Preparation is the key to success in any interview. In this post, we’ll explore crucial Luxury Vinyl Plank (LVP) Flooring Installation interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Luxury Vinyl Plank (LVP) Flooring Installation Interview

Q 1. What are the different types of LVP underlayments and when would you use each?

LVP underlayments are crucial for a successful installation, providing cushioning, moisture protection, and sound insulation. The type you choose depends on your specific needs and subfloor conditions.

- Foam Underlayment: This is the most common type, offering excellent cushioning for comfort and sound dampening. It’s relatively inexpensive and easy to install. I typically recommend this for applications where the subfloor is relatively level and dry. Think of it as adding a comfy mattress under your new floor.

- Cork Underlayment: A more premium option, cork provides superior sound insulation and moisture resistance. It’s a great choice for basements or areas with concrete subfloors prone to dampness. The added benefit is that cork is naturally a good insulator, which can help maintain a consistent temperature in the room. However, it’s more expensive than foam.

- Rubber Underlayment: Offers superior impact absorption and sound reduction, making it ideal for apartments or homes where noise is a concern. It also provides a good barrier against moisture, although often less than cork. It’s a bit pricier than foam but provides superior performance in noise-sensitive environments.

- LVL (Laminated Veneer Lumber) Underlayment: Used primarily to level significantly uneven subfloors. This isn’t a typical underlayment in the same sense as the above, it is more of a subfloor leveling solution to ensure an even surface before LVP installation. It’s critical to address unevenness correctly, as neglecting to do so will lead to premature flooring failure.

Choosing the right underlayment is vital. In one recent project, a client opted for cork underlayment in their basement, significantly reducing noise transmission from the floor below and creating a warmer feeling underfoot. In contrast, for a bustling family home, we used a thicker foam underlayment to maximize comfort and sound dampening without impacting the budget too much.

Q 2. Explain the process of acclimating LVP before installation.

Acclimation is crucial to prevent problems like buckling or gapping after installation. Think of it as allowing the LVP to adjust to the temperature and humidity of the room. The process typically involves storing the unopened boxes of LVP in the room where they will be installed for at least 48 hours, and preferably 72 hours. The ideal temperature should be between 65°F and 75°F, and the relative humidity should be between 30% and 65%. This allows the planks to expand or contract to match their environment before they’re laid, preventing future issues. Failing to acclimate leads to dimensional changes after installation, causing gaps or buckling. In one instance, a client rushed the installation, and a few planks started to buckle within weeks. Had we properly acclimated the flooring, the project would have been much smoother, and the client would have avoided extra cost and stress.

Q 3. Describe the proper methods for cutting LVP around obstacles like pipes and doorways.

Cutting LVP around obstacles requires precision and the right tools. For pipes, I generally use a jigsaw with a fine-tooth blade for the cleanest cut. Marking the exact outline is crucial to avoid errors. After cutting, ensure a tight fit, using a utility knife to trim slightly if needed. For doorways, a sharp utility knife is often sufficient, scoring the plank multiple times before snapping it along the score line. For more intricate cuts, a jigsaw is still the best option. Always wear safety glasses and take your time. Rushing this process is a guaranteed path to mistakes. I remember one project where a client had a particularly ornate baseboard. Taking the extra time to carefully measure and make precise cuts resulted in an installation so flawless that the client was overjoyed.

Q 4. How do you ensure proper expansion gaps when installing LVP?

Maintaining proper expansion gaps is essential for preventing buckling and gapping. These gaps allow the LVP to expand and contract with changes in temperature and humidity without stressing the planks. Generally, a gap of 1/4 inch to 3/8 inch should be left around the perimeter of the room, as well as around fixed objects such as columns and fireplaces. I use spacers to maintain a consistent gap throughout the installation. Leaving adequate expansion space is akin to giving the flooring “breathing room,” accommodating natural changes. Neglecting this step leads to irreversible damage, and the expansion of the flooring can often cause baseboards or door frames to be damaged in the process.

