The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Loop Pile Tufted Carpet Production interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Loop Pile Tufted Carpet Production Interview

Q 1. Explain the difference between loop pile and cut pile tufted carpets.

The key difference between loop pile and cut pile tufted carpets lies in the finishing of the yarn loops. In loop pile carpets, the yarn loops are left uncut, creating a textured, durable surface. Think of it like a tightly woven chain link fence – each loop is visible and contributes to the overall strength. Cut pile carpets, on the other hand, have the yarn loops cut after tufting, resulting in a plusher, softer surface. Imagine a shag carpet – the cut yarn ends create a fuzzy, luxurious feel. This difference directly impacts the carpet’s appearance, texture, durability, and ultimately, its cost and intended use.

Q 2. Describe the tufting process for loop pile carpets.

The tufting process for loop pile carpets involves a specialized machine that inserts yarn loops into a primary backing material. This process is similar to sewing, but on a much larger scale. Imagine a giant sewing machine that moves across a wide backing fabric, injecting yarn loops at a pre-determined spacing and height. The machine uses needles with a loop-forming mechanism; instead of simply passing a yarn through the backing, the needle creates a loop and securely holds it in place. This creates a dense, even surface of yarn loops. The crucial element is that these loops remain uncut after this process, distinguishing it from cut pile tufting.

Q 3. What are the common yarn types used in loop pile carpet manufacturing?

Several yarn types are commonly employed in loop pile carpet manufacturing, each offering unique characteristics. Nylon is a popular choice due to its exceptional durability, stain resistance, and resilience. It’s ideal for high-traffic areas. Polyester provides a softer feel and is often more cost-effective than nylon, making it suitable for residential settings. Olefin (polypropylene) is known for its excellent stain and water resistance, making it a common choice for outdoor carpets or areas prone to spills. Wool, while more expensive, offers superior softness, natural resilience, and excellent insulation, making it a premium option for luxurious carpets. The choice of yarn depends on the desired properties and the intended application of the carpet.

Q 4. Explain the role of the tufting machine in loop pile carpet production.

The tufting machine is the heart of loop pile carpet production. It’s a sophisticated piece of machinery that simultaneously inserts the yarn loops, spaces them evenly, and secures them to the primary backing. Think of it as a high-speed embroidery machine on steroids. The machine uses hundreds of needles that inject the yarn, forming the loops at a rate of several hundred stitches per minute. The key components include the needle bars, yarn feeders, backing feed rollers, and loop-forming mechanisms. The speed, needle gauge, and loop-forming mechanisms are carefully controlled to achieve the desired pile density, height, and pattern. Different machines can create a huge variety of carpet textures and styles.

Q 5. How is pile height controlled in loop pile carpet manufacturing?

Pile height control in loop pile carpet manufacturing is achieved primarily through adjustments to the tufting machine. The height is determined by the length of the yarn inserted during the tufting process and the design of the needle bar. Higher pile heights need longer yarn lengths. A critical adjustment is the needle penetration depth into the backing fabric. The deeper the needle penetrates, the shorter the loop will be, allowing for very precise control. This process uses a combination of machine settings and the yarn properties to create a specific pile height. Variations in pile height can be used to create texture and patterns within the carpet.

Q 6. What are the different types of backing materials used in loop pile carpets?

Various backing materials provide crucial support and stability to tufted loop pile carpets. Primary backings, which are directly contacted by the tufting process, often consist of woven polypropylene or jute fabrics. Secondary backings are laminated to the primary backing to enhance the carpet’s strength and dimensional stability. These secondary backings can be made from various materials including latex, polyurethane foam, or other synthetic materials. The choice of backing material impacts factors like durability, dimensional stability, and cost, directly influencing the carpet’s overall performance.

Q 7. Describe the process of applying backing to tufted carpet.

Applying backing to tufted carpet is a crucial step in the manufacturing process, enhancing its strength, durability, and dimensional stability. The process usually involves a specialized coating or laminating machine. The primary backing (the fabric the loops are tufted into) is often coated with a latex or other adhesive. Then the secondary backing is laminated to this primary backing, creating a composite structure. This process bonds the layers together, creating a stronger, more stable carpet. The choice of adhesive and the application method are critical to ensure a strong, consistent bond, preventing delamination and ensuring long-term carpet performance. Think of it as creating a layered sandwich with the carpet loops as the filling.

