or failures.

Q 23. Describe your experience with different types of engineering documentation.

My experience encompasses a wide range of engineering documentation, from detailed design specifications to concise reports. I’m proficient in creating and interpreting various types, including:

- Technical Drawings: I’m adept at using CAD software (SolidWorks, AutoCAD) to create detailed 2D and 3D drawings, including orthographic projections, isometric views, and assembly drawings. These are critical for manufacturing and construction.

- Schematics and Diagrams: I create electrical schematics, block diagrams, flowcharts, and piping and instrumentation diagrams (P&IDs), depending on the project’s needs. These documents visually represent system architectures and functionality.

- Specifications and Standards: I develop comprehensive specifications outlining material properties, performance requirements, and testing procedures. This ensures consistency and quality throughout the project.

- Reports and Analyses: I write technical reports summarizing project findings, analyses, and recommendations. These reports are vital for stakeholder communication and decision-making.

- User Manuals and Documentation: For products intended for end-users, I create user-friendly manuals and other documentation to ensure safe and efficient operation.

I’m familiar with various document management systems and version control tools (like Git) to maintain accuracy and facilitate collaboration.

Q 24. Explain your understanding of intellectual property rights in engineering.

Understanding intellectual property (IP) rights is essential in engineering. It protects the innovative creations and prevents unauthorized use. This includes:

- Patents: These grant exclusive rights to inventors for a set period, protecting novel inventions and processes. A patent application requires a detailed description of the invention and its functionality.

- Trade Secrets: This involves protecting confidential information that provides a competitive advantage, such as unique manufacturing techniques or proprietary algorithms. Maintaining secrecy and controlling access are crucial.

- Copyrights: This applies to original works of authorship, such as software code, design documents, and technical drawings. Copyright protection arises automatically upon creation.

- Trademarks: These protect brand names and logos, distinguishing products and services in the marketplace.

In my work, I’m careful to respect IP rights by properly citing sources, obtaining necessary licenses, and ensuring our designs do not infringe on existing patents or copyrights. I also actively contribute to the protection of our company’s IP by documenting innovations and processes appropriately.

Q 25. How do you handle technical challenges and setbacks in engineering projects?

Handling technical challenges is an inherent part of engineering. My approach involves a structured problem-solving process:

- Problem Definition: Clearly define the problem, including its symptoms, impact, and constraints.

- Root Cause Analysis: Investigate the root cause using methods such as the 5 Whys or fishbone diagrams. This prevents treating just the symptoms.

- Solution Brainstorming: Generate a range of potential solutions, considering feasibility, cost, and risk.

- Solution Evaluation and Selection: Evaluate the potential solutions based on predefined criteria and select the most appropriate one.

- Implementation and Monitoring: Implement the chosen solution and monitor its effectiveness. Make adjustments as needed.

- Documentation and Lessons Learned: Document the entire process, including the problem, solution, and lessons learned, for future reference.

For example, during a project involving a failing sensor, I meticulously traced the signal path, conducted thorough testing, and identified a faulty connection. By systematically addressing the issue, I ensured the project’s success.

Q 26. Describe your experience with process improvement methodologies (e.g., Lean, Six Sigma).

I have experience applying Lean and Six Sigma methodologies to improve engineering processes. Lean focuses on eliminating waste and maximizing value, while Six Sigma aims to reduce defects and variability.

- Lean: I’ve used Lean principles to streamline workflows, reducing lead times and improving efficiency. For example, I implemented a Kanban system to manage tasks and prevent bottlenecks in a design review process. This improved turnaround time and reduced rework.

- Six Sigma: I’ve used Six Sigma’s DMAIC (Define, Measure, Analyze, Improve, Control) methodology to solve complex problems. In one instance, I used statistical process control (SPC) charts to identify and eliminate variations in manufacturing tolerances, resulting in a significant decrease in defects.

Combining Lean and Six Sigma often provides synergistic benefits, leading to greater efficiency and quality improvements. It requires a data-driven approach and a commitment to continuous improvement.

Q 27. Explain your understanding of different types of engineering drawings and schematics.

Engineering drawings and schematics are essential for communication and manufacturing. I’m familiar with various types:

- Orthographic Projections: These show multiple views (top, front, side) of an object to accurately represent its shape and dimensions.

- Isometric Drawings: These provide a three-dimensional view of an object, useful for visualization and assembly.

- Assembly Drawings: These show how different components fit together to form a complete assembly.

- Electrical Schematics: These diagrams show the connections between electrical components, including wires, resistors, capacitors, and integrated circuits.

- Piping and Instrumentation Diagrams (P&IDs): These diagrams are used in process engineering to illustrate piping systems, instrumentation, and control loops.

- Block Diagrams: These high-level diagrams show the major components and their interconnections in a system.

Understanding these different types is crucial for accurately interpreting designs, creating manufacturing instructions, and troubleshooting problems.

Q 28. How do you communicate technical information effectively to both technical and non-technical audiences?

Effective communication is vital in engineering. My approach is tailored to the audience:

- Technical Audiences: When communicating with engineers and other technical professionals, I use precise technical language, detailed diagrams, and quantitative data. I might use simulations or modeling results to support my points.

- Non-Technical Audiences: When communicating with management, clients, or the public, I avoid technical jargon and use clear, concise language. I use visuals, analogies, and real-world examples to explain complex concepts. I focus on the key takeaways and avoid overwhelming them with details.