Q 5. What are the common causes of LVP buckling or gapping?

Buckling and gapping are common issues with LVP, often stemming from several factors.

- Improper Acclimation: Failure to allow sufficient time for the planks to adjust to the room’s environment is a primary culprit.

- Uneven Subfloor: A bumpy or uneven subfloor will cause stress on the planks, leading to buckling.

- Insufficient Expansion Gaps: Not leaving enough space for expansion and contraction due to temperature and humidity changes.

- Moisture Issues: Excessive moisture in the subfloor can cause the LVP to swell and buckle. This is especially true for basements or areas without proper moisture barriers.

- Incorrect Installation: Not following the manufacturer’s instructions regarding locking mechanisms, underlayment selection, or proper adhesive use (if applicable).

Diagnosing the root cause is crucial for effective problem-solving. Recently, I encountered a buckling issue that was traced to a section of the subfloor that had been improperly leveled before the installation. After addressing the subfloor issue, the new LVP installation was successful.

Q 6. Explain your experience with different LVP locking systems.

I’ve worked extensively with various LVP locking systems, including click-lock and drop-lock systems. Click-lock systems generally involve angling the planks and clicking them together. They are often easier for DIYers but can be less forgiving if the planks aren’t aligned perfectly. Drop-lock systems involve dropping the end of one plank into the groove of another. They often result in tighter joints and are less prone to separation. Each system has its nuances, but proper technique and attention to detail are key regardless of the specific system. Experience with different systems helps in selecting the right tools and techniques to avoid common pitfalls. I always carefully review the manufacturer’s instructions for each specific product to ensure a successful and lasting installation.

Q 7. How do you handle uneven subfloors before installing LVP?

Uneven subfloors are a significant challenge in LVP installation. Ignoring this will inevitably result in problems down the line. Addressing this requires a multi-step approach:

- Assessment: Thoroughly assess the unevenness using a straight edge and level. This helps determine the extent of the problem and the appropriate solution.

- Leveling Compound: For minor imperfections, a self-leveling compound can be used to create a smooth, even surface. This is a relatively quick and cost-effective solution for minor imperfections.

- Plywood Underlayment: For more significant unevenness, installing a layer of plywood underlayment can create a level base. Ensure the plywood is properly secured and leveled.

- LVL (Laminated Veneer Lumber): For severely uneven subfloors, LVL is a much more robust solution offering significant leveling capabilities. This is often used in conjunction with plywood for optimal results.

The choice of method depends on the severity of the unevenness and the project’s budget and timeframe. I recently worked on a project with a significantly uneven concrete slab. Using LVL and plywood created a perfectly level surface, ensuring a flawless LVP installation. This upfront effort prevented future issues and guaranteed client satisfaction.

Q 8. What tools and equipment are essential for efficient LVP installation?

Efficient LVP installation requires a range of tools, from basic measuring and cutting instruments to specialized equipment for ensuring a seamless finish. Think of it like assembling a fine piece of furniture – you need the right tools for a quality outcome.

- Measuring Tools: Tape measure, speed square, measuring wheel.

- Cutting Tools: Utility knife with sharp blades, circular saw (with fine-tooth blade specifically for LVP), miter saw (for precise cuts, especially for transitions).

- Installation Tools: Spacer wedges (to maintain consistent expansion gaps), tapping block (to prevent damage to planks), pull bar (for aligning planks), knee kicker (for aligning planks in tight spaces).

- Other Essentials: Safety glasses, work gloves, trowel (for adhesive application if not using click-lock system), underlayment (depending on subfloor condition), damp mop (for cleaning).

Having these tools readily available saves time and prevents frustrations during the installation process. For example, using a tapping block instead of a hammer prevents chipping the planks, ensuring a professional finish.

Q 9. Describe your experience with installing LVP in various room sizes and layouts.