Q 8. Explain the function of a heat-setting process in loop pile carpet production.

Heat-setting is a crucial post-tufting process in loop pile carpet production. It involves exposing the newly tufted carpet to high temperatures, typically using specialized ovens. This process permanently sets the fibers’ shape and crimp, enhancing the carpet’s durability, resilience, and appearance. Think of it like setting the ‘perm’ in your hair – it locks in the desired style.

Specifically, heat-setting improves dimensional stability, preventing shrinkage or stretching over time. It also enhances the carpet’s pile twist and texture, leading to a richer, more uniform look and feel. The process also helps to improve the dye’s fastness, ensuring the colors remain vibrant for longer. Different yarns require different heat-setting parameters, and incorrect settings can lead to fiber damage or uneven shrinkage. For example, nylon yarns generally require higher temperatures than polypropylene yarns.

Q 9. What are common quality control checks during loop pile carpet production?

Quality control in loop pile carpet production is multifaceted and begins from yarn inspection to the final product. We employ several checks throughout the process:

- Yarn Quality: We meticulously inspect incoming yarn for fiber defects, inconsistencies in thickness, and color variations. This ensures the final carpet’s uniformity and quality.

- Tufting Process Monitoring: During tufting, we regularly monitor machine settings, yarn feed, and needle penetration to maintain consistent pile height, density, and loop formation. Any deviation is immediately addressed.

- Dye Lot Consistency: We carefully manage dye lots to ensure color consistency across different batches of carpet. This avoids noticeable color variations within the same roll or across different orders.

- Post-Tufting Inspections: After tufting, we perform visual inspections for defects like missing tufts, uneven pile height, and shading. We also measure dimensions to ensure they meet specifications. This often includes using specialized equipment to detect subtle irregularities.

- Physical Testing: We conduct rigorous physical tests including abrasion resistance, pile crush recovery, and tensile strength to verify that the finished carpet meets the required performance standards. This is vital for guaranteeing the longevity of the product.

These checks guarantee a consistent, high-quality final product that meets customer expectations and industry standards.

Q 10. How do you identify and address common defects in loop pile carpets?

Identifying and addressing defects in loop pile carpets requires a keen eye and a systematic approach. Common defects include:

- Missing Tufts: These appear as bare patches and are often caused by needle malfunctions or yarn breaks. We usually repair these manually or through secondary tufting processes.

- Uneven Pile Height: Inconsistent pile height can result from faulty machine settings or incorrect yarn feed. Addressing this might involve adjusting machine parameters or re-tufting sections.

- Shading: Slight variations in color can result from inconsistent dye application or yarn inconsistencies. Careful dye lot control and yarn selection are key to preventing this.

- Extraneous Fibers: These occur when stray fibers are incorporated into the carpet during production. Careful cleaning and improved machine maintenance can reduce this.

Our approach is to first identify the root cause of the defect. Then, we select the most efficient and cost-effective method for correction. This can range from simple repairs for minor issues to complete re-tufting for severe defects. Documentation and analysis of defects help us to improve processes and prevent future occurrences. For example, a recurring issue of missing tufts might point to a need for regular maintenance on a specific part of the machine.

Q 11. What are the key performance indicators (KPIs) for loop pile carpet production?

Key Performance Indicators (KPIs) for loop pile carpet production are crucial for monitoring efficiency and quality. We focus on:

- Production Rate (Meters per hour): This measures the speed of the tufting process, reflecting machine efficiency and operator skill. Tracking this helps to identify bottlenecks and improve overall output.

- Defect Rate (Defects per square meter): This KPI indicates the quality of the production process. A low defect rate signals effective quality control measures.

- Yarn Yield (Meters of yarn per square meter of carpet): This helps us to manage yarn consumption and minimize waste. Optimizing this KPI contributes to cost savings.

- Machine Uptime (%): This measures the percentage of time the tufting machines are operational, highlighting efficiency and potential downtime issues.