Regardless of the audience, I emphasize clarity, conciseness, and visual aids. Active listening and adapting to the audience’s understanding are essential for successful communication.

Key Topics to Learn for Knowledge of engineering principles and practices Interview

- Fundamentals of Engineering Design: Understanding design processes, including requirements gathering, conceptual design, detailed design, and testing. Explore different design methodologies like Agile and Waterfall.

- Materials Science and Engineering: Knowledge of material properties (strength, ductility, etc.), selection criteria, and failure analysis. Practical application includes choosing appropriate materials for specific engineering applications.

- Thermodynamics and Heat Transfer: Understanding fundamental concepts like energy conservation, entropy, and heat transfer mechanisms (conduction, convection, radiation). Practical applications involve designing efficient thermal systems.

- Fluid Mechanics: Understanding fluid behavior, pressure, flow, and viscosity. Practical applications include designing pipelines, pumps, and other fluid handling systems.

- Statics and Dynamics: Understanding forces, moments, and equilibrium. Practical application includes structural analysis and design.

- Electrical Engineering Principles (if applicable): Basic circuit analysis, Ohm’s Law, Kirchhoff’s Laws. This is crucial if the engineering role involves electrical components or systems.

- Problem-Solving and Analytical Skills: Demonstrate your ability to approach complex engineering problems systematically, utilizing analytical tools and techniques.

- Safety and Ethical Considerations: Understanding and applying relevant safety regulations and ethical principles in engineering design and practice.

- Project Management Basics: Familiarity with project planning, scheduling, and execution, including risk management.

Next Steps

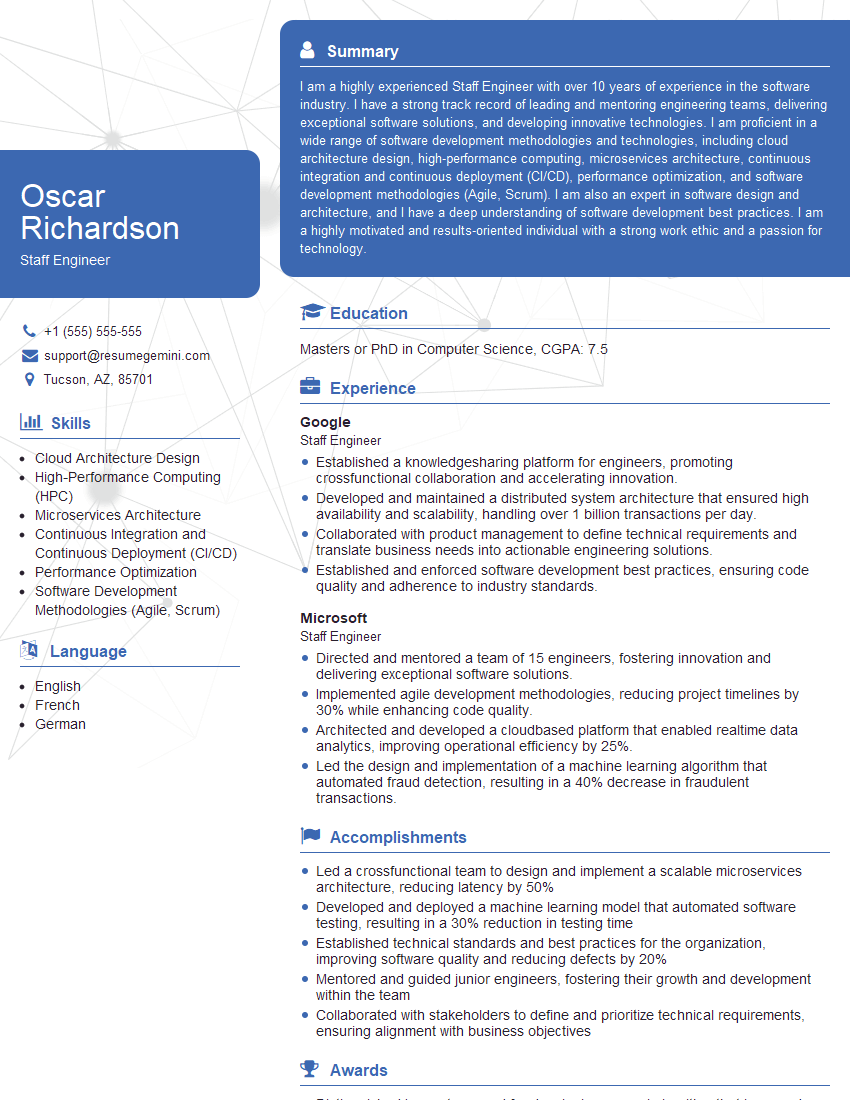

Mastering engineering principles and practices is crucial for career advancement in any engineering field. A strong understanding of these concepts demonstrates your competency and opens doors to exciting opportunities. To maximize your job prospects, it’s vital to create a resume that effectively highlights your skills and experience to Applicant Tracking Systems (ATS). ResumeGemini is a trusted resource to help you build a professional and ATS-friendly resume that showcases your expertise. Examples of resumes tailored to showcasing knowledge of engineering principles and practices are available to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I represent a social media marketing agency that creates 15 engaging posts per month for businesses like yours. Our clients typically see a 40-60% increase in followers and engagement for just $199/month. Would you be interested?”

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?