The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Linoleum Flooring Installation interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Linoleum Flooring Installation Interview

Q 1. What types of adhesives are suitable for linoleum installation?

Choosing the right adhesive is crucial for a successful linoleum installation. The best adhesive depends on the type of linoleum (sheet or tile), the subfloor material, and the environmental conditions. Generally, we use pressure-sensitive adhesives for sheet linoleum and construction adhesives for tile linoleum.

- Pressure-sensitive adhesives (PSA): These are self-adhesive backings found on many sheet linoleums. They’re easy to use but require a very smooth, clean, and dry subfloor for optimal adhesion. Think of it like a really strong sticker.

- Water-based adhesives: These are suitable for various subfloors and offer good adhesion. They require a longer drying time than solvent-based adhesives. They are environmentally friendly.

- Solvent-based adhesives: These offer strong adhesion and are ideal for challenging situations, like uneven subfloors or extreme temperatures. However, they have strong fumes and require more careful handling.

- Construction adhesives: Specifically formulated for tile linoleum, these adhesives provide strong bonds and excellent durability. Think of it like the glue that holds tiles to a wall.

The wrong adhesive can lead to lifting, bubbling, or even complete failure of the linoleum, so selecting the appropriate adhesive is paramount.

Q 2. Explain the process of preparing a subfloor for linoleum installation.

Subfloor preparation is the most critical step in linoleum installation. A poorly prepared subfloor will inevitably lead to problems down the line. Imagine trying to build a house on a shaky foundation – it won’t last!

- Cleaning: Thoroughly remove any dirt, dust, debris, grease, or old adhesive residue. A shop vac and a stiff brush are invaluable here.

- Repairing: Address any cracks, holes, or unevenness in the subfloor. This might involve filling cracks with patching compound, sanding down high spots, or using self-leveling compound to create a perfectly smooth surface. The goal is a flat, stable surface.

- Priming: Applying a primer, especially to absorbent subfloors like concrete, helps create a uniform surface and promotes better adhesion of the adhesive. It prevents the subfloor from sucking the moisture out of the adhesive.

- Moisture Testing: For concrete subfloors, a moisture test is essential. Excessive moisture can cause the linoleum to bubble or peel. Various meters exist for this purpose.

- Drying: Ensure the subfloor is completely dry before starting the installation. This prevents moisture problems later on.

Remember, the smoother and drier your subfloor, the better your linoleum installation will look and last. This step is not negotiable.

Q 3. Describe different methods for cutting linoleum.

Cutting linoleum accurately requires precision. Different methods are employed depending on the linoleum type and the cut required.

- Utility Knife: A sharp utility knife with a fresh blade is excellent for straight cuts and intricate trimming. Scoring the linoleum first will make the cut cleaner.

- Circular Saw with a Fine-Tooth Blade: A circular saw is ideal for straight, long cuts, especially when working with thicker linoleum. Use a fine-tooth blade to prevent chipping.

- Rotary Cutter: For precise cuts and curves, a rotary cutter with a sharp blade is a great tool. It’s similar to using a pizza cutter.

- Jigsaw: For intricate cuts and curves, a jigsaw is a more flexible option than a rotary cutter. It can handle a range of materials and shapes.

Regardless of the method, always use a straightedge or template to guide your cuts for the most accurate results.

Q 4. How do you ensure proper seam alignment during linoleum installation?

Proper seam alignment is vital for a professional-looking installation. Improper alignment leads to unsightly gaps and potential issues with water damage.

- Accurate Measurement and Cutting: Precise measurements and cutting are essential. Using a measuring tape and a straight edge are fundamental to success.

- Butt Joints: Butt joints should be carefully aligned and butted tightly together. If using sheet linoleum, we will use a seam sealer to seal the joints.

- Seaming Tape: For added security, especially in high-moisture areas, we can use seam tape to reinforce the joint, which can prevent cracking.

- Seam Roller: After the adhesive is applied, use a seam roller to press the linoleum sheets together tightly, ensuring complete adhesion and a secure seam.

