Preparation is the key to success in any interview. In this post, we’ll explore crucial Load Plan interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Load Plan Interview

Q 1. Explain the process of creating a load plan.

Creating a load plan is a meticulous process that ensures efficient and safe transportation of goods. It involves optimizing space, weight distribution, and securing cargo to prevent damage during transit. Think of it like a complex puzzle where you need to fit all the pieces (goods) into a limited space (truck or container) in the most effective way.

- Needs Assessment: The first step involves understanding the shipment details: dimensions, weight, fragility, and any special handling requirements of each item.

- Space Optimization: Using software or even manual calculations, the planner strategically places items to maximize space utilization, minimizing wasted cubic feet and preventing instability.

- Weight Distribution: Proper weight distribution is crucial for safe handling and driving. Heavier items are generally placed lower and towards the center of gravity to maintain balance and stability.

- Securing Cargo: This step is critical for preventing damage during transit. Appropriate securing methods like straps, dunnage (protective material), and blocking and bracing are selected based on the cargo’s characteristics and the type of transportation.

- Documentation: The load plan is documented, providing details like item placement, weight distribution, and securing methods. This documentation serves as a reference for loading, unloading, and potential claims in case of damage.

For example, if I’m planning a shipment of furniture, I would place heavier items like sofas and armoires at the bottom, securing them firmly to prevent shifting during transport. Lighter items like chairs and tables would be placed on top, appropriately secured. This prevents damage and ensures a smooth delivery.

Q 2. What software or tools are you familiar with for load planning?

I’m proficient in several software and tools used for load planning. These range from simple spreadsheet programs to sophisticated 3D modeling software.

- Spreadsheet Software (Excel, Google Sheets): Great for basic load planning, particularly for smaller shipments. I can use formulas to calculate volume and weight, creating simple load diagrams.

- Transportation Management Systems (TMS): These comprehensive systems offer advanced features like route optimization, load consolidation, and real-time tracking. Examples include Oracle Transportation Management and SAP Transportation Management.

- 3D Load Planning Software: These programs provide visual representations of the loading process, allowing for precise placement of goods and efficient space utilization. Examples include 3DLoad and EasyCargo.

- Custom-built applications: Many companies develop in-house load planning software tailored to their specific needs and types of cargo.

The choice of software depends on the complexity of the shipments and the company’s resources. For complex intermodal shipments, a TMS or 3D modeling software is essential, while spreadsheet software might suffice for smaller, simpler loads.

Q 3. How do you determine the optimal number of trucks or containers needed for a shipment?

Determining the optimal number of trucks or containers involves careful consideration of several factors. It’s not just about fitting everything in; it’s about minimizing cost while ensuring timely delivery.

- Total Volume and Weight: Calculate the total cubic volume and weight of the goods to be shipped.

- Truck or Container Capacity: Consider the available space and weight capacity of the chosen vehicles (standard truck, high-cube trailer, different container sizes).

- Load Factor: Aim for a high load factor (percentage of available space utilized) to optimize cost-effectiveness. However, avoid overpacking, which can lead to damage and delays.

- Delivery Deadlines and Route Optimization: Consider the distance and transit time. Multiple smaller shipments might be faster than one large shipment, depending on the route and available drivers.

- Regulations and Restrictions: Comply with all weight and dimensional regulations, considering factors like bridge height restrictions and weight limits for certain roads or bridges.

For instance, if we have 100 cubic meters of goods and a standard truck offers 80 cubic meters, it’s more efficient to use two trucks rather than overloading one, which is both unsafe and possibly illegal. Careful consideration of these factors prevents unnecessary costs and delays.

Q 4. Describe your experience with different types of load planning, such as LTL, FTL, or intermodal.

My experience spans various load planning scenarios: Less-than-Truckload (LTL), Full Truckload (FTL), and intermodal shipments.

- LTL: This involves consolidating smaller shipments from multiple customers into a single truck. The key here is efficient space utilization and accurate weight distribution to ensure balance and prevent damage to individual packages.

- FTL: This involves using an entire truck for a single shipment. While seemingly simpler, it still requires careful planning to optimize space and secure the load effectively to prevent shifting during transit. This often involves larger items and specialized handling.

- Intermodal: This involves using multiple modes of transportation (truck, rail, sea). It adds complexity, requiring meticulous coordination across various carriers and handling potential issues related to cargo transfers between modes. This demands excellent communication and documentation.

I’ve handled projects requiring specialized loading techniques, such as shipping oversized or hazardous materials, adapting the load plan to conform with specific regulations and safety procedures. Each type of load plan demands a tailored approach, emphasizing specific elements like packaging, securing, and route planning.

Q 5. How do you handle unexpected delays or changes in a load plan?

Unexpected delays or changes are inevitable in transportation. My approach focuses on proactive communication and adaptable planning.

- Real-time Tracking and Monitoring: Utilizing GPS tracking and other technologies to monitor shipments in real-time allows for quick responses to unforeseen events like traffic jams or weather disruptions.

- Contingency Planning: Develop alternative routes or transportation methods to mitigate potential delays. Having backup options reduces the impact of unexpected events.