- Labor Productivity (Square meters per labor hour): This evaluates the efficiency of the workforce and can guide training and process improvement initiatives.

- Customer Returns (%): This measures the rate of carpet returns due to quality issues or other problems, providing feedback on overall product quality and customer satisfaction.

Regular monitoring of these KPIs allows us to identify areas for improvement and ensure the continuous enhancement of our production process and the quality of our products.

Q 12. Describe your experience with different types of tufting machines.

My experience encompasses a range of tufting machines, from older single-needle models to advanced multi-needle high-speed machines. I’ve worked extensively with both single- and multi-needle machines, each with its unique characteristics. For example, single-needle machines offer precise control but are slower, while multi-needle machines are faster but require more careful setup and maintenance.

I’m familiar with machines from various manufacturers, including [Manufacturer A] and [Manufacturer B], and understand the nuances of their operational procedures and maintenance requirements. This experience has provided me with a broad understanding of different machine capabilities and limitations, allowing me to optimize production for specific carpet designs and qualities.

Furthermore, I’m proficient in utilizing computer-aided design (CAD) systems to program designs into modern computerized tufting machines, offering a significant advantage in flexibility and precision. I can easily adapt to new models and technologies, understanding the principles behind their mechanics and software interfaces.

Q 13. How do you maintain and troubleshoot tufting machine malfunctions?

Maintaining and troubleshooting tufting machine malfunctions is a crucial part of my role. Proactive maintenance is key; this includes regular cleaning, lubrication, and inspection of critical components like needles, grippers, and yarn feeds. This prevents breakdowns and ensures consistent production. I use scheduled maintenance checklists and logs to meticulously track machine performance and identify potential problems before they cause significant downtime.

When malfunctions occur, my approach is systematic and problem-solving oriented. I follow these steps:

- Identify the Problem: Pinpoint the specific malfunction by observing the machine’s behavior and analyzing error codes (if any).

- Isolate the Cause: Determine the underlying cause using troubleshooting manuals, technical drawings, and experience. This might involve checking individual components, testing electrical circuits, or reviewing machine settings.

- Implement Corrective Actions: Once the cause is identified, I implement the appropriate corrective action, which could range from simple repairs like replacing a broken needle to more complex tasks involving adjustments to machine settings or calling in specialized technicians.

- Document and Prevent Recurrence: I meticulously document the malfunction, its cause, and the corrective actions taken. This information is valuable for future troubleshooting and helps to identify patterns that could lead to preventive maintenance protocols. For example, repeated failures of a certain component might suggest a need for improved quality parts or a modification to a production step.

My experience allows me to efficiently diagnose and rectify most common malfunctions, minimizing production downtime and ensuring consistent output.

Q 14. Explain your experience with yarn management and inventory control.

Effective yarn management and inventory control are vital for efficient and cost-effective loop pile carpet production. My experience involves overseeing the entire process, from yarn procurement to its utilization in the tufting process. We use a sophisticated inventory management system that tracks yarn quantities, colors, types, and lot numbers to ensure optimal stock levels and prevent shortages.

We utilize a Just-in-Time (JIT) inventory approach whenever possible to minimize storage costs and reduce the risk of yarn obsolescence. This requires careful forecasting of yarn requirements based on production schedules and customer orders. We also utilize robust quality control checks at the yarn receiving stage to ensure that only high-quality materials are used.

Minimizing yarn waste is crucial. We carefully monitor yarn consumption during the tufting process and analyze any discrepancies to identify areas for improvement, such as fine-tuning machine settings or implementing better training for operators. This combination of strategic planning and meticulous tracking ensures efficient yarn usage and minimal waste.

Q 15. What are the safety protocols you follow in a carpet manufacturing environment?