Take your time and double-check the alignment before applying adhesive. A little extra care here prevents major headaches later.

Q 5. What tools and equipment are essential for linoleum installation?

Having the right tools makes all the difference in a linoleum installation. Improper tools can lead to poor results, injury, or increased installation time.

- Measuring Tape: Accurate measurements are crucial for a precise fit.

- Utility Knife: For cutting and trimming.

- Straight Edge: To guide cuts and ensure straight lines.

- Seam Roller: To ensure good adhesion along seams.

- Putty Knife: For spreading adhesive and removing excess.

- Roller (for adhesive application): This allows for even adhesive distribution.

- Floor Scraper: For removing old adhesive or levelling the floor.

- Safety Glasses and Gloves: Essential for protection from sharp objects and adhesive.

Investing in quality tools is a worthwhile investment for any serious DIYer or professional installer. This ensures the work is done efficiently and safely.

Q 6. How do you handle uneven subfloors during linoleum installation?

Uneven subfloors are a common challenge in linoleum installation. Ignoring them will result in a bumpy and potentially damaged floor. We address this through a multi-step process:

- Assessment: Thoroughly assess the unevenness. Is it minor imperfections or significant dips and bumps?

- Leveling: For minor imperfections, sanding might suffice. For larger issues, a self-leveling compound is often the solution. This compound is poured onto the subfloor and self-levels, creating a smooth surface.

- Patching: Large holes or cracks need to be patched using appropriate patching compounds before levelling.

- Underlayment (in some cases): In certain situations where the subfloor is excessively uneven or damaged, an underlayment can be used to create a smooth and level surface.

Addressing subfloor unevenness might add time and cost to the project, but it’s far more cost-effective than dealing with a failed linoleum installation later.

Q 7. Describe your experience with different types of linoleum.

My experience encompasses a wide range of linoleum types, each with its own characteristics and applications:

- Sheet Linoleum: This is the traditional type, coming in large rolls. It’s durable, relatively inexpensive, and comes in various patterns and colours. It’s ideal for larger spaces.

- Tile Linoleum: These are individual tiles that allow for easy replacement if damaged. They offer greater design flexibility compared to sheet linoleum.

- Inlaid Linoleum: This type has the pattern going all the way through, so it’s more durable and resistant to wear. It’s a premium choice, often more expensive.

- Printed Linoleum: A more affordable option where the pattern is printed onto the surface. It’s less durable than inlaid types.

- Commercial-grade Linoleum: Heavier-duty linoleum designed for high-traffic areas such as offices or retail spaces, it’s much more durable.

Each type has its own strengths and weaknesses, and I select the appropriate type based on the client’s needs, budget, and the intended use of the space. Understanding these differences is crucial for recommending the best solution for each project.

Q 8. How do you measure and calculate the amount of linoleum needed for a project?

Accurately measuring for linoleum is crucial to avoid waste and ensure a perfect fit. First, carefully measure the length and width of each area to be covered. Remember to account for any irregularities in the floor, and always add extra to compensate for cuts and potential mistakes. For rectangular rooms, simply multiply length by width to get the square footage. For complex shapes, break the area into smaller, easily measurable sections (rectangles, triangles) and calculate each area separately before summing them up.

For example, if you’re covering a kitchen and a hallway, measure the kitchen’s length and width separately, calculate its area, and then do the same for the hallway. Add the areas together to get the total square footage needed. Remember to always add 5-10% extra to account for waste, especially for patterns that need matching.

Let’s say a kitchen measures 12ft x 10ft (120 sq ft) and a hallway is 5ft x 20ft (100 sq ft). The total is 220 sq ft. Adding 10% (22 sq ft) for waste, you would need to order at least 242 sq ft of linoleum.

Q 9. What safety precautions do you take during linoleum installation?