My experience spans a wide variety of projects, from small bathrooms to large open-concept living areas. Each space presents unique challenges, requiring adaptability and precise planning. For instance, installing LVP in a small bathroom with intricate plumbing fixtures requires meticulous measuring and cutting, while a large living room necessitates careful planning to manage expansion and contraction of the flooring.

I’ve worked with various layouts including hallways with awkward angles, rooms with multiple doorways and thresholds, and even spaces with curved walls. Each time, I carefully assess the space, plan the layout to minimize waste and maximize the visual appeal, and then execute the installation with precision. I view each project as a puzzle to solve, leveraging my experience to find the optimal solution.

Q 10. How do you maintain consistent spacing and alignment during LVP installation?

Maintaining consistent spacing and alignment is crucial for a professional-looking LVP floor. It’s like building with Lego bricks – each piece needs to fit perfectly. I utilize several key techniques:

- Spacer Wedges: These are essential for maintaining the required expansion gap around the perimeter of the room and between the planks themselves. This prevents buckling and warping due to temperature and humidity fluctuations.

- Careful Planning: I meticulously plan the layout before starting installation, ensuring that cuts are minimized and the pattern flows naturally across the room.

- Regular Checks: I frequently check alignment using a straight edge and speed square, adjusting planks as needed throughout the installation process.

- Tapping Block and Pull Bar: These tools help to gently tap planks into place and pull them into alignment without damaging the material.

By combining these methods, I ensure a uniform, professional-looking installation that meets the highest standards.

Q 11. What safety precautions do you take during LVP installation?

Safety is paramount. LVP installation, while not inherently dangerous, involves sharp tools and potentially awkward positions. My safety precautions include:

- Personal Protective Equipment (PPE): Always wearing safety glasses to protect my eyes from flying debris, and work gloves to protect my hands from cuts and splinters.

- Proper Tool Usage: Using tools correctly and carefully, following manufacturer’s instructions for all power tools.

- Work Area Safety: Maintaining a clean and organized work area to minimize tripping hazards.

- Lifting Techniques: Employing proper lifting techniques to avoid back injuries when handling boxes of LVP planks.

- Ventilation: Ensuring adequate ventilation, particularly when using adhesives, to avoid inhaling harmful fumes.

By prioritizing safety, I ensure both my own well-being and the safety of those around me. Safety isn’t optional; it’s a core value in my work.

Q 12. How do you handle transitions between different flooring types?

Transitioning between different flooring types requires careful planning and precise execution. Think of it as seamlessly blending different materials in a mosaic. The key is to choose the right transition strip and to make clean, precise cuts.

I typically use transition strips designed for LVP and the adjacent flooring type (e.g., carpet, tile). These strips are available in various styles to match the overall aesthetic. The process involves carefully measuring, cutting the LVP and transition strip, and securing them using appropriate adhesive or fasteners. This ensures a smooth, visually appealing, and functional transition between the flooring materials.

Q 13. Explain your process for cleaning up after an LVP installation.

Cleaning up after an LVP installation is crucial for maintaining a safe and tidy work environment. My cleanup process involves these key steps:

- Waste Removal: Disposing of all waste materials, such as cardboard packaging, excess LVP planks, and any damaged pieces, in a responsible manner.

- Debris Removal: Thoroughly sweeping or vacuuming the floor to remove any sawdust, debris, or adhesive residue.

- Final Cleaning: Damp mopping the floor with a clean mop and water (avoiding excessive water) to remove any lingering dust or particles.

- Tools & Equipment Cleanup: Cleaning and storing all tools and equipment properly. Sharp blades are cleaned and stored safely.

A clean and organized site signifies professionalism and respect for the client’s property. A meticulous cleanup ensures a perfect finish to the project.

Q 14. What are the common problems encountered during LVP installation, and how do you address them?

Common problems during LVP installation include uneven subfloors, incorrect expansion gap measurements, improper cutting, and adhesive issues (if applicable). Addressing these requires a systematic approach.

- Uneven Subfloors: A self-leveling compound can address minor imperfections. For significant unevenness, subfloor repair may be needed before installation begins.

- Incorrect Expansion Gaps: Consistent use of spacers is key. Incorrect gaps can lead to buckling. If this occurs, planks need to be removed and reinstalled correctly.

- Improper Cutting: Using the right tools and techniques is crucial. Poor cuts are usually noticeable and often need to be redone.

- Adhesive Issues: If using adhesive, ensure it’s the correct type for LVP and the subfloor. Follow manufacturer’s instructions precisely.

Proactive planning and attention to detail during the installation process significantly minimizes these issues. Thorough inspection before starting work helps prevent many problems down the line.

Q 15. Describe your experience working with different brands of LVP.

My experience with LVP brands is extensive, encompassing both well-known brands like Shaw, Coretec, and Luxury Plank, and lesser-known but equally high-quality options. I’ve worked with various product lines within each brand, including those with different wear layers, core types (WPC, SPC, etc.), and click-lock or glue-down installation methods. This broad experience allows me to select the optimal LVP for a project based on budget, desired aesthetic, and client needs. For example, I might recommend a thicker, WPC-core LVP for high-traffic areas, while a thinner, SPC option would be suitable for areas with less foot traffic. Understanding the specific characteristics of each brand’s product line is key to a successful installation and client satisfaction.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is your experience with moisture mitigation in LVP installations?

Moisture mitigation is paramount in LVP installations, as excessive moisture can lead to buckling, warping, and premature failure. My experience includes employing various techniques to prevent moisture-related issues. This starts with a thorough assessment of the subfloor’s moisture content using a moisture meter. If high moisture levels are detected, I implement corrective measures such as addressing leaks, improving ventilation, or utilizing moisture barriers like a polyethylene sheet or a specialized underlayment designed for moisture control. The correct underlayment also plays a crucial role – some offer built-in moisture protection. Finally, proper acclimation of the LVP in the installation environment prior to installation is crucial. I always follow the manufacturer’s recommendations on this, as acclimation times can vary.

Q 17. How do you ensure the proper moisture content of the subfloor?

Ensuring proper subfloor moisture content is critical. I use a calibrated moisture meter to measure the moisture content of the subfloor in multiple locations. The acceptable moisture levels vary depending on the LVP manufacturer and the type of subfloor (concrete, plywood, etc.). I always consult the manufacturer’s installation instructions, as exceeding the maximum moisture content can void the warranty. If the moisture content is too high, I’ll recommend solutions such as allowing the subfloor to dry naturally, using a dehumidifier, or in extreme cases, subfloor replacement. Documenting all moisture readings and remediation efforts is essential for maintaining a record of the installation process and to protect against potential future warranty issues. Think of it like baking a cake; you need the right ingredients and environment for a perfect result. With LVP, that ‘ingredient’ is a properly dried subfloor.

Q 18. What methods do you use to ensure a smooth and seamless transition between planks?

Achieving smooth, seamless transitions between LVP planks requires precision and attention to detail. I utilize a variety of techniques, depending on the situation. Proper planning and accurate cuts are fundamental. For straight cuts, I use a sharp utility knife or a power miter saw. For more complex cuts, I might use a jigsaw. Additionally, using spacers to maintain consistent expansion gaps between the planks and the walls is important. In situations requiring transitions between different floor heights or materials, I’ll use transition strips or reducers which provide a smooth, aesthetically pleasing transition, concealing any height discrepancies. Finally, using a tapping block to gently seat planks together prevents damage while ensuring a tight fit is crucial. Careful planning and skillful execution create a beautiful, even surface.

Q 19. How do you handle damaged or defective LVP planks?

Handling damaged or defective LVP planks requires a proactive approach. I always conduct a thorough inspection of the LVP before starting the installation. Any damaged planks are immediately set aside. If minor damage occurs during installation, I’ll attempt to repair it using appropriate repair methods, if possible. For extensive damage, I’ll contact the supplier for replacements. It is important to note that the number of replacement planks needed should be accounted for during the initial material estimation, to account for unexpected issues. Keeping a detailed record of damaged or defective planks, including photos, is crucial for any potential warranty claims. I always follow the manufacturer’s guidelines regarding the handling of damaged goods.

Q 20. Describe your experience using a variety of cutting tools for LVP.

My experience with LVP cutting tools is comprehensive. I regularly utilize a variety of tools, including utility knives for straight cuts, especially in tight spaces. For more precise and faster cutting of multiple planks, a miter saw is invaluable. A jigsaw is indispensable for intricate cuts around obstacles such as pipes or doorways. The choice of tool depends on the specific cut required. I always ensure my tools are sharp to prevent chipping or damaging the LVP. Regular maintenance of these tools is essential for maintaining clean, precise cuts. A sharp blade is the key to a clean, professional looking installation.

Q 21. How do you measure and estimate the amount of LVP needed for a project?

Accurate measurement and estimation are crucial to avoid material shortages or excessive waste. I begin by carefully measuring the area to be covered, accounting for any obstructions or irregular shapes. I then add a percentage for waste (typically 5-10%, depending on the complexity of the project). This percentage accounts for cuts, mistakes, and potential damaged planks. I will consult the manufacturer’s packaging to determine the square footage per box of LVP, and then divide the total square footage needed by the square footage per box to determine the required number of boxes. Software tools are sometimes utilized to create a visual representation of the plan and to better estimate needs. Accurate measurement is the foundation of a successful and cost-effective project.

Q 22. What is your experience with LVP installation in high-traffic areas?

High-traffic areas demand extra attention during LVP installation. I’ve completed numerous projects in commercial settings like offices and retail spaces, as well as high-use residential areas like kitchens and hallways. My approach focuses on selecting appropriate, heavy-duty LVP planks with higher wear layers for superior durability. Proper subfloor preparation is paramount – ensuring a perfectly level and stable base is critical to prevent premature wear and tear in these high-stress zones. I also pay meticulous attention to proper adhesive selection and application, ensuring a strong bond that can withstand significant foot traffic. For instance, in a recent project at a busy restaurant, I opted for a commercial-grade LVP with a 20-mil wear layer and utilized a high-performance adhesive specifically designed for heavy-traffic areas. The result was a floor that maintained its integrity and aesthetic appeal even after months of intense use.

Q 23. Explain your understanding of industry standards and codes related to flooring installation.

My understanding of industry standards and codes is comprehensive. I’m familiar with ANSI (American National Standards Institute) and ASTM (American Society for Testing and Materials) standards for flooring installation, ensuring adherence to best practices for moisture mitigation, subfloor preparation, and adhesive selection. I always check local building codes before commencing any project, ensuring compliance with specific regulations for flooring materials and installation methods. This includes understanding requirements for proper acclimation of the LVP planks to the environment before installation, and adhering to manufacturers’ specifications regarding expansion gaps. For instance, I consistently use a moisture meter to assess subfloor moisture content before any installation starts, preventing costly problems down the line. I meticulously document every step of the process, ensuring a paper trail that verifies compliance with all relevant standards.

Q 24. How do you manage your time effectively during an LVP installation project?

Efficient time management is crucial in LVP installation. I begin with a detailed project plan, meticulously measuring the area, calculating material needs, and scheduling the work in logical phases. This includes factoring in time for subfloor preparation, acclimation of the LVP, and potential unexpected issues. I prioritize tasks based on their importance and dependencies, focusing on critical path activities first. Furthermore, I maintain a clean and organized workspace, ensuring efficient movement and minimizing wasted time searching for tools or materials. My experience allows me to anticipate potential problems and proactively address them, avoiding costly delays. I also utilize project management apps to track progress, schedule deliveries, and communicate effectively with clients and suppliers. For example, I might allocate a specific time block for subfloor leveling, allowing the adhesive to cure properly before proceeding with the LVP installation.

Q 25. Describe your experience with working independently and as part of a team.

I’m comfortable working both independently and collaboratively. I’m adept at managing solo projects, demonstrating self-motivation and the ability to solve problems efficiently without direct supervision. My experience also includes collaborative projects where I’ve effectively communicated with team members, coordinating tasks to meet deadlines and maintain high-quality standards. In team settings, I prioritize clear communication, mutual respect, and a collaborative problem-solving approach. For example, on a recent large-scale project, I led a small team, assigning tasks based on individual strengths, ensuring a smooth and efficient workflow. My ability to work effectively in various settings adds versatility and efficiency to my contributions.

Q 26. How do you handle customer concerns or complaints related to LVP installation?

Addressing customer concerns is a key aspect of my approach. I actively listen to the customer’s concerns, ensuring I fully understand their perspective. I respond calmly and professionally, providing clear and concise explanations. If the issue is valid, I promptly address it, providing solutions and taking responsibility for rectifying the problem. My goal is always customer satisfaction, and this often includes demonstrating the root cause of the issue, explaining the corrective steps, and ensuring their peace of mind. For instance, if a customer reports a slight unevenness, I might inspect the subfloor to rule out any underlying issues and offer solutions like localized repair or replacement, as appropriate. Clear communication and a commitment to resolving the issue effectively are essential.

Q 27. What are your strengths and weaknesses as an LVP installer?

My greatest strengths as an LVP installer include my meticulous attention to detail, my problem-solving skills, and my commitment to delivering high-quality work. I’m adept at troubleshooting unforeseen issues and finding efficient solutions. I also pride myself on my ability to communicate effectively with clients, ensuring their satisfaction throughout the project. My primary area for development is expanding my knowledge of the latest advancements in LVP technology and installation techniques – I am actively pursuing continuing education to stay at the forefront of the industry. This continuous learning ensures that I am always equipped to deliver the best possible results for my clients.

Q 28. What are your salary expectations for this position?

My salary expectations are commensurate with my experience and expertise. Considering my extensive experience in LVP installation, my proven ability to manage projects efficiently, and my commitment to exceeding client expectations, I am seeking a competitive salary range of [Insert Salary Range Here]. I am open to discussing this further and am confident that my contributions will provide significant value to your organization.

Key Topics to Learn for Luxury Vinyl Plank (LVP) Flooring Installation Interview

- Understanding LVP Types and Substrates: Learn the differences between click-lock, glue-down, and self-adhesive LVP, and how substrate choices (concrete, wood, etc.) impact installation methods.

- Acclimation and Moisture Management: Master the importance of acclimating LVP to the installation environment and understanding moisture barriers and their applications to prevent future issues.

- Precise Measurement and Cutting Techniques: Develop proficiency in accurate room measurements, calculating material needs, and using various cutting tools for precise cuts around obstacles.

- Installation Methods: Gain hands-on experience with different installation techniques for various LVP types, including proper handling to avoid damage.

- Troubleshooting Common Installation Problems: Learn to identify and resolve common issues such as uneven subfloors, expansion gaps, and damaged planks. Understand solutions for clicking and seaming challenges.

- Adhesive Selection and Application: Understand the different types of adhesives used for glue-down LVP and their proper application techniques for optimal bonding.

- Tools and Equipment: Familiarize yourself with essential tools, from measuring tapes and saws to specialized underlayment installation tools. Understand their maintenance and safe usage.

- Safety Procedures and Best Practices: Understand and adhere to safety regulations for handling tools, materials, and working in various environments.

- Finishing Touches and Trim Work: Master techniques for installing transition strips, baseboards, and other finishing elements for a professional look.

- Understanding Manufacturer Specifications: Emphasize the importance of reading and following manufacturer instructions for each specific LVP product.

Next Steps

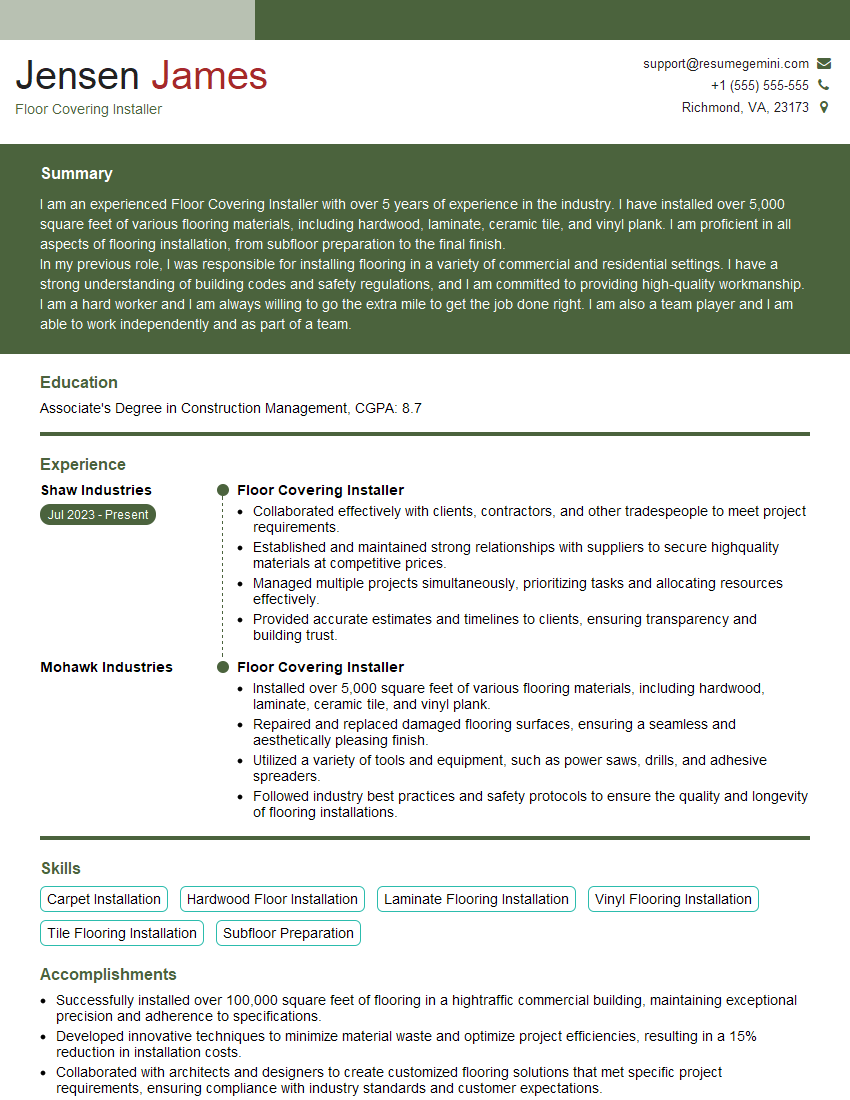

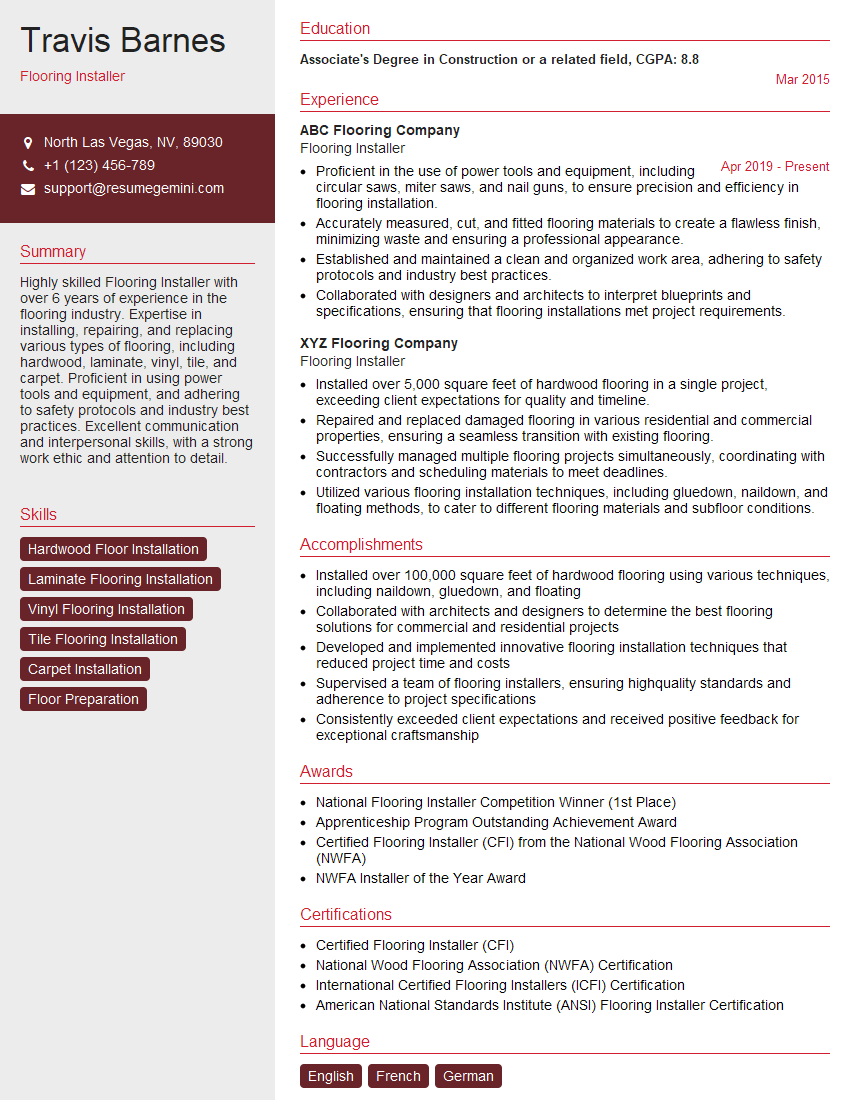

Mastering Luxury Vinyl Plank (LVP) flooring installation opens doors to rewarding careers with excellent growth potential in the construction and remodeling industries. To maximize your job prospects, create a strong, ATS-friendly resume that highlights your skills and experience. ResumeGemini is a trusted resource that can help you build a professional resume that effectively showcases your abilities. Examples of resumes tailored to Luxury Vinyl Plank (LVP) Flooring Installation are available to guide you. Take the next step and craft a resume that reflects your expertise and gets you noticed!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

hello,

Our consultant firm based in the USA and our client are interested in your products.

Could you provide your company brochure and respond from your official email id (if different from the current in use), so i can send you the client’s requirement.

Payment before production.

I await your answer.

Regards,

MrSmith

hello,

Our consultant firm based in the USA and our client are interested in your products.

Could you provide your company brochure and respond from your official email id (if different from the current in use), so i can send you the client’s requirement.

Payment before production.

I await your answer.

Regards,

MrSmith

These apartments are so amazing, posting them online would break the algorithm.

https://bit.ly/Lovely2BedsApartmentHudsonYards

Reach out at [email protected] and let’s get started!

Take a look at this stunning 2-bedroom apartment perfectly situated NYC’s coveted Hudson Yards!

https://bit.ly/Lovely2BedsApartmentHudsonYards

Live Rent Free!

https://bit.ly/LiveRentFREE

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?