Safety is paramount in our loop pile tufted carpet manufacturing facility. We adhere to a comprehensive safety program encompassing several key areas. This starts with rigorous training for all employees on safe operating procedures for machinery, proper handling of chemicals (like dyes and cleaning agents), and the use of personal protective equipment (PPE). PPE includes safety glasses, hearing protection, gloves, and steel-toed boots, depending on the specific task. We conduct regular safety audits and inspections to identify and rectify potential hazards, such as ensuring machinery guards are in place and functional, and that emergency exits are clearly marked and unobstructed. We also maintain detailed safety records, tracking incidents, conducting root cause analyses, and implementing corrective actions to prevent recurrence. Furthermore, we emphasize a culture of safety, encouraging employees to report any near misses or unsafe conditions immediately. Think of it like this: a safe workplace is not just a rulebook, it’s a shared responsibility.

- Regular Safety Training: We provide both initial and refresher training on all safety protocols.

- PPE Provision and Enforcement: Employees are provided with and required to use appropriate PPE.

- Emergency Procedures: Clear emergency procedures are in place and regularly practiced.

- Regular Inspections and Audits: Proactive identification and mitigation of safety hazards.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with different types of carpet dyes and finishing techniques.

My experience with carpet dyes is extensive, encompassing both solution-dyed nylon and acid dyes for other fiber types. Solution dyeing, where the color is added to the nylon chips before fiber extrusion, results in exceptional colorfastness and light resistance – perfect for high-traffic areas. Acid dyes, on the other hand, offer a wider range of colors and shades, applied after the yarn is spun. In terms of finishing techniques, I’m proficient in various methods designed to enhance the carpet’s appearance, durability, and stain resistance. These include heat setting to stabilize the tufts, anti-static treatments to reduce static cling, and the application of stain-resistant coatings, often using fluorochemicals or other advanced formulations. We choose finishing techniques based on the desired properties of the final product and the specific fiber used. For instance, a carpet destined for a commercial setting might require a more durable and stain-resistant finish than one intended for a residential bedroom.

- Solution Dyeing: Provides superior colorfastness and light resistance.

- Acid Dyeing: Offers a broader color palette.

- Heat Setting: Improves dimensional stability and tuft retention.

- Anti-Static Treatments: Reduces static electricity build-up.

- Stain-Resistant Coatings: Enhances stain resistance and cleanability.

Q 17. How do you ensure consistent color and quality throughout the production process?

Maintaining consistent color and quality is crucial. We achieve this through a multi-faceted approach. First, we use precise color measurement tools, such as spectrophotometers, throughout the process, from raw materials to finished goods. This allows us to monitor and adjust dye lots to maintain consistency. We also employ strict quality control procedures at each stage of production, including regular inspections of yarn, tufting, and finishing. Any deviations from the established standards are promptly addressed through adjustments to the process or rejection of non-conforming materials. Additionally, we maintain detailed records of each batch, including dye formulations and processing parameters. Think of it like baking a cake – precise measurements and consistent procedures are essential for a consistently delicious outcome. A slight variation in ingredients or baking time could significantly affect the final result. In carpet manufacturing, meticulous tracking and control of every step guarantee a uniform final product.

- Spectrophotometer use: Precise color measurement and control.

- Strict Quality Control: Regular inspections at every production stage.

- Detailed Batch Records: Tracking of all parameters for reproducibility.

Q 18. What is your experience with production scheduling and planning?

My experience with production scheduling and planning involves utilizing various software tools and methodologies to optimize production flow and meet customer deadlines. I’m adept at developing detailed production schedules based on order requirements, machine capacity, and material availability. This often involves using tools like MRP (Material Requirements Planning) software to ensure we have the necessary materials on hand when needed. I work closely with the purchasing department to manage raw material inventory and ensure timely delivery. We regularly review and adjust our schedules based on production performance, addressing potential bottlenecks and prioritizing urgent orders. A key part of my role is proactive identification of potential delays, such as anticipated material shortages or machine downtime, and developing contingency plans to mitigate their impact. Imagine a well-orchestrated symphony: each instrument (machine) plays its part at the right time and with the right intensity to create a harmonious result (finished product on time).

- MRP Software: Optimizing material procurement and inventory management.

- Detailed Production Schedules: Planning for efficient workflow and on-time delivery.

- Contingency Planning: Mitigating the impact of potential delays.

Q 19. How do you manage production costs and optimize efficiency?

Managing production costs and optimizing efficiency is an ongoing challenge. We achieve this through several strategies. We focus on minimizing waste by optimizing material usage, reducing energy consumption, and improving machine utilization. This often involves implementing lean manufacturing principles (discussed further in the next question). We continuously evaluate our processes, seeking opportunities to streamline operations and reduce bottlenecks. We also negotiate favorable contracts with our suppliers to secure competitive pricing on raw materials. We regularly analyze our production costs, identifying areas for potential savings. For example, reducing defects through improved quality control translates directly into cost savings by minimizing waste and rework. Think of it as running a well-oiled machine – every part contributes to efficiency, and reducing friction in the process saves both time and money.

- Waste Reduction: Optimizing material usage and energy consumption.

- Process Streamlining: Identifying and eliminating bottlenecks.

- Supplier Negotiation: Securing favorable pricing on raw materials.

- Cost Analysis: Regular review of production costs to identify savings opportunities.

Q 20. Describe your experience with lean manufacturing principles in carpet production.

Lean manufacturing principles are integral to our operation. We’ve implemented several key lean practices, including 5S (Sort, Set in Order, Shine, Standardize, Sustain) to organize our workspace and improve efficiency. We utilize Kanban systems to manage the flow of materials and reduce inventory. We also employ Kaizen events – continuous improvement initiatives – to identify and eliminate waste in our processes. This often involves engaging our workforce in identifying areas for improvement. For example, by streamlining a particular step in the production process, we might reduce processing time by several minutes, which, multiplied across thousands of carpets produced daily, translates into substantial savings. The ultimate goal is to create a continuous flow of production with minimal waste and maximum efficiency. Think of it like a river – the goal is to create a smooth, unobstructed flow to reach the final destination (finished product) as efficiently as possible.

- 5S Methodology: Organizing the workspace for improved efficiency.

- Kanban System: Managing material flow and inventory.

- Kaizen Events: Continuous improvement initiatives.

Q 21. How do you handle production delays or unexpected issues?

Handling production delays or unexpected issues requires a proactive and systematic approach. When a delay occurs, our first step is to identify the root cause. This might involve reviewing production logs, examining the machinery, or interviewing employees. Once the cause is identified, we develop a mitigation plan. This could involve adjusting the production schedule, re-allocating resources, or sourcing alternative materials. We also communicate transparently with our customers, keeping them informed of the situation and providing realistic timelines for delivery. We utilize various project management tools to track progress and ensure the timely resolution of issues. A critical aspect of our response is conducting a post-incident review to understand what went wrong, what we learned, and how we can prevent similar issues in the future. It’s important to treat each delay as a learning opportunity. Just as a doctor diagnoses a patient’s ailment before prescribing treatment, we methodically diagnose the problem before implementing a solution.

- Root Cause Analysis: Identifying the underlying cause of the delay.

- Mitigation Plan Development: Developing strategies to address the issue.

- Transparent Communication: Keeping customers informed of the situation.

- Post-Incident Review: Learning from mistakes and preventing future occurrences.

Q 22. What is your experience with different types of carpet adhesives?

My experience with carpet adhesives spans various types, each suited for different applications and substrates. The most common are latex adhesives, known for their flexibility and good adhesion. These are often preferred for their relatively low VOCs (Volatile Organic Compounds). We also use hot-melt adhesives, which offer faster setting times and are suitable for high-speed tufting lines, but require precise temperature control. Finally, I’ve worked with pressure-sensitive adhesives (PSAs), typically used in backing applications or for specialized niche products. Choosing the right adhesive depends on factors like the backing material (jute, polypropylene, etc.), the carpet fiber type, and the desired final properties of the carpet, such as its durability and resilience. For example, a heavier-duty carpet for commercial use might require a stronger, more durable adhesive like a high-solids latex, whereas a residential carpet could utilize a more standard latex formulation. The selection process always involves careful consideration of factors like cost-effectiveness, environmental impact, and performance requirements.

Q 23. Explain the importance of proper tension control during the tufting process.

Proper tension control is absolutely critical in loop pile tufting. Think of it like weaving a tightly woven fabric; inconsistent tension leads to a poorly constructed, uneven product. Maintaining consistent yarn tension ensures uniform loop height and density across the entire carpet width. Too much tension can cause yarn breakage and damage the tufting needles, leading to downtime and defects. Too little tension results in loose, uneven loops, affecting the carpet’s appearance, durability, and overall quality. We constantly monitor tension using various instruments, making adjustments to ensure consistent yarn feed and proper loop formation throughout the production run. This often involves fine-tuning the settings on the tufting machine based on the specific yarn type and carpet design. Regular maintenance checks on the tensioning devices are key to preventing production issues and maintaining consistent quality.

Q 24. How do you calculate the production output for loop pile carpets?

Calculating production output for loop pile carpets involves several factors. The most basic calculation is based on the machine’s production speed (typically measured in square meters per hour or yards per hour) multiplied by the operating hours. However, this needs to be adjusted for factors like machine downtime, yarn changes, and quality control checks. A more precise calculation would consider the effective production time – that is, the actual time the machine is producing usable carpet. This might involve tracking downtime due to maintenance, cleaning, and repairs. The formula might look like this: Production Output = (Machine Speed x Effective Operating Hours) x Efficiency Factor where the efficiency factor accounts for unavoidable slowdowns or downtime. We also account for the width of the carpet being produced, as production speed is often expressed per unit width. Accurate record-keeping is crucial for precisely calculating production output and for identifying potential bottlenecks in the process.

Q 25. What are your experience with different types of carpet patterns and designs?

My experience encompasses a wide range of carpet patterns and designs, from simple solid colors to intricate, complex patterns. I’m proficient in working with various design techniques, including those using different types of yarn, textures, and colors to create visual effects. This includes understanding how pattern repeat lengths affect the overall design and production efficiency. I’ve worked extensively with cut-and-loop designs, creating textures and patterns using a combination of cut and uncut loops. I’m also familiar with creating patterns using different yarn weights and blends to enhance the aesthetic appeal and durability of the finished carpet. Recent projects involved recreating intricate Persian-inspired designs and developing modern geometric patterns for commercial spaces, requiring careful planning and execution to ensure accuracy and consistent quality. Understanding the limitations and capabilities of the tufting machine regarding complex patterns is equally vital.

Q 26. How do you ensure the final product meets customer specifications?

Ensuring the final product meets customer specifications is a multi-stage process, beginning with meticulous order review and pre-production sampling. We carefully review the customer’s specifications, which may include details regarding yarn type, color, weight, pattern, and quality standards. We create samples to confirm the accuracy of the design and color reproduction, allowing for any necessary adjustments before mass production. Throughout the production process, we conduct regular quality control checks, inspecting the carpet for defects such as inconsistent loop height, yarn slippage, or color variations. We use sophisticated quality control tools like automated inspection systems to detect subtle variations that might escape the naked eye. Before shipping, a final inspection verifies that the carpet meets all specifications and quality standards. This stringent quality control process ensures customer satisfaction and maintains our reputation for high-quality loop pile tufted carpets.

Q 27. Describe your problem-solving skills related to carpet production challenges.

Problem-solving is an integral part of this role. I approach challenges using a systematic approach. For example, if we experience a consistent yarn breakage issue, I wouldn’t just replace the yarn; I’d investigate the cause. This might involve examining the tension settings, checking the condition of the tufting needles, analyzing the yarn itself for flaws, or even reviewing the environmental conditions in the production area, such as humidity and temperature. If a production line experiences a significant slowdown, I’d examine various aspects, from machine settings and maintenance schedules to operator performance and potential supply chain disruptions. I use data analysis to identify recurring problems and implement preventative measures. I believe in fostering a collaborative problem-solving environment, where team members can contribute their expertise and we can leverage collective intelligence to resolve issues efficiently and effectively.

Q 28. What are your career goals within the loop pile tufted carpet industry?

My career goals are focused on continued growth and leadership within the loop pile tufted carpet industry. I aim to expand my expertise in advanced tufting technologies and explore innovative design solutions. I’m particularly interested in sustainable production methods, incorporating eco-friendly materials and processes. I envision myself taking on a managerial role, where I can mentor and lead teams, optimizing production processes, and contributing to the company’s overall success. Ultimately, I want to play a significant role in shaping the future of loop pile carpet manufacturing, driving innovation, and ensuring the production of high-quality, sustainable products.