Safety is paramount during linoleum installation. Always wear appropriate safety gear, including safety glasses to protect your eyes from debris, a dust mask to prevent inhaling adhesive fumes, and sturdy work gloves to protect your hands from cuts and chemicals. Ensure the work area is well-ventilated to minimize exposure to fumes. If using a utility knife or other sharp tools, handle them with care and always cut away from yourself. Wear knee pads for prolonged kneeling and consider using a safety harness if working at heights. Finally, be mindful of electrical outlets and water pipes to prevent accidental damage or injury.

For example, I recently worked on a job where the client had exposed electrical wiring near the baseboards. We shut off the power entirely before even beginning that area of the project, and covered the wires with protective tape to prevent any accidental contact.

Q 10. Explain the process of installing linoleum around obstacles like pipes and doorways.

Installing around obstacles requires precision and careful planning. For pipes, measure the pipe’s circumference and cut a hole slightly larger than this measurement. This allows the linoleum to fit snugly around the pipe without causing tension. The best approach is to carefully cut the linoleum around the obstacle, leaving a small amount of extra material to tuck in against the pipe. For doorways, carefully measure the doorway’s dimensions and cut the linoleum accordingly, ensuring a clean, straight line. Use a utility knife with a sharp blade for accurate cutting and a metal straight edge for precise lines.

A common method is to score the linoleum along the cut line before cutting, preventing tearing. Use a seam roller to compress the edges after installation around the obstacle and ensure a seamless finish.

Q 11. How do you address moisture problems before installing linoleum?

Moisture is the linoleum installer’s biggest enemy. Before installation, thoroughly assess the subfloor for moisture. High moisture levels can lead to buckling, bubbling, and mold growth. A moisture meter is a valuable tool to accurately measure the moisture content of the subfloor. If moisture levels are too high, the subfloor needs to be dried completely before installation. This can be achieved through ventilation or using dehumidifiers. In some cases, moisture barriers, such as polyethylene sheeting, are used to protect the linoleum from rising moisture.

A particularly challenging project involved a basement floor that previously suffered from water damage. We had to first use a specialized dehumidification process to bring the moisture content of the subfloor well within acceptable limits before installation.

Q 12. How do you clean up excess adhesive after linoleum installation?

Cleaning up excess adhesive depends on the type of adhesive used. Water-based adhesives can often be cleaned with warm, soapy water and a damp sponge. Solvent-based adhesives may require a specialized adhesive remover. Always follow the manufacturer’s instructions for safe and effective cleanup. For stubborn adhesive residue, a plastic scraper can be helpful, but use it cautiously to avoid damaging the linoleum. After cleaning, rinse the area thoroughly and allow it to dry completely.

For instance, I once used a non-toxic citrus adhesive remover to lift some stubborn adhesive from a hardwood floor. It’s important to always test the remover on a small, inconspicuous area first to see if there’s any reaction.

Q 13. What are common problems encountered during linoleum installation?

Several common problems can occur during linoleum installation. Uneven subfloors can lead to wrinkling and bubbling. Incorrect adhesive application can cause lifting or adhesive failure. Improper cutting or measurement can result in gaps or misaligned seams. Moisture problems, as mentioned earlier, are a major concern. Inadequate ventilation during adhesive drying can also lead to problems. And finally, improper seam sealing can allow moisture to penetrate, leading to damage.

Q 14. How do you troubleshoot issues like bubbling or wrinkling in linoleum?

Bubbling and wrinkling are often caused by improper subfloor preparation, insufficient adhesive, or trapped air. To address bubbling, carefully pierce the bubble with a sharp needle and press out the trapped air using a roller. If the bubble is large, you may need to lift a section of the linoleum, add more adhesive, and re-install it. Wrinkling is often caused by stretching the linoleum during installation or an uneven subfloor. In some cases, it might be necessary to remove and replace a section of the linoleum.

In one instance, I encountered significant wrinkling that turned out to be caused by a subfloor that was not perfectly level. We used self-leveling compound to create an even surface before installing the linoleum and this entirely solved the issue.