- Communication and Collaboration: Maintain open communication with carriers, customers, and other stakeholders. This enables collaborative problem-solving and quick decision-making when changes occur.

- Documentation and Updates: Keep the load plan updated with all changes and relevant information. This ensures transparency and facilitates efficient communication and quick resolution of problems.

For example, if a severe weather event closes a major highway, I’ll immediately explore alternative routes or potentially postpone the shipment, keeping stakeholders informed every step of the way. The goal is to minimize disruption and maintain transparency throughout.

Q 6. What are some common challenges you face in load planning, and how do you overcome them?

Load planning presents numerous challenges. However, experience and structured approaches help overcome them.

- Inaccurate Information: Incorrect dimensions or weight can disrupt the entire plan. This is addressed through thorough verification of information from the source.

- Conflicting Priorities: Balancing space optimization, weight distribution, and securing requirements can be challenging. This requires careful prioritization based on the cargo’s sensitivity and the specific risks involved.

- Unexpected Delays: Weather, traffic, or mechanical issues can disrupt schedules. Contingency planning and real-time monitoring are vital to mitigate delays.

- Communication Gaps: Poor communication among stakeholders can lead to errors or inefficiencies. This is countered with transparent and proactive communication strategies.

For instance, dealing with conflicting priorities, I might prioritize securing fragile items over achieving maximum space utilization if the risk of damage is higher. Proactive risk assessment is a key strategy.

Q 7. How do you prioritize shipments when dealing with multiple deadlines?

Prioritizing shipments with multiple deadlines requires a systematic approach. It’s about more than just the ‘first come, first served’ mentality.

- Criticality Assessment: Evaluate each shipment’s importance and urgency, assigning priority levels based on factors like delivery deadlines, product value, and customer impact.

- Resource Allocation: Allocate resources (trucks, drivers, equipment) based on the priority levels, ensuring that high-priority shipments receive timely attention and resources.

- Communication and Transparency: Maintain open communication with customers regarding potential delays or changes in schedules, managing expectations proactively.

- Dynamic Adjustment: Be prepared to adjust the schedule in response to unforeseen events or changes in priority. Flexibility is key in managing multiple deadlines.

I might use a prioritization matrix, scoring shipments based on urgency and importance to determine the order of execution. This helps ensure that the most critical shipments are delivered on time, even with limited resources.

Q 8. Explain your understanding of load balancing and its importance.

Load balancing is the process of distributing workloads across multiple servers or resources to prevent any single system from becoming overloaded. Think of it like distributing toys among children – if one child gets all the toys, they’ll be overwhelmed, but if you distribute them fairly, everyone can play happily. In the context of transportation and logistics, load balancing ensures efficient use of vehicles and resources, preventing delays and optimizing delivery times. Its importance stems from preventing system crashes, ensuring consistent performance, and maximizing resource utilization. For example, a large e-commerce company might use load balancing to distribute incoming customer requests across multiple web servers. This prevents any single server from being overwhelmed during peak traffic times, ensuring website availability and a positive customer experience. Without load balancing, a surge in demand could lead to slowdowns or even complete system failures.

Q 9. How do you ensure the safety and security of shipments during the load planning process?

Ensuring shipment safety and security during load planning involves a multi-faceted approach. It begins with proper cargo securing techniques, using appropriate materials like straps, dunnage, and protective coverings to prevent shifting or damage during transit. This is especially crucial for fragile goods or those sensitive to vibration. Next, accurate weight and dimension data is essential to prevent overloading vehicles and exceeding legal limits. This information informs the choice of appropriate vehicle type and ensures balanced weight distribution. We also have to consider security aspects, such as using tamper-evident seals, GPS tracking devices, and secure storage facilities. Furthermore, thorough documentation and risk assessment, including identifying potential hazards and implementing mitigation strategies, are critical. For example, transporting hazardous materials requires specialized containers, permits, and route planning to minimize risks. In my previous role, we implemented a system for digitally documenting every step of the process, including loading and unloading, to enhance traceability and accountability, thereby enhancing security and making tracing potential issues much easier.

Q 10. What is your experience with load optimization techniques?

My experience with load optimization techniques is extensive, encompassing both software-based solutions and manual strategies. I’ve worked with various algorithms, including bin packing and vehicle routing optimization, to minimize empty space in vehicles and optimize delivery routes. I’m proficient in using software that can generate load plans based on specific constraints like weight, volume, and fragility. For instance, I’ve used software that allows for 3D visualization of the load, ensuring efficient space utilization. Besides software, manual techniques like strategic item placement to prevent shifting and balancing weight distribution across the vehicle are also part of my skillset. In a recent project, I improved a client’s delivery efficiency by 15% by optimizing their loading process with a combination of software and manual techniques. This resulted in fewer trucks needed, reduced fuel costs, and faster delivery times.

Q 11. How do you calculate transportation costs associated with a load plan?