Key Topics to Learn for Loop Pile Tufted Carpet Production Interview

- Tufted Carpet Construction: Understand the fundamental principles of loop pile tufting, including yarn types, backing materials, and the tufting process itself. Consider the differences between different loop pile heights and densities.

- Machine Operation & Maintenance: Familiarize yourself with the machinery involved in loop pile tufting, from the tufting machine itself to secondary processes like latex application and finishing. Be prepared to discuss preventative maintenance and troubleshooting common issues.

- Yarn Handling & Quality Control: Learn about the importance of proper yarn handling to prevent defects and maintain consistent quality throughout the production process. Understand quality control measures used to identify and address imperfections.

- Dyeing and Finishing Techniques: Gain knowledge of different dyeing processes and their impact on the final product’s appearance and durability. Understand post-tufting finishing techniques like shearing, heat setting, and backing treatments.

- Production Efficiency and Optimization: Explore strategies for improving production efficiency, reducing waste, and optimizing the use of resources. This could include understanding lean manufacturing principles or Six Sigma methodologies.

- Safety Regulations and Procedures: Be familiar with relevant safety regulations and procedures within a carpet manufacturing environment. This demonstrates your commitment to workplace safety.

- Waste Management and Sustainability: Understand current industry trends toward sustainable manufacturing practices and how loop pile production can minimize environmental impact.

Next Steps

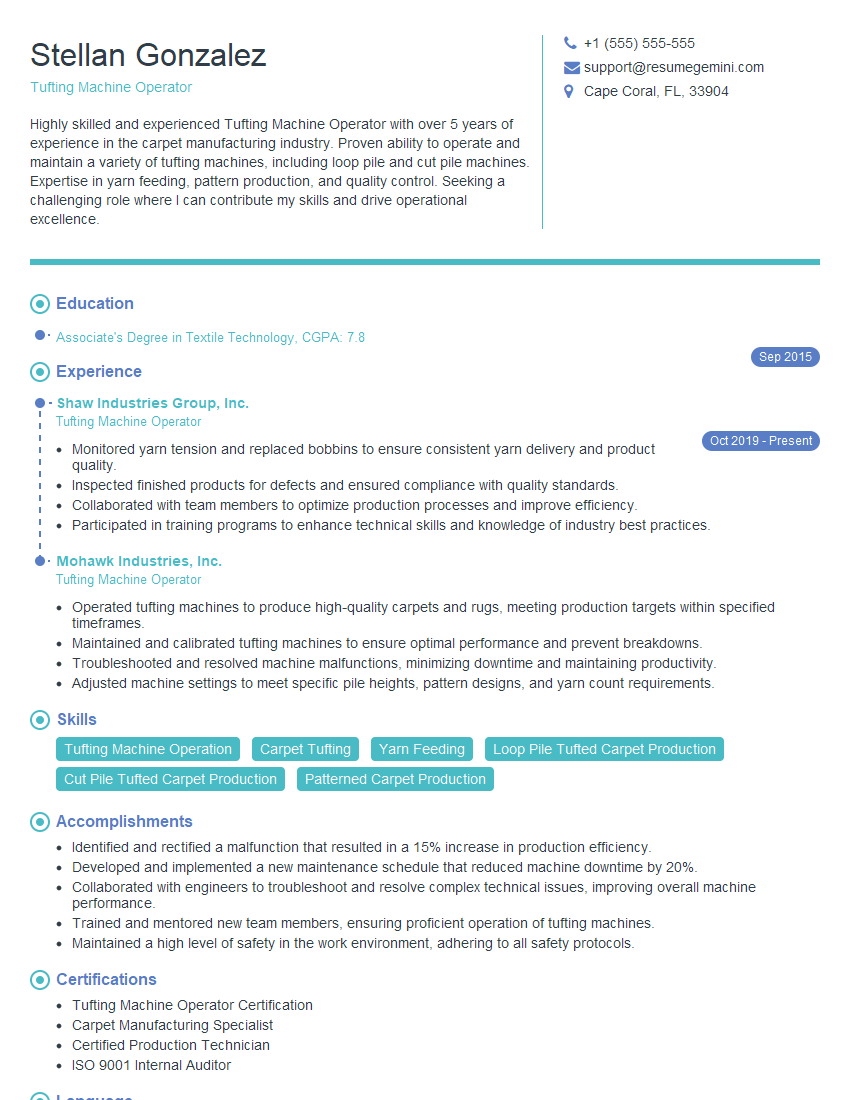

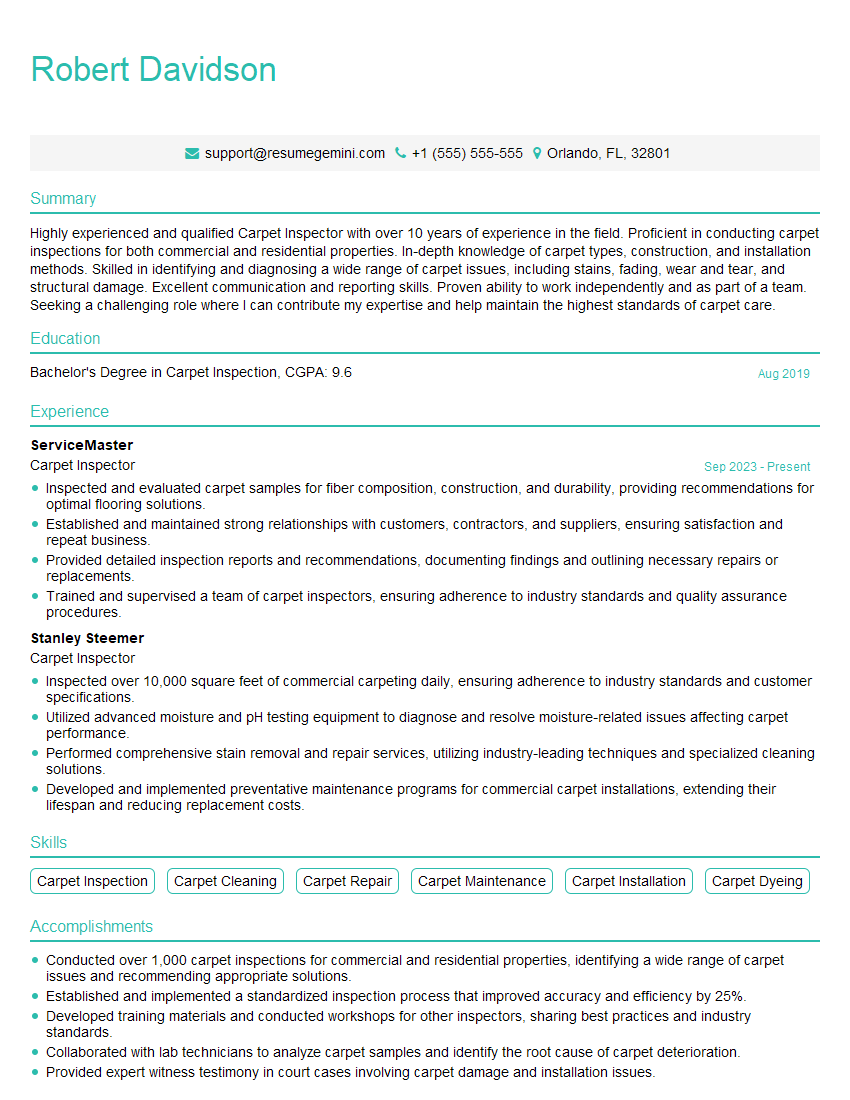

Mastering Loop Pile Tufted Carpet Production opens doors to rewarding and specialized roles within the textile industry. To stand out from the competition, a well-crafted, ATS-friendly resume is essential. ResumeGemini is a trusted resource to help you build a professional and impactful resume that highlights your skills and experience effectively. We provide examples of resumes tailored to Loop Pile Tufted Carpet Production to guide you. Take the next step towards your dream career by creating a resume that showcases your expertise and secures you that interview.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?