Q 15. Describe your experience with different types of linoleum adhesives.

Over my 15 years installing linoleum, I’ve worked with a wide range of adhesives, each with its own properties and best uses. The most common types I encounter are pressure-sensitive adhesives (PSAs), water-based dispersions, and solvent-based adhesives. PSAs are convenient for smaller projects or DIY installations because they require no mixing, only firm pressure for bonding. Water-based dispersions are environmentally friendly and easier to clean up, making them a favorite for many residential jobs. However, they require a longer drying time. Solvent-based adhesives offer superior strength and adhesion, particularly for larger commercial spaces or areas with high traffic, but they require more ventilation and careful handling due to their strong fumes.

- Pressure-Sensitive Adhesives (PSAs): Think of the sticky backing on a sticker – simple to use but may not be as durable for high-traffic areas.

- Water-based dispersions (e.g., acrylic adhesives): These are low-VOC (volatile organic compound), making them healthier for the installer and occupants. They bond well and offer good flexibility.

- Solvent-based adhesives: These create a strong bond, but require proper ventilation and longer drying times. They’re more suited for commercial settings and heavy-duty applications.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you determine the correct adhesive type for a specific job?

Choosing the right adhesive is crucial for a successful linoleum installation. I consider several factors: the type of linoleum (sheet vs. tile), the subfloor condition (concrete, wood, etc.), the location (high traffic or low traffic), and the specific needs of the client. For example, a busy commercial kitchen needs a solvent-based adhesive for its superior strength and water resistance. A residential bathroom, however, might be perfectly suited to a water-based adhesive for its ease of use and lower odor. I always check the manufacturer’s recommendations for both the linoleum and the adhesive to ensure compatibility.

I recently worked on a project where the client wanted a specific type of resilient sheet flooring in a high-traffic office lobby. Given the location and foot traffic, we opted for a high-performance solvent-based adhesive that guarantees a long-lasting installation, even under heavy use. This prevented any future issues like bubbling or lifting.

Q 17. What is the proper method for rolling linoleum after installation?

Rolling the linoleum after installation is essential to ensure proper adhesion and eliminate air bubbles. I use a weighted roller, typically around 100-150 lbs, and begin rolling from the center of the flooring outwards toward the edges. This process squeezes out any trapped air and creates a tight bond between the linoleum and the adhesive. I work in overlapping passes to guarantee complete coverage. The rolling process needs to be thorough and consistent; it’s like gently coaxing the linoleum to lie flat and stick perfectly. You can’t rush this process; it takes patience and attention to detail.

A common mistake is insufficient rolling, leading to air pockets that can later cause bubbling or lifting of the linoleum.

Q 18. Explain the importance of acclimating linoleum before installation.

Acclimating linoleum is a critical step often overlooked. It means allowing the material to adjust to the temperature and humidity of the room where it will be installed. Linoleum is susceptible to expansion and contraction with changes in temperature and moisture levels. If it’s installed directly from a cold storage area into a warm room, it might expand and buckle, ruining the installation. I typically recommend acclimating the linoleum for at least 24-48 hours, or even longer depending on the size of the area and the environmental conditions. This ensures a smoother, more stable, and longer-lasting installation.

Think of it like preheating an oven before baking a cake – the proper acclimation process minimizes problems later on!

Q 19. How do you ensure proper ventilation during and after linoleum installation?

Proper ventilation is crucial throughout the entire installation process, especially when working with solvent-based adhesives which release strong fumes. I always ensure the work area is well-ventilated, either by opening windows and doors or using industrial-grade fans to circulate fresh air. This minimizes exposure to harmful fumes for both the installers and occupants. After installation, sufficient ventilation helps the adhesive cure properly and prevents the build-up of moisture, which can lead to mold and mildew.

For projects in confined spaces or with limited ventilation, I use respirators and ensure proper safety measures are in place to protect the health of my team.

Q 20. What are the differences between residential and commercial linoleum installation?

Residential and commercial linoleum installations differ primarily in the scale of the project and the demands placed on the flooring. Commercial installations often involve larger spaces, heavier foot traffic, and stricter requirements regarding durability, stain resistance, and ease of cleaning. The adhesives used are typically stronger and more resilient. In residential settings, the focus is usually on aesthetics and budget constraints, with a lesser emphasis on extreme durability. Preparation of the subfloor is also more critical in commercial settings due to the higher expectations of longevity.

For example, I recently installed linoleum in a high-traffic hospital corridor, using heavy-duty adhesives and a reinforced subfloor to ensure the flooring could withstand years of constant use. A residential kitchen installation, on the other hand, allows for more flexibility in material selection and installation methods.

Q 21. Describe your experience with installing linoleum in various settings (e.g., kitchens, bathrooms).

My experience spans a variety of settings, from kitchens and bathrooms to offices and retail spaces. Kitchens and bathrooms require materials that are waterproof and resistant to stains and spills. In kitchens, I often see linoleum chosen for its ease of cleaning and durability, while in bathrooms, it offers a moisture-resistant surface that is easy to maintain. Office spaces may prioritize durability and stain resistance, while retail settings may place a stronger emphasis on aesthetics and the ability to withstand high traffic. In each case, I tailor the installation method and material choices to meet the specific requirements of the space and the client’s expectations. I adapt my approach to ensure the final product is both functional and visually appealing within its environment.

One memorable project involved installing a custom-designed linoleum pattern in a high-end boutique. The client wanted a unique and eye-catching design, so we had to meticulously plan the installation to ensure the pattern was aligned and perfectly placed. That project required a higher level of precision and attention to detail.

Q 22. How do you manage a project timeline and budget for linoleum installation?

Managing a linoleum installation project’s timeline and budget requires meticulous planning and execution. I begin by conducting a thorough site survey to accurately assess the area, identify any potential challenges (e.g., uneven subfloors, existing damage), and determine the exact quantity of materials needed. This prevents costly overruns.

Next, I create a detailed project schedule, breaking down the installation process into manageable tasks with allocated timeframes. This includes subfloor preparation, underlayment installation, linoleum cutting and fitting, adhesive application, and final cleaning. I then develop a comprehensive budget encompassing material costs (linoleum, adhesive, underlayment), labor costs, and contingency funds for unexpected issues. I regularly monitor progress against the schedule and budget, making adjustments as needed, and keeping the client informed every step of the way. For example, if I encounter unexpected subfloor damage requiring extra repair time, I’ll immediately communicate this to the client, outlining the impact on the timeline and budget, and propose solutions. This proactive approach ensures transparency and maintains client trust.

Q 23. What are your methods for quality control during linoleum installation?

Quality control is paramount in linoleum installation. My methods begin with meticulous subfloor preparation – ensuring it’s clean, dry, level, and free from debris. This prevents issues like uneven seams or bubbling. I then carefully inspect the linoleum rolls for any defects before installation. During installation, I pay close attention to detail, ensuring proper adhesive application, accurate seam alignment, and consistent pressure to prevent air pockets or wrinkles. I use a seam welder or heat sealer to create strong, invisible seams. After the adhesive has cured, I perform a final inspection, checking for imperfections, loose seams, or any other defects. Think of it like baking a cake – you wouldn’t serve a cake with uneven frosting or a burnt edge. The same applies to linoleum installation. A thorough final inspection guarantees a professional, high-quality result, and this is further documented with photographs.

Q 24. Describe your experience working with different types of flooring underlayment.

My experience encompasses various flooring underlayments, each serving a different purpose. I’ve worked with foam underlayments, which offer cushioning and sound insulation; felt underlayments, which provide a smooth surface for the linoleum; and self-leveling compounds, essential for correcting uneven subfloors. The choice of underlayment depends on the specific project requirements and the condition of the existing subfloor. For example, in a high-traffic commercial setting, a more durable underlayment like a high-density foam might be preferred for longevity. In a residential setting with a relatively level subfloor, a thinner felt underlayment might suffice. I carefully assess the subfloor conditions to select the appropriate underlayment that guarantees the long-term success of the linoleum installation.

Q 25. How do you maintain safety standards while working with adhesives and other chemicals?

Safety is my top priority when working with adhesives and other chemicals. I always wear appropriate personal protective equipment (PPE), including gloves, eye protection, and respirators, as per the manufacturer’s instructions. I ensure adequate ventilation in the workspace, particularly when using solvent-based adhesives, to minimize exposure to harmful fumes. I store chemicals properly according to safety regulations, keeping them away from heat sources and out of reach of children. I also follow the manufacturer’s instructions carefully for the mixing and application of adhesives. Before starting any project, I thoroughly review the Safety Data Sheets (SDS) for all materials to understand potential hazards and necessary precautions. This proactive approach ensures both my safety and the safety of those around me.

Q 26. How do you handle customer concerns or complaints regarding linoleum installation?

Addressing customer concerns is critical. I listen attentively to their complaints, ask clarifying questions to fully understand the issue, and then objectively assess the situation. If a genuine defect exists, I promptly address it, offering solutions such as repair or replacement, depending on the nature of the problem and the warranty terms. I strive to resolve the issue efficiently and effectively, maintaining open communication throughout the process. For example, if a customer is unhappy with a seam, I would re-examine it, ensuring the seam was properly sealed and determining if there was a subfloor issue that contributed to the problem. If the seam needs to be re-done, I’d take ownership, schedule a time to correct the issue, and make sure the customer is satisfied with the outcome. The goal is always customer satisfaction.

Q 27. Explain your understanding of relevant building codes and regulations related to flooring.

I have a thorough understanding of relevant building codes and regulations related to flooring, including those concerning fire safety, slip resistance, and accessibility. These vary depending on the location and type of building. For instance, in commercial settings, specific regulations might mandate fire-resistant flooring materials or certain slip-resistance ratings. I always ensure my installations comply with all applicable codes and regulations, often working in conjunction with building inspectors or project managers to avoid delays and ensure compliance. This understanding is essential for not only completing a job correctly but also for the safety and legality of the finished product.

Q 28. Describe your experience with using specialized tools like seam welders or heat sealers.

I’m proficient in using specialized tools like seam welders and heat sealers. Seam welders create strong, durable, and virtually invisible seams by melting the edges of the linoleum together, ensuring a seamless, professional finish. Heat sealers are used for smaller seams or repairs. The proper use of these tools is crucial for achieving a high-quality installation. Choosing the right tool for the job depends on factors like the type of linoleum and the size of the seam. For example, a larger, thicker commercial linoleum might require a more powerful seam welder compared to a residential application. My expertise in using these tools minimizes visible seams and contributes to the overall aesthetic appeal of the finished floor.

Key Topics to Learn for Linoleum Flooring Installation Interview

- Substrate Preparation: Understanding different subfloor types (concrete, plywood, etc.), leveling techniques, moisture mitigation, and proper priming for optimal adhesion.

- Measurement and Material Calculation: Accurate room measurement, waste factor calculation, and ordering sufficient materials to avoid delays and extra costs. Practical application involves demonstrating proficiency in calculating square footage and accounting for patterns and cuts.

- Installation Techniques: Mastering various installation methods (full-spread adhesive, loose-lay, etc.), understanding the importance of proper seam alignment and adhesive application for a seamless finish.

- Tool Selection and Usage: Familiarity with essential tools (measuring tapes, utility knives, rollers, trowels, etc.) and their correct application for efficient and precise installation.

- Troubleshooting and Problem Solving: Identifying and resolving common issues such as uneven surfaces, adhesive problems, seam imperfections, and damage control during installation. This involves practical application of problem-solving skills and demonstrating the ability to find solutions efficiently.

- Health and Safety: Understanding and adhering to safety regulations regarding handling adhesives, using sharp tools, and maintaining a clean and organized work environment.

- Finishing Touches: Proper trimming, cove base installation, and cleaning techniques to ensure a professional and high-quality final product.

- Industry Standards and Codes: Familiarity with relevant building codes and industry best practices for linoleum installation.

Next Steps

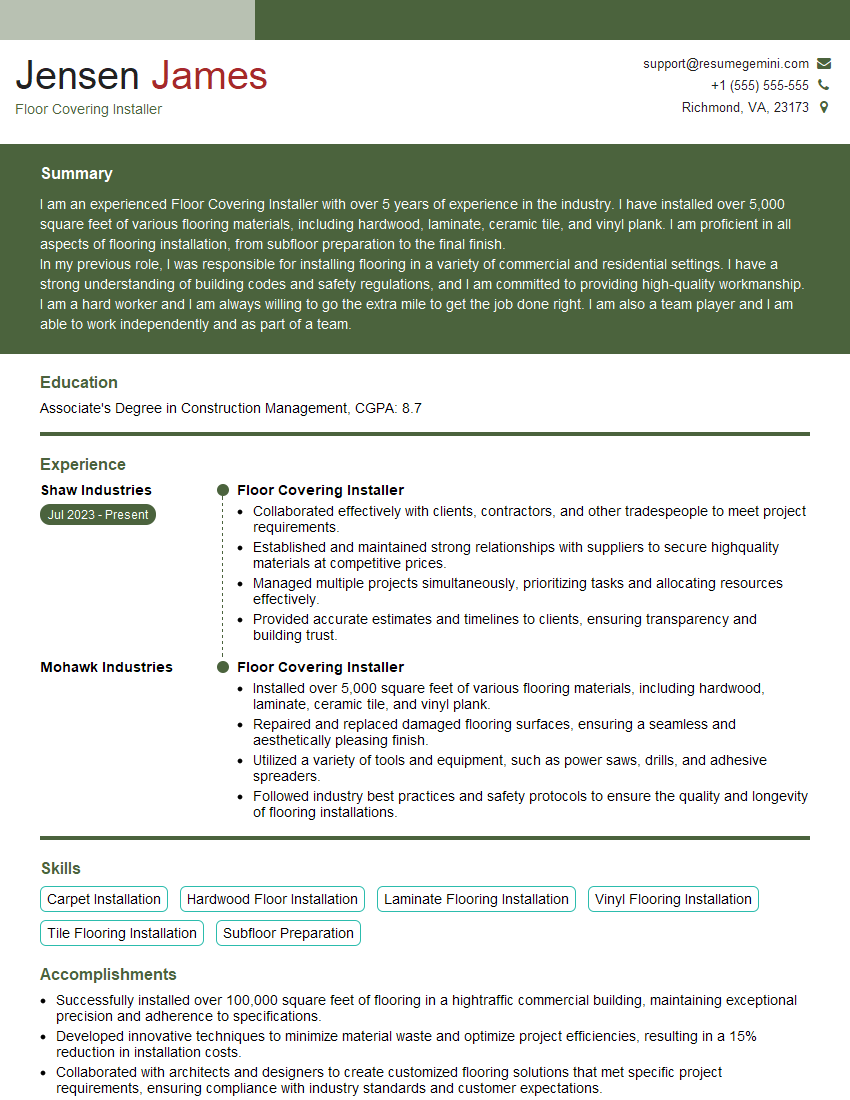

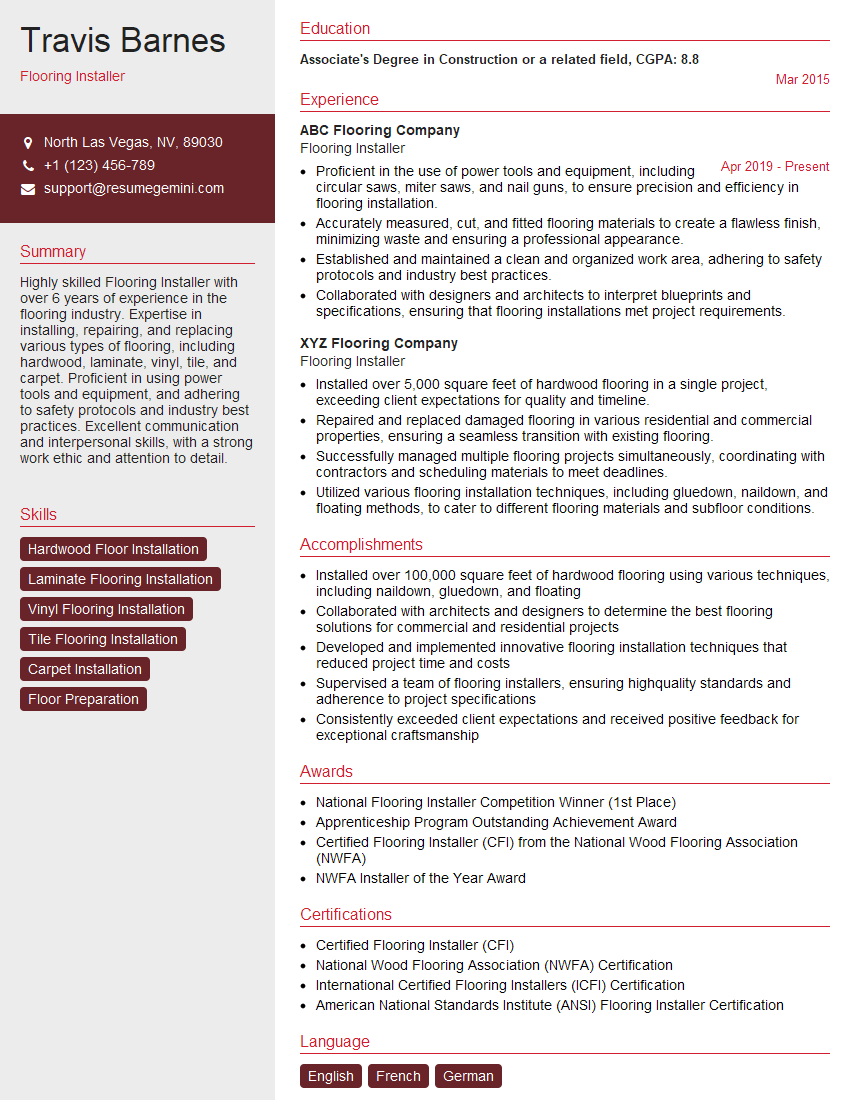

Mastering linoleum flooring installation opens doors to a rewarding career with opportunities for growth, from entry-level installer to team lead or even project management. To stand out, a strong, ATS-friendly resume is crucial. Make sure your skills and experience are highlighted effectively to attract recruiters. ResumeGemini is a trusted resource that can help you create a professional and impactful resume tailored to the specific demands of the linoleum flooring industry. Examples of resumes tailored to Linoleum Flooring Installation are available to help guide you. Invest time in crafting a compelling resume – it’s your first impression!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

hello,

Our consultant firm based in the USA and our client are interested in your products.

Could you provide your company brochure and respond from your official email id (if different from the current in use), so i can send you the client’s requirement.

Payment before production.

I await your answer.

Regards,

MrSmith

hello,

Our consultant firm based in the USA and our client are interested in your products.

Could you provide your company brochure and respond from your official email id (if different from the current in use), so i can send you the client’s requirement.

Payment before production.

I await your answer.

Regards,

MrSmith

These apartments are so amazing, posting them online would break the algorithm.

https://bit.ly/Lovely2BedsApartmentHudsonYards

Reach out at [email protected] and let’s get started!

Take a look at this stunning 2-bedroom apartment perfectly situated NYC’s coveted Hudson Yards!

https://bit.ly/Lovely2BedsApartmentHudsonYards

Live Rent Free!

https://bit.ly/LiveRentFREE

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?