Calculating transportation costs associated with a load plan involves several factors. First, the distance of the route is a key component. This is multiplied by the fuel cost per mile for the specific vehicle type. Next, we consider the vehicle type and its associated operating costs including driver wages, maintenance, and insurance. The weight and volume of the load can influence the number of vehicles required and, consequently, the overall cost. Additional charges such as tolls, permits, and potential surcharges for fuel price increases or inclement weather are factored in. The calculation might be straightforward for single-leg shipments but gets more complex for multi-leg or multi-stop routes that require calculations for each leg and the associated time and mileage. For example: Total Cost = (Distance x Fuel Cost per Mile) + (Vehicle Operating Cost) + (Tolls) + (Permits) + (Surcharges)

Q 12. How do you incorporate different transportation modes into a load plan?

Incorporating different transportation modes into a load plan requires careful consideration of the characteristics of each mode and the goods being transported. For example, a shipment might begin with a truck for local pickup, then transition to a rail transport for long distances to reduce fuel costs and emissions, and finally finish with a smaller delivery truck for final delivery to the customer. This is known as intermodal transportation. Factors to consider include the cost, transit time, reliability, and accessibility of each mode. The selection depends on the urgency of delivery, the size and type of cargo, the infrastructure available, and cost considerations. Choosing the right combination of modes allows for efficient and cost-effective delivery while meeting customer requirements. I’ve successfully implemented intermodal solutions for several clients, resulting in significant cost savings without compromising delivery times.

Q 13. How do you handle weight and dimension restrictions during load planning?

Handling weight and dimension restrictions during load planning is critical for compliance with regulations and safe transportation. This involves knowing the weight and dimensional limits of the chosen vehicle and the regulatory restrictions in place for various routes. Careful consideration is given to the weight distribution within the vehicle to prevent overloading or imbalance. Software and specialized tools can help in visualizing the load and identifying potential issues before loading. For example, I’ve used software that simulates the load and provides warnings if weight or dimensional limits are exceeded. If restrictions are violated, adjustments may involve using a larger vehicle, re-evaluating the route, or optimizing the load arrangement to comply with all regulations. Documentation of weights and dimensions is key for compliance purposes and to facilitate any potential claims.

Q 14. How do you manage different types of cargo with varying handling requirements?

Managing different types of cargo with varying handling requirements necessitates a structured approach. First, I carefully categorize the cargo based on its fragility, hazardous nature, temperature sensitivity, and other special handling needs. Then, I allocate appropriate loading spaces and utilize specialized equipment or packaging as required. For example, fragile items would be placed away from heavier items, and temperature-sensitive products would require refrigerated trucks and monitored conditions. Hazardous materials require specific handling procedures and documentation, including safety data sheets (SDS), ensuring compliance with all relevant regulations. Proper segregation of incompatible goods is also critical to prevent damage or accidents. I always prioritize the safety of personnel involved in the handling and transportation of the goods.

Q 15. Describe your experience with route optimization software.

Route optimization software is crucial for efficient load planning. My experience encompasses using various software solutions, including those with advanced features like dynamic routing, real-time traffic updates, and multi-stop optimization. I’m proficient in inputting parameters such as delivery addresses, weight constraints, time windows, and vehicle specifications to generate optimal routes. For example, in a recent project involving 20 delivery points across a sprawling metropolitan area, utilizing route optimization software reduced our overall travel time by 15%, leading to significant cost savings and improved on-time delivery rates. I’m familiar with both cloud-based and on-premise solutions, and I can adapt my approach based on the specific requirements of the project and the available technology.

I have experience with software like Route4Me, OptimoRoute, and EasyRoute, each offering a slightly different approach to problem-solving. My skillset allows me to quickly learn and implement new route optimization tools as needed.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain your process for documenting and tracking load plans.

My process for documenting and tracking load plans is meticulous and organized, ensuring transparency and accountability throughout the entire delivery process. I typically use a combination of digital and physical tools. Digitally, I leverage a robust Transportation Management System (TMS) which allows me to create, store, and manage load plans electronically. This system provides features for scheduling, assigning loads to drivers, tracking shipments in real-time, and generating reports on key performance indicators (KPIs).

Physically, I maintain a printed copy of the load plan for each shipment, acting as a backup and readily available reference during transit. This printed version includes essential details like route maps, delivery addresses, contact information, and any special handling instructions. The TMS integrates with our GPS tracking system allowing for real-time monitoring of the location of each shipment, while the physical copy serves as a readily available reference, especially in areas with limited network connectivity.

Q 17. How do you communicate load plan details to relevant stakeholders?

Effective communication is critical in load planning. I use multiple channels to ensure all relevant stakeholders receive timely and accurate updates. This includes the use of email for formal communications, such as the initial load plan distribution and final delivery reports. The TMS provides a central dashboard where drivers can access their assigned routes, real-time updates on their schedules, and any changes or delays. I utilize instant messaging platforms (such as Slack or Teams) for quick updates and urgent notifications concerning potential delays or unforeseen circumstances. Regular meetings with the operations team and clients provide opportunities to discuss load plan performance, identify issues, and proactively adjust the strategy where necessary. Transparency is key, and I ensure everyone has access to the information they need to perform their jobs effectively.

Q 18. How do you measure the efficiency and effectiveness of your load plans?

Measuring the efficiency and effectiveness of load plans involves tracking several KPIs. Key metrics include on-time delivery rates, fuel consumption, overall transportation costs, vehicle utilization, and driver productivity. The TMS provides detailed reporting features allowing us to monitor these KPIs regularly. For example, we track the percentage of deliveries completed within the scheduled time window – a high percentage reflects efficient planning. We also analyze fuel consumption data to identify areas for improvement, such as route optimization or driver training. We regularly compare planned versus actual delivery times, identify discrepancies, and use this data to refine our planning process. By continuously analyzing these metrics, we can make data-driven improvements to our load planning strategies, leading to increased efficiency and cost savings.

Q 19. Describe your experience with load consolidation strategies.

Load consolidation strategies are crucial for maximizing efficiency and minimizing transportation costs. My experience includes implementing various strategies depending on the specific circumstances. For instance, I’ve successfully implemented LTL (Less-than-Truckload) consolidation by grouping smaller shipments destined for the same region into single, larger loads. This reduces the number of trucks required and lowers overall transportation costs. I also have experience with milk run strategies, optimizing delivery routes to pick up and deliver multiple shipments along a single route. This requires careful planning and coordination but significantly reduces empty mileage and improves overall efficiency. For example, in one project involving multiple small businesses, implementing a milk run strategy reduced the number of trips by 40%, resulting in significant fuel and labor cost savings.

Q 20. How do you handle issues related to load capacity and utilization?

Load capacity and utilization are constantly monitored to avoid issues. When faced with challenges, I adopt a multi-faceted approach. If a load exceeds the capacity of a single vehicle, I split it into multiple shipments. If a vehicle is underutilized, I explore possibilities to consolidate it with other loads heading in the same general direction. Regularly monitoring and analyzing vehicle utilization rates helps in identifying underutilized vehicles and planning efficient consolidation strategies. This involves using data analysis to identify patterns of underutilization and strategically adjusting routes and load assignments. For example, if a vehicle consistently operates at 60% capacity, we could explore options like consolidating shipments or adjusting delivery schedules to increase its utilization rate.

Q 21. What is your approach to managing risk in load planning?

Risk management in load planning is paramount. My approach involves identifying potential risks, assessing their likelihood and impact, and implementing mitigation strategies. Potential risks include weather conditions, traffic congestion, driver availability, and unforeseen delays. We utilize real-time traffic and weather data to proactively adjust routes and schedules. Maintaining backup drivers and vehicles minimizes the impact of driver unavailability. Contingency plans, such as alternative routes, are developed to address potential traffic congestion or unexpected road closures. Regular communication with drivers keeps us updated on potential issues. A robust communication plan ensures all parties can quickly report and respond to unforeseen circumstances, thus minimizing the impact of potential risks on delivery timelines and overall efficiency.

Q 22. How familiar are you with compliance regulations related to load planning and transportation?

Compliance in load planning and transportation is paramount. It involves adhering to a complex web of regulations ensuring safety, security, and environmental protection. My familiarity extends to regulations like those set by the Department of Transportation (DOT), including weight limits, hazardous materials handling (HAZMAT), and driver hours of service. I’m also well-versed in international regulations, understanding the nuances of shipping across borders and adhering to different countries’ specific requirements. For example, knowing the weight restrictions for bridges in various states and understanding the proper classification and documentation for hazardous materials are crucial. Failure to comply can result in hefty fines, legal issues, and reputational damage. I regularly consult updated regulatory databases and participate in professional development to maintain my knowledge.

Q 23. Describe your experience with different types of load securing techniques.

Load securing is crucial for safety and preventing cargo damage. I’ve extensive experience with various techniques, categorized by the type of cargo and transport method. For instance, I’m proficient in using:

- Strapping: This involves using strong straps, often with ratchets or winches, to secure palletized goods or individual items. The tension needs to be calculated to prevent shifting but not damage the goods.

- Blocking and bracing: This technique uses wood or other materials to create a rigid framework around the load, preventing movement. It’s particularly important for irregular or heavy items.

- Dunnage: Using filler materials, like air bags or foam, to fill gaps and prevent shifting within the load. The selection of the right dunnage depends on the cargo’s fragility and transportation conditions.

- Load binders: These are metal chains or straps secured using a tightening mechanism, ideal for heavy loads and open-top trailers.

My experience includes selecting the appropriate technique based on factors like the cargo’s weight, dimensions, fragility, and the transportation conditions. I always prioritize safety and compliance with relevant regulations in selecting and applying these techniques.

Q 24. How do you incorporate environmental considerations into your load planning?

Environmental considerations are increasingly important in load planning. I incorporate these factors by optimizing routes to reduce fuel consumption and emissions. This includes using route planning software that considers factors like traffic, road conditions, and elevation changes to find the most efficient path. I also prioritize the use of sustainable packaging materials and reduce overall packaging waste whenever possible. For example, choosing reusable containers over single-use options or minimizing the use of plastic wraps. Furthermore, I’m actively aware of and follow regulations related to the transportation of environmentally sensitive goods and ensuring their proper containment to prevent spills and leaks.

Q 25. How do you handle customer requests or changes to an existing load plan?

Handling customer requests and changes requires a flexible yet organized approach. I start by carefully evaluating the impact of the requested change on the existing plan. This includes assessing the potential changes to weight distribution, dimensions, securing methods, and compliance with relevant regulations. If the changes are minor and don’t significantly affect the plan’s feasibility, I’ll make the necessary adjustments promptly and communicate the updates to all stakeholders. If the changes are substantial, I might need to collaborate with the customer to explore alternative solutions, potentially involving re-routing, additional equipment, or slight delays. Transparency and proactive communication are key throughout the process, keeping the customer informed at every step.

Q 26. How do you stay up-to-date on industry best practices in load planning?

Staying current with industry best practices is an ongoing commitment. I achieve this through various methods. I actively participate in professional organizations related to logistics and transportation, attending conferences, webinars, and workshops. This provides opportunities for networking and learning about new technologies and techniques. I regularly read industry publications and journals, keeping abreast of the latest regulations and innovations. I also utilize online resources and training programs to expand my knowledge. Moreover, I actively seek feedback from colleagues and industry experts, fostering a continuous learning environment.

Q 27. Describe a situation where you had to make a critical decision during load planning under pressure.

In one instance, we had a last-minute request to add a significant amount of weight to an already loaded truck bound for a time-sensitive delivery. The added weight exceeded the truck’s initial capacity, and exceeding weight limits was not an option. The pressure was immense, as the delivery was crucial for the customer. After assessing the situation, I quickly identified a solution: We rerouted the shipment using a larger vehicle and rescheduled the delivery. This involved immediate communication with the customer, the driver, and dispatch to coordinate the new arrangements. While it slightly delayed the original delivery time, it ensured compliance with safety regulations and prevented potential accidents or fines. This demonstrates my ability to adapt swiftly and make informed decisions under pressure while maintaining a focus on safety and compliance.

Q 28. How do you use data analysis to improve your load planning process?

Data analysis plays a critical role in improving load planning efficiency and profitability. I leverage data from various sources, including historical shipment data, GPS tracking, and weather forecasts. I analyze this data to identify patterns, predict potential issues, and optimize routes. For instance, analyzing historical data on delivery times helps in creating more realistic delivery schedules, improving customer satisfaction and reducing delays. By analyzing fuel consumption data related to specific routes and vehicle types, I optimize fuel efficiency and reduce environmental impact. Using predictive analytics tools, I anticipate potential disruptions like bad weather or traffic congestion, allowing me to proactively adjust plans and mitigate risks.

Key Topics to Learn for Load Plan Interview

- Load Optimization Strategies: Understanding different algorithms and techniques for optimizing load distribution, minimizing transportation costs, and maximizing vehicle utilization. Explore various constraints and their impact on the planning process.

- Route Planning & Optimization: Practical application of route optimization algorithms (e.g., Dijkstra’s algorithm, A* search) to create efficient delivery routes considering factors like distance, time windows, and traffic conditions. Consider real-world scenarios involving multiple stops and deliveries.

- Capacity Planning & Constraints: Analyze vehicle capacity limitations, weight restrictions, and dimensional constraints. Learn how to effectively manage these constraints within the load planning process to avoid exceeding limits.

- Warehouse Management Integration: Explore how load planning interacts with warehouse operations, including order picking, packing, and staging. Understand the importance of efficient warehouse layout and processes in optimizing load plans.

- Software & Tools: Familiarize yourself with common Load Planning software and tools. Understand their functionalities and how they assist in creating and managing efficient load plans. Be prepared to discuss your experience with relevant software.

- Safety & Compliance Regulations: Understand and discuss relevant safety regulations and compliance requirements related to load securing, weight distribution, and transportation laws.

- Problem-solving & Scenario Analysis: Practice analyzing complex scenarios involving unexpected delays, changes in delivery schedules, or variations in product dimensions. Develop problem-solving skills to adapt load plans effectively.

Next Steps

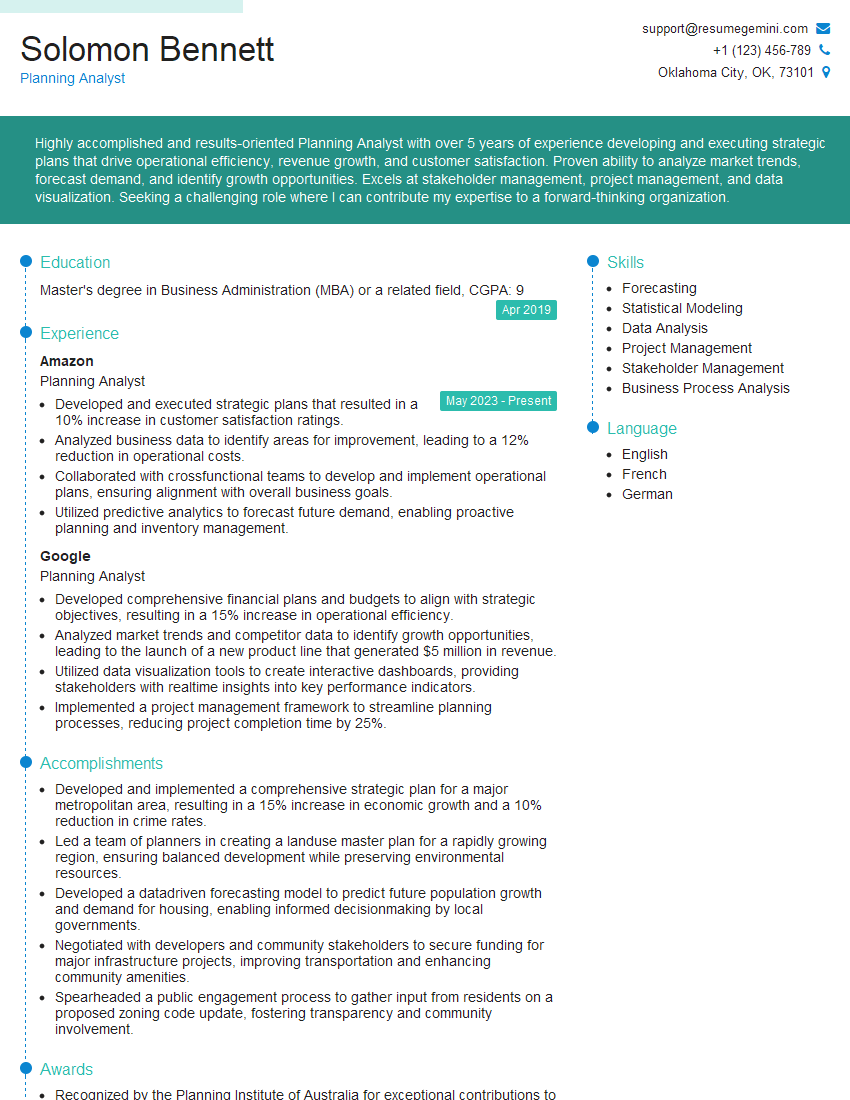

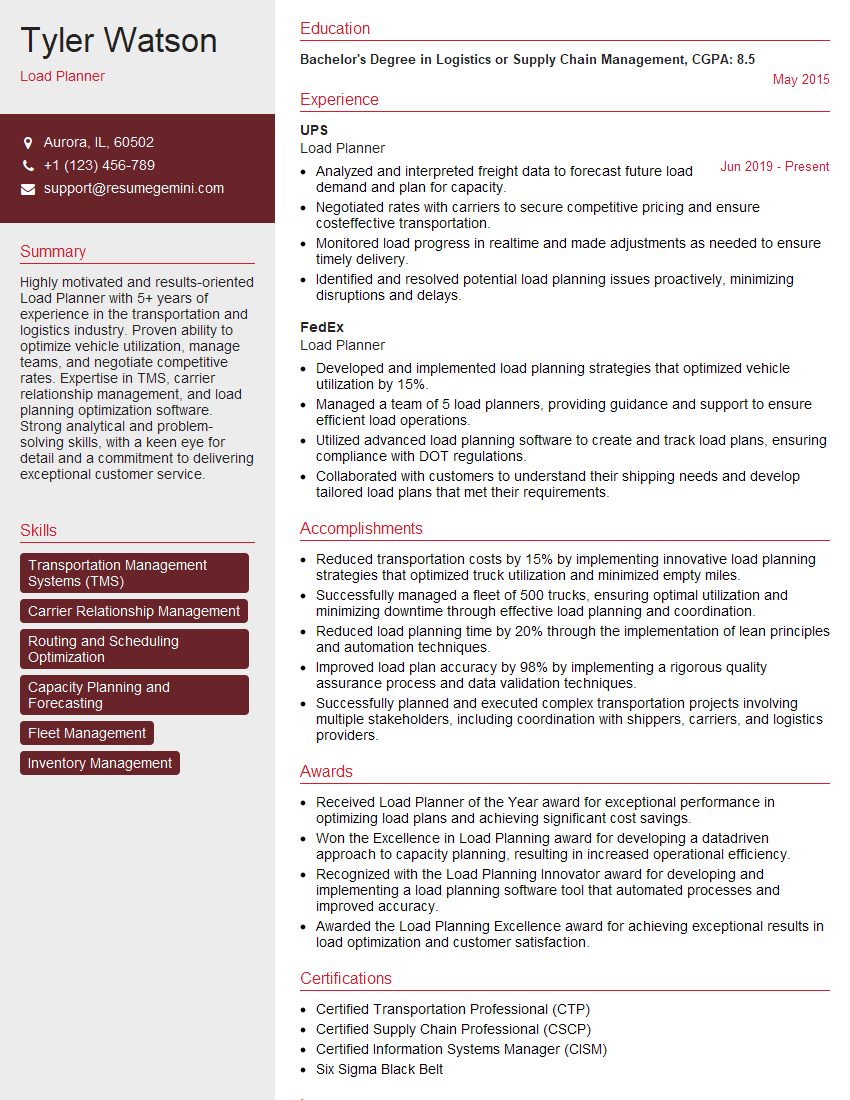

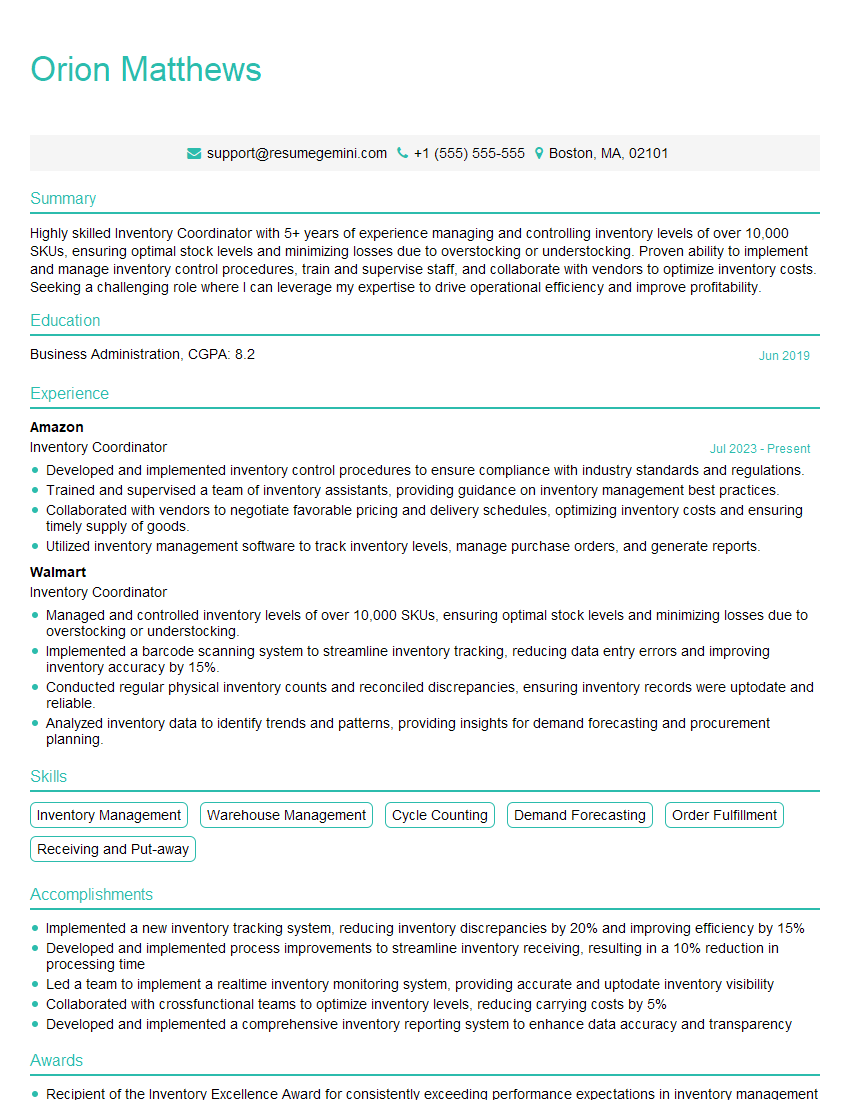

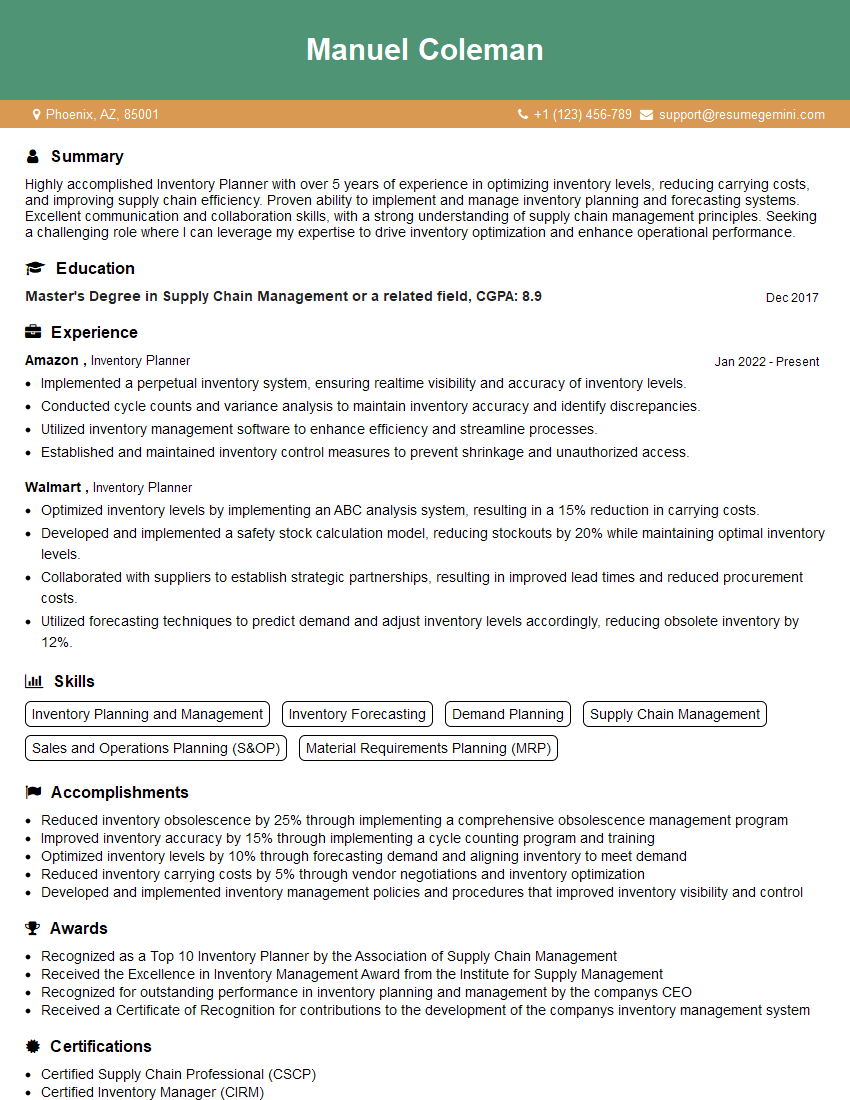

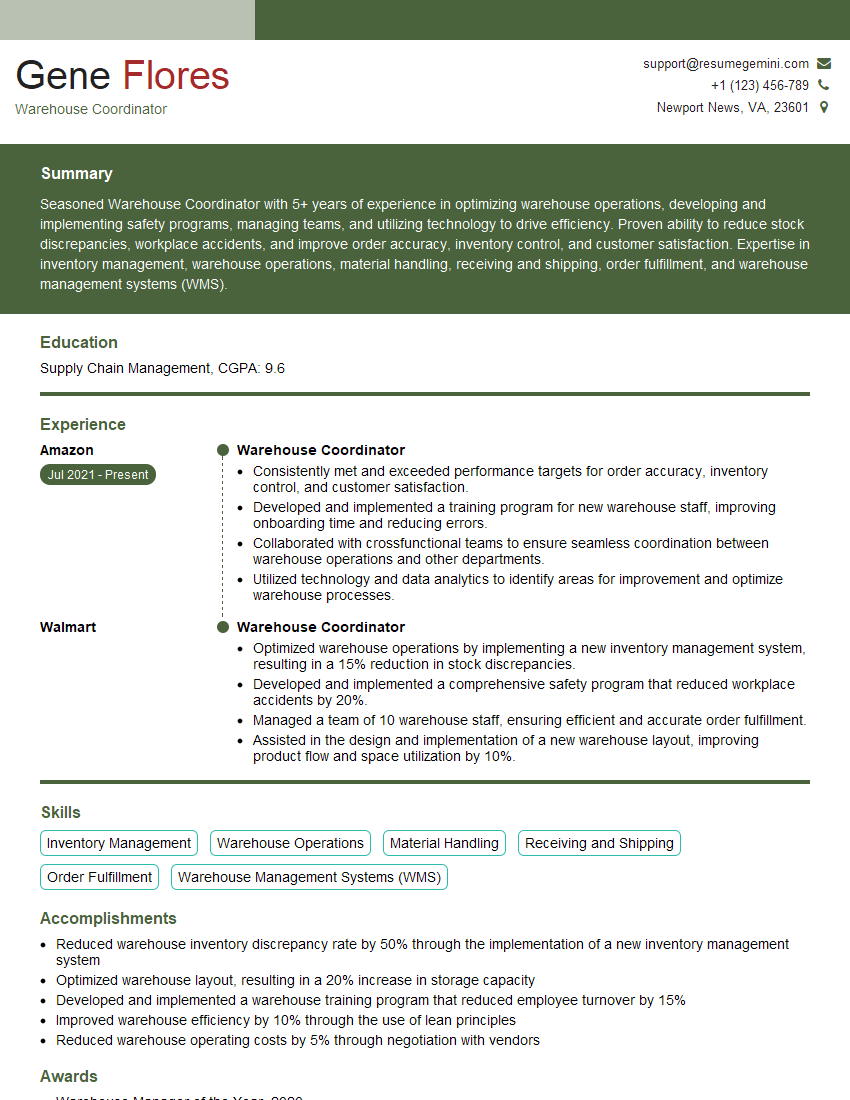

Mastering Load Plan is crucial for career advancement in logistics, supply chain management, and transportation industries. A strong understanding of these concepts significantly enhances your problem-solving abilities and opens doors to exciting opportunities. To increase your job prospects, it’s vital to create an ATS-friendly resume that effectively showcases your skills and experience. We highly recommend using ResumeGemini, a trusted resource for building professional resumes, to craft a compelling document that highlights your expertise in Load Plan. Examples of resumes tailored to Load Plan are provided to help guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Live Rent Free!

https://bit.ly/LiveRentFREE